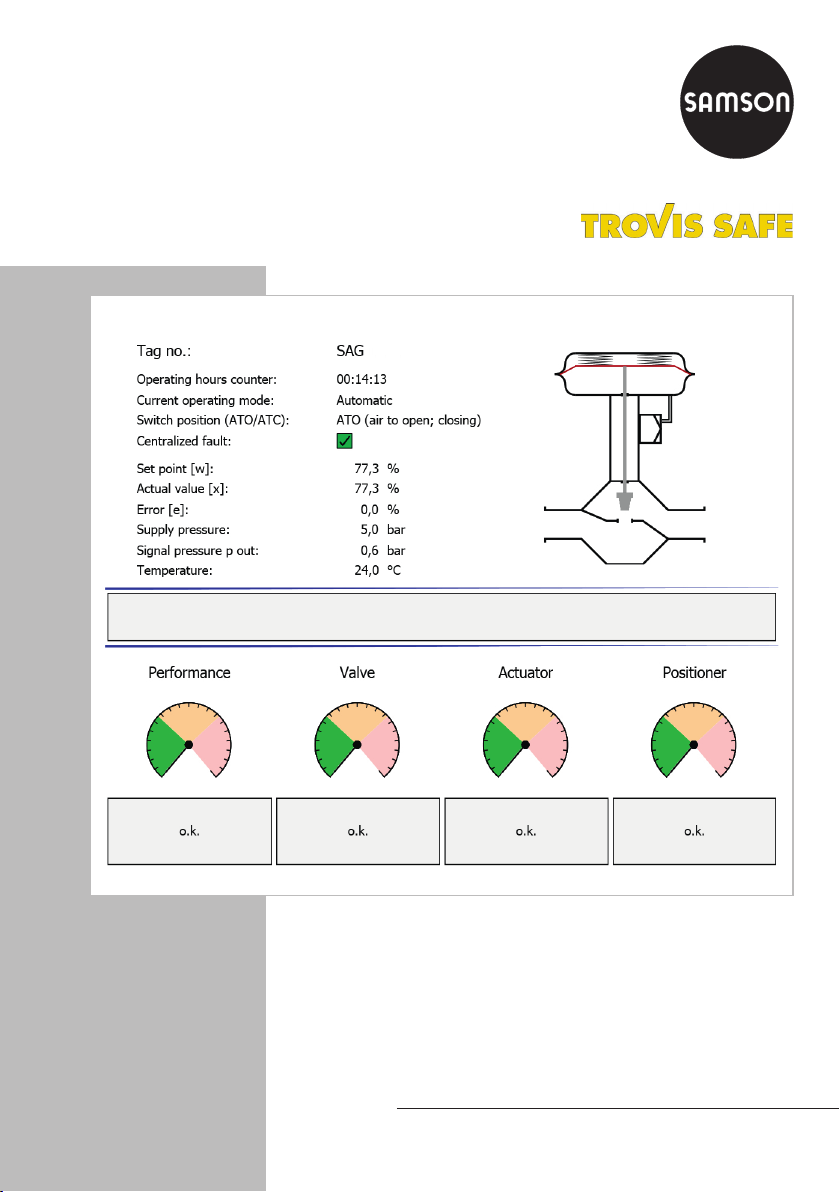

Samson TROVIS SAFE 3730 Series, TROVIS SAFE 3730-6, 3730 Series, 3730-6 Operating Instructions Manual

Page 1

Series 3730

TROVIS SAFE 3730-6 Electropneumatic

Positioner

EXPERTplus Valve Diagnostics

Operating Instructions

EB 8389-1S EN

Firmware version 1.1x

Edition May 2015

Page 2

Denition of signal words

DANGER!

Hazardous situations which, if not

avoided, will result in death or serious

injury

WARNING!

Hazardous situations which, if not

avoided, could result in death or serious injury

2 EB 8389-1S EN

NOTICE

Property damage message or malfunction

Note:

Additional information

Tip:

Recommended action

Page 3

Contents

1 Description ....................................................................................................7

1.1 General ........................................................................................................7

1.2 Start-up .........................................................................................................9

1.3 Diagnostic functions .....................................................................................10

1.3.1 Type of application.......................................................................................11

1.3.2 Assessment ..................................................................................................11

2 Monitoring ..................................................................................................13

2.1 Status messages ...........................................................................................13

2.1.1 Resetting status messages .............................................................................13

2.1.2 Condensed state ..........................................................................................17

2.2 Logging .......................................................................................................18

3 Data logger ................................................................................................21

3.1 Permanent data logging ...............................................................................21

3.2 Triggered data logging ................................................................................. 22

3.2.1 Triggered by condensed state ........................................................................22

3.2.2 Triggered by set point, valve position, set point deviation or signal pressure ......23

3.2.3 Triggered by binary input .............................................................................24

3.2.4 Triggered by internal solenoid valve/forced venting ........................................25

3.2.5 Triggered by set point or internal solenoid valve/forced venting .......................25

4 Valve signature ...........................................................................................27

4.1 Reference graphs .........................................................................................28

4.1.1 Analysis and monitoring ...............................................................................28

4.2 Valve signature, signal pressure(x) .................................................................29

4.2.1 Analysis and monitoring ...............................................................................30

4.3 Course of supply pressure .............................................................................31

4.3.1 Analysis and monitoring ...............................................................................32

4.4 Valve signature, friction(x) ............................................................................33

4.4.1 Analysis and monitoring ...............................................................................34

4.5 Resetting single status messages ....................................................................34

5 On/off valve ...............................................................................................37

5.1 Diagnostics for on/off valve ..........................................................................38

5.2 Analysis and monitoring ...............................................................................39

5.3 Resetting single status messages ....................................................................40

EB 8389-1S EN 3

Page 4

Contents

6 Valve position x histogram ..........................................................................41

6.1 Analysis and monitoring ...............................................................................42

6.2 Resetting single status messages ....................................................................42

7 Set point deviation e histogram ....................................................................44

7.1 Analysis and monitoring ...............................................................................45

7.2 Resetting single status messages ....................................................................46

8 Cycle counter histogram ..............................................................................49

8.1 Analysis and monitoring ...............................................................................50

8.2 Resetting single status messages ....................................................................50

9 Leakage sensor ...........................................................................................53

9.1 Start-up of the leakage sensor .......................................................................54

9.1.1 Manufacturer reference ................................................................................54

9.1.2 Process reference .........................................................................................57

9.2 Short-term monitoring ..................................................................................62

9.2.3 Resetting single status messages ....................................................................63

9.3 Long-term monitoring ...................................................................................63

9.3.1 Resetting single status messages ....................................................................63

9.4 Sound level(x) ..............................................................................................64

9.4.2 Resetting single status messages ....................................................................64

10 Course of end position .................................................................................67

10.1 Analysis and monitoring ...............................................................................68

10.2 Resetting single status messages ....................................................................68

11 Valve dead band ......................................................................................... 69

11.1 Resetting single status messages ....................................................................70

12 Partial stroke test (PST) ................................................................................73

12.1 Start triggered by the set point ......................................................................78

12.2 Start triggered by the binary input.................................................................78

12.3 Analysis and monitoring ...............................................................................79

12.4 Resetting single status messages ....................................................................80

13 Full stroke test (FST) .....................................................................................83

13.1 Analysis and monitoring ...............................................................................87

4 EB 8389-1S EN

Page 5

Contents

13.2 Resetting single status messages ....................................................................87

14 SIL operator test ..........................................................................................88

14.1 Analysis and monitoring ...............................................................................90

15 Binary input ................................................................................................ 91

®

16 Dynamic HART

variables ............................................................................93

17 Appendix ....................................................................................................95

17.1 Code list ......................................................................................................95

17.2 Error messages and recommended corrective action .....................................102

17.3 Diagnostic data points saved in a non-volatile memory ................................. 107

17.4 Resetting parameters ..................................................................................108

EB 8389-1S EN 5

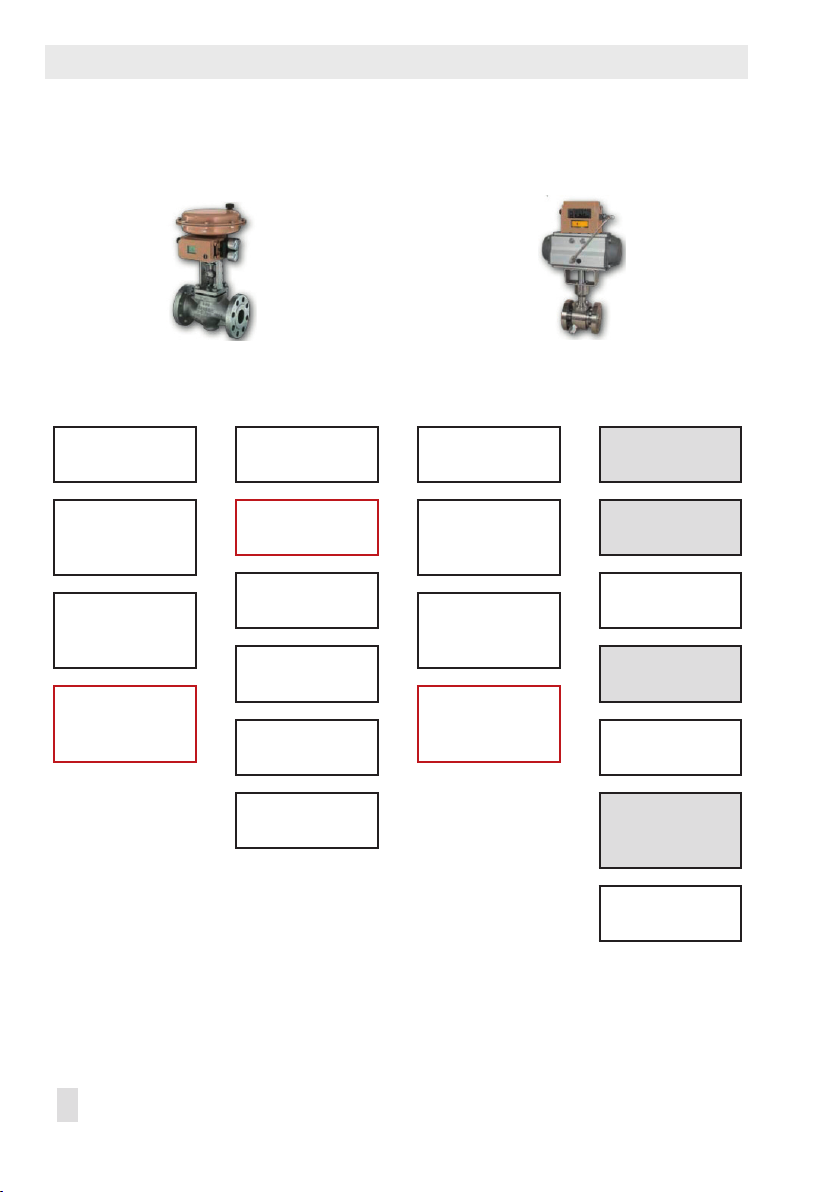

Page 6

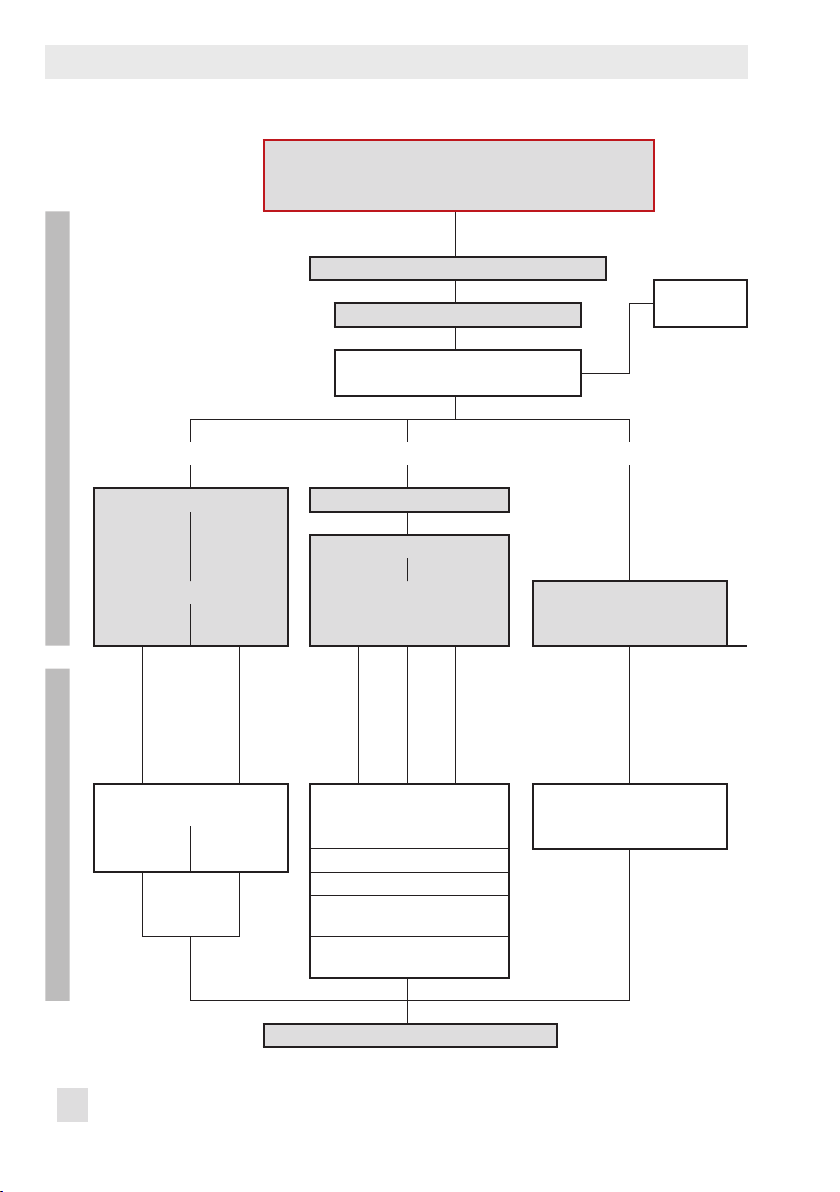

Overview

Throttling service

On/off service

No conguration

required for

monitoring

Travel histogram

u Section 6

Set point deviation

histogram e

u Section 7

Cycle counter

histogram

u Section 8

Course of end

position

u Section 10

Note:

