Samsung 3759 User Manual

SAMSUNGDV MTMAir Conditioner

SAMSUNG ELECTRONICS

II

IIII

IIIIII

Overview

1. DVM system series

1-1. What is DVM?

1-2. Features of DVM

1-3. DVM vs VAV

2. DVM line-up

2-1. Numbering system of

model

2-2. Combination

Control

system

1. Remote controller

6

1-1. Wireless remote controller

7

1-2. Wired remote controller

12

1-3. Centralized controller

1-4. Function controller

2. Receiver & display

14

20

unit (Duct type)

2-1. Concealed type

2-2. Standard type

3. Transmitter

4. Installation

4-1. Wireless remote controller

4-2. Wired remote controller

4-3. Centralized controller

4-4. Function controller

4-5. Receiver & display unit -

concealed type

4-6. Receiver & display unit -

standard type

4-7. Transmitter

5. Assigning address

5-1. Indoor unit

5-2. Outdoor unit

6. Indoor unit PCB

option code

6-1.

PCB option code input method

6-2. Option code

7. S-Net

8. Indoor unit PCB

option code

9.

Building management

system

Indoor

unit

1. Features

2

1-1. 1-way cassette type

4

1-2. 4-way cassette type

6

1-3. Duct type

6

1-4. Wall-mounted type

1-5. Floor standing type

1-6. Ceiling type

2. Specification

7

2-1. 1-way cassette type

8

2-2. 4-way cassette type

2-3. Duct type (Low silhouette)

2-4. Duct type (Built-in)

2-5. Duct type (High pressure)

2-6. Wall-mounted type

2-7. Floor standing type

2-8. Ceiling type

10

11

3. Functional parts and

14

19

21

22

23

25

26

27

32

safety devices

3-1. 1-way cassette type

3-2. 4-way cassette type

3-3. Duct type (Low silhouette)

3-4. Duct type (Built-in)

3-5. Duct type (High pressure)

3-6. Wall-mounted type

3-7. Floor standing type

3-8. Ceiling type

4. Capacity table

4-1. 50Hz

4-2. 60Hz

5. Dimension

5-1. 1-way cassette type

5-2. 4-way cassette type

5-3. Duct type (Low silhouette)

5-4. Duct type (Built-in)

5-5. Duct type (High pressure)

5-6. Wall-mounted type

5-7. Floor standing type

5-8. Ceiling type

5-9. Wireless remote controller /

Receiver

5-10. Wired remote controller

5-11. Option controller

2

4

6

8

10

12

14

16

18

20

24

26

30

32

34

34

35

36

36

37

38

38

39

45

51

52

54

55

57

58

60

61

62

70

72

IIVV

VV

6.

Refrigerant system diagram

(Cooling only & heat pump)

6-1.

Refrigerant system diagram

6-2. Main parts status

Electric circuit diagram

7.

7-1. 1-way cassette type

7-2. 4-way cassette type

7-3. Duct type

7-4. Wall-mounted type

7-5. Floor standing type

7-6. Ceiling type

8. Noise level

8. Noise level

8-1. Overall

8-2. Octave band level

9.

Velocity of air flow &

73

73

74

76

78

80

82

84

86

87

temperature distribution

9-1. 1-way cassette type

9-2. 4-way cassette type

9-3. Wall-mounted type

9-4. Ceiling type

102

103

105

107

10. Fan specifications

10-1.

Duct type(Low silhouette)

10-2.

Duct type(Built-in)

10-3.

Duct type(High pressure)

108

109

110

11. Panel

11-1. 1-way cassette type

11-2. 4-way cassette type

111

112

12. Electronic expansion

valve kit

12-1. Design

12-2. Status depending on the

combination

113

113

13. Options

Outdoor

unit

1. Unit selection

(with cooling load)

2. Specification

2-1. 50Hz

2-2. 60Hz

3. Functional parts and

safety devices

3-1. Outdoor unit

3-2. Super cooler

4. Capacity table

4-1. 50Hz

4-2. 60Hz

5. Dimension

5-1. Upward (2-FAN)

5-2. Onward

5-3. Upward (1-FAN)

5-4. Upward (Super cooler)

6.

Refrigerant system diagram

6-1. Cooling only

6-2. Heat pump

7.

Electric circuit diagram

7-1. Cooling only

7-2. Heat pump

8.

Consideration for

outdoor unit selection

8-1.

Change of capacity depending

on refrigerant piping length

8-2.

Condition of operating

restriction

9. Noise level

10. Options

4

6

8

13

14

20

31

32

33

34

35

38

42

44

46

47

Installation

1. Product

1-1. Preparation for installation

1-2. Deciding on where to install

the air conditioner

1-3. Space requirements for the

air conditioner

1-4. Accessories

1-5. Installation

2. Panel

2-1. 1-way cassette type

2-2. 4-way cassette type

2-3. Duct type (Built-in)

3. Connecting the indoor

unit refrigerant pipe

4. Drain hose installation

5. Drain pump installation

5-1. Accessories

5-2. Installation

6. Wiring

6-1.

Overall system configuration

6-2.

Cable specification for outdoor unit

6-3.

Connection cord specification

6-4. Wiring diagram

6-5.

Connection cord wiring diagram

6-6.

Power wiring and communication

wiring configuration

6-7.

Communication cable connection

7. Piping and refnet

joint selection

7-1.

Refrigerant piping system diagram

7-2. Piping selection

7-3. Refnet joint selection

8.

Charge/recovery of refrigerant

8-1. Refrigerant charging

Additional refrigerant amount

8-2.

calculation method

8-3. Recovery of refrigerant

2

3

4

8

11

13

15

16

22

22

23

24

24

24

25

25

26

33

33

34

35

36

37

9. Testing operation

10.

Cautions for refrigerant leaks

I

Overview

1. DVM system series

1-1. What is DVM?

1-2. Features of DVM

1-3. DVM vs VAV

2.

DVM line-up

6

7

12

2-1. Numbering system of model

2-2. Combination

14

20

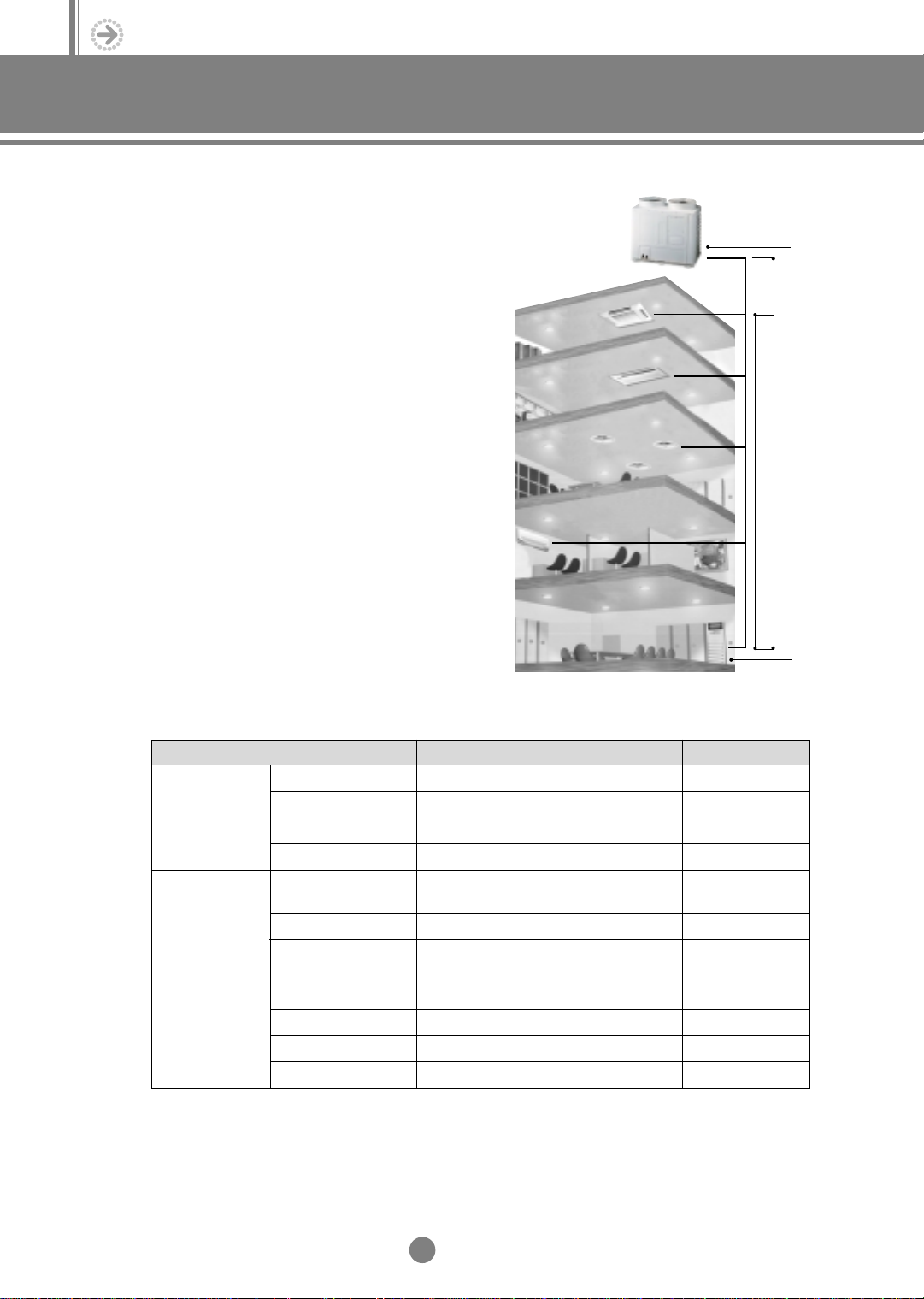

I. Overview

1. DVM system series

1-1. What is DVM?

