Samsung AM***FXVAF Series, AM***FXVAJ Series, AM***HXVAF Series, AM***KXVGJ Series, AM***KXVTJ Series Installation Manual

...

DVM S

AM✴✴✴FXVAF✴ Series

AM✴✴✴FXVAJ✴ Series

AM✴✴✴HXVAF✴ Series

AM✴✴✴HXVAJ✴ Series

AM✴✴✴KXVTF✴ Series

AM✴✴✴KXVTJ✴ Series

AM✴✴✴KXVGJ✴ Series

Air Conditioner

installation manual

imagine the possibilities

Thank you for purchasing this Samsung product.

k}tGzG㨰䛙G㐘㞬ὤGptluki]_TWZ_XYhTW_UGGGX YWX_TW]TXXGGG㝘䟸G[a[_aYY

2

Contents

Safety precautions ....................................................................................................... 3

Preparing for installation ................................................................................................. 6

Selecting installation location ........................................................................................... 11

Space requirement for installation ...................................................................................... 13

Accessories ............................................................................................................. 15

Base construction and installation of the outdoor unit ................................................................... 17

Installing the wind/snow prevention duct ............................................................................... 22

Refrigerant pipe installation ............................................................................................. 24

Electrical wiring work ................................................................................................... 59

Air tightness test and vacuum drying ................................................................................... 75

Pipe insulation .......................................................................................................... 77

Charging additional refrigerant ......................................................................................... 81

Basic segment display .................................................................................................. 83

Setting outdoor unit option switch and key function .................................................................... 83

Setting the MCU and Pipe Addresses (for HR Only) ...................................................................... 93

Things to check after completing the installation ........................................................................ 97

Inspection and trial operation ........................................................................................... 99

Automatic refrigerant amount detection function ...................................................................... 105

k}tGzG㨰䛙G㐘㞬ὤGptluki]_TWZ_XYhTW_UGGGY YWX_TW]TXXGGG㝘䟸G[a[_aYZ

3

ENGLISH

Safety precautions

WARNING

State of California Proposition 65 Warning (US only)

This product contains chemicals known to the State of California to cause cancer and birth defects or other reproductive

harm.

Please follow the following safety information for safety of the installer and the user.

❋ DVM S air conditioner uses R-410A refrigerant.

• When using R-410A, moisture or foreign substances may aect the performance and reliability of the product.

Safety precautions must be obeyed when installing the refrigerant pipe.

• The designed maximum pressure of the system is 4.1MPa(594.6 psi) and therefore select appropriate material and

thickness according to the regulations.

• R-410A is a quasi-azeotrope of two refrigerants and it has to be charged in liquid phase when lling the refrigerant.

(If you charge vapor refrigerant, it may change the blend of the refrigerant and cause product malfunction.)

❋ You must connect the indoor units for R-410A refrigerant. Refer to product catalog to nd out the models names

for connectable indoor units. (If you connect the indoor units that are not designed for R-410A, it cannot operated

normally.)

❋ After completing the installation and trial operation, explain to the user how to use and maintain the product. Also, hand

over this installation manual so that it can be stored by the user.

❋ Manufacturer is not responsible for the incidents occurred by improper installation. Installer is responsible for any

installation related claims from the user occurred by neglecting warnings and cautions stated in this manual. (Installer

will be responsible for any service charges that may occur)

❋ Generally, system air conditioners should not be relocated after installation. But when it has to be relocated for inevitable

reasons, please contact Samsung’s qualied dealers for system air conditioners.

WARNING

• Hazards or unsafe practices that may result in severe personal injury or death.

CAUTION

• Hazards or unsafe practices that may result in minor personal injury (to installer/user) or

property damage.

SEVERE WARNING SIGNS

Consult qualied installer or dealer for installation.

f When installation is done by unqualied person, problems such as water leakage, electric shock or re may occur.

Installation work must be done properly according to this installation manual.

f When installation is not done properly, it may cause water leakage, electric shock or re.

When installing the unit in a small room, take measure to keep the refrigerant concentration from exceeding allowable

safety limits in case of refrigerant leakage. Consult the dealer for precautionary measure before the installation.

f When refrigerant leaks and exceed dangerous concentration level, it may cause suocation accidents.

If any gas or impurities, except R-410A refrigerant, come into the refrigerant pipe, serious problem may occur and it

may cause injury.

Use the supplied accessories, specied components and tools for the installation.

f Do not use the pipe and the installation product used for the R-22 refrigerant.

f Failure to use the specied components can cause product fall down, water leakage, electrical shock, and re. (The pipe

and are components used for R-22 refrigerant must not be used)

Install the outdoor unit on a hard and even place that can support its weight.

f If the place cannot support its weight, the outdoor unit may fall down and it may cause injury.

k}tGzG㨰䛙G㐘㞬ὤGptluki]_TWZ_XYhTW_UGGGZ YWX_TW]TXXGGG㝘䟸G[a[_aYZ

4

Safety precautions

Check the following before installation and service work.

f Before welding, remove dangerous and inammable things that may cause an explosion and re around the work.

f Before welding, remove the refrigerant from inside the pipe or the product.

- If you perform welding while refrigerant is in the pipe, it may increase the pressure of the refrigerant and cause the pipe

to burst. If the pipe bursts or explodes, it may cause severe injury to the installer.

f When welding, use the nitrogen gas to eliminate oxidation inside the pipe.

Do not modify the product on your own.

f Potential risk of electric shock, re, product failure or injury.

Fix the outdoor unit securely on foundation to resist strong wind or earthquake.

f If the outdoor unit is not properly xed, it turns over and accidents may occur.

Electric work must be done by qualied persons, complying the national wiring regulations and installed according to

the instruction stated in the installation manual with leased circuit.

f Capacity shortage on the leased circuit and improper installation may cause electric shock or re.

Make sure to perform grounding work.

f Do not connect the ground wire to a gas pipe, water pipe, lightning rod or telephone grounding. Improper grounding

could cause electric shock.

Wiring must be connected with the designated wires and it must be xed securely so that it does not apply any external

force to the connection part of the terminals.

f If connection for xation is not properly done, it may cause heat generation or re.

Neatly arrange the wires in the electrical parts to make sure that electrical cover is closed securely without any gaps.

f If the cover is not properly closed, heat may generate on the electrical terminal and cause electric shock or re.

Exclusive circuit breaker (MCCB, ELB) must be installed to the power supply.

f When overcurrent or current leakage occurs with no circuit breaker installed, power will not be cut-o and it may cause

electric shock or re.

f Do not use damaged parts. It may cause re or electric shock.

You must cut-o the power before you work on, or adjust any power supply part for product installation, maintenance,

repair or any other services.

f There is risk of electric shock.

f Even when the power is o, it is dangerous when you come in contact with inverter PCB, fan PCB since high pressure DC

voltage is charged to those parts.

f When replacing/repairing the PCB, cut-o the power and wait until the DC voltage is discharged before replacing/

repairing them. (Wait for more than 15 minutes to allow it to discharge naturally.)

If the refrigerant gas leaks during the installation, you should ventilate the room.

f When the refrigerant gas gets in contact with ammable substance, it may generate toxic gas.

Gas leakage must be checked after installation is completed.

f When the refrigerant gas gets in contact with ammable substance, it may generate toxic gas.

You can get a frostbite if you get in contact with the leaked refrigerant gas.

Supply power to the product during winter time since the product will operate in protection mode itself when the

temperature decrease below 0°C(32°F).

f If you cut-o the power, compressor protection mode cannot be operated and may cause damage to the product.

k}tGzG㨰䛙G㐘㞬ὤGptluki]_TWZ_XYhTW_UGGG[ YWX_TW]TXXGGG㝘䟸G[a[_aYZ

5

ENGLISH

CAUTION SIGNS

Do not install the drain pipe directly to the bottom part of the outdoor unit and built a proper drainage so that water

drains out smoothly. If not, pipe may freeze or bursts during winter time and cause damage to the product or water

leakage.

f When the draining work is not done properly, water leak may occur and cause property damage.

Install the power cable and communication cable of the indoor and outdoor unit at least 1.5m(4.92ft) away from the

electric appliances and install it at least 2m(6.56ft) away from the lightning conductor.

f Noise may be generated from the electronic devices, depending on the status of the electric wave.

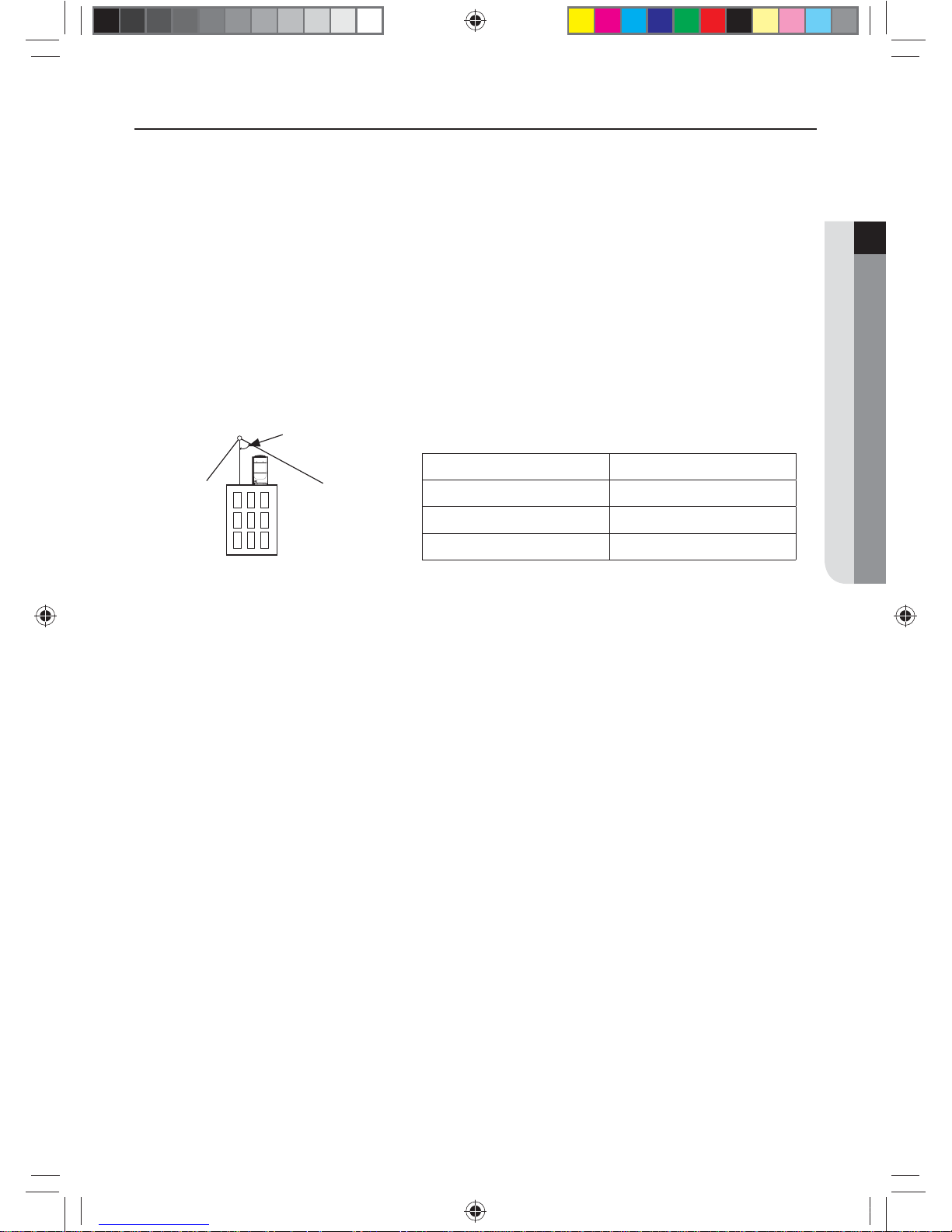

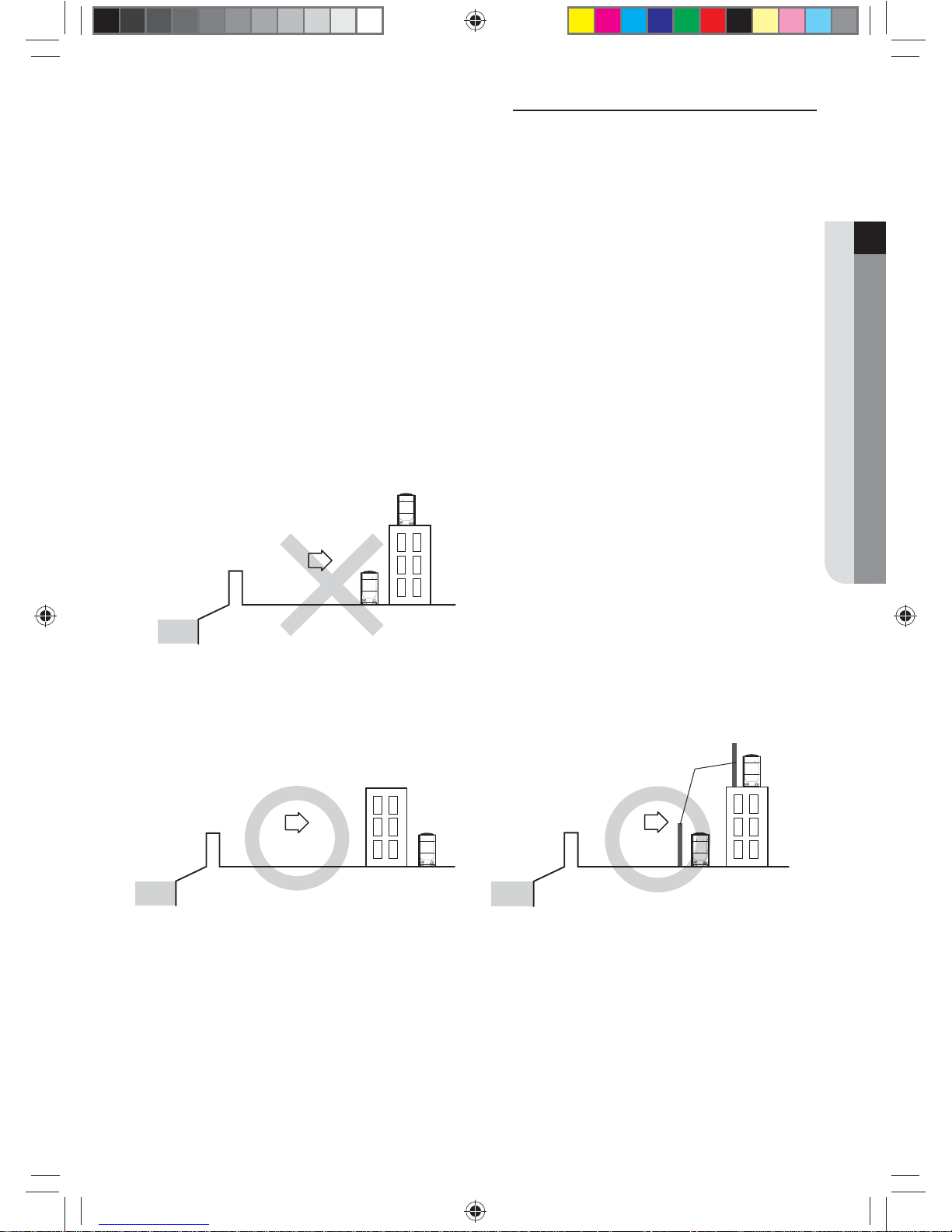

Install the outdoor unit within the angle stated in the table, according to the height of the building.

f Do not leave the refrigerant container under the hot sunlight. (There is risk of explosion.)

f You must use the appropriate pipes according to the standard since the pressure of the refrigerant is very high.

f Make sure that the pipes does not get any weaker by welding it too much.

f Make sure to install the product away from children’s’ reach. (Sharp parts of the heat exchanger is may cause personal

injury and when parts of the product gets damage, it may decrease product’s performance.)

Lighting rod

Protective angle: 25˚~55˚

Height of the building Protection control

20m(65.6 ft) or less 55˚

40m(131.2 ft) or less 35˚

60m(196.9 ft) or less 25˚

Install the indoor unit away from lighting apparatus that uses ballast stabilizer.

f If you use the wireless remote control, it may not operate normally due to ballast stabilizer.

Do not install the product in following places.

f Place where outdoor unit’s noise and warm air may disturb neighbors. (It may cause property loss.)

f Do not leave any obstacles around the inlet and outlet of the product. (It may cause damage or accidents.)

f The place where there is mineral oil or arsenic acid.

- Those parts may get damaged due to burned resin and cause water leakage or product may fall.

- The eciency of the heat exchanger may reduce or product may break.

f The place where corrosive gas such as sulfurous acid gas generates from the vent pipe or air outlet.

- The copper pipe or connection pipe may corrode and refrigerant may leak.

f The place where there is a machine that generates electromagnetic waves.

- The air conditioner may not operate normally due to problems in control system.

f The place where there is a danger of combustible gas leakage or place where thinner or gasoline is handled.

(There is risk of re or explosion.)

f The place with carbon ber or ammable dust.

f The place near seashore or hot spring where there is risk of outdoor unit corrosion.

f Do not install the product in a place where thermohygrostat is needed (such as server room, machinery room, computer

room, etc.) Those places do not provide guaranteed operation condition of the product therefore performance can be

poor in these places.

f Do not install the product in a ship or a vehicle(such as a campervan).

Salt, vibration or other environmental factor may cause the product malfunction, electric shock or re.

k}tGzG㨰䛙G㐘㞬ὤGptluki]_TWZ_XYhTW_UGGG\ YWX_TW]TXXGGG㝘䟸G[a[_aYZ

6

Safety precautions

Changes in DVM S (inverter) compare to conventional models that has to noted when installing

f For optimal distribution of the refrigerant, you must use Y-joint as branch joint for connecting outdoor units. (Do not use

T-joint)

f You cannot operate normally if you do not complete the trial operation through outdoor unit key mode. You must use

KEY MODE to run trial operation.

f DVM S air conditioner uses R-410A refrigerant.

f Check the compatibility of other products such as indoor unit, EEV kits etc. which will be connected to DVM S.

f Make sure to note that outdoor unit combination is dierent from DVM PLUS III and IV.

f The length of maximum piping, level dierence, the quantity of connectable indoor units, the installation at the outdoor

joints and the outdoor unit combinations are dierent from the conventional models.

f If the pipe length is over 2m(6.56ft) between outdoor units, make traps to prevent oil stagnation. Oil stagnation may

occur when outdoor unit at the end of module stops while other outdoor units are still in operation.

