Samsung AS07A5MA, AS12ABMCF, US07A5MA, AS07A6MA, US07A6MA Service Manual

...

Manual

SERVICE

SPLIT TYPE AIR CONDITIONER

Indoor Unit

AS07A5(6)MA

AS09A5(6)MAF

AS12AA(B)MCF

Outdoor Unit

US07A5(6)MA

US09A5(6)MAF

US12AA(B)MCF

E DB98-15774A(1)

Safety Precautions

The following safety precautions must be taken when using your air conditioner.

WARNING

I

NSTALLING THE UNIT

POWER SUPPLY LINE,

FUSE OR CIRCUIT

BREAKER

Risk of electric shock. • Can cause injury or death. • Disconnect all remote electric

power supplies before servicing, installing or cleaning. • This must be done by the

manufacturer or its service agent or a similar qualified person in order to avoid a

hazard.

◆ The unit should not be installed by the user. Ask the dealer or authorized

company to install the units except room air conditioners for the U.S.A and

Canada area.

◆ If the unit is installed improperly, water leakage, electric shock or fire may

result.

◆ The air conditioner must be installed in accordance with national wiring

regulations and safety regulations wherever applicable.

◆ Mount with the lowest moving parts at least 8.2ft(2.5m) above the floor or

grade level. (If applicable)

◆ The manufacturer does not assume responsibility for accidents or injury

caused by an incorrectly installed air conditioner. If you are unsure about

installation, contact an installation specialist.

◆ When installing the built-in type air conditioner, keep all electrical cables

such as the power cable and the connection cord in pipe, ducts, cable

channels e.t.c to protect them against liquids, outside impacts and so on.

◆ If the power cord of this air conditioner is damaged, it must be replaced by

the manufacturer, its service agent or similarly qualified persons in order to

avoid a hazard.

◆ The unit must be plugged into an independent circuit if applicable or

connect the power cable to the auxiliary circuit breaker. An all pole

disconnection from the power supply must be incorporated in the fixed

wiring with a contact opening of >3mm.

◆ Do not use an extension cord with this product.

◆ If the unit is equipped with a power supply cord and a plug, the plug must

be accessible after installation.

◆ This appliance must be installed accordance with the national wiring

regulations.

2

Contents

ΙΙ

DISASSEMBLE AND REASSEMBLE

1. Indoor unit

2. Outdoor unit

ΙΙΙΙ

ET UP THE OPTION CODE 10

S

ΙΙΙΙΙΙ

TROUBLESHOOTING

1. Items to be checked first

2. Abnormal diagnosis by symptom

ΙΙΛΛ

ASSEMBLY DRAWING AND PART’S LIST

1. Indoor unit

2. Outdoor unit

3. Assembly control in

4. Assembly control out

ΛΛ

REFRIGERATING CYCLE BLOCK DIAGRAM 31

ΛΛ

ΙΙ

PERFORMANCE CURVE 32

4

6

13

14

22

24

28

29

ΙΙΙΙ

ΛΛ

WIRING DIAGRAMS

1. Indoor unit

2. Outdoor unit

ΛΛΙΙΙΙΙΙ

S

CHEMATIC

1. Indoor unit

2. Outdoor unit

DIAGRAMS

SPLIT TYPE

AIR CONDITIONER

41

42

44

45

3

ΙΙ

Disassemble and reassemble

Stop operation of the air conditioner and remove the power cable before repairing the unit.

