Page 1

Mounting and

Operating Instructions

EB 6611-2 EN

Firmware version 3.53

Translation of original instructions

Edition October 2017

TROVIS 6600 Automation System

TROVIS6611-2 Control and Automation

Unit

Page 2

2 EB 6611-2 EN

Note on these mounting and operating instructions

These mounting and operating instructions assist you in mounting and operating the device

safely. The instructions are binding for handling SAMSON devices.

Î For the safe and proper use of these instructions, read them carefully and keep them for

later reference.

Î If you have any questions about these instructions, contact SAMSON‘s After-sales Service

Department (aftersalesservice@samson.de).

The mounting and operating instructions for the devices are included in

the scope of delivery. The latest documentation is available on our website

(www.samson.de) > Product documentation. You can enter the document

number or type number in the [Find:] eld to look for a document.

Denition of signal words

Hazardous situations which, if not avoided,

will result in death or serious injury

Hazardous situations which, if not avoided,

could result in death or serious injury

Property damage message or malfunction

Additional information

Recommended action

DANGER

!

WARNING

!

NOTICE

!

Note

Tip

Page 3

Contents

EB 6611-2 EN 3

1 Safety instructions and measures ...................................................................5

1.1 Notes on possible property damage ................................................................8

2 Markings on the device .................................................................................9

3 Design and principle of operation ..................................................................9

3.1 Operating controls .......................................................................................10

3.1.1 Front panel ..................................................................................................10

3.1.2 Back of device .............................................................................................12

3.2 Accessories .................................................................................................14

3.3 Technical data .............................................................................................14

3.4 Dimensions in mm ........................................................................................15

4 Measures for preparation ............................................................................16

4.1 Unpacking ..................................................................................................16

4.2 Transporting ................................................................................................16

4.3 Storage .......................................................................................................16

5 Mounting and start-up ................................................................................. 16

5.1 Installation ...................................................................................................16

5.2 Electrical connection .....................................................................................17

5.3 Start-up ....................................................................................................... 17

5.3.1 User login ...................................................................................................17

5.3.2 Loading a project .........................................................................................17

5.3.3 Setting the system time .................................................................................18

5.3.4 Network settings ..........................................................................................18

5.3.5 Assigning modules .......................................................................................19

5.3.6 Calibrating the touch screen..........................................................................19

5.4 Quick check ................................................................................................19

6 Operation ...................................................................................................21

6.1 User administration ......................................................................................21

6.2 Operating the system ...................................................................................21

6.3 Reset unit.....................................................................................................21

6.4 Setting up a WiFi hotspot .............................................................................21

7 Servicing.....................................................................................................22

7.1 Updating the rmware .................................................................................22

Page 4

4 EB 6611-2 EN

Contents

7.2 Preparation for return shipment .....................................................................22

8 Malfunctions ...............................................................................................22

9 Decommissioning and disassembly ..............................................................22

9.1 Decommissioning .........................................................................................22

9.2 Disposal ......................................................................................................23

10 Annex.........................................................................................................23

10.1 After-sales service ........................................................................................23

10.2 Licenses .......................................................................................................24

10.2.1 GNU GENERAL PUBLIC LICENSE, Version 2, June 1991 .................................24

10.2.2 GNU GENERAL PUBLIC LICENSE, Version 3, 29 June 2007 ............................29

10.2.3 GNU LESSER GENERAL PUBLIC LICENSE, Version 3, 29 June 2007 ................40

10.3 EU declaration of conformity .........................................................................43

Page 5

EB 6611-2 EN 5

Safety instructions and measures

1 Safety instructions and measures

Intended use

The TROVIS6611-2 Control and Automation Unit is freely programmable and allows autonomous operation and management of six I/O modules. It has an integrated color touch screen

for visualization.

To allow the control and automation unit to access the I/O modules in the required manner,

the I/O modules must be mapped logically as a project in the unit. For this purpose,

SAMSON provides ready-made applications. Alternatively, a project can be programmed

using the

SAMSON graphical project management tool (logic circuits, menu navigation,

visualization and start-up).

The control and automation unit as well as the I/O modules are designed to operate under

exactly dened conditions (e.g. power supply, ambient conditions). Therefore, operators must

ensure that the unit is only used in applications where the operating conditions correspond to

the technical data. In case operators intend to use the unit in other applications or conditions

than specied, contact SAMSON.

SAMSON does not assume any liability for damage resulting from the failure to use the device for its intended purpose or for damage caused by external forces or any other external

factors.

Î Refer to the technical data for limits and elds of application as well as possible uses. See

section3.3.

The operator is responsible for the physical and logical project management, if not agreed

otherwise.

Reasonably foreseeable misuse

The control and automation unit is not suitable for the following applications:

− Use outside the limits dened during sizing and by the technical data

Furthermore, the following activities do not comply with the intended use:

− Use of non-original spare parts

− Performing service and repair work not described in these instructions

Page 6

6 EB 6611-2 EN

Safety instructions and measures

Qualications of operating personnel

− The unit must be mounted, started up, serviced and repaired by fully trained and quali-

ed personnel only; the accepted industry codes and practices are to be observed.

− The projects must be congured and set by trained and experienced personnel only.

According to these mounting and operating instructions, trained personnel refers to individuals who are able to judge the work they are assigned to and recognize possible hazards due

to their specialized training, their knowledge and experience as well as their knowledge of

the applicable standards.

Personal protective equipment

No personal protective equipment is required.

Revisions and other modications

Revisions, conversions or other modications to the product are not authorized by SAMSON.

They are performed at the user's own risk and may lead to safety hazards, for example. Furthermore, the product may no longer meet the requirements for its intended use.

Safety features

The operation of the unit is password-protected to protect it from unauthorized access. A user

role with individual privileges and password is assigned to each user.

Warning against residual hazards

The control and automation unit has direct inuence on controlled plant components (e.g.

control valves and pumps) over the I/O modules. To avoid personal injury or property damage, plant operators and operating personnel must prevent hazards that could be caused in

the plant components by the process medium, the operating pressure, the signal pressure or

by moving parts by taking appropriate precautions. They must observe all hazard statements, warning and caution notes in the referenced documents.

Responsibilities of the operator

The operator is responsible for proper operation and compliance with the safety regulations.

Operators are obliged to provide these mounting and operating instructions to the operating

personnel and to instruct them in proper operation. Furthermore, the operator must ensure

that operating personnel or third persons are not exposed to any danger.

Page 7

EB 6611-2 EN 7

Safety instructions and measures

Responsibilities of operating personnel

Operating personnel must read and understand these mounting and operating instructions as

well as the specied hazard statements, warning and caution notes. Furthermore, the operating personnel must be familiar with the applicable health, safety and accident prevention

regulations and comply with them.

Referenced standards and regulations

The control and automation unit fullls the requirements of the Directives 2014/30/EU and

2011/65/EU. The declaration of conformity includes information about the applied conformity assessment procedure. This declaration of conformity is included in the appendix of

these instructions.

The control and automation unit is designed for use in low voltage installations.

Î For wiring, maintenance and repair, observe the relevant safety regulations.

Referenced documentation

The following documents apply in addition to these mounting and operating instructions:

uAB6600: System integration guidelines for electrical technicians

uT6620-1 for TROVIS6620-1 I/O Module

uT6625 for TROVIS6625 Input Module

uT6630 for TROVIS6630 AO Module

uT6640 for TROVIS6640 AI Module

− Technical documentation for the room panel in use

Page 8

8 EB 6611-2 EN

Safety instructions and measures

1.1 Notes on possible property damage

NOTICE

!

Damage due to water entering the device.

The front pane of the control and automation unit is protected against vertically falling

drops of water (IP41).

Î Avoid drops, sprays and jets of water.

Manipulation of settings due to unauthorized access.

The TROVIS6611-2 Control and Automation Unit supports various communications

protocol (e.g. a web server). This allows remote access. To protect it from unauthorized

access, the onsite and remote operation of the unit is password-protected:

Î Change the initial administrator password after rst start-up.

Î Regularly change all user passwords.