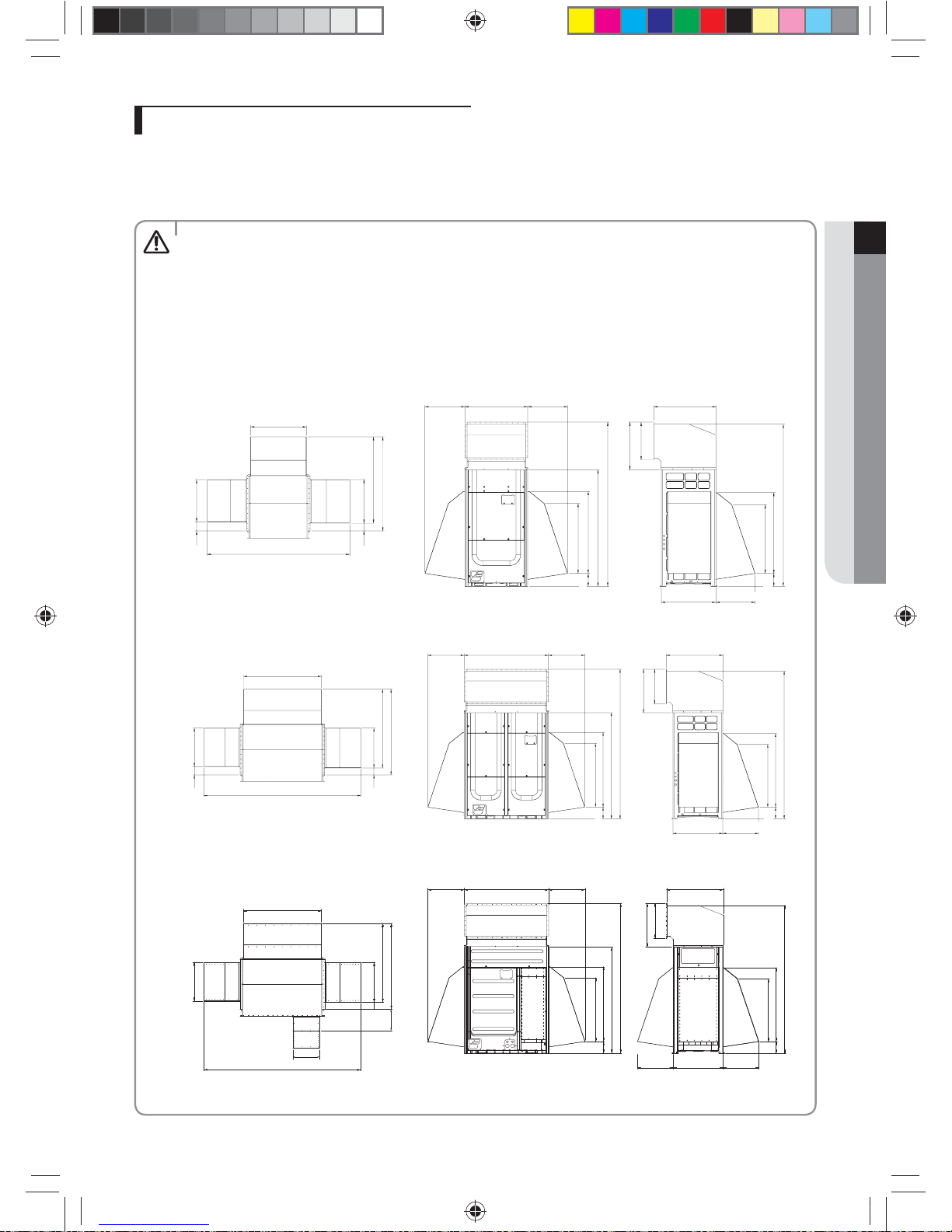

Preparing for installation

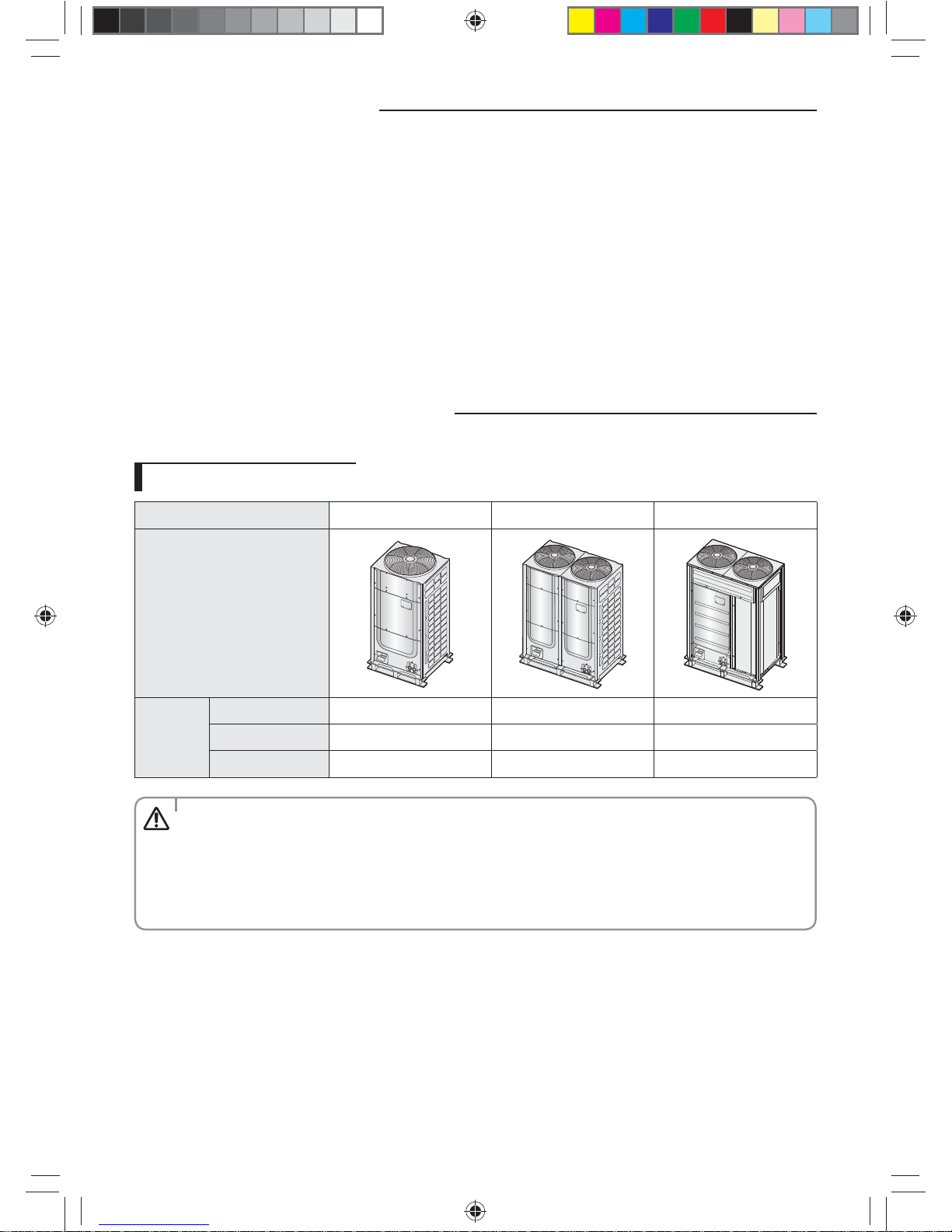

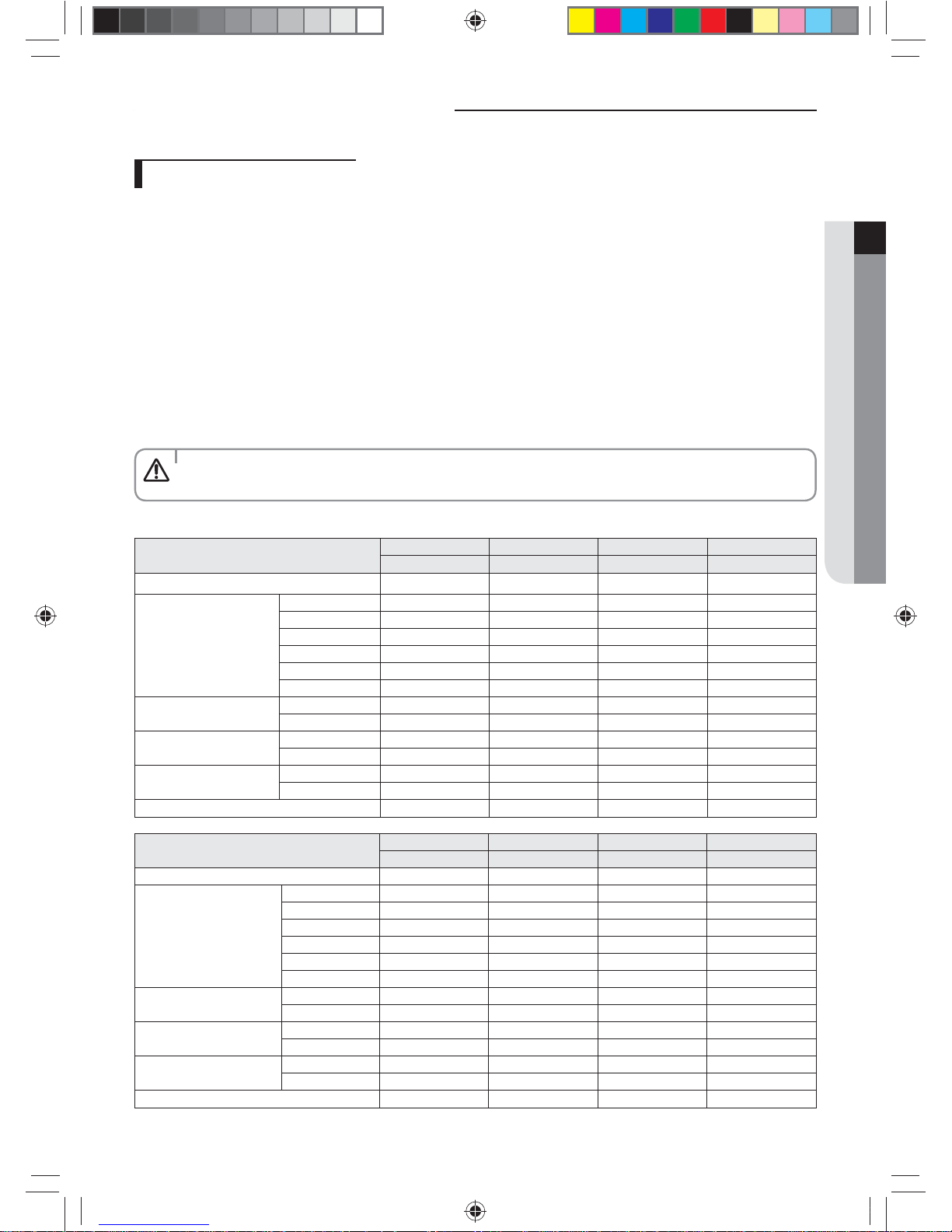

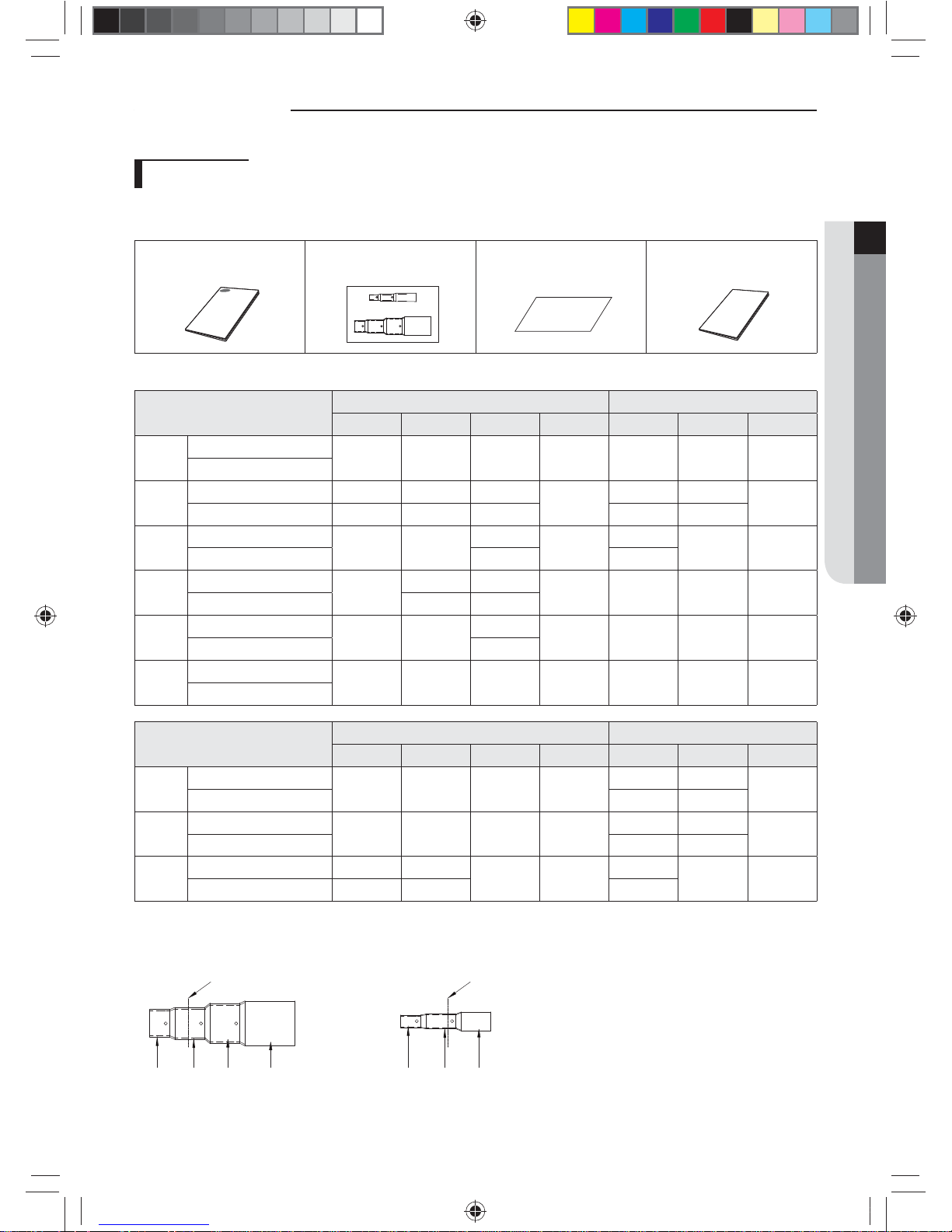

Outdoor unit classication

Classication Small type Large A type Large B type

Appearance

Models

AM✴✴✴F✴ Series AM072✴✴✴ AM096/120/144✴✴✴

AM✴✴✴H✴ Series AM168/192✴✴✴

AM✴✴✴K✴ Series AM072/096✴✴✴ AM216KXVGJ✴

Packaging material disposition

• Safely store or dispose the packaging materials.

- Sharp metals such as nails or wooden material packaging that may break into pieces become a cause for

personal injury.

- Make sure to store or dispose the vinyl type packaging material to keep it out of reach of children. Children

may put them over their face, which is very dangerous since it may lead them to suocation.