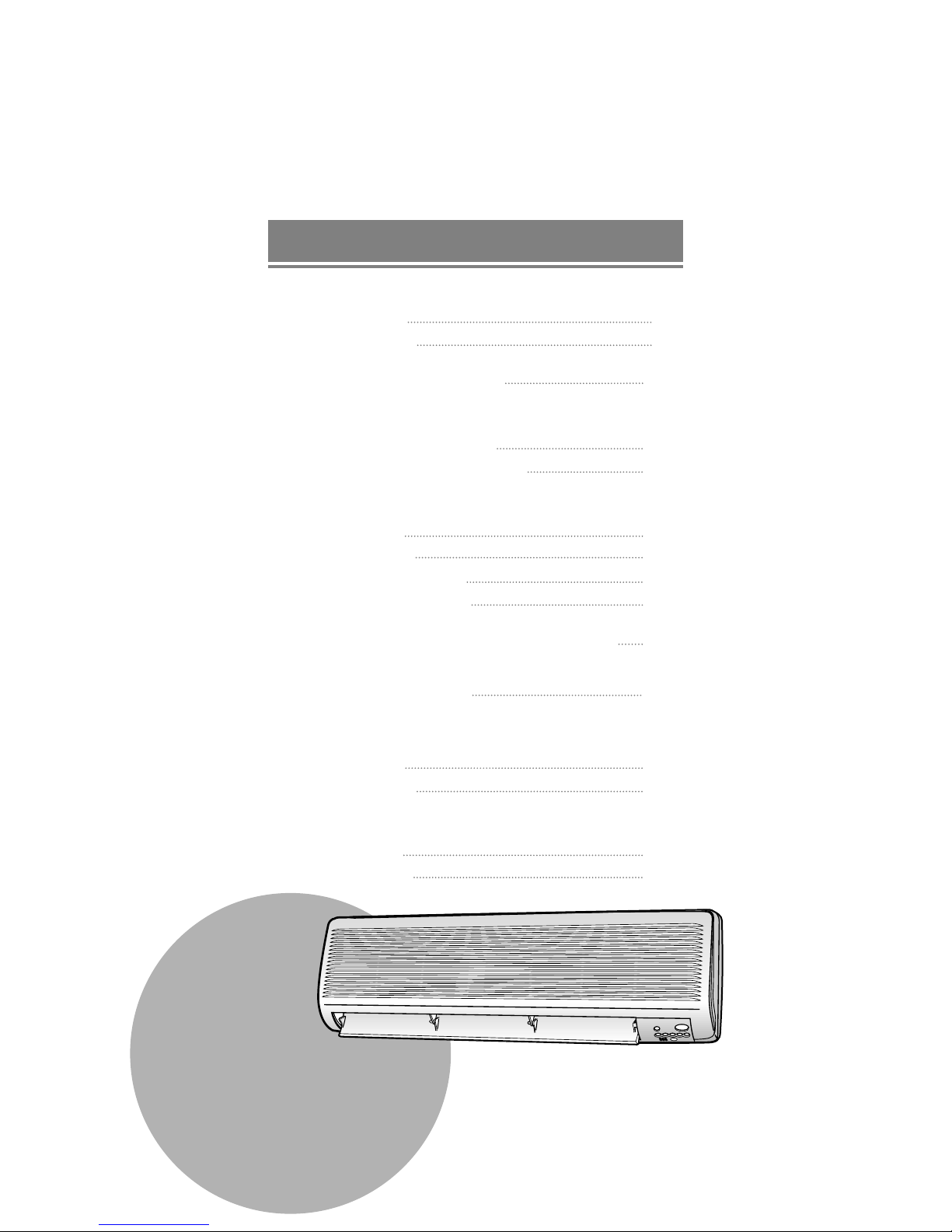

1 Indoor unit

If you disassemble the heat exchanger, you must pump down at first.

No. Part Procedure Remark

1

Front Panel

1) Stop the operation of the air conditioner

and block the main power.

2)Separate the tape from the front panel.

3)Contract the second finger to the left,

and right handle. And pull the inlet grille

to open.

4)Take the left and right filter out.

*Taking off the deodorizing filter.

5)Loosen one of the right screw and

separate the terminal cover.

6)Loosen three screws of front panel.

7)Pull the upper left, center and right of

discharge softly so that the outside

cover is pulled out.

8)Pull softly the lower part of discharge and

push it up.

Caution

Assemble the front panel and fix the

hooks of left, center and right.

4

No.

Part

Procedure Remark

2

3

4

Electrical

Parts

(Main PCB)

Assembly Tray

Drain

Heat

Exchanger

1) Take all the connector of PCB

on the upper part. (Included Power cord)

2) Separate the outdoor unit connection

wire from the terminal block.

3) If you pull out the main PCB up, it will be

taken out.

1) Separate the drain hose from the

extension drain hose.

2) Pull tray drain out from the back body.

1) Loosen two ground screws at the

right side.

2) Separate the connection pipe.

3) Separate the holder pipe at the rear side.

4) Loosen three screws at the right and

left side.

5) Lift the heat exchanger up a little to push

the upper side to separate it from the

indoor unit.