− Tests highlighted in red border require an initialization with valve signature

− Tests highlighted in gray can optimize the proper functioning of safety equipment according to IEC61508 and IEC61511,

provided these tests are performed regularly.

Conguration

required for

diagnosis

Data logger

u Section 3

Valve signature

u Section 4

Packing

u Section 8

Leakage sensor

u Section 9

Valve dead band

u Section 11

Full stroke test (FST)

u Section 13

No conguration

required for

monitoring

Travel histogram

u Section 6

Set point deviation

histogram e

u Section 7

Cycle counter

histogram

u Section 8

Course of end

position

u Section 10

Conguration

required for

diagnosis

Data logger

u Section 3

On/off diagnosis

u Section 5

Packing

u Section 8

Leakage sensor

u Section 9

Valve dead band

u Section 11

Partial stroke test

(PST)

u Section 12

Full stroke test (FST)

u Section 13

6 EB 8389-1S EN

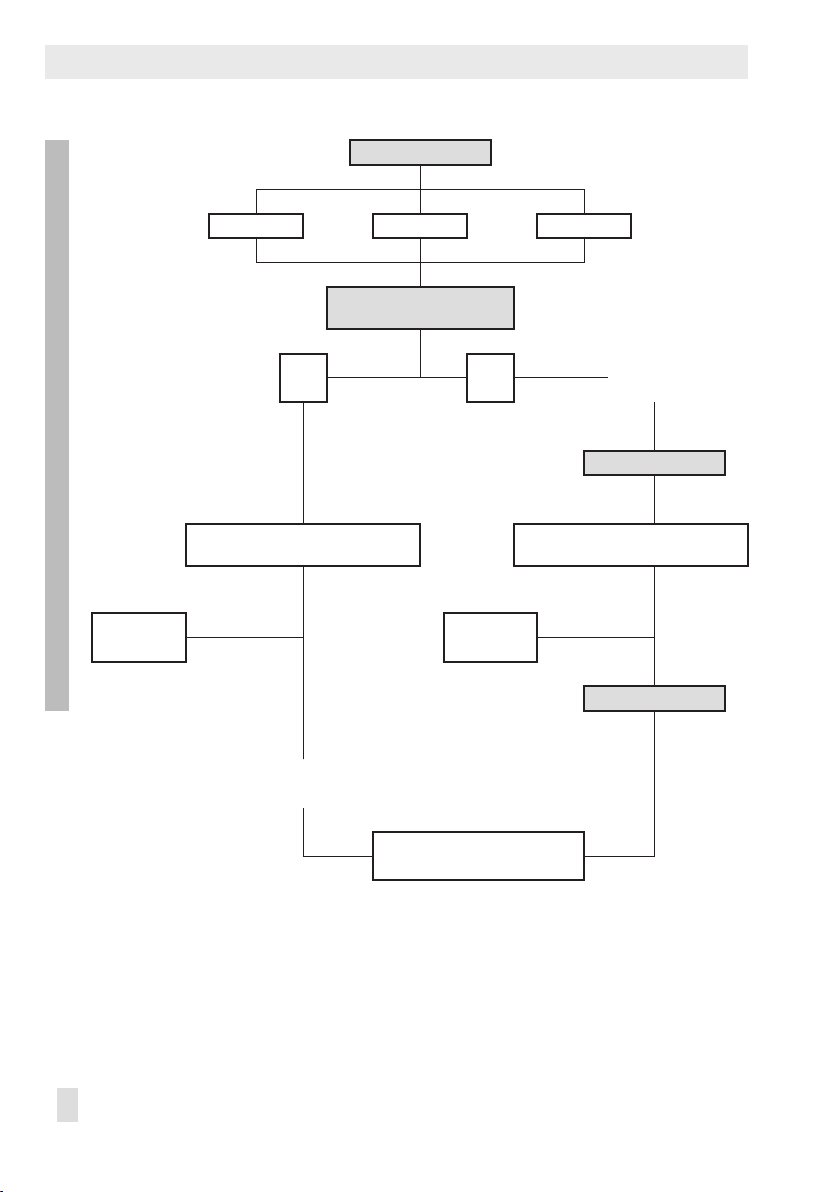

Page 7

Description

1 Description

1.1 General

These instructions supplement the standard

Mounting and Operating Instructions for the

TROVIS SAFE3730-6 Positioner

(uEB8384-6S EN).

EXPERTplus is a diagnostic rmware inte-

grated into the positioner which allows the

predictive, status-oriented maintenance of

valves with pneumatic actuators.

EXPERTplus records the valve condition while

the process is running (in automatic mode)

and generates messages on the required

maintenance work. In addition, numerous

tests can be performed in manual mode to

pinpoint emerging faults.

The diagnostic functions of EXPERTplus are

completely integrated into the positioner. Diagnostic data are compiled, saved and ana-

lyzed in the positioner itself. Classied status

messages on the state of the valve are generated from the analysis.

All the parameter settings that are changed

must also be downloaded onto the positioner to allow them to become effective.

Local operation

Some parameters can be changed at the positioner as well as over the operator interface.

T

he positioner code of these parameters are

written in parentheses. Refer to the Mounting

and Operating Instructions of the TROVIS

SAFE3730-6 Positioner (EB8384-6SEN) for

a list of all parameters that can be changed

at the positioner.

The operation described in the following

sections illustrates operation using TROVISVIEW4. The default settings of the positioner and TROVIS-VIEW4 are written in

square brackets [ ]. Settings highlighted in

gray refer to operation using TROVISVIEW4.

Operation using TROVIS-VIEW 4/DD/DTM/

eDD

EXPERTplus allows the parameters to be

viewed or changed using the TROVIS-

VIEW4 software or DD/DTM/eDD.

TROVIS-VIEW4 · SAMSON operator inter-

face used to congure various SAMSON de-

vices

− DTM · Device type manager to describe

the device and communication properties

− DD/eDD · Device description/enhanced

device description

EB 8389-1S EN 7

Page 8

DescriptionDescription

Initialization mode

â â â

MAX NOM MAN/MAN2

â

Initialization including valve

signature

ß à

Yes

START-UP

â â

Zero

Valve signature (D1)

Code 81 Code 81

ß Not successful

ß Successful

Automatic change to

AUTO operating mode

à

No

Throttling or on/off service

Later recording of

reference graphs

â

Operating mode = MAN

Valve signature (D1)

All reference values are overwritten!

ß Not successful

â

Operating mode = AUTO

ß

8 EB 8389-1S EN

Page 9

Description

1.2 Start-up

The positioner must be initialized to use the

full scope of the valve diagnostics. During initialization the positioner adapts itself optimally to the friction conditions and the signal

pr

essure required by the control valve. The

positioner can be initialized using one of the

following initialization modes: maximum

range (MAX), nominal range (NOM), manual

setting 1 (MAN) and manual setting 2

(MAN2).

− Maximum range (MAX)

Initialization mode for simple start-up of

valves with two clearly dened mechanical end positions, e.g. three-way valves

− Nominal range (NOM)

Initialization mode for all globe valves

− Manual setting 1 (MAN)

Initialization mode for globe valves re-

quiring OPEN position to be entered

manually

− Manual setting 2 (MAN2)

Initialization mode for globe valves re-

quiring the end positions (OPEN and

CLOSED positions) to be entered manually

The type of application, pressure limit and

the start-up parameters required for the selected initialization must be entered to initialize the positioner.

Note:

Positioner start-up is described in detail

in the associated Mounting and Operating Instructions (

uEB8384-6S EN

).

The monitoring of friction, supply pressure,

leakage, actuator springs, course of end position and zero point shift requires additional

reference tests of the valve signature to be

performed. Refer to Section 4. The reference

tests required for the diagnostic functions

cannot be performed if the positioner has

been initialized in the substitute calibration

(SUB) mode. By setting 'Initialization including valve signature' = Yes, the positioner re-

cords the reference data automatically after

initialization.

Start-up

− Type of application (Code 49 - h0): Control

valve, [On/off valve]

− Initialization mode (Code 6): [Maximum

range(MAX)], Nominal range (NOM), Manual

setting 1 (MAN) or Manual setting 2 (MAN2)

− Initialization including valve signature

(Code 48 - h0): [Yes]

− Pin position (Code 4): [Off], 17, 25, 35, 50,

70, 100, 200 mm, 90°

− Pressure limit (Code 16): 1.4 to [7.0] bar

During positioner initialization, the 'Kp level'

and 'Tv level' are optimally set. If the posi-

tioner tends to overshoot impermissibly due

to other disturbances, the proportional-action coefcient (Kp level) and derivative-action time (Tv level) can be adapted accordingly. Increment the derivative-action time

until the desired behavior is reached. When

the maximum value of 4 is reached for the

derivative-action time, the proportional-ac-

tion coefcient can be reduced in steps.

EB 8389-1S EN 9

Page 10

Description

NOTICE

Kp level changes affect the set point

deviation.

After changing the proportional-action coef-

cient 'Kp level', we recommend to recalibrate the ne lter in the positioner. Use the

'Fine-tuning after Kp change' function for

this.

Start-up > Control parameters

− Proportional-action coefcient Kp level

(Code 17): 0 to 17, [7]

− Derivative-action time Tv level (Code 18): Off, 1

to 4, [2]

− Fine-tuning after Kp change

1.3 Diagnostic functions

There are two different types of diagnostic

functions:

1. Monitoring functions

Data are compiled, saved and analyzed

by the positioner while the process is

running without disrupting the process.

The positioner follows the set point to po-

sition the valve. A classied status alarm

or fault alarm is generated if the positioner detects an event.

2. Dynamic tests

Similar to the monitoring function, data

are compiled, saved and analyzed by

the positioner. However, in this case, the

valve position is not determined by the

set point, but by the settings of the test.

The dynamic tests can only be started

when the conditions in the plant allow it

(e.g. plant shutdown or service work in

the workshop). For reasons of safety, the

dynamic tests, except for partial stroke

testing, can only be performed in the

MAN operating mode.

A dynamic test is stopped and the positioner changes to the fail-safe position

when the electrical signal falls below a

certain level or when the solenoid valve

is triggered or the forced venting function is activated.

10 EB 8389-1S EN

Page 11

1.3.1 Type of application

Different diagnostic functions are available

depending on the type of application selected in EXPERTplus. The types of application

'Control valve' and 'On/off valve' are

available. Depending on the type of application selected, the positioner behaves differently in the automatic mode (AUTO):

− Control valve

The positioner uses the set point to position the valve.

The valve position (current position) appears in % on the display.

− On/off valve

Discrete analysis of the set point

The valve position (current position) in %

and O/C (Open/Close) appear in alternating sequence on the display. See

uSection 5.

Description

1.3.2 Assessment

Table 1 shows the diagnostic functions and

their statements on the condition of the valve

depending on the type of application.