CAUTION

k}tGzG㨰䛙G㐘㞬ὤGptluki]_TWZ_XYhTW_UGGG] YWX_TW]TXXGGG㝘䟸G[a[_aYZ

7

ENGLISH

Preparing for installation

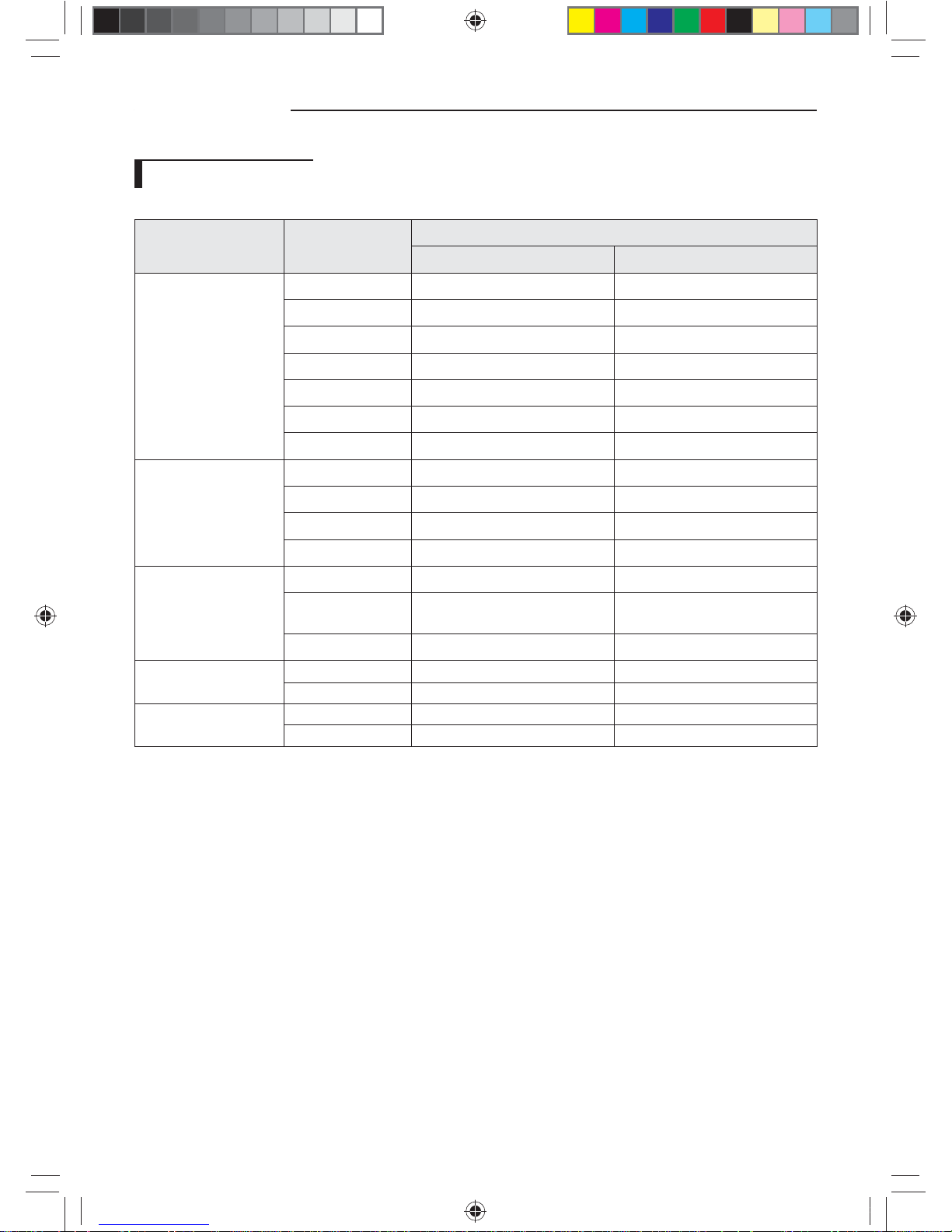

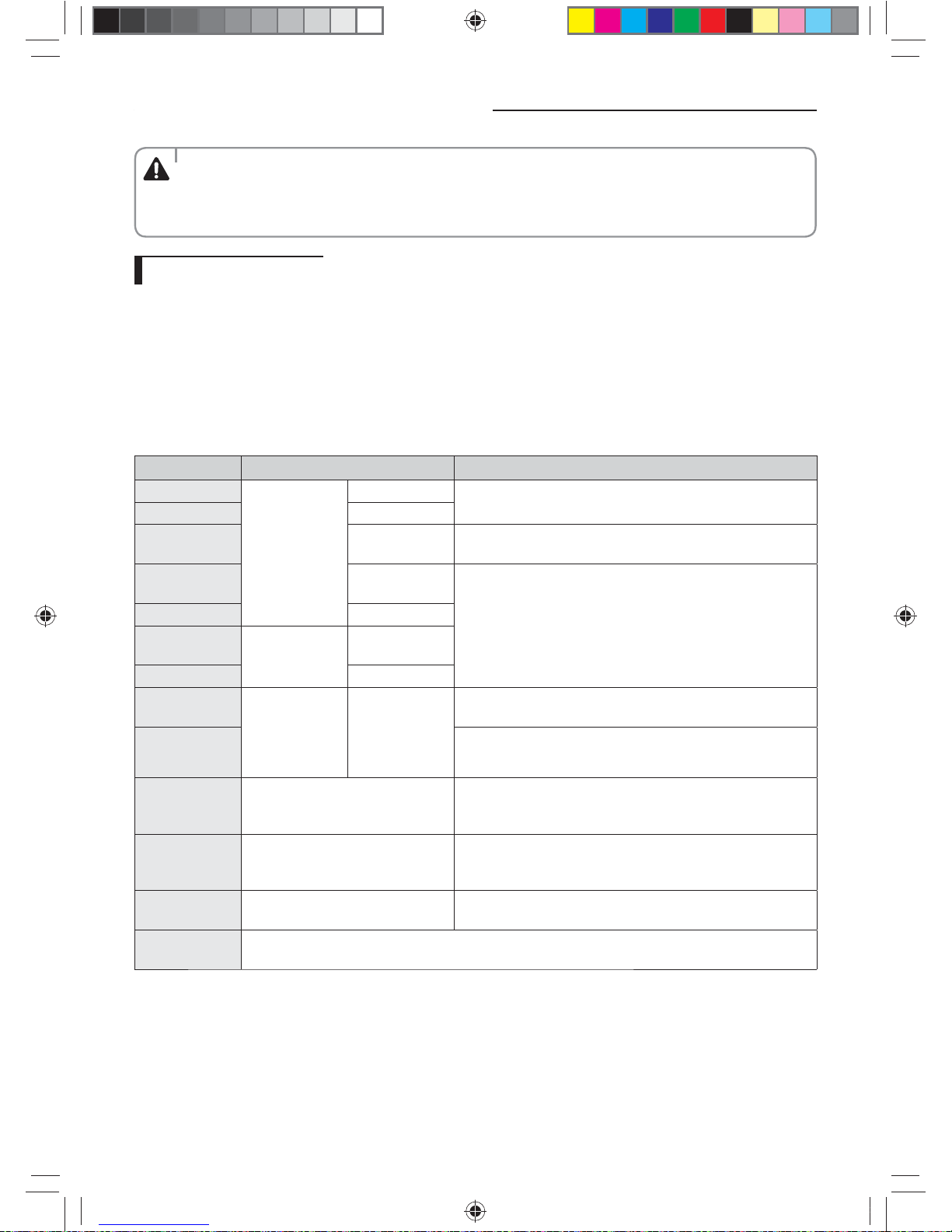

Outdoor unit combination

f Make sure to use an indoor unit that is compatible with DVM S.

f Indoor units can be connected within the range indicated in following table.

f If the total capacity of the connected indoor units exceeds the indicated maximum capacity, cooling and heating capacity

of the indoor unit may decrease.

f Total capacity of the connected indoor units can be allowed from 50% to 130% of the total outdoor unit capacity.

0.5 × Σ(Outdoor unit capacity) ≤ Total capacity of the connected indoor units ≤ 1.3 × Σ(Outdoor unit capacity)

❋ You can connect maximum 64 indoor units to the outdoor unit. Maximum quantity of connectable indoor unit is set to 64

since outdoor unit only support up to 64 communication address. Indoor unit address can be assigned from 0~63. If the

indoor unit address was assigned from 64~79, E201 error will occur.

❋ Maximum 32 Wall-mount type indoor units with EEV (AM✴✴✴HNQDC✴) can be connected.

❋ Do not install 1st-generation MCU and 2nd-generation MCU together.

- 1st-generation MCU: MCU-S✴NEE✴N, MCU-S2NEK1N

- 2nd-generation MCU: MCU-S✴NEK2N, MCU-S4NEK3N, MCU-S1NEK1N

• Use the following table to determine the size and number of outdoor units needed to achieve thecapacity

requirements.

CAUTION

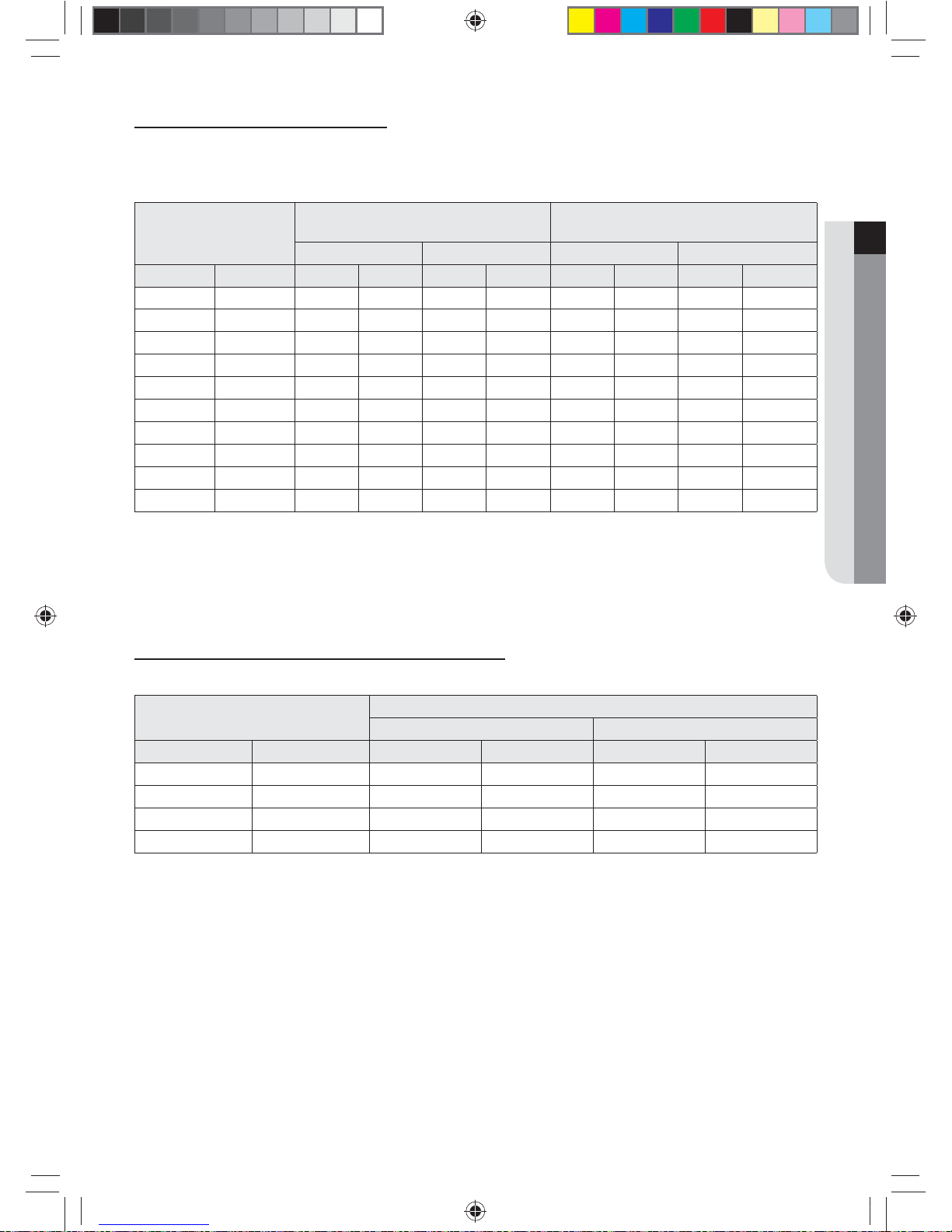

Module combination for AM✴✴✴F✴ Series, AM✴✴✴H✴ Series

Model name for Combination

6TON 8TON 10TON 12TON

AM072FXVA✴✴ AM096FXVA✴✴ AM120FXVA✴✴ AM144FXVA✴✴

Number of individual outdoor units

1111

Combined outdoor unit

AM072✴✴✴

1

AM096✴✴✴

1

AM120✴✴✴

1

AM144✴✴✴

1

AM168✴✴✴

AM192✴✴✴

Nominal Capacity

Cooling(btu/h)

72000 96000 120000 144000

Heating(btu/h)

81000 108000 135000 162000

Rated Capacity

Cooling(btu/h)

69000 92000 114000 138000

Heating(btu/h)

77000 103000 129000 154000

Total capacity of the connected

indoor units (cooling)

Minimum(btu/h)

36000 48000 60000 72000

Maximum(btu/h)

93600 124800 156000 187200

Maximum number of connectable indoor units

12 16 20 25

Model name for Combination

14TON 16TON 18TON 20TON

AM168HXVA✴✴ AM192HXVA✴✴ AM216JXVA✴✴ AM240JXVA✴✴

Number of individual outdoor units

1122

Combined outdoor unit

AM072✴✴✴

11

AM096✴✴✴

AM120✴✴✴

AM144✴✴✴

1

AM168✴✴✴

11

AM192✴✴✴

1

Nominal Capacity

Cooling(btu/h)

168000 192000 216000 240000

Heating(btu/h)

189000 216000 243000 270000

Rated Capacity

Cooling(btu/h)

160000 184000 206000 228000

Heating(btu/h)

180000 206000 230000 258000

Total capacity of the connected

indoor units(cooling)

Minimum(btu/h)

84000 96000 108000 120000

Maximum(btu/h)

218400 249600 280800 312000

Maximum number of connectable indoor units

29 33 37 41

k}tGzG㨰䛙G㐘㞬ὤGptluki]_TWZ_XYhTW_UGGG^ YWX_TW]TXXGGG㝘䟸G[a[_aYZ

8

Preparing for installation

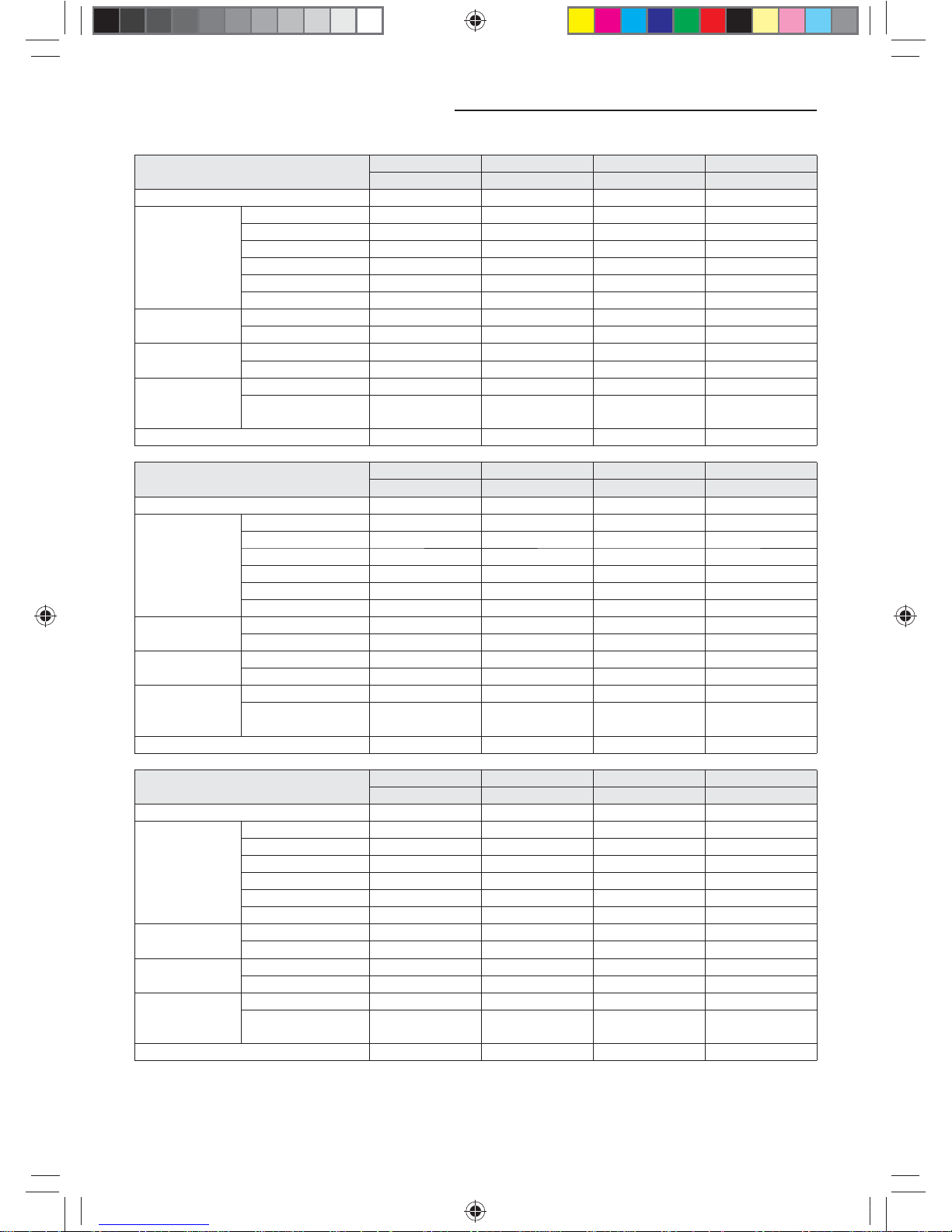

Model name for Combination

22TON 24TON 26TON 28TON

AM264JXVA✴✴ AM288JXVA✴✴ AM312JXVA✴✴ AM336JXVA✴✴

Number of individual outdoor units

2222

Combined outdoor

unit

AM072✴✴✴

1

AM096✴✴✴

AM120✴✴✴

AM144✴✴✴

21

AM168✴✴✴

12

AM192✴✴✴

1

Nominal Capacity

Cooling(btu/h)

264000 288000 312000 336000

Heating(btu/h)

297000 324000 351000 378000

Rated Capacity

Cooling(btu/h)

252000 276000 298000 320000

Heating(btu/h)

282000 308000 334000 360000

Total capacity of the

connected indoor

units(cooling)

Minimum(btu/h)

132000 144000 156000 168000

Maximum(btu/h)

343200 374400 405600 436800

Maximum number of connectable indoor units

45 49 54 58

Model name for Combination

30TON 32TON 34TON 36TON

AM360JXVA✴✴ AM384JXVA✴✴ AM408JXVA✴✴ AM432JXVA✴✴

Number of individual outdoor units

2233

Combined outdoor

unit

AM072✴✴✴

1

AM096✴✴✴

AM120✴✴✴

AM144✴✴✴

13

AM168✴✴✴

1

AM192✴✴✴

121

Nominal Capacity

Cooling(btu/h)

360000 384000 408000 432000

Heating(btu/h)

405000 432000 459000 486000

Rated Capacity

Cooling(btu/h)

344000 366000 390000 415000

Heating(btu/h)

386000 410000 435000 460000

Total capacity of the

connected indoor

units(cooling)

Minimum(btu/h)

180000 192000 204000 216000

Maximum(btu/h)

468000 499200 530400 561600

Maximum number of connectable indoor units

62 64 64 64

Model name for Combination

38 TON 40 TON 42 TON 44 TON

AM456JXVA✴✴ AM480JXVA✴✴ AM504JXVA✴✴ AM528JXVA✴✴

Number of individual outdoor units

3333

Combined outdoor

unit

AM072✴✴✴

AM096✴✴✴

AM120✴✴✴

1

AM144✴✴✴

1

AM168✴✴✴

2232

AM192✴✴✴

1

Nominal Capacity

Cooling(btu/h)

456000 480000 504000 528000

Heating(btu/h)

513000 540000 567000 594000

Rated Capacity

Cooling(btu/h)

435000 455000 480000 500000

Heating(btu/h)

490000 510000 535000 560000

Total capacity of the

connected indoor

units(cooling)

Minimum(btu/h)

228000 240000 252000 264000

Maximum(btu/h)

