Page 1

INSTRUCTION MANUAL

HPR

LIQUID RING PUMP

®

TRUCK MASTER

INSTRUCTION MANUAL FOR SAMSON LIQUID RING PUMP

TRUCK MASTER 2500

• Technical data

• Design of a system

• Installation and start-up

• Service

• Troubleshooting

• Spare parts

2500

DOC9056J

Page 2

CONTENTS

1 Introduction .............................................................................................................................. 4

1.1 Declaration of conformity ........................................................................................................ 4

1.2 Explanation of warning symbols .............................................................................................. 5

1.3 Field of application .................................................................................................................. 5

1.4 Disposal .................................................................................................................................. 5

2 Technical data .......................................................................................................................... 6

2.1 Dimensions ............................................................................................................................. 6

2.2 Specifications .......................................................................................................................... 7

2.3 Power consumption and output ............................................................................................... 8

2.3.1 Vacuum .................................................................................................................................. 8

2.3.2 Pressure .................................................................................................................................. 8

2.3.3 Correction factor - Temperature ............................................................................................. 9

2.3.4 Correction factor - Wet and dry gas ......................................................................................... 9

2.4 Handling and transport ......................................................................................................... 10

2.5 Pump storage and draining procedure ................................................................................... 11

3 Design of a system ..............................................................................................................12

3.1 Function and design of a liquid separator .............................................................................. 13

3.2 Air cooling with fan cooler .................................................................................................... 14

3.3 Fan cooler ............................................................................................................................. 15

3.4 Water consumption ............................................................................................................... 16

3.5 Dome valve system ............................................................................................................... 16

3.6 Cavitation ............................................................................................................................. 17

3.7 Service liquid requirement ..................................................................................................... 17

4 Installation and start-up ...................................................................................................18

4.1 Securing the pump ................................................................................................................ 18

4.2 Connections to the pump ...................................................................................................... 18

4.3 Connecting the service liquid ................................................................................................ 19

4.4 Transmission ........................................................................................................................ 19

4.5 Prior to start-up .................................................................................................................... 20

4.6 Direction of rotation ............................................................................................................. 20

2

Page 3

5 Service, operation, maintenance and inspection intervals............................................. 21

5.1 Draining the liquid separator ................................................................................................. 21

5.2 Check grease cartridges ....................................................................................................... 21

5.3 Winterization ......................................................................................................................... 21

5.4 Lubrication of bearings ......................................................................................................... 22

5.5 Inspection and cleaning of service liquid’s supply pipe .......................................................... 22

5.6 Inspection and cleaning of internal channels ........................................................................ 22

6 Troubleshooting ...................................................................................................................23

7 Spare parts and tools ..........................................................................................................24

7.1 Marking and identification ..................................................................................................... 24

7.2 How to order ......................................................................................................................... 25

7.3 Spare parts ............................................................................................................................ 26

7.4 Adaptor ................................................................................................................................. 30

7.5 Gasket set ............................................................................................................................. 31

7.6 Special tool set ...................................................................................................................... 32

Truck Master 2500

3

Page 4

E-Mail

Web www.samson-pumps.com Phone | +45 87 50 95 70 DK-8800 Viborg

1 INTRODUCTION

1.1 Declaration of conformity

Dec

Hereby declares that the following products:

ruck Master 350, Truck Master 600, Truck Master 1600,

T

ruck Master 2500, Truck Master 3400

T

laration of Conformity

Annex IIA

Samson Pumps A/S

Petersmindevej 21

DK-8800 Viborg

Liquid ring pump

Conforms to the directive:

Machinery Directive 2006/42/EC

I hereby declare that the liquid ring pumps are in conformity with the following harmonized standards:

DS/EN ISO 12100:2011 Safety of machinery - General principles for design - Risk assessment and risk

DS/EN 1012-2 + A1:2009 Compressors and Pumps - Safety requirements - Part 2: Vacuum pumps

The standards above only apply to the extent that it is relevant for the purpose of the pump.

The product must not be used before the complete system, which it must be incorporated in, has been conformity

assessed and found to comply with all relevant health and safety requirements of 2006/42/EC and other relevant

directives. The product must be included in the overall risk assessment.

Viborg, 03.10.2018 _______________________

Kelvin Storm Jensen

R&D Manager

Samson Pumps A/S

reduction

DOC4044

DOC4044

info@samson-pumps.com Samson Pumps A/S Petersmindevej 21

4

Page 5

1.2 Explanation of warning symbols

Important technical and safety instructions are shown by symbols. If the instructions are not performed

correctly, it can lead to personnel injuries or incorrect function of the pump.

To be used with all safety instructions that must be followed. A failure to follow the

instructions may result in injuries and/or incorrect machine operation

1.3 Field of application

Inlet of foreign objects can damage the pump

The pump is designed exclusively to pump gases, including atmospheric air

WARNING!

Avoid cavitation of the pump! For further information, see instruction manual for the

Samson Pumps vacuum limiter

It must be ensured that the inlet gas cannot react with the service liquid and create aggressive bonds that

break down the pump's components.

For other operating data, see specifications.

• The pump must only be used with media that is not aggressive to the pump's materials. See section 7

for components and materials.

1.4 Disposal

Samson’s liquid ring pump is manufactured so that most of the device can be reused/recycled.

Samson Pumps offer users of the company’s pumps the option of returning used pumps to be restored or

scrapped.

Alternatively, the pump must be taken apart and sorted into its separate components, by the customer

(see section 7 for the pump’s material).

These components must be disposed of in accordance with national regulations.

