ROOM AIR CONDITIONER

INDOOR UNIT

AD26B1C13

AD18B1C09

SERVICE

OUTDOOR UNIT

UD26B1C2

UD18B1C2

Manual

CONTENTSAIR CONDITIONER

1. Installation

2. Disassembly and Reassembly

3. Troubleshooting

4. Exploded Views and Parts List

5. Refrigerating Cycle Block Diagrams

6. Wiring Diagrams

E DB98-05645A(1)

7. Schematic Diagrams

1. Installation

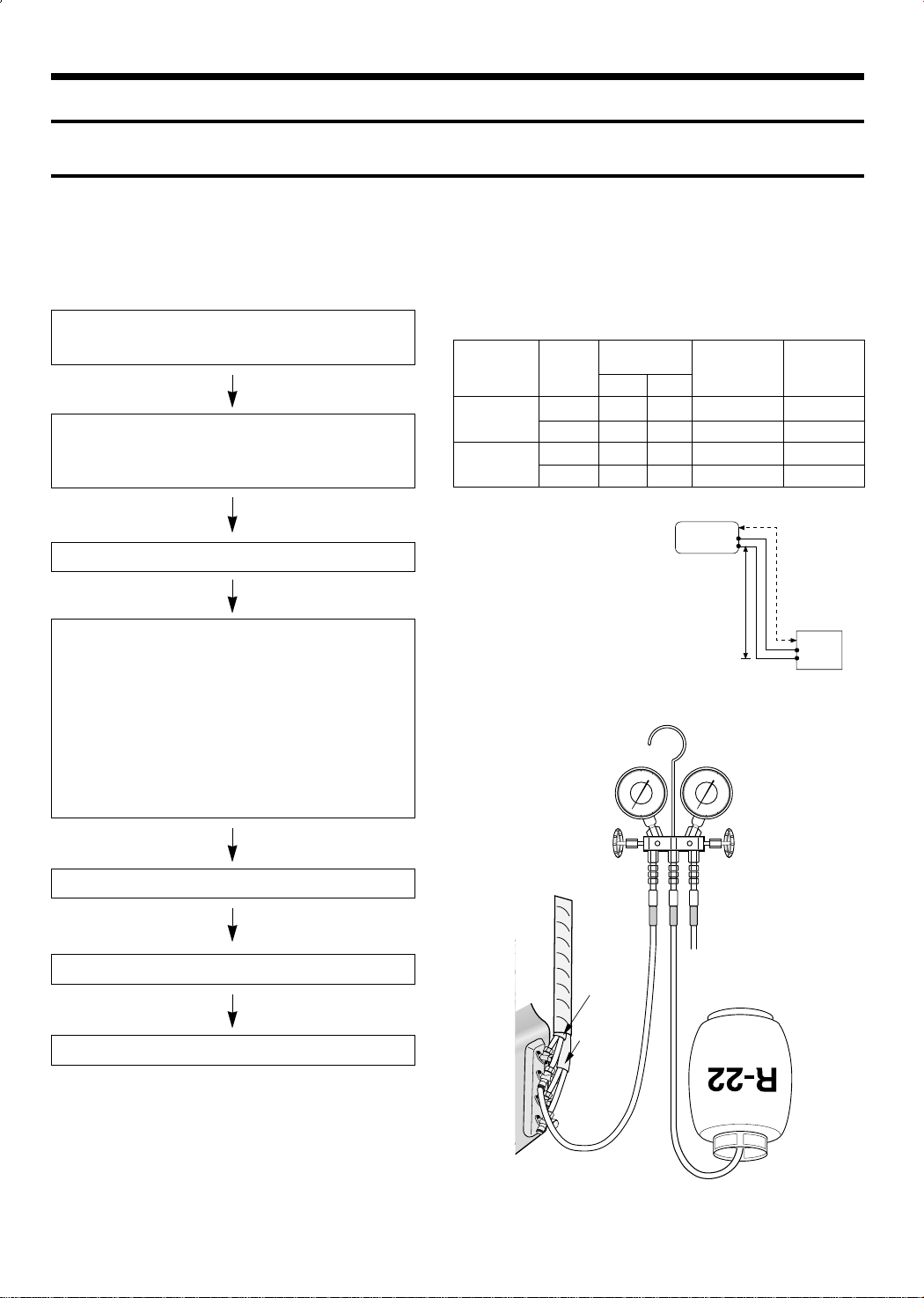

1-1 Refrigerant Refill Procedure

If connecting pipe of more than 5 metres is installed, additional refrigerant should be charged by extra

metre. You don’t have to charge additional refrigerant up to 5 metres of connecting pipe.

1. Remove the valve stem cap and service port of 3-way

valve.

2. Connect the charging hose of low pressure side of

Manifold gauge to the packed valve having a charging

port(1/2” Packed valve) as shown at the right figure.

3. Operate the unit at the cooling mode.

4. Slowly open the valve of the low pressure side of

Manifold gauge counterclockwise until the low pressure

of manifold gauge indicates 4.8 to 5.5 kg/cm

2

(68 a

78psi) at the high cool operation (1-unit operation) and

the standard temperature.

It is recommend that refrigerant should be slowly put in.

If the refrigerant is put in too quickly, compressor will be

damaged.

• Piping length and the height

Pipe Size

LIQUID GAS

AD26B1C13

AD18B1C09

Additional refrigerant charge

(R22,g)

• When length of the pipe is

over 5u by the unit, you

should charge

the refrigerant Formulas

A-UNIT : 20gx(La-5)/m

B-UNIT : 20gx(Lb-5)/m

(La:the length of A-unit’s

pipe Lb:the length of

B-unit’s pipe)

A-UNIT 1/4” 1/2” 15m(49ft 3in) 7m(23ft)

B-UNIT 1/4” 1/2” 15m(49ft 3in) 7m(23ft)

A-UNIT 1/4” 3/8” 15m(49ft 3in) 7m(23ft)

B-UNIT 1/4” 3/8” 15m(49ft 3in) 7m(23ft)