5

Fan Motor and

Cross Fan

1) Loosen two screws and separate the

motor holder.

2) Loosen the screw of fan motor.

(By use of M3 wrench)

3)Separate the fan motor from the fan.

4)Separate the fan from the left holder

bearing.

5

ΙΙ

Disassemble and reassemble (cont’d)

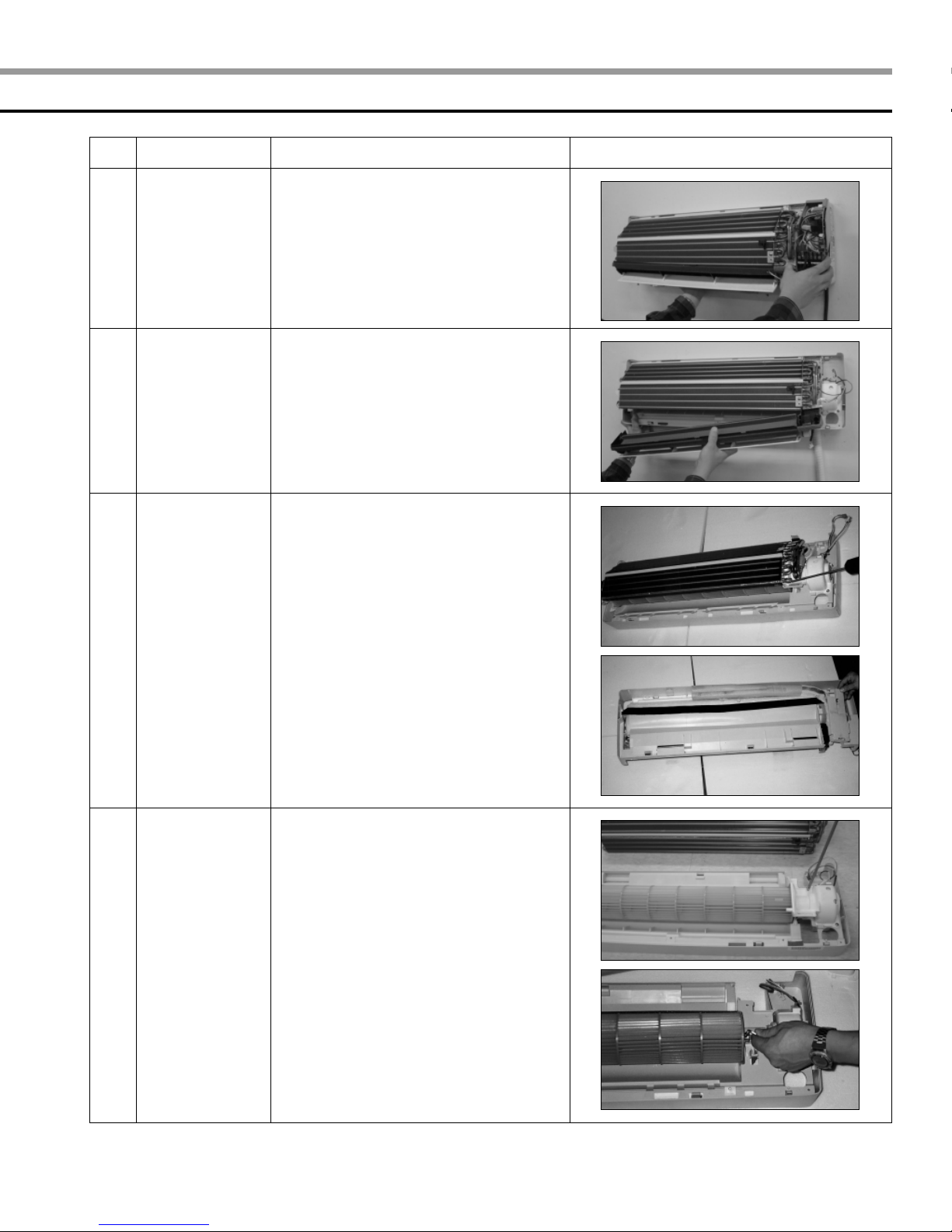

2 Outdoor unit

■ US07A5(6)MA/US09A5(6)MAF

No. Part Procedure Remark

1

Common Work

1)Loosen screws and separate the cover

E-part.