Truck Master 2500

5

Page 6

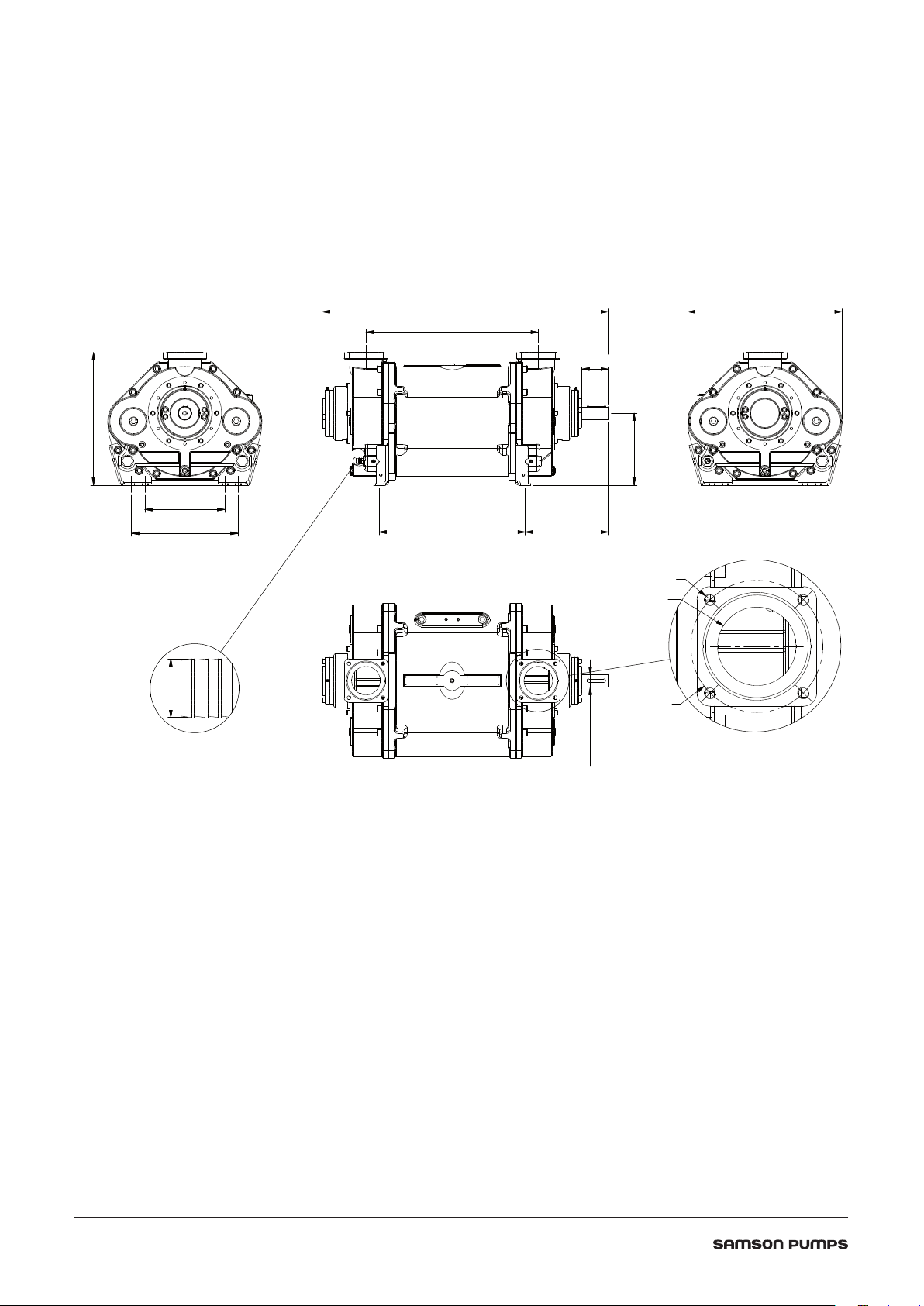

2 TECHNICAL DATA

498

48 k6Ø

270

20Ø

2.1 Dimensions

300

400

1074

647

100

579

549 312

M16x2

Ø107

Ø180

DOC1627354_1D

6

Page 7

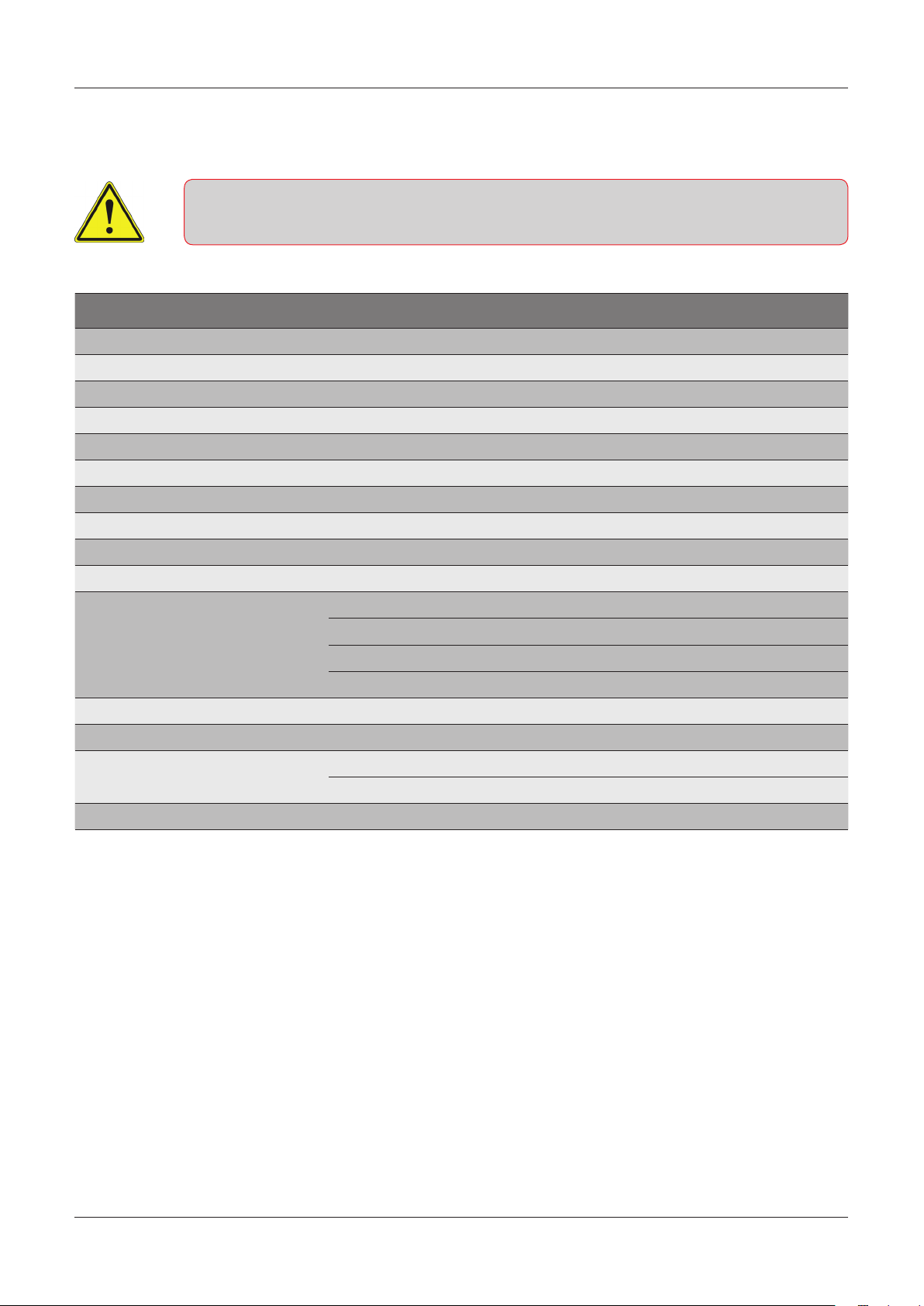

2.2 Specifications

A failure to meet these specifications may result in damage to the pump

Description Minimum Maximum

Ambient temperature, operation Below 0°C - see chapter 5.3 -20°C 55°C

Ambient temperature, storage -20°C 55°C

Humidity - 100%

Intake temperature, suction side - 60°C

Intake temperature, service liquid - 60°C

Service liquid pipe connection, dimension ¾” -

Service liquid pipe connection, length - 6 m

Noise level - 80 dB(A)

Water volume - 34 L

Maximum radial load on drive shaft - 3480 N

1200 rpm 33 kW -

Heat input for cooler calculation

Revolutions 1200 rpm 1500 rpm

Pressure 150 mbar abs. 1 bar(g)

Lubricating grease

Weight 321 kg

1300 rpm 36 kW -

1400 rpm 41 kW -

1500 rpm 48 kW -

Type of grease SKF LGWA2

Automatic lubrication SKF LAGD 125/WA2

Truck Master 2500

7

Page 8

2.3 Power consumption and output

2.3.1 Vacuum

Vacuum [%] 80 70 60 50 40 30 20

1200 [rpm]

