SAMSUNG AM14A1E2 Service Manual

ROOM AIR CONDITIONER

INDOOR UNIT

AM14A1(B1)E07

AM20A1(B1)E06

AM20A1(B1)E08

SERVICE

OUTDOOR UNIT

UM14A1(B1)E2

UM20A1(B1)E3

Manual

CONTENTSAIR CONDITIONER

1. Pre c a u t i o n s

2. Product Specifications

3. Operating Instructions and

I n s t a l l a t i o n

4. Disassembly and Reassembly

5. Tro u b l e s h o o t i n g

6. Exploded Views and Parts List

7. Block Diagrams

8. PCB Diagrams

9. Wiring Diagrams

10. Schematic Diagrams

© Samsung Electronics Co., Ltd. MAR. 1999.

Printed in Korea.

Code No. DB81-10184A(1)

1. Precautions

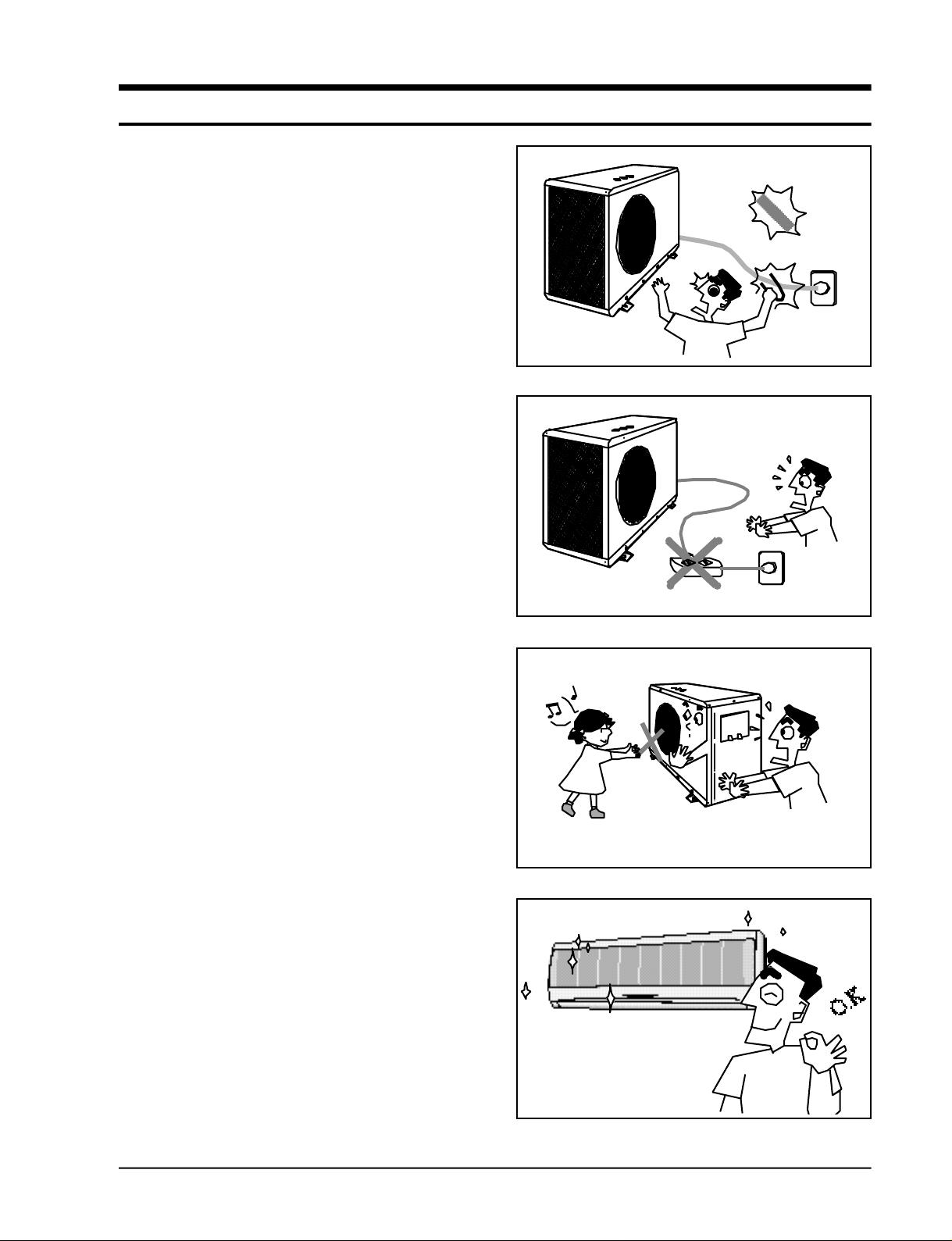

1 . Warning: Prior to re p a i r, disconnect the

power cord from the circuit bre a k e r.

2 . Use proper parts: Use only exact

replacement parts. (Also, we re c o m m e n d

replacing parts rather than repairing them.)

3 . Use the proper tools: Use the proper tools

and test equipment, and know how to use

them. Using defective tools or test

equipment may cause problems laterintermittent contact, for example.

4 . Power Cord: Prior to re p a i r, check the power

c o rd and replace it if necessary.

5 . Avoid using an extension cord, and avoid

tapping into a power cord. This practice

may result in malfunction or fire .

6 . After completing repairs and re a s s e m b l y,

check the insulation resistance. Pro c e d u re :

Prior to applying power, measure the

resistance between the power cord and the

g round terminal. The resistance must be

g reater than 30 megohms.

Fig. 1-1 Avoid Dangerous Contact

Fig. 1-2 No Tapping and No Extension Cords

7 . Make sure that the grounds are adequate.

8 . Make sure that the installation conditions

a re satisfactory. Relocate the unit if

n e c e s s a r y.

9 . Keep children away from the unit while it is

being re p a i re d .

1 0 . Be sure to clean the unit and its surro u n d i n g

a re a .

Fig. 1-3 No Kids Nearby!

Fig. 1-4 Clean the Unit

Samsung Electronics

1-1

M E M O

1-2

Samsung Electronics

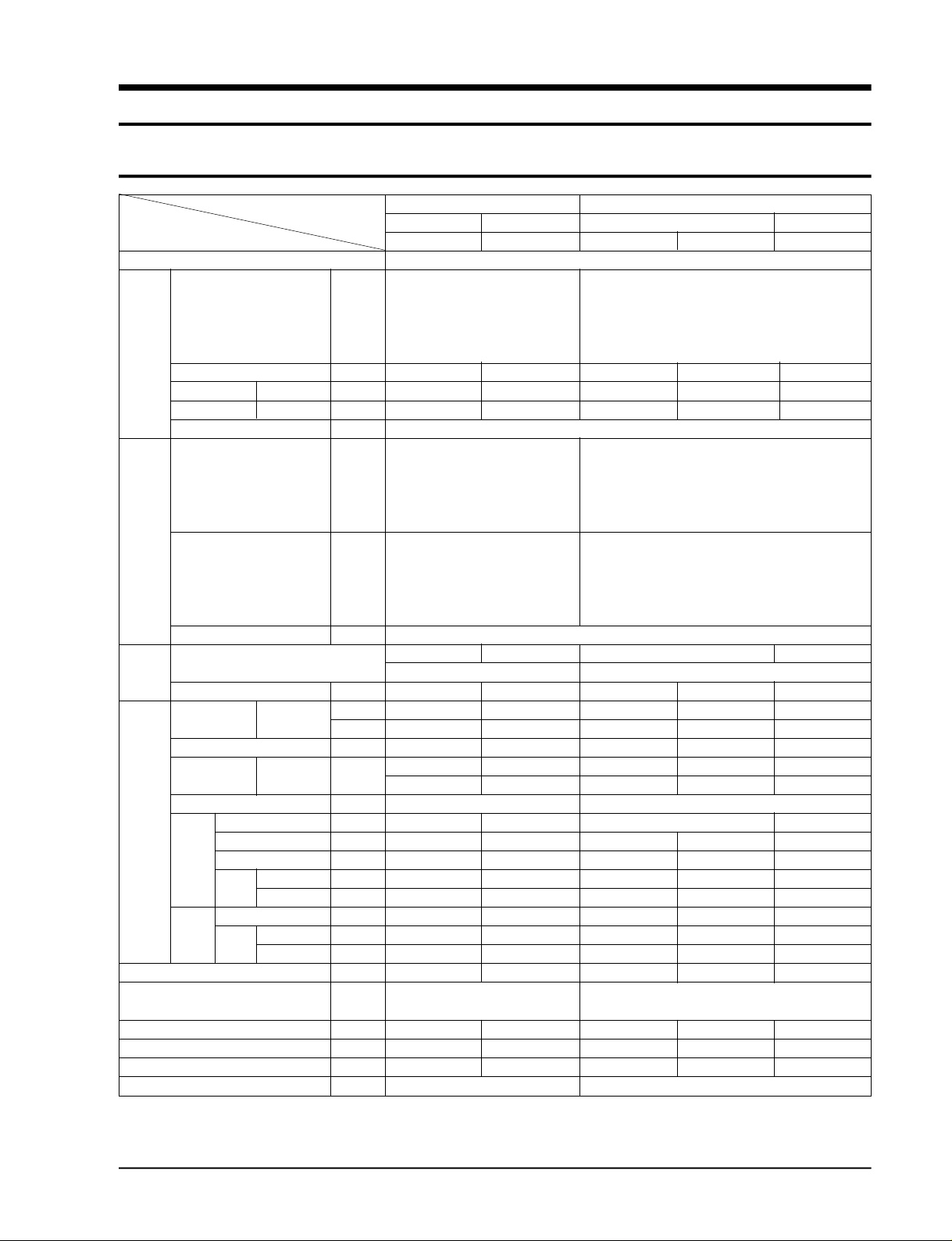

2. Product Specifications

2-1 Table

Model AM14A1(B1)E2 AM20A1(B1)E2

INDOOR UNIT OUTDOOR UNIT INDOOR UNIT OUTDOOR UNIT

Item AM14A1(B1)E07 UM14A1(B1)E2 AM20A1(B1)E08 AM20A1(B1)E06 UM20A1(B1)E3

Type Wall-Mounting Multi Split

Cooling 1 unit(A) 9,000 9,000

1 unit(B)

2 unit(A+B) 14,000 (7,000x2) 16,300 (9,000+7,300)

Performance

Power

Dehumiditying I/h 1.2 - 1.6 1.1 Air volume Cooling m3/min 7.0 - 8.5 6.0 Noise Cooling dB 35 55 38 35 54

Power V-Hz 1-220-240V~, 50Hz

Power 1 unit(A) 1,100 1,010

Consumption 1 unit(B) 1,100 930

Operating 1 unit(A) 4.7 4.3

Current 1 unit(B) 4.7 3.9

Starting current A 30

Power cable(Option)

Fuse capacity A 3.15 - 3.15 3.15 Outer

dimension xDepth inch 32.08x11.73x7.17 28.35x20.67x9.65 32.08x11.73x7.17 29.33x10.23x6.96 30.98x24.41x12.6

Weight kg 9.6 35 9.6 8.0 54

Refrigerant Liquid

pipe Gas 9.52x5 - 9.52x5 9.52x5 Drain hose

Size

Comp Capacitor 30µFx420VAC 30µFx370VAC 40µFx450VAC ressor

Blower

Heat exchanger 2Row 12Step 2Row 20Step 2Row 12Step 2Row 10Step 2Row 24Step

Refrigerant control unit

Freezer oil capacity - 410 360 350 Refrigerant to change(R-22) - 1,000 700 860 630/860

Protection device - MRA12030-12008 MRA12037-12007 MRA12054-12008 -

Standard Conditions ISO R5151 Standard ISO R5151 Standard

• The basic performance test is based on the piping of 5MT.(Be sure to check the installing conditions as extension of the piping may lead to

performance degradetion.)