EB 8389-1S EN 11

Page 12

Description

Description

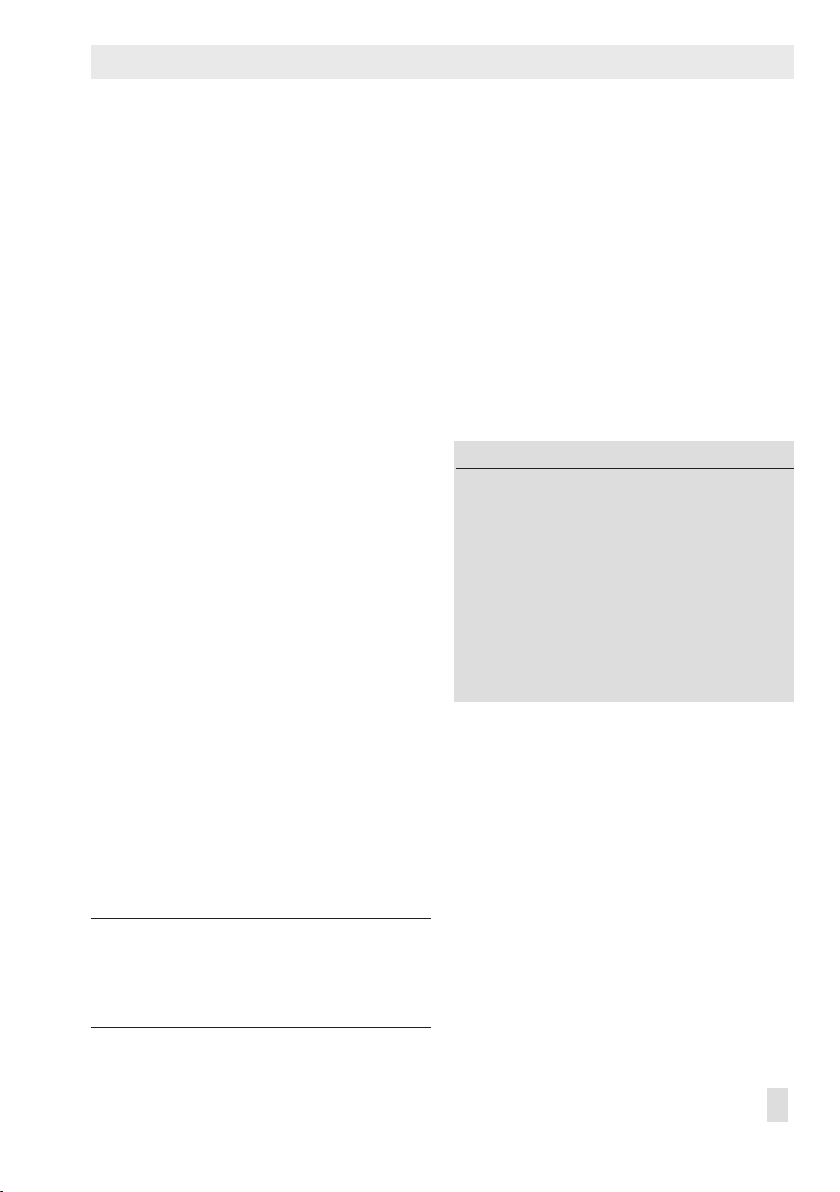

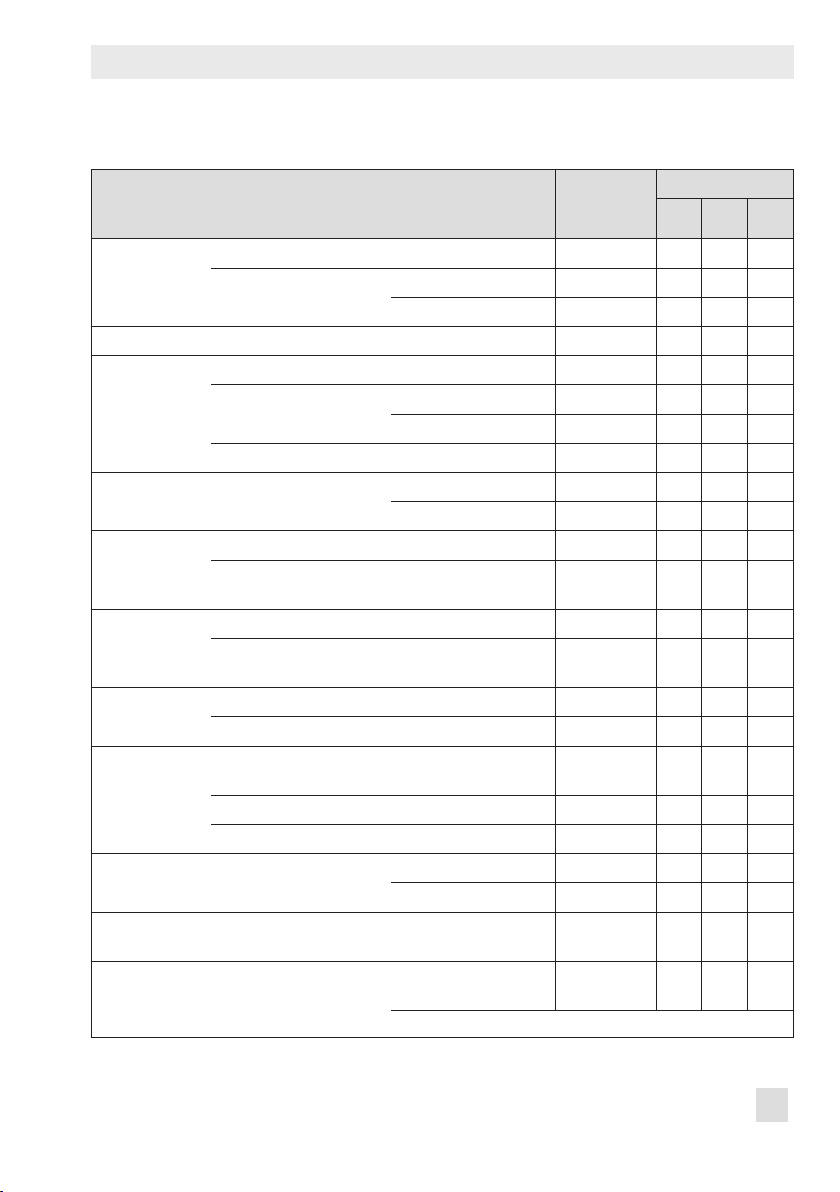

Table 1: Diagnostic functions and test analysis

Control

Diagnostic functions

valve

Monitoring

Data logger • • Depending on trigger status

Valve signature •

On/off valve – • − Breakaway time

Valve position

histogram

Set point deviation

histogram

Cycle counter

histogram

Leakage sensor • • − Seat leakage u 9 on page 53

Course of end

position

Dynamic tests

Valve dead band • • − Dead band u 11 on page 69

Partial stroke test

(PST)

Full stroke test (FST) • • − Overshooting

• Full scope of functions

U Function is performed, but not analyzed

– Function is not performed

On/off

valve Assessment See section

selected

U

− Change in friction

− Supply pressure

− Defective actuator springs

− Pneumatic leakage

− Transit time

− Valve end position

•

U

− Change in manipulated variable

range

− Manipulated variable range

• • − Manipulated variable range

limitation

− Seat leakage

− Positioner-valve linkage

− Average set point deviation

• • − Packing leakage

− Dynamic stress factor

• • − Course of end position

− Zero shift

• • − Overshooting

− Dead time

− T86

− Settling time

− Dead time

− T86

− Settling time

u 3 on page 21

u 4 on page 27

u 5 on page 37

u 6 on page 41

u 7 on page 44

u 8 on page 49

u 10 on page 67

u 12 on page 73

u

13 on page 83

12 EB 8389-1S EN

Page 13

Monitoring

2 Monitoring

2.1 Status messages

The valve diagnostics integrated into the po-

sitioner generates classied status messages.

Messages generated from the analysis of the

diagnosis can be classied according to the

possible causes. See u Section 4 to 13.

The following classications are possible:

− No message

If an event is classied as “No message”,

this event does not have any affect on the

condensed state.

− Function check

Test or calibration procedures are performed in the positioner. The positioner is

temporarily unable to perform its control

task as long as the procedure is taking

place.

− Maintenance request/maintenance re-

quired

The positioner still performs its control

task (with restrictions). A maintenance

demand or above average wear has

been determined. The wear tolerance will

soon be exhausted or is reducing at a

faster rate than expected. Maintenance is

necessary in the medium term.

− Out of specication

The positioner is running outside the

specied operating conditions.

− Failure

The positioner cannot perform its control

task due to a functional fault in the positioner itself or in one of its peripherals or

an initialization has not yet been successfully completed.

You can view these messages in TROVIS-

VIEW4 in the Diagnostics folder (> Monitor-

ing) and its subfolders. The 'Positioner status', 'Valve status', 'Actuator status' and

'Valve position status' messages provide a

condensed state of the status messages of

each subfolder.

2.1.1 Resetting status messages

When a status message is generated, you

should rst locate the source of the fault and

take action to remedy it.

For recommended action concerning the sta-

tus messages see u Section 17.2.

Status messages can be reset individually or

using the reset function. Table 2 on page

15 contains an overview on how the diagnosis can be reset. Resetting is performed

in the Diagnostics folder (> Service/maintenance > Reset).

If you want to keep measured data and the

analysis after resetting the positioner, it is

possible to upload them onto a computer.

Resetting single status messages

− Status messages represented by a code

in the positioner can be conrmed at the

positioner itself. Select the error code

and conrm it by pushing the rotary

pushbutton. See the standard instructions

of the positioner u EB 8384-6S EN.

− On resetting histograms and diagrams,

the data for short-term monitoring are

also reset.

EB 8389-1S EN 13

Page 14

Monitoring

− Resetting measured data does not cause

the diagnostic parameters and reference

value to be reset as well.

− The positioner does not need to be re-ini-

tialized after resetting.

Reset measured diagnostic data

Code 36 - Diag

− Parameters are reset as described in u

Section 17.4.

− Resets diagnostics assessment.

− Reference values remain unchanged.

− Status classication and data logs re-

main saved.

− The positioner does not need to be re-ini-

tialized after resetting.

− If the diagnostic data are to be reset at

regular intervals, enter the time in "Desired time until ‘Reset measured diagnostic data" (Code 48 - h3). The setting

"00:00:00" causes the resetting at regular intervals to be deactivated.

Reset start-up parameters

Code 36 - Std

− Parameters are reset as described in

u Section 17.4.

− Resets diagnostics assessment.

− Reference values are deleted.

− Status classication remains unchanged.

− Data logs are reset.

− The positioner must be re-initialized after

resetting.

Reset to default settings

Code 36 - DS

− Parameters are reset as described in

u Section 17.4.

− Resets diagnostics assessment.

− Reference values are deleted.

− Status classication and data logs are

deleted.

− The positioner must be re-initialized after

resetting.

Note:

Before mounting the positioner on a

new control valve, perform a reset by

selecting the command 'Reset to de-

fault settings' (Code 36 - DS) and re-

initialize the positioner.

