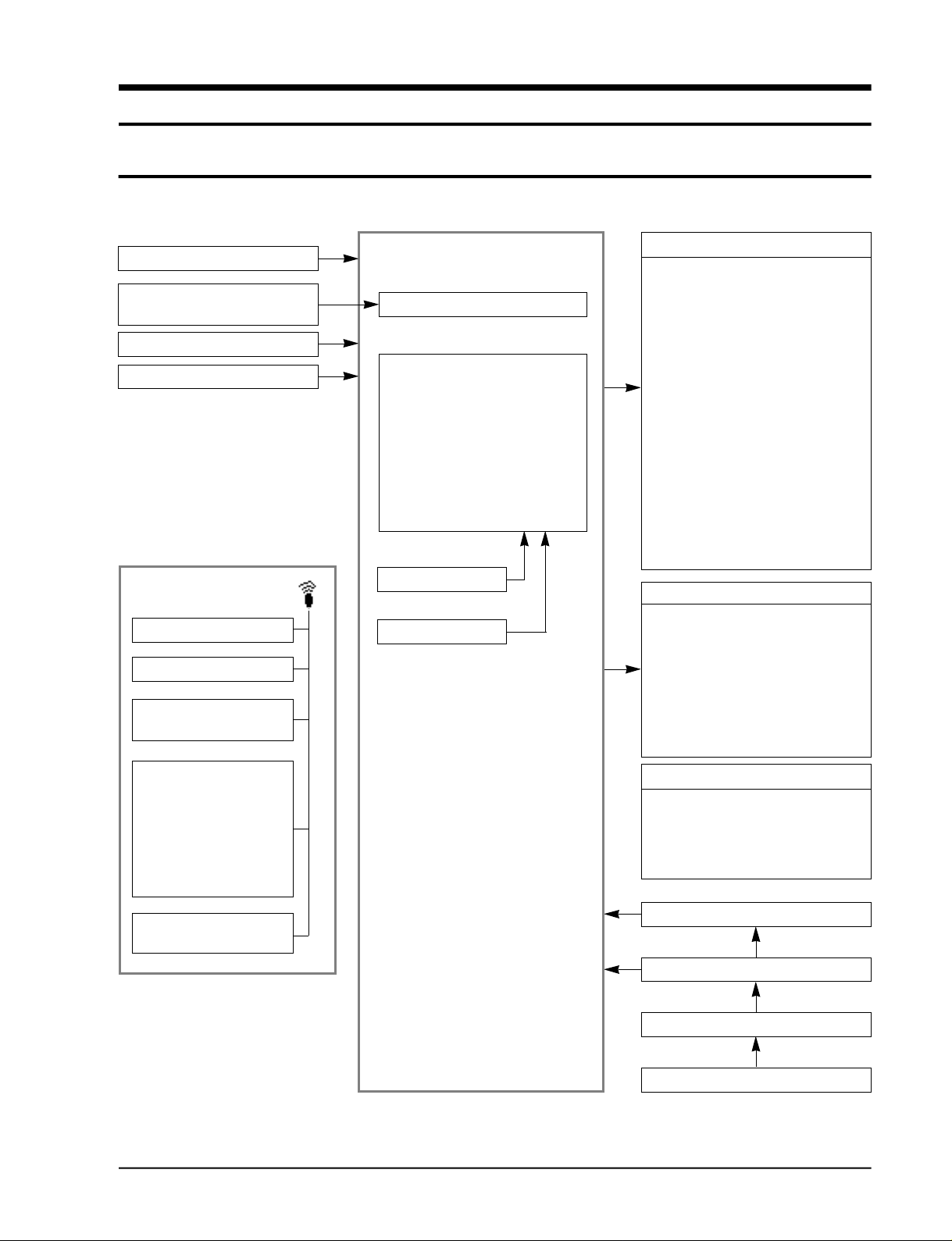

7. Block Diagrams

7-1 Micro Computer Block Diagram

Time condensor

Real temperature

perception sensor(R-TH)

Remote control receiver

Lamp examiner

REMOTE CONTROLLER

On/Off

Left-right turn

Cooling selector-

high, medium, low

INDOOR CONTROL PANEL

A/D transformer

Temperature controller

Compressor controller

Indoor fan controller

Left-right motor controller

Buzzer controller

Reset circuit

Oscillator circuit

Indoor indicators

•Temperature lamp

•Cooling lamp

•Low-medium-high turbo lamp

•Timer lamp

•Power lamp

•Mode selector lamp: Auto, cool, fan

•Outdoor unit motion lamp

•Left-right lamp

•Lamp to indicate desired temperature

•Lamp to indicate desired temperature

•Lamp to indicate present temperature

•Timer lamp to indicate reservation

•Lamp to indicate present time

•Turbo lamp

Operation of room switches

•On/Off

•Temperature(time) - high,

temperature(time) - low

•Function selector

•Convenience reservation

•Cool selector

•Change indicator

Function selector

Auto

Cool

Fan

Turbo

Temperature control:

low, high

Samsung Electronics

Workload operation

•Indoor fan motor - low, medium, high,

turbo

•Left-right motor

•Compressor

Electric circuit(DC+5V)