592800 624000 655200 686400

Maximum number of connectable indoor units

64 64 64 64

k}tGzG㨰䛙G㐘㞬ὤGptluki]_TWZ_XYhTW_UGGG_ YWX_TW]TXXGGG㝘䟸G[a[_aYZ

9

ENGLISH

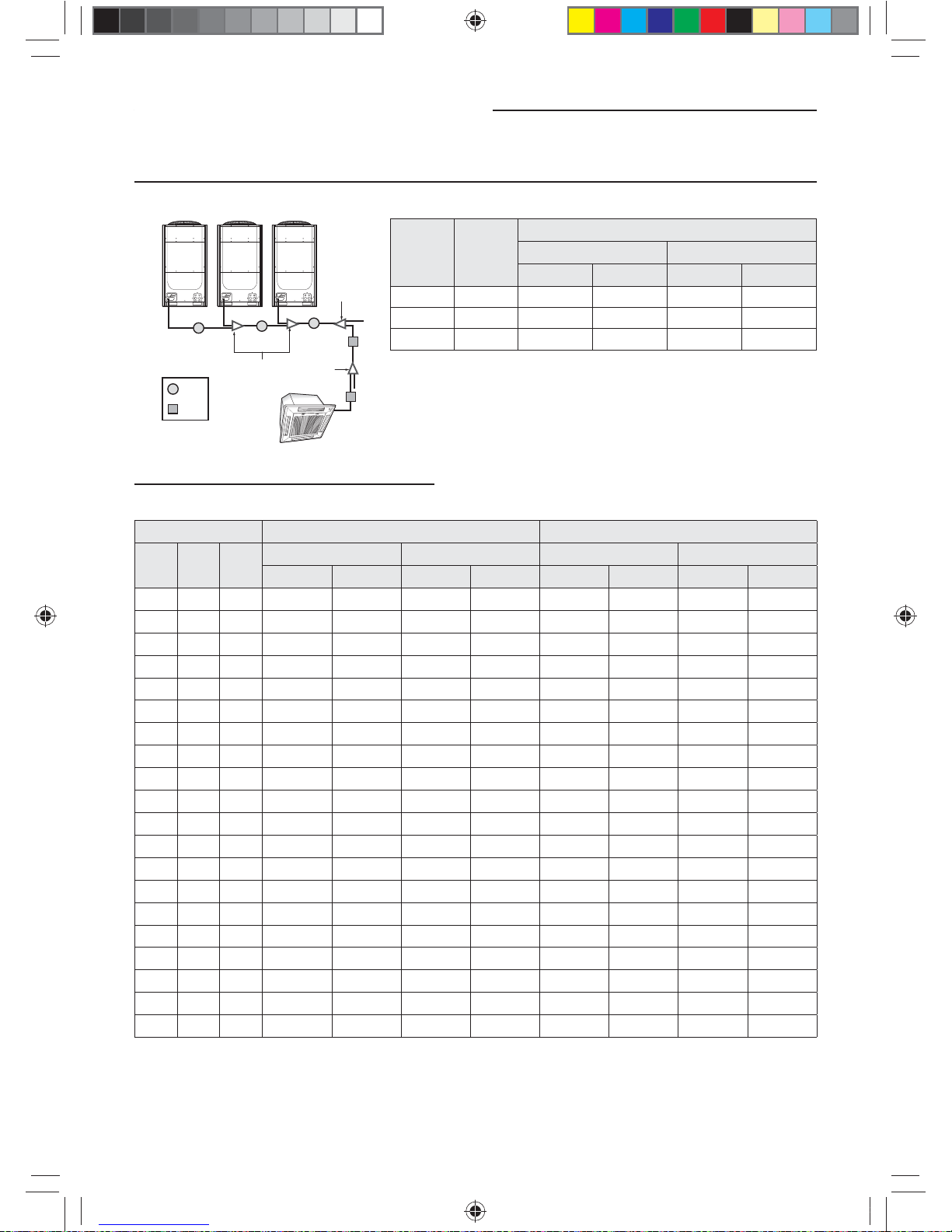

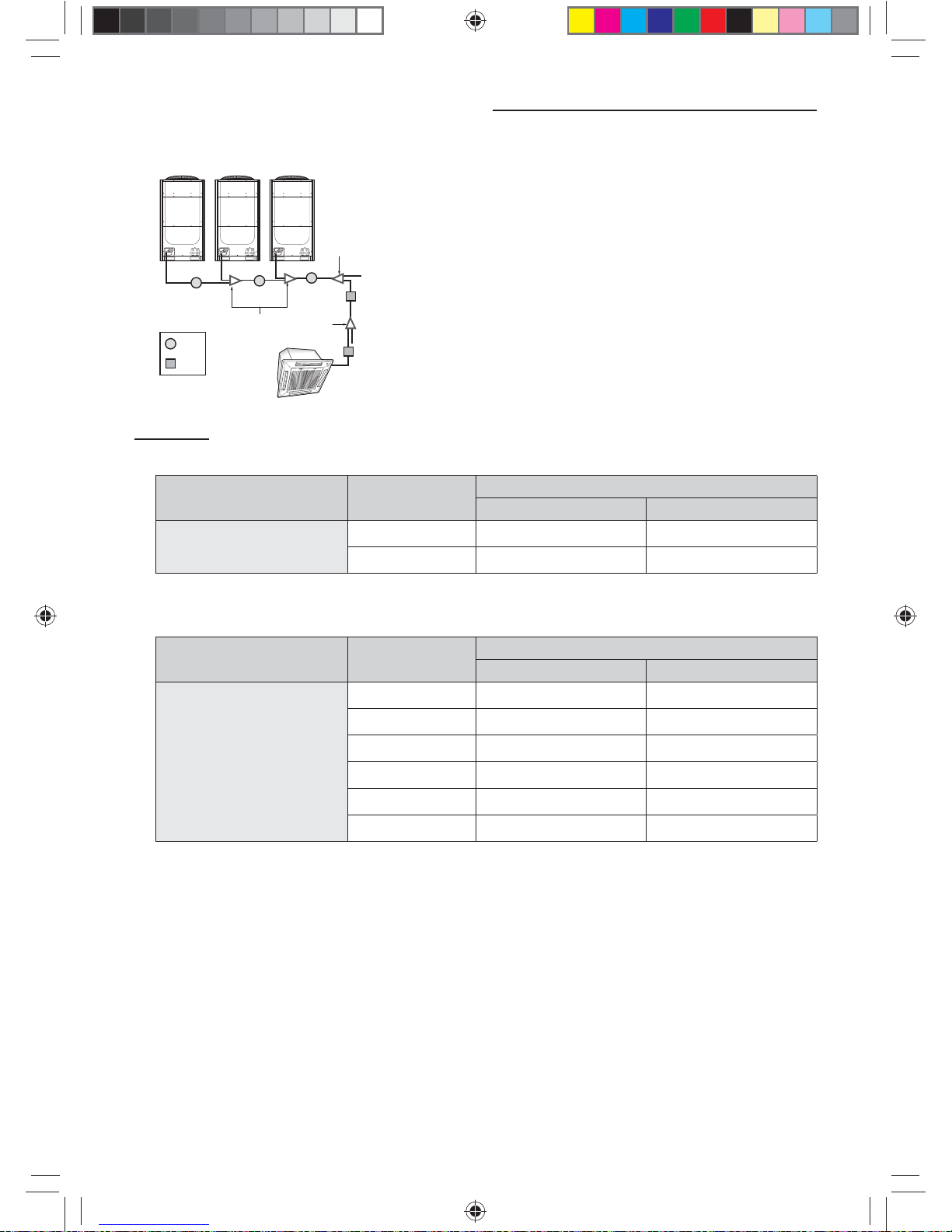

f Module combination for AM192H✴✴✴J✴ , AM216K✴✴✴J✴

Model name for Combination

18 TON 34 TON 36 TON

AM216KXVGJ✴ AM408KXVGJ✴ AM432KXVGJ✴

Number of individual outdoor units

122

Combined outdoor

unit

AM192H✴✴✴J✴

(Large A type)

1

AM216K✴✴✴J✴

(Large B type)

112

Nominal Capacity

Cooling(btu/h)

216000 408000 432000

Heating(btu/h)

243000 459000 486000

Rated Capacity

Cooling(btu/h)

206000 390000 415000

Heating(btu/h)

230000 435000 460000

Total capacity of

the connected

indoor

units(cooling)

Minimum(btu/h)

108000 204000 216000

Maximum(btu/h)

280800 530400 561600

Maximum number of connectable indoor units

37 64 64

f Module combination for AM✴✴✴K✴ Series

Model name for Combination

6 TON 8 TON 12 TON 14 TON

AM072KXVT✴✴ AM096KXVT✴✴ AM144KXVT✴✴ AM168KXVT✴✴

Number of individual outdoor units

1122

Combined outdoor

unit

AM072✴✴✴

121

AM096✴✴✴

11

Nominal Capacity

Cooling(btu/h)

72000 96000 144000 168000

Heating(btu/h)

81000 108000 162000 189000

Rated Capacity

Cooling(btu/h)

69000 92000 138000 160000

Heating(btu/h)

77000 103000 154000 180000

Total capacity of the

connected indoor

units(cooling)

Minimum(btu/h)

36000 48000 72000 84000

Maximum(btu/h)

93600 124800 187200 218400

Maximum number of connectable indoor units

12 16 25 29

Model name for Combination

16 TON 18 TON 20 TON 22 TON 24 TON

AM192KXVT✴✴ AM216KXVT✴✴ AM240KXVT✴✴ AM264KXVT✴✴ AM288KXVT✴✴

Number of individual outdoor units

23333

Combined outdoor

unit

AM072✴✴✴

321

AM096✴✴✴

2123

Nominal Capacity

Cooling(btu/h)

192000 216000 240000 264000 288000

Heating(btu/h)

216000 243000 270000 297000 324000

Rated Capacity

Cooling(btu/h)

184000 206000 228000 252000 276000

Heating(btu/h)

206000 230000 258000 282000 308000

Total capacity of the

connected indoor

units(cooling)

Minimum(btu/h)

96000 108000 120000 132000 144000

Maximum(btu/h)

249600 280800 312000 343200 374400

Maximum number of connectable indoor units

33 37 41 45 49

❋ You can connect maximum 64 indoor units to the outdoor unit. Maximum quantity of connectable indoor unit is set to 64

since outdoor unit only support up to 64 communication address. Indoor unit address can be assigned from 0~63. If the

indoor unit address was assigned from 64~79, E201 error will occur.

❋ Minimum capacity of the indoor unit is 6.0 MBH.

• Installation combination must be complied when composing outdoor unit combination.

CAUTION

k}tGzG㨰䛙G㐘㞬ὤGptluki]_TWZ_XYhTW_UGGG` YWX_TW]TXXGGG㝘䟸G[a[_aY[

10

Preparing for installation

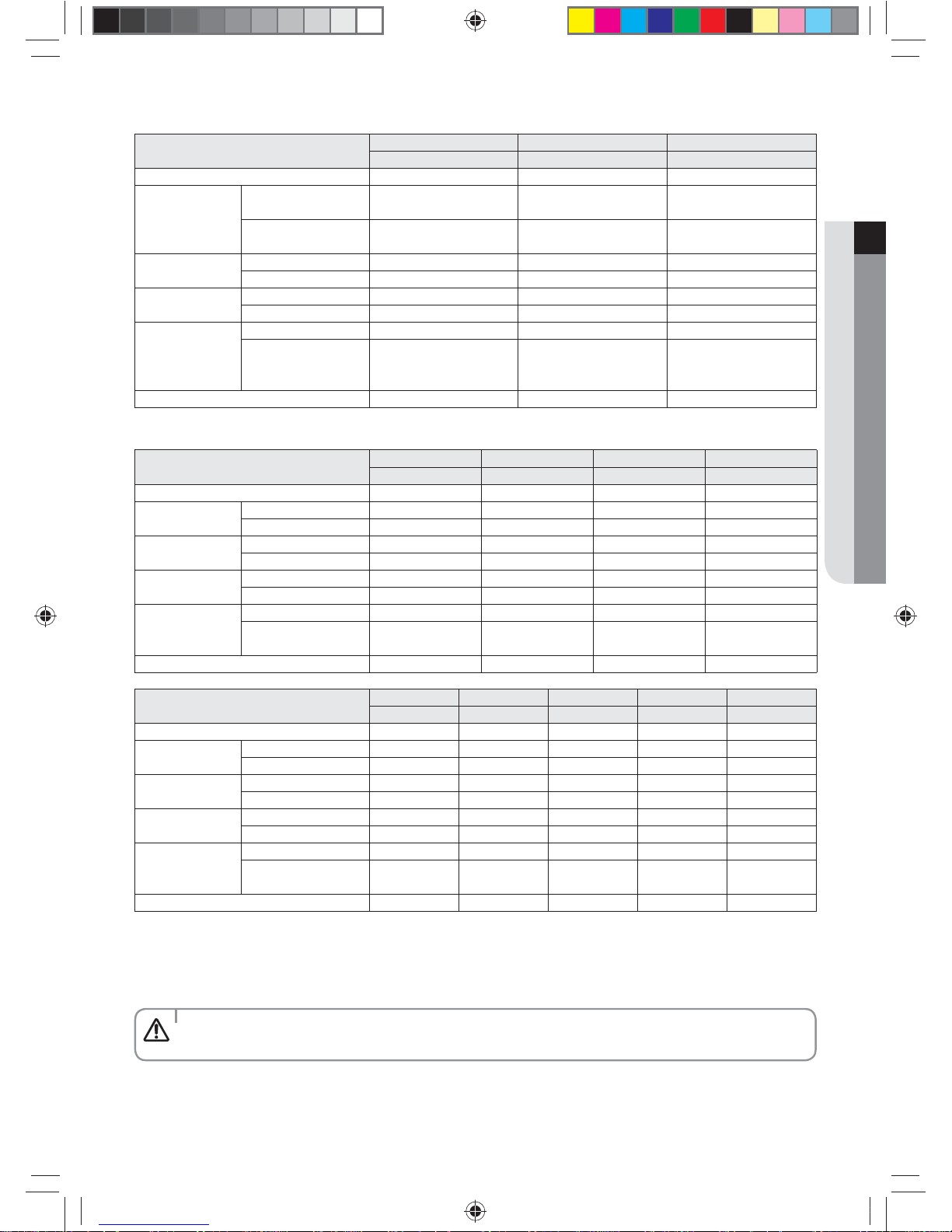

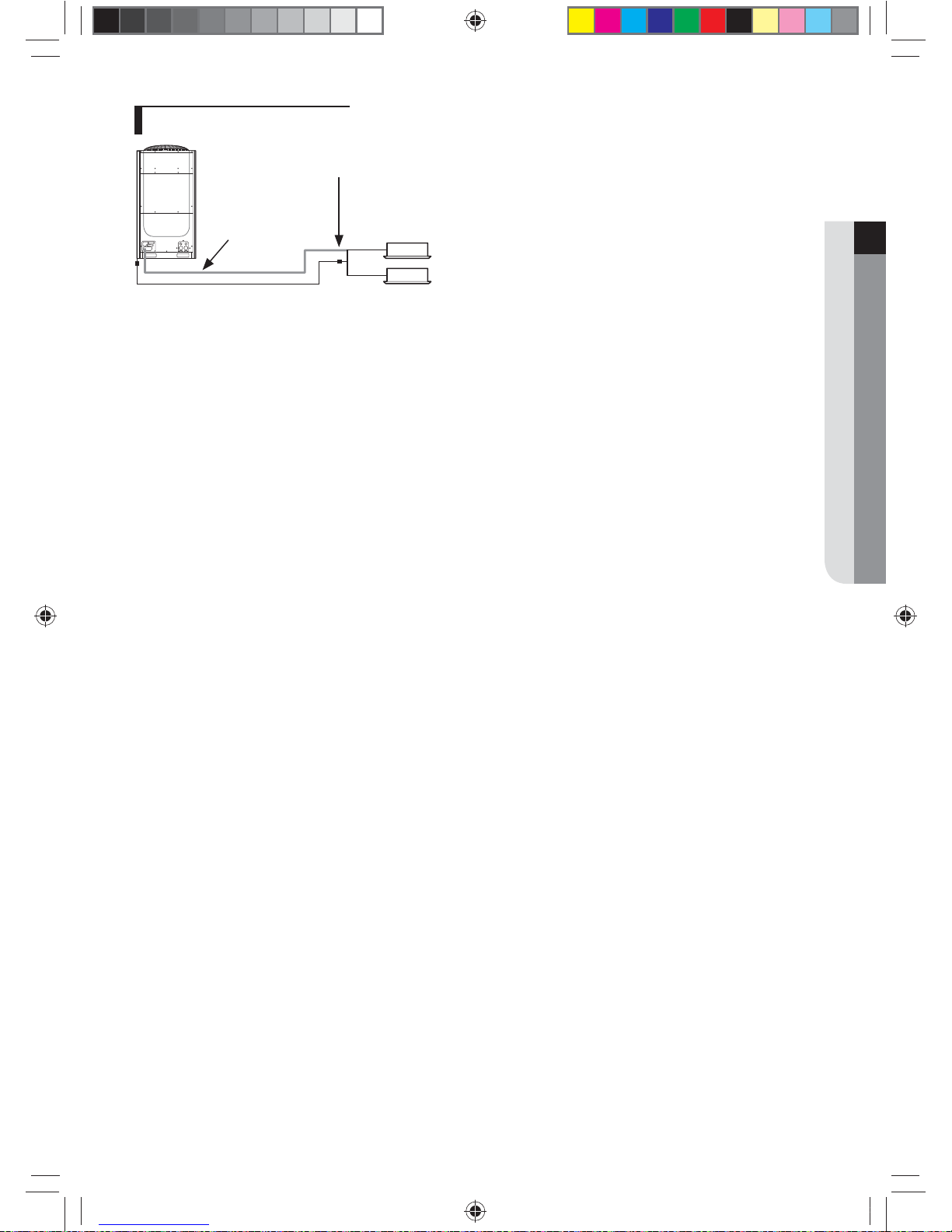

Moving the outdoor unit

f Select the moving path in advance.

f Be sure that moving path can support weight of the outdoor unit.

f Do not slant the product more than 30˚ when carrying it. (Do not lay the product down in sideways.)

f Surface of the heat exchanger is sharp. Be careful not to get injured while moving the product.

• You must use certain part of the product when moving the product.

CAUTION

When moving with a crane

f Fasten the wire rope as shown in the gure.

f To protect damage or scratches, insert a piece of cloth between the

outdoor unit and the wire rope.

Wire rope

Holes for wire rope to go

through

When moving with a forklift

f Carefully insert the forklift forks into the forklift holes at the bottom of

the outdoor unit.

f Be careful with the forklift from damaging the product.

Forklift

Forklift holes

Holes for forklift forks

to go through

When moving the product without wooden pallet and the crane is not available for use

f Connect a wire rope to the outdoor unit as you would move it with a

crane.

f Hang the wire rope to the forklift fork to move the outdoor unit.

Wire rope

Forklift

k}tGzG㨰䛙G㐘㞬ὤGptluki]_TWZ_XYhTW_UGGGXW YWX_TW]TXXGGG㝘䟸G[a[_aY[

11

ENGLISH

Selecting installation location

Decide the installation location, with the consideration of the following conditions, under user’s approval.

f Place where hot discharge air or noise from the outdoor unit may not disturb the neighbor (Especially in residential areas,

keep the operation hours in mind.)

f Place where structure can bear the weight and vibration of the outdoor unit.

f Place with at surface where rainwater does not settle or leak.

f Place where it is not exposed to strong wind.

f Well ventilated place with sucient service place for repairs and maintenance. (Discharge duct can be purchased

separately)

f Place where you can connect the refrigerant pipes between indoor and outdoor units within allowable distance.

f Place where it allows easy waterproong and draining work for the condensation water generated from the outdoor unit

during heating operation.

f Place where there is no risk of inammable gas leakage.

f Place where there is no direct inuence of snow or rain.

f Do not install the product in a place where it will be directly exposed to sea breeze.

- Consult an installation expert (or company) since you will need to take extra anti-corrosion measures if you need to

install the product in a place where it can be exposed to direct sea breeze. (You have to remove dusts and salinity on

the heat exchanger and apply designated rust inhibitor more than once a year.)

Sea

Sea breeze

Outdoor

unit

Outdoor

unit

❋ Caution when installing the product in seashore

- When installing the product in seashore, make sure to install it behind a structure (such as building) that can block the

sea breeze or install protection wall around the outdoor unit.

- Make sure to install the product in a place where it allows smooth drainage.

Protection wall should be constructed with a solid material that

can block the sea breeze and the height and width of the wall

should be 1.5 times larger than the size of the outdoor unit. (You

must secure more than 700mm(28inch) of space between the

protection wall and the outdoor unit for air circulation.)

Sea

Sea breeze

Outdoor

unit

Protection wall

Outdoor unit

Sea

Sea breeze

Outdoor

unit

k}tGzG㨰䛙G㐘㞬ὤGptluki]_TWZ_XYhTW_UGGGXX YWX_TW]TXXGGG㝘䟸G[a[_aY[

12

Selecting installation location

• System air conditioner may cause static noise when listening to AM stations. Therefore, select an installation

location for indoor unit where electrical wiring can be done while keeping certain distance from a radio,

computer and stereo equipment.

- Especially, keep the unit at least 3m(9.84inch) away from the electrical equipment in an area with weak

electromagnetic waves and put the main power cable and communication cables in a separately installed

protection tube.

- Make sure that there is no equipment that generates electromagnetic waves. If not electromagnetic waves

may cause problem to the control systems which may lead to air conditioner malfunction. (Example: Remote

control sensor of the indoor unit may not receive the signal very well, due to ballast stabilizer of the lighting

equipment.)