14 EB 8389-1S EN

Page 15

Monitoring

Monitoring

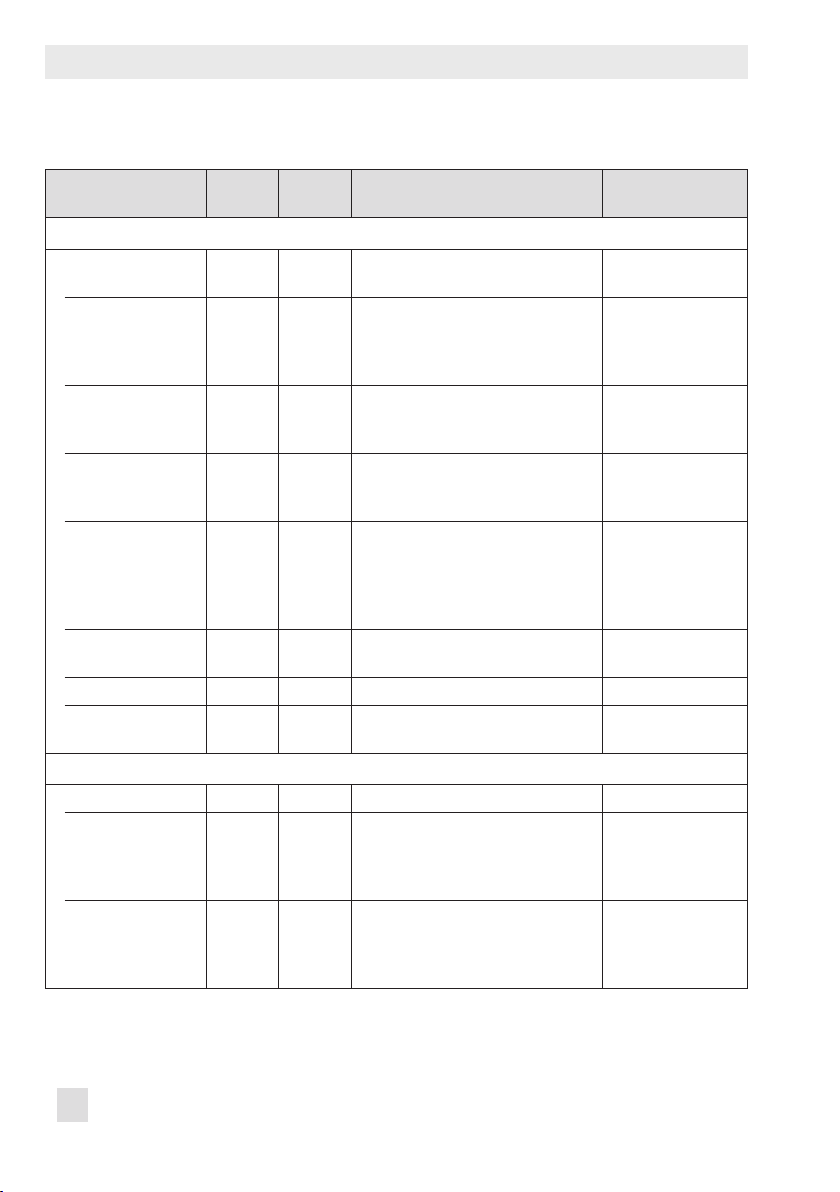

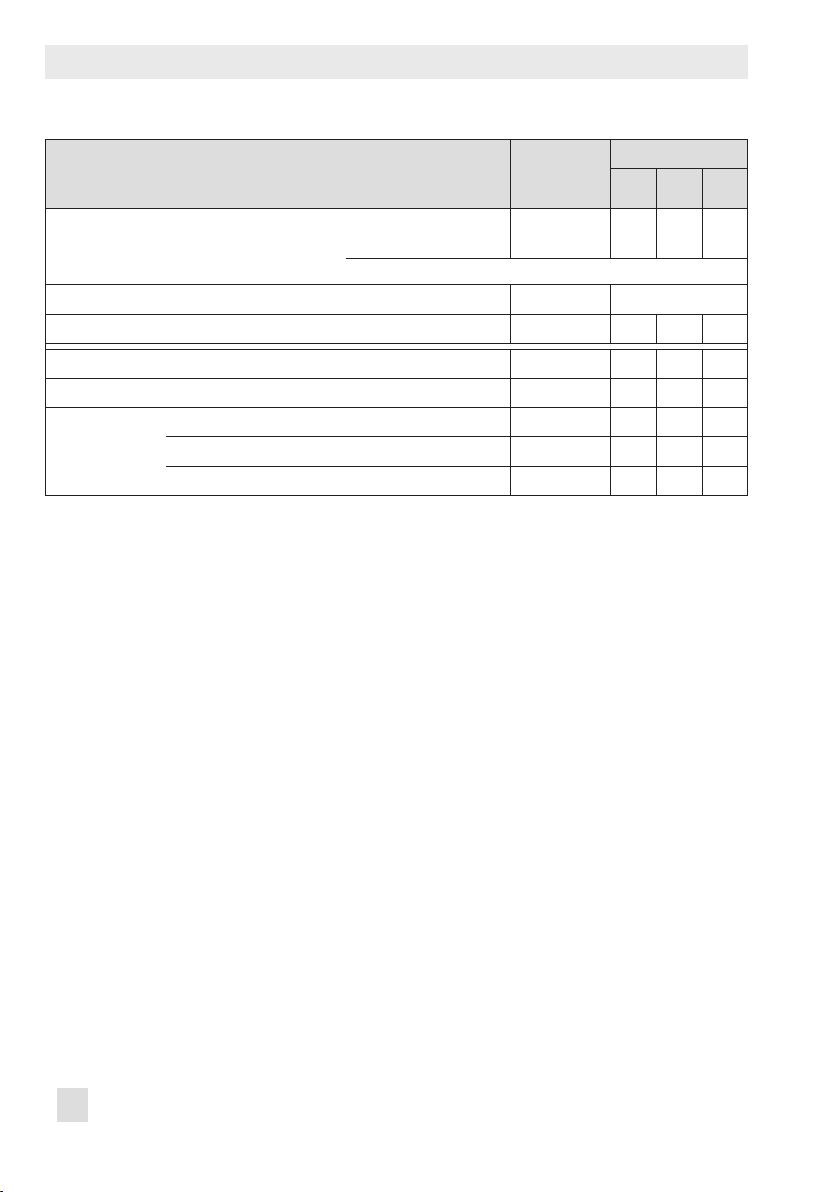

Table 2: Resetting the diagnosis

Resetting

single status

messages

Reference

graphs

Data logger Conguration and measured values NO YES YES YES

Valve signature Signal pressure(x) Measured values YES YES YES YES

On/off valve Conguration YES NO YES YES

Valve position x histogram Measured values YES YES YES YES

Set point deviation e histogram Measured values YES YES YES YES

Cycle counter histogram Measured values YES YES YES YES

Leakage sensor Short-term monitoring 'Sensitivity sound level'

Course of lower end position Measured values YES YES YES YES

Valve dead band Conguration and

Partial stroke test (PST) Conguration and

Valve signature NO NO YES YES

Leakage sensor Manufacturer reference YES NO YES YES

Process reference YES NO YES YES

Course of supply pressure Conguration NO NO YES YES

Measured values YES YES YES YES

Friction(x) Measured values YES YES YES YES

Measured values YES YES YES YES

Short-term monitoring 'Sampling time' and

measured values

Short-term monitoring 'Sampling time' and

measured values

Short-term monitoring Measured values YES YES YES YES

and measured values

Long-term monitoring Measured values YES YES YES YES

Sound level(x) Measured values YES YES YES YES

Reference value YES NO YES YES

measured values

measured values

* Except for 'Sampling time' parameter

YES YES YES YES

YES YES YES YES

YES YES YES YES

YES YES YES YES

YES NO* YES YES

Code 36

Diag Std DS

EB 8389-1S EN 15

Page 16

Monitoring

Resetting

single status

messages

Full stroke test (FST) Conguration and

measured values

* Except for 'Sampling time' and 'Max. test duration' parameters

Alarm settings NO See uSec.17.4

Status classication according to NAMUR107 NO NO NO YES

All logged messages, see u Section 2.2 YES NO YES YES

Operating hours counter NO NO NO NO

Device in operation NO NO YES YES

Device switched on since initialization NO NO YES YES

Device in operation since initialization NO NO YES YES

YES NO* YES YES

Code 36

Diag Std DS

16 EB 8389-1S EN

Page 17

Monitoring

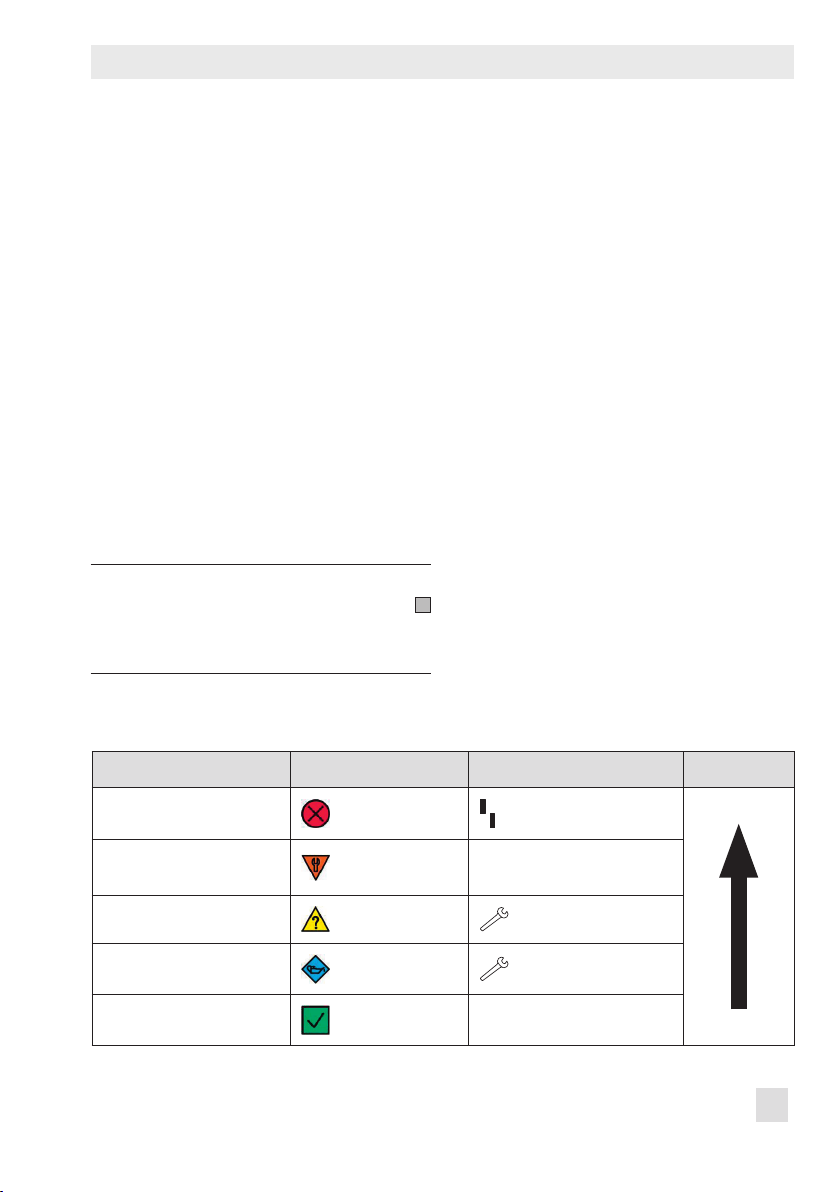

2.1.2 Condensed state

To provide a better overview on the condition of the positioner, all status messages are

summarized in a condensed state which is

made up from a summary of all classied

messages in the positioner. The status message with the highest priority determines

which condensed state is set.

The condensed state appears in TROVIS-

VIEW4 on the right-hand side of the info

bar and in the Measured process values

folder. See u Table 3 for a description of the

icons and their meaning.

Additionally, the condensed state can be

used to trigger the data logger. See uSection 3.2.1.

Note:

The condensed state is marked by

until the positioner data have been uploaded.

The condensed state can be read in the positioner display in Code 48 - d6. See u Table

3.

Condensed state at the fault alarm output

The condensed state also be read out at the

fault alarm output if one of the following

conditions occurs:

1. Condensed state 'Failure' is activated.

2. Condensed state 'Function check' is activated and the fault alarm output is activated.

3. Condensed state 'Maintenance required'

or 'Out of specication' is activated and

the fault alarm output is activated.

Table 3: Condensed state reading

Status message TROVIS-VIEW 4/DTM Positioner Priority

Failure

Function check

Out of specication

Maintenance request/

maintenance required

No message, OK

EB 8389-1S EN 17

red

orange

yellow

blue

green

Text e.g. TESTING, TUNE or

TEST

blinking

Page 18

Monitoring

Device settings > Alarm settings

− Fault alarm at condensed state 'Function

2.

check' (Code 32): Yes

3. − Error message in case of 'Maintenance re-

quired' and 'Out of specication' con-

densed states (Code 33): Yes

2.2 Logging

The last 30 generated messages are saved in

the positioner with a time-stamp (logged by

the operating hours counter) and with details

on how long the message exists.

You can view these messages in TROVISVIEW4 in the Diagnostics folder (> Monitor-

ing > Logging).

Logging starts automatically 15 minutes after

initialization. It does not need to be activated

by the user.

Messages are logged when:

− Their status classication is not 'No mes-

sage'.

− Their recording in the logging is activat-

ed.

− The 'Internal solenoid valve/forced vent-

ing/supply pressure' message is only additionally logged when the time entered

in 'Min. interval for new logging of internal solenoid valve' has elapsed between

the generation of two 'Internal solenoid

valve/forced venting/supply pressure'

messages.

Note:

Logging can only be deactivated when

the associated status classication is

set to 'No message'.