INDOOR UNIT

Max.piping

length

A

B

Max

height

B

A

OUTDOOR UNIT

5. Stop operation of the air conditioner.

6. Disconnect the charge hose of manifold gauge.

7. Close the cap of each valve.

INDOOR

A-UNIT

INDOOR

B-UNIT

1

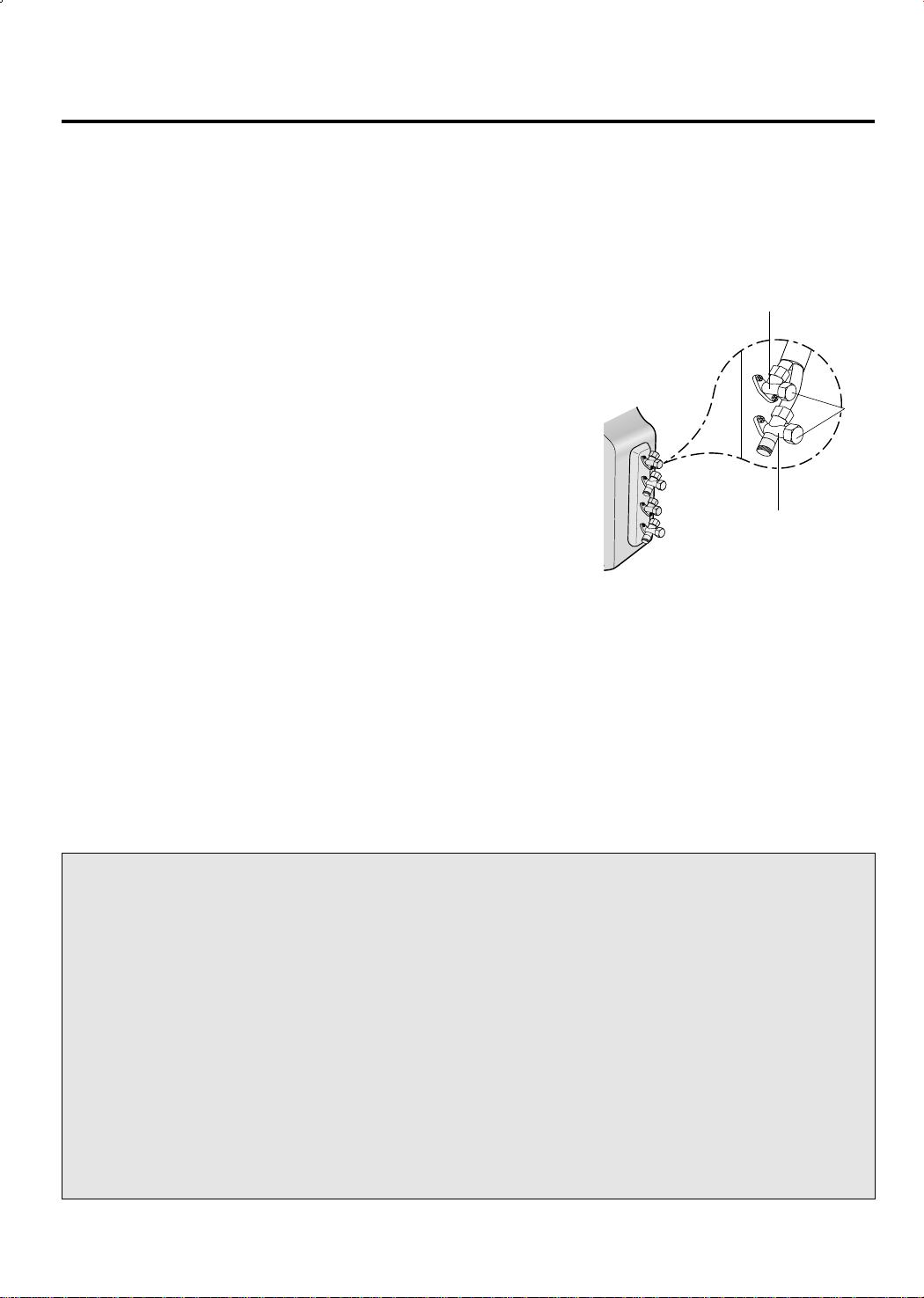

1-2 “Pump down” Procedure

1. Confirm that both the 2-way and 3-way valves are set to

the open position.

(1) Remove the valve stem caps.

(2) Be sure to use a hexagonal wrench to operate the Gas

side valve stems.

2. Operate the unit for 10 to 15 minutes.

3. Stop operation and wait for 3 minutes, then connect the

charge set to the service port of the 3-way valve.

(1) Connect the charge hose with the push pin to the ser-

vice port.

4. Air purging of the charge hose.

(1) Open the low-pressure valve on the charge set slightly

to air purge from the charge hose.

5. Set the liquid side 2-way valve to the closed position.

6. Operate the air conditioner at the cooling cycle and stop

operation immediately after setting the 3-way valve to the

closed position when the gauge indicates 0 kg/cm2G.

If the unit can not be operated at the Cooling Mode(weater

is rather cool), operate the unit at the Trubo Mode.

So that the unit can be operated.

7. Disconnect the charge set, and mount the both 3-way

valve’s stem nuts and the service port cap.

2-Way Valve

Cap

3-Way Valve

Relocation of the air conditioner

• Refer to this procedure when the unit is relocated.

1. Carry out the pump down procedure

(refer to the details of ‘pump down’).

2. Remove the power cord.

3. Disconnect the assembly cable from the

indoor and outdoor units.

4. Remove the flare nut connecting the indoor

unit and the pipe.

At this time, cover the pipe of the indoor

unit and the other pipe using a cap or vinyl

plug to avoid foreign material entering.

2

5. Disconnect the pipe connected to the outdoor unit.

At this time, cover the valve of the outdoor

unit and the other pipe using a cap or vinyl

plug to avoid foreign material entering.

6. Make sure you do not bend the connection

pipes in the middle and store together with

the cables.

7. Move the indoor and outdoor units to a new

location.

8. Remove the mounting plate for the indoor

unit and move it to a new location.