1300 [rpm]

1400 [rpm]

1500 [rpm]

Flow

Flow

Wet

Dry

[m³/h]

1261 1846 1777 1803 1852 1846 1860

941 1442 1545 1596 1699 1709 1738

Consumption [kW] 45

Torque [Nm] 358

Flow

Flow

Wet

Dry

[m³/h]

1522 1941 1914 1963 1972 1980 1965

1136 1517 1665 1737 1809 1833 1837

Consumption [kW] 48

Torque [Nm] 353

Flow

Flow

Wet

Dry

[m³/h]

1655 2126 2055 2159 2137 2205 2075

1235 1661 1787 1910 1960 2042 1939

Consumption [kW] 56

Torque [Nm] 382

Flow

Flow

Wet

Dry

[m³/h]

1962 2389 2361 2423 2445 2465 2322

1464 1866 2053 2144 2243 2282 2170

Consumption [kW] 64

Torque [Nm] 407

2.3.2 Pressure

Pressure [bar(g)] 0 0.25 0.5 0.75 1

Flow [m³/h] 1300 1226 1179 1070 993

1200 [rpm]

1300 [rpm]

1400 [rpm]

1500 [rpm]

The data Flow

• Air temperature 20°C

• Service liquid temperature 15°C

• Test performed with dry air and 1,013 mbar absolute pressure

• Tolerance ±10%

Consumption [kW] 39 43 49 54 59

Torque [Nm] 310 342 390 430 470

Flow [m³/h] 1425 1328 1261 1171 1097

Consumption [kW] 41 49 55 61 67

Torque [Nm] 301 360 404 448 492

Flow [m³/h] 1605 1569 1433 1341 1271

Consumption [kW] 54 55 61 68 74

Torque [Nm] 368 375 416 464 505

Flow [m³/h] 1824 1636 1633 1531 1390

Consumption [kW] 62 64 70 76 82

Torque [Nm] 395 407 446 484 522

is based on the following parameters:

Dry

8

Page 9

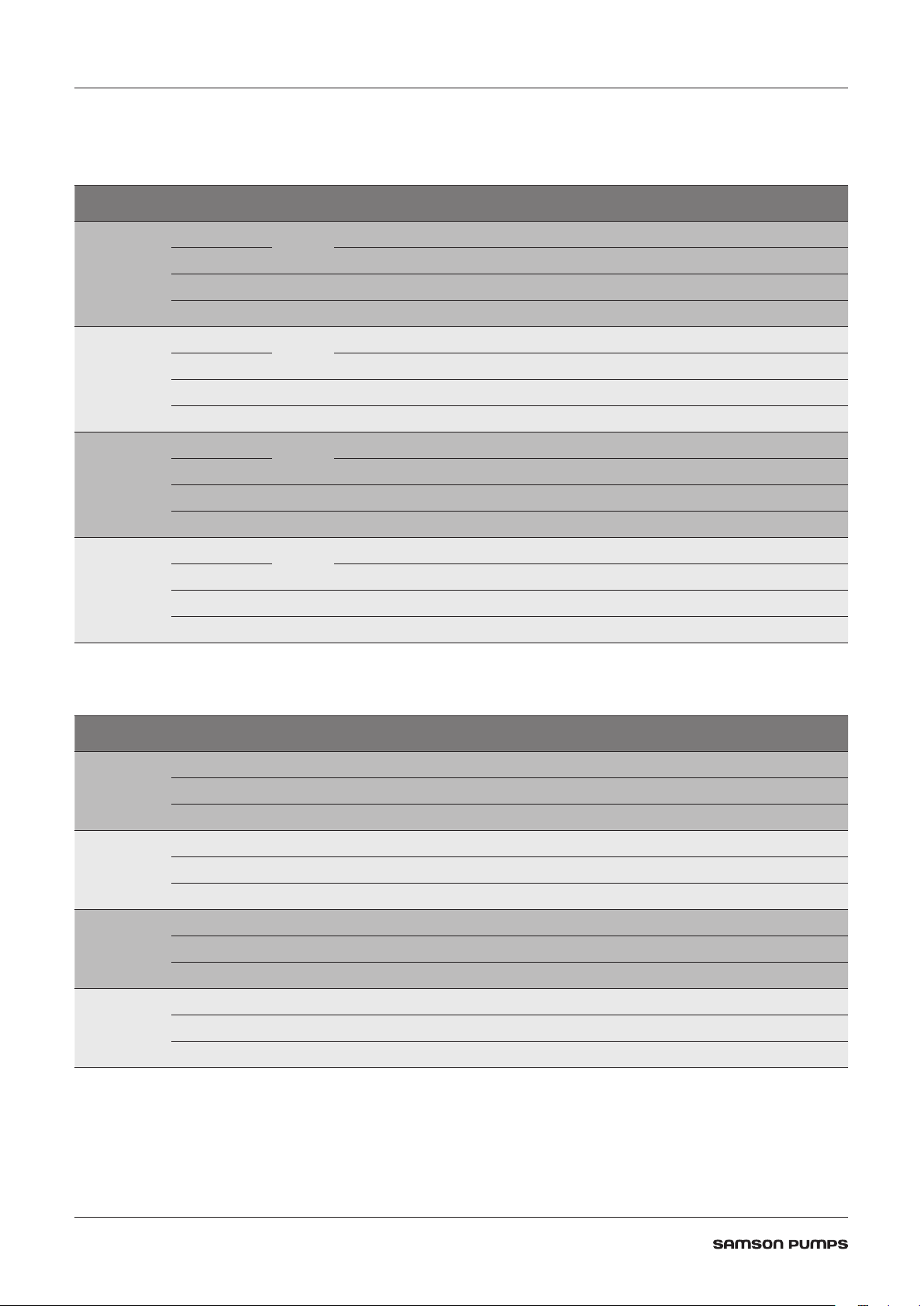

2.3.3 Correction factor - Temperature

When the temperature of the service liquid

exceeds 15°C, the pump’s capacity will be affected

with respect to the specified values.

To determine the output at a higher temperature,

the correction factor can be used.

Capacity at service liquid temperature

higher than 15°C :

= Q

x K

Q

t>15

15

1

DOC1628005_1A

2.3.4 Correction factor - Wet and dry gas

Normal atmospheric air contains water vapor. In this case water will condense inside the pump and will

create a higher flow.

Below you can find a correction factor table for the performance based on condensing gas with an inlet

temperature of 50°C 100% saturated and service liquid temperature of 15°C.