2 unit(B+C) - 10,800 (5,400+5,400)

3 unit(A+B+C)

2 unit(A+B) W 1,200 1,800

2 unit(B+C) - 1,010

3 unit(A+B+C)

2 unit(A+B) A 5.2 7.5

2 unit(B+C) - 4.3

3 unit(A+B+C)

WidthxHeight

Type - Rotary - Rotary

Model name - 48A124JV1E5 44B092JW1E6 44B102JW1EG -

Type(model) - - - - -

Motor

Rated output W - 1210 895 950 -

Type Cross-fan Propeller Cross-fan Cross-fan Propeller

Type Resin Still Resin Resin Still

Motor

Rated output W 35 60 35 35 60

BTU/h

mm 815x298x182 720x525x245 815x298x182 745x260x177 787x620x320

OD(mm)xL(m)

ID(mm)xL(m)

6.35x5 - 6.35x5 6.35x5 -

A+B-UNIT : Capillary Tube

9,000 7,300

- 19,800(9,000+5,400+5,400)

- 1,900

- 8.2

- H05RNF25 - H07RNF2.5

H05RNF (4G 1mm2) H05RNF (4G 1mm2)

17x2,000 17x2,000

+ Solenoid valve

A+B/C-UNIT : Capillary Tube + Solenoid valve

Samsung Electronics

2-1

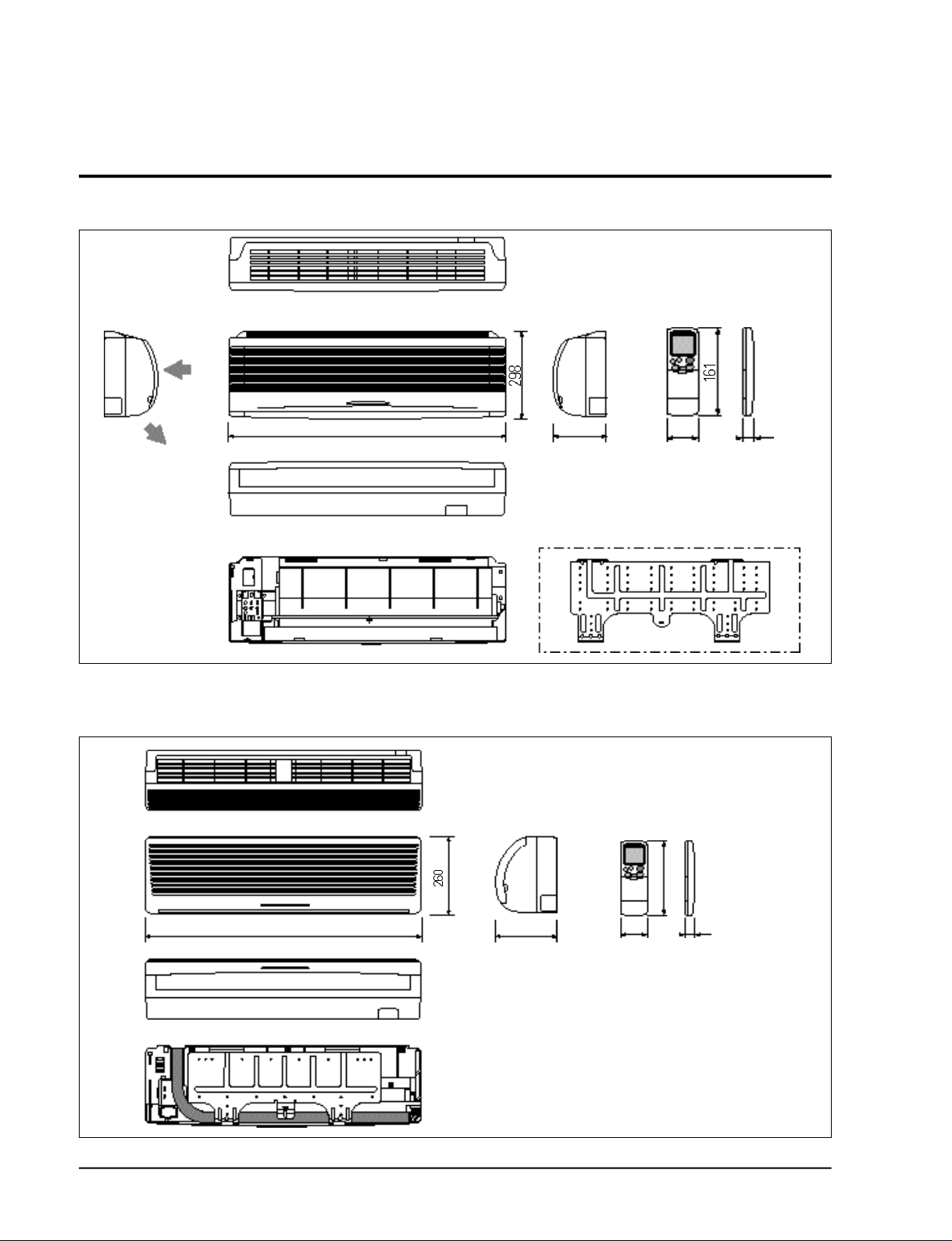

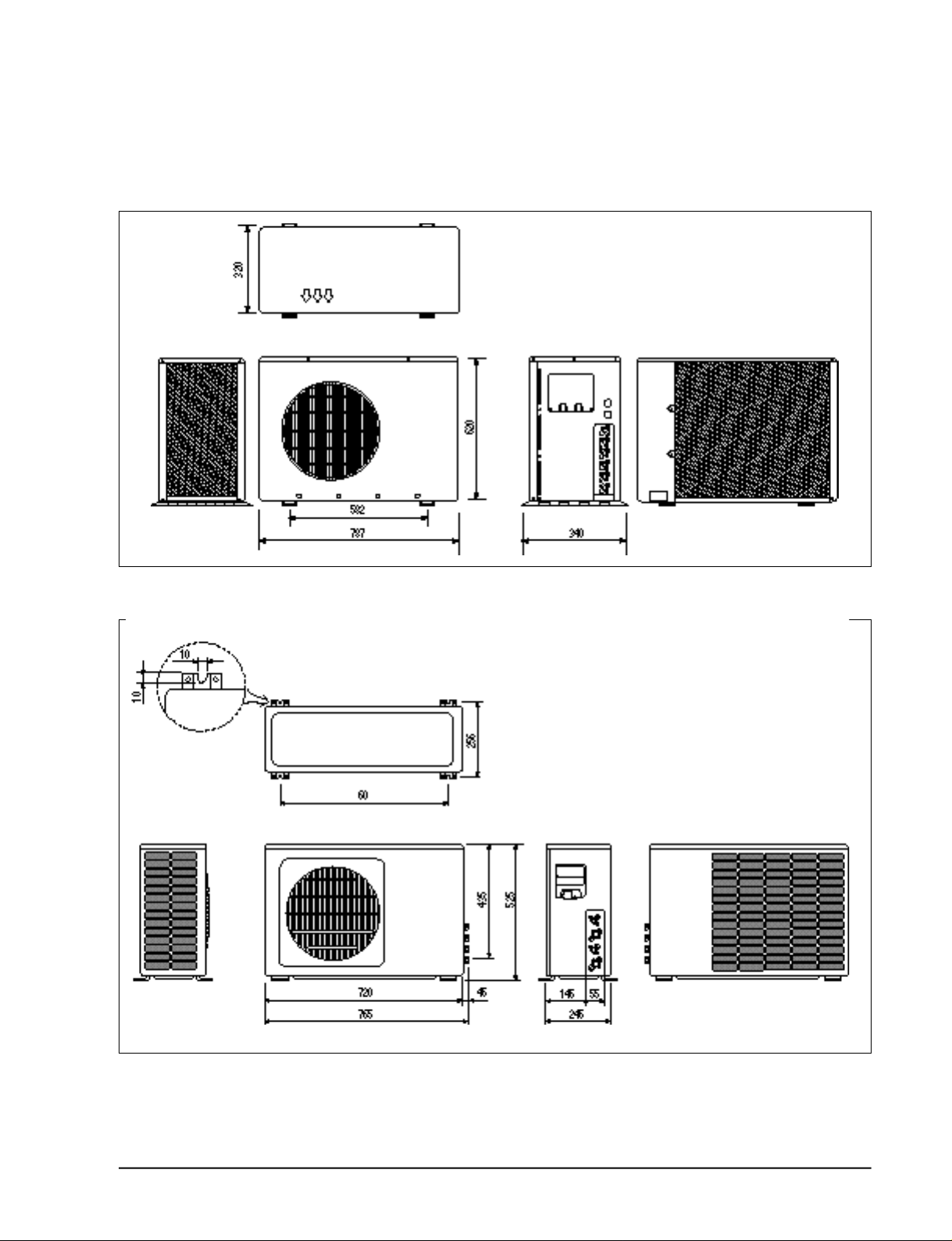

2-2 Dimensions

2-2-1(a) Indoor Unit (AM14A1(B1)E07/AM20A1(B1)E08)

(Front view)

Air

in

Air out

(Rear view)

2-2-1(b) Indoor Unit (AM20A1(B1)E06)

815 182

(Remote control)

58

22

Installation plate

2-2

(Front view)

(Rear view)

745

(Remote control)

58177

22

Samsung Electronics

2-2-2 Outdoor Unit

2-2-2(a) UM20A1(B1)E3

Product Specifications

2-2-2(b) UM14A1(B1)E2

(Front view)

(Rear view)

Samsung Electronics

(Front view)

(Rear view)

2-3

2-3 Refrigerating Cycle Block Diagram

2-3-1(a) UM14A1(B1)E2

INDOOR UNIT

(A) (B)

Heat

exchanger

(Evaporator)

T1

Liquid side

T2 Gas side

2-way valve

3-way valve

OUTDOOR UNIT

Capillary tube

Compressor-B

Compressor-A

Heat

exchanger

(Condenser)

Cooling

Gas leak

check point

Refrigerating cycle temperature and pressure

STD Pressure Piping Temp.(°C) Temp. Condition (°C)

Operating Condition (kg/cm2G)

3-way valve DB WB DB WB

Standard 5.0~5.2 11 11 27 19 35 24

A or B Max over load 6.0~6.3 16 15 32 23 43 26

Cooling Low temp. 3.4~3.6 3 2 21 15 21 15

Standard 5.0~5.2 12 10 27 19 35 24

A + B Max over load 6.0~6.3 16 15 32 23 43 26

Low temp. 3.4~3.6 3 2 21 15 21 15

2-4

T1 T2

Indoor Outdoor

(Pipe Length:5m)