Electric circuit(DC+12V)

Electric transformer

Electric power input

7-1

Troubleshooting

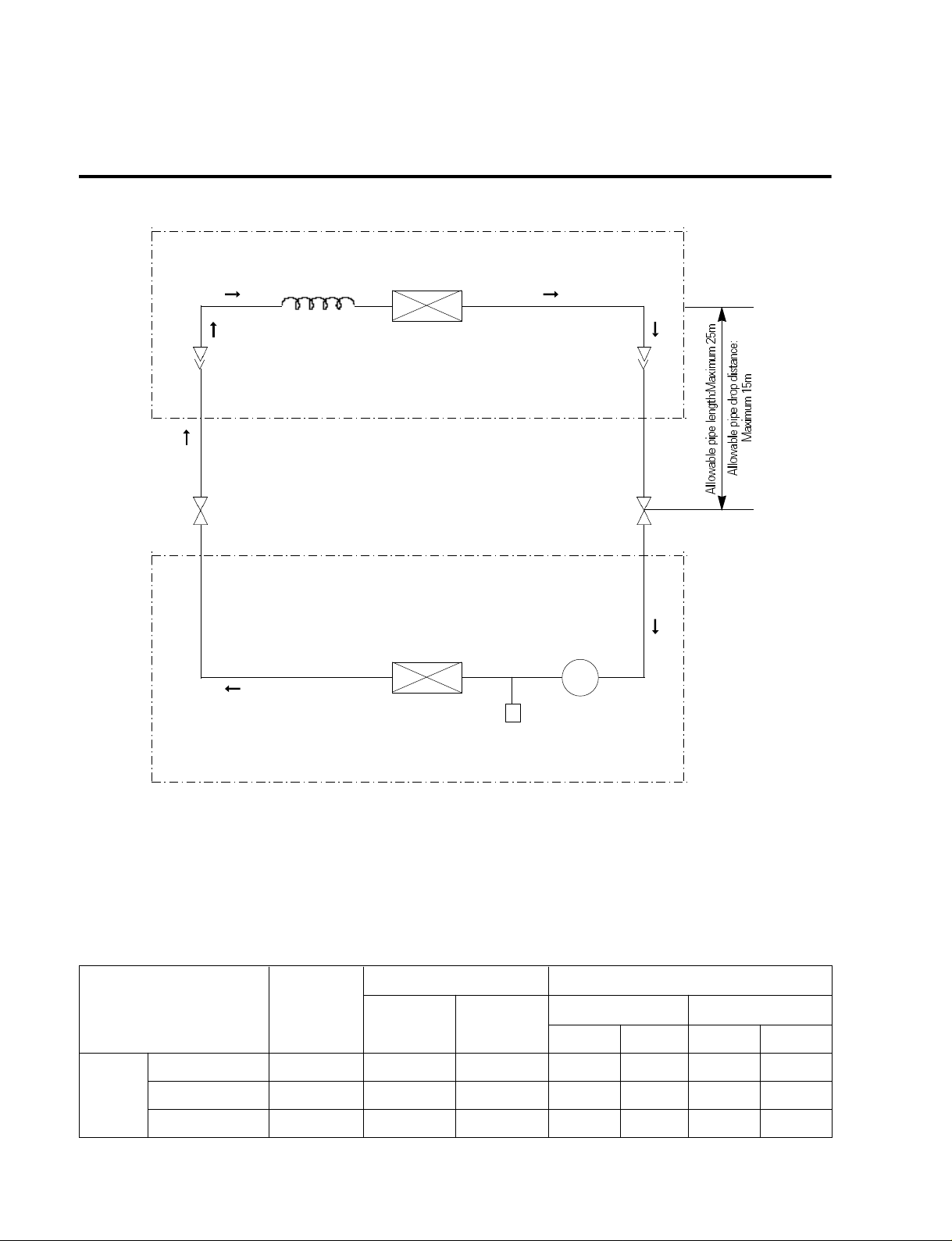

7-2 Refrigerating Cycle Block Diagram

INDOOR UNIT

Heat exchanger

Capillary

(Evaporator)

Heat exchanger

(Condenser)

High Pressure S/W

Compressor

OUTDOOR UNIT

* Additional supplementary amount per meter for extension:

When you utilize more than 5m of the tube, you must supplement 50g of R-22 freezing catalyzer gas per additional meter.

Refrigerating cycle temperature and pressure

STD Pressure Piping Temp.(°C) UseTemp. Condition (°C)

Operating Condition (kg/cm2G)

T1 T2

(GAS SIDE) DB WB DB WB

Standard 4.5~5.5 40~45 9~12 27 19 35 24

Cooling Max over load 6.5~7.5 50~55 14~18 32 23 43 26

Low temp 3~4 30~35 1~4 21 16 21 16

Indoor Outdoor

7-2

Samsung Electronics

M E M O

Samsung Electronics

7-3

Loading...

Loading...