The DVM(Digital Variable Multi) air conditioning system is operated by a variable-capacity compressor

and is accommodated by multiple evaporators (indoor units). It is touted as the next-generation modular

system in the world of high-efficiency air conditioning. lt has undoubtedly changed the face of cooling

associated with high-storied buildings. It provides a broad range of different applications for settings such

as offices, hotels and schools. With its easy installation and simple controlling system, the DVM will more

than meet the demands of the air conditioning market.

Duct type (Low silhouette) Duct type (Built-in)

Duct type (High pressure) Wall-mounted type

Floor standing type 1-way cassette type

Ceiling type

Outdoor unit

4-way cassette type

6

I

1-2. Features of DVM

(1) Customized air conditioner

1) Up to 16 indoor units can be connected to one outdoor unit.

2) Indoor units can be combined by various methods, according to each room’s use and shape.

3) There are several indoor units which can be applied; 1-way cassette type, 4-way cassette type,

Ceiling, Duct (Low silhouette, Built-in, High pressure), Wall-mounted and Floor standing type.

(2) Comparison of DVM with conventional air conditioners

1) DVM air conditioner

Variable capacity (Energy Saving)

①

Competitive price (Compared with the Inverter type)

②

Can be installed in houses / commercial buildings

③

Versatile combination of indoor units

④

Various remote controls

⑤

2) Conventional air conditioners

Fixed capacity

①

Unfavorable in case of installing more than 3 units / system

②

7

I

I. Overview

1. DVM system series

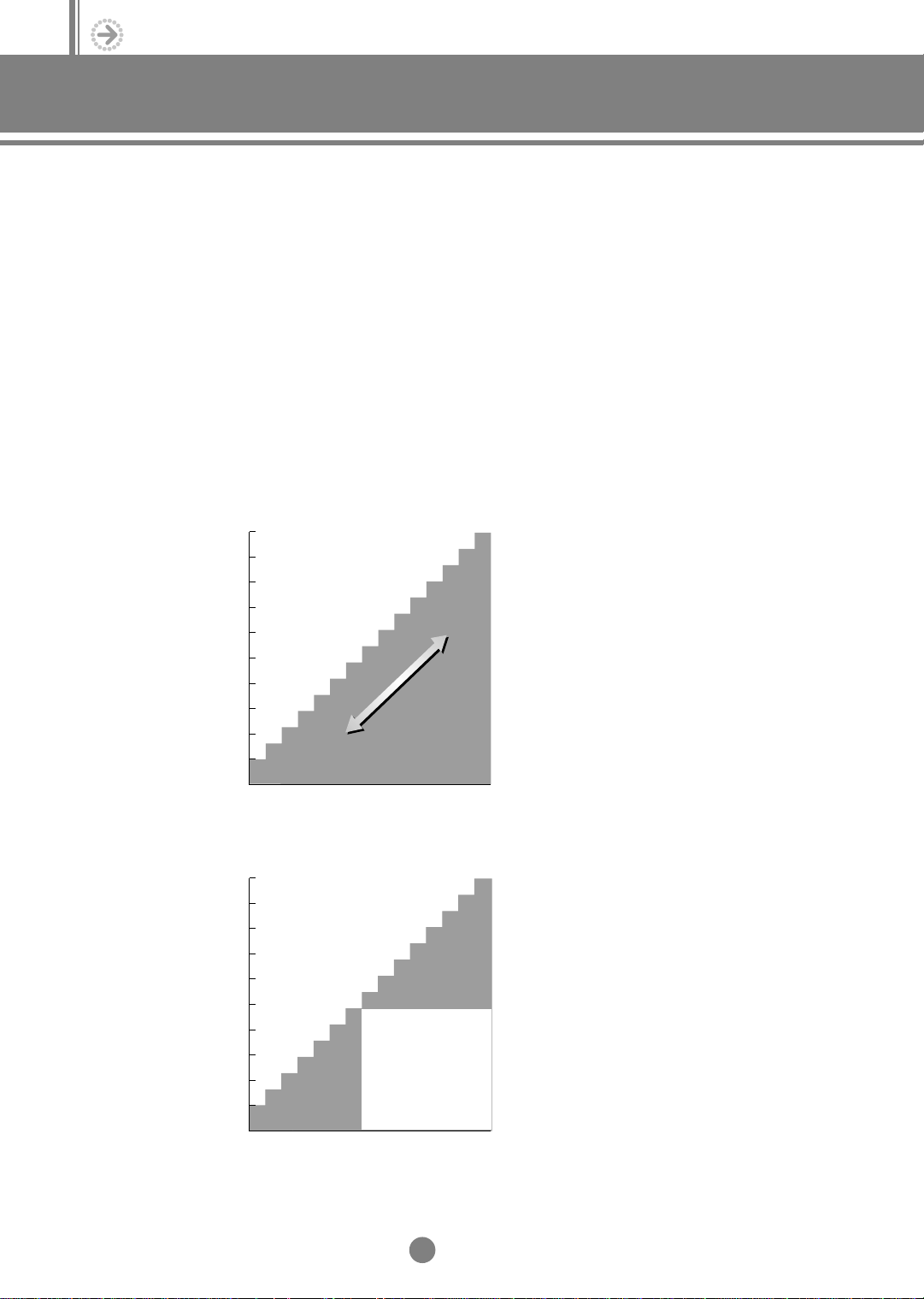

(3) Variable compressor

The world’s first PWM(Pulse Width Modulation) compressor controls the cooling & heating capacity

automatically, depending on the load.

1) Principle of the digital compressor

Composition

①

The solenoid valve is installed for the compressor´s loading / unloading between the upper part of the

fixed scroll and the suction pipe.

Mechanism

②

a. When the solenoid valve is turned off, the fixed scroll is closed to the orbiting scroll (Loading),

b. When the solenoid valve is turned on, the fixed scroll is separated from the orbiting scroll (Unloading),

c. This process controls the On / Off times of the valve and the rotating refrigerants in the circle,

thus adjusting the capacity.

d. The cooling capacity of the outdoor unit is controlled automatically,depending on the

number of operating indoor unit(s).

< 1 Compressor >

100

90

80

70

60

50

40

30

20

Running ratio of compressor(%)

10

0

3000 6000 9000 12000 15000 18000

< 2 Compressor >

100

90

80

70

60

50

40

30

20

Running ratio of compressor(%)

10

0

3000 6000 9000 12000 15000 18000

unloading

Total capacity of operating indoor unit(s)

(kcal/h)

Digital operating

Fixed compressor

operating

Digital only

operating

Total capacity of operating indoor unit(s)

(kcal/h)

loading

8

I

2) PWM (Pulse Width Modulation) valve

PWM valve is the valve to take away the fixed scroll by lifting up through the difference of pressure after the digital

scroll compress being connected to the outlet and inlet of suction. Therefore, the capacity of compressor is controlled

automatically according to the operation status such as loading when the valve is closed or unloading when the valve

is opened. PWM means the control of ON/OFF signal to the valve for loading/unloading.

Relationship between PWM valve and loading/unloading

compression

PWM valve open PWM valve close

non-compression

(rotating in vain)

Unloading

Period (Cycle Time, T)

Loading

(4) Refrigerant flow rates control

Refrigerant flow rates through the electronic expansion valve are controlled by the 2 factors which are the

temperature difference between inlet and outlet of evaporator and the difference between room and set temperature.

a. An electronic expansion valve optimally distributes refrigerant flow rates to each room and the fuzzy logic enables

comfortable cooling more precisely; refer to the figure below.

b. The air conditioner senses the temperature difference between inlet and outlet of evaporator, plus the temperature

difference between room and set temperature. And it calculates the superheat and the room temperature status,

then adjusts refrigerant flow rates after deciding the opening steps of valve.

①②

1

0.5

-0.5

0

-1

④

③

Falling room temperature

①

Rising room temperature

②

Open electronic expansion valve

③

Closed electronic expansion valve

④

9

I

I. Overview

1. DVM system series

(5) Long & single piping system

1) Piping can be extended up to 100 meters; refer to the figure.

2) The outdoor unit is connected with each indoor unit by

single refrigerant piping.

(6) Convenient centralized control

50m (8.0~10.0HP), 30m (7.5HP ) (Height between indoor and outdoor unit)

1) Every indoor unit has its own remote controller.

In addition, a maximum of 16 indoor units

can be controlled with the centralized controller.

2) A maximum of 256 indoor units can be controlled

by using the PC Control.

(7) Easy installation

Simple planning and installation during the early

stage of building construction or renovation.

(8) Minimizing operation costs

The cooling / heating capacity is adjusted automatically

with the variable compressor, which reduces power

consumption and running costs.

DVMDivision

Equipment

Initial cost (US$)

Running cost

(US$)

❋ The results are based on Samsung Lab., therefore there may be differences according to the condition of

installation and the environment of the use.