Samsung Electronics

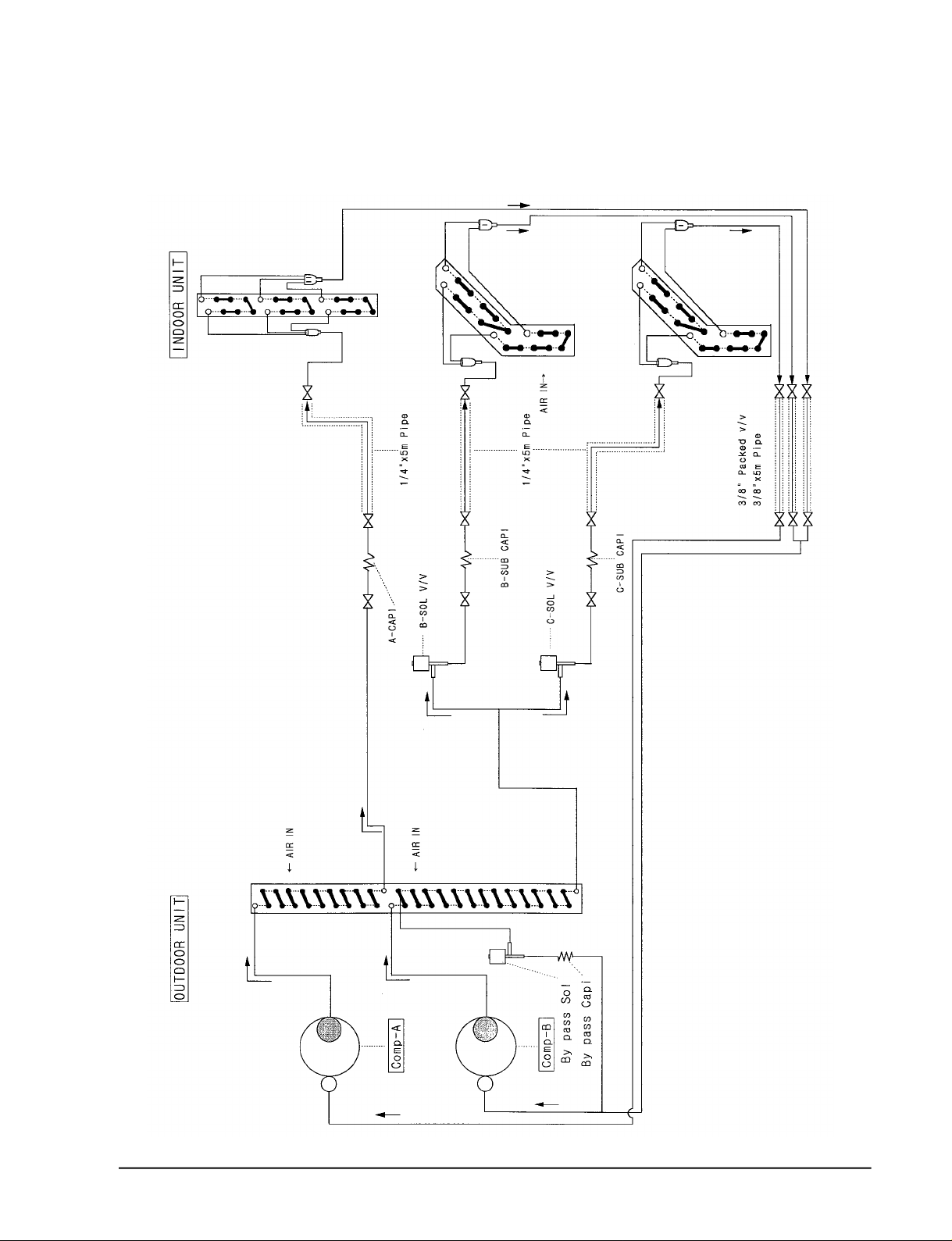

2-3-2(b) UM20A1(B1)E3

Product Specifications

Samsung Electronics

2-5

M E M O

2-6

Samsung Electronics

3. Operating Instructions and Installation

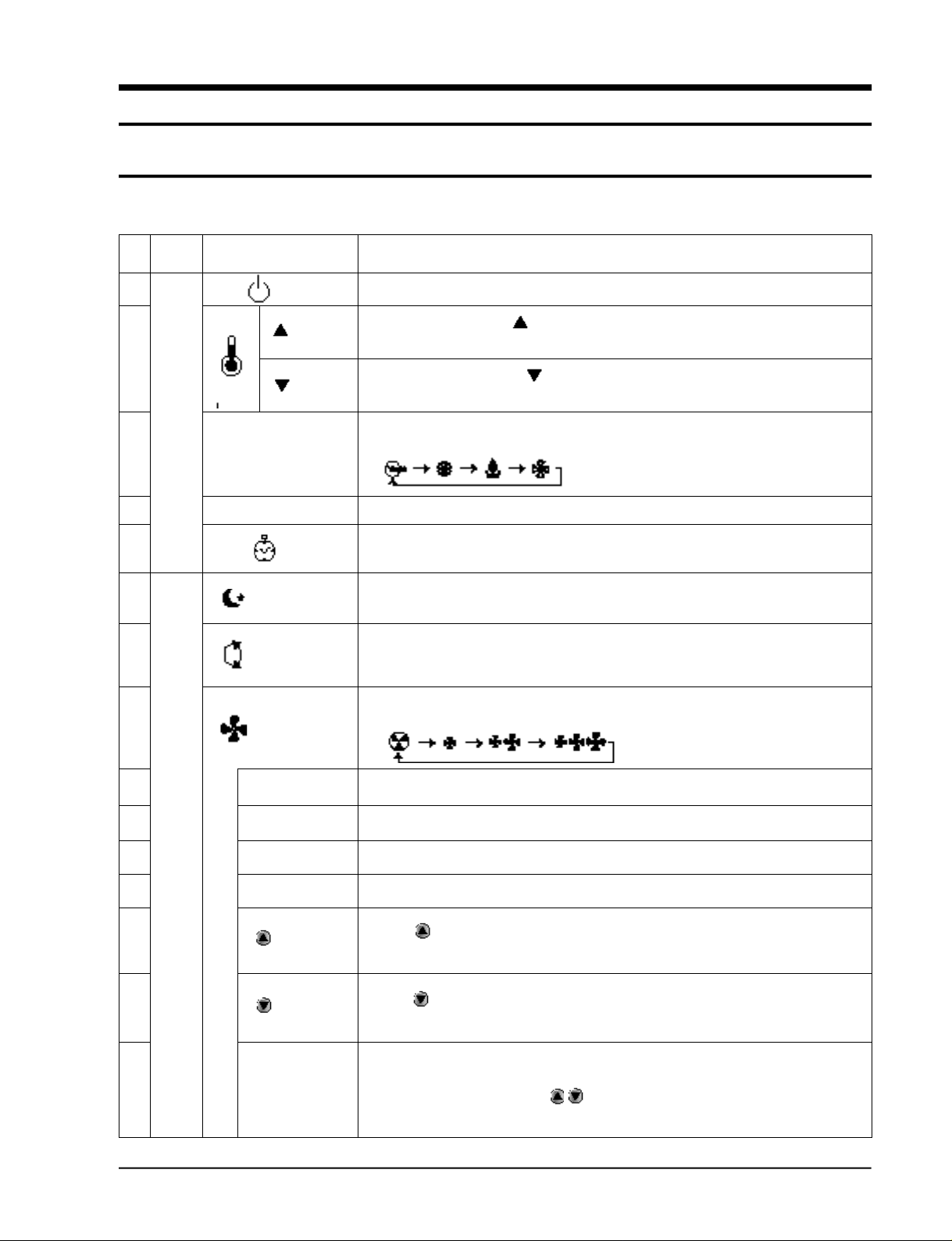

3-1 Operating Instructions

3-1-1 Name & Function of Key in remote controller

NO

NAMED OF KEY

1

2

3

MODE

4

5

6

7

8

TURBO

OFF

(UP)

(DOWN)

On/Off Button. Use this button to start and stop air conditioner.

Temp. up button. If the button is pressed once,

the setting temperature is increased by 1°C

Temp. down button. If the button is pressed once,

the setting temperature is decreased by 1°C

Each time you press this button,

MODE is changed in the following order.

Use this button to provide heavy duty cooling & Heating for 30 minutes.

Set up the reserve or cancel the timer on and timer off quickly

Use this button for sleep operation.

(The SLEEP mode can be selected at COOL and HEAT mode.)

Adjusts air flow vertically.

Each time you press this button,

BLADE-H rotates by 10.58° (Changable range 42.3°)

Each time you press this button,

FAN SPEED is changed in the following order.

FUNCTION OF KEY

9

C

O

10

V

E

R

11

12

13

14

15

Samsung Electronics

T

I

M

E

R

ON TIMER

OFF TIMER

SET

CANCEL

TIME

(UP)

(DOWN)

Set up the time that operation start.

Set up the time that operation stop.

Use this button to reserve the timer on.

Use this button to reserve or cancel the timer on and timer off.

If the button is pressed once, the time increase by one minute

during the time set mode, and ten minutes during the timer set mode.

If the button is pressed once, the time decrease by one minute

during the time set mode, and ten minutes during the timer set mode.

Without regard to ON/OFF condition in remote controller,

use this button to set current time.

Adjust the current time using button.

(Data can be transmitted after setting up the time)

3-1

Operating Instructions and Installation

3-1-1 Name & Function of Key in remote controller

1. A U TO MODE : In this mode, operation

C O O L mode is selected automatically by the

room temperature of initial operation.

Operation Type

Tr≥ 24.5°C+∆T Compressor ON

Cool Operation

Tr≤ 24°C+∆T Compressor OFF

∆T= -1°, -2°C, 0°C+1°C+2°C

∆T is controlled by setting temperature

up/down key of remote contro l l e r

* FAN SPEED : A U TO

2. C O O L MODE : The unit operates accord i n g

to the diff e rence between the setting and

room temperature. (18°C~30°C)

3. D RY MODE : Has 3 states, each determined

by room temperature .

The unit operates in DRY m o d e .

*Co m p ressor ON/OFF Time is contro l l e d

compulsorily(can not set up the fan speed,

always bre e z e ) .

* P rotective function : Low temperature

release. (Prevention against fre e z e )

Room Temp

4. TURBO MODE : This mode is available in

A U TO, COOL, DRY, FAN MODE.

When this button is pressed at first, the air

conditioner is operated “powerful” state for

30 minutes re g a rdless of the set temperat u re, room temperature .

When this button is pressed again, or when

the operating time is 30 minutes, turbo

operation mode is canceled and returned to

the previous mode.

*But, if you press the TURBO button in DRY

or FAN mode that is changed with A U TO

mode automatically.

5 . S L E E P MODE : Sleep mode is available

only in COOL m o d e .

The operation will stop after 6 hours.

*In COOL mode : The setting temperature

is automatically raised by 1°C each 1hour

When the temperature has been raised by

total of 2°C, that temperature is maint a i n e d .

6. FAN SPEED : Manual (3 step), Auto (4 step)

Fan speed automatically varies depending

on both the diff e rence between setting and

the room temperature .

3-2

Samsung Electronics

Operating Instructions and Installation

7 . C O M P U L S O RY O P E R ATION :

For operating the air conditioner without

the remote contro l l e r.

* A U TO : The operating is the same function that A U TO MODE in the remote cont ro l l e r.

8 . SWING : BLADE-H is rotated vertically by

the stepping motor.

*Memory louver : When ON/OFF button is

p ressed at stop state, the BLADE-H re t u r n s

to its original location which is operating

state before stop

*Swing auto : The BLADE-H can ro t a t e

within about 10,500 in the original position

set by the SWING SET button.

*Swing Set : Press the button under the

remote control is displayed on LCD the ,

and the blades move up and down, about 43°.

If the one more time press the button, blatles location is stop.

9 . Quick OFF TIMER: OFF timer (quick timer)

allows reservation or cancel the timer on

and timer off quickly

When OFF timer button is pressed at operating state, LCD displays the polling state

s e q u e n t i a l l y.

The LCD also displays the time re m a i n i n g .

1 0 . 24-Hour ON/OFF Real Setting Ti m e r. : The

air conditioner is turned ON at a specified

time using .

ON TIMER

OFF TIMER : The air Conditioner is turned

OFF at a specified time using .

OFF TIMER

*ON TIMER : Only timer LED lights on.

*OFF TIMER : Both timer and operation

LED lights on.

*3 minutes delay timer.