Suction pressure % Vacuum 80 70 60 50 40 30 20

Correction factor wet gas

K

1,34 1,28 1,15 1,13 1,09 1,08 1,07

Wet

The performance of the pump can thereby be calculated as:

V

= V

Dry

x K

Wet

Wet

Truck Master 2500

9

Page 10

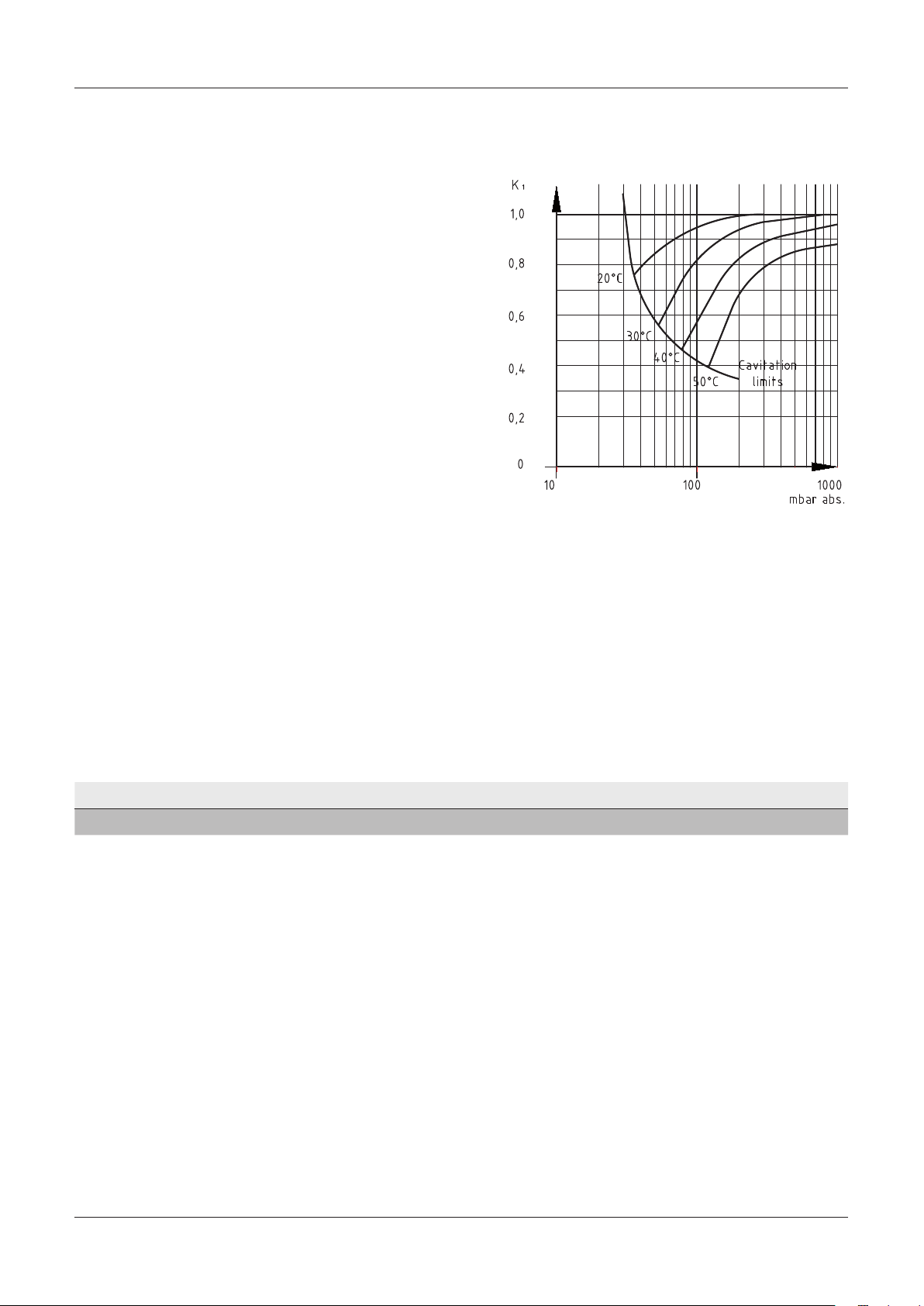

2.4 Handling and transport

The pump must not be used if it is damaged or the identification plate is missing

The pump must be transported in such way that

it is not exposed to vibrations and impacts that

can overload the bearings.

The pump must be inspected for damages upon

delivery. If the pump is damaged, it must not be

used and the damage must be reported to the

manufacturer.

Ensure that the pump’s identification plate

is intact and that the marking of the pump

corresponds to its use.

The pump must only be handled using approved

lifting eyes, in accordance with nationally

applicable regulations and only in a vertical

motion.

DOC1627355_1

The pump can be transported in the following

ways:

DOC11093A

10

Page 11

2.5 Pump storage and draining procedure

A failure to comply with the requirements for storing the pump may result in internal

damage to the device

If the temperature is below freezing point of the service liquid, it could damage the pump

Under these conditions, the pump must be drained completely

All plugs and protective covers must be fitted during storage

The pump’s service liquid is drained on delivery, and the pump can be immediately stored in accordance

with the technical specifications.

After operation, the pump can be stored for 30 days without further action.

If the pump remains out of operation for a longer period of time after use, its service liquid must be

drained, and the liquid supply to the pump must be shut off.

When emptying the pump, it is important that all chambers inside the pump are emptied.

The pump can be fitted with valves in the draining connections. See below.

Truck Master 2500

DOC1627356_1

11

Page 12

3 DESIGN OF A SYSTEM

Pos. Description

1

2

3

4

5

6

7

8

Liquid ring pump

Non return valve

4-way valve

Vacuum limiter

Service liquid valve

Fan cooler

Liquid separator

Dome valve

12

DOC1627390

Page 13

3.1 Function and design of a liquid separator

Together with the air there will be a water flow out of the pump up to 6 m3/h.

The water will be separated from the air in the liquid separator.

Depending of the size of particles, water will be carried with the water when the air velocity is more than

3-4 m/s.

The inlet speed to the separator can be more than 50 m/s and this must be reduced to 3 m/s.

Below you find an illustration showing how to reduce the speed and control that no water will be in contact

with the high velocity air stream. The round velocity reducer can be placed inside any tank geometry.

Air flow [m³/h] øD minimum [mm]

2500 540

2400 530

2300 520

2200 510

2100 500

2000 490

DOC1627391

øD so the velocity is below 3 m/s

H=4 to 6*d depending on the geometry. A smooth diameter conversion will give a low factor.

Truck Master 2500

13

Page 14

3.2 Air cooling with fan cooler

Compression of air inside the liquid ring pump will create heat that is transferred to the service liquid.

Therefore, it can be necessary to install a fan cooler depending on the expected use, the climate etc. The

time it takes to heat up the water also depends on for example ambient temperature, suction pressure,

amount of water and the cooling effect in the truck itself.

The operation temperature will go up until there is a balance between the heat input and the heat output.

So basically, there are only two things that can lower the operation temperature. Reduce the heat input or

increase the heat output.

The amount of water has no or only a little influence on the final operating temperature. The truck itself

will work as a big radiator and if there is a huge amount of water in the liquid separator and thereby good

contact area between the water and the steel tank, it will give a higher cooling effect. This in combination

with low ambient temperature and short time of operation, could mean that the truck can operate without

any additional cooling.

In general, the time it takes to heat up the water can be calculated from the formula below.

x m x Δt

C

=

p

Q

t

sec

t

C

Δt

m

Q

Example:

We have a tank with 300 litres of water corresponding to 300 kg. The heat input is 30 kW.

How long will it take to heat it up from 20°C to 40°C ?

The temperature will continue to go up until the steel construction can absorb the heat and transfer it to

the surroundings.