2)Separate the connection wire from the

terminal block.

3)Loosen five screws and separate the

upper cabinet.

4) Loosen the screw of the control box.

5) Loosen nine screws and separate the

side cabinet.

2

6

Fan Motor

1) Loosen four screws and separate

Guard Fan from the front cabinet.

No. Part Procedure Remark

2) Remove the nut flange

(Turn to the clockwise).

3)Separate the fan.

4)Loosen four screws to separate the motor.

3

4

Heat

Exchanger

Compressor

1)Release the refrigerant.

2)Loosen two screws of left and right side.

3)Disassemble the inlet and outlet pipe by

welding.

4)Separate the heat exchanger.

1)Release the refrigerant.

2)Loosen the nut on the terminal cover

and open the terminal cover.

3)Separate the OLP and the compressor

wire.

4)Disassemble the inlet and outlet pipe

of compressor by welding.

5)Disassemble the inlet and outlet pipe

of condenser by welding.

6) Loosen three bolts of the lower part.

7)Separate the compressor.

7

ΙΙ

Disassemble and reassemble(cont’d)

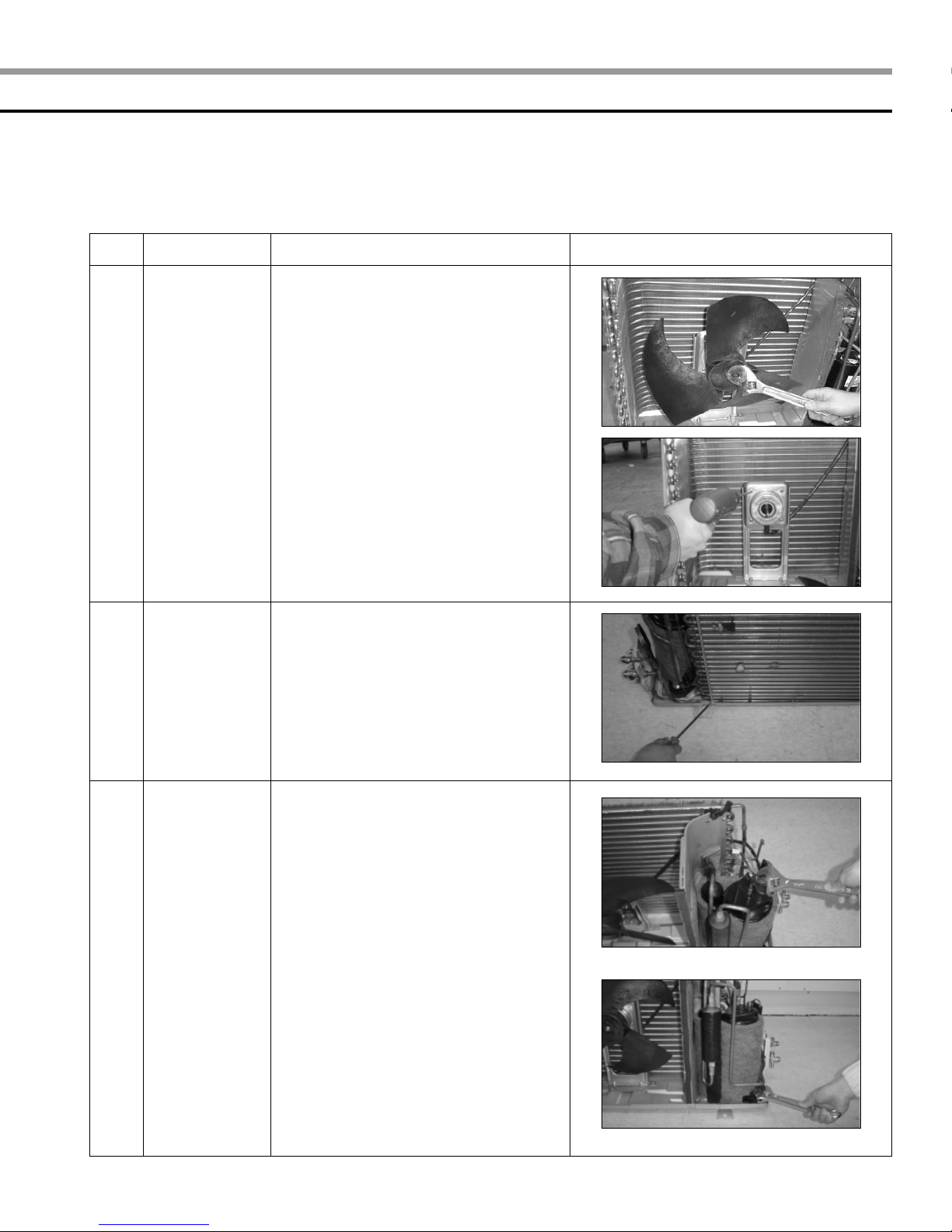

■ US12AA(B)MCF

No. Part Procedure Remark

1

Common Work

1) Loosen a screw and separate the cover

E-part.

2)Separate the connection wire from the

terminal block.

3) Loosen thirteen screws and separate

the front cabinet.

4) Loosen a screw of the control box.

5) Loosen four screws and separate the

side cabinet.

8

No. Part Procedure Remark

2

3

Fan and Motor

Heat Exchanger

1) Remove the nut flange

(Turn to the clockwise).

2) Separate the fan.

3) Loosen four screws to separate the motor.

4) Loosen five screws and separate the

motor bracket from the base.

1)Release the refrigerant.

2)Loosen screws of left and right side.

3)Disassemble the inlet and outlet pipe by

welding.

4)Separate the heat exchanger.

4

Compressor

1)Release the refrigerant.

2)Open the terminal cover of compressor

and unscrew the connection terminal.

3)Separate the OLP and the compressor

wire.

4)Disassemble the inlet and outlet pipe of

compressor by welding.

5) Loosen three bolts of the lower part.

6) Separate the compressor.