Î Do not pass login data on to unauthorized persons. Keep them in a safe place in-

accessible to unauthorized persons.

Page 9

EB 6611-2 EN 9

Design and principle of operation

2 Markings on the device

SAMSON

TROVIS 6611

Power supply

24 V AC / DC 8 VA / W

Model 6611 - 2000

Var.-ID

Serial no.

Made in Germany

Fig.1: Nameplate

3 Design and principle of oper-

ation

TROVIS 6611-2 is a freely programmable

control and automation unit for autonomous

operation and management of six I/O mod

ules (up to 120 physical data points). It has

an integrated color touch screen for visual

ization. The SAMSON graphical project

management tool is required to create appli

-

cations.

The control and automation unit does not

contain any applications in the delivered

state.

System-specic applications can be ordered

from SAMSON.

Max. number of units

Modules

− 6x I/O modules (TROVIS6620,

6625, 6630 or 6640) per

TROVIS6611-2

− 32x TROVIS6611-2 per application

(graphical project management

tool)

Cable length without repeaters, hubs, etc.

− Ethernet 100BASE-T type: LAN

− I/O bus 1200m

− 24VAC/DC Max. 1.5mm² strand

(12mm-long wire end

ferrule)

− Ethernet Min. Cat 5 cable, shielded

(STP)

− I/O bus Jy(St) Y 2 x 2 x 0.8

(12mm-long wire end

ferrule)

Note

Page 10

10 EB 6611-2 EN

Design and principle of operation

3.1 Operating controls

3.1.1 Front panel

F1

F2

F1

Display

F2

USB port

(USB ash drive not included in the scope of delivery)

Fig.2: Operating controls located on the front panel of the device

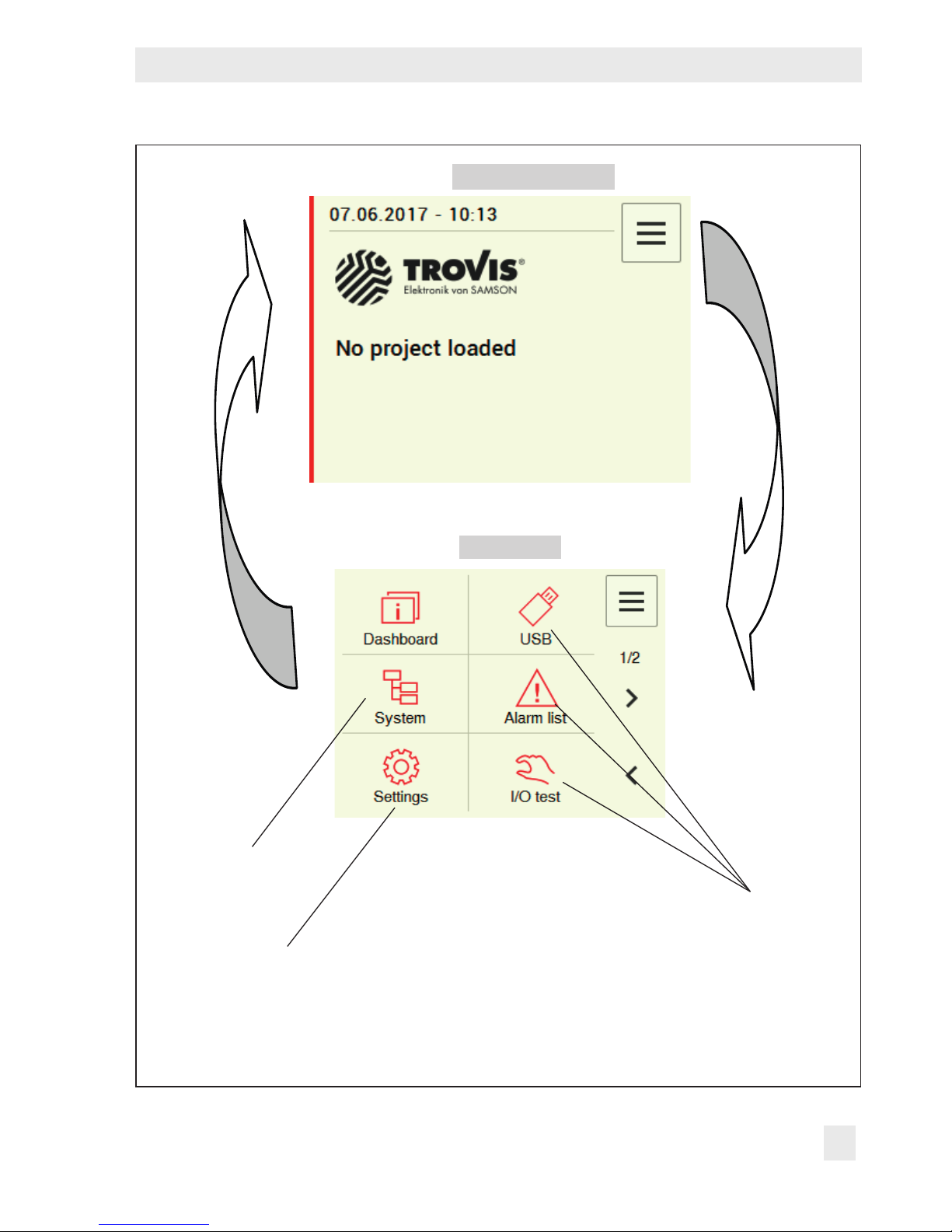

Touch screen (

F1

)

The touch screen is the main operating element.

Tap the menu button on the top right-hand corner of the screen to open various levels. Depending on the level, various functions can be executed by tapping the dis-

played buttons (see Fig.3).

USB port (

F2

)

The USB port is accessible after opening the lid. Data can be transferred from a USB ash

drive inserted into the port to the unit and vice versa.

− USB ash drive requirements: 2.0 with FAT32

Page 11

EB 6611-2 EN 11

Design and principle of operation

Dashboard

Main menu

Main menu or

login

Buttons for frequent

actions

Menu structure de-

pending on project

System settings

Appearance varies depending on the program and the user privileges.