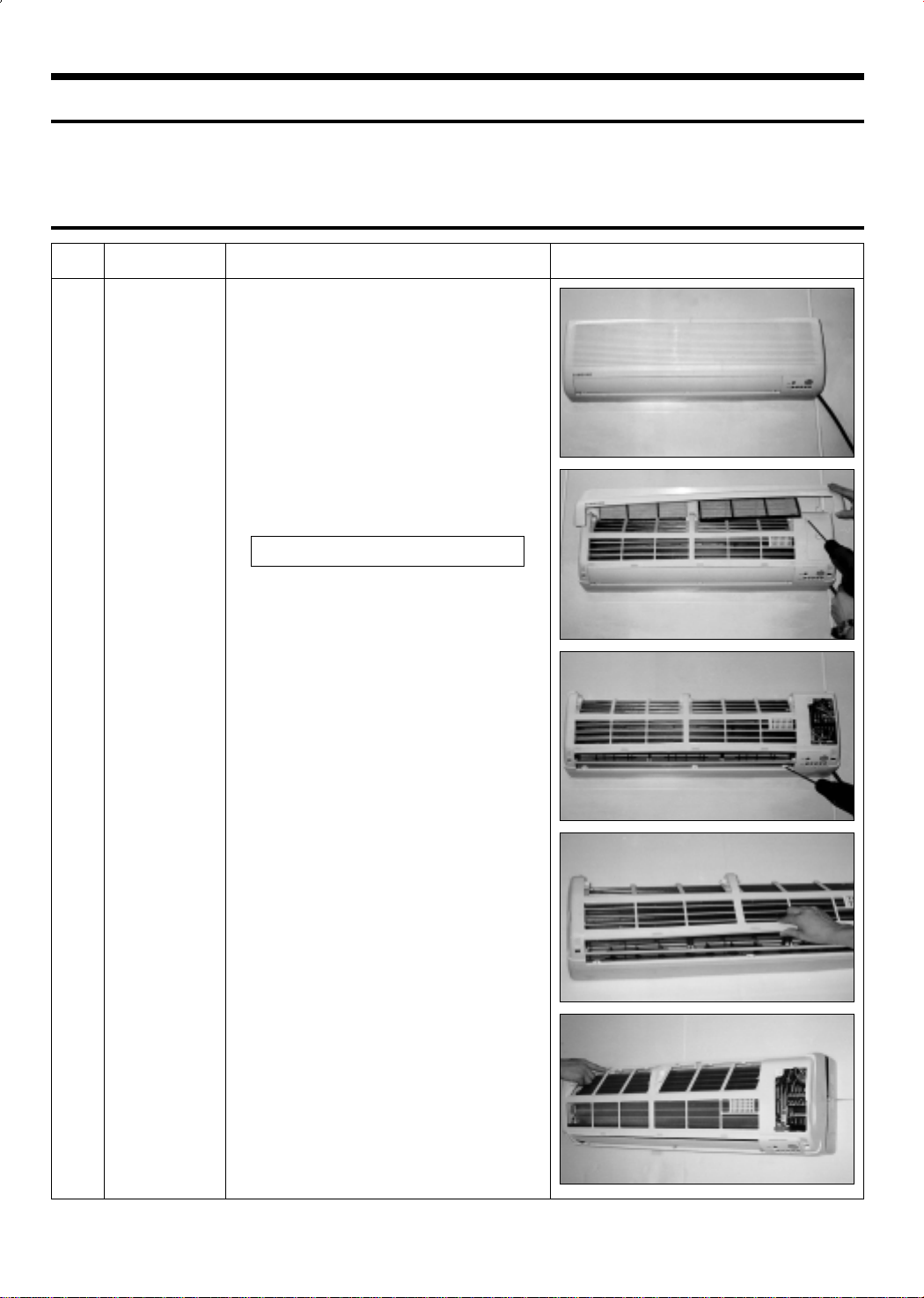

2. Disassembly and Reassembly

Stop operation of the air conditioner and remove the power cable before repairing the unit.

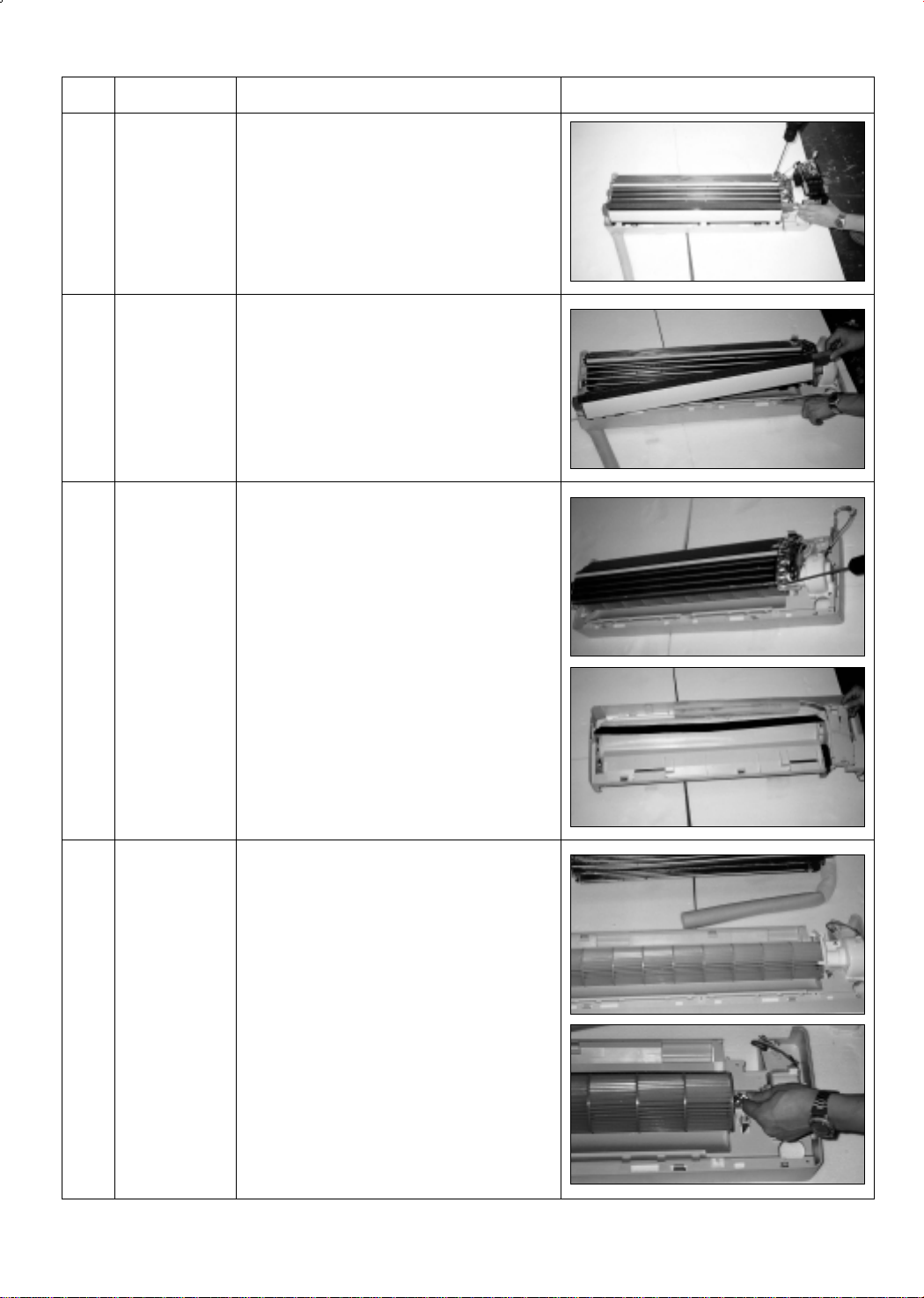

2-1 Indoor Unit

No Parts Procedure Remark

Front Grille1 1) Stop the air conditioner operation and block the

main power.

2) Separate tape of front panel upper.

3) Contract the second finger to the left, and right

handle and pull to open the inlet grille.

4) Take the left and right filter out.

*Taking off the deodorizing filter.

5) Loosen one of the right fixing screw and separate the terminal cover.

6) Loosen three fixing screws of front grille.

7) Pull the upper left and right of discharge softly

for the outside cover to be pulled out.

8) Pull softly the lower part of discharge and push

it up.

Caution;

Assemble the front panel and fix the

hooks of left and right.

3

No Parts Procedure Remark

2

3

4

Electrical Parts

(Main PCB)

Ass’y Tray Drain.

Heat Exchanger

1) Do “1”above.

2) Take all the connector of PCB upper side out.

(Inclusion Power cord)

3) Separate the outdoor unit connection wire from

the terminal block.

4) If pulling the Main PCB up. it will be taken out.

1) Do “1”, “2”, above.

Separate the drain hose from the extension

drain hose.

2) Pull tray drain out from the back body.

1) Do “1” and “2”, “3”, above.

2) Loosen two fixing earth screws of right side.

3) Separate the connection pipe.

4) Separate the holder pipe at the rearside.

5

Fan Motor and

Cross Fan

5) Loosen the three fixing screws of right and left

side.

6) Lifting the heat exchanger up a little to push the

up side for separation from the indoor unit.

1) Do “1”, “2”, ”3”, “4”, above.

2) Loosen the fixing two screws and separate the

motor holder.

3) Loosen the fixing screw of fan motor.

(By use of M3 wrench)

4) Separate the fan motor from the fan.

5) Separate the fan from the left holder bearing.