9

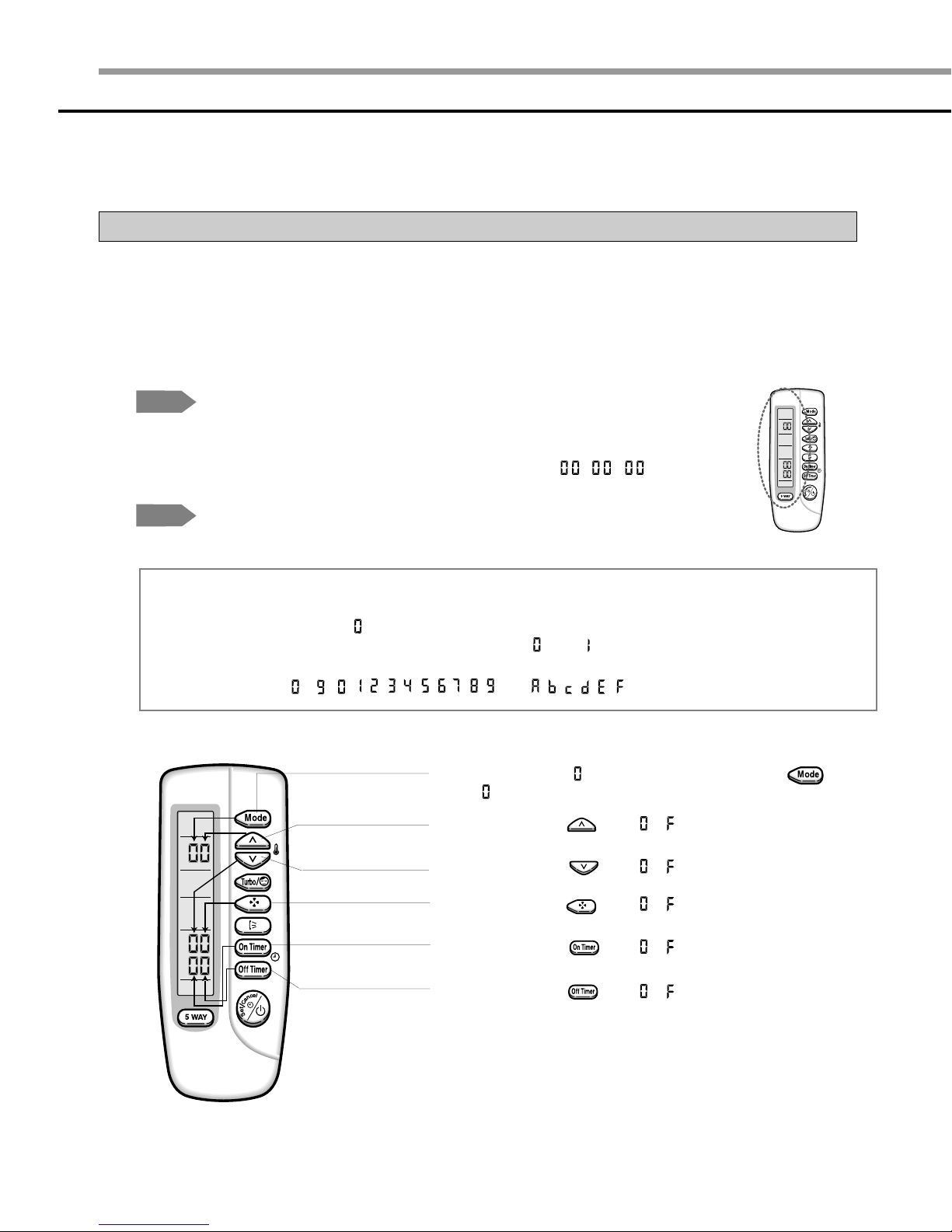

ΙΙΙΙ

Set up the option code

The method for setting up the model option with the remote control

◆ It is necessary to set up option codes after replacing the main PCB with service parts.

Make sure that you can set up option codes of the remote control after replacing the main PBA.

Otherwise, the unit won’t be working properly and all LED lamps on display will be flickering.

Step 1

Step 2

NNNNoooottttee

Preparing for the remote control to the main PCB option set.

1. Remove the battery from the remote control.

2. Press the temperature button simultaneously and insert the battery again.

3. Make sure the remote control display shown as .

Preparing for the remote control option set.

ee

In case that the wrong letter has been selected; continue to press the button until the

correct letter appears.

1. If the number “ ”appears on the display, proceed to the second stage.

2. Every time you press the 1) and 7) button, “ ” and “ ” continue to appear.

3. Every time you press the 2), 3), 4), 5), 6), 8), 9), 10), 11), 12) button, the number increases

from ~ ( , , , , , , , , , ) and , , , , , in order.

1) If the first number is , it is correct. Otherwise, press the button

until appears.

2) When pressing the button ~ on the display, select one of them.

10

3) When pressing the button ~ on the display, select one of them.

4) When pressing the button ~ on the display, select one of them.

5) When pressing the button ~ on the display, select one of them.

6) When pressing the button ~ on the display, select one of them.

7) If the first number is , it is correct. Otherwise, press the button

until appears.

8) When pressing the button ~ on the display, select one of them.