❋ Heat loads : 90,000 kcal/h in Korea

❋ Total area : 750m

❋ Running : 3 months in every summer and winter

2

Piping

Duct-install

Grand

Power consumption

Monthly consumption

Annual consumption

(6 months in a year)

1 year rate

3 year rate

5 year rate

Comparison

29,812

2

17/m

39,812

44.2kW X 0.8

(Variable Compressor)

12,906kWh

77,436kWh

5,575

16,726

27,877

100%

Chiller Unitary

25,558

5,111

2

17/m

40,670

43kW X 1.0

15,695kWh

94,170kWh

6,780

20,340

33,900

121%

→

27,500

37,500

52.5kW X 1.0

19,162kWh

114,972kWh

24,833

41,389

17/m

8,277

148%

100m (Max. piping length)

15m (Height between indoor units)

➞

2

→

10

I

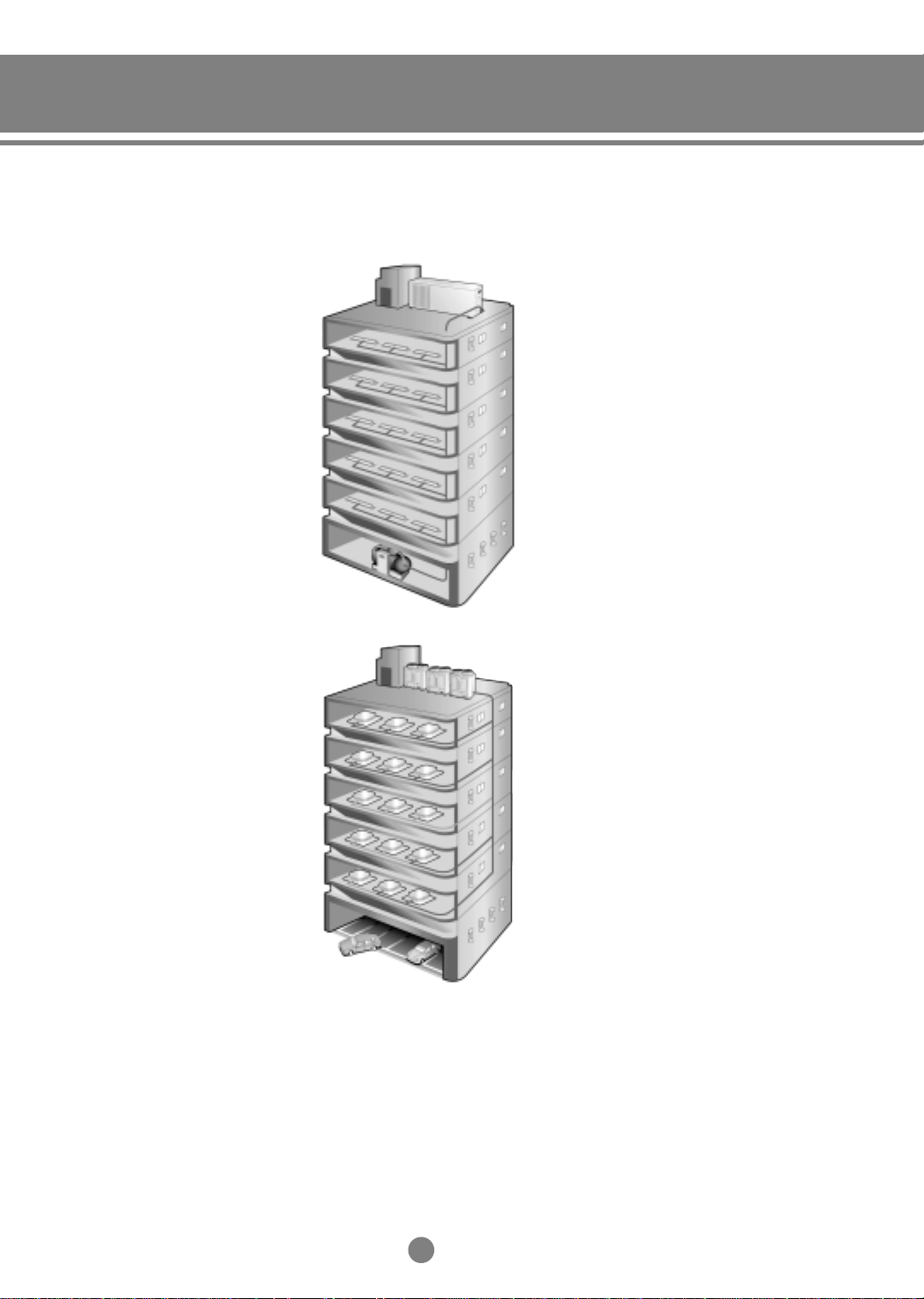

(9) Space Saving

The outdoor units connected with several indoor units do not require much space.

1) Conventional System

2) DVM System

11

I

I. Overview

1. DVM system series

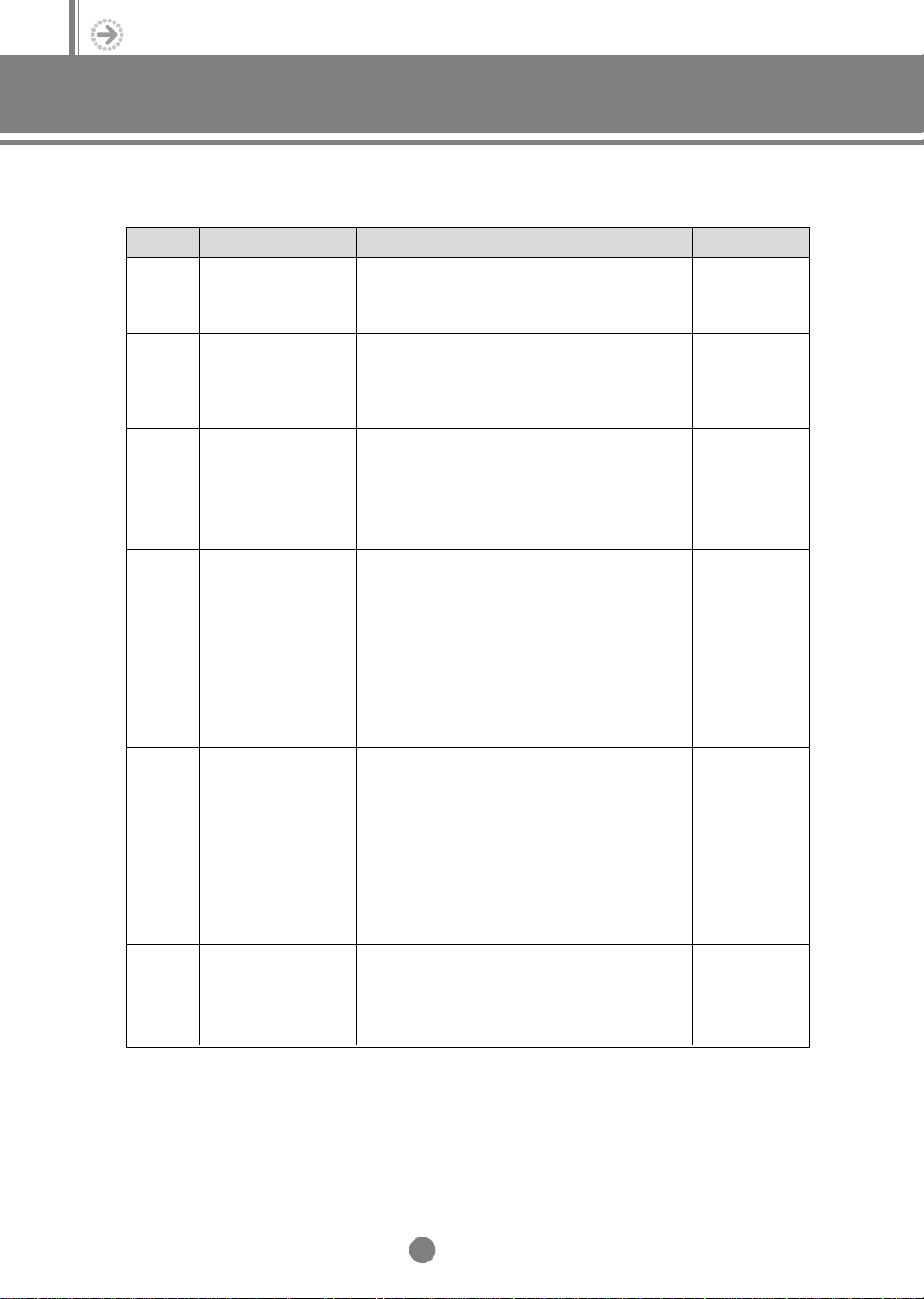

1-3. DVM vs VAV

(1) Excellent energy efficiency

Zone

control

25%

50%

75%

100%

❋ The results are based on Samsung Lab., therefore there may be differences according to the condition of

installation and the environment of the use.

❋ Heat loads : 90,000 kcal/h in Korea. The SEER of the DVM is 8~75% higher than the VAV, and increasing

❋ Condition A : DB26.7/WB19.4°C, DB35/WB23.9°C

Test

condition

B : DB26.7/WB19.4°C, DB27.8/WB18.3°C

Opening

A

B

A

B

A

B

A

100%

B

the zone control is different from decreasing the SEER.

ratio

25%

50%

75%

Capacity

(W)

7344

8016

11997

13015

15857

16996

17200

19007

Power

(W)

7138

6313

7353

6486

7504

6626

7630

6802

SEER

(W/W)

1.134

1.794

2.298

2.492

Opening

ratio

Max.

Min.

Max.

Min.

Max.

Min.

Max.

Min.

Max.

Min.

Max.

Min.

Max.

Min.

Max.

Min.

Capacity

(W)

5381

3997

5510

4365

11222

7119

11597

8177

16692

11666

17329

12567

19836

15512

20786

15880

DVMVAV

Power

(W)

2593

1977

2353

2073

4457

3238

4164

3118

6190

4630

5680

4216

7336

5897

6666

5152

SEER

(W/W)

1.944

2.478

2.790

2.860

12

I

(2) DVM test condition

Pipe (Copper)

(21kW)

■

Zone control conditions

#1 (5.2kW) #2 (5.2kW) #3 (5.2kW) #4 (5.2kW)

Indoor unitOutdoor unit

Zone control Sample #1 Sample #2 Sample #3

25%

50%

75%

100%

On

On

On

On

Off

On

On

On

(3) VAV test condition

Cord

Static pressure gauge

Discharge duct

Damper

Test unit

tester #1

Off

Off

On

On

tester #2

Test unit

Sample #4

Off

Off

Off

On

Cord

Flexible hose

Air flow

Discharge duct

Suction duct

■

Zone control conditions

Zone control No. of duct opening Zone control No. of d u c t o p ening

25%

50%

Outdoor unit : Fixed compressor(21kW)

❋ The static pressure is equal to the maximum open position by adjusting the damper.