4

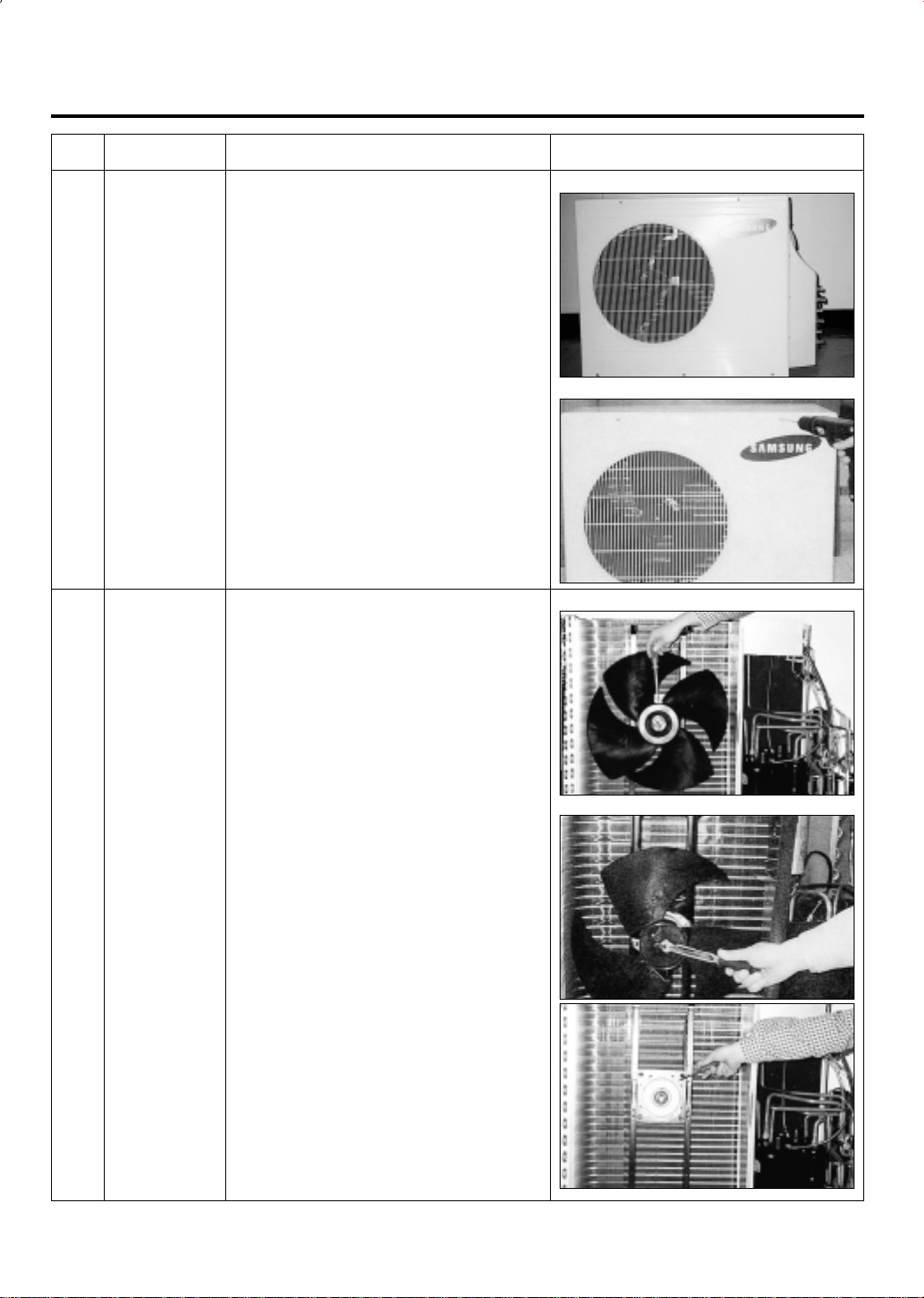

2-2 Outdoor Unit

No Parts Procedure Remark

1

2

Cabinet

Fan Motor

&

Propeller Fan

1) Turn off the unit and remove the power cable.

2) Remove the top cover.

3) Remove the control box cover.

4) Unplug the ass'y cable.

5) Remove the cabi-side.

6) Remove the cabi-front.

* When you assemble the parts, check if the

each parts and electric connectors are fixed

firmly.

1) Do Procedure “1” above.

2) Remove the nut flange.

(Turn to the right to remove as it is a left turned

screw)

3) Disassemble the propeller fan.

<UD26B1C2>

<UD18B1C2>

<UD26B1C2>

<UD18B1C2>

5

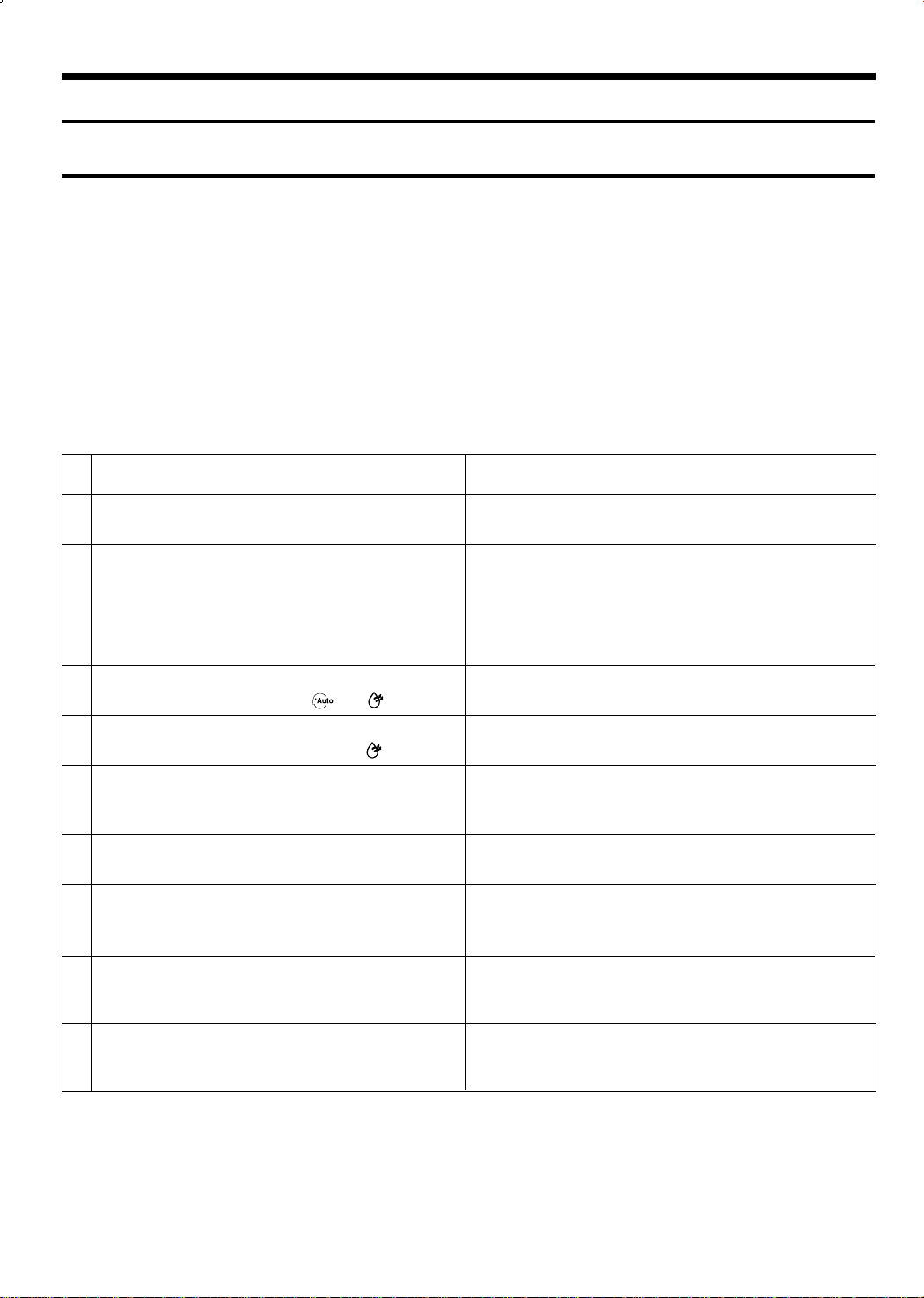

3. Troubleshooting

3-1 Items to be checked first

1) The input voltage should be rating voltage ±10% range.