• In regions with heavy snowfall, make sure to install the outdoor unit where there is no concerns of direct

snowfall on the outdoor unit. Also, build higher base support so that accumulated snow does not block the air

inlet or the heat exchanger.

• R-410A refrigerant is a safe, nontoxic and nonammable refrigerant. However, if the place holds any concerns for

exceeding dangerous level of refrigerant concentration in case of refrigerant leakage, extra ventilation system is

required.

• When you install the outdoor unit in a high places such as roof, install fence or guardrail around it. When there is

no fence or guardrail, service person could fall.

• Do not install the product in places where corrosive gases such as sulfur oxides, ammonia, and sulfurous gas are

produced. (e.g. Toilet outlet, ventilation opening, sewage works, dyeing complex, cattle shed, sulfuric hot spring,

nuclear power plant, ship etc.) When installing the product in those places, contact an installation specialty

store as the copper pipe and brazing part will need additional corrosion proof or anti-rust additive to prevent

corrosion.

• Make sure to keep away inammable materials (such as wooden materials, oil etc.) around the outdoor unit.

When there's re, those inammable material will easily catch the re and may pass it on to the product.

• Depending on the condition of power supply, unstable power or voltage any cause malfunction of the parts or

control system. (At the ship or places using power supply from electric generator...etc)

• Make sure to install MCU when using HR products.

• When you select the location to install MCU, the location is far away from indoor rooms because the refrigerant

running of MCU may create noise.

CAUTION

k}tGzG㨰䛙G㐘㞬ὤGptluki]_TWZ_XYhTW_UGGGXY YWX_TW]TXXGGG㝘䟸G[a[_aY[

13

ENGLISH

Space requirement for installation

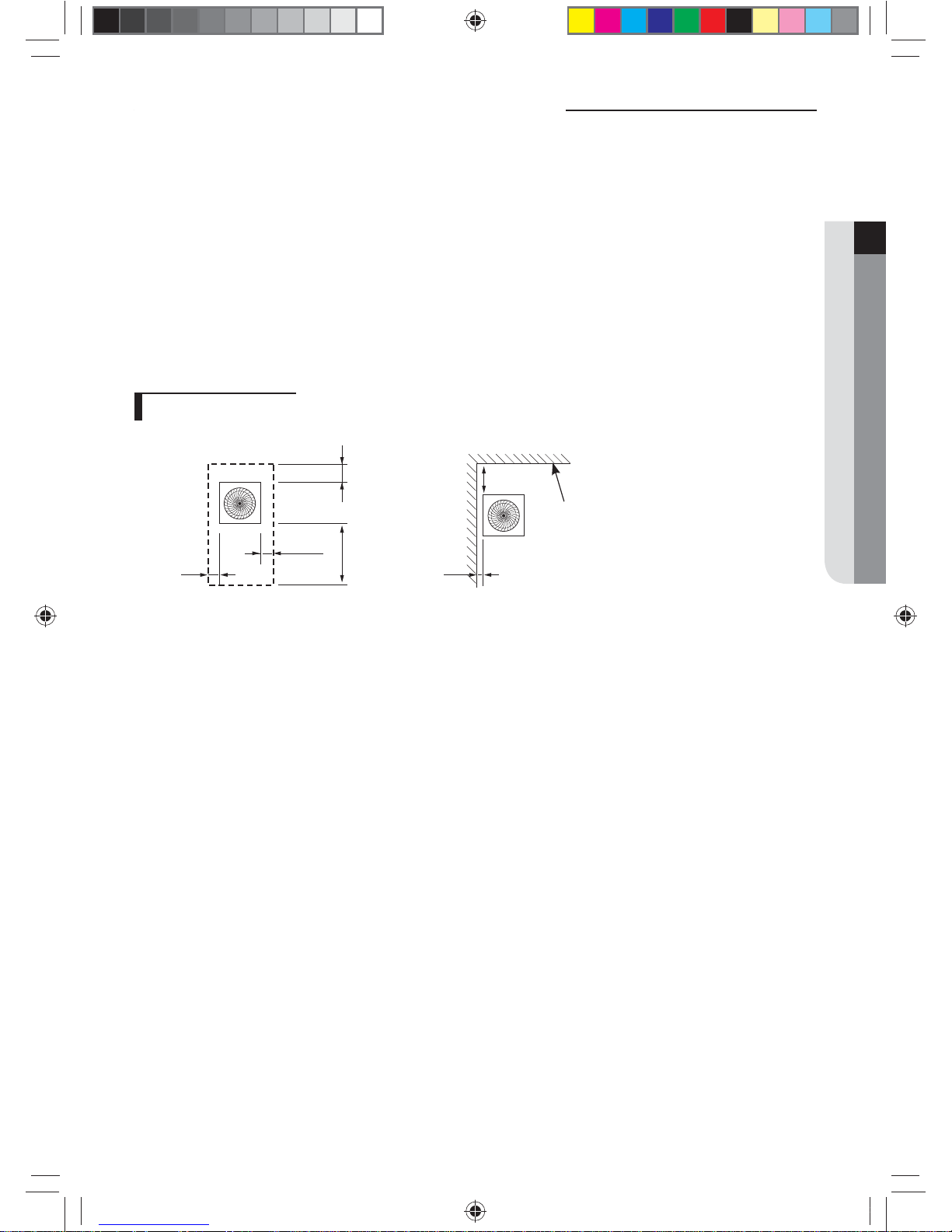

f Space requirement was decided based on following conditions; Cooling mode, outdoor temperature of 35°C (95°F).

Larger space is required if the outdoor temperature is higher than 35°C (95°F) or if the place is heated easily by quantity of

solar radiation.

f When you secure installation space, consider path for people and the direction of the wind.

f Secure installation space as shown in the below illustration, considering ventilation and the service space.

f If the installation space is narrow, installer or other worker may get injured during work and may also cause problem to

the product.

f If you install multiple number of outdoor units in one space, make sure to secure enough ventilation space if there’s

any walls around the product that may disturb the air ow. If enough ventilation space is not secured, product may

malfunction.

f You may install the outdoor units with 20mm (0.78 inch) of space between the product, but product’s performance may

decrease depending on the installation environment.

Single installation

Unit: mm (inch)

Height of the wall is

unlimited

Over 100 (4)

[S2]

Over 500 (20)

[S1]

Over 100 (4) Over 100 (4)

Front

side

Over 100 (4)

Over 300 (12)

<Case 1> <Case 2>

Front side

k}tGzG㨰䛙G㐘㞬ὤGptluki]_TWZ_XYhTW_UGGGXZ YWX_TW]TXXGGG㝘䟸G[a[_aY[

14

Space requirement for installation

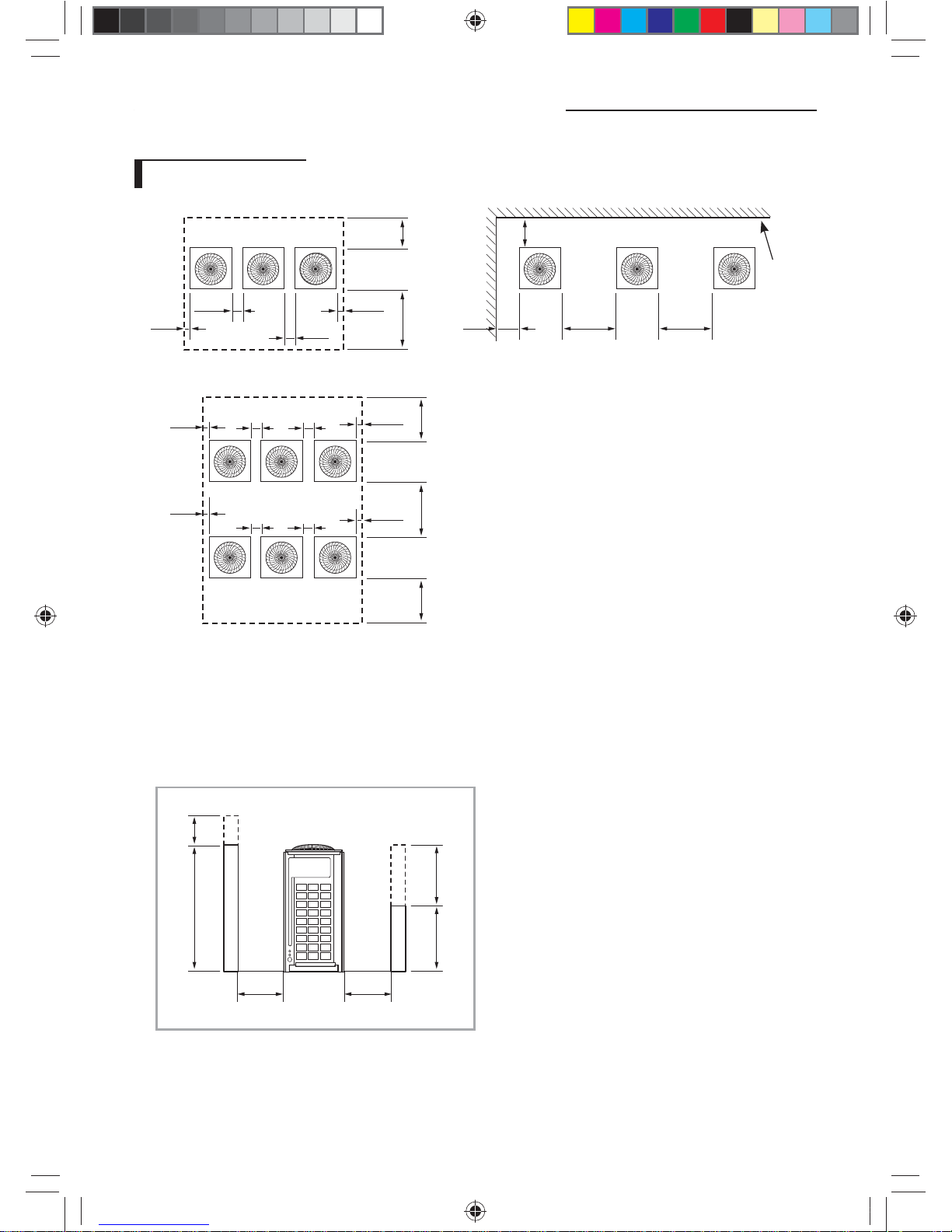

Module installation

<Case 3>

Over 500

(20)

Over 500

(20)

Over 600

(24)

Over 100 (4) Over 100 (4)

Over 100 (4)

Over 100 (4)

Over 100 (4) Over 100 (4) Over 100 (4)

Over 100 (4)

Front side

Front side

<Case 1> <Case 2>

Over 200 (8)

Over 100 (4)

Over 300 (12)

[S2]

Over 500

(S1)

Over 100 (4)

Over 100 (4)

Over 100 (4)

Over 300 (12)

Over 400

(16)

Over 400

(16)

Height of

the wall is

unlimited

Front

side

Front side

❋ For <Case 1> or <Case 3>

• Height of the wall on the front side should not be higher than 1500mm (60 inch).

• Height of the wall on the air inlet side should not be higher than 500mm (20 inch).

• Height of the wall on the side is not limited.

• If the height of the wall exceeds by certain value (h1, h2), additional clearance [(h1)/2, (h2)/2 : Half of the exceeded

distance] should be added to the service space (S1, S2).

1500 (60) h1

500 (20) h2

Front side

Air inlet side

Unit: mm (inch)

S1+h1/2 S2+h2/2

k}tGzG㨰䛙G㐘㞬ὤGptluki]_TWZ_XYhTW_UGGGX[ YWX_TW]TXXGGG㝘䟸G[a[_aY[

15

ENGLISH

Accessories

Accessories

f You must keep following accessories until the installation is nished.

f Hand over the installation manual to the customer after nishing the installation.

Installation manual (1) *Installation socket (1) Brand Label (1) Instruction sheet (1)

❋ Models with installaton socket

MODEL

(AM✴✴✴F✴, AM✴✴✴H✴ Series)

HR HP

GAS LIQUID HIGH GAS SOCKET GAS LIQUID SOCKET

6TON

Pipe in Production

3/4" 3/8" 5/8" X 3/4" 3/8" X

Installaton Pipe

8TON✴

Pipe in Production 1-1/8" 1/2" 7/8"

O

1" 1/2"

O

Installaton Pipe 7/8" 3/8" 3/4" 7/8" 3/8"

10TON

Pipe in Production

1-1/8" 1/2"

7/8"

O

1"

1/2" O

Installaton Pipe 3/4" 1-1/8"

12TON

Pipe in Production

1-1/8"

5/8" 1-1/8"

O 1-1/8" 1/2" X

Installaton Pipe 1/2" 7/8"

14TON

Pipe in Production

1-1/8" 5/8"

1-1/8"

O 1-1/8" 5/8" X

Installation Pipe 7/8"

16TON

Pipe in Production

1-1/8" 5/8" 1-1/8" X 1-1/8" 5/8" X

Installation Pipe

MODEL (AM✴✴✴K✴ Series)

HR HP

GAS LIQUID HIGH GAS SOCKET GAS LIQUID SOCKET

6TON✴

Pipe in Production

----

1-1/8" 1/2"

O

Installaton Pipe 3/4" 3/8"

8TON✴

Pipe in Production

----

1-1/8" 5/8"

O

Installaton Pipe 7/8" 3/8"

18TON✴

Pipe in Production 1-3/8" 3/4"

1-1/8" O

1-3/8"

5/8" O

Installaton Pipe 1-1/8" 5/8" 1-1/8"

EX) Cut the scoket for high gas pipe and liquid pepe (In case of 8TON HR)

ID3/4" ID7/8" ID 1 1/8" OD 1 3/8"

cutting line cutting line

Socket for Gas and High gas pipe

ID3/8" ID1/2" ID 5/8"

Socket for Liquid pipe

k}tGzG㨰䛙G㐘㞬ὤGptluki]_TWZ_XYhTW_UGGGX\ YWX_TW]TXXGGG㝘䟸G[a[_aY\

16

Accessories

Optional accessories

f Following optional accessories are needed for connecting pipes between the indoor and outdoor units.

Classication Model Name

Specication

MBH KW

Y-Joint

MXJ-YA1509M 51 below 15.0 and below

MXJ-YA2512M Over 51~136 and below Over 15.0 ~40.0 and below

MXJ-YA2812M Over 136~154 and below Over 40.0 ~45.0 and below

MXJ-YA2815M Over 154~240 and below Over 45.0 ~70.3 and below

MXJ-YA3419M Over 240~336 and below Over 70.3 ~98.4 and below

MXJ-YA4119M Over 336~461 and below Over 98.4 ~135.2 and below

MXJ-YA4422M Over 461 Over 135.2

Y-Joint (Only H/R)

MXJ-YA1500M 76 and below 22.4 and below

MXJ-YA2500M Over 76~240 and below Over 22.4 ~70.3 and below

MXJ-YA3100M Over 240~461 and below Over 70.3 ~135.2 and below

MXJ-YA3800M Over 461 Over 135.2

Distribution header

MXJ-HA2512M 154 and below (for 4 rooms) 45.0 and below (for 4 rooms)

MXJ-HA3115M

Over 240 ~ 461 and below

(for 8 rooms)

Over 70.3 ~ 135.2 and below

(for 8 rooms)

MXJ-HA3819M Over 240 (for 8 rooms) Over 70.3 (for 8 rooms)

Y-Joint

- Outdoor unit

MXJ-TA3819M 461 and below 135.2 and below

MXJ-TA4422M 478.4 and over 140.2 and over

Y-Joint (Only H/R)

- Outdoor unit

MXJ-TA3100M 461.3 and below 135.2 and below

MXJ-TA3800M 478.4 and over 140.2 and over

❋ If you use an indoor unit with no internal EEV(Electric Expansion Valve), you will need an EEV kit.

❋ Only use the genuine accessories listed in above table and do not use imitated accessories.

k}tGzG㨰䛙G㐘㞬ὤGptluki]_TWZ_XYhTW_UGGGX] YWX_TW]TXXGGG㝘䟸G[a[_aY\

17

ENGLISH

Base construction and installation of the outdoor unit

• Make sure to remove the wooden pallet before installing the outdoor unit. If you do not remove the wooden

pallet, there is risk of re during welding the pipes. If the outdoor unit is installed with wooden pallet on, and

it was used for long period time, wooden palette may break and cause electrical hazard or high pressure may

damage the pipes.

WARNING

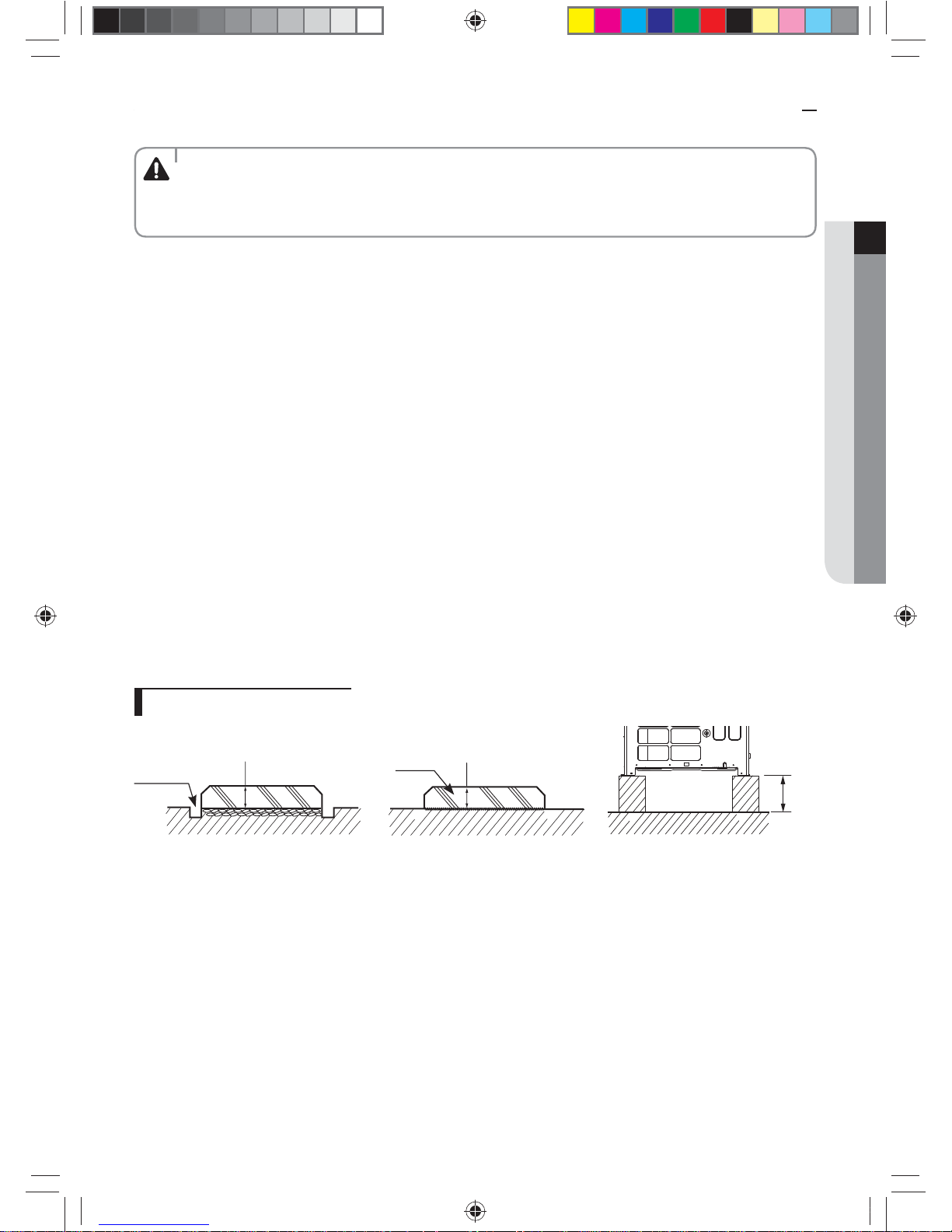

❋ Fix an outdoor unit rmly on the base ground with anchor bolts.