1

2

13

I

75%

100%

3

4

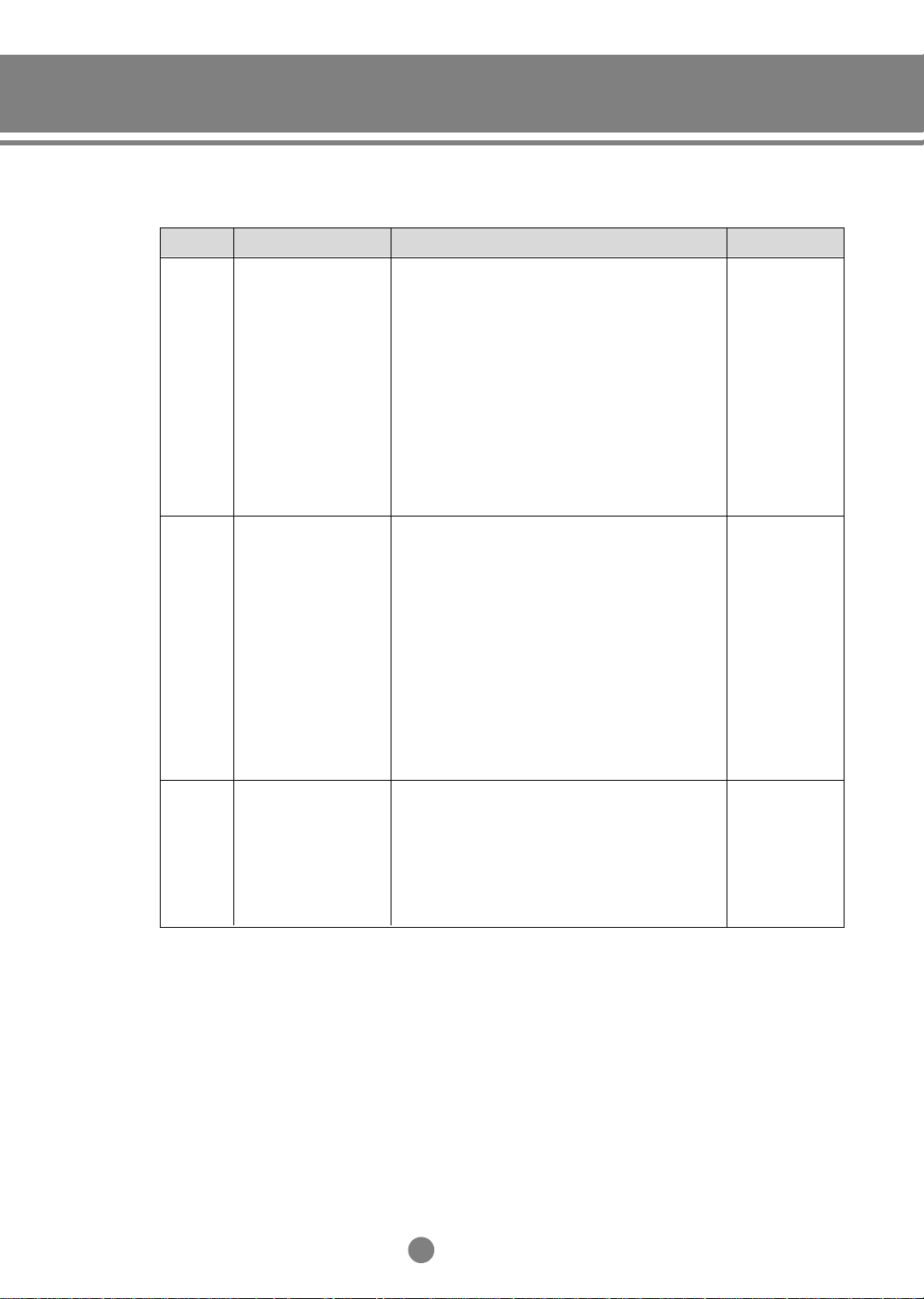

I. Overview

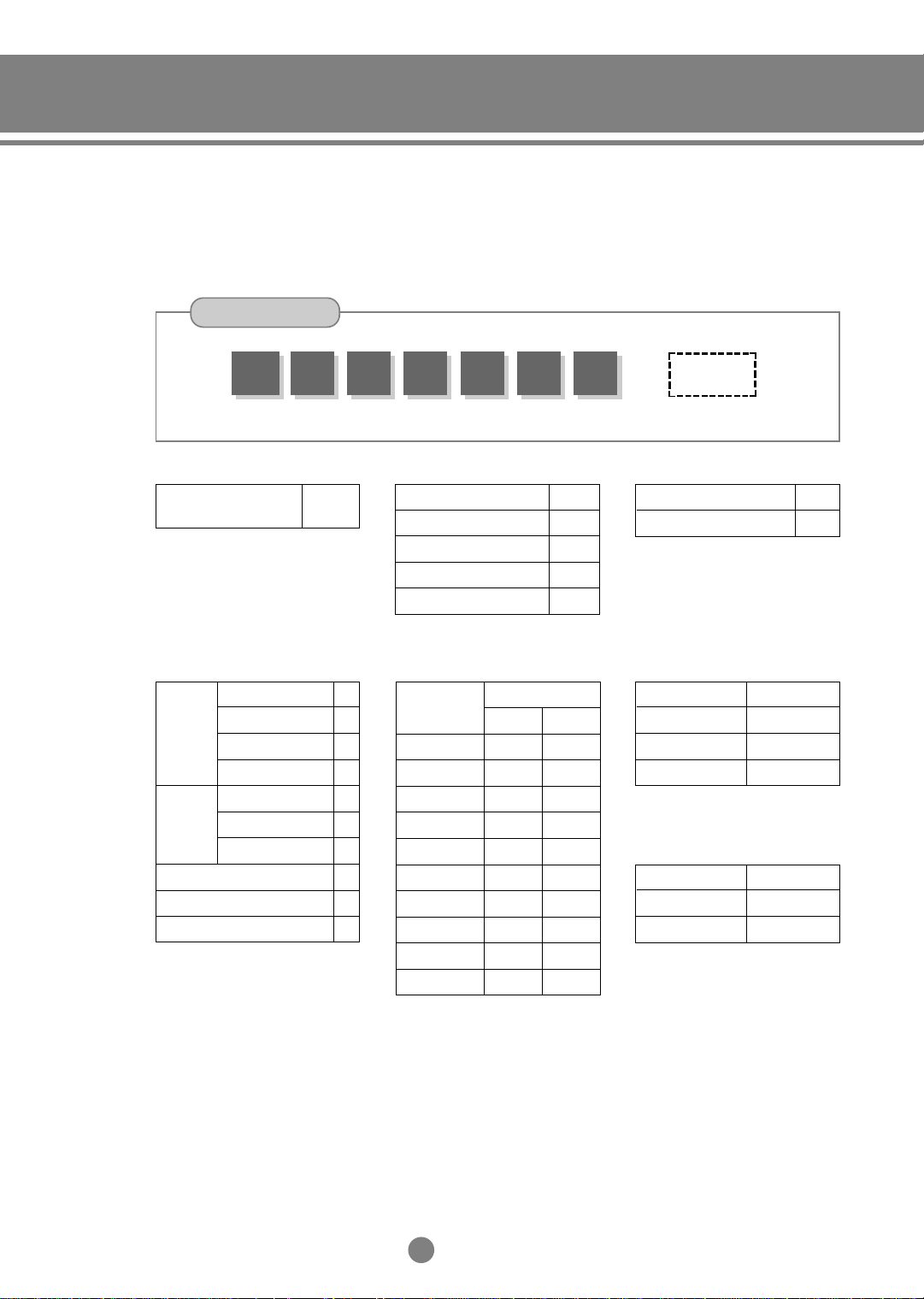

2. DVM line-up

2-1. Numbering system of model

(1) Indoor unit and outdoor unit (Conventional model)

Model

DM

A

①

Semi-finished product

①

Indoor unit

Outdoor unit

Classification of product

②

1-way cassette type

4-way cassette type

Duct type

Outdoor unit

Capacity (Btu x 100)

③

Option

④

Indoor unit

Outdoor unit

Function

version

Recipro

PWM

-

180 0

③②

A

M

KM

BM

DM

UF

0

1

0

1

④

A

⑤

0

⑥

Power supply

⑤

- Indoor unit

115V, 60Hz

220V, 60Hz

208~230V, 60Hz

200~220V, 50Hz

220~240V, 50Hz

127V, 50Hz

220~240V, 50/60Hz, 1ø

- Outdoor unit

115V, 60Hz

220V, 60Hz

208~230V, 60Hz

200~220V, 50Hz

220~240V, 50Hz

220V, 60Hz, 3ø

380~415V, 50Hz, 3ø

127V, 50Hz

220~240V, 50/60Hz, 1ø

380V, 60Hz, 3ø

460V, 60Hz, 3ø

A

B

C

D

E

M

N

A

B

C

D

E

F

G

M

N

H

J

Version

⑥

14

I

(2) Indoor unit and outdoor unit (New Model)

1) Indoor unit

Model

AVM①K

Semi-finished product

①

Variable capacity free

joint multi (DVM)

Classification of product

②

1-way

Cassette

Duct type

Floor standing type (PAC)

4-way

type

2-way

Exposed

Low silhouette

High pressure

Built-in

Wall-mounted type

Ceiling type

②

AVM

W

H

100④B

③

Mode

③

Cooling only (C/O)

Heat pump (H/P)

C/O+Hot water heater

Capacity (kW x 100, 3 digits)