The airconditioner may not operate properly if the voltage is out of this range.

2) Is the link cable linking the indoor unit and the outdoor unit linked properly?

The indoor unit and the outdoor unit shall be linked by 5 cables.

Check the terminals if the indoor unit and outdoor unit are properly linked by the same number

of cables. Otherwise the airconditioner may not operate properly.

3) When a problem occurs due to the contents illustrated in the table below it is a symptom not

related to the malfunction of the airconditioner.

NO Operation of air conditioner

1 The STD operation indication LED blinks when a

power plug of the indoor unit is plugged in for the first time.

2 In a COOL operation mode, the compressor does not

operate at a room temperature higher than the setting

temperature that the IN DOOR FAN should operate.

In a HEAT operation mode, the compressor does not

operate at a room temperature lower than the setting

temperature that indoor fan should operate.

3 Fan speed setting is not allowed in AUTO or DRY mode.

4 Compressor stops operation intermittently in DRY mode.

5 Compressor of the outdoor unit is operating although it is

turned off in a HEAT mode.

6 Timer LED only of the indoor unit lights up and the

air conditioner does not operate.

7 The compressor and indoor fan stop intermittently in HEAT

mode.

8 Indoor fan and outdoor fan stop operation intermittently in

a HEAT mode.

Explanation

It indicates power is on. The LED stops blinking if the operation

ON/OFF button on the remote control unit is pushed.

In happens after a delay of 3 minutes when the compressor is

reoperated. The same phenomenon occurs when a power is on.

As a phenomenon that the compressor is reoperated after a delay

of 3 minutes, the indoor fan is adjusted automatically with reference to a temperature of the air blew

The speed of the indoor fan is set to LL in DRY mode.

Fan speed is 5 steps is selected automatically in AUTO mode.

Compressor operation is controlled automatically in DRY mode

depending on the room temperature and humidity.

When the unit is turned off while de-ice is activated, the compressor continues operation for up to 9 minutes (maximum) until

the deice is completed.

Timer is being activated and the unit is in ready mode.

The unit operates normally if the timer operation is cancelled.

The compressor and indoor fan stop intermittently if room temperature exceeds a setting temperature in order to protect the compressor from overheated air in a HEAT mode.

The compressor operates in a reverse cycle to remove exterior ice

in a HEAT mode, and indoor fan and outdoor fan do not operate

intermittently for within 20% of the total heater operation

9 The compressor stops intermittently in a COOL mode or DRY

mode, and fan speed of the indoor unit decreases.

6

The compressor stops intermittently or the fan speed of the indoor

unit decreases to prevent inside/outside air frozen depending on

the inside/outside air temperature.

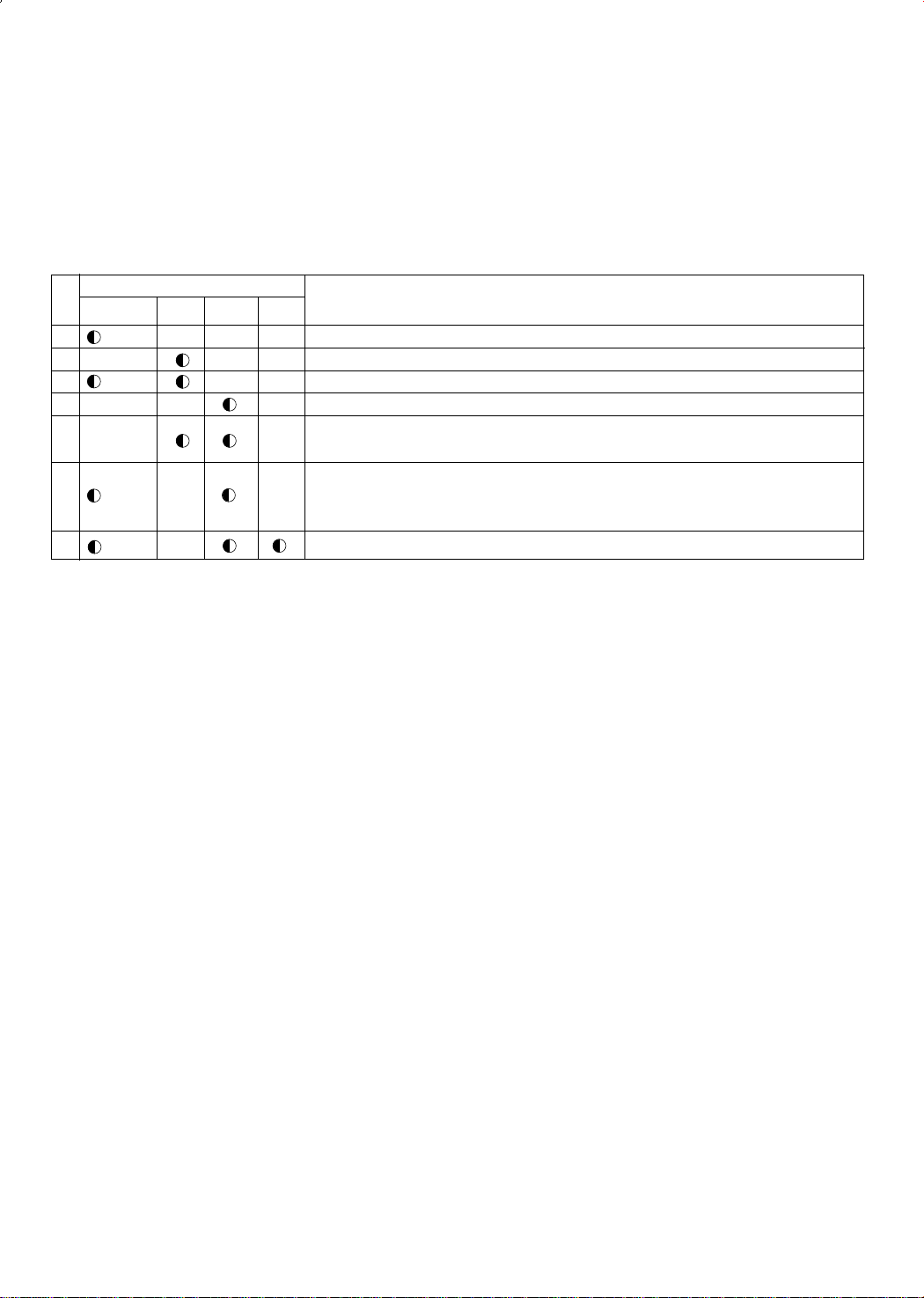

4) Indoor unit observes operation condition of the air conditioner, and displays self diagnosis details

on the display panel.