Device settings > Alarm settings > Status

classication > Logging

− Supply pressure: [Yes], No

− Change in friction: [Yes], No

− Seat leakage: [Yes], No

− Packing leakage: [Yes], No

− Pneumatic leakage: [Yes], No

− Defective actuator springs: [Yes], No

− Manipulated variable range limitation: [Yes],

No

− Course of end position: [Yes], No

− Positioner-valve linkage: [Yes], No

− Manipulated variable range: [Yes], No

− Change in manipulated variable range: [Yes],

No

− Partial stroke test (PST) [Yes], No

− Full stroke test (FST): [Yes], No

− On/off valve: [Yes], No

− Code 50-58, 61, 63, 76, 81: [Yes], No

− Binary input: [Yes], No

− Data logger: [Yes], No

− Internal solenoid valve/forced venting/supply

pressure: [Yes], No

− Min. interval for new logging of internal

solenoid valve: 0 to 5000 s, [300 s]

18 EB 8389-1S EN

Page 19

The following messages are not logged if

they are generated due to a hardware error:

− Packing leakage

− Pneumatic leakage

− Manipulated variable range limitation

− Course of end position

− Positioner-valve linkage

− Manipulated variable range

− Change in manipulated variable range

In this case, only the original hardware error

is logged:

− x > range (Code 50)

− Internal solenoid valve/forced venting/

supply pressure (Code 54)

− Transit time not reached (Code55)

− Inconsistent data memory (Code 59)

− Internal device error (Code 60)

− x signal (Code 62)

− i/p converter (Code 64)

− Hardware (Code 65)

Monitoring

EB 8389-1S EN 19

Page 20

Monitoring

Data logger

â â

Permanent Triggered

â â

Sampling time

â

Start

START-UP

â

100 measured val-

(w, x, e, p

Function

1)

â â â â â

Con-

densed

state

â â â

Trigger condition

ues

) â

out

Triggered by

, x, e

w

or p

out

Trigger value

Trigger band

Trigger condition

Trigger lead time

Sampling time

Start

Solenoid

BE

valve/

forced

venting

w or solenoid

valve/forced

venting

Trigger value

Trigger band

Trigger condition

â

1)

â

Trigger event

â

Logged by operating hours

counter

â â

PROCESS

Measured values (w, x, e, pout) before trigger

event

(Number = Trigger lead/Sampling time)

Measured values (w, x, e, pout) after trigger event

+

(Number = 100 – Trigger lead/Sampling time)

â

Total 100 measured values (w, x, e, pout)

1)

The data logger is started by the software, e.g. TROVIS-VIEW 4

20 EB 8389-1S EN

Page 21

Data logger

3 Data logger

The data logger records the measured variables (valve position x, set point w, set point

deviation e and signal pressure p

corded data are plotted against time in a

graph.

Note:

The data logger is interrupted and

must be reactivated when one of the

following events occurs:

−

Failure of power supply of the positioner

−

Failure of power supply of the external solenoid valve

). The re-

out

3.1 Permanent data logging

The measured variables are logged at the

rate dened in 'Sampling time' and saved in

a circular buffer, which holds 100 data

points per measured variable at one time.

Note:

You can read the measured data

logged over the past 24 hours from

the 'Data logger' graph when the Diagnostics folder (> Data logger) is left

open over this period.

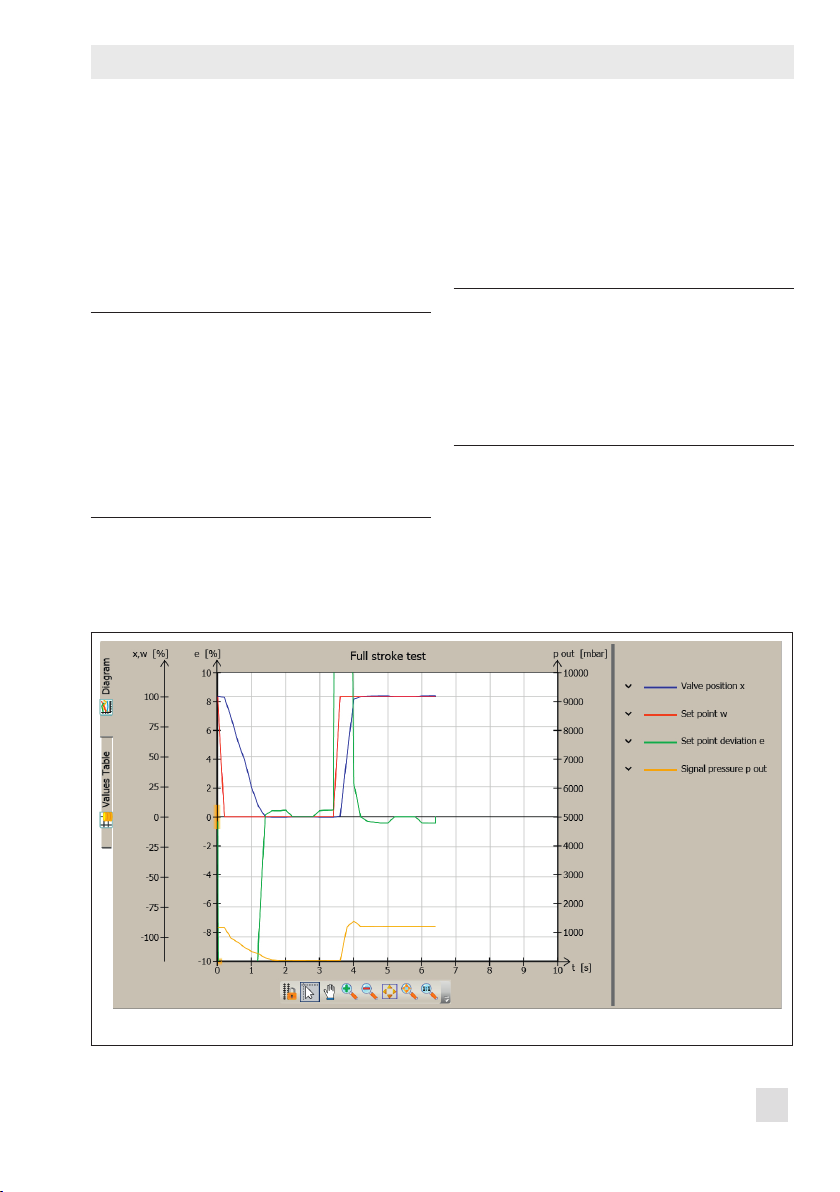

Fig. 1: Diagnostics > Data logger

EB 8389-1S EN 21

Page 22

Data logger

Dening parameters

1. Select 'Permanent' (Function).

2. Enter sampling time.

3. Start data logger.

The 'Test information' status indicates

'Test active'.

Diagnostics > Data logger

1.

− Function: [Permanent]

2. − Sampling time: 0.2 to 3600.0 s, [1.0 s]

3. − Start data logger

Note:

Right-click 'Cancel data logger' and

select 'Execute' to stop the data logger

('Test information' = 'Test not active').

3.2 Triggered data logging

Measured values are saved in a circular buf-

fer after the event dened in 'Triggered by'

has occurred (see u Section 3.2.1 to 3.2.5).

The event that has triggered data logging is

recorded. Data logging is terminated after

100 measured values per measured variable

have been saved in the circular buffer. The

'Sampling time' determines the time between

recordings. A 'Trigger lead time' greater

than 0 also leads to the measuring values

before the triggering event for the time selected being included in the 100 measured

values per measured variable. The 'Trigger

lead time' may include the value 100 x

'Sampling time' at the maximum.

Dening parameters

1. Select 'Triggered' (Function).

2. Select the triggering event.

3. Enter sampling time.

4. Start data logger.

The 'Test information' status indicates

'Test active'.

When the data logging is nished, the

Progress bar indicates 'Memory full, data

recording completed'.

Note:

Right-click 'Cancel data logger' and

select 'Execute' to stop the data logger

('Test information' = 'Test not active').

3.2.1 Triggered by condensed

state

The measured values are included in the triggered event when the condensed state dened in 'Triggered by condensed state' arises.

Note:

If 'Function check' is selected as the

condensed state ('Triggered by condensed state'), data are logged when

a dynamic test starts. Data from each

test start are logged.

Diagnostics > Data logger

1.

− Function: Triggered.

2. − Sampling time: 0.2 to 3600.0 s, [1.0 s]

3. − Triggered by: Condensed state

22 EB 8389-1S EN

Page 23

Data logger

rigger band

gg

w, x, y, e

ger band

w, x, y, e

rigger band

rigger band

w, x, y, e

− Trigger lead time:

0.0 s to 100 x 'Sampling time', [20.0 s]

− Triggered by condensed state: No message,

Function check [Maintenance required],

Maintenance demanded, Out of specication, Failure

4. − Start data logger

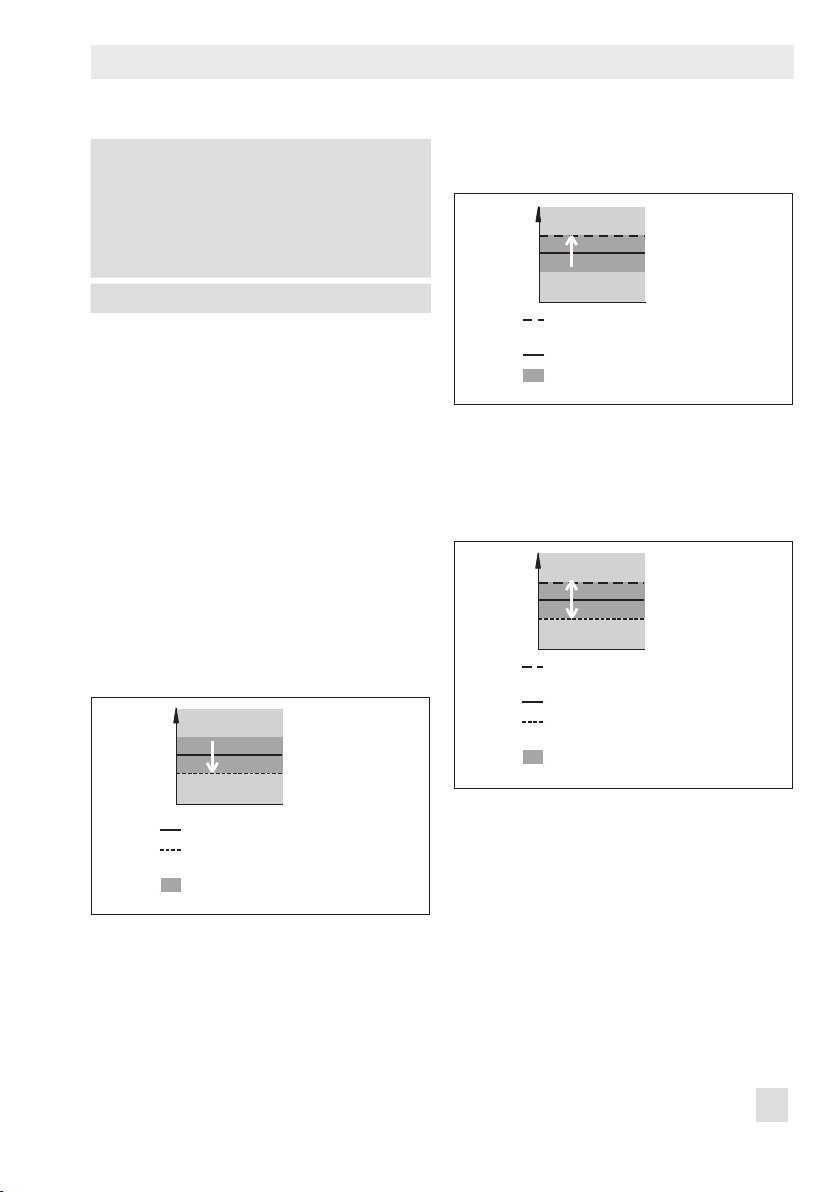

3.2.2 Triggered by set point,

valve position, set point

deviation or signal pressure

The measured values are included in the triggered data logging when the conditions for

the selected measured variable (set point w,

valve position x, set point deviation e or signal pressure p

'Trigger band' and 'Trigger condition' are

met.

'Trigger condition' = Decreasing signal/

lower band value undercut

) dened in 'Trigger value',

out

'Trigger condition' = Increasing signal/

upper band value exceeded

Upper band limit =

Trigger value

Trigger value

Trigger band

+ ½ Trig

The conditions for starting a trigger event

are met when the value falls below the limit

('Trigger value' – ½ 'Trigger band').

'Trigger condition' = Band exit

Upper band limit =

Trigger value + ½ T

Trigger value

Lower band limit =

Trigger value - ½ T

Trigger band

Trigger value

Lower band limit =

Trigger value – ½ T

er band

Tri

The conditions for starting a trigger event

are met when the value falls below the limit

('Trigger value' – ½ 'Trigger band') or exceeds the limit ('Trigger value' + ½ 'Trigger

band').

The conditions for starting a trigger event

are met when the value falls below the limit

This function is only active when 'Trigger

band' ≠ 0.