④

K

C

G

N

D

H

B

F

P

⑤

H/P+Heater

C/O+Heater

Btu/h

7K

9K

12K

18K

20K

24K

28K

36K

44K

48K

Watt

50Hz

2000W

2600W

3500W

5200W

6000W

7000W

8200W

10500W

12800W

14000W

A

⑥

C

H

E

G

N

60Hz

2000W

3200W

4000W

5200W

6000W

7200W

8300W

10500W

12800W

14000W

0

⑦

0 0 0

Power supply

⑤

208~230V, 60Hz

220~240V, 50Hz

Classification by refrigerant

⑥

Refrigerant

R407C

R410A

Version

⑦

R22

~

~

Classification

C

E

A

B

C

0

1

2

15

I

I. Overview

2. DVM line-up

2) Outdoor unit

Model

RVM①H

Semi-finished product

①

Variable capacity free

joint multi (DVM)

Mode

②

Cooling only (C/O)

Heat pump (H/P)

Capacity (HP x 10, 3 digits)

③

②

RVM

060③B

C

H

A

④

Power supply

④

208~230V, 60Hz, 3ø

380~415V, 50Hz, 3ø

Refrigerant / Discharge direction

⑤

Refrigerant

R22

R407C

R410A

⑤

208~230V, 60Hz

380V, 60Hz, 3ø

460V, 60Hz, 3ø

Discharge

direction

Upward

Onward

Upward

Onward

Upward

Onward

A

⑥

Classification

A

B

C

D

E

F

0

0 0 0

⑦

Combination of indoor unit

⑥

C

F

G

H

J

Cassette

type

Duct type

Floor standing type (PAC)

Version

⑦

1-way

4-way

2-way

Exposed

Low silhouette

High pressure

Built-in

Wall-mounted type

Ceiling type

Free

K

C

G

N

D

H

B

W

F

P

M

16

I

(3) Options

Parts Model Example

Electronic

expansion

valve kit

Distributor

kit

Discharge

duct

Refnet kit ● MXJ-1509B

Drain

pump

MEV- ①②③

MXD- ①②③④⑤

MDF- ①②

MXJ- ①②③

MDP- ①②③

MEV : Optional electronic expansion valve

: Electronic expansion valve model (2 digits)

①

: Manufacturer

②

: Version

③

MXD : Optional distributor kit

: Max diameter (2 digits)

①

: Kinds (marked as K2 for two kinds)

②

: Minimum diameter

③

(Marked as 00 only for use of one kind and marked

with minimum diameter for use of two kinds)

: Kinds (marked as K2 for two kinds)

④

: Version

⑤

MDF : Optional distributor duct flange

: Hole size(ø, cm, 2 digits)

①

: Version

②

MXJ : Optional refnet (Y-joint) kit

: Inlet pipe diameter (2 digits)

①

: Outlet pipe diameter (2 digits)

②

: Version

③

MDP : Optional drain pump

: Discharge pressure (cm, 3 digits), 75cm ➔ 075

①

: Manufacturer

②

: Version

③

Standard for model name

● MEV-14SA

● MEV-18SA

● MEV-24SA

● MXD-14K300A

(1/4” 3)

● MXD-14K218A

(1/4” 2, 1/8” 1)

● MDF-45A

(Inlet pipe 15mm,

Outlet pipe 9mm)

● MDP-075SA

Front

panel

Wireless

remote

controller

M①②③④⑤⑥⑦

MR- ①②③④

: Grille application (Front panel)

①

: Type of indoor unit (K: 1-Way cassette, G: 2-Way

②

cassette, C: 4-Way cassette, B: Built-in duct)

: C: Cooling only, H: heat pump, N: No use of

③

wireless remote controller

: Size (Mark the longer side, cm, 3 digits)

④

: Color (G: gray, I: Ivory)

⑤

: Language (E: English only, C: Chinese,

⑥

A: Arabic&English, M: 8 Languages)

: Version

⑦

MR : Optional wireless remote controller

: Design(A~Compact)

①

: Mode (C: cooling only, H: heat pump)

②

: Version

③, ④

17

I

● MGKC118IE0

● MR-AC00

● MR-AC00C

(For China)

I. Overview

2. DVM line-up

Parts Model Example

Receiver

& display

unit wire

Interface

module

MRW- ①②

MIM- ①②③

MRW : Optional receiver & display unit wire

: Length (m, 2 digits)

①

: Version

②

MIM : Optional interface module

: Applicable location

①

②, ③

Controller ● MCM-A200

MCM- ①②③④

MCM : Optional controller

: Function

①

: LCD Application (1: yes, 2: none)

②

③, ④

Wired

remote

controller

MWR- ①②③④

MWR : Optional wired remote controller

: Design (A - present)

①

: Classification of function

②

③, ④

Receiver

& display

unit kit

Filter ● MF-C1B0

MRK- ①②③

MF- ①②③④

MRK : Optional receiver & display unit kit

: Receiver kit design (A)

①

②, ③

MF : Optional filter

: Classification of product

①

: Specification of filter

②

: Color (B: black G: green)

③

: Version

④

Standard for model name

(A: indoor unit B: outdoor unit, C: others)

: Version

(A: controller, B: measuring instrument, C: others)

: Version

(C: cooling only, H: heat pump)

: Version

: Version

(0: air filter

1: bio-pure & deodorizing filter

2: on-board electric dust collector

3: scroll electric dust collector)

● MRW-10A

● MRW-10AC

(For China)

● MIM-B00

● MIM-B00C

(For China)

● MCM-A200C

(For China)

● MWR-AC00

● MWR-AC00C

(For China)

● MRK-A00

● MRK-A00C

(For China)

● MF-C1B0C

(For China)

Duct

flange

MDP- ①②③④

MDP : Duct flange

: Hole size (ø, cm)

①, ②

: Number of hole

③

: Version

④

18

I

● MDP-2030

● MDP-2030C

(For China)

Parts Model ExampleStandard for model name

Super

cooler

Super

heater

MSC- ①②③④⑤

MSH- ①②③④⑤

MSC : Super cooler

: HP of applicable outdoor unit

①, ②

(marked as 00 if it is 10.0 HP)

: Power supply

③

B:220V, 60Hz

C:208~230V, 60Hz

E:220~240V, 50Hz

H:380V, 60Hz, 3ø

J:460V, 60Hz, 3ø

: Design (A: front B: top)

④

: Version

⑤

MSH : Super heater

: HP of applicable outdoor unit

①, ②

(marked as 00 if it is 10.0 HP)

: Specification of power source

③

B:220V, 60Hz

C:208~230V, 60Hz

E:220~240V, 50Hz

H:380V, 60Hz, 3ø

J:460V, 60Hz, 3ø

: Design (A: front B: top )

④

: Version

⑤

● MSC-00EB0

(Applied to the

top of 10.0HP

outdoor unit)

● MSC-45EA0

(Applied to the

front of 4.5HP

outdoor unit)

● MSH-00EB0

(Applied to the

top of 10.0HP

outdoor unit)

● MSH-45EA0

(Applied to the

front of 4.5HP

outdoor unit)

Water

coil

MWC- ①②③④⑤

MWC : Water coil

①, ②, ③

④

⑤

: Capacity of applicable indoor unit

(x 10 kW)

: Applicable product (H: High pressure duct,

D: Low silhouette duct, B: Built-in duct)

: Version

19

I

● MWC-083D0

(For 8300W

Low silhouette

duct)