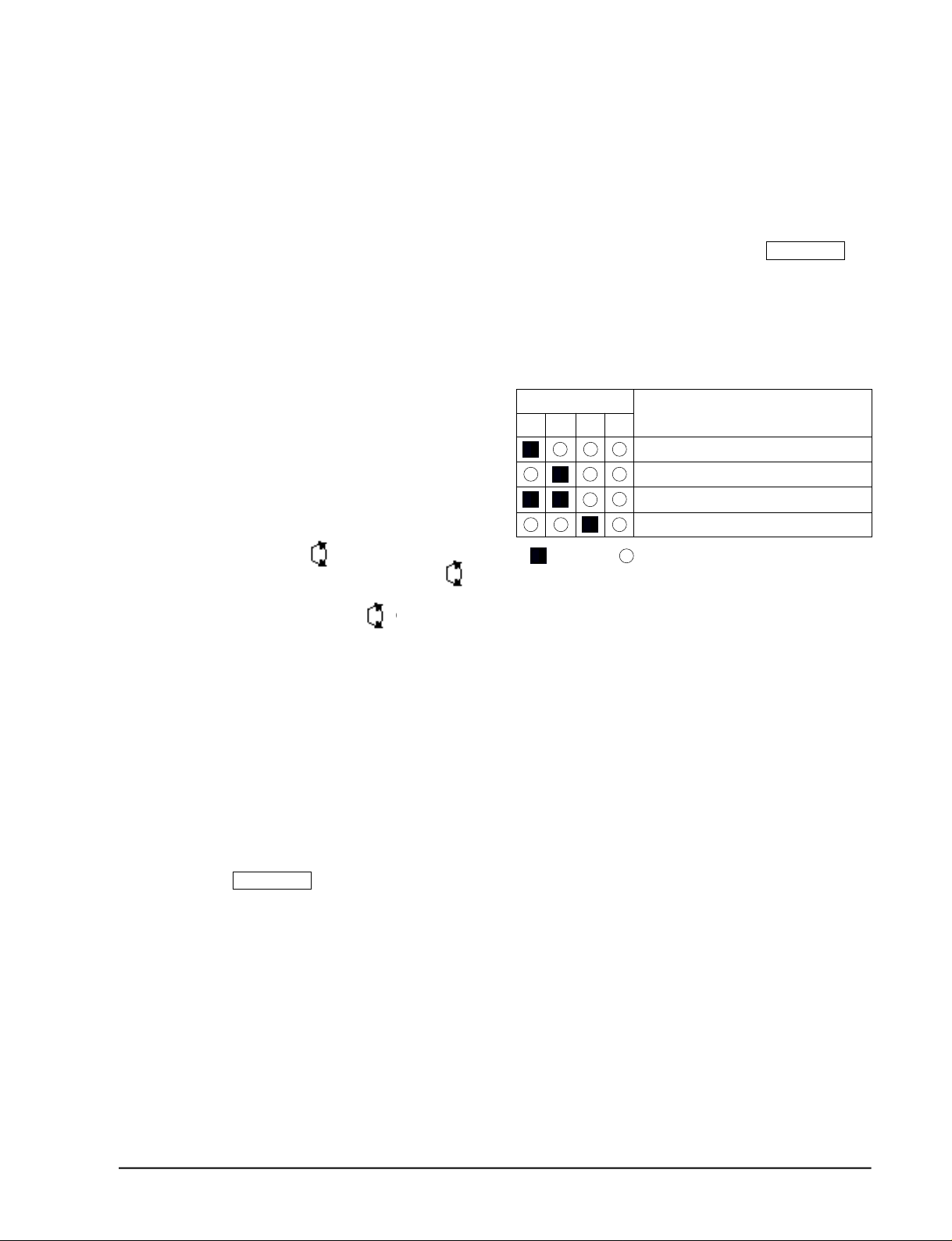

11 . SELF Diagnosis

LED DISPLAY

o p e r-

T I M E R

a t i o n

FA N

Tu r b o

Check Point

I n t e r ruption of electric power and Power on.

Abnormal condition of the room sensor.

Abnormal condition of the indoor unit's heat exchanger sensor.

Indoor unit fan motor lock.

L E D

:

b l i n k i n g

: LED off

1 2 . TIME SHORTENING : If the "Time short"

connector pin is shorted on the main P. C. B,

the compressor's three minutes delay function is cancelled, and each operation time is

shortened to one fiftieth of its original time.

1 3 . BUZZER SOUND : Whenever the ON/OFF

button is pressed or whenever change

occurs to the condition which is set up or

select, the compulsory operation mode,

buzzer is sounded "beep"

Samsung Electronics

3-3

3-2. Outdoor unit controlling spec (Each load controlling condition)

3-2-1 Indoor unit signal(Rooms "B",

and "C" signal)

1 ) On condition : A time point where the

d e s i red temperature at each indoor unit is

+0.5°C against the current temperature .

(When the compressor motor relay of each

assembly main PCB is turned on.)

2) O ff condition : A time point where the

d e s i red temperature at each indoor unit is

against the current temperature. (When the

c o m p ressor motor relay of each assembly

main PCB is turned off . )

3-2-2 SV-BY control

1) On condition :

•When only any one of the two indoor unit

rooms (Rooms B and C) is turned on.

•F o rce it to operate for about 2 minutes

seconds when both of the two indoor unit

rooms (Rooms B and C) are turned off .

2) O ff condition :

•When all of the two indoor unit rooms

(Rooms B and C) are turned on.

•It is automatically turned off after

operating for about 2 minutes

+3 0

- 0

seconds when all of the two indoor unit

rooms (Rooms B and C) are turned off .

3-2-3 SV-B(Indoor unit room "B"

solenoid valve) control

SV-C(Indoor unit room "C"

solenoid valve) control

1) On condition :

•Only the SV-B solenoid valve operate

when the indoor unit room "B" is turned

o n .

•Only the SV-C solenoid valve operate

when the indoor unit room "C" is turned

o n .

•Both of the SV-B and SV-C solenoid valves

operate when all of the indoor unit room B

+ 3 0

- 0

and room C are activated.

•When both of the indoor unit room B and

room C are turned off, it is forced to operate for about 2 minutes seconds.

+3 0

- 0

2) O ff condition :

•The SV-C solenoid valve is turned off

when the indoor unit room "B" is operated.

•The SV-B solenoid valve is turned off

when the indoor unit room "C" is operated.

•When both of the indoor unit room "B"

and room "C" are turned off, it is automatically turned off after operating for about 2

minutes seconds.

+3 0

- 0

3-2-4 Compressor control

1) F o rce the compressor to stop for 3 minutes

at each indoor unit when applying power to

two rooms of the indoor unit(Room "B", and

room "C"). (Delayed operation for thre e

m i n u t e s )

2) A delay time of about 2 minutes 30 seconds

is set up at the outdoor unit PCB when

turning it off (Both of the rooms B and C are

turned off) by comparing the desired temp e r a t u re at each indoor unit against the

c u r rent temperature .

3) When both rooms (Rooms B and C) of the

indoor unit are turned off, force the comp ressor to stop, and then turn on the SV- B Y,

S V-B (room "B" valve), and SV-C (room C

valve) to achieve the pre s s u re balance of the

c o m p re s s o r.

4) When applying the power to the outdoor

unit PCB initially, disre g a rd the time of

f o rcing the outdoor unit compressor (About

2 minutes seconds).

+3 0

- 0

3-4

Samsung Electronics

Operating Instructions and Installation

3-2-5 Outdoor unit fan motor control (1 step)

1) On condition : When the compressor is "ON".

2) O ff condition : When the compressor is "OFF".

3) The motor is operated in "High" rpm mode re g a rdless of the number of the indoor units

o p e r a t e d .

(Note)

1. C o n t rolling the solenoid valve of the outdoor unit according to the operation of the indoor

units (Room B, Room C)

Combination of indoor units Control of solenoid valve Remarks

Room "B" Room "C" SV-B SV-C SV-BY

Room 0 • • • Off after operating for about 2 minutes seconds

Room 1 • • •

• • •

Room 2 • • • •

+ 30

- 0

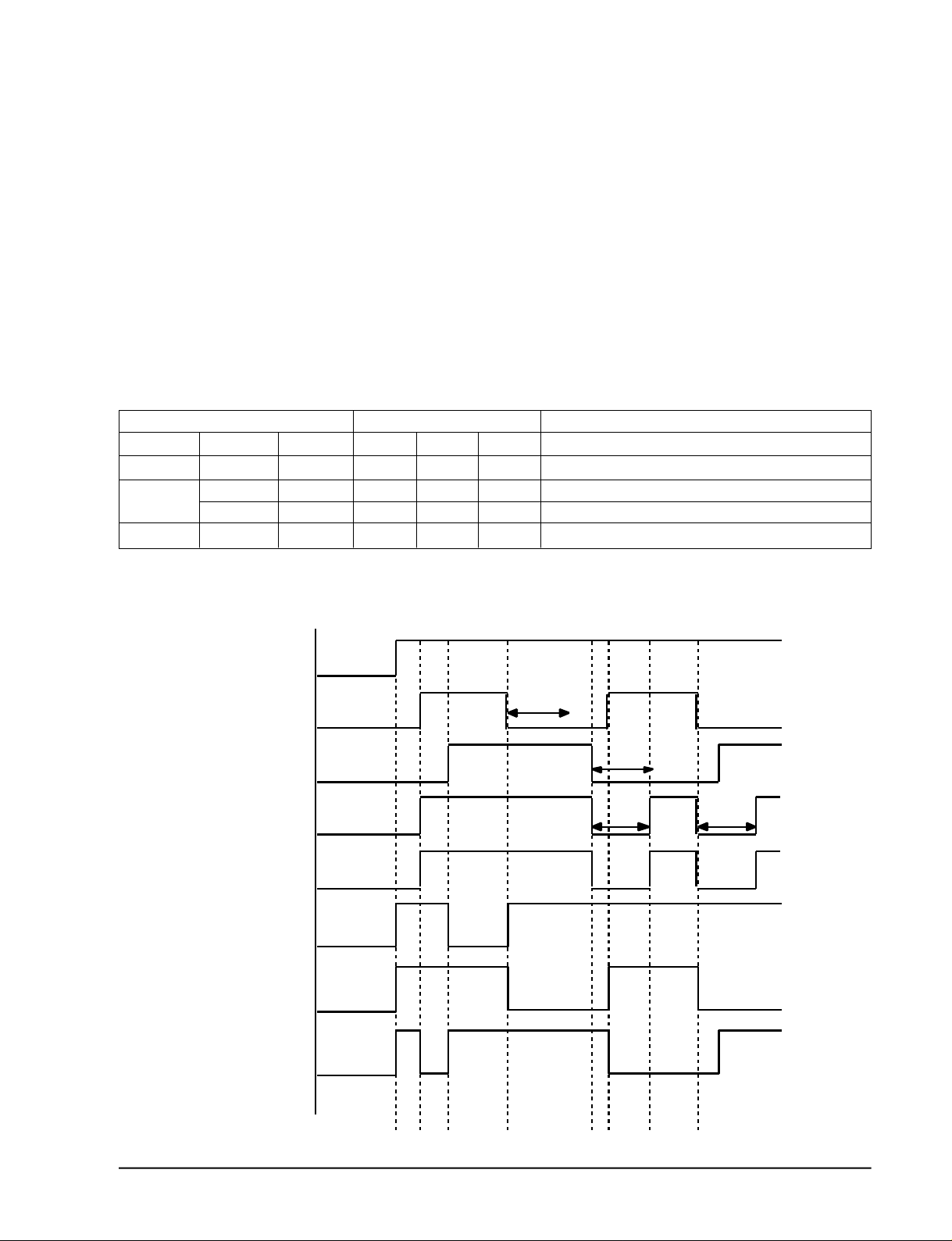

2. Outdoor unit load time chart according to the operating conditions for the indoor unit.

Outdoor unit power supply

Delay of 3 minutes

Indoor unit room "B"

Delay of 3 minutes

Indoor unit room "C"

About 2 minutes About 2 minutes

Compressor

Outdoor fan motor

SV-BY

SV-B (room"B"

soldnoid valve)

SV-C (room"C"

soldnoid valve)

Samsung Electronics

3-5

3-3 Installation

3-3-1 Selecting Area for Installation

Select an area for installation that is suitable

to the customer's needs.

3-3-1(a) Indoor Unit

1 . Make sure that you install the indoor unit in

an area providing good ventilation. It must

not be blocked by an obstacle affecting the

airflow near the air inlet and the air outlet.