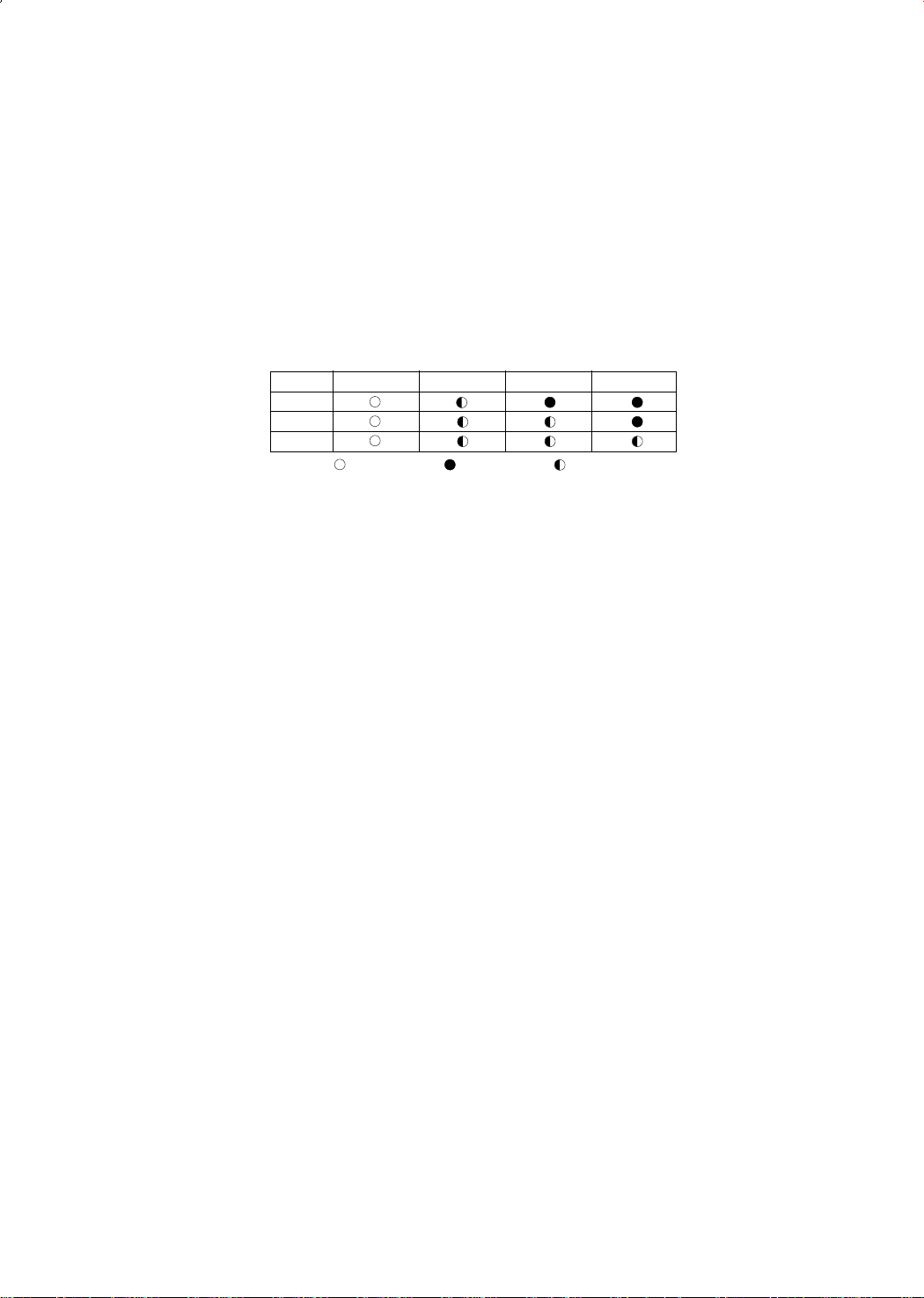

NO

Display

Standard Timer Nature Power

(GREEN)

1

2

3

4

5

6

7

X

(GREEN)

X

X

(GREEN)

(GREEN)

X

X

X

X

X

X

X

Self Diagnosis

Restore from power failure (input initial power)

X

Indoor unit Room sensor Error (open or short)

X

Indoor unit heat exchanger temperature sensor Error (open or short)

X

Indoor fan malfunctioning (for speed is below 450rpm)

X

In case that the communication between the indoor unit and outdoor unit is not made

X

for 60 seconds

Outdoor sensor Error (open or short)

- Outdoor sensor

X

- Pipe sensor A, B

The malfunction ot 4way valve in heat mode operation.