I. Overview

2. DVM line-up

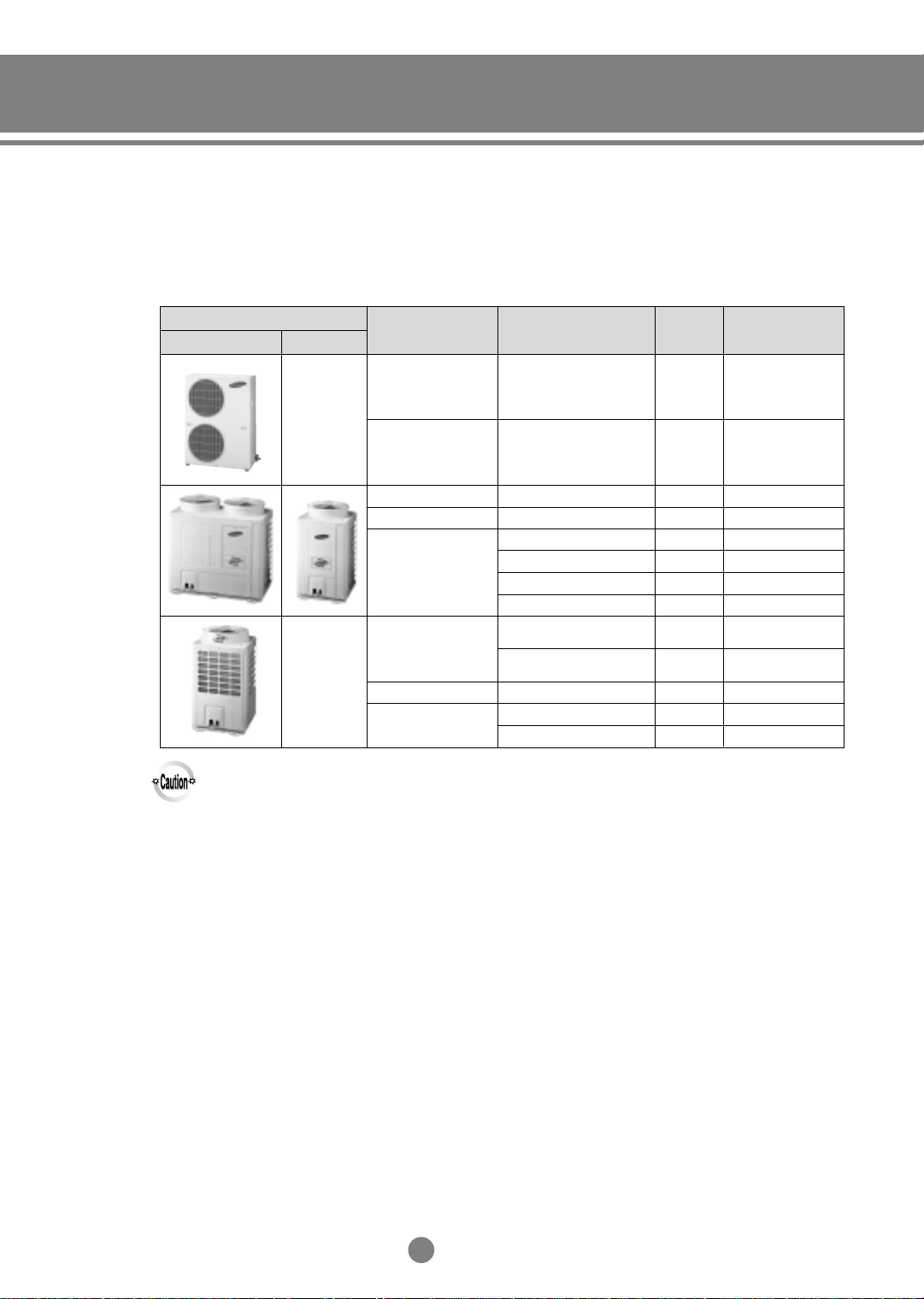

2-2. Combination

(1) Outdoor unit

1) Cooling only

Design

Main

◆ The system enables the connection of indoor units with a total capacity of between 50 to 130% of that of

the corresponding outdoor unit but where this capacity ratio exceeds 100% then the actual capacity of

each indoor unit will fall a little short of its individual rated capacity when all the units are operated

simultaneously. (Except Middle East models)

◆ The specification of super cooler may differ, depending on the model.

Super cooler

-

-

Power supply Model

50Hz

60Hz

50Hz

60Hz

50Hz

60Hz

380~415V, 3ø

208~230V, 3ø

380~415V, 3ø

380~415V, 3ø

380V, 3ø

208~230V, 3ø

380~415V, 3ø

208~230V, 3ø

208~230V, 3ø

RVMC060GDM0

RVMC050CBM0

RVMC060GAM0

RVMC060GAM1

MUF7201F1

RVMC075FAM0

RVMC100GAM0

RVMC080FAM0

RVMC100FAM0

Capacity(HP)

6

5

6

6

7.5

7.5

10

8

10

Refrigerant

R407C

R22

R22

R22

R22

R22

R22

R22

R22

20

I

Main

Design

Super cooler

Max. connectible

indoor units

Total capacity of indoor

units (kW, ISO standard)

Super

cooler

Remark

8

7

8

8

10

14

-

◆ The system enables the connection of indoor units with a total capacity of between 50 to 130% of that of

the corresponding outdoor unit but where this capacity ratio exceeds 100% then the actual capacity of

each indoor unit will fall a little short of its individual rated capacity when all the units are operated

simultaneously. (Except Middle East models)

◆ The specification of super cooler may differ, depending on the model.

11

14

8.0~20.8

7.2~18.8

8.0~20.8

8.0~16.0

10.5~27.3

10.5~21.0

10.5~27.3

10.5~21.0

14.0~36.4

14.0~28.0

11.1~29.0

14.0~36.4

14.0~28.0

-

-

-

-

For Middle East

-

O

-

-

-

-

-

-

-

For Middle East

For Middle East

For Middle East

For Middle East

21

I

I. Overview

2. DVM line-up

2) Heat pump

Design

Main

◆ The system enables the connection of indoor units with a total capacity of between 50 to 130% of that of

the corresponding outdoor unit but where this capacity ratio exceeds 100% then the actual capacity of

each indoor unit will fall a little short of its individual rated capacity when all the units are operated

simultaneously. (Except Middle East models)

◆ The specification of super cooler may differ, depending on the model.

Super cooler

-

-

Power supply Model

50Hz

60Hz

50Hz

60Hz

380~415V, 3ø

380~415V, 3ø

208~230V, 3ø

380~415V, 3ø

380~415V, 3ø

380~415V, 3ø

208~230V, 3ø

RVMH060GBM0

RVMH060GDM0

RVMH050CBM0

RVMH080GAM0

RVMH100GAM0

RVMH100GCM0

RVMH100FAM0

Capacity(HP)

6

6

5

8

10

10

10

Refrigerant

R22

R407C

R22

R22

R22

R22

R22

22

I

Main

Design

Super cooler

Max. connectible

indoor units

8

Total capacity of indoor

units (kW, ISO standard)

8.0~20.8

Super

cooler

-

Remark

8

7

11

14

-

◆ The system enables the connection of indoor units with a total capacity of between 50 to 130% of that of

the corresponding outdoor unit but where this capacity ratio exceeds 100% then the actual capacity of

each indoor unit will fall a little short of its individual rated capacity when all the units are operated

simultaneously. (Except Middle East models)

◆ The specification of super cooler may differ, depending on the model.

14

14

8.0~20.8

7.2~18.8

11.0~29.0

14.0~36.4

14.0~28.0

14.0~36.4

14.0~36.4

14.0~28.0

-

-

-

-

-

-

-

-

For Middle East

For Middle East

23

I

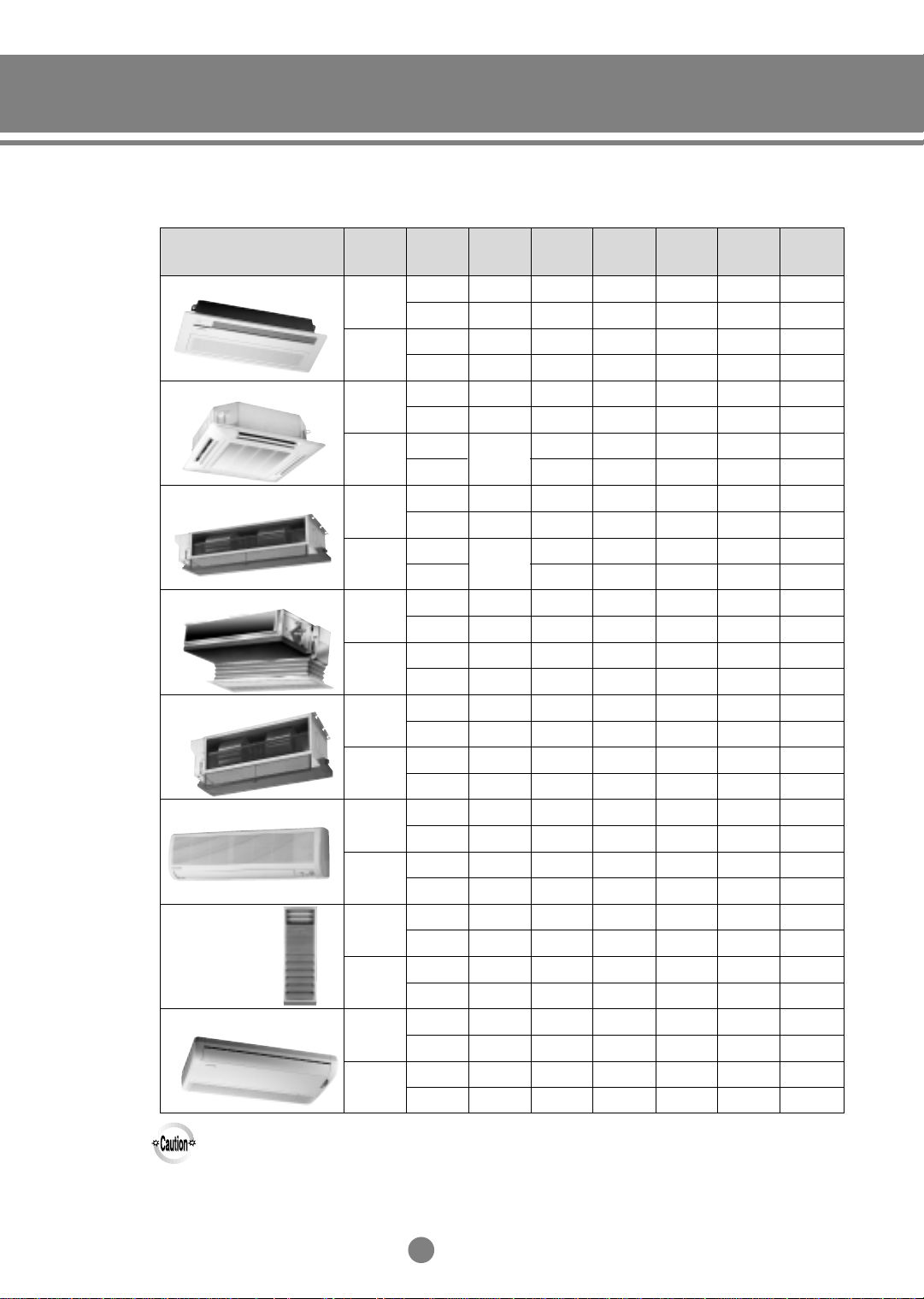

I. Overview

1. System line-up

(2) Indoor unit

Design

1-way cassette type

4-way cassette type

Duct type(Low silhouette)

Duct type (Built-in)

Duct type(High pressure)

Wall-mounted type

Floor standing type

Ceiling type

Power

supply

50Hz

60Hz

50Hz

60Hz

50Hz

60Hz

50Hz

60Hz

50Hz

60Hz

50Hz

60Hz

50Hz

60Hz

50Hz

60Hz

2.0kW

(7000Btu/h)

AVMKC020EA0

AVMKH020EA0

AVMKC020CA0

AVMKH020CA0

AVMBC020EA0

AVMBH020EA0

AVMBC020CA0

AVMBH020CA0

AVMWC020EA0

AVMWH020EA0

AVMWC020CA0

AVMWH020CA0

2.6kW

(9000Btu/h)