Fig.4: Structure of the TROVIS6611-2 Control and Automation Unit

Page 12

12 EB 6611-2 EN

Design and principle of operation

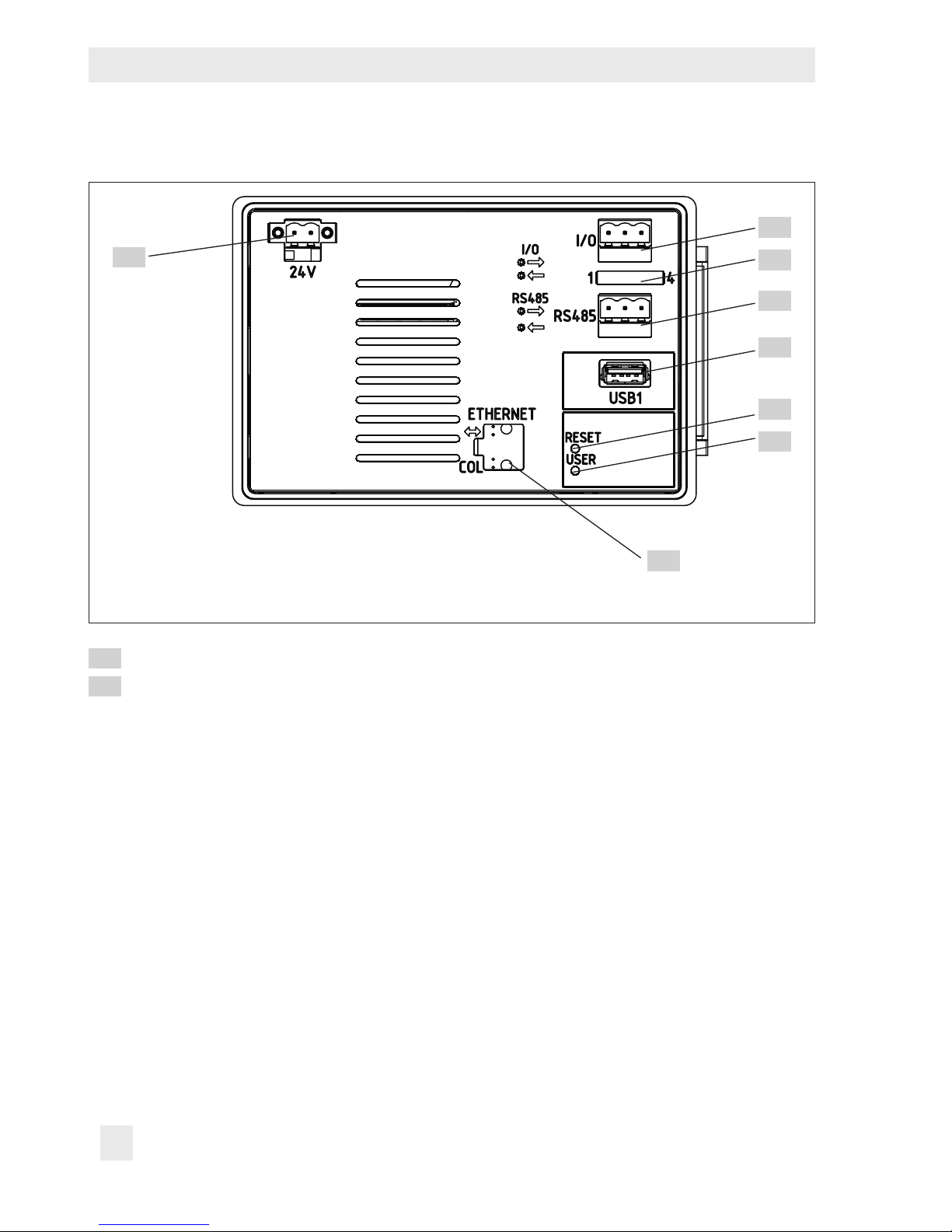

3.1.2 Back of device

R1

R8

R7

R6

R5

R4

R3

R2

Fig.3: Operating controls located on the back of the device

Power supply (see section5.2)

Connection for I/O bus (physical inputs on the input/output modules)

Distributed I/O modules are required to connect the physical input and outputs. The

two terminals are labeled "lA" and "lB" and must be wired consistently in exactly the

same way.

Maximum cable core length: 1200m

A maximum of six I/O modules (e.g. TROVIS6620, 6625, 6630 or 6640) can be

connected to one TROVIS6611-2 Control and Automation Unit.

R1

R2

Page 13

EB 6611-2 EN 13

Design and principle of operation

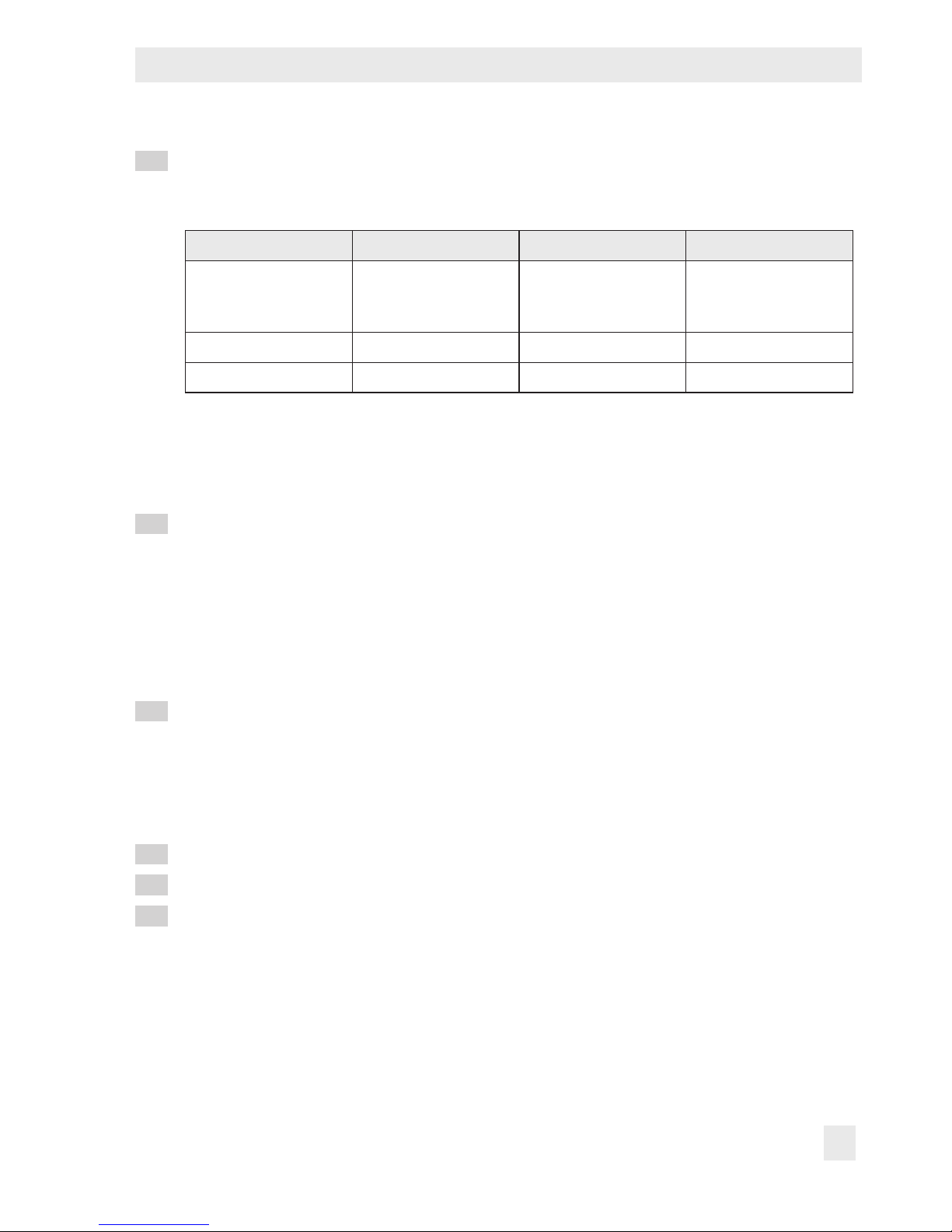

Jumper for RS-485 conguration

The jumpers are not set in the delivered state. Refer to the following table for the required setting.

1 2 3 4

Bus termination fur

I/O bus

Bus bias voltage for

Modbus (jumper3

must be closed)

Bus bias voltage for

Modbus (jumper2

must be closed)

Bus termination fur

Modbus

Closed = Active Closed = Active Closed = Active Closed = Active

Open = Not active Open = Not active Open = Not active Open = Not active

Close jumper1 if TROVIS6611-2 is at the end of the I/O bus line.

Close jumpers 2 and 3 to activate the Modbus bias voltage (if TROVIS6611-2 is used as a

Modbus RTU master).

Close jumper4 if TROVIS6611-2 is at the end of the bus.

Connection for Modbus (RS-485 2W)

The TROVIS6611-2 Control and Automation Unit supports the Modbus-RTU eldbus

protocol with two-wire system. The corresponding jumpers must be set for the terminating resistors or bias voltage. Bus properties, such as master or slave operation, data

bits, parity and stop bits must be congured in the SAMSON Graphical Project Management Tool software. The two terminals are labeled "RA" and "RB" and must be

wired consistently in exactly the same way.

USB port

Functions:

− Load and save data

− Memory extension for historical data

USB ash drive requirements: 2.0 with FAT32

Reset key for restart

User key

Ethernet connection

Data transmission rate: 100Mbit/s

Host name: Fallback IP-Adresse 172.30.66.11

The Ethernet connection can be congured and activated on site at the device. The services (SSH, FTPES, HTTPS, AVAHI (see section5.3.4) are deactivated in the delivered

state. However, the TROVIS6611-2 Control and Automation Unit in the default state

obtains the IP addresses over DHCP.