❋ Manufacturer is not responsible for the damage occurred by not following the installation standards.

1. Make sure that the height of the base ground is 200mm or higher to protect the outdoor unit from rain water or other

external conditions. Also, install a draining pit around the base ground and connect the drain pipe to the drainage.

2. Considering the vibration and weight of the outdoor unit, strength of the base ground must be strong to prevent noise

and the top surface of it should be at.

3. Base ground should be 1.5 times larger than the bottom of the outdoor unit.

4. Outdoor unit must be xed rmly so that it can withstand the wind speed of 30m/s. If you cannot x the outdoor unit on

the base ground, x it by side or use extra structure.

5. In heating operation, defrost water may form so you must really care about the drainage and waterproong the oor. To

prevent defrost water from stagnating or freezing, construct a drainage with over 1/50 slope. (Ice may form on the oor

in winter time.)

6. It is necessary to add wire mesh or steel bar during concrete construction for the base ground to prevent damages or

cracks.

7. When installing multiple outdoor units at the same place, construct a H beam or an anti-vibration frame on the base

ground to install the outdoor unit.

8. After installing a H beam or an anti-vibration frame, apply corrosion protection and other necessary coating.

9. When concrete construction for outdoor unit installation is completed, install an anti-vibration pad (t=20mm/0.78 inch or

more) or an anti-vibration frame to prevent vibration of the outdoor unit from transferring to the base ground.

10. Place the outdoor unit on a H beam or an anti-vibration frame and x it with the bolt, nut and washer. (The bearing force

has to be over 3.5kN)

Base ground construction

<When installing on the ground>

Draining pit

Over 200mm (8inch)

<When installing on the roof>

Bottom surface of the base

ground must be horizontally

leveled

Over 200mm (8inch)

Over 200mm (8inch)

k}tGzG㨰䛙G㐘㞬ὤGptluki]_TWZ_XYhTW_UGGGX^ YWX_TW]TXXGGG㝘䟸G[a[_aY\

18

Base construction and installation of the outdoor unit

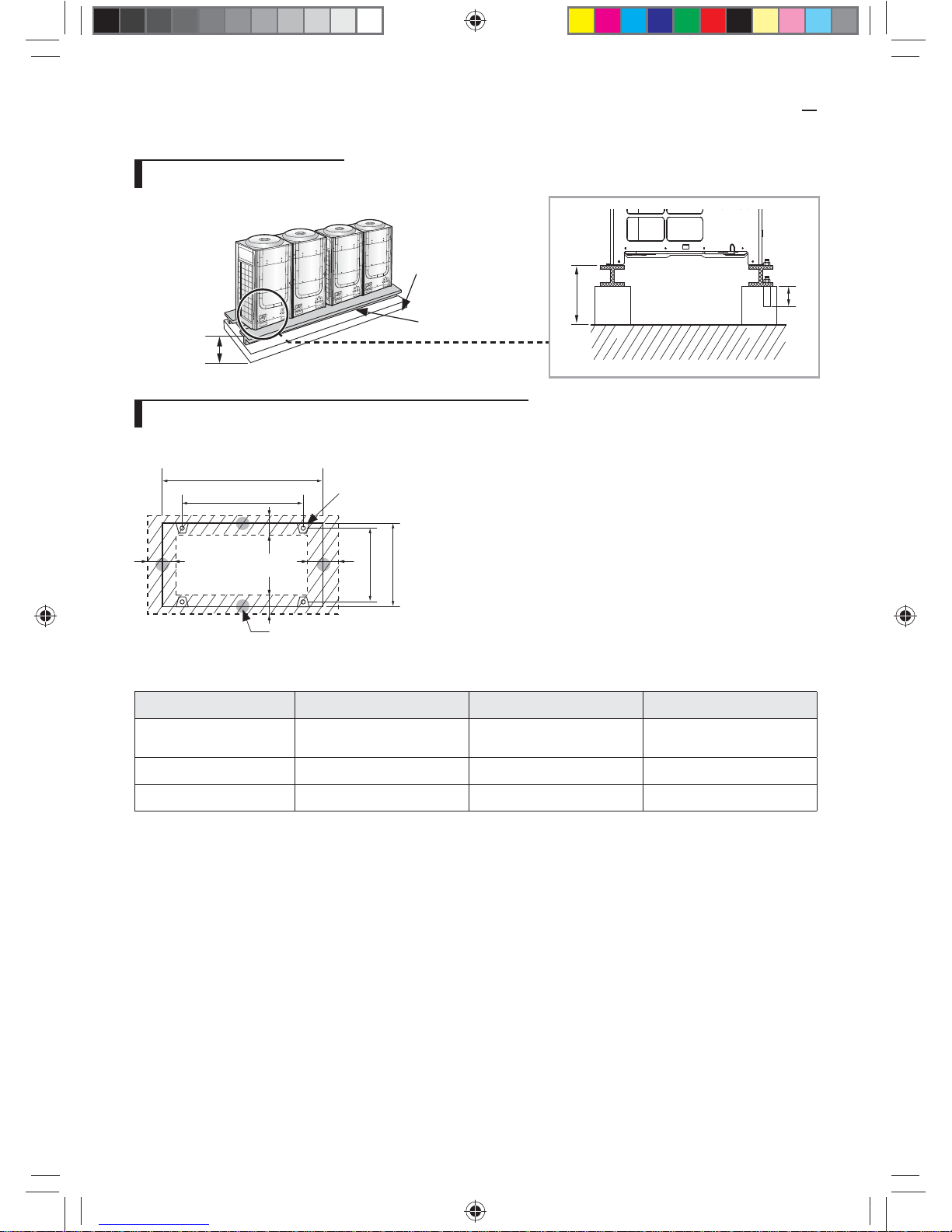

Outdoor unit installation

Over 200mm (8inch)

Over 50mm (2inch)

Base ground

H beam or anti-vibration

frame

Over 200mm

(8inch)

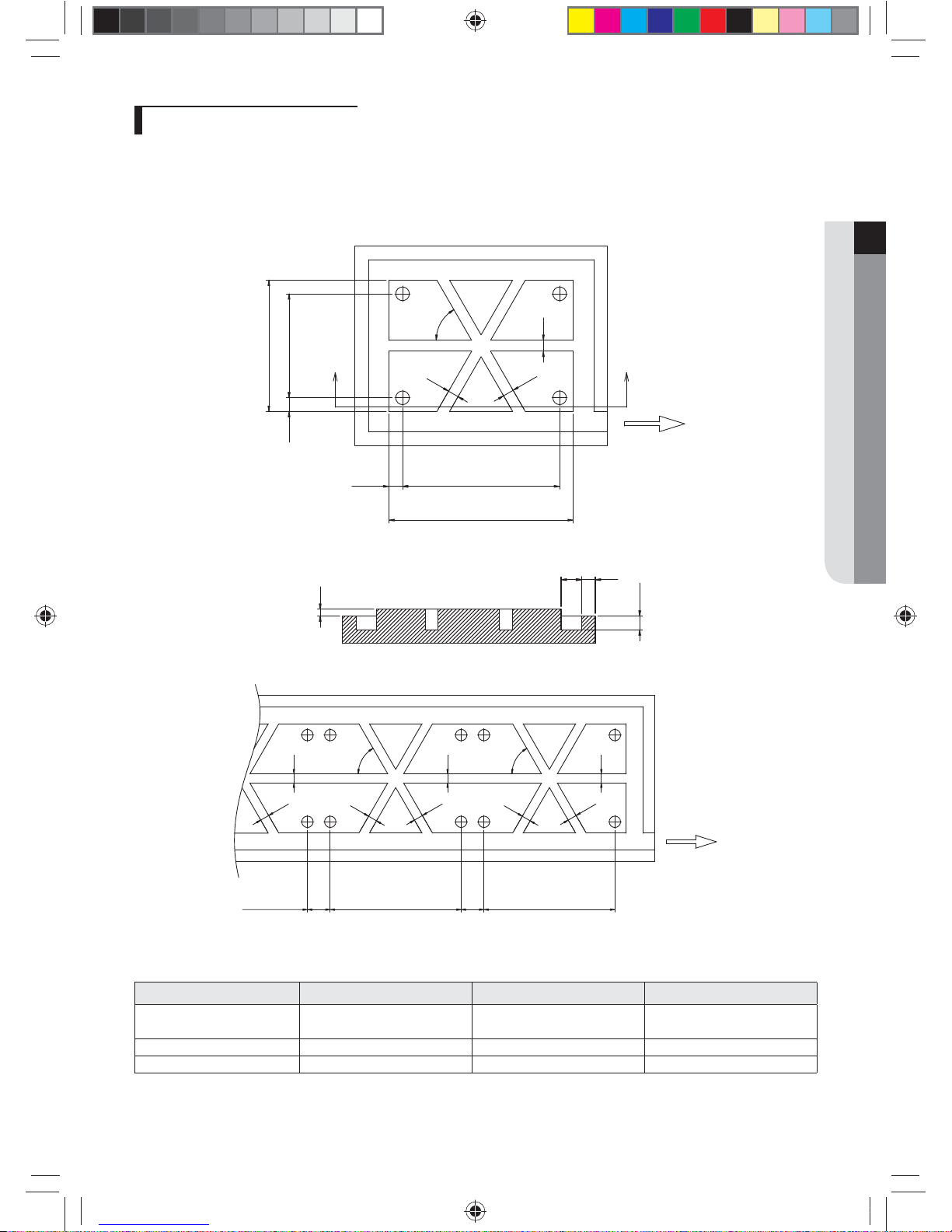

Outdoor unit base mount and anchor bolt position

Unit: mm (inch)

A

B

54

(2.13)

761 (29.96)

803 (31.61)

54

(2.13)

Outdoor unit - Anti-vibration

frame (4-Ø 12)

Anti-vibration - Base ground

(4-Ø 18)

Unit: mm (inch)

Classication Small type Large A type Large B type

Models AM072F✴

AM096/120/144F✴,

AM168/192H✴, AM072/096K✴

AM216KXVGJ✴

A 880 (34.65) 1,295 (50.98) 1,295 (50.98)

B 740 (29.13) 1,150 (45.28) 1,150 (45.28)

❋ Refer to the blueprints in technical data book to make a holes for connecting the anti-vibration pad.

k}tGzG㨰䛙G㐘㞬ὤGptluki]_TWZ_XYhTW_UGGGX_ YWX_TW]TXXGGG㝘䟸G[a[_aY\

19

ENGLISH

Examples of draining work

f Construct the drainage ditch with reinforced concretes and make sure that water-proong work is done.

f For smooth draining of defrost water, make sure to apply 1/50 slope.

f Construct a drainage around the outdoor unit to prevent the defrost water (from the outdoor unit) from stagnating,

overowing or freezing near the installation space.

f When the outdoor unit is installed on the roof, check the strength and waterproof status of the roof.

Unit: mm (inch)

960 (37.80)

760 (29.92)

100 (3.94)

80 (3.15)

80 (3.15)

80 (3

.

15)

60°

100 (3.94)

X

X’

Direction of the drainage

(Slope 1/50)

<Drainage work for single installation>

B

A

50 (1.97)

100

(3.94)

150 (5.91) 100 (3.94)

<X-X’ SECTION>

80 (3.15)

80 (3.15)

80 (3.15)

80 (3.15)

80 (3.15)

80 (3.15)

80 (3.15)

80 (3.15)

60°

60°

200

(7.87)

BB

200

(7.87)

Direction of the drainage

(Slope 1/50)

<Drainage work for module installation>

Unit: mm (inch)

Classication Small type Large A type Large B type

Models AM072F✴

AM096/120/144F✴,

AM168/192H✴, AM072/096K✴

AM216KXVGJ✴

A 940 (37.01) 1,350 (53.15) 1,350 (53.15)

B 740 (29.13) 1,150 (45.28) 1,150 (45.28)

k}tGzG㨰䛙G㐘㞬ὤGptluki]_TWZ_XYhTW_UGGGX` YWX_TW]TXXGGG㝘䟸G[a[_aY\

20

Base construction and installation of the outdoor unit

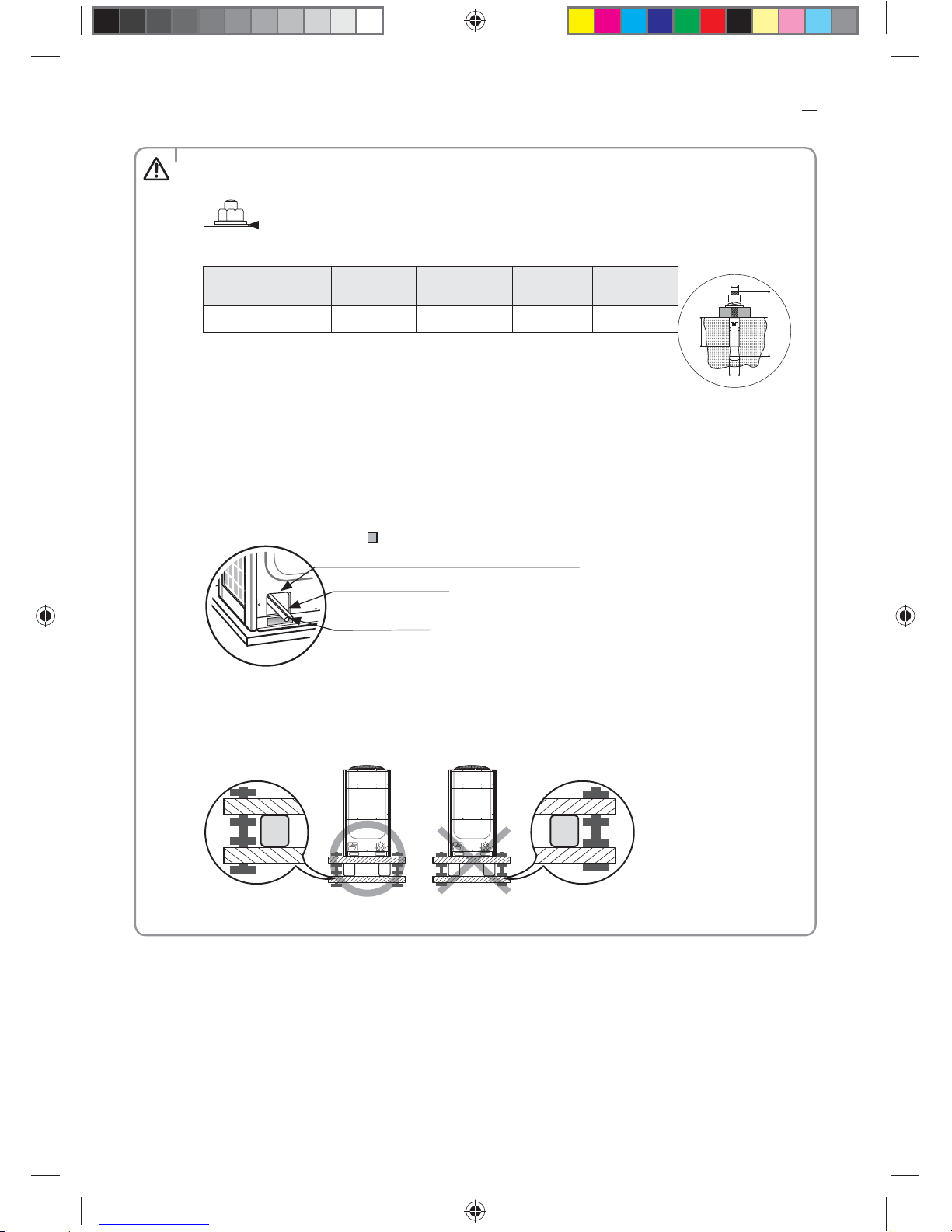

Cautions regarding on connecting the anchor bolt

f Tighten the rubber washer to prevent the bolt connection part of the outdoor unit from corroding.

Rubber washer

f Anchor specication

Size

Diameter of

drill bit (a)

Anchor length

(b)

Sleeve length

(b)

Insert depth

Fastening

torque

B

C

D

N

Ø 10 14mm (1/2") 75mm (3") 40mm (1-1/2") 50mm (2") 30 N·m

❋ Use the anchor bolts and nuts that is zinc plated or made of STS material. Regular

anchor bolts or nuts may get damaged by corrosion.

Cautions regarding on connecting the pipe

f If you install the outdoor unit on the rooftop, check the strength and make sure to waterproof the rooftop.

f Construct draining pit around the base construction and pay attention to the drainage around the outdoor

unit. (Condensation or defrost water may form during outdoor unit operation.)

f If there's any possibility of small animals from entering the pipe outlet, block the outlet as shown in the

illustration.

Liquid side pipe

Gas side pipe

Block the

part. (When withdrawing the pipe from

the front side)

Cautions regarding on anti-vibration frame installation

f During installation, make sure there is no gap between the base ground and the supporting structures such as

anti-vibration frame or H beam.

f Base ground must be constructed strongly to support the bottom part of the anti-vibration mount.

f After installing the anti-vibration frame, untighten the xing part on the top and bottom part of the frame.