AVMKC026EA0

AVMKH026EA0

-

-

-

-

-

-

-

AVMBC026EA0

AVMBH026EA0

-

-

-

-

AVMWC026EA0

AVMWH026EA0

-

-

-

-

-

-

-

-

(11000Btu/h)

-

AVMKC032CA0

-

AVMKH032CA0

-

-

-

-

-

-

-

-

-

AVMBC032CA0

-

AVMBH032CA0

-

-

-

-

-

AVMWC032CA0

-

AVMWH032CA0

-

-

-

-

-

-

-

-

3.2kW

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

3.5kW

(12000Btu/h)

AVMKC035EA0

AVMKH035EA0

AVMBC035EA0

AVMBH035EA0

AVMWC035EA0

AVMWH035EA0

(13500Btu/h)

-

AVMKC040CA0

-

AVMKH040CA0

-

-

-

-

-

-

-

-

-

AVMBC040CA0

-

AVMBH040CA0

-

-

-

-

-

AVMWC040CA0

-

AVMWH040CA0

-

-

-

-

-

-

-

-

4.0kW

(18000Btu/h)

-

-

-

AVMCC052EA0

-

AVMCH052EA0

AVMCC052CA0

ABM1800B1

-

AVMCH052CA0

-

AVMDC052EA0

-

AVMDH052EA0

AVMDC052CA0

ADM1800B1

-

AVMDH052CA0

-

AVMBC052EA0

-

AVMBH052EA0

AVMBC052CA0

AVMBH052CA0

-

-

-

-

-

AVMWC052EA0

-

AVMWH052EA0

AVMWC052CA0

AVMWH052CA0

-

-

-

-

-

AVMFC052EA0

-

AVMFH052EA0

-

AVMFC052CA0

-

AVMFH052CA0

5.2kW

-

-

-

-

-

-

-

-

-

-

-

-

6.0kW

(20000Btu/h)

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

AVMPC060EA0

AVMPH060EA0

AVMPC060CA0

AVMPH060CA0

-

-

-

-

◆ The design and capacity of indoor unit are subject to change without notice.

24

I

Design

1-way cassette type

4-way cassette type

Duct type(Low silhouette)

Duct type (Built-in)

Duct type(High pressure)

Wall-mounted type

Floor standing type

Ceiling type

Power

supply

50Hz

60Hz

50Hz

60Hz

50Hz

60Hz

50Hz

60Hz

50Hz

60Hz

50Hz

60Hz

50Hz

60Hz

50Hz

60Hz

7.0kW

(24000Btu/h)

-

-

-

AVMCC070EA0

AVMCH070EA0

-

AVMDC070EA0

AVMDH070EA0

-

-

AVMBC070EA0

AVMBH070EA0

-

-

-

-

-

-

AVMWC070EA0

AVMWH070EA0

-

-

AVMPC070EA0

AVMPH070EA0

-

-

AVMFC070EA0

AVMFH070EA0

-

-

7.2kW

(24000Btu/h)

AVMCC072CA0

ABM2400B1

AVMCH072CA0

AVMDC072CA0

ADM2400B1

AVMDH072CA0

AVMBC072CA0

AVMBH072CA0

AVMWC072CA0

AVMWH072CA0

AVMPC072CA0

AVMPH072CA0

AVMFC072CA0

AVMFH072CA0

(28000Btu/h)

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

AVMPC082EA0

-

AVMPH082EA0

-

-

8.2kW

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

8.3kW

(28000Btu/h)

AVMPC083CA0

AVMPH083CA0

(36000Btu/h)

-

-

-

-

-

AVMCC105EA0

-

AVMCH105EA0

-

AVMCC105CA0

-

AVMCH105CA0

-

-

-

-

-

-

-

-

-

AVMHC105EA0

-

AVMHH105EA0

-

AVMHC105CA0

-

AVMHH105CA0

-

-

-

-

-

-

-

-

-

-

10.5kW

(44000Btu/h)

-

-

-

-

-

-

-

-

-

-

-

AVMHC128EA0

AVMHH128EA0

AVMHC128CA0

AVMHH128CA0

-

-

-

-

-

-

-

-

-

-

-

-

12.8kW

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

Remark

◆ The design and capacity of indoor unit are subject to change without notice.

25

I

II

Control System

1.

Remote controller

1-1. Wireless remote controller

1-2. Wired remote controller

1-3. Centralized controller

1-4. Function controller

2.

Receiver & display unit (Duct type)

2

4

6

6

2-1. Concealed type

2-2. Standard type

3.

Transmitter

Installation

4.

4-1. Wireless remote controller

4-2. Wired remote controller

4-3. Centralized controller

4-4. Function controller

4-5. Receiver & display unit - concealed type

4-6. Receiver & display unit - standard type

4-7. Transmitter

5.

Assigning address

5-1. Indoor unit

5-2. Outdoor unit

6.

Indoor unit PCB option code

6-1. PCB option code input method

6-2. Option code

7

8

10

11

14

19

21

22

23

25

26

27

32

7.

S-Net

Integrating power distribution system

8.

9.

Building management system

II. Control System

1. Remote controller

1-1. Wireless remote controller

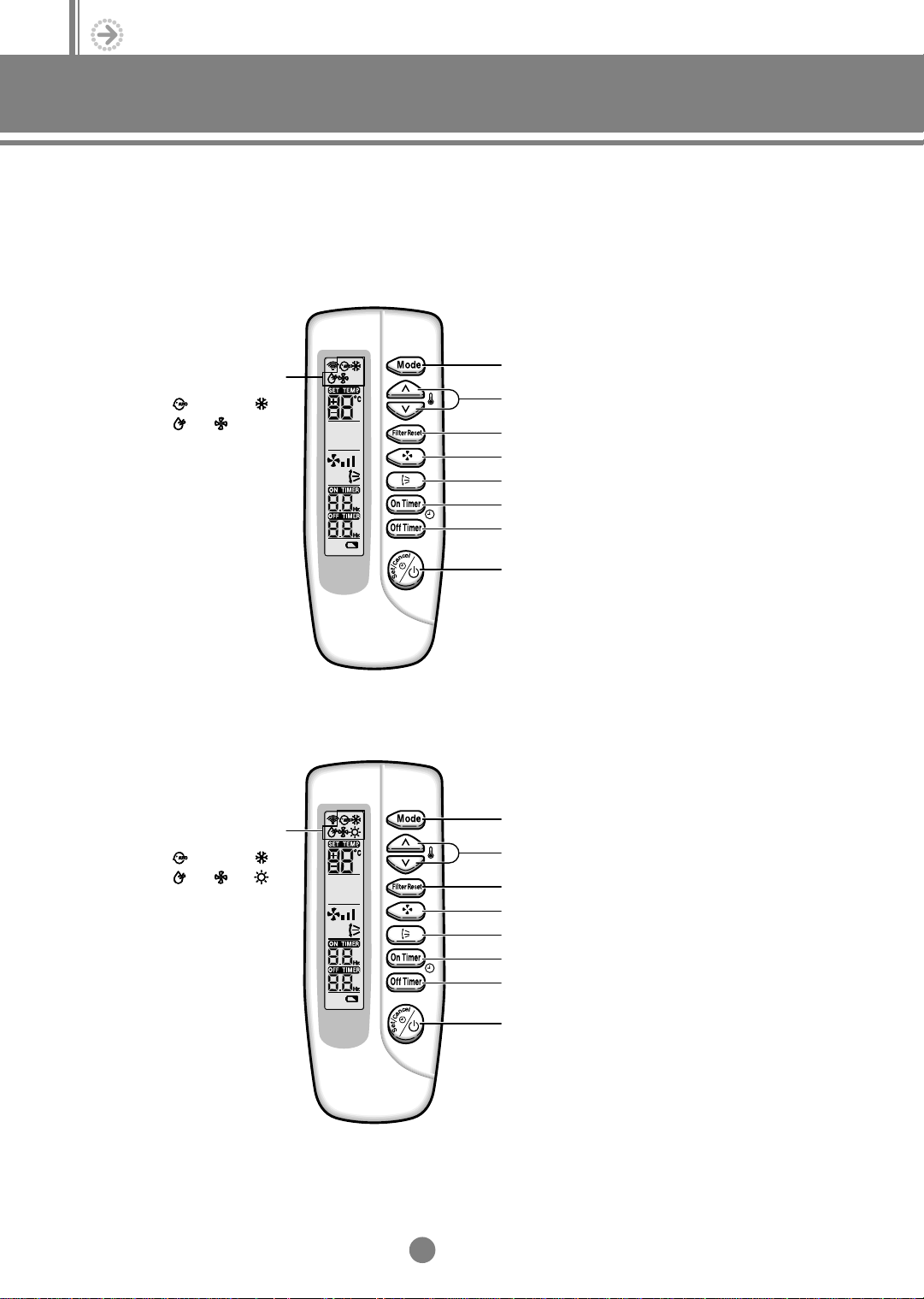

(1) 1-way / 4-way cassette / Wall-mounted / Floor standing / Ceiling type

1) Cooling only (MR-AC01)