2 . Make sure that you install the indoor unit in

an area allowing good air handling and

endurance of vibration of the indoor unit.

3. Make sure that you install the indoor unit in

an area where there is no source of heat or

vapor nearby.

4 . Make sure that you install the indoor unit in

an area from which hot or cool air is spre a d

evenly in a ro o m .

5 . Make sure that you install the indoor unit in

an area away from TVs, audio units, cordless phones, fluorescent lighting fixture s

and other electrical appliances (at least 1

m e t e r ) .

6 . Make sure that you install the indoor unit in

an area which provides easy pipe connection with the outdoor unit, and easy

drainage for condensed water.

7. Make sure that you install the indoor unit in

an area which is large enough to accomodate the measurements shown in figure on

the next page.

3-3-1(b) Outdoor Unit

1 . Make sure that you install the outdoor unit

in area not exposed to the rain or direct sun

l i g h t .

(Install a separate sunblind if exposed to

d i rect sun light.)

2 . Make sure that you install the outdoor unit

in area allowing good air moment, not

amplifying noise or vibration, especially to

avoid disturbing neighbours.

(Fix the unit firmly if it is mounted in a

high place.)

3 . Make sure that you install the outdoor unit

in area providing good ventilation and

which is not dusty. It must not be blocked

by any obstacle affecting the airflow near

the air inlet and the air outlet.

4 . Make sure that you install the outdoor unit

in area free from animals or plants.

5 . Make sure that you install the outdoor unit

in area not blocking the traff i c .

6. Make sure that you install the outdoor unit

in area easy to drain condensed water fro m

the indoor unit.

7. Make sure that you install the outdoor unit

in area which provides easy connection

within the maximum allowable length of a

coolant pipe(15 meters).

Note

1. Add 10 grams of refrigerant (R-22) for

every 1 meter if the pipe length exceeds

the standard pipe length of 5 meters.

2. Maintain a height between the indoor and

outdoor units of less than 3 meters.

8 . Make sure that you install the outdoor unit

in an area which is large enough to accommodate the measurements

shown in figure on the next page.

3-3-1(c) Remote Control Unit

1 . Make sure that you install the remote con-

t rol unit in an area free from obstacles such

as curtains etc, which may block signals

f rom the remote control unit.

2. Make sure that you install the remote cont rol unit in an area not exposed to

d i rect sunlight, and where there is no sourc e

of heat.

3. Make sure that you install the remote cont rol unit in an area away from TVs, audio

units, cordless phones, fluorescent lighting

f i x t u res and other electrical appliances (at

least 1 meter).

Caution :

It is harmful to the air conditioner if it is used in the following environments: greasy areas (including areas near machines),

salty areas such as coast areas, areas where sulfuric gas is present such as hot spring areas. Contact your dealer for advice.

3-6

Samsung Electronics

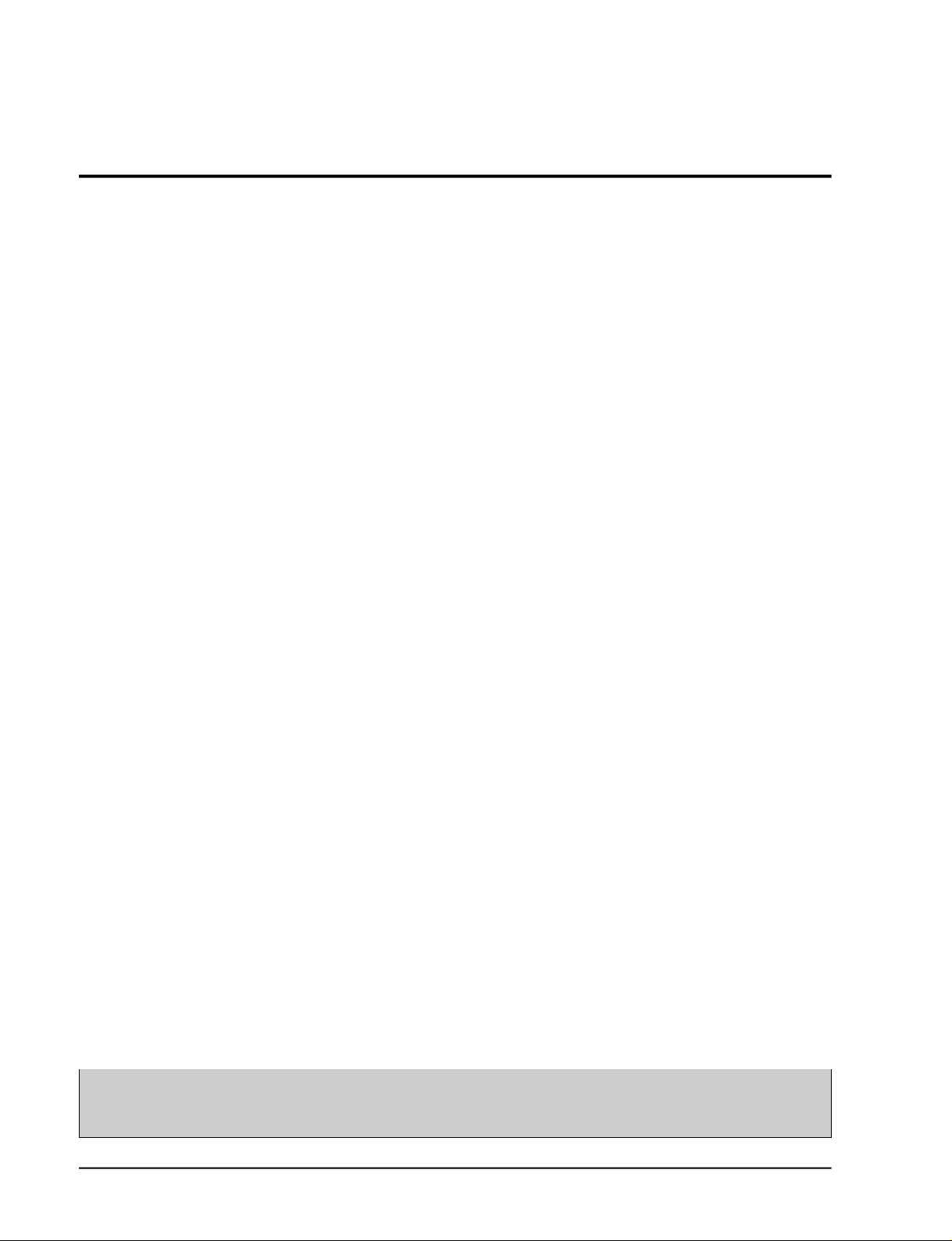

3-2-2 Installation diagram of indoor unit and outdoor unit

Operating Instructions and Installation

A Indoor unit gas leak test check point

Indoor unit

Piping

1

3

2

Tape vinyl

B Drain hose installation

Cut the piping hole

sloped slightly

Piping may be laid to the rear, left,

right or down .

Right

Rear

5

6

Down

Remote controlRemote control holder

Rear

7

Left

1

2

3

4

5

Samsung Electronics

4

10

Piping (Liquid) 1/4” Clamper tube

Piping (Gas) 3/8” Installation plate

Installation tube Pipe-connection

Vinyl tape Screw

Putty Drain hose

6

7

8

9

10

UNIT-A

UNIT-B

4

Outdoor unit check point

UNIT-C

10

3-7

Operating Instructions and Installation

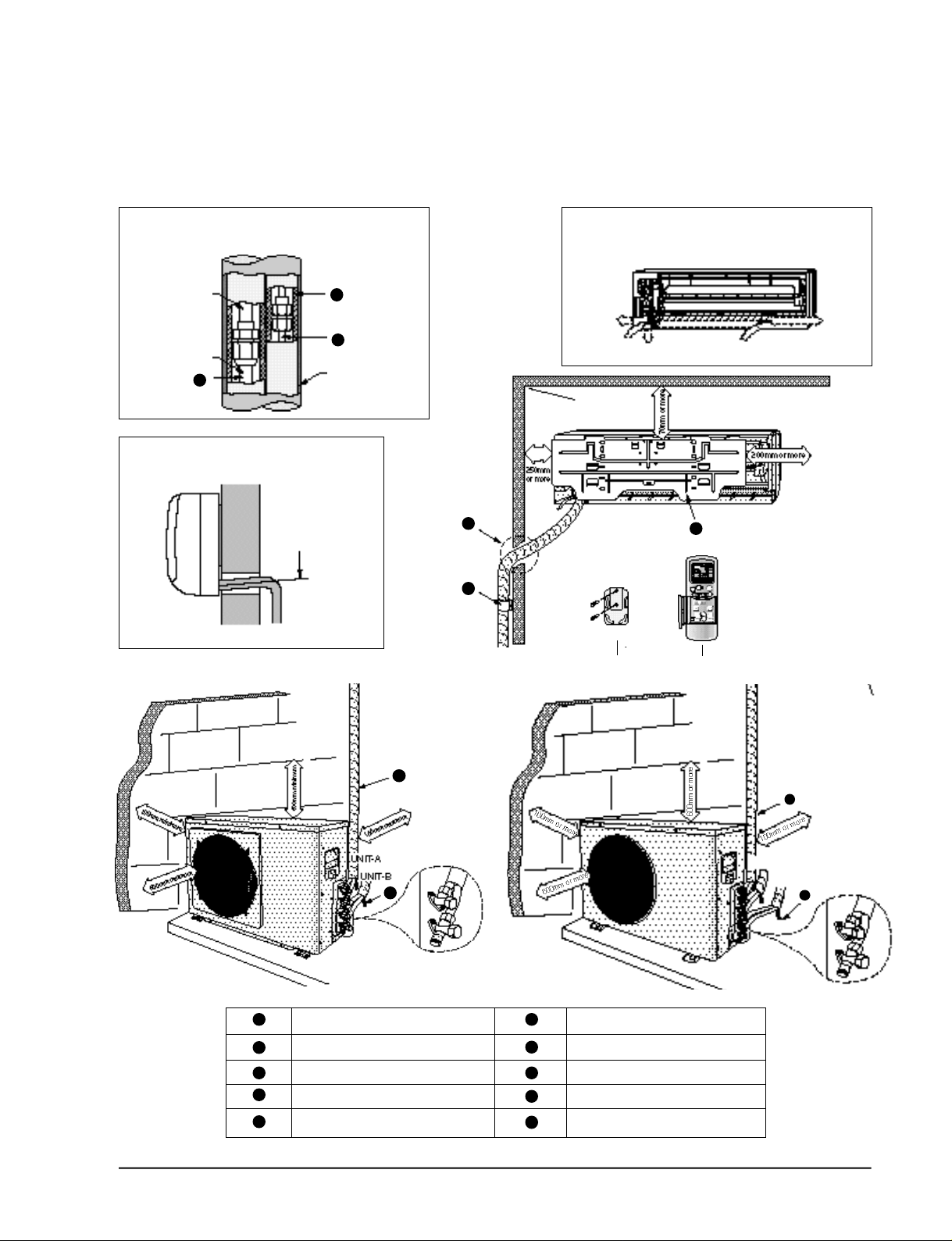

3-3-2(a) Fixing the Installation Plate

(Unit : mm)

(Unit : mm)

Installation plate

280

340

Pipe hole

(ø65mm)

1. Determine the position of the pipe and drain hose hole

using the right figure and drill the hole with an inner

diameter of 65mm so that it slants slightly downwards.

2. If you are fixing the indoor unit to a… Then follow Steps…

Wall 3.

Window frame 4 to 6.

3. Fix the installation plate to the wall in a manner appropriate to the weight of the indoor unit.

If you are mounting the plate on a concrete wall with

anchor bolts, the anchor bolts must not project by more

than 20mm.

4. Determine the positions of the wooden uprights to be

attached to the window frame.

3-3-2(b) Purging the Unit

5. Attach the wooden uprights to the window frame in a

manner appropriate to the weight of the indoor unit.