CAUTION

k}tGzG㨰䛙G㐘㞬ὤGptluki]_TWZ_XYhTW_UGGGYW YWX_TW]TXXGGG㝘䟸G[a[_aY]

21

ENGLISH

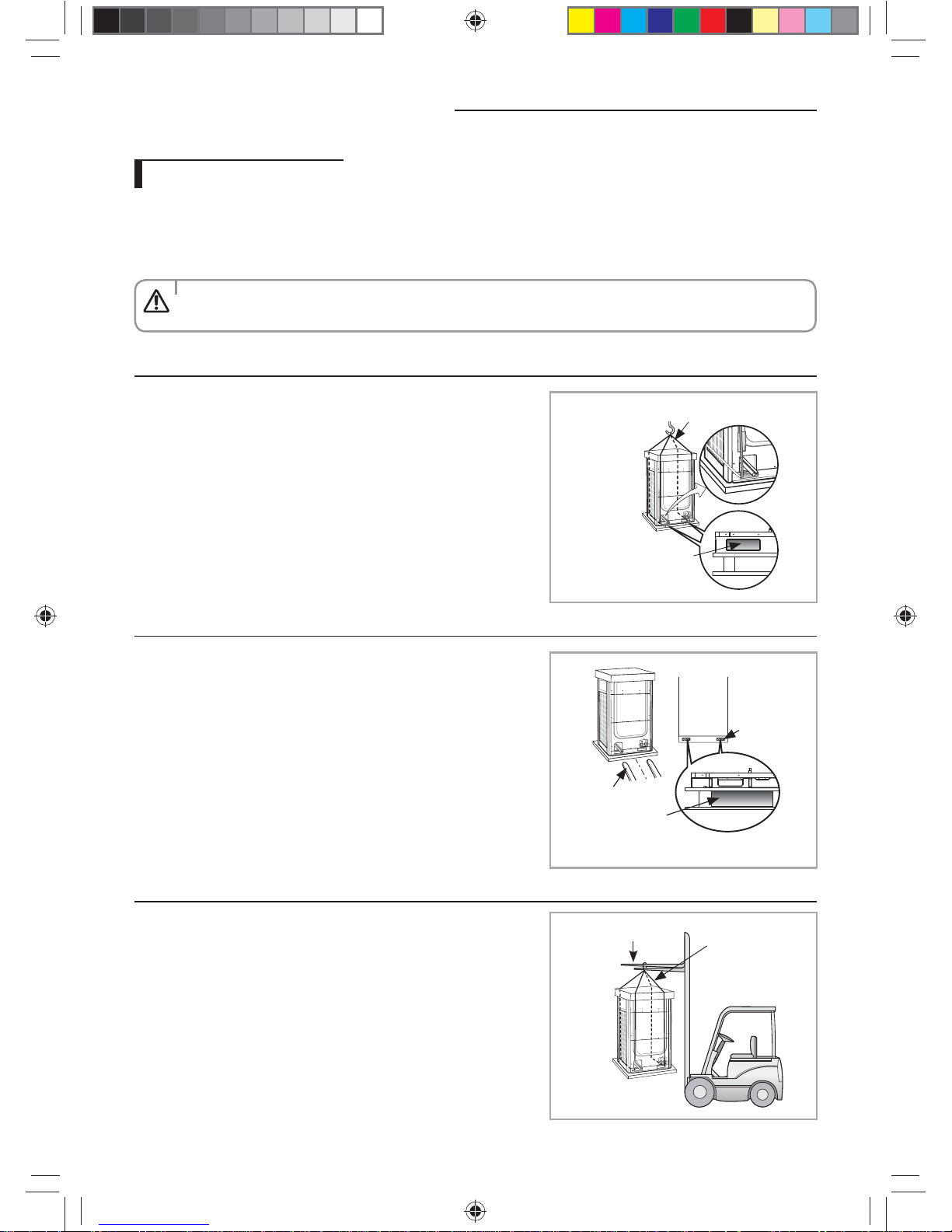

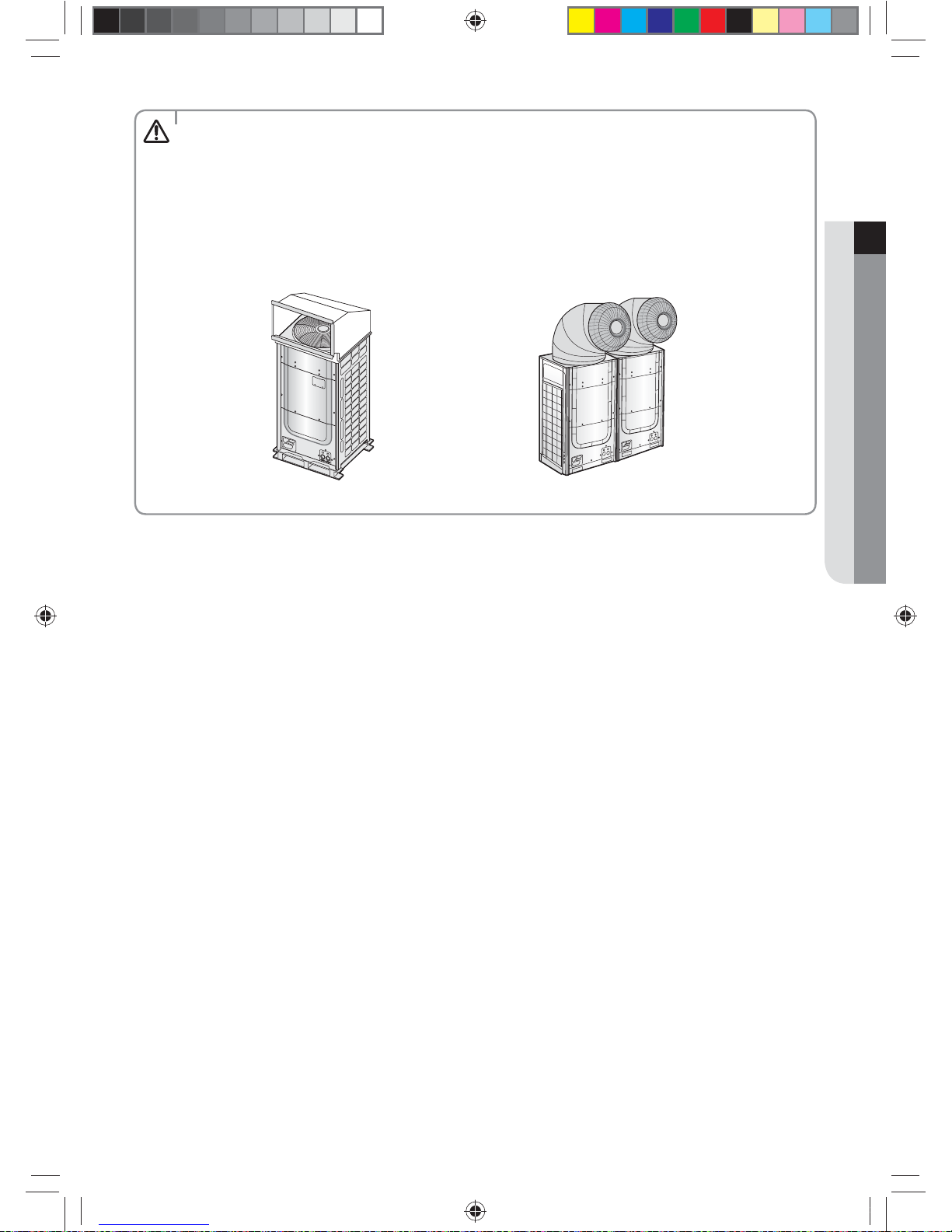

Caution for installing discharge duct

f Static pressure of the discharge duct should be within the standard specication 78.45 Pa (0.315 W.G) when

installing the duct.

f If you remove the fan guard to install the discharge duct, make sure to install a safety net on the duct outlet.

Foreign substance may enter into the product and there could be a risk of personal injury.

f Wear protection equipment at all times when making galvanized sheet metal duct, since the worker may get

injured by the sharp parts.

f When installing the outdoor unit under the tree or near forest, leafs may get into the product and cause

problems on the product. Therefore, install a discharge duct to prevent foreign substance inltration.

<Protecting discharge duct> <Preventing foreign substance inltration>

CAUTION

k}tGzG㨰䛙G㐘㞬ὤGptluki]_TWZ_XYhTW_UGGGYX YWX_TW]TXXGGG㝘䟸G[a[_aY]

22

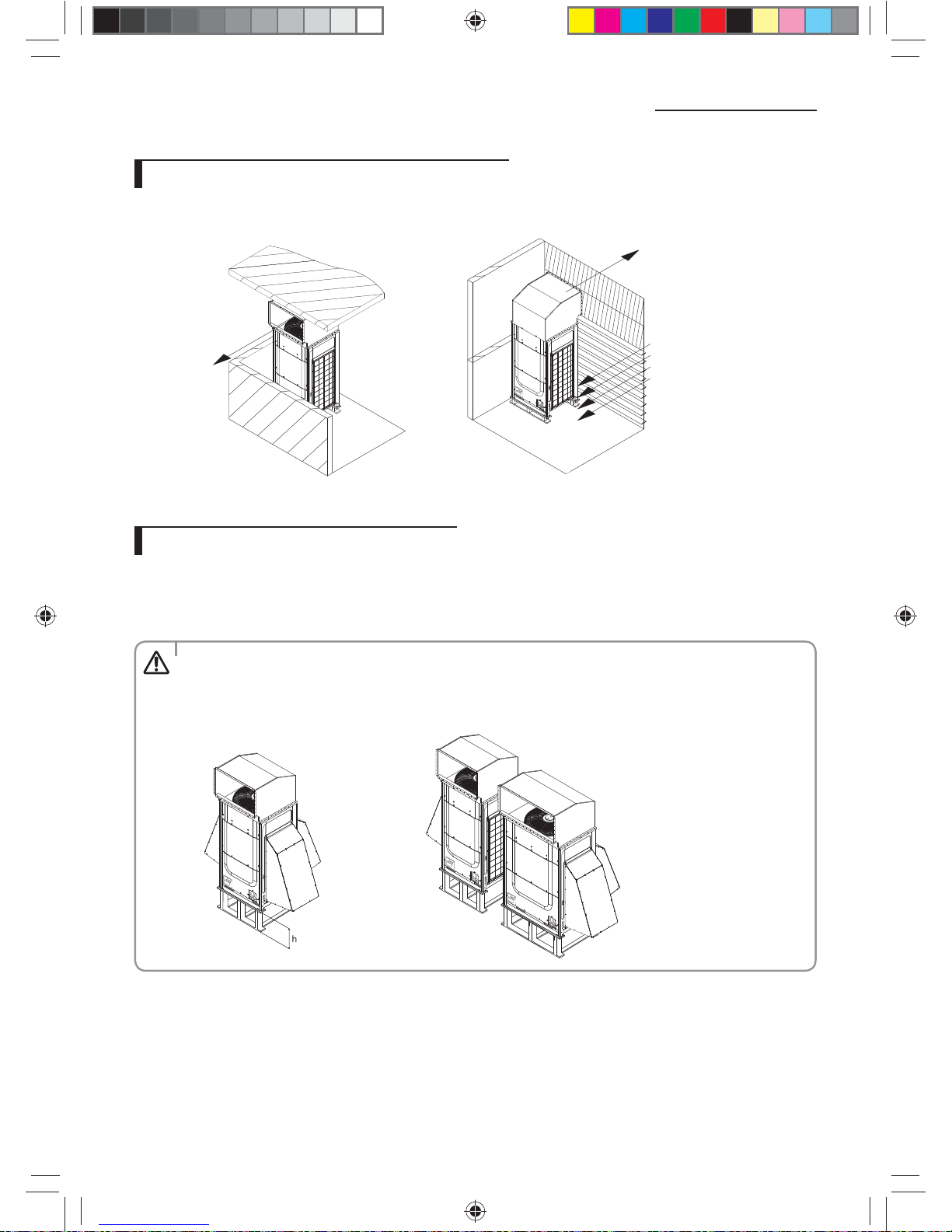

Installing the wind/snow prevention duct

Installing the outdoor unit around the obstacles

f It is necessary to install a wind/snow prevention duct(eld supply) to direct exhaust from the fan horizontally, when it is

dicult to provide a minimum space of 2m (6.56ft) between the air outlet and a nearby obstacle.

Discharged air

Grille/louver

Suction air

Upper oor

Discharged air

Ex.) Balcony Ex.) Mechanical room

Installing the outdoor unit in cold region

f In cold regions with lots of snowfall, install a snow prevention duct, as a sucient countermeasure, to prevent snow from

accumulating on the outdoor unit. When the snow prevention duct is not installed, frost may accumulate on the heat

exchanger and heating operation may not work normally.

f Air outlet of the duct should not be directed to the enclosed space.

Cautions regarding on installing the frame and selecting the base ground

• Height (h) of the frame and the base ground should be higher than the "heaviest expected snowfall".

• Area of the frame and the base ground should not be larger than the are of the outdoor unit. Snow may

accumulate if the area of the frame or the base ground is larger.

CAUTION

k}tGzG㨰䛙G㐘㞬ὤGptluki]_TWZ_XYhTW_UGGGYY YWX_TW]TXXGGG㝘䟸G[a[_aY]

23

ENGLISH

Installing the outdoor unit in windy region

f In windy regions such as near sea shores, protection wall or wind protection duct must be installed for normal operation

of the outdoor unit. (Refer to the illustration of the snow prevention duct, for installing the wind protection duct.)

f Install the wind prevention duct with the consideration of major wind direction. If the direction of the discharge part is

same as major direction of the wind, it could cause product’s performance decrease.

Cautions regarding on installing the frame and selecting the base ground

• The base ground must be solid and the outdoor unit must be xed with anchor bolts.

• Make sure to install outdoor unit in a place strong enough to withstand its weight. If the place cannot withstand

the weight of the outdoor unit, outdoor unit may fall and cause personal injury.

• When installing on a rooftop subject to strong wind, countermeasures must be taken to prevent the unit from

falling down.

• Use a frame that is resistant to corrosion.

782 (30.79)

560 (22.05) 880 (34.05) 560 (22.05)

871 (34.29)

765 ( 30.12)

2300 (90.55)

668 (26.30)

532 (20.94)

2271 (89.41)

1134 (44.65)

965 (37.99)

180 (7.09)

1632 (64.25)

1150 (45.28)

980 (38.58)

180 (7.09)

2000 (78.74)

127 (5) 593 (23.35)

1318 (51.89)

1210 (47.64)

612 (24.09)

108 (4.25)

550 (21.65)

<AM072F✴Series>

Unit: mm (inch)

1197 (47.13)

2415 (95.08)

560 (22.05) 560 (22.05)1295 (50.98)

593 (23. 35)

127 (5)

1318 (51.89)

1210 (47.64)

612 (24.09)

108 (4.25)

2300 (90.55)

1632 (64.25)

1150 (45.28)

980 (38.58)

180 (7.09)

871 (34.29)

765 ( 30.12)

668 (26.30)

532 (20.94)

2271 (89.41)

1134 (44.65)

965 (37.99)

180 (7.09)

550 (21.65)

<AM096/120/144F✴, AM168/192H✴, AM072/096K✴ Series>

<AM216KXVGJ✴>

406

2415

550

180

1080

640

1252

1315

552

1192

560 560 8711295

1255

1732

1080

1255

2371

2400

668

532

180

550 550765

CAUTION

k}tGzG㨰䛙G㐘㞬ὤGptluki]_TWZ_XYhTW_UGGGYZ YWX_TW]TXXGGG㝘䟸G[a[_aY^

24

Refrigerant pipe installation

• When installing, make sure there is no leakage. When collecting the refrigerant, stop the compressor rst before

removing the connection pipe. If the refrigerant pipe is not properly connected and the compressor works

with the service valve open, the pipe inhales the air and it makes the pressure inside of the refrigerant cycle

abnormally high which may lead to explosion and injury.

WARNING

Refrigerant pipe work

f The length of refrigerant pipe should be as short as possible and the height dierence between an indoor and outdoor

unit should be minimized.

f Piping work must be done within allowable piping length, height dierence, and the allowable length after branching.

f The pressure of the R-410A is high. Use only certied refrigerant pipe and follow the installation method.

f After installing the pipes, calculate the total length of the pipe to check if additional refrigerant is needed. When you need

to charge the additional refrigerant, make sure to use R-410A refrigerant.

f Use clean refrigerant pipe and there shouldn’t be any harmful ion, oxide, dust, iron content or moisture inside pipe.

f Use tools and accessories that t on R-410A only.

Tool Installation process/purpose Compatibility with conventional tool

Pipe cutter

Refrigerant pipe

installation

Pipe cutting

Compatible

Flaring tool Pipe aring

Refrigerant

machine oil

Apply refrigerant

oil on ared part

Exclusive ether oil, ester oil, alkali benzene oil or synthetic oil

Torque wrench

Connect are nut

with pipe

Compatible

Pipe bender Pipe bending

Nitrogen gas

Air tightness test

Prevent oxidation

within the pipe

Welder Pipe welding

Manifold gage Air tightness

test ~ additional

refrigerant

charging

Vacuuming,

charging

refrigerant

and checking

operation

Need exclusive one to prevent mixture of R-22 refrigerant oil use and

also the measurement is not available due to high pressure

Refrigerant

charging hose

Need exclusive one since there is risk of refrigerant leakage or inow

of impurities

Vacuum pump Pipe drying

Compatible (Use products which contain the check valve to prevent

the oil from owing backward into the outdoor unit.) Use the one

that can be vacuumed up to -100.7kpa(5Torr).

Scale for

refrigerant

charging

Charging refrigerant Compatible

Gas leak detector Gas leak test

Need exclusive one

(Ones used for R-134a is compatible)

Flare nut

Must use the are nut equipped with the product. Refrigerant leakage may occur when the conventional are

nut for R-22 is used.

k}tGzG㨰䛙G㐘㞬ὤGptluki]_TWZ_XYhTW_UGGGY[ YWX_TW]TXXGGG㝘䟸G[a[_aY^

25

ENGLISH

Selecting refrigerant pipe

First branch joint

Increase the main

pipe size

f Install the refrigerant pipe according to main pipe size of each outdoor unit capacity.

f When the pipe length (including elbow) between an outdoor unit and the farthest indoor unit exceeds 90m (295.28ft),

you must increase the size of the pipe (main pipe) by one grade which connects between the outdoor unit to the rst

branch joint.

f For H/R model, When the pipe length (including elbow) between an outdoor unit and the farthest indoor unit exceeds

90m, you must increase the size of the liquid pipe by one grade among the pipes(main pipe) which connects between

the outdoor unit to the rst branch joint.

k}tGzG㨰䛙G㐘㞬ὤGptluki]_TWZ_XYhTW_UGGGY\ YWX_TW]TXXGGG㝘䟸G[a[_aY^

26

Refrigerant pipe installation

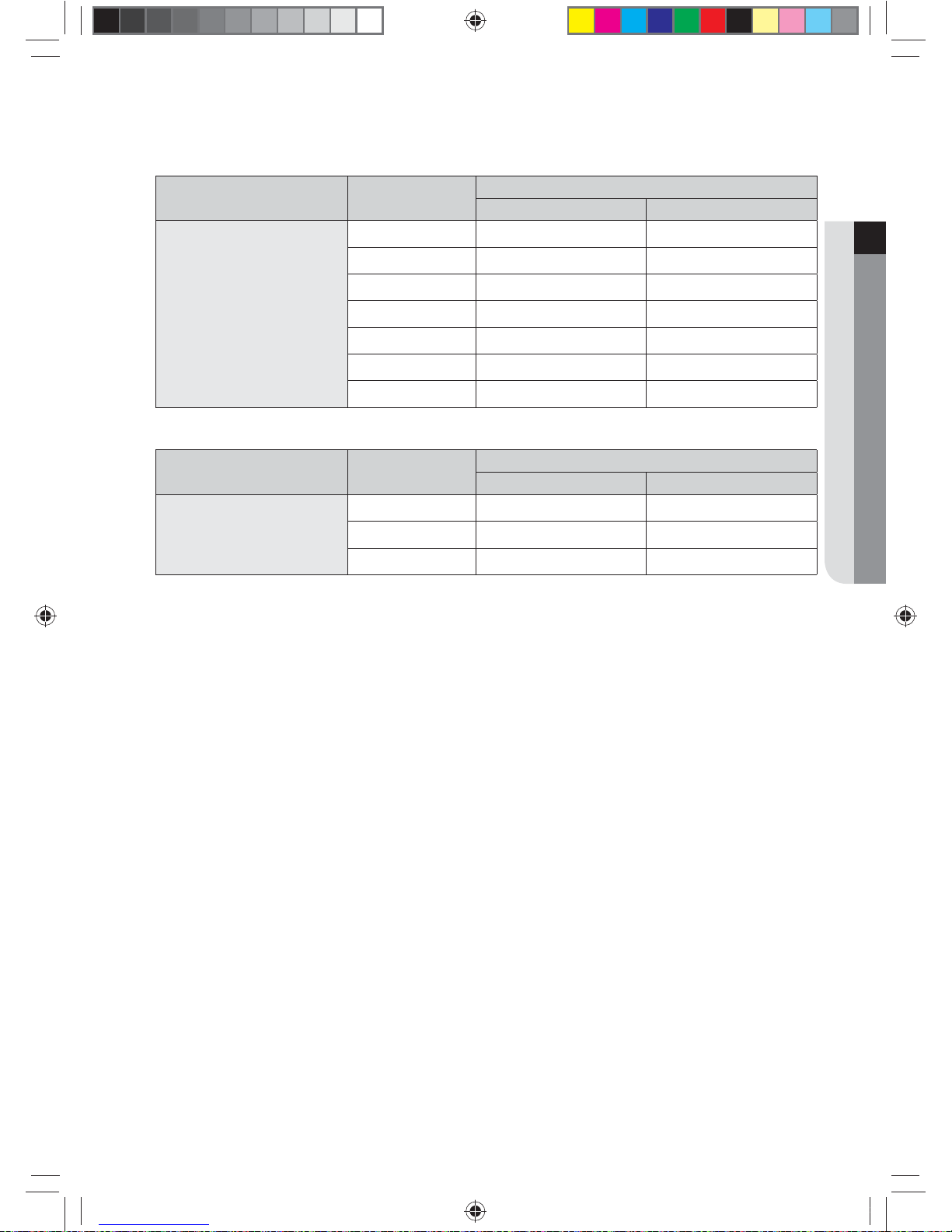

H/P

16Ton 12Ton

(D)

(E)(C)

(A)

(B)

(3)(2)(1)

6Ton

Ex.) 34 Ton

Ton No.