R3

R4

R5

R6

R7

R8

Page 14

14 EB 6611-2 EN

Design and principle of operation

3.2 Accessories

Accessories

− Terminal and installation set (included in the scope of delivery) ........ Item no. 1402-1561

− TROVIS6620-1 I/O Module ........................................................ Conf. ID: 4829008

− TROVIS6625 Input Module

1)

....................................................... Conf. ID: 2649861

− TROVIS 6630 AO Module ............................................................Conf. ID: 3714719

− TROVIS 6640 AI Module ..............................................................Conf. ID: 3714720

− Room panel depending on application .......................................... On request

− TROVIS6690 Graphical Project Management Tool (demo version) .. Conf. ID: 3004922

− TROVIS6690 Graphical Project Management Tool (1 AS version) ... Conf. ID: 3004921

− TROVIS6690 Graphical Project Management Tool (3 AS version) ... Conf. ID: 3004920

− TROVIS6690 Graphical Project Management Tool (full version) ...... Conf. ID: 2039168

1)

Only with 24VAC power supply (not DC)

3.3 Technical data

Auxiliary power

Power supply 24VAC/DC

Power consumption 8VA/W

Connection 2-pin screw clamp terminal (orange)

Wire cross-section Up to 1.5mm²

Permissible ambient conditions

Operating temperature 0 to 55°C

Transportation and storage

temperature

–20 to +70°C

Relative humidity 5 to 95%, no dew formation

Electromagnetic compatibility

Noise emission According to EN 61000-6-3

Noise immunity According to EN 61000-6-2

Device safety

Degree of protection II according to DINEN61140

Overvoltage category II according to DINEN60664-1

Degree of contamination 2 according to DINEN60664-1

Degree of protection With seal for panel mounting: IP41 according to IEC60529

Page 15

EB 6611-2 EN 15

Design and principle of operation

Display

Key gures 3.5“ QVGA, resistive touch screen

Resolution 320 x 240 pixel

Installation

Dimensions W x H x D including terminals: 147 x 96 x 50mm

Mounting Panel mounting

Panel cutout W x H: 138 x 92mm (recommended installation depth: min.

80mm)

Weight Approx. 0.4kg

Interfaces

Serial interfaces 1x RS-485 Modbus-RTU (3-pin screw clamp terminal)

1x RS-485 I/O bus (3-pin screw clamp terminal) for

TROVIS6620

Ethernet 1x RJ-45 10/100Mbit, BACnet IP (AMEV Prole AS-A,

AS-B)

USB 2x USB 2.0A, (FAT32)

Compliance

·

3.4 Dimensions in mm

Required mounting

depth: min. 80mm

147

9650

10

Page 16

16 EB 6611-2 EN

Mounting and start-up

4 Measures for preparation

After receiving the shipment, proceed as follows:

1. Check the scope of delivery. Compare

the shipment received against the delivery note.

2. Check the shipment for transportation

damage. Report any damage to

SAMSON and the forwarding agent

(refer to delivery note).

4.1 Unpacking

Do not remove the packaging until immediately before mounting and start-up.

1. Remove the packaging from the control

and automation unit.

2. Dispose of the packaging in accordance

with the valid regulations.

4.2 Transporting

− Protect the unit against external inuenc-

es (e.g. impact).

− Protect the unit against moisture and dirt.

− Observe the permissible transportation

temperature of –20 to +70°C.

4.3 Storage

Risk of damage to the unit due to improper

storage.

− Observe storage instructions.

− Avoid long storage times.

− Contact SAMSON in case of different stor-

age conditions or long storage periods.

We recommend regularly checking the unit

and the prevailing storage conditions during

long storage times.

Storage instructions

− Protect the unit against moisture, dirt and

other external inuences (e.g. impact).

− Make sure that the ambient air is free of

acids or other corrosive media.

− Observe the permissible storage tem-

perature from –20 to +70°C.

− Do not place any objects on the unit.

5 Mounting and start-up

5.1 Installation

The control and automation unit is mainly

designed for panel mounting.

Panel cut-out (W x H): 138 x 92mm

Required mounting depth: min. 80mm

Î Make the panel cut-out.

Note

NOTICE

!

Note

Page 17

EB 6611-2 EN 17

Mounting and start-up

Î Push the unit from the front through the

panel cut-out.

Î Slide the supplied screw rails into the

guide rails: the clamps on the screw rails

must face towards the control panel.

Î Fasten the screw rails with the supplied

screws: the tips of the screws must point

towards the control panel.

Î Connect the wiring as described in sec-

tion5.2.

5.2 Electrical connection

Malfunction due to incorrect electrical connection.

− Upon installation of the electric cables, you

are required to observe the VDE regulations as well as the regulations of your local power supplier.

− Do not ground the power supply (trans-

former or switch-mode power supply).

− The wiring must be performed by properly

trained and experienced personnel only.

Surge protection

Î If signal lines are installed outside build-

ings or over large distances, make sure

appropriate surge or overvoltage protection measures are taken. Such measures

are indispensable for bus lines.

Î The shield of signal lines installed outside

buildings must have current conducting

capacity and must be grounded on both

sides.

Î Install surge diverters at the control cabi-

net inlet.

Electrical connection

The terminals have reverse polarity protection:

Î Connect the unit to the power

supply (24V).

5.3 Start-up

5.3.1 User login

Î Select "Login" in the menu ( button).

Î Enter your user name and password

("admin").

Insufcient security due to generally accessible password.

Change the administrator password

("admin") after rst login.

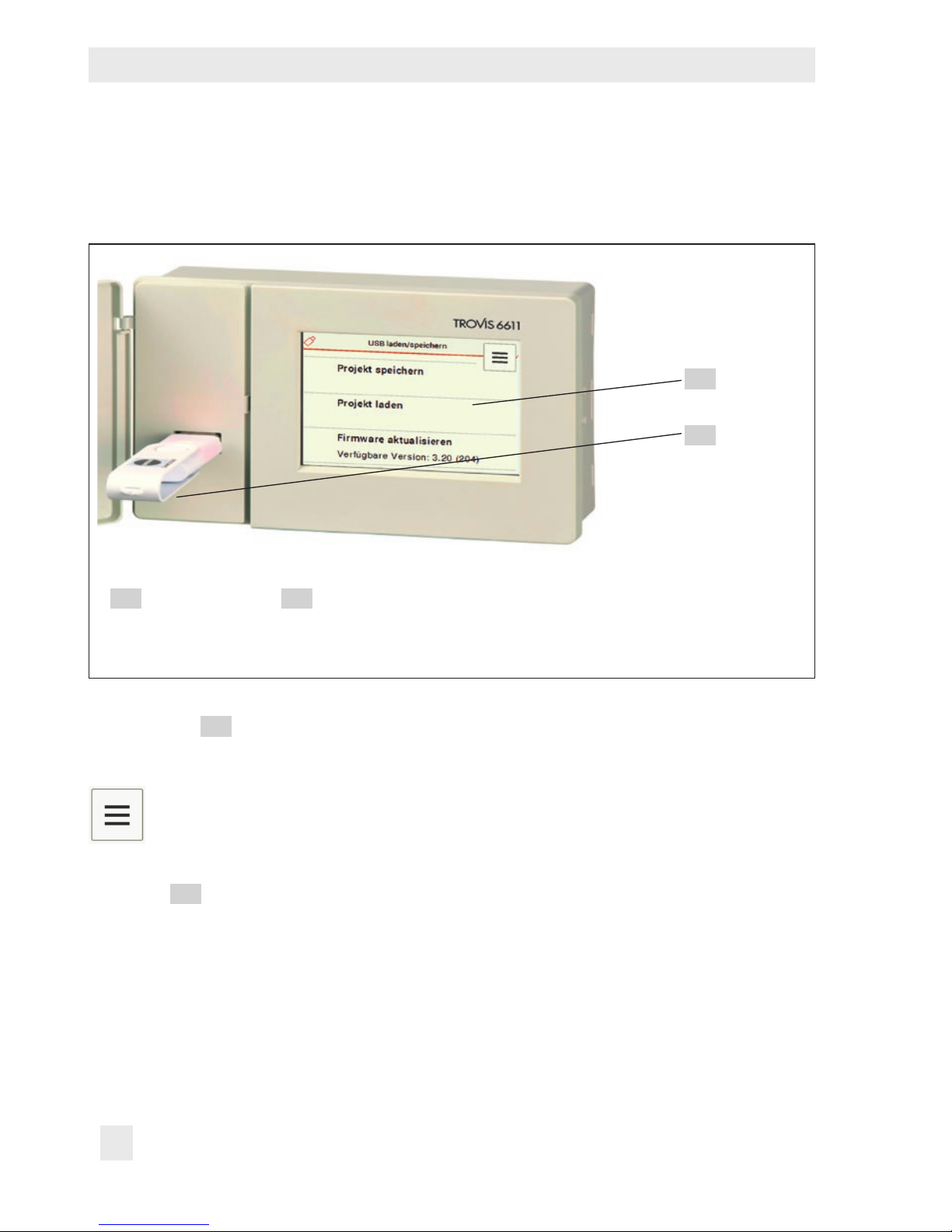

5.3.2 Loading a project

Î Insert the USB ash drive containing the

project into the front USB port.