6. Using tapped screws, attach the installation plate to the

wooden uprights, as illustrated in the last figure opposite.

On delivery, the indoor unit is loaded with an inert gas.

All this gas must therefore be purged before connecting the

assembly piping. To purge the inert gas, proceed as fol lows.

Unscrew the caps at the end of each pipe.

Result : All inert gas escapes from the indoor unit.

• To prevent dirt or foreign objects from getting into

the pipes during installation, do NOT remove the

caps completely until you are ready to connect the

piping.

3-8

Samsung Electronics

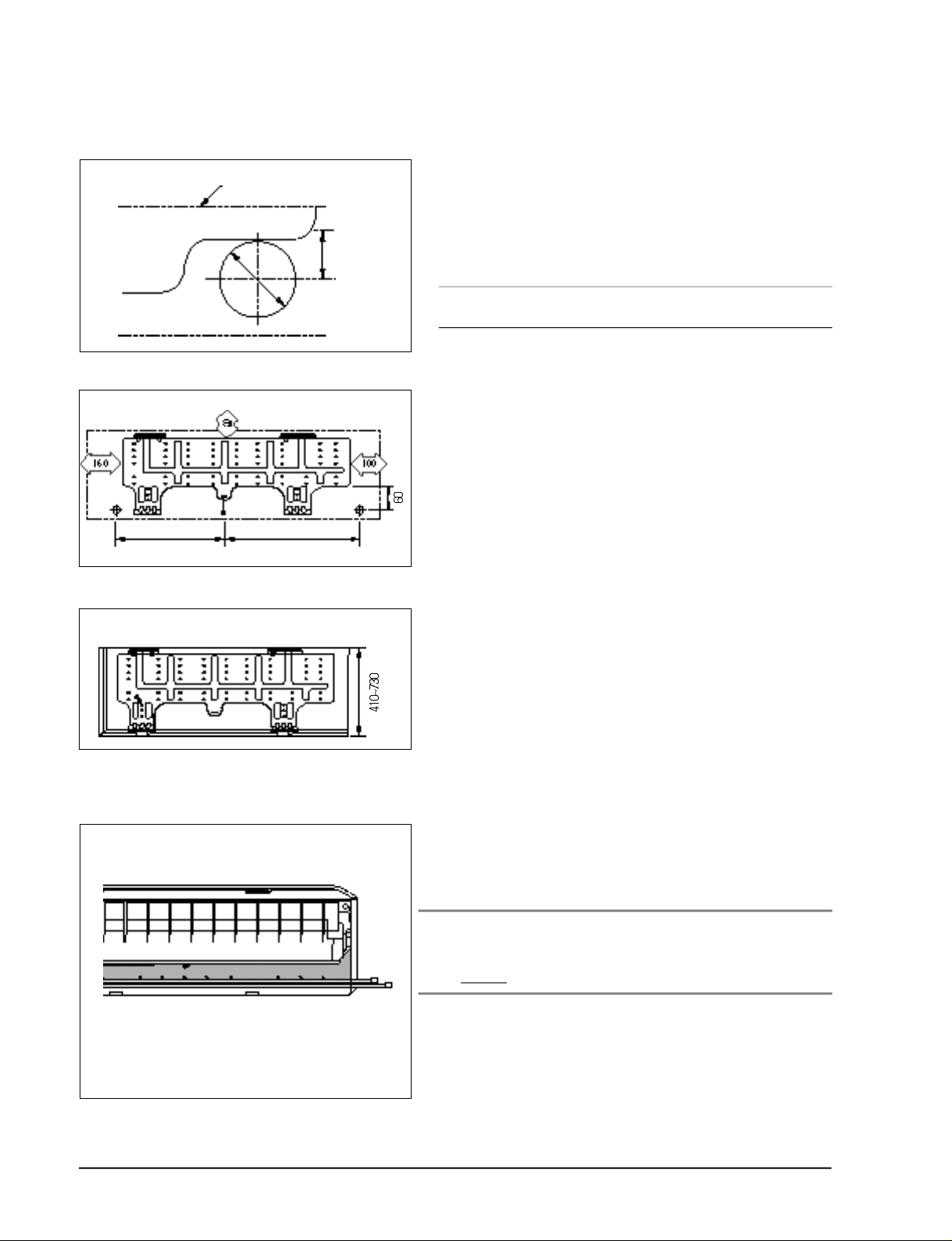

3-3-2(c) Connecting the Assembly Cable.

The outdoor unit is powered from the indoor unit via the assembly

cable. If the outdoor unit is more than five metres away from the

indoor unit, the cable must first be extended to a maximum of

ten metre s .

1 . Extend the assembly cable if necessary.

2 . Open the front grille by pulling on the tabs on the lower right and

left sides of the indoor unit.

3 . Remove the screw securing the connector cover.

4 . Pass the assembly cable through the rear of the indoor unit and

connect the assembly cable to terminals 1 to 5.

• Each wire is labelled with the corresponding terminal number.

5 . Pass the other end of the cable through the 65mm hole in the wall.

6 . Replace the connector cover, carefully tightening the scre w.

7 . Close the front grille.

8 . For further details on how to plug the other end of the assembly

cable into the outdoor unit, refer to page 3-10.

Operating Instructions and Installation

3-3-2(d) Installing and Connecting the Indoor Unit Drain Hose

C a re must be taken when installing the drain hose for the indoor unit to ensure that any condensa tion water is correctly drained outside.l When passing the drain hose through the 65mm hole drilled

in the wall, check that none of the following situations occur.

The hose must

NOT slope upw

ards.

To install the drain hose, proceed as follows.

1. If necessary, connect the 2-metre extension to the drain hose.

2 . If you are using the extension, insulate the inside part of the extension drain hose with a shield.

3. Pass the drain hose under the refrigerant piping, taking care to keep the drain hose tight.

4. Pass the drain hose through the hole in the wall, making sure that it is sloping downwards, as

shown in the illustrations above.

The end of the drain

hose must NOT be

placed in water.

Do NOT bend the

hose in different

directions.

Keep a clearance of at

least 5cm between the

end of the hose and the

ground.

Do NOT place the end

of the drain hose in a

hollow.

Shield

Drain hose Extension drain hose

Samsung Electronics

The hose will be fixed permanently into position once

the whole installation has been tested for gas leaks;

refer to page 16 for further details.