('Trigger value' – ½ 'Trigger band').

EB 8389-1S EN 23

Page 24

Data logger

ger band

w, x, y, e

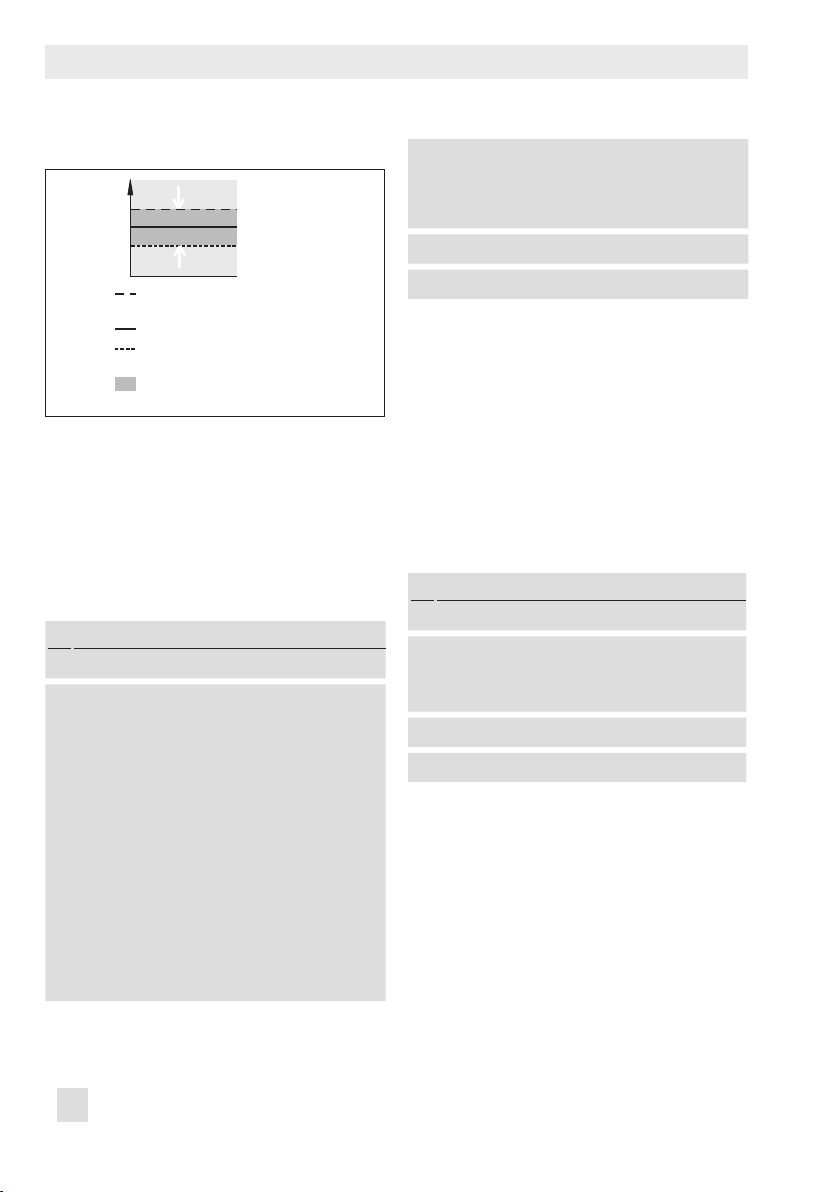

'Trigger condition' = Band entry

Upper band limit =

Trigger value

Trigger value

Lower band limit =

Trigger value - ½ Trigger band

Trigger band

+ ½ Trig

The conditions for starting a trigger event

are met when the value exceeds the limit

('Trigger value' – ½ 'Trigger band') or falls

below the limit ('Trigger value' + ½ 'Trigger

band').

This function is only active when 'Trigger

band' ≠ 0.

Diagnostics > Data logger

1.

− Function: Triggered

2. − Triggered by: Valve position, set point devi-

ation, signal pressure or set point

− Trigger value:

0.0 to 100.0 %, [99.0 %] (set point, valve

position, set point deviation)

0.0 to 7000.0 mbar, [99.0 mbar] (signal

pressure)

− Trigger band:

0.0 to 100.0 %, [99.0 %] (set point, valve

position, set point deviation)

0.0 to 10000.0 1/s, [99.0 1/s] (drive signal)

− Trigger lead time:

0.0 s to 100 x 'Sampling time', [20.0 s]

− Trigger condition: [Decreasing signal/lower

band value undercut], Increasing signal/up-

per band value exceeded, Band exit, Band

entry

3. − Sampling time: 0.2 to 3600.0 s, [1.0 s]

4. − Start data logger

3.2.3 Triggered by binary input

This setting is only active when a binary input is installed in the positioner. If this is not

the case, the Progress bar indicates 'Cannot

start data logger – trigger cannot be set'.

The measured values are included in the triggered data logging when the state of the binary input changes.

Diagnostics > Data logger

1.

− Function: Triggered

2. − Triggered by: Binary input

− Trigger lead time:

0.0 s to 100 x 'Sampling time', [20.0 s]

3. − Sampling time: 0.2 to 3600.0 s, [1.0 s]

4. − Start data logger

24 EB 8389-1S EN

Page 25

Data logger

3.2.4 Triggered by internal solenoid valve/forced

venting

This setting is only active when an internal

solenoid valve/forced venting is installed in

the positioner. See 'Internal solenoid valve/

forced venting' reading. If this is not the

case, the Progress bar indicates 'Cannot start

data logger – trigger cannot be set'.

The measured values are included in the triggered data logging when the solenoid valve

is triggered or the forced venting is activated.

Diagnostics > Data logger

1.

− Function: Triggered

2. − Triggered by: Internal solenoid valve/

forced venting

− Trigger lead time:

0.0 s to 100 x 'Sampling time', [20.0 s]

3. − Sampling time: 0.2 to 3600.0 s, [1.0 s]

4. − Start data logger

tions dened in 'Triggered by internal solenoid valve/forced venting“ or 'Triggered by

set point' are met.

Diagnostics > Data logger

1.

− Function: Triggered

− Triggered by: Set point or internal solenoid

valve/forced venting

− Trigger value: 0.0 to 100.0 %, [99.0%]

− Trigger band: 0.0 to 100.0 %, [99.0 %]

− Trigger lead time:

0.0 s to 100 x 'Sampling time', [1.0 s]

− Trigger condition: [Decreasing signal/lower

band value undercut], Increasing signal/up-

per band value exceeded, Band exit, Band

entry

3. − Sampling time: 0.2 to 3600.0 s, [20.0 s]

4. − Start data logger

3.2.5 Triggered by set point or

internal solenoid valve/

forced venting

This setting is only active when an internal

solenoid valve/forced venting is installed in

the positioner. See 'Internal solenoid valve/

forced venting' reading. If this is not the

case, the Progress bar indicates 'Cannot start

data logger – trigger cannot be set'.

The measured values are included in the triggered data logging when one of the condi-

EB 8389-1S EN 25

Page 26

Data logger

Valve signature

Requirements:

– Actuator: Single-acting

– Type of application: Control valve

Only applies to rst start-up after reset with Code 36 –

DS or Std.

â

Initialization including valve signature

â à

Start initialization

â

Valve signature recording

â

START-UP

Valve signature, signal pressure(x) Course of supply pressure Valve signature, friction(x)

â â

Alarm settings Recording threshold

Alar

â

m settings

ATC ATO and ATC

Zero limit,

lag time

Lower limit Upper limit

Status classication (NE 107) Status classication (NE 107) Status classication (NE 107)

Zero

x0 >

(ZP

+ Zero limit)

Init

x0 < (– Zero limit)

Spring pre-load

-

ing

Reduced spring

pre-loading

essure Change in friction

Supply pr

Not

available

Too low

Perm.

Too high

limit

exceeded

â â â â â â

Analysis (NE 107)/logged by

operating hours counter

PROCESS

Zero

Defective actuator

springs

Analysis (NE 107)/logged by

operating hours counter

Analysis (NE 107)/logged by

operating hours counter

Supply pressure status Change in friction

Min. supply pressure

Max. supply pressure

Dwell time (supply pressure

< 1.0bar)

l time (supply pressure

Dwel

> 7.0bar)

Valve signature

canceled

Not successful

â

Lower in total range

Lower/higher in mid-

position

Lower/higher near

max. OPEN position

Lower/higher near

CLOSED position

â

R

eset 'Pressure sensor monitoring values'

26 EB 8389-1S EN

Page 27

Valve signature

4 Valve signature

The valve signature plots the signal pressure

p

as a function of valve position x.

out

All diagnostic functions dependent on the

signal pressure are based on the valve signature, e.g. to detect pneumatic leakage or

to reveal an excessively high or low supply

pressure.

Note:

Additionally, the pneumatics are monitored using the 'Leakage limit' param

eter, which is adjustable between 0

and 100% in the Device settings fold-

er (> Alarm settings). The positioner

generates the 'Pneumatic leakage'

message whenever the leakage ex

ceeds this limit value. 'No message' is

assigned by default.

Requirements

1. A single-acting actuator is mounted on

the valve.

2. The valve operates as a control valve.

Device settings > Actuator

1.

− Principle of operation (Code 48 - d11):

Single-acting

Start-up

2.

− Type of application (Code 49 - h0):

Control valve

-

To perform monitoring while the process is

running, the reference graph must rst be

plotted.

-

Fig. 2: Start-up > Reference graphs > Valve signature

EB 8389-1S EN 27

Page 28

Valve signature

4.1 Reference graphs

During the plotting of the reference graph

(Fig. 2), the valve is moved very slowly from

the end position at which no pressure is applied to the actuator to the position at which

the maximum air signal is applied to the actuator. The valve is then moved back again

to its end position. During which, the positioner switches to open-loop control (control

without feedback).

The sensitivity of reference graph plotting de-

nes at which speed the valve is moved. The

time span how long the reference graph is to

be plotted depends on the sensitivity select-

ed. Select 'High' for valves with small bench

ranges and/or high friction.

After the reference graph has been plotted,

the recorded data points for signal pressure

p

and valve position x are converted into

out

xed points.

Note:

The valve positions cannot be predicted in open-loop control (control without feedback). The reference graph

may differ for the same valve after

each logging.

Dening parameters

The reference graph is automatically plotted

after initialization when 'Initialization including valve signature' = Yes.

Start-up

− Initialization including valve signature

(Code 48 - h0): [Yes]

The reference graph can also be plotted separately outside initialization.

1. Switch to manual mode.

2. Select 'Sensitivity' from the drop-down

list.

3. Start test.

The 'Test information' status indicates

'Test active'. 'D1' and 'TEST' are indicat-

ed in alternating sequence on the positioner display.

'Function check'

is activated as the

condensed state.

Start-up

1.

− Enter operating mode (Code 0): Manual

2.Start-up > Reference graphs > Valve

signature

− Sensitivity: Low, [Medium], High

3. − Start test

4.1.1 Analysis and monitoring

The positioner records the data for lling and

venting the actuator. It then determines the

characteristic values listed below:

− 'Mean hysteresis': Average hysteresis

(average signal pressure change Δp

relation to the spring range)

− 'Min. hysteresis': Lowest possible hystere-

sis (minimum signal pressure change

Δp

in relation to the spring range)

out

− 'Max. hysteresis': Highest possible hys-

teresis (maximum signal pressure change

Δp

in relation to the spring range)

out

in

out

28 EB 8389-1S EN

Page 29

Valve signature

− 'Detected lower spring range value': Sig-

nal pressure p

lled with the minimum amount of air

− 'Detected upper spring range value': Sig-

nal pressure p

lled with the maximum amount of air

The 'Valve signature canceled' message is

generated if the test is canceled.

Start-up > Initialization result

− Valve signature canceled (Code 81):

, , ,

The 'Test status' reading indicates the reason

why the test was canceled:

− No supply pressure: The supply pressure

was under 500mbar during the test.

− Valve moved too quickly. Recommended

action: Increase sensitivity

− Position at p

air):

(1) Even though the pressure was in-

creased in steps from 0bar to the maximum amount of air for lling the actua-

tor, the valve was not able to reach the

maximum position in closed-loop operation.

(2) The minimum valve position without

tight-closing is below 96%.

Recommended action: Increase supply

pressure.

− Position at p

(1) Even though the pressure was reduced in steps from the maximum

amount of air for lling the actuator, the

valve was not able to reach the minimum

when the actuator is

out

when the actuator is

out

not reached (lling with

max

not reached (venting):

min

position in closed-loop operation. The

valve might be jammed.

(2) The minimum valve position without

tight-closing is above 4%.