With a temperature difference on 20°C it is typical to have a radiator affect in a truck on somewhere

between 5 to 20 kW depending on the construction.

Time in seconds

=

sec

Heat capacity of the media. Water= 4,2

=

p

Temperature difference

=

Mass of the media heating up [Kg]

=

Heat input in [kW] See specifications, chapter 2.2

=

x 300 x 20

4,2

t

=

sec

30

= 840 s

= 14 min

The table below shows truck radiator effect at a temperature difference of 20°C.

5 kW 10 kW 20 kW

Small liquid separator mounted

external from the truck tank

Water content below 100 L

Small liquid separator inside

slurry tank. Located with only

minor contact to the product

Water content 300 L

Normal liquid separator inside

slurry tank with good contact to

the product

Water content 400 L

14

Page 15

3.3 Fan cooler

The fan cooler will increase the heat output from the construction and thereby stabilize the temperature

at a lower level. However, this cooler will use the air to cool down the water and therefore we will always

see that the temperature will be stabilized above the ambient temperature. It’s very simple to find the right

cooler based on the curves from the cooler manufacturer. Typically you will find the cooler capacity as kW/

Δt meaning for example 1.5 kW cooler capacity each °C in temperature difference between the water and

the air. Note that the water flow through the cooler will also affect the cooling capacity.

Typical fan cooler characteristic.

Practical calculation example:

The truck is used mostly to work with an operation pressure around 70% vacuum. From the technical data

sheet, we find the heat input from the pump to be 35 kW.

The liquid separator is built inside the slurry tank with a good contact to the product and a radiator effect

estimated to 20 kW with a temperature difference of 20°C.

The truck will work with ambient temperature up to 28°C during the summer and we will accept a maximum

temperature on 40°C.

First, we have to reduce the radiator effect based on a temperature difference of 12°C.

DOC1627392

12

Q

out Truck

The total cooling effect required is thereby:

= 20 x

= 12 kW

20

Q

out Pump

- Q

Truck Master 2500

out Truck

= 35 - 12 = 23 kW

15

Page 16

Summary

Pump model Description Truck Master 2500

Heat input from technical specifications Q

Ambient temperature t

in Pump

amb

35 kW

28°C

Maximum Working Temperature of the water.

This is determined by you. The temperature

t

op

40°C

has influence on the pump performance

Temperature difference Δ

Truck radiator effect based on 20 °C in

temperature difference

Truck radiator effect based on 12 °C in

temperature difference

Total cooling requirement from fan cooler Q

t

Q

out Truck 20

Q

out Truck 12

fan cooler

tOp- t

20 kW

12/20*20 = 12 kW

Q

= 12°C

amb

in Pump-Qout Truck 12

= 35-12 = 23 kW

We need to find a fan cooler that can transfer 23 kW with a temperature difference on 12°C.

That is 1,92 kW/°C.

If we for example accept a higher temperature, for instance 48°C, we will have full cooling effect from the

truck on 20 kW and a cooling requirement on 15 kW. The fan cooler we need to find is thereby on 15/20 =

0,75 kW/°C and a big difference to the bigger model calculated above.

3.4 Water consumption

It is possible to design the liquid separator so that almost 100% of the water is separated from the air.

However, the air will be heated up and thereby it can content more water. Also, the relative humidity will go

up and end near 100%.

So, the air will flow into the pump with maybe 50% relative humidity at a low temperature and be

discharged at a higher temperature and humidity. Therefore, there will be an evaporation from the system.

Choose your water temperature

Temp.

20°C 30°C 40°C 50°C 55°C

Vacuum

50% 18 27 53 93 152

70% 10 16 32 56 91

80% 5 11 21 37 60

Water consumption Liters per hour

3.5 Dome valve system

The liquid ring pump can handle liquid and particles in the inlet but it is of course

recommendable to avoid this.

A dome valve or floating valve will ensure that the suction will be closed when the liquid

level reaches the top of the tank.

In many situations there will be foam on the liquid surface inside the tank. It can be

difficult to avoid that this will be transported into the suction line before the dome valve

will close.

Therefore, it will be recommended to make a combination of a filter and dome valve as

illustrated below.

The filter will prevent particles lifted by the foam to enter the pump.

DOC1627393

16

Page 17

3.6 Cavitation

When the temperature reaches the boiling point of the water, steam bobbles will be created in the liquid

ring.

These bobbles cannot exist when they enter the discharge side of the pump and therefore they will

collapse. The impact force on the surface of the rotor and flow plate will damage the pump and can lead to

a total breakdown. It is a very harmful situation that must be avoided.

It is the combination of the pressure and the temperature that will lead to the cavitation. Therefore, it is

recommended to install a cavitation valve, see illustration below that shows a clockwise rotating pump.

If counter-clockwise rotating pump, mount in opposite manifold.

DOC1627417

Below you find the boiling point of water as a function of the pressure.

Vacuum 50% 75% 80% 90%

Temperature °C 80 64 59 44

Maximum discharge temperature 70 50 40 30

Note that the temperature of the gas inside the pump will heat up the water and the water surface therefore

will become a higher temperature than the measured temperature on the discharge side of the pump.

Cavitation will therefore start at a lower temperature and the maximum discharge temperature of the water

must be kept lower.

3.7 Service liquid requirement

During operation it is normal that small amount of product will enter the pump, or the gas will react with

the water which becomes aggressive.

A normal recommendation is to add glycol to the water in order to protect the liquid ring pump. Glycol will

protect the pump and for example the aluminum cooler, but shall only be used in periods with temperature

below freezing point.

Due to economical aspect it is more efficient to drain the liquid separator and refill with fresh water instead

of protecting with glycol and drain the separator more rarely.