3-9

Operating Instructions and

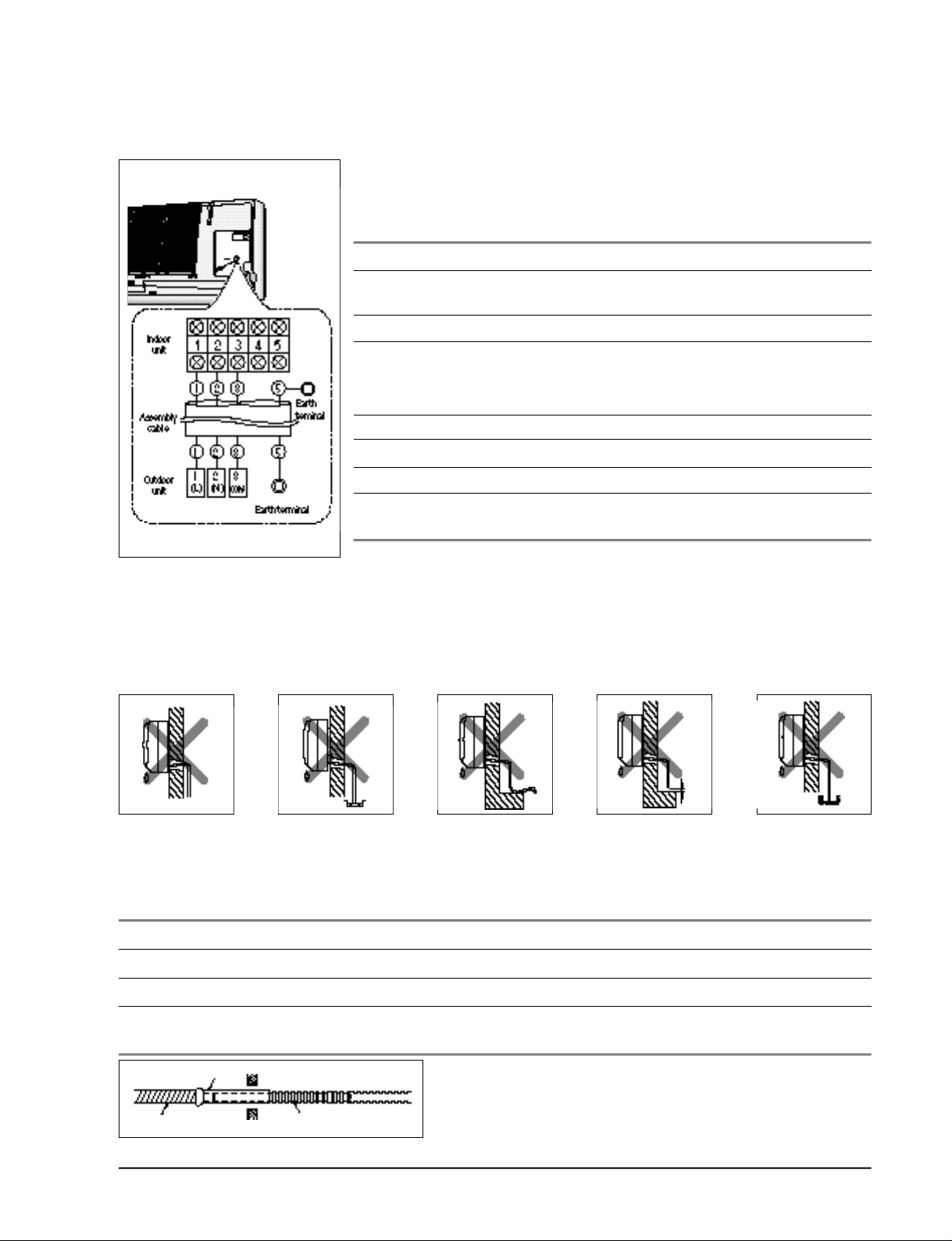

3-3-2(e) Outdoor unit installation

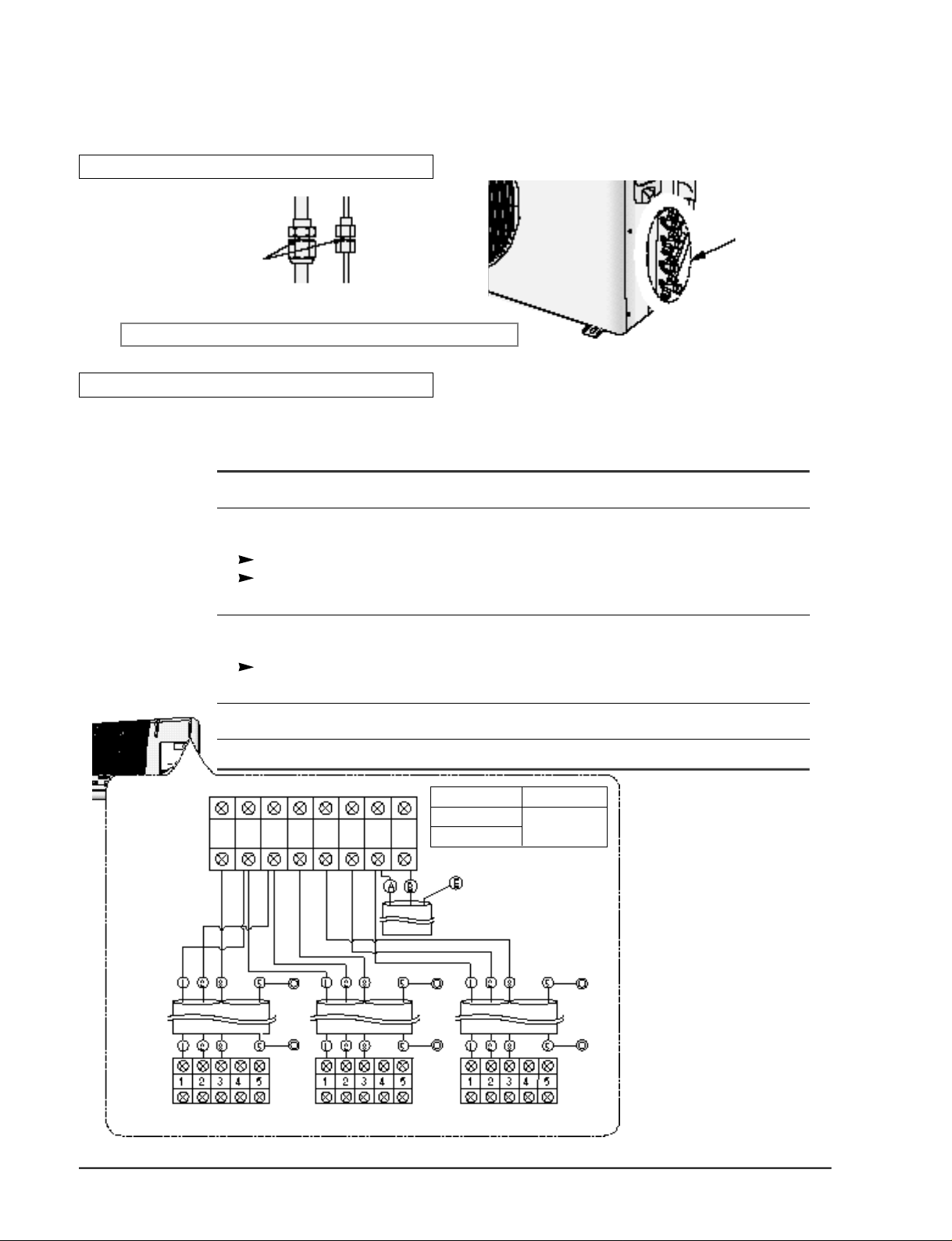

GAS LEAK TEST

Indoor unit check point

Check for gas leak from the flare nut connections with leak detector.

WIRING CONNECTION

Two electric cables must be connected to the outdoor unit:

• The assembly cable connecting the indoor unit to the outdoor unit.

• The power cable connecting the auxiliary circuit breaker to the outdoor unit.

1 Remove the terminal board cover on the side of the outdoor unit.

Outdoor unit check point

Terminal Block

2 Connect the assembly cable to terminals 1 to 5 and connect the power cable to therminals A to B.

Each wire is labelled with the corresponding terminal number.

E n s u re that the wire number of the indoor unit and the terminal number of the outdoor unit.

3 Connect the earthing wires to the earth terminals.

Refer to the page opposite for further details on how to check that earthing is corre c t .

4 Replace the terminal board cover, carefully tightening the screw.

5 connect the power cable to the auxiliary circuit breaker.

Outdoor unit

1

3

(L)

COM

Earth

terminal

2

(N)

3

COM3COM

2

1

(N)

2

(L)

(N)

Indoor Unit Outdoor Unit

AM20A1(B1)E08

AM20A1(B1)E06

Earth

terminal

Circuit Breaker

(Main Power cable)

UM20A1(B1)E3

3-10

Assembly

cable

Indoor unit

A-unit

AM20A1(B1)E08

Earth

terminal

Earth

terminal

B-unit

AM20A1(B1)E06

Earth

terminal

Earth

terminal

Earth

terminal

Earth

terminal

C-unit

AM20A1(B1)E06

Samsung Electronics

Outdoor unit

NLB21A

Operating Instructions and

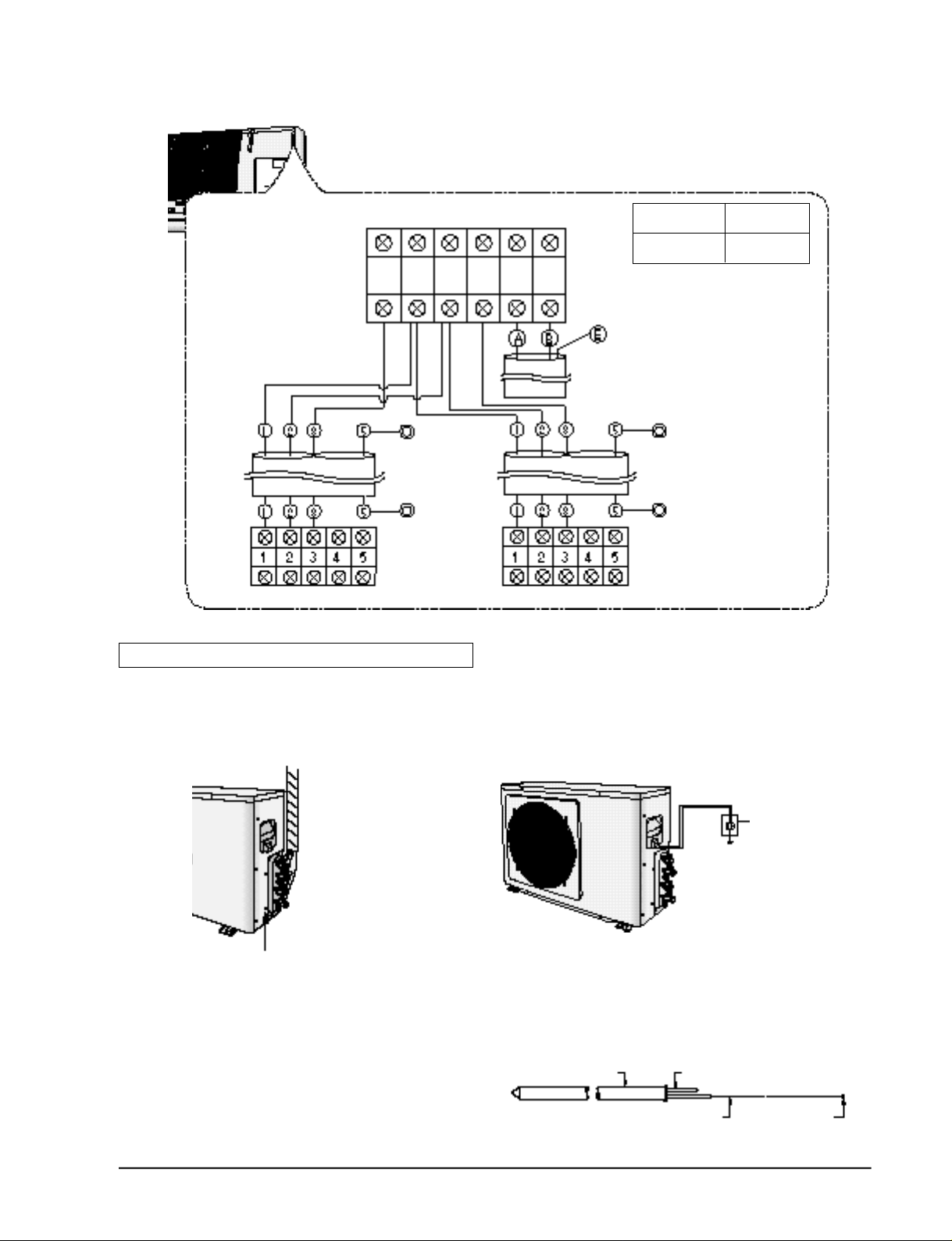

Indoor Unit Outdoor Unit

AM14E1(B1)E07 UM14A1(B1)E2

Terminal Block

Earth

terminal

Circuit Breaker

(Main Power cable)

Indoor

unit

A-unit B-unit

Grounding

(The parts for this work are optional.)

• A g rounding terminal can be found on

the outdoor unit as illustrated.

Earth

terminal

Earth

terminal

Earth

terminal

Assembly cable

Earth

terminal

1 . When an existing grounding terminal is available.

( G rounding wire of ®™1.6mm or larg e r < s o l i d

w i re>or 2mm2 or larger <standard wire>)

Terminal used

exclusively for

grounding.

Grounding resistance:

less than 100 ohms

(existing grounding electrode)

Grounding screw hole

Samsung Electronics

2 . Use of a grounding electro d e .

• Specifications of grounding electro d e .

Carbon plastic Steel core

PVC-insulated wire(2mm2x3.5m), green Terminal, M4

3-11

Operating Instructions and Installation

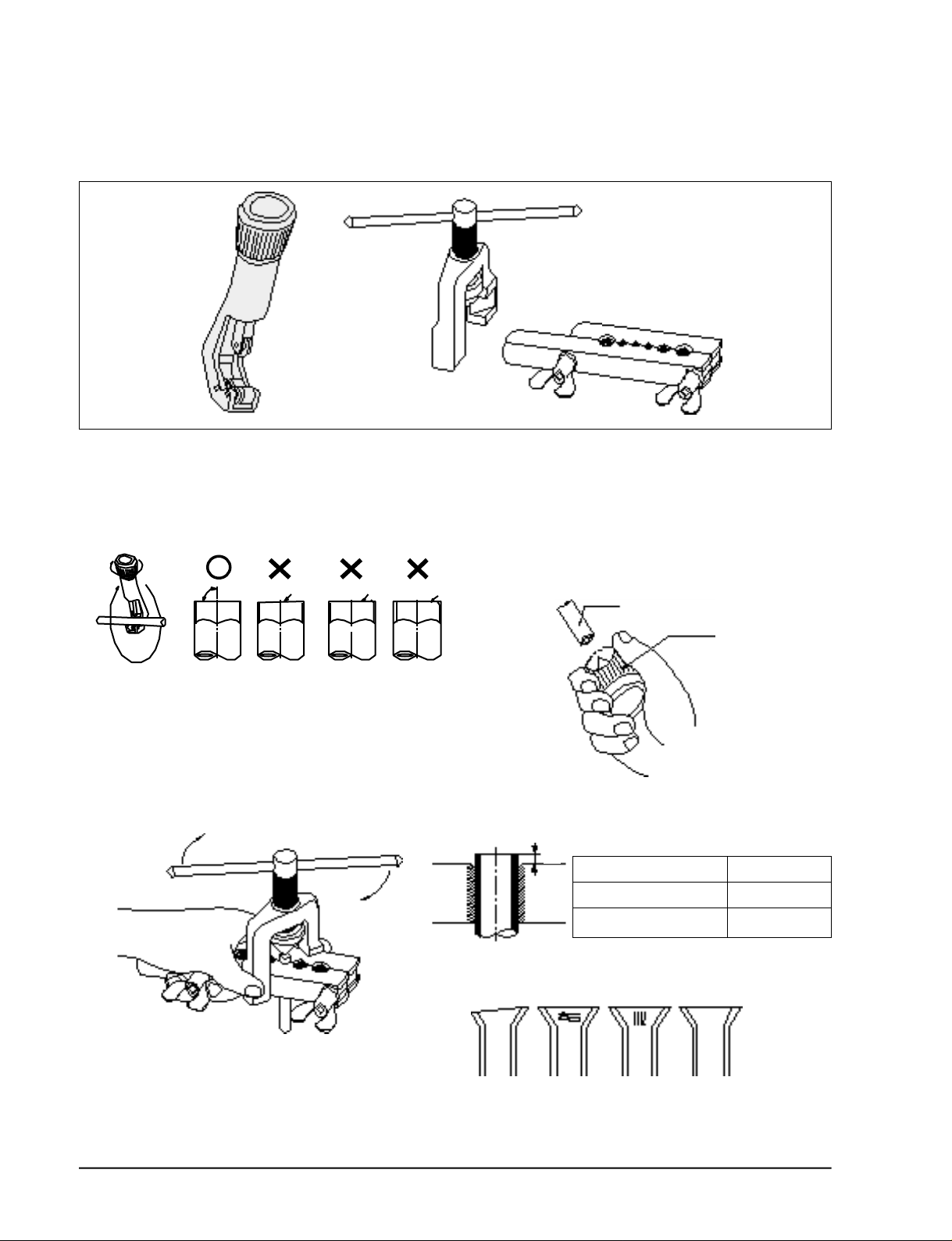

3-3-2(f) Flare Modification

• Tools used

Flare modification procedure

1 ) Cut the pipe using a pipe cutter.