Pipe size (O.D)

Liquid pipe Gas pipe

mm inch mm inch

16 (1) 15.88 5/8 28.58 1 1/8

28 (2) 19.05 3/4 34.92 1 3/8

34 (3) 19.05 3/4 41.28 1 5/8

Size of the pipe connected to the outdoor unit (A)

Select the size of the pipe according to the below table.

Outdoor unit capacity Main pipe length within 90m (295.3ft) Size up(Main pipe length over 90m (295.3ft))

Ton MBH KW

Liquid Gas Liquid Gas

mm inch mm inch mm inch mm inch

6 72 21.1 9.52 3/8 19.05 3/4 12.7 1/2 22.22 7/8

8 96 28.1 9.52 3/8 22.22 7/8 12.7 1/2 25.4 1

note1)

10 120 35.2 12.7 1/2 28.58 1 1/8 15.88 5/8 28.58 1 1/8

12 144 42.2 12.7 1/2 28.58 1 1/8 15.88 5/8 31.75 1 1/4

note2)

14 168 49.2 15.88 5/8 28.58 1 1/8 19.05 3/4 31.75 1 1/4

note2)

16 192 56.3 15.88 5/8 28.58 1 1/8 19.05 3/4 31.75 1 1/4

note2)

18 216 63.3 15.88 5/8 28.58 1 1/8 19.05 3/4 31.75 1 1/4

note2)

20 240 70.3 15.88 5/8 28.58 1 1/8 19.05 3/4 31.75 1 1/4

note2)

22 264 77.4 19.05 3/4 34.92 1 3/8 22.22 7/8 38.1 1 1/2

note3)

24 288 84.4 19.05 3/4 34.92 1 3/8 22.22 7/8 38.1 1 1/2

note3)

26 312 91.4 19.05 3/4 34.92 1 3/8 22.22 7/8 38.1 1 1/2

note3)

28 336 98.4 19.05 3/4 34.92 1 3/8 22.22 7/8 38.1 1 1/2

note3)

30 360 105.5 19.05 3/4 41.28 1 5/8 22.22 7/8 41.28 1 5/8

32 384 112.5 19.05 3/4 41.28 1 5/8 22.22 7/8 41.28 1 5/8

34 408 119.5 19.05 3/4 41.28 1 5/8 22.22 7/8 41.28 1 5/8

36 432 126.6 19.05 3/4 41.28 1 5/8 22.22 7/8 41.28 1 5/8

38 456 133.6 19.05 3/4 41.28 1 5/8 22.22 7/8 41.28 1 5/8

40 480 140.7 19.05 3/4 41.28 1 5/8 22.22 7/8 41.28 1 5/8

42 504 147.7 19.05 3/4 41.28 1 5/8 22.22 7/8 41.28 1 5/8

44 528 154.7 19.05 3/4 41.28 1 5/8 22.22 7/8 41.28 1 5/8

Note1) If 1" (25.4mm) pipe is not available on site, use 1 1/8" (28.58mm) pipe.

Note2) If 1 1/4" (31.75mm) pipe is not available on site, use 1 3/8" (34.92mm) pipe.

Note3) If 1 1/2" (38.1mm) pipe is not available on site, use 1 5/8" (41.28mm) pipe.

k}tGzG㨰䛙G㐘㞬ὤGptluki]_TWZ_XYhTW_UGGGY] YWX_TW]TXXGGG㝘䟸G[a[_aY^

27

ENGLISH

Size of the pipe between branch joints (B)

Select the pipe size according to the sum of indoor unit capacity which will be connected after the branch.

❋ However, if the size of the pipe between branch joints (B) is bigger than the size of the pipe connected to the outdoor

unit (A), apply the pipe size (A).

Indoor unit capacity

Branch pipe length within 45m(147.6ft)

note1)

Branch pipe length between

45~90m(147.6~295.3ft)

note1)

Liquid Gas Liquid Gas

MBH KW mm inch mm inch mm inch mm inch

~51 ~15.0 9.52 3/8 15.88 5/8 12.7 1/2 19.05 3/4

51~76 15.0~22.4 9.52 3/8 19.05 3/4 12.7 1/2 22.22 7/8

76~96 22.4~28.1 9.52 3/8 22.22 7/8 12.7 1/2 25.4 1

note2)

96~136 28.1~40.0 12.7 1/2 28.58 1 1/8 15.88 5/8 28.58 1 1/8

136~154 40.0~45.0 12.7 1/2 28.58 1 1/8 15.88 5/8 31.75 1 1/4

note3)

154~240 45.0~70.3 15.88 5/8 28.58 1 1/8 19.05 3/4 31.75 1 1/4

note3)

240~336 70.3~98.4 19.05 3/4 34.92 1 3/8 22.22 7/8 38.1 1 1/2

note4)

336~461 98.4~135.2 19.05 3/4 41.28 1 5/8 22.22 7/8 41.28 1 5/8

461~577 135.2~169 19.05 3/4 41.28 1 5/8 22.22 7/8 53.98 2 1/8

577 ~ 169.0 ~ 22.22 7/8 53.98 2 1/8 25.40 1

note2)

53.98 2 1/8

Note1) Note on measuring distance between branch joints (B) : You must measure the distance between rst branch joint

to the last indoor unit. (NOT from rst joint to the last branch joint)

Note2) If 1" (25.4mm) pipe is not available on site, use 1 1/8" (28.58mm) pipe.

Note3) If 1 1/4" (31.75mm) pipe is not available on site, use 1 3/8" (34.92mm) pipe.

Note4) If 1 1/2" (38.1mm) pipe is not available on site, use 1 5/8" (41.28mm) pipe.

Size of the pipe between the branch joint and the indoor unit

Make a selection according to outdoor unit capacity.

Indoor unit capacity

Pipe Size(O.D)

Liquid Gas

MBH KW mm inch mm inch

~20 ~6.0 6.35 1/4 12.7 1/2

24~52 7.1~16.0 9.52 3/8 15.88 5/8

68~78 20.0~23.0 9.52 3/8 19.05 3/4

78~96 23.0~29.0 9.52 3/8 22.22 7/8

k}tGzG㨰䛙G㐘㞬ὤGptluki]_TWZ_XYhTW_UGGGY^ YWX_TW]TXXGGG㝘䟸G[a[_aY^

28

Refrigerant pipe installation

16Ton 12Ton

(D)

(E)(C)

(A)

(B)

(3)(2)(1)

6Ton

Branch joint

f Branch joint between outdoor units (C)

Classication Model name

Specication

MBH kW

Y-joint for outdoor unit (C)

MXJ-TA3819M 461 and below 135.2 and below

MXJ-TA4422M 478 and over 140.2 and over

f First branch joint (D)

Make a selection according to outdoor unit capacity.

Classication Model name

Outdoor unit capacity

MBH kW

Y-joint (D)

MXJ-YA2512M Over 51 ~ 136 and below Over 15.0 ~ 40.0 and below

MXJ-YA2812M Over 136 ~ 154 and below Over 40.0 ~ 45.0 and below

MXJ-YA2815M Over 154 ~ 240 and below Over 45.0 ~ 70.3 and below

MXJ-YA3419M Over 240 ~ 336 and below Over 70.3 ~ 98.4 and below

MXJ-YA4119M Over 336 ~ 461 and below Over 98.4 ~ 135.2 and below

MXJ-YA4422M Over 461 Over 135.2

k}tGzG㨰䛙G㐘㞬ὤGptluki]_TWZ_XYhTW_UGGGY_ YWX_TW]TXXGGG㝘䟸G[a[_aY^

29

ENGLISH

f Branch joint (E)

Select a branch joint according to the sum of indoor unit capacity which will be connected after the branch.

1) Y-joint

Classication Model name

Specication

MBH kW

Y-joint (E)

MXJ-YA1509M 51 and below 15.0 and below

MXJ-YA2512M Over 51 ~ 136 and below Over 15.0 ~ 40.0 and below

MXJ-YA2812M Over 136 ~ 154 and below Over 40.0 ~ 45.0 and below

MXJ-YA2815M Over 154 ~ 240 and below Over 45.0 ~ 70.3 and below

MXJ-YA3419M Over 240 ~ 336 and below Over 70.3 ~ 98.4 and below

MXJ-YA4119M Over 336 ~ 461 and below Over 98.4 ~ 135.2 and below

MXJ-YA4422M Over 461 Over 135.2

2) Distribution header

Classication Model name

Specication

MBH kW

Distribution header (E)

MXJ-HA2512M 154 and below (for 4 rooms) 45.0 and below (for 4 rooms)

MXJ-HA3115M 240 and below (for 8 rooms) 70.3 and below (for 8 rooms)

MXJ-HA3819M Over 240 (for 8 rooms) Over 70.3 (for 8 rooms)

k}tGzG㨰䛙G㐘㞬ὤGptluki]_TWZ_XYhTW_UGGGY` YWX_TW]TXXGGG㝘䟸G[a[_aY^

30

Refrigerant pipe installation

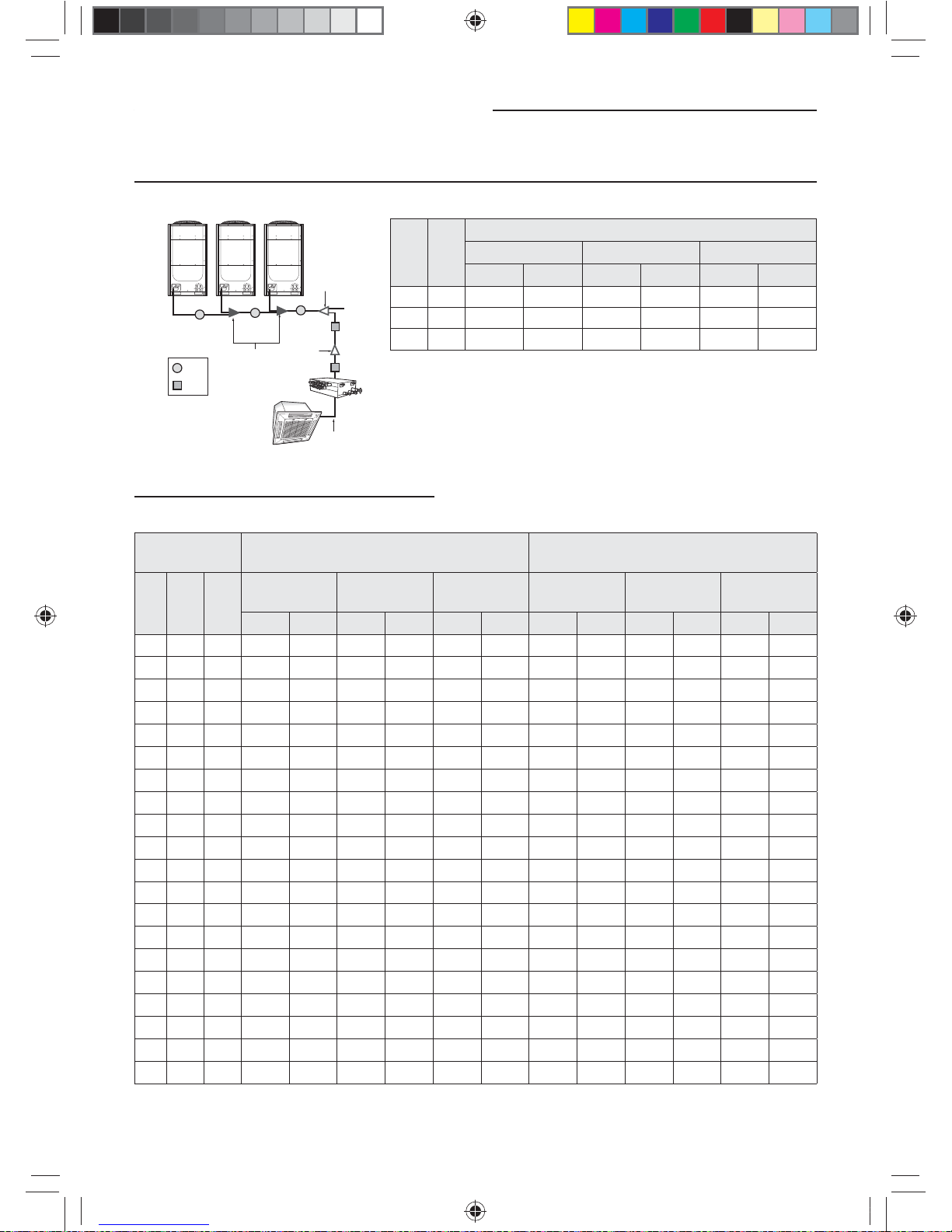

H/R

(A)

(B)

16Ton 12Ton

(D)

(E)

(F)

(C)

(3)

(2)

(1)

6Ton

Ex.) 34 Ton

Ton N o.

Pipe size (O.D)

Liquid Gas High pressure Gas

mm inch mm inch mm inch

10 (1) 15.88 5/8 28.58 1 1/8 28.58 1 1/8

28 (2) 19.05 3/4 34.92 1 3/8 28.58 1 1/8

34 (3) 19.05 3/4 41.28 1 5/8 34.92 1 3/8

Size of the pipe connected to the outdoor unit (A)

Select the size of the pipe according to the below table.

Outdoor unit

capacity

Main pipe length within 90m (295.3ft) Size up(Main pipe length over 90m (295.3ft))

Ton MBH KW

Liquid Gas

High pressure

Gas

Liquid Gas

High pressure

Gas

mm inch mm inch mm inch mm inch mm inch mm inch

6 72 21.1 9.52 3/8 19.05 3/4 15.88 5/8 12.7 1/2 19.05 3/4 15.88 5/8

8 96 28.1 9.52 3/8 22.22 7/8 19.05 3/4 12.7 1/2 22.22 7/8 19.05 3/4

10 120 35.2 12.7 1/2 28.58 1 1/8 22.22 7/8 15.88 5/8 28.58 1 1/8 22.22 7/8

12 144 42.2 12.7 1/2 28.58 1 1/8 22.22 7/8 15.88 5/8 28.58 1 1/8 22.22 7/8

14 168 49.2 15.88 5/8 28.58 1 1/8 22.22 7/8 19.05 3/4 28.58 1 1/8 22.22 7/8

16 192 56.3 15.88 5/8 28.58 1 1/8 28.58 1 1/8 19.05 3/4 28.58 1 1/8 28.58 1 1/8

18 216 63.3 15.88 5/8 28.58 1 1/8 28.58 1 1/8 19.05 3/4 28.58 1 1/8 28.58 1 1/8

20 240 70.3 15.88 5/8 28.58 1 1/8 28.58 1 1/8 19.05 3/4 28.58 1 1/8 28.58 1 1/8

22 264 77.4 19.05 3/4 34.92 1 3/8 28.58 1 1/8 22.22 7/8 34.92 1 3/8 28.58 1 1/8

24 288 84.4 19.05 3/4 34.92 1 3/8 28.58 1 1/8 22.22 7/8 34.92 1 3/8 28.58 1 1/8

26 312 91.4 19.05 3/4 34.92 1 3/8 28.58 1 1/8 22.22 7/8 34.92 1 3/8 28.58 1 1/8

28 336 98.4 19.05 3/4 34.92 1 3/8 28.58 1 1/8 22.22 7/8 34.92 1 3/8 28.58 1 1/8

30 360 105.5 19.05 3/4 41.28 1 5/8 34.92 1 3/8 22.22 7/8 41.28 1 5/8 34.92 1 3/8

32 384 112.5 19.05 3/4 41.28 1 5/8 34.92 1 3/8 22.22 7/8 41.28 1 5/8 34.92 1 3/8

34 408 119.5 19.05 3/4 41.28 1 5/8 34.92 1 3/8 22.22 7/8 41.28 1 5/8 34.92 1 3/8

36 432 126.6 19.05 3/4 41.28 1 5/8 34.92 1 3/8 22.22 7/8 41.28 1 5/8 34.92 1 3/8

38 456 133.6 19.05 3/4 41.28 1 5/8 34.92 1 3/8 22.22 7/8 41.28 1 5/8 34.92 1 3/8

40 480 140.7 19.05 3/4 41.28 1 5/8 34.92 1 3/8 22.22 7/8 41.28 1 5/8 34.92 1 3/8

42 504 147.7 19.05 3/4 41.28 1 5/8 34.92 1 3/8 22.22 7/8 41.28 1 5/8 34.92 1 3/8

44 528 154.7 19.05 3/4 41.28 1 5/8 34.92 1 3/8 22.22 7/8 41.28 1 5/8 34.92 1 3/8

❋ For HR model, only increase the size of the liquid pipe If pipe length exceeds 90m

k}tGzG㨰䛙G㐘㞬ὤGptluki]_TWZ_XYhTW_UGGGZW YWX_TW]TXXGGG㝘䟸G[a[_aY_

Loading...

Loading...