7

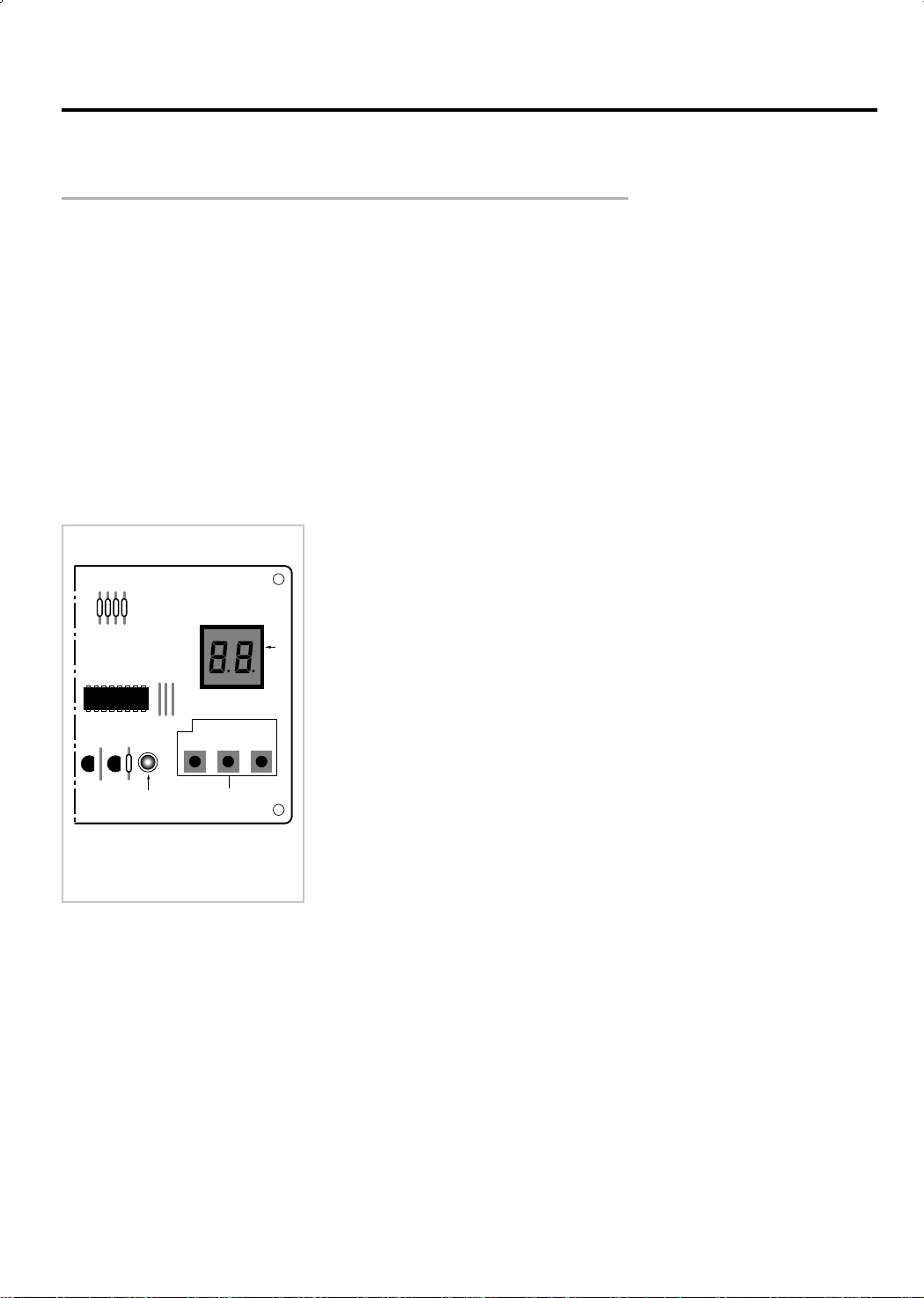

3-2 Checking and Testing Operations (Outdoor Unit)

C

a

b

TEST OPERATING

CB

A

To complete the installation, perform the following checks and tests to ensure that

the air conditioner is operating correctly.

1. Review all the following elements in the installation:

• Installation site strength

• Piping connection tightness to detect any gas leakages

• Connection wiring

• Heat-resistant insulation of the piping

• Drainage

• Earthing wire connection

• Correct operations (follow the steps below)

• Room select switch in the indoor unit

2. Apply the power to the outdoor unit.

- Check the fuse (250V~, 5A) : The fuse is open when the power line (L1, N2) is short.

OUTDOOR UNIT

A : PCB display

B : Red LED

C : PCB switch

3. Check the connection of PCB communication of outdoor unit.

(Check whether the red LED of outdoor unit PCB is flickering.)

• The communication lamp is flickering after the display of each

unit on the outdoor PCB display part. (every one second).

LED is not flikering, if the connection is bad or the room select

switch is located in the wrong position.

- LED lamp (red) flickering after display of A (0.5 sec)

- LED lamp (red) flickering after display of b (0.5 sec)

- LED lamp (red) flickering after display of C (0.5 sec)

Note : PCB switch “C” is used for triple split multi air conditioner.

Result : If all of three units display lamps are flickering, the connection

wires and the room option connections are good.

8

If the lamp is not flickering, check as follows:

A. Check the display part of indoor unit of each unit (A,B) after outdoor unit PCB switch S/W-Ais on.

A. Check the status of each unit indoor room select switch.

A. (Adjust the select switch suitable to the unit A, B.)

A. - A unit : STANDARD LED on, TIMER LED flickering

A. - B unit : STANDARD LED on, TIMER and NATURE LED flickering

A. - C unit : STANDARD LED on, TIMER and NATURE, POWER LED flickering (In case of triple

split multi air conditioner)

UNIT

STANDARD TIMER NATURE POWER

A

B

C

Lamp ON

Lamp OFF Lamp Flasher

4. Check the test operation status by pressing the PCB switch

4. S/W-A and S/W-B of outdoor unit.

4. • Check the operation status by pushing the switch one at time.

4. • Perform the test operation only for the unit selected last.

4. • Check the pipe pressure and the other operation status during the test operation.

4. • Check items when the error occurs during the test operation (each unit)

- Check there is enough refrigerant.

- Check pipe connections.

9

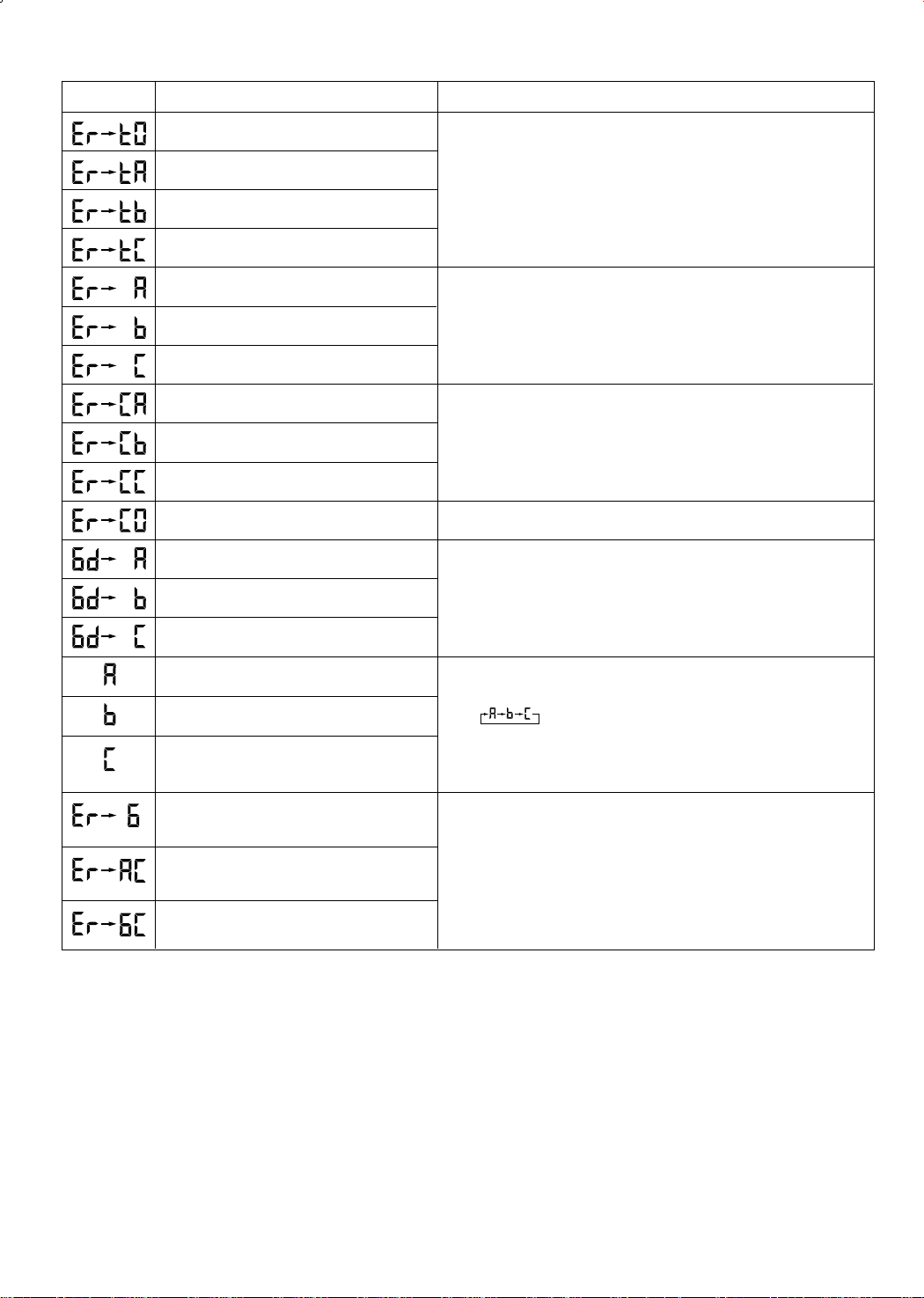

DISPLAY EXPLANATION

REMARK

Outdoor sensor error (Short/Open)

Outdoor A cond pipe sensor error (Short/Open)

Outdoor B cond pipe sensor error (Short/Open)

Outdoor C cond pipe sensor error (Short/Open)

A unit test operation error

B unit test operation error

C unit test operation error

A unit test communication error

B unit test communication error

C unit test communication error

A,B,C unit all communication error

A room test operation OK

B room test operation OK

Be sure to check after applying the power to the outdoor unit.