9) When pressing the button ~ on the display, select one of them.

10) When pressing the button ~ on the display, select one of them.

11) When pressing the button ~ on the display, select one of them.

12) When pressing the button ~ on the display, select one of them.

Step 3

Step 4

Step 5

NNNNoooottttee

Reconfirming the option set after completing

Example : 000000-1700b7

Press the button for the “ ” mode and the display will be shown as .

Press the button for the “ ” mode and the display will be shown as .

Pressing the (On/Off)button

When pressing the (On/Off)button in the direction of the remote control for unit,

it sounds beep or ringing and the first LED lamp on the left side is flickering at the

same time, then the input option is completed. If it doesn’t sound ringing, try again by

pressing the (On/Off)button.

Testing the unit

1 Remove the battery from the remote control.

2. Insert the battery into the remote control.

3. Press the (On/Off)button in the direction of the remote control for set.

Error mode

ee

1. If all lamps of the indoor units are flickering, plug out and in again and press the

(On/Off) button again.

2. If the unit doesn’t work properly or all lamps are continuously flickering after setting the option

code, check that the option code is set properly for its own model.

11

ΙΙΙΙ

Set up the option code(cont’d)

A table of the option code

Model

AS07A5MA

AS07A6MA

AS09A5MAF

AS09A6MAF

AS12AAMCF

AS12ABMCF

Option code

010000-1700b7

000000-1700b7

010000-1700Fb

000000-1700Fb

010000-170340

000000-170340

12

ΙΙΙΙΙΙ

Troubleshooting

1 Items to be checked first

1) The input voltage should be voltage rating within ±10% range.