Î Go to the main menu ( button).

Î Select "Load project" in "USB" and select

the required project.

Select "USB" to perform further actions:

− Save project

− Update the rmware

NOTICE

!

NOTICE

!

NOTICE

!

Page 18

18 EB 6611-2 EN

Mounting and start-up

5.3.3 Setting the system time

Î Go to the main menu ( button).

Î Select "Date and time" in "Settings".

Î Change the time and date.

Î Select "Apply" in the menu (

button) to

save changes.

5.3.4 Network settings

The unit has an integrated web server

(TROVIS MOBILE), which can be simply accessed over the network and browser

through the IP address. It must have the same

address as the end device (smartphone,

notebook, tablet computer, computer, etc.)

and an active HTTPS.

TROVIS MOBILE is designed for modern web

browsers, e.g. Mozilla Firefox in version

V.45 and higher. Access to the Internet requires port forwarding using a router (e.g.

VPN) to be set up on site.

The LAN setting is set to DHCP in the default

setting. In this setting, it is assumed that the

TROVIS6611-2 Control and Automation

Unit is assigned to an IP address, e.g.

belonging to a router. However, the IP

address is not assigned, for example, when

the TROVIS6611-2 unit is directly connected

to a laptop using a network cable. In this

case, DHCP must be deactivated to allow the

preset static IP address to be used. The

currently used and active IP address can be

found in [Main menu > Device information >

Network: eth0]. This information is available

regardless of the user role.

Î Go to the main menu ( button).

Î Select "Network settings" in "Settings".

Î Set the "LAN port" to ON.

Î Select "Back one level" in the menu (

button) to exit the level.

Î Set all other parameters in "LAN set-

tings":

− DHCP: ON (= default)

− IP address: 172.30.66.11 (= default)

− Subnet mask:

255.255.0.0

(= default)

− Host name: TROVIS-6111-2-xxx (xxx

= device-specic MAC address)

− DNS server

− NTP server

Î If necessary, select "Services" in "Net-

work":

− Activate FTPS for use with graphical

project management (default = OFF)

− Activate HTTPS for the use of the inte-

grated TROVIS-MOBILE web server

(default = OFF)

− SSH for console access using the

"root" user role

Impaired device function and loss of warranty through the improper use of the "root"

user role.

− Only activate SSH for troubleshooting and

administration activities performed by

trained personnel.

− Do not leave the SSH constantly activated.

− Assign a "root" password to protect its ac-

cess.

Note

NOTICE

!

Page 19

EB 6611-2 EN 19

Mounting and start-up

Î Select "Apply" in the menu ( button) to

save changes.

5.3.5 Assigning modules

Î Go to the main menu ( button).

Î Select "Module assignment" in "Set-

tings".

The logical modules are listed.

Î Select one physical module for each logi-

cal module one after the other.

Î The LEDs of a physical module blink after

it has been selected. Conrm selection by

checking the box (top right) or repeat selection procedure until the correct physical module has been selected.

Î Select "Apply" in the menu (

button) to

save changes.

We recommend performing the restore

function (“Restoring the system” in “Settings”)

after assigning the module. This ensures that

the settings remain saved even after a power

failure.

5.3.6 Calibrating the touch

screen

Î Go to the main menu ( button).

Î Select "Touch screen calibration" in "Set-

tings". Select "Start touch screen calibration".

Î Tap the crosshair with a pointed item

each time it appears on the screen.

5.4 Quick check

"I/O test" allows the unit's ability to function

to be checked. It allows you to check all the

connected modules and the physical inputs

and outputs.

Î After changing to the main menu (

but-

ton), select "I/O test".

Î Manually switch the outputs one after the

other to check that they function.

Note

Page 20

20 EB 6611-2 EN

Mounting and start-up

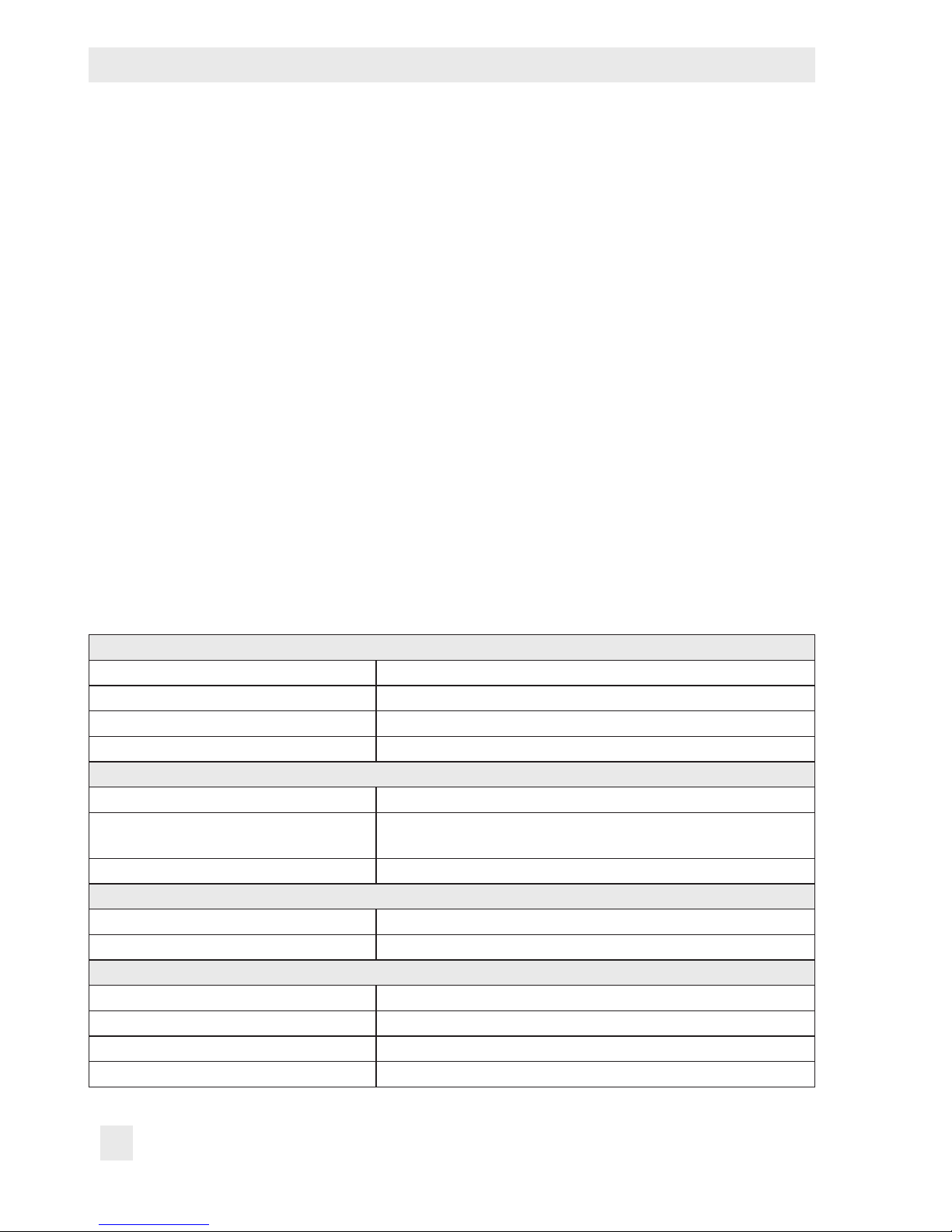

User

Load project

Set system time

Set network

Assign modules

Calibrate touch screen

Operate system on site

Reset unit

Create new user

Update the rmware

Default user NO NO NO NO NO YES NO NO NO

User NO YES NO NO NO YES NO NO NO

Service YES YES YES YES YES YES YES NO NO

Administrator YES YES YES YES YES YES YES YES YES

Fig.5: User roles

Fig.6: TROVIS MOBILE

Page 21

EB 6611-2 EN 21

Operation

6 Operation

6.1 User administration

User administration is performed over the

TROVIS MOBILE web server (see sec-

tion5.3.4 and Fig.6).