Operating mode

Automatic

Dry Fan

2) Heat pump

Operating mode

Automatic

Dry HeatFan

Cool

Cool

Operating mode selection button

Temperature adjustment buttons

Filter Reset button

Fan speed adjustment button

Air flow direction adjustment button

On timer button

Off timer button

On/Off & Timer set/cancel button

Operating mode selection button

Temperature adjustment buttons

Filter Reset button

Fan speed adjustment button

Air flow direction adjustment button

On timer button

Off timer button

On/Off & Timer set/cancel button

2

II

(2) Duct type

1) Cooling only

Operating mode

Automatic Cool

Dry Fan

2) Heat pump

Operating mode

Automatic Cool

Dry HeatFan

Operating mode selection button

Temperature adjustment buttons

Filter Reset button

Fan speed adjustment button

Timer Cancel button

On timer button

Off timer button

On/Off & Timer set/cancel button

Operating mode selection button

Temperature adjustment buttons

Filter Reset button

Fan speed adjustment button

Timer Cancel button

On timer button

Off timer button

On/Off & Timer set/cancel button

3

II

II. Control System

1. Remote controller

1-2. Wired remote controller

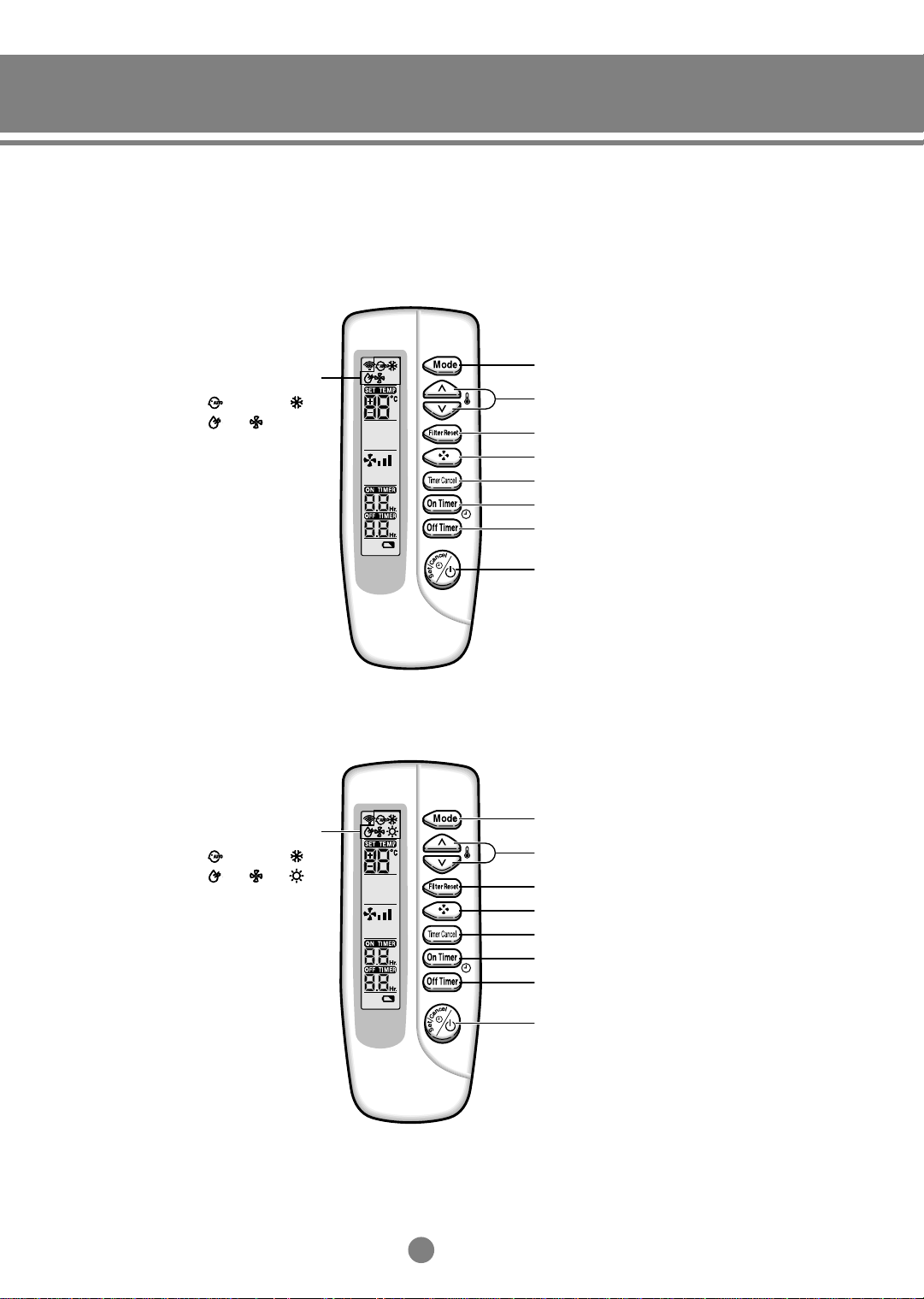

(1) 1-way / 4-way cassette / Wall-mounted / Floor standing / Ceiling type

1) Cooling only

Operating mode

Automatic Cool

Dry Fan

Temperature

adjustment buttons

On/Off timer button

Test operation button

Operating mode

selection button

2) Heat pump

Temperature

adjustment buttons

On/Off timer button

Test operation button

On/Off & Timer set/cancel button

Operating indicator

Fan speed adjustment button

Air flow direction adjustment button

Filter Reset button

Operating mode

Automatic Cool

Dry HeatFan

On/Off & Timer set/cancel button

Operating indicator

Fan speed adjustment button

Air flow direction adjustment button

Filter Reset button

Operating mode

selection button

4

II

(2) Duct type

1) Cooling only

Operating mode

Automatic Cool

Dry Fan

Temperature

adjustment buttons

On/Off timer button

Test operation button

Operating mode

selection button

2) Heat pump

Temperature

adjustment buttons

On/Off timer button

On/Off & Timer set/cancel button

Operating indicator

Fan speed adjustment button

Filter Reset button

Operating mode

Automatic Cool

Dry HeatFan

On/Off & Timer set/cancel button

Operating indicator

Fan speed adjustment button

Test operation button

Operating mode

selection button

Filter Reset button

5

II

II. Control System

1. Remote controller

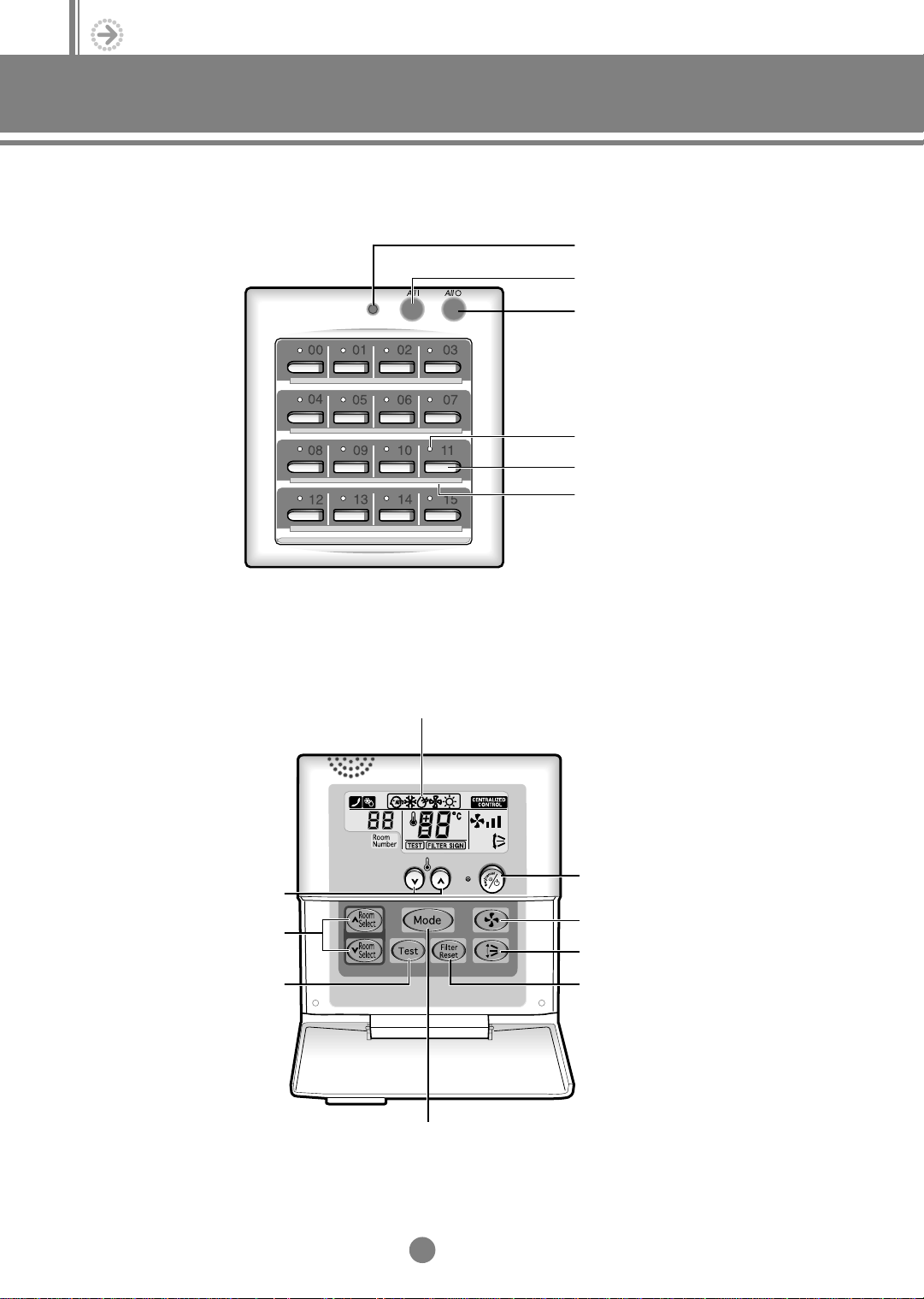

1-3. Centralized controller

Operating lamp

All On button

All Off button

On/off indicators

Individual On/Off button

Index

1-4. Function controller

Temperature adjustment

buttons

Indoor unit selection buttons

Test button

Operating mode

On/Off button

Fan speed adjustment button

Swing button

Filter reset button

Mode selection button

6

II

Loading...

Loading...