The air conditioner may not operate properly if the voltage is out of this range.

2) Is the connection cable linking the indoor unit and the outdoor unit properly?

The indoor unit and the outdoor unit shall be linked by five cables.

Check the terminals if the indoor unit and outdoor unit are properly linked by the same number of cables.

Otherwise the air conditioner may not operate properly.

3) When a problem occurs due to the contents illustrated in the table below, it is not a symptom related

to the malfunction of the air conditioner.

No.

The STD operation indicator, LED blinks when a

1

power plug of the indoor unit is plugged in at first.

In the Cool mode, the compressor does not operate

at a room temperature higher than the setting

temperature while the indoor fan operates.

2

The Fan speed operating is not allowed in the Auto

3

or Dry mode.

Compressor stops operating intermittently in the Dry

4

mode.

Timer LED of the indoor unit lights up

and the air conditioner does not operate.

5

The compressor stops intermittently in the Cool or

Dry mode, and the fan speed of the indoor unit

6

decreases.

Operation of air conditioner

It indicates power is on. The LED stops blinking if the

On/Off button on the remote control is pushed.

It happens after three minutes when the compressor is

reoperated. The same phenomenon occurs when a power

is on. As a phenomenon that the compressor is

reoperated after three minutes, the indoor fan is adjusted

automatically with reference to a temperature of the air.

The speed of the indoor fan is set to LL in the Dry mode.

The Fan speed is five steps are selected automatically in

the Auto mode.

The compressor is controlled automatically in the Dry

mode depending on the room temperature and humidity.

The timer is being activated and the unit is in the ready

mode. The unit operates normally if the timer operation is

cancelled.

The compressor stops intermittently or the fan speed of the

indoor unit decreases to prevent inside/outside air from

freezing depending on the inside/outside air temperature.

Explanation

4) Indoor unit observes operation condition of the air conditioner and displays self diagnosis on the

display panel.

No.

STD LED blinking (1Hz)

1

TIMER LED blinking (1Hz)

2

STD and TIMER LED blinking (1Hz)

3

NATURE LED blinking (1Hz)

4

All LED blinking (1Hz)

5

Display

Self Diagnosis

Restore from power failure (input initial power)

Indoor unit Room sensor Error (open or short)

Indoor unit heat exchanger temperature sensor Error (open or short)

Indoor fan malfunctioning (for speed is below 450rpm)

Option Error

13

ΙΙΙΙΙΙ

Troubleshooting (cont’d)