Truck Master 2500

17

Page 18

4 INSTALLATION AND START-UP

4.1 Securing the pump

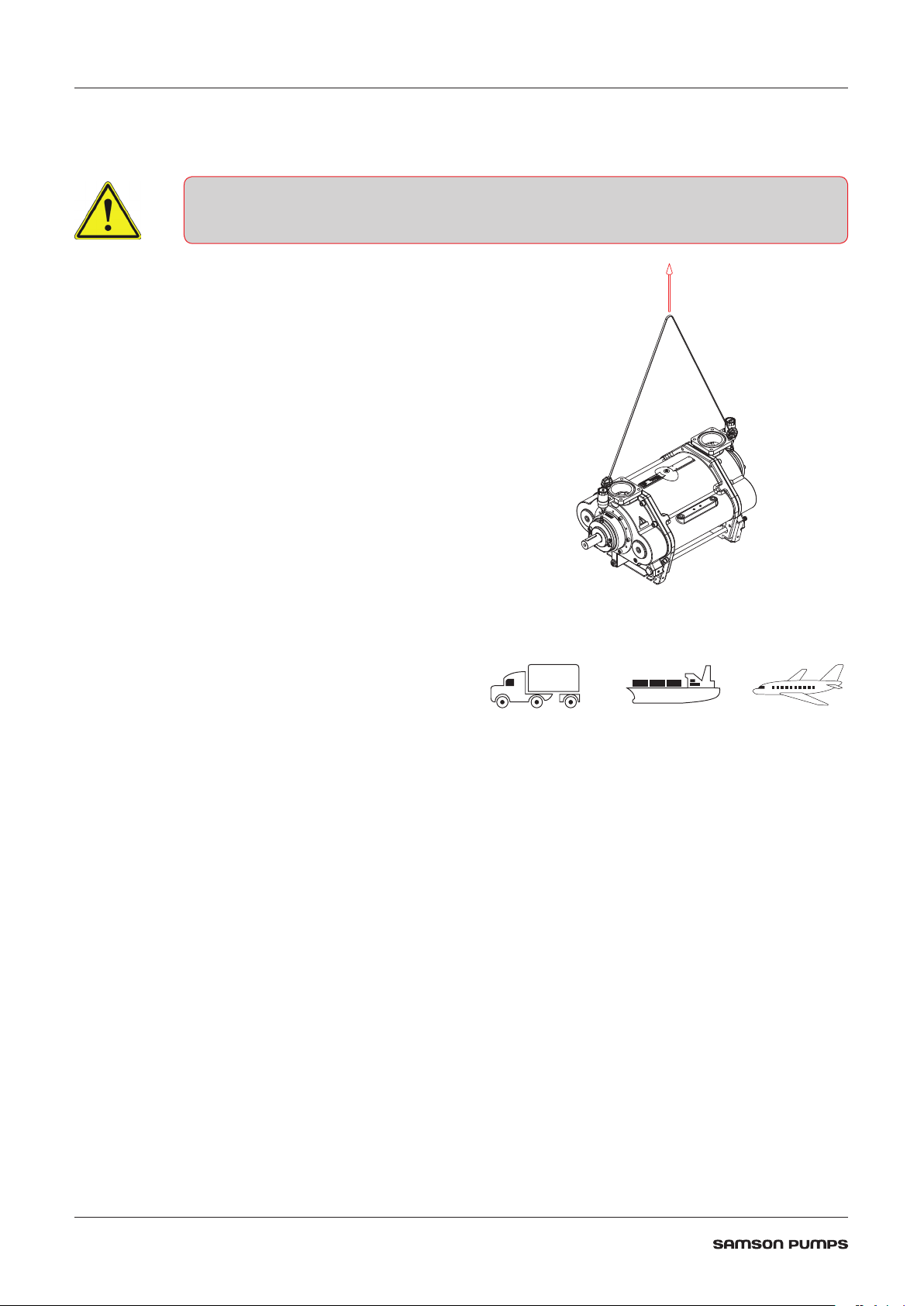

Installation requirements must be observed, otherwise there is a risk of damage

The pump must be installed on a stable foundation, which must be level and stable, so that the pump is not

twisted or exposed to a profile distortion.

The pump must be installed with M16 bolts on all four legs, which must be tightened to 180 Nm (A).

A

A

DOC1627358_5

4.2 Connections to the pump

• Check for foreign objects in the pump and physical damage on pump

• Gaskets to be handeled with highest degree of caution

• Gasket and sealing surfaces must be cleaned before assembly

Immediate before connecting the pipes, remove protective covers. Connection of the pump’s suction and

pressure pipe connections must be made with a gasket in between (C).

The M16 bolts must be tightened with 180 Nm (B).

In order to prevent tensions in the pump, the pipe connections (A) must be tensionless while tightening the

bolts.

C

A

B

18

DOC1627358_2

Page 19

4.3 Connecting the service liquid

The service liquid must be connected to the pump at the hose connection, see illustration below.

DOC1627356_5

4.4 Transmission

The pump can be connected direct or through belt transmission. For belt transmission, it must be ensured

that the permissible radial force is not exceeded. See specifications.

For belt transmission, note the direction of rotation, see illustration below.

DOC1627416_1

Truck Master 2500

19

Page 20

4.5 Prior to start-up

• Do not start the pump without service liquid, as this will damage the mechanical shaft

seals

• Do not start the pump if it is completely filled with service liquid

• Do not start the pump before the grease cartridges have been activated, as this can

damage the pump (if equipped)

• Stop the pump immediately if the rotational direction does not correspond to the

directional arrow

• A failure to follow the above guidelines may result in damage to the pump

Activating the grease cartridges (Accessories)

Turn the handle in NDE clockwise to position 12.

Turn the handle in DE clockwise to position 12.

The pump has been lubricated from factory and is ready to start.

NDE

DOC1627356_6

DE

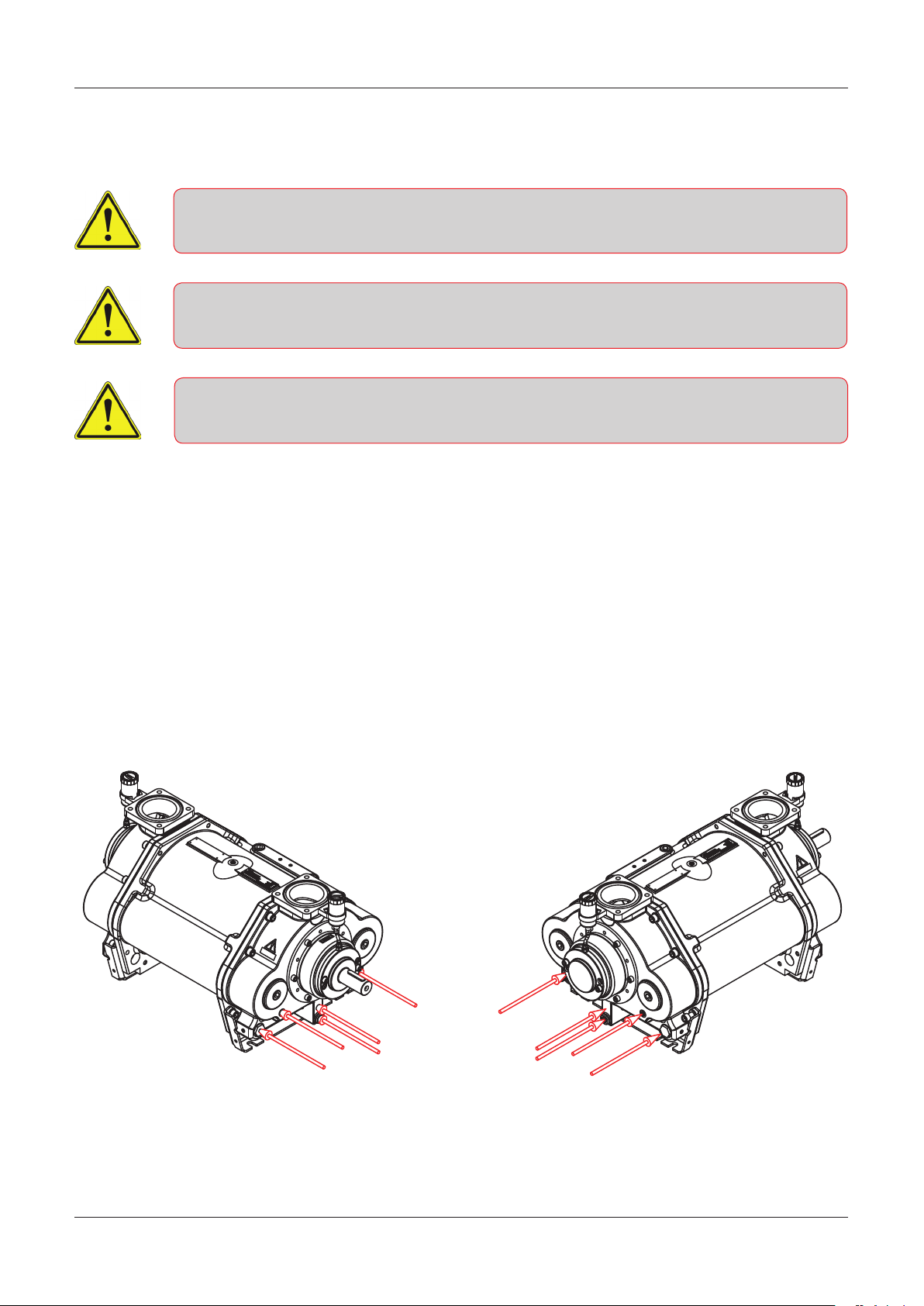

4.6 Direction of rotation

Check the direction of rotation by briefly starting the pump.