− Time-out

− Double-acting actuator

− Internal error

− Current too low

− Internal solenoid valve/forced venting

triggered

− SUB initialization

4.2 Valve signature, signal

pressure(x)

The positioner records the data for lling and

venting the actuator during closed-loop operation. The recorded data can be directly

compared with the reference graph. Additionally, the minimum, maximum and current

supply pressure are shown in the graph.

Data are recorded in the background regardless of the operating mode selected if a

reference graph has already been plotted.

Data logging does not need to be activated.

Note:

The positioner determines the minimum and maximum supply pressure

while plotting the reference graph. The

current supply pressure may fall below

the minimum supply pressure and exceed the maximum supply pressure.

Dening parameters

1. Record reference graph. u Section 4.2.

EB 8389-1S EN 29

Page 30

Valve signature

2. Set the limit for zero monitoring in control valves with closed position ATC (air

to close).

3. Select classication for status messages.

See u Section 4.2.1.

Device settings > Alarm settings

2.

− Zero limit (Code 48 - d5):

0.0 to 100.0 %, [5.0 %]

− Lag time: 1 to 9999 s, [30 s]

3.Device settings > Alarm settings > Status

classication > Positioner

− Zero (Code 58):

Device settings > Alarm settings > Status

classication > Actuator

Defective actuator springs

− Reduced spring pre-loading:

, [ ], ,

[ ], , ,

4.2.1 Analysis and monitoring

If the monitoring line has a smaller gradient

than the reference line, this pinpoints to a reduced compression of the actuator springs.

Diagnostics > Monitoring > Actuator

− Defective actuator springs:

Valves with ATC (air to close) closed position

In valves with ATC closed position, the positioner generates a zero error when the valve

position in the tight-closing position is larger

than the sum of the initialization zero points

and 'Zero limit' or smaller than the negative

'Zero limit' after the adjusted 'Lag time' has

elapsed.

Diagnostics > Monitoring > Positioner

− Zero (Code 58):

, , ,

, , ,

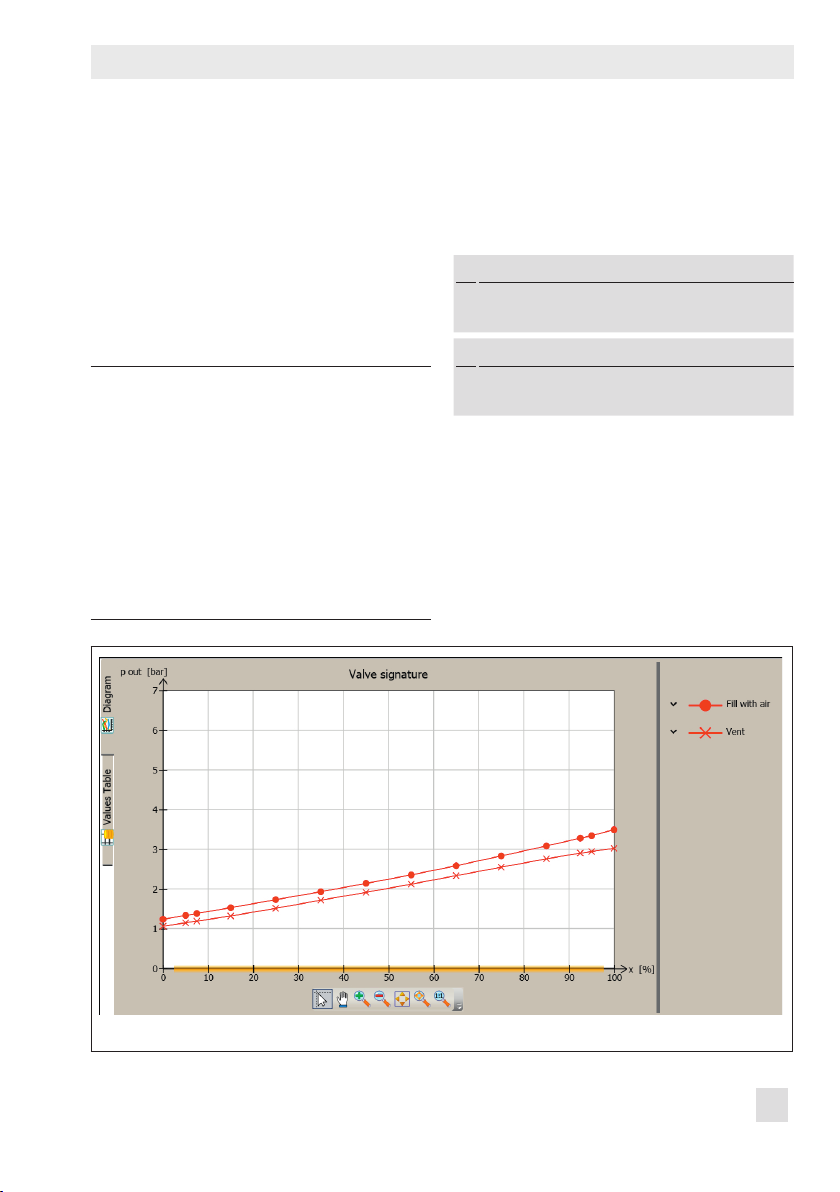

Fig. 3: Diagnostics > Monitoring/tests > Valve signature > Valve signature, signal pressure(x)

30 EB 8389-1S EN

Page 31

Valve signature

4.3 Course of supply pressure

During control-loop operation, ve values of

the supply pressure are recorded and saved

in a circular buffer. A new supply pressure is

recorded and saved in the circular buffer

when it deviates from the last value plotted in

the graph by the amount entered in 'Recording threshold'.

Data are recorded in the background regardless of the operating mode selected. Data logging does not need to be activated. To

monitor the limits ('Lower limit' and 'Upper

limit'), the corresponding limit must be activated rst. The limits are automatically deter-

mined while the valve signature is being

plotted. Alternatively, user-dened limits can

be entered.

Dening parameters

1. Dene 'Recording threshold'.

2. Enter limits for monitoring. See u Section 4.3.1.

3. Select classication for status messages.

See u Section 4.3.1.

1.Diagnostics > Monitoring/tests > Valve

signature > Course of supply pressure

− Recording threshold:

0.10 to 14.00 bar, [0.50 bar]

Device settings > Alarm settings

2.

− Activate lower limit: [Yes], No

− Lower limit: [0.0] to 7.0 bar

− Activate upper limit: Yes, [No]

− Upper limit: [0.0] to 7.0 bar

Fig. 4: Diagnostics > Monitoring/tests > Valve signature > Course of supply pressure

EB 8389-1S EN 31

Page 32

Valve signature

3.Device settings > Alarm settings > Status

classication > Supply pressure

− Permissible limit exceeded:

, , , [ ]

− Too high: , [ ], ,

− Fluctuates: [ ], , ,

− Too low: , [ ], ,

− Not available: , , , [ ]

4.3.1 Analysis and monitoring

The positioner generates the 'Supply pressure status' message with the dened status

classication.

− 'Too high' if the supply pressure exceeds

the 'Upper limit'.

− 'Not available' if the supply pressure falls

below 0.1bar.

− 'Too low' if the supply pressure exceeds

the 'Lower limit'.

− 'Permissible limit exceeded' if the supply

pressure exceeds 7.0bar.

A uctuating supply pressure is recognized

by the positioner whenever the supply pres-

sure continuously falls below the 'Lower limit'

and rises above the 'Upper limit'. In such

cases, the positioner generates the 'Supply

pressure status' message with the dened

status classication.

− Min. supply pressure

− Time stamp of min. supply pressure

− Max. supply pressure

− Time stamp of max. supply pressure

− Dwell time (supply pressure < 1.0 bar)

− Dwell time (supply pressure > 7.0 bar)

Diagnostics > Monitoring > Actuator

− Supply pressure status:

− Supply pressure (Code 48 - d7)

, , ,

32 EB 8389-1S EN

Page 33

Valve signature

4.4 Valve signature, friction(x)

The positioner calculates the friction during

closed-loop operation and compares it with

the friction determined when the reference

graph was plotted.

Data are recorded automatically 15 minutes

after initialization (regardless of the operating mode selected) if a reference graph has

already been plotted. Data logging does not

need to be activated.

Dening parameters

1. Record the reference graph. See u Section 4.1.

2. Select classication for status messages.

See uSection 4.2.1.

2.Device settings > Alarm settings > Status

classication > Valve

Change in friction

− Higher in total range: [

− Lower in total range: [ ], , ,

− Higher in mid-position: [ ], , ,

− Lower in mid-position: [ ], , ,

− Higher near max. OPEN position:

[ ], , ,

− Lower near max. OPEN position:

[ ], , ,

− Higher near CLOSED position:

[ ], , ,

− Lower near CLOSED position:

[ ], , ,

], , ,

Fig. 5: Diagnostics > Monitoring/tests > Valve signature > Valve signature, friction(x)

EB 8389-1S EN 33

Page 34

Valve signature

4.4.1 Analysis and monitoring

The positioner generates the 'Change in friction' message with the selected status classi-

cation. The friction for the total range of the

valve, the mid valve position and for the

ranges near to the end positions are compared.

The positioner calculates the friction during

closed-loop operation from the actuator lling and venting graphs at the point where a

directional change in valve travel takes

place. The positioner converts the friction data into xed points close to the point of directional change and compares them to the

reference friction.

If the friction at a xed point increases to

more than double of the reference friction,

the friction is regarded to be higher.

If the friction at a xed point drops to less

than half of the reference friction, the friction

is regarded to be lower.

Note:

To ensure that sufcient data points

are available for calculating the friction, the valve must not be moved too

quickly.

4.5 Resetting single status messages

All messages generated by the valve signature can be reset together by selecting and

executing "Reset 'Pressure sensor monitoring

values". These messages include:

− Change in friction

− Supply pressure status

− Defective actuator springs

− Zero

At the same time, the supply pressure data

(supply pressure, min. supply pressure and

max. supply pressure) are reset as well.

Diagnostics > Service/maintenance > Reset

− Reset 'Pressure sensor monitoring values'

Diagnostics > Monitoring > Valve

− Change in friction:

34 EB 8389-1S EN

, , ,

Page 35

Page 36

Valve signature

On/off valve

START-UP

Prerequisite:

– Type of application: On/off valve

â

Operating point, Limit fail-safe position, Limit operating point

â

Travel time assessment limit

Valve end position limit

Status classication (NE 107)

Breakaway time increasing/decreasing

Transit time increasing/decreasing

Final travel/angle value not reached

Final travel/angle value increasing/

easing

decr

â â

On/off diagnosis Discrete set point analysis PST

Dene parameters for partial stroke

test, see u Section 12

â

First analysis after dening parameters =

Breakaway time, transit

time, valve end position

(increasing/decreasing)

logged by operating hours counter

PROCESS

Reset measured 'On/off valve' values

Reset all 'On/off valve' parameters

Reference

â â

Analysis (NE 107)/

On/off valve status

â

Analysis, see

u Section 12.3

36 EB 8389-1S EN

Page 37

On/off valve

Operating point limit

Fail-safe action limit

x [%]

Operating point limit

Fail-safe action limit

x [%]

Lower range value (PST)

Upper range value (PST)

x [%]

5 On/off valve

The travel range of open/close (on/off) is

dened by the fail-safe position and the operating point. As a result, the following parameters to determine the working range

and set point range are not analyzed and

cannot be changed.

− Lower travel/angle range value

− Upper travel/angle range value

− Lower travel/angle limit

− Upper limit for travel/angle

− Lower set point range value

− Upper set point range value

The discrete analysis of the reference variable is performed in automatic mode.

If the set point ( ) is below 'Operating point

limit' when the automatic mode starts, the

valve (

the set point increases and exceeds 'Operating point limit', the valve moves to the 'Operating point'. The valve moves back to the

fail-safe position (0% in the example) if the

set point then falls below 'Fail-safe action

limit'.

) moves to the fail-safe position.

w [%]

Operating point

If

If the set point ( ) is above 'Operating

point limit' when the automatic mode

starts, the valve (

) moves to the operating

point. The valve moves back to the fail-safe

position (0% in the example) if the set point

then falls below 'Fail-safe action limit'.

w [%]

Operating point

50

25

Fail-safe position

t <6s

t [s]

Starting the partial stroke test (PST)

A partial stroke test is started when the set

point ( ) moves in the range between 25

and 50% of the travel range and remains

there for longer than six seconds. See

uSection 12.1.

w [%]

Operating point =

Operating point limit

Stop PSTStart PST

50

25

>6s

t

t [s]

Fail-safe position

50

25

∆t > 6 s

Fail-safe action limit

Fail-safe position

t [s]

EB 8389-1S EN 37

Page 38

On/off valve

The PST diagnostic parameter 'Lower range

value' must be within the dened position ±

'Tolerance limit' for the partial stroke test to

start.