Display when the test operation finishes.

• When the pipe temperature difference of indoor unit

• (pipe temperature 4 minutes before - Actual pipe temperature)

• is less than 5˚C.

Be sure to check during the test operation.

Display of power application.

Display 4 minutes after the COMP is on.

C room test operation OK

Communication unit number display : A unit

Communication unit number display : B unit

Communication unit number display : C unit

(In case of triple split multi air conditioner)

Refrigerant leaks

High temperature of the A cond

High temperature of the B cond

•Normal operation

•Unit A,B and C are changed every one second.

•The communication lamp is flickering after display of each unit.

•(possibility to check the communication status)

•During the test operation the unit under test is on and off every 0.25s.

10

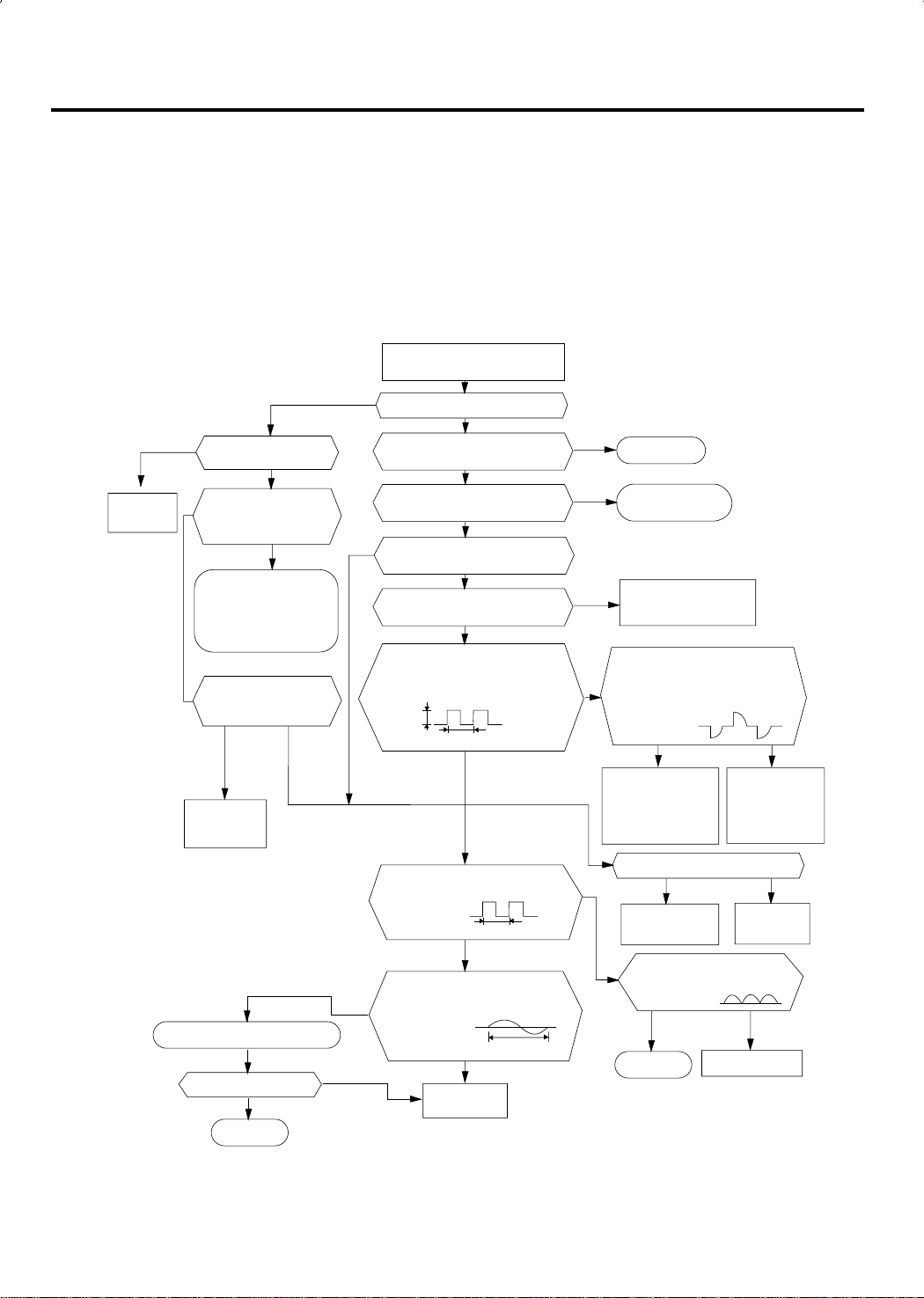

3-3 Fault Diagnosis by Symptom

3-3-1 No Power (completely dead)-Initial diagnosis

1) Checklist :

(1) Is input voltage normal?

(2) Is AC power linked correctly?

(3) Is output voltage of DC regulator IC KA7805 (IC02) normal? (4.5VDC-5.5VDC)

2) Troubleshooting procedure

Remove power cord and plug in

again in approx. 5 seconds

YES

Replace

PCB display

Is DC voltage of PCB

display normal?

NO

Is rating voltage ±10%

range applied to the

primary side (~,~)

of the “BD71”

NO

•Check linkage between

power cord and

terminal tap

•Check fuse

Is 14~18VAC appear in

the secondary side (+, -)

of “BD71”

NO

Replace

SMPS PARTS

Replace resonator (X301)

Is operation normal?

YES

YES

OK

NO

Is operation lamp blinking?

Does operation start when

run/stop button on the remote

controller unit pushed?

Is transmission display of the

remote controller unit blinking?

Is "beep"sound heard from the

NO

Is DC voltage of the PCB module

5VDC Is voltage of #60 (indoor fan)

DC5V

Is voltage at #52 terminal of the

Are voltage at #48 and #49 of the

NO

NO

main unit?

normal?

of the micom normal?

10ms

micom normal?

micom normal?

Replace micom

YES

NO

YES

YES

YES

NO

YES

YES

10ms

250ns

YES

NO

NO

YES

NO

Normal

Refer to remote control

unit fault diagnosis

Replace PCB module.

Is voltage at SS71(indoor fan)

Check connections

compressor 4-way

valve, outdoor fan and

indoor fan.

Is output voltage of ICO2 normal?

Check PCB pattern.

Replace main PCB.

Is voltage output terminal of

TLP180(PC02) normal?

YES

OK

DC12V

YES

Replace RY71,

RY73, RY72 and

YES

Replace ICO2

Replace TLP180(pc02)

NO

SS71

NO

NO

11

Loading...

Loading...