Four different user roles can be assigned to

users (see Fig.5).

6.2 Operating the system

The system is operated in "System". It depends on the loaded project.

Î After changing to the main menu ( but-

ton), select "System".

6.3 Reset unit

Resetting to rst start-up

By resetting to rst start-up, all system parameters are set to the state upon delivery of

the project.

Î Press the reset key on the back of the de-

vice.

Restoring the system

The "Restore system" command in "Settings"

allows the system to be restored to a certain

point. Once set, settings can be reset to this

point again at any time.

Î Go to the main menu (

button).

Î Select "Restore system" in "Settings".

Resetting to default settings

Resetting to default settings causes all settings made during start-up (project, system

time, network, module assignment) to be deleted.

Î Save data to a USB ash drive before re-

setting to default settings.

Î Press reset and user keys on the back of

the device simultaneously. Hold the user

key pressed until the reading indicates a

reset to default settings.

6.4 Setting up a WiFi hotspot

External hardware (e.g. computer, laptop,

smartphone, tablet computer) can be used to

establish a WiFi connection to the

TROVIS6611-2 Control and Automation

Unit. The unit's released services (e.g. web

server, connection to the graphical project

management tool) can be accessed over a

WiFi hotspot. It can only be established

using a WiFi stick

1)

, within wireless

coverage and when the end devices have

been connected properly to the WiFi

provided by the stick.

1)

WiFi sticks must support the approved chips

with appropriate drives, e.g. Edimax EW7811Un.

Page 22

22 EB 6611-2 EN

Decommissioning and disassembly

7 Servicing

The control and automation unit was

checked by SAMSON before it left the factory.

− The product warranty becomes void if

service or repair work not described in

these instructions is performed without

prior agreement by SAMSON's After-sales

Service department.

− Only use original spare parts by

SAMSON, which comply with the original

specications.

7.1 Updating the rmware

The unit's rmware needs to be updated after certain applications and functions have

been revised. The rmware is updated using

a USB ash drive

1)

containing the latest rm-

ware.

1)

The USB ash drive must have the FAT32 format, assigned the name "TROVIS6611" and

have the same folder structure.

This procedure requires administrator privileges.

Î Insert the USB ash drive containing the

rmware into the front USB port.

Î Go to the main menu ( button).

Î Select "Update rmware" in "USB" and

select the required project.

7.2 Preparation for return shipment

Defective units can be returned to SAMSON

for repair.

Proceed as follows to return devices to

SAMSON:

1. Put the unit out of operation.

2. Send the unit to your nearest SAMSON

subsidiary. SAMSON subsidiaries are

listed on our website at

uwww.samson.de > Contact.

8 Malfunctions

Î Troubleshooting (see Table1)

Contact SAMSON's After-sales Service department for malfunctions not listed in the ta-

ble.

9 Decommissioning and disas-

sembly

9.1 Decommissioning

1. Disconnect the unit from the power sup-

ply.

2. Undo the screws on the guide rails and

remove the unit.

Note

Note

Page 23

EB 6611-2 EN 23

Annex

9.2 Disposal

Î Observe local, national and internation-

al refuse regulations.

Î Do not dispose of components, lubri-

cants, and hazardous substances together with your other household waste.

10 Annex

10.1 After-sales service

Contact SAMSON's After-sales Service department for support concerning service or

repair work or when malfunctions or defects

arise.

E-mail

You can reach the After-sales Service Department at aftersalesservice@samson.de.

Addresses of SAMSONAG and its subsidiaries

The addresses of SAMSON AG, its subsidiaries, representatives and service facilities

worldwide can be found on the SAMSON

website (www.samson.de) or in all SAMSON

product catalogs.

Required specications

Please submit the following details:

− Order number and position number in

the order

− Type, serial number, rmware version,

device version

Table1: Troubleshooting

Error Possible reasons Recommended action

Screen remains black. No or incorrect power supply

connected.

Check the power supply and con-

nections (see section5.2).

Readings on screen not

legible.

No or incorrectly set reading

area of the screen.

Recalibrate screen (see sec-

tion5.3.6).

System components do not

perform the required actions.

Wrong project loaded or project

deleted.

Reload project (see section5.3.2).

Modules incorrectly/not

assigned.

Perform quick check (see sec-

tion5.4) and reassign modules, if

necessary (see section5.3.5).

TROVIS MOBILE web server

cannot be used.

Network settings are incorrect. Check settings and change, if

necessary (see section5.3.4).

Page 24

10.2 Licenses

10.2.1 GNU GENERAL PUBLIC LICENSE, Version 2, June 1991

Copyright (C) 1989, 1991 Free Software Foundation, Inc.

51 Franklin Street, Fifth Floor, Boston, MA 02110-1301, USA

Everyone is permitted to copy and distribute verbatim copies of this license document, but changing it is

not allowed.

Preamble

The licenses for most software are designed to take away your freedom to share and change it. By contrast, the GNU General Public License is intended to guarantee your freedom to share and change free

software--to make sure the software is free for all its users. This General Public License applies to most of

the Free Software Foundation‘s software and to any other program whose authors commit to using it.

(Some other Free Software Foundation software is covered by the GNU Lesser General Public License instead.) You can apply it to your programs, too.

When we speak of free software, we are referring to freedom, not price. Our General Public

Licenses are designed to make sure that you have the freedom to distribute copies of free

software (and charge for this service if you wish), that you receive source code or can get it if

you want it, that you can change the software or use pieces of it in new free programs; and

that you know you can do these things.

To protect your rights, we need to make restrictions that forbid anyone to deny you these

rights or to ask you to surrender the rights. These restrictions translate to certain responsibilities for you if you distribute copies of the software, or if you modify it.

For example, if you distribute copies of such a program, whether gratis or for a fee, you must

give the recipients all the rights that you have. You must make sure that they, too, receive or

can get the source code. And you must show them these terms so they know their rights.

We protect your rights with two steps: (1) copyright the software, and (2) offer you this license which gives you legal permission to copy, distribute and/or modify the software.

Also, for each author‘s protection and ours, we want to make certain that everyone under-

stands that there is no warranty for this free software. If the software is modied by someone

else and passed on, we want its recipients to know that what they have is not the original, so

that any problems introduced by others will not reect on the original authors‘ reputations.

Finally, any free program is threatened constantly by software patents. We wish to avoid the

danger that redistributors of a free program will individually obtain patent licenses, in effect

24 EB 6611-2 EN

Annex

Page 25

making the program proprietary. To prevent this, we have made it clear that any patent must

be licensed for everyone‘s free use or not licensed at all.

The precise terms and conditions for copying, distribution and modication follow.

TERMS AND CONDITIONS FOR COPYING, DISTRIBUTION AND MODIFICATION

0. This License applies to any program or other work which contains a notice placed by the copyright

holder saying it may be distributed under the terms of this General Public License. The „Program“,

below, refers to any such program or work, and a „work based on the Program“ means either the

Program or any derivative work under copyright law: that is to say, a work containing the Program

or a portion of it, either verbatim or with modications and/or translated into another language.