The direction of rotation of the rotor must correspond to the direction arrow!

Below left, a right-side pump is shown which has a clockwise direction of rotation (CW)

Below right, a left-side pump is shown which has a counter-clockwise direction of rotation (CCW)

DOC3707

20

DOC1627357_1 DOC1627414_1

Page 21

5 SERVICE, OPERATION, MAINTENANCE AND INSPECTION INTERVALS

A failure to observe the inspection intervals described in table below may result in

damage to the pump

Section Operation Interval

5.1 Drain liquid separator to remove contaminants Weekly

5.2 Check grease cartridges (if equipped) Weekly

5.3 Winterization When below 0°C

5.4 Lubrication of bearings Per 500 duty hours

5.5 Inspection and cleaning of service liquid’s supply pipe Monthly

5.6 Inspection and cleaning of internal channels Monthly

5.1 Draining the liquid separator

While the pump is stopped, the liquid separator must be drained to remove contaminants.

5.2 Check grease cartridges

If the pump is equipped with an automatic lubrication feature. It must be inspected and

replaced as needed.

When the pump is commissioned for the first time, the cartridges must be activated by

turning the arrow in the clockwise direction.

The cartridge is set to 12, which corresponds to an emptying time of 12 months.

The cartridge must be replaced when empty.

It is only allowed to use automatic lubricator of type LAGD 125/WA2.

DOC3707

5.3 Winterization

If the pump needs to be used at a temperature below freezing point of the service liquid, it is necessary to

protect the liquid from freezing by adding anti freeze liquid.

Truck Master 2500

21

Page 22

5.4 Lubrication of bearings

Over-lubrication of bearings may result in bearing damage! Do NOT exceed the

amount of grease specified below!

The bearings must be lubricated with grease of type SKF LGWA2, per 500 duty hours.

It is recommended to lubricate the bearings while pump is running.

Lubrication interval per 500 duty hours

Drive end (DE) 4 g

Non drive end (NDE) 3 g

NDE

DOC1627356_7

5.5 Inspection and cleaning of service liquid’s supply pipe

The pipe connection between the liquid separator and pump must be inspected at least once a month, and

any contaminants must be removed.

5.6 Inspection and cleaning of internal channels

The pump is designed with internal water channels for lubrication of the mechanical shaft seals.

Remove the plug as illustrated below and clean the channel using a ø5 mm 150 mm long screw driver or

similar.

DE

22

DOC1627356_8

Page 23

6 TROUBLESHOOTING

Problem Cause Effect Corrective measure

The pump is unable to

create a vacuum

The start-up power is

too high

Noise during operation • Cavitation • Severe damage to the

Leakage from the

bearing housing’s drain

holes

• Service liquid valve is

closed

• The pump is not

receiving enough

service liquid

• The temperature of the

service liquid is too

high

• Too much service liquid

in the pump prior to

start-up

• Damaged shaft seal • Bearings may become

• Reduced output

• The pump can become

damaged during

cavitation

• Noise at start-up and

possible overload of

the power supply

pump and potential risk

of breakdown

damaged

• Potential risk of

explosive gas leak

• Check service liquid

valve

• Check the liquid

supply

• Stop the pump

and wait until

the temperature

has dropped to

a sufficient level,

or lower the

temperature of the

service liquid inlet

• Check the stop valves

in the liquid supply

for leakage

• Increase the suction

pressure or lower the

temperature of the

service liquid

• Stop the pump

and contact the

manufacturer

Truck Master 2500

23

Page 24

7 SPARE PARTS AND TOOLS

7.1 Marking and identification

The pump is equipped with an identification plate as shown below.

CE CONFORMITY MARK

ORDER CONFIRMATION NO. / A NO.

Configuration example:

Type:

Model:

Rotation:

Rotor type:

Pump housing:

Shell:

Flow plates:

Mechanical shaft seals:

Gaskets:

Colour:

MANUFACTURING DATE / SERIAL NO.

PRODUCT CODE

TM 2500 R 0 S S B 0 0 T SD

Documentation:

24

Location of ID plate

DOC107939

Page 25

7.2 How to order

Example:

Model:

2500

Rotation:

Clockwise

Counter clockwise

Rotor type:

Welded AISI 316

Pump housing:

Cast iron EN-GJL-250; EN1561

Shell:

Cast iron EN-GJL-250; EN1561

Flow plates:

Cast iron EN-GJL-250; EN1561

Bronze GC-CU Sn10 DIN1705

TM 2500 R 0 S S S 0 0 P SD

2500

R

L

0

S

S

S

B

Mechanical shaft seals:

NBR / AISI 316

Gaskets:

Oakenstrong

Colour:

Grey primer

Truck Master Orange

On request

Documentation:

Samson standard

ATEX Zone 1

ATEX Zone 0

Truck Master 2500

0

0

P

T

X

SD

X1

X5

25

Page 26

8

11

9

26

31

7.3 Spare parts

56

53

52

51

35

1

5

6

*

13

44

50

49

16

45

12

2

24

*

48

3

36

22

34

*

17

32

15

4

26

41

58

47

*

Page 27

8

1

26

10

19

21

55

57

54

40

*

14

33

23

31

18

20

7

43

38

25

*

26

30

27

42

29

39

*

37

*

46

28

*

1

9

*

*

- Included in gasket set.