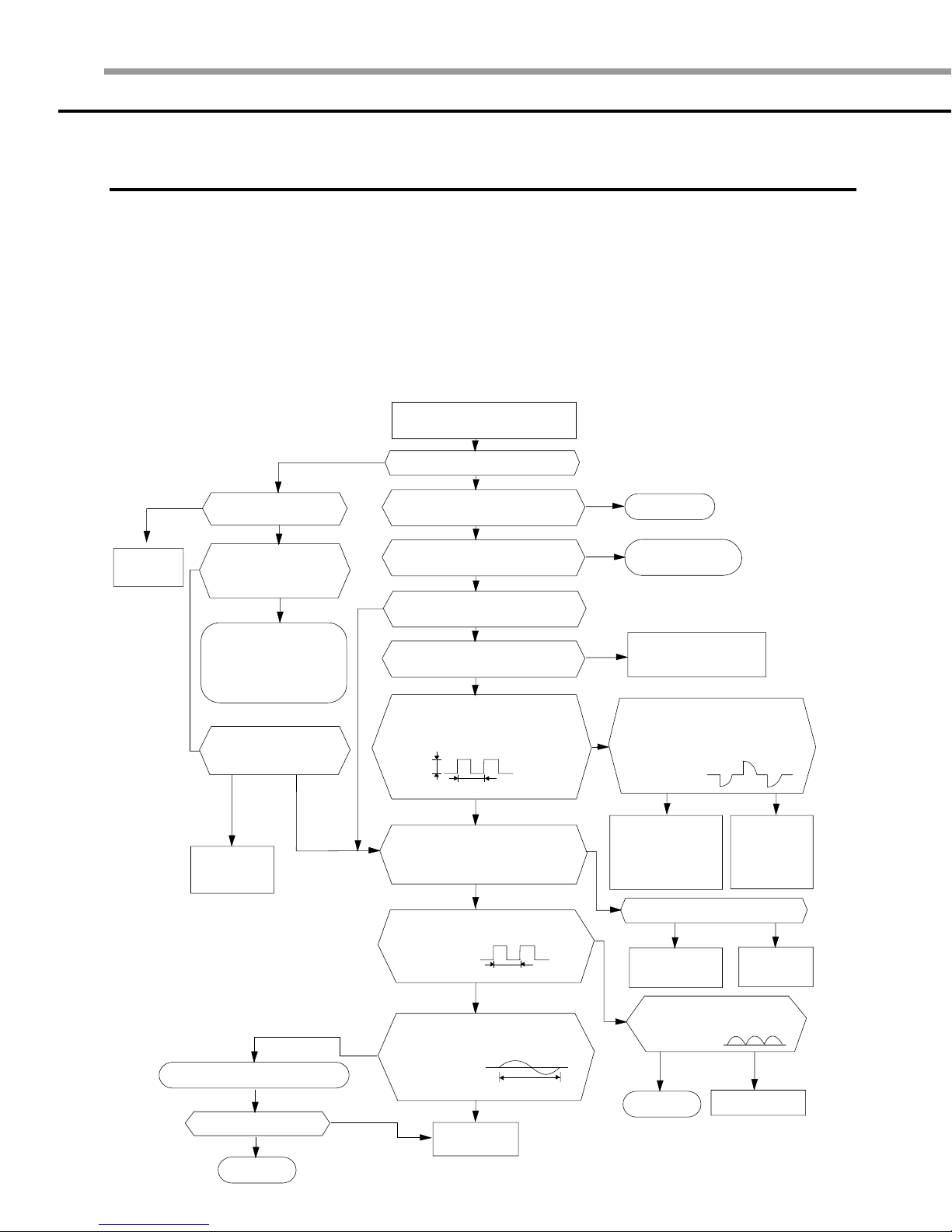

2 Abnormal diagnosis by symptom

1. No Power - Initial diagnosis

1. No Power - Initial diagnosis

1) Checklist :

(1) Is input voltage normal?

(2) Is AC power linked correctly?

(3) Is output voltage of DC regulator IC KA78L05 (IC02) normal? (4.5VDC-5.5VDC)

2) Troubleshooting procedure

Remove the power cord and plug in

again in approx. five seconds

14

YES

Replace PCB

display

Is DC voltage of PCB

display normal?

NO

Is voltage rating within ±10%

range applied to the primary

side(~,~) of the “BD71”?

NO

Check linkage between

a power cord and

a terminal tap

Check fuse

Does 325VDC appear in

the secondary side (+, -)

of “BD71”?

YESNO

Replace

SMPS PARTS

Replace resonator (X301)

Is operation normal?

YES

OK

NO

Does the lamp blink?

Does it start operating when

you push the On/Off button

on the remote control?

Is transmission display of the

remote control unit blinking?

Does the ‘beep’ sound from the

NO

Is DC voltage of the PCB module

Are voltages of #33 (IC04 : compressor)

of Micom normal? 5VDC

Is voltage of #32 (IC04 : indoor fan) of

DC5V

Is voltage of #10(IC04) terminal of Micom normal?

Is voltage of #9(IC04) terminal of Micom normal?

Is voltage of #3(IC04) terminal of

Are voltages of #12(IC04) and

NO

NO

#11(IC04) of Micom normal?

YES

NO

YES

main unit?

YES

normal?

YES

Micom normal?

10ms

NO

0VDC

5VDC

YES

Micom normal?

10ms

YES

250ns

YES

Replace

Micom

YES

NO

NO

YES

NO

NO

Normal

Refer to remote control

unit abnormal diagnosis

Replace PCB

module

.

Are voltages of RY71(Compressor)

normal? DC12V

Is voltage of SS71(indoor fan)?

YES

Check connections

of compressor

and indoor fan.

Is output voltage of ICO2 normal?

YES

Check PCB pattern

Replace the main PCB

Is voltage output terminal of

PC814A(PC02) normal?

YES

OK

Replace

RY71 and

SS71

Replace ICO2

NO

Replace PC814A(PC02)

NO

NO

Loading...

Loading...