(Hereinafter, translation is included without limitation in the term „modication“.) Each licensee is

addressed as „you“.

Activities other than copying, distribution and modication are not covered by this License; they are

outside its scope. The act of running the Program is not restricted, and the output from the Program is

covered only if its contents constitute a work based on the Program (independent of having been

made by running the Program). Whether that is true depends on what the Program does.

1. You may copy and distribute verbatim copies of the Program‘s source code as you receive it, in any

medium, provided that you conspicuously and appropriately publish on each copy an appropriate

copyright notice and disclaimer of warranty; keep intact all the notices that refer to this License and

to the absence of any warranty; and give any other recipients of the Program a copy of this License

along with the Program.

You may charge a fee for the physical act of transferring a copy, and you may at your option offer

warranty protection in exchange for a fee.

2. You may modify your copy or copies of the Program or any portion of it, thus forming a work based

on the Program, and copy and distribute such modications or work under the terms of Section 1

above, provided that you also meet all of these conditions:

a) You must cause the modied les to carry prominent notices stating that you changed the les

and the date of any change.

b) You must cause any work that you distribute or publish, that in whole or in part contains or is

derived from the Program or any part thereof, to be licensed as a whole at no charge to all third

parties under the terms of this License.

c) If the modied program normally reads commands interactively when run, you must cause it,

when started running for such interactive use in the most ordinary way, to print or display an

announcement including an appropriate copyright notice and a notice that there is no warranty

(or else, saying that you provide a warranty) and that users may redistribute the program under

these conditions, and telling the user how to view a copy of this License. (Exception: if the Pro-

EB 6611-2 EN 25

Annex

Page 26

gram itself is interactive but does not normally print such an announcement, your work based on

the Program is not required to print an announcement.)

These requirements apply to the modied work as a whole. If identiable sections of that work are

not derived from the Program, and can be reasonably considered independent and separate works

in themselves, then this License, and its terms, do not apply to those sections when you distribute

them as separate works. But when you distribute the same sections as part of a whole which is a

work based on the Program, the distribution of the whole must be on the terms of this License, whose

permissions for other licensees extend to the entire whole, and thus to each and every part regardless of who wrote it.

Thus, it is not the intent of this section to claim rights or contest your rights to work written entirely by

you; rather, the intent is to exercise the right to control the distribution of derivative or collective

works based on the Program.

In addition, mere aggregation of another work not based on the Program with the Program (or with

a work based on the Program) on a volume of a storage or distribution medium does not bring the

other work under the scope of this License.

3. You may copy and distribute the Program (or a work based on it, under Section 2) in object code or

executable form under the terms of Sections 1 and 2 above provided that you also do one of the following:

a) Accompany it with the complete corresponding machine-readable source code, which must be

distributed under the terms of Sections 1 and 2 above on a medium customarily used for soft-

ware interchange; or.

b) Accompany it with a written offer, valid for at least three years, to give any third party, for a

charge no more than your cost of physically performing source distribution, a complete machine-readable copy of the corresponding source code, to be distributed under the terms of Sec-

tions 1 and 2 above on a medium customarily used for software interchange; or.

c) Accompany it with the information you received as to the offer to distribute corresponding

source code. (This alternative is allowed only for noncommercial distribution and only if you received the program in object code or executable form with such an offer, in accord with Subsection b above.)

The source code for a work means the preferred form of the work for making modications to it. For

an executable work, complete source code means all the source code for all modules it contains, plus

any associated interface denition les, plus the scripts used to control compilation and installation

of the executable. However, as a special exception, the source code distributed need not include

anything that is normally distributed (in either source or binary form) with the major components

(compiler, kernel, and so on) of the operating system on which the executable runs, unless that component itself accompanies the executable.

26 EB 6611-2 EN

Annex

Page 27

If distribution of executable or object code is made by offering access to copy from a designated

place, then offering equivalent access to copy the source code from the same place counts as distribution of the source code, even though third parties are not compelled to copy the source along with

the object code.

4. You may not copy, modify, sublicense, or distribute the Program except as expressly provided under

this License. Any attempt otherwise to copy, modify, sublicense or distribute the Program is void, and

will automatically terminate your rights under this License. However, parties who have received copies, or rights, from you under this License will not have their licenses terminated so long as such parties remain in full compliance.

5. You are not required to accept this License, since you have not signed it. However, nothing else

grants you permission to modify or distribute the Program or its derivative works. These actions are

prohibited by law if you do not accept this License. Therefore, by modifying or distributing the Program (or any work based on the Program), you indicate your acceptance of this License to do so,

and all its terms and conditions for copying, distributing or modifying the Program or works based

on it.

6. Each time you redistribute the Program (or any work based on the Program), the recipient automatically receives a license from the original licensor to copy, distribute or modify the Program subject to

these terms and conditions. You may not impose any further restrictions on the recipients‘ exercise of

the rights granted herein. You are not responsible for enforcing compliance by third parties to this License.

7. If, as a consequence of a court judgment or allegation of patent infringement or for any other reason (not limited to patent issues), conditions are imposed on you (whether by court order, agreement

or otherwise) that contradict the conditions of this License, they do not excuse you from the conditions of this License. If you cannot distribute so as to satisfy simultaneously your obligations under

this License and any other pertinent obligations, then as a consequence you may not distribute the

Program at all. For example, if a patent license would not permit royalty-free redistribution of the

Program by all those who receive copies directly or indirectly through you, then the only way you

could satisfy both it and this License would be to refrain entirely from distribution of the Program.

If any portion of this section is held invalid or unenforceable under any particular circumstance, the

balance of the section is intended to apply and the section as a whole is intended to apply in other

circumstances.

It is not the purpose of this section to induce you to infringe any patents or other property right

claims or to contest validity of any such claims; this section has the sole purpose of protecting the integrity of the free software distribution system, which is implemented by public license practices. Many people have made generous contributions to the wide range of software distributed through that

system in reliance on consistent application of that system; it is up to the author/donor to decide if

EB 6611-2 EN 27

Annex

Page 28

he or she is willing to distribute software through any other system and a licensee cannot impose

that choice.

This section is intended to make thoroughly clear what is believed to be a consequence of the rest of

this License.

8. If the distribution and/or use of the Program is restricted in certain countries either by patents or by

copyrighted interfaces, the original copyright holder who places the Program under this License may

add an explicit geographical distribution limitation excluding those countries, so that distribution is

permitted only in or among countries not thus excluded. In such case, this License incorporates the

limitation as if written in the body of this License.

9. The Free Software Foundation may publish revised and/or new versions of the General Public License from time to time. Such new versions will be similar in spirit to the present version, but may

differ in detail to address new problems or concerns.

Each version is given a distinguishing version number. If the Program species a version

number of this License which applies to it and „any later version“, you have the option of

following the terms and conditions either of that version or of any later version published

by the Free Software Foundation. If the Program does not specify a version number of this

License, you may choose any version ever published by the Free Software Foundation.

10. If you wish to incorporate parts of the Program into other free programs whose distribution conditions are different, write to the author to ask for permission. For software which is copyrighted by the

Free Software Foundation, write to the Free Software Foundation; we sometimes make exceptions for

this. Our decision will be guided by the two goals of preserving the free status of all derivatives of

our free software and of promoting the sharing and reuse of software generally.

NO WARRANTY

11. BECAUSE THE PROGRAM IS LICENSED FREE OF CHARGE, THERE IS NO WARRANTY FOR THE

PROGRAM, TO THE EXTENT PERMITTED BY APPLICABLE LAW. EXCEPT WHEN OTHERWISE STATED IN WRITING THE COPYRIGHT HOLDERS AND/OR OTHER PARTIES PROVIDE THE PROGRAM

„AS IS“ WITHOUT WARRANTY OF ANY KIND, EITHER EXPRESSED OR IMPLIED, INCLUDING, BUT

NOT LIMITED TO, THE IMPLIED WARRANTIES OF MERCHANTABILITY AND FITNESS FOR A PARTICULAR PURPOSE. THE ENTIRE RISK AS TO THE QUALITY AND PERFORMANCE OF THE PROGRAM IS WITH YOU. SHOULD THE PROGRAM PROVE DEFECTIVE, YOU ASSUME THE COST OF

ALL NECESSARY SERVICING, REPAIR OR CORRECTION.