90°

3 ) Insert a flare nut into the pipe and modifty flare .

Oblique

Raughness

2 ) Remove burrs at the tip of the pipe cut.

Burr

* Unproper flaring

C a u t i o n : Burrs not removed may result in

leakage of gas.

Pipe

Reamer

D

A

Outer diameter A(mm)

ø6.35mm 1.3

ø9.52mm 1.8

3-12

Inclined Surface

damaged

Cracked Uneven

thickness

Samsung Electronics

Operating Instructions and

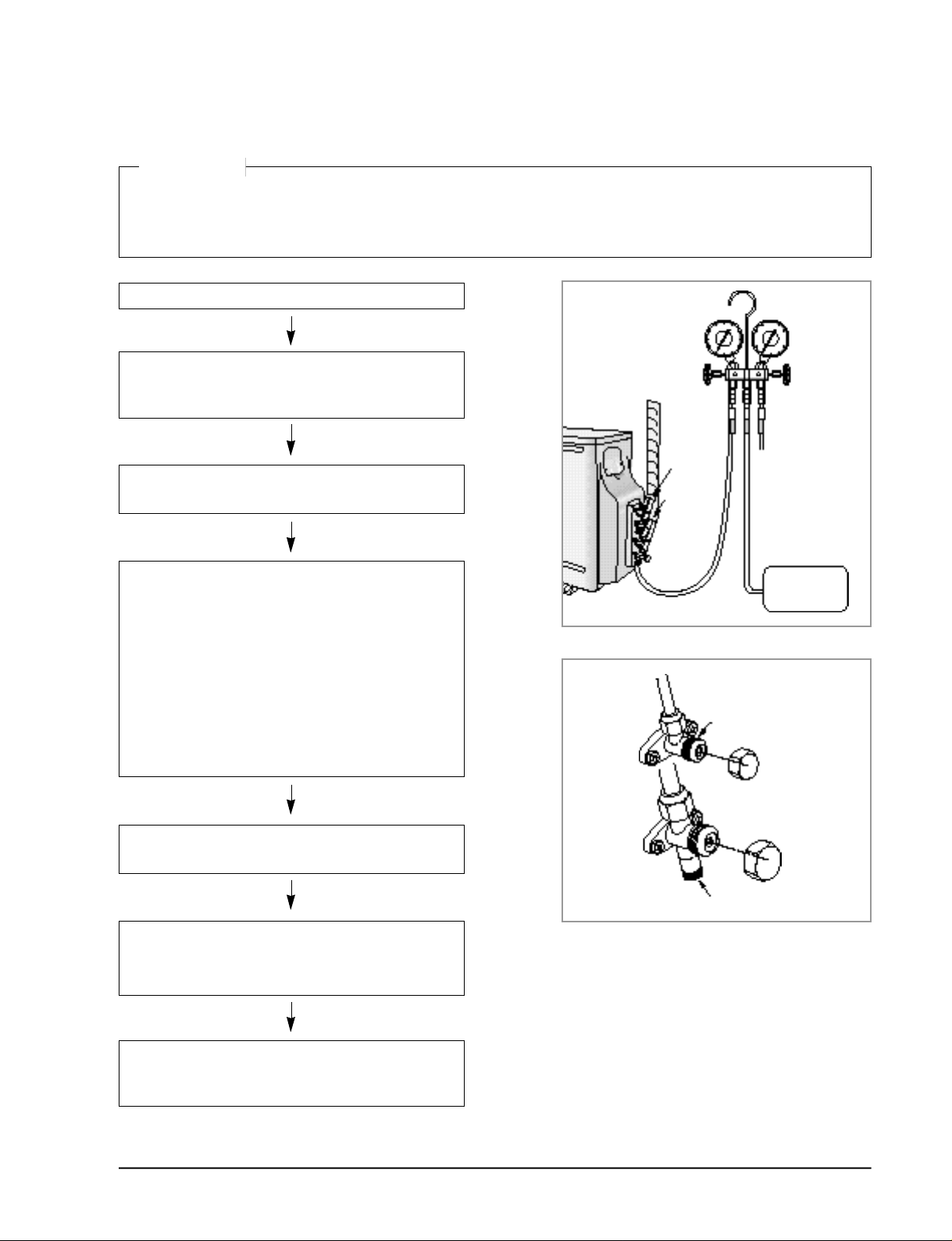

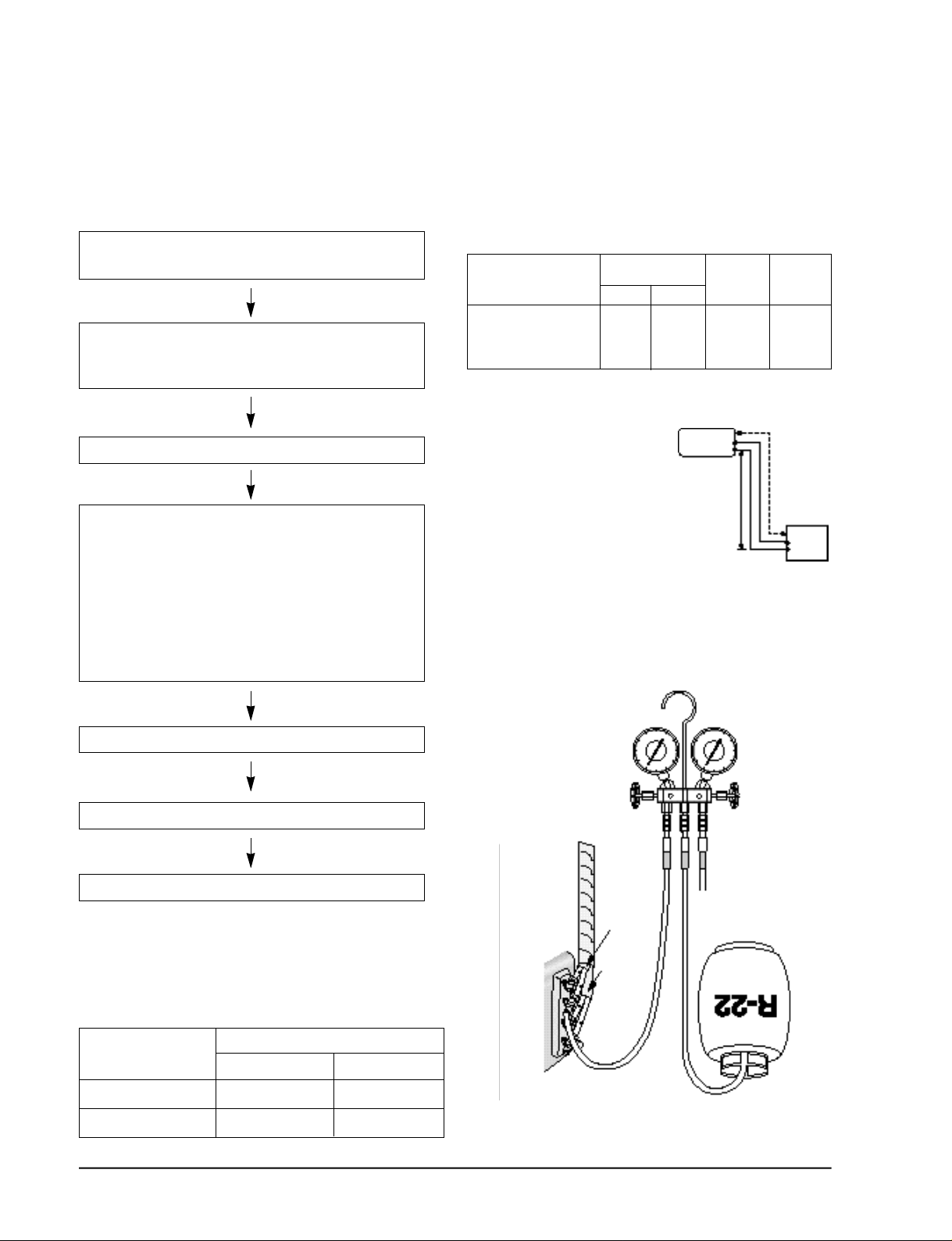

3-2-2(g) Air-Purging

CAUTION

The air in indoor unit and in the pipe must be purged. If air remains in the refrigeration pipes, it will affect the compressor,

reduce to cooling capacity, and could lead to a malfuction. Refrigerant for air purging is not charged in the outdoor unit. Use

vacuum pump as shown at the right figure. Each unit must be purged in turn

1. Check the piping connections

2. Connect the charging hose of low pressure side of

Manifold gauge to the packed valve having a service

port (3/8” or 1/2” Packed valve) as shown at the right

Indoor

3. Open the valve of the low pressure side of Manifold

gauge counterclockwise.

A-unit

Indoor

B-unit

4. Purge the air from the system using vacuum pump for

about 10 minutes.

- Close the valve of the low pressure side of manifold

gauge clockwise.

- Make sure that pressure gauge show -0.1MPa(-

76cmHg) after about 10minutes.

This procedure is very important in order to avoid gas

leak.

- Turn off the vacuum pump

- Remove the hose of the low pressure side of mani -

fold gauge.

5. Set valve cork of both liquid side and gas side of

packed valve to the open position.

6. Mount the valve stem nuts and the service port cap to

the valve, and tighten them at the torque of 18N.m

with a torque wrench.

Liquid side

Gas side

Vacuum Pump

Valve stem

Stem cap

Service port

7. Check for gas leakage.

-At this time, especially check for gas leakage from the

3-way valve’s stem nuts, and from the service port cap.

Samsung Electronics

3-13

Operating Instructions and Installation

3-2-2(h) Refrigerant Refill

If connecting pipe of more than 10 metres is installed, additional refrigerant should be charged by

extra metre. You don’t have to charge additional refrigerant up to 10 metres of connecting pipe.

1. Remove the valve stem cap and service port of 3-way

valve.

2. Connect the charging hose of low pressure side of

Manifold gauge to the packed valve having a charging

port(1/2” Packed valve) as shown at the right figure.

3. Operate the unit at the cooling mode.

4. Slowly open the valve of the low pressure side of

Manifold gauge counterclockwise until the low pressure of manifold gauge indicates 4.8 to 5.5 kg/cm2 (68

a 78psi) at the high cool operation (1-unit operation)

and the standard temperature.

It is recommend that refrigerant should be slowly put

in. If the refrigerant is put in too quickly, compressor

will be damaged.

• Piping length and the height

Pipe Size

AM14A1(B1)E07

AM20A1(B1)E08

1/4” 3/8”

AM20A1(B1)E06

Additional refrigerant charg e

( R 2 2 , g )

• When length of the pipe is

over 5u by the unit, you

should charge

the refrigerant Formulas

A-UNIT : 10gx(La- 1 0 ) / m

B-UNIT : 10gx(Lb- 1 0 ) / m

( La:the length of A-unit’s

pipe Lb:the length of

B-unit’s pipe)

INDOOR UNIT

M a x . p i p i n g

length

A

15m

B

Max

height

BLIQUID GAS

3m

A

OUTDOOR UNIT

5. Stop operation of the air conditioner.

6. Disconnect the charge hose of manifold gauge.

7. Close the cap of each valve.

3-2-2(i) Flare unt fixing torque

Outter diameter

Fixing Torque Final Torque

ø6.35(Liquid Side) 160 200

ø9.52(Gas Side) 300 350

3-14

Torque (kg-cm)

INDOOR

A-UNIT

INDOOR

B-UNIT

Samsung Electronics

Loading...

Loading...