After the partial stroke test is completed, the

valve moves back to its last position (fail-safe

position or operating point).

Canceling the partial stroke test (PST)

The partial stroke test is canceled whenever

the set point (

'Fail-safe action limit' and 'Operating point

limit', falling below 'Operating point limit'.

After the partial stroke test is canceled, the

valve moves back to its last position (fail-safe

position or operating point).

Dening parameters

Note:

The parameters can only be dened in

TROVIS-VIEW4 after the 'Type of ap-

plication' has been set to 'On/off

valve'.

1. Select the type of application.

2. Dene parameters for on/off valve.

3. Dene parameters for partial stroke test

(PST). See u Section 12.

Start-up

1.

− Type of application (Code 49 - h0): On/off

valve

2.Device settings > Positioner > Transfer

characteristic on/off

− Operating point (Code 49 - h1): 0.0 to

100%, [100 %]

) leaves the range between

− Fail-safe action limit (Code 49 - h2): 0.0 to

20.0 %, [12.5 %]

− Operating point limit (Code 49 - h5):

55.0 to 100.0 %, [75.0 %]

3.Diagnostics > Monitoring/tests > Dynamic

tests > Partial stroke test (PST)

See u Section 12

5.1 Diagnostics for on/off

valve

The diagnostics for on/off valve provide

statements on the valve end positions, transit

times (increasing/decreasing) and breakaway times (increasing/decreasing).

The data are recorded automatically for the

diagnostics for on/off valve in automatic

mode. Data logging does not need to be activated.

The positioner compares the current breakaway time, transit time and valve position

with the values recorded during the reference

measurement (rst analysis) while the plant is

running.

Dening parameters

Note:

The parameters can only be dened in

TROVIS-VIEW4 after the 'Type of ap-

plication' has been set to 'On/off

valve'.

1. Enter limits for monitoring. See u

5.2.

2. Select classication for status messages.

Section

38 EB 8389-1S EN

Page 39

On/off valve

(decreasing)

(increasing)

x [%]

t [s]

Device settings > Alarm settings

1.

− Travel time assessment limit (Code 49 - h7):

[0.6] to 30.0 s

− Valve end position limit (Code 49 - h8):

[0.3] to 100.0 %

2.Device settings > Alarm settings > Status

classication > On/off valve

− Increasing breakaway time: [

− Decreasing breakaway time:

[ ], , ,

− Transit time increasing: [ ], , ,

− Transit time (decreasing): [ ], , ,

− Final travel/angle value not reached:

[ ], , ,

− Increasing nal travel/angle value:

[ ], , ,

− Decreasing nal travel/angle value:

[ ], , ,

5.2 Analysis and monitoring

The analysis pinpoints to a fault when at

least one of the following conditions is met

while the valve is moving:

− The current 'Increasing breakaway time'

differs from the reference value by the

amount entered in 'Travel time assessment limit'.

− The current 'Decreasing breakaway time'

differs from the reference value by the

amount entered in 'Travel time assessment limit'.

− The current 'Transit time increasing' dif-

fers from the reference value by the

amount entered in 'Travel time assessment limit'.

], , ,

− The current 'Transit time (decreasing)' dif-

fers from the reference value by the

amount entered in 'Travel time assessment limit'.

− The current 'Transit time increasing' dif-

fers from the reference value by the

amount entered in 'Valve end position

limit'.

− The current 'Transit time (decreasing)' dif-

fers from the reference value by the

amount entered in 'Valve end position

limit'.

− The valve end position is not reached.

w [%]

Valve end position

(increasing)

Valve end position

(decreasing)

Breakaway time

(decreasing)

Transit time

Breakaway time

(increasing)

Transit time

Fig. 6: Analysis of diagnostics for on/off valve

If one of these conditions is met, the position-

er generates an 'On/off valve status' message according the selected status classica-

tion.

Diagnostics > Monitoring

− On/off valve status (Code 85):

, , ,

EB 8389-1S EN 39

Page 40

On/off valve

5.3 Resetting single status messages

The message and the limit values are reset

by selecting and executing "Reset measured

'On/off valve' values".

The positioner saves the reference analysis

and two further test analyses. The analysis of

the oldest test is deleted when another test is

performed.

Diagnostics > Service/maintenance > Reset

− Reset measured 'On/off valve' values

40 EB 8389-1S EN

Page 41

Valve position x histogram

6 Valve position x histogram

The valve position histogram is a statistical

analysis of the plotted valve positions. The

histogram provides information about where

the valve mainly spends the majority of its

time during its service life and whether it

shows a recent trend concerning changes in

its operating range.

Data are recorded automatically 15 minutes

after initialization (regardless of the operating mode selected). Data logging does not

need to be activated.

The positioner records the valve position every second and assigns the data into predened valve position classes. The distribution showing how often the sound level occurred within a valve position class is shown

in a bar graph.

− 'Mean value': Average class assignment

of valve positions throughout 'Monitoring

duration'.

− 'Number of measurement points': Total

number of values recorded during the

'Monitoring duration'.

− 'Monitoring duration'

The measured data are saved every 24

hours in the positioner.

Short-term monitoring

In order to be able to recognize any shortterm changes in valve position, the positioner records the valve positions according to

the adjusted 'Sampling time' and analyses

the last 100 measured values.

− 'Mean time': Contains the average class

assignment of valve positions for the last

100 measured values.

− 'Adjusted monitoring duration': 100 x

'Sampling time'

The positioner saves the valve positions in a

circular buffer, which holds 100 measured

values at one time.

Fig. 7: Diagnostics > Monitoring/tests > Histograms > Valve position x histogram

EB 8389-1S EN 41

Page 42

Valve position x histogram

Note:

Changing 'Sampling time' causes all

existing measured values to be deleted from the circular buffer.

Dening parameters

1. Set the 'Sampling time' for the short-term

monitoring.

2. Select classication for status messages.

See u Section 6.1.

Diagnostics > Monitoring/tests > Histograms

> Valve position x histogram > Short-term

monitoring

1.

− Sampling time: Adjustable as required,

[00:14:24 d.h:min:s]

2.Device settings > Alarm settings > Status

classication > Valve position

Manipulated variable range

− Mainly near CLOSED position:

], , ,

[

− Mainly near max. OPEN position:

[ ], , ,

− Mainly in CLOSED position:

[ ], , ,

− Mainly near max. OPEN position:

[ ], , ,

Change in manipulated variable range:

− Operating range shifted to CLOSED

position: [ ], , ,

− Operating range shifted to max. OPEN

position: [ ], , ,

− Short-term change: [ ], , ,

6.1 Analysis and monitoring

Analysis of the histogram for control valves

starts one hour after the monitoring period

begins. No analysis is performed for on/off

valves.

If the control valve mainly works during the

monitoring duration near or in one of the

end positions, the positioner generates the

'Manipulated variable range' message with

the selected status classication.

For analysis of the short-term monitoring, a

complete set of data (100 measured values)

is required. The analysis is only active when

the sampling time setting is greater or equal

to one minute.

The positioner generates the 'Change in manipulated variable range' message with the

selected status classication whenever a

trend showing a change in the operating

range is found from the analysis of the histogram and the short-term monitoring.

Diagnostics > Monitoring > Valve position

− Manipulated variable range:

− Change in manipulated variable range: ,

, ,

, , ,

6.2 Resetting single status messages

The 'Manipulated variable range' and the

'Change in manipulated variable range'

messages can be reset by selecting and executing the command "Reset 'Reset valve position x histogram". This command resets all

diagnostic parameters and measured data

42 EB 8389-1S EN

Page 43

of the histogram and the short-term monitoring.

By selecting and executing the command

"Reset 'Short-term valve position x histo-

gram", the diagnostic parameters and measured data in the Short-term monitoring

folder are reset.

Diagnostics > Service/maintenance > Reset

− Reset 'Valve position x histogram'

− Reset 'Short-term valve position x histogram'

Valve position x histogram

EB 8389-1S EN 43

Page 44

Set point deviation e histogram

7 Set point deviation e histo-

gram

The set point deviation histogram contains a

statistical analysis of any set point deviations

recorded. It provides information on to which

extent a set point deviation has occurred

during the valve service life and whether

faults may occur due to a restricted operating range or due to seat leakage.

Data are recorded automatically 15 minutes

after initialization (regardless of the operating mode selected). Data logging does not

need to be activated.

The positioner records the set point deviation

every second and assigns the data into pre-

dened classes. The distribution showing

how often the set point deviation remained

within a class is shown in a bar graph.

− 'Mean value': Average class assignment

of set point deviation throughout 'Monitoring duration'.

− 'Number of measurement points': Total

number of values recorded during the

'Monitoring duration'.

− 'Monitoring duration'

The measured data are saved every 24

hours in the positioner.

Short-term monitoring

In order to be able to recognize any shortterm changes in set point deviation, the positioner records the set point deviation accord-

ing to the adjusted 'Sampling time' and

analyses the last 100 measured values.

− 'Mean time': Contains the average class

assignment of set point deviations for the

last 100 measured values.

− 'Adjusted monitoring duration': 100 x

'Sampling time'

The positioner saves the set point deviations

in a circular buffer, which holds 100 measured values at one time.

Fig. 8: Diagnostics > Monitoring/tests > Histograms > Set point deviation e histogram

44 EB 8389-1S EN

Page 45

Set point deviation e histogram

Note:

Changing 'Sampling time' causes all

existing measured values to be deleted from the circular buffer.

Dening parameters

1. Set the 'Sampling time' for the short-term

monitoring.

2. Select classication for status messages.

See u Section 7.1.

Diagnostics > Monitoring/tests > Histograms

> Set point deviation e histogram > Shortterm monitoring

1.

− Sampling time: Adjustable as required,

[00:14:24 d.h:min:s]

2.Device settings > Alarm settings > Status

classication > Valve

Seat leakage

− May exist: [

Device settings > Alarm settings > Status

classication > Valve position

Manipulated variable range limitation

− Lower: [

− Upper: [ ], , ,

− No change possible: [ ], , ,

Positioner-valve linkage

− Travel transmission not optimal:

[ ], , ,

], , ,

], , ,

7.1 Analysis and monitoring

Ideally, the set point deviation should be

nearly 0%.

Set point deviations greater than 1% follow-

ing in quick succession pinpoint to a limitation of the upper operating range. In this

case, the positioner generates the 'Manipulated variable range limitation' and 'Positioner-valve linkage' messages with the selected status classications.

Set point deviations smaller than 1% follow-

ing in quick succession pinpoint to a limitation of the lower operating range or to seat

leakage. The positioner generates the 'Manipulated variable range limitation', 'Positioner-valve linkage' and 'Seat leakage'

messages with the selected status classica-

tions.

If almost all set point deviations during the

short-term monitoring are greater than 1%

or smaller than –1%, this may indicated that

the actuator or valve stem is jammed. The

positioner generates the 'Manipulated variable range limitation' and 'Positioner-valve

linkage' messages with the selected status

classications.

Diagnostics > Monitoring > Valve

− Seat leakage:

Diagnostics > Monitoring > Valve position

− Manipulated variable range limitation:

, ,

− Positioner-valve linkage: , , ,

, , ,

,

EB 8389-1S EN 45

Page 46

Set point deviation e histogram

7.2 Resetting single status messages

The 'Seat leakage', 'Manipulated variable

range limitation' and 'Positioner-valve linkage' messages can be reset by selecting and

executing the command "Reset 'Set point deviation e histogram" or "Reset 'Short-term set

point deviation e histogram".

By selecting and executing the "Reset 'Set

point deviation e histogram" command, all

diagnostic parameters and measured data

of the histogram and the short-term monitoring are reset.

By selecting and executing the command

"Reset 'Short-term set point deviation e histo-

gram", the diagnostic parameters and measured data in the Short-term monitoring

folder are reset.

Diagnostics > Service/maintenance > Reset

− Reset 'Set point deviation histogram e'

− Reset 'Short-term set point deviation e histo-

gram'

46 EB 8389-1S EN

Page 47

Page 48

Set point deviation e histogram

t [s]

x [%]

t [s]

x [%]

Cycle counter histogram

Stem seal

â

â â â â

Self-adjusting Adjustable Other, -/- Bellows seal

â

Max. cycle count

START-UP

PROCESS

â â â

â â

Status classication (NE 107)

External leakage possibly to be

expected soon

â â

Determining the cycle spans

1

3

2

4

â â

Dynamic stress factor Dynamic stress factor

Dynamic stress factor > 90

%

â â

Analysis (NE 107)/

logged by operating hours counter

acking leakage

P

Status classication (NE 107)

External leakage possibly to be

expected soon

Determining the cycle height