*

DOC1627359_1

Truck Master 2500

27

Page 28

Pos. Part number Description Qty. Material

1 - Identification plate 1 Stainless steel

2 - Direction arrow 1 Aluminum

3 1615002 Pump housing 2 Cast iron

4 1615003 Bearing housing 2 Cast iron

5*

6*

7 1615045 Gasket set Truck Master 2500 1 -

8 1615012 Shell 1 Cast iron

9 1615045 Gasket set Truck Master 2500 1 -

10*

11 1615045 Gasket set Truck Master 2500 1 -

12 1615017 Retainer 2 Stainless steel

13 1615019 Bearing cover DE 1 Cast iron

14 1615020 Bearing cover NDE 1 Cast iron

15 1615021 Rear cap 2 Stainless steel

16 1615022 Foot bracket 2 Steel

17 1615024 Pipe fitting 1 Brass

18 1615025 Pipe for water supply 1 Stainless steel

19 1615030 Plug 2 Brass

1615005 Rotor R 1 Stainless steel

1615034 Rotor L 1 Stainless steel

1615010 Flow plate 1 Cast iron

1615036 Flow plate 1 Bronze

1615014 Flow plate 1 Cast iron

1615038 Flow plate 1 Bronze

20 1620203 Bush 4 Sintered Bronze

21 910300102 Allen screw 16 Steel

22 910100148 Washer 24 Stainless steel

23 910300072 Allen screw 4 Steel

24 910300075 Allen screw 16 Steel

25 910300080 Allen screw 4 Steel

26 910300182 Plug 6 Steel

27 910300184 Plug 2 Steel

28 910300185 Plug 4 Steel

29 1615040 Mounting sleeve 1 Brass

30 910300188 Plug 5 Steel

31 910300281 Plug 4 Steel

32 915000023 Parallel key 1 Steel

33* 915000050 Grease nipple 2 Steel

34 922000265 Mechanical shaft seal 2 Steel

35 1615045 Gasket set Truck Master 2500 1 -

* -See section 7.1 for identification of pump.

**-Optional. Not equipped as standard.

28

Page 29

Pos. Part number Description Qty. Material

36 1615045 Gasket set Truck Master 2500 1 -

37 1615045 Gasket set Truck Master 2500 1 -

38 1615045 Gasket set Truck Master 2500 1 -

39 1615045 Gasket set Truck Master 2500 1 -

40 1615045 Gasket set Truck Master 2500 1 -

41 1615045 Gasket set Truck Master 2500 1 -

42 925000246 Hose nipple 1 Brass

43 930000314 Ball bearing 1 Steel

44 1615045 Gasket set Truck Master 2500 1 -

45 910300455 Allen screw 6 Steel

46 910300476 Allen screw 8 Steel

47 930200020 Shaft nut 2 Steel

48 1624020 Sticker Warning! 2 Plastic foil

49** 1634773 Thread nipple 2 Brass

50** 915000215 Push-in nipple 2 Brass

51** 915000232 Clamp for automatic lubricator 2 Plastic

52** 915000225 Automatic lubricator LAGD 125/WA2 2 Plastic / grease

53** 915000214 Push-in nipple 2 Brass

54** 910300447 Allen screw 2 Stainless steel

55** 910100125 Washer 2 Stainless steel

56** 915000217 Plastic pipe 0,1 m Plastic

57** 915000217 Plastic pipe 0,1 m Plastic

58 930000317 Roler bearing spherical 1 Steel

* -See section 7.1 for identification of pump.

**-Optional. Not equipped as standard.

Truck Master 2500

29

Page 30

7.4 Adaptor

DBI dut for grease nipple cap, yellow

194830001614

HRC rubber element 180

193240004913

Half coupling HRC-F 180 For Taperlock 2517

293240004812

Taperlock bush 2517-48193230000411

Taperlock bush 2517-45193230000310

Sealing ring 50x7x8 DIN 3760A NBR TYpe: OA

19222002669

Grease nipple M8x1,25 H1

19150000508

Plug 3/4

” black conical hexagon.

3910300186

7

M12x55 Allen bolt DIN 912 stainless steel A4

4

9103000796

M20x75 Steel Bolt ISO 4014 8.8 FZV

2910000508

5

M20 Washer DIN 125-A 8.8 FZV

4

910000423

4

M20 Nut DIN 934 8.8 FZV29100004223

Flange for adapter and Parker motor model: F12-110/125 ISO, Machinined

116346232

Adapte; Machined

116150321

Title

Qty

Part numberPos

7

148

5

4

2

12

10

13

11

1 3

4

9

6

DOC1627361_2

Pos. Part number Description Qty. Material

1 1615032 Adaptor 1 Cast iron

2 1634623

3 910000422 M20 Nut 2 Steel

4 910000423 M20 Washer 4 Steel

5 910000508 M20x75 Bolt 2 Steel

6 910300080 M12x55 Allen bolt 4 Steel

7 910300186 Plug 3/4” 3 Steel

8 915000050 Grease nipple 1 Steel

9 922200266 Radial shaft seal 1 Rubber / Steel

10 932300003 Taperlock bush 1 Cast iron

11 932300004 Taperlock bush 1 Cast iron

12 932400048 Half coupling 2 Cast iron

13 932400049 Rubber element 1 Rubber

14 948300016 DBI dut for grease nipple cap 1 Plastic

Flange for adaptor

Parker motor model: F12-110/125 ISO

1 Cast iron

30

Page 31

7.5 Gasket set

DOC11587

Pos. Part number Description Qty. Material

7 1615011 Gasket for pump housing / flow plate 1 mm 2 Paper

1615013 Gasket for shell / flow plate 0,5 mm 2 Paper

9

11 1615015 Gasket for pump cover / housing 5 mm 2 Rubber

35 922100085 O-ring Ø134,30x5,70 2 Rubber

36 922100370 O-ring Ø20,0x2,5 2 Rubber

37 922100371 O-ring Ø23,39x3,53 4 Rubber

38 922100368 O-ring Ø113,97x2,62 3 Rubber

39 922100369 O-ring Ø30,0x3,0 4 Rubber

40 922200225 Radial shaft seal 60x80x8 2 Rubber / Steel

41 922200266 Radial shaft seal 50x72x8 1 Rubber / Steel

44 930200016 Lock washer 2 Steel

1615023 Gasket for shell / flow plate 0,8 mm 2 Paper

1615029 Gasket for shell / flow plate 1 mm 2 Paper

See spare parts drawing (DOC1627359_1) for positions.

Truck Master 2500

31

Page 32

2

6

1

3

5

4

7.6 Special tool set

Pos. Part number Description Qty. Material

1 1629239 Mandrel radial shaft seal Ø50 + Ø60 1 Plastic

2 1629237 Machined bearing cap complete 1 Steel

3 1629190 Bearing mounting tool set NDE 1 Steel

4 1629191 Bearing mounting tool set DE 1 Steel

5 1629235 Bearing tool set 1 Steel

6 1629240 Mounting sleeve for Ø60 mechanical shaft seal 2 Plastic

DOC1629241_1

32

Page 33

Notes:

Truck Master 2500

33

Page 34

Notes:

34

Page 35

Notes:

Truck Master 2500

35

Page 36

SAMSON PUMPS

Samson Pumps is the only company in the world to specialise exclusively in

liquid ring vacuum pumps. Samson pumps are made in Denmark and used

around the globe. We offer worldwide delivery, and we export to more than 80

countries around the world.

For over 40 years, our name has been synonymous with the strongest pumps

for vacuum trucks and tankers. We constantly adapt our products to meet the

changing needs of our customers. Today, it is not enough to simply produce a

pump. Products must be refined so the customer can concentrate on what they

do best. We therefore offer a wide range of standardised components that allow

our customers to build vacuum systems without the need for specialist in-house

expertise.

Strength and durability are our hallmarks! We have often heard from customers

that our pumps are working in many years, and in most cases without the need

for maintenance or repair. This emboldens us to say that we have the strongest

program of pumps on the market.

E-Mail info@samson-pumps.com Samson Pumps A/S Petersmindevej 21

Web www.samson-pumps.com Phone | +45 87 50 95 70 DK-8800 Viborg

Loading...

Loading...