12. IN NO EVENT UNLESS REQUIRED BY APPLICABLE LAW OR AGREED TO IN WRITING WILL ANY

COPYRIGHT HOLDER, OR ANY OTHER PARTY WHO MAY MODIFY AND/OR REDISTRIBUTE THE

PROGRAM AS PERMITTED ABOVE, BE LIABLE TO YOU FOR DAMAGES, INCLUDING ANY GENERAL, SPECIAL, INCIDENTAL OR CONSEQUENTIAL DAMAGES ARISING OUT OF THE USE OR

INABILITY TO USE THE PROGRAM (INCLUDING BUT NOT LIMITED TO LOSS OF DATA OR DATA

28 EB 6611-2 EN

Annex

Page 29

BEING RENDERED INACCURATE OR LOSSES SUSTAINED BY YOU OR THIRD PARTIES OR A FAILURE OF THE PROGRAM TO OPERATE WITH ANY OTHER PROGRAMS), EVEN IF SUCH HOLDER

OR OTHER PARTY HAS BEEN ADVISED OF THE POSSIBILITY OF SUCH DAMAGES.

END OF TERMS AND CONDITIONS

10.2.2 GNU GENERAL PUBLIC LICENSE, Version 3, 29 June 2007

Copyright © 2007 Free Software Foundation, Inc. <http://fsf.org/>

Everyone is permitted to copy and distribute verbatim copies of this license document, but changing it is

not allowed.

Preamble

The GNU General Public License is a free, copyleft license for software and other kinds of works.

The licenses for most software and other practical works are designed to take away your freedom to

share and change the works. By contrast, the GNU General Public License is intended to guarantee your

freedom to share and change all versions of a program--to make sure it remains free software for all its

users. We, the Free Software Foundation, use the GNU General Public License for most of our software;

it applies also to any other work released this way by its authors. You can apply it to your programs,

too.

When we speak of free software, we are referring to freedom, not price. Our General Public Licenses

are designed to make sure that you have the freedom to distribute copies of free software (and charge

for them if you wish), that you receive source code or can get it if you want it, that you can change the

software or use pieces of it in new free programs, and that you know you can do these things.

To protect your rights, we need to prevent others from denying you these rights or asking you to surrender the rights. Therefore, you have certain responsibilities if you distribute copies of the software, or if

you modify it: responsibilities to respect the freedom of others.

For example, if you distribute copies of such a program, whether gratis or for a fee, you must pass on to

the recipients the same freedoms that you received. You must make sure that they, too, receive or can get

the source code. And you must show them these terms so they know their rights.

Developers that use the GNU GPL protect your rights with two steps: (1) assert copyright on the software,

and (2) offer you this License giving you legal permission to copy, distribute and/or modify it.

For the developers‘ and authors‘ protection, the GPL clearly explains that there is no warranty for this

free software. For both users‘ and authors‘ sake, the GPL requires that modied versions be marked as

changed, so that their problems will not be attributed erroneously to authors of previous versions.

Some devices are designed to deny users access to install or run modied versions of the software inside

them, although the manufacturer can do so. This is fundamentally incompatible with the aim of protect-

EB 6611-2 EN 29

Annex

Page 30

ing users‘ freedom to change the software. The systematic pattern of such abuse occurs in the area of

products for individuals to use, which is precisely where it is most unacceptable. Therefore, we have designed this version of the GPL to prohibit the practice for those products. If such problems arise substantially in other domains, we stand ready to extend this provision to those domains in future versions of the

GPL, as needed to protect the freedom of users.

Finally, every program is threatened constantly by software patents. States should not allow patents to

restrict development and use of software on general-purpose computers, but in those that do, we wish to

avoid the special danger that patents applied to a free program could make it effectively proprietary. To

prevent this, the GPL assures that patents cannot be used to render the program non-free.

The precise terms and conditions for copying, distribution and modication follow.

TERMS AND CONDITIONS

0. Denitions.

“This License” refers to version 3 of the GNU General Public License.

“Copyright” also means copyright-like laws that apply to other kinds of works, such as semiconduc-

tor masks.

“The Program” refers to any copyrightable work licensed under this License. Each licensee is ad-

dressed as “you”. “Licensees” and “recipients” may be individuals or organizations.

To “modify” a work means to copy from or adapt all or part of the work in a fashion requiring copy-

right permission, other than the making of an exact copy. The resulting work is called a “modied

version” of the earlier work or a work “based on” the earlier work.

A “covered work” means either the unmodied Program or a work based on the Program.

To “propagate” a work means to do anything with it that, without permission, would make you directly or secondarily liable for infringement under applicable copyright law, except executing it on a

computer or modifying a private copy. Propagation includes copying, distribution (with or without

modication), making available to the public, and in some countries other activities as well.

To “convey” a work means any kind of propagation that enables other parties to make or receive

copies. Mere interaction with a user through a computer network, with no transfer of a copy, is not

conveying.

An interactive user interface displays “Appropriate Legal Notices” to the extent that it includes a convenient and prominently visible feature that (1) displays an appropriate copyright notice, and (2)

tells the user that there is no warranty for the work (except to the extent that warranties are provided), that licensees may convey the work under this License, and how to view a copy of this License. If

the interface presents a list of user commands or options, such as a menu, a prominent item in the

list meets this criterion.

30 EB 6611-2 EN

Annex

Page 31

1. Source Code.

The “source code” for a work means the preferred form of the work for making modications to it.

“Object code” means any non-source form of a work.

A “Standard Interface” means an interface that either is an ofcial standard dened by a recognized standards body, or, in the case of interfaces specied for a particular programming language,

one that is widely used among developers working in that language.

The “System Libraries” of an executable work include anything, other than the work as a whole, that

(a) is included in the normal form of packaging a Major Component, but which is not part of that

Major Component, and (b) serves only to enable use of the work with that Major Component, or to

implement a Standard Interface for which an implementation is available to the public in source

code form. A “Major Component”, in this context, means a major essential component (kernel, win-

dow system, and so on) of the specic operating system (if any) on which the executable work runs,

or a compiler used to produce the work, or an object code interpreter used to run it.

The “Corresponding Source” for a work in object code form means all the source code needed to

generate, install, and (for an executable work) run the object code and to modify the work, including scripts to control those activities. However, it does not include the work‘s System Libraries, or

general-purpose tools or generally available free programs which are used unmodied in performing those activities but which are not part of the work. For example, Corresponding Source includes

interface denition les associated with source les for the work, and the source code for shared libraries and dynamically linked subprograms that the work is specically designed to require, such

as by intimate data communication or control ow between those subprograms and other parts of

the work.

The Corresponding Source need not include anything that users can regenerate automatically from

other parts of the Corresponding Source.

The Corresponding Source for a work in source code form is that same work.

2. Basic Permissions.

All rights granted under this License are granted for the term of copyright on the Program, and are

irrevocable provided the stated conditions are met. This License explicitly afrms your unlimited permission to run the unmodied Program. The output from running a covered work is covered by this

License only if the output, given its content, constitutes a covered work. This License acknowledges

your rights of fair use or other equivalent, as provided by copyright law.

You may make, run and propagate covered works that you do not convey, without conditions so

long as your license otherwise remains in force. You may convey covered works to others for the sole

purpose of having them make modications exclusively for you, or provide you with facilities for

running those works, provided that you comply with the terms of this License in conveying all material for which you do not control copyright. Those thus making or running the covered works for you

EB 6611-2 EN 31

Annex

Page 32

must do so exclusively on your behalf, under your direction and control, on terms that prohibit them

from making any copies of your copyrighted material outside their relationship with you.

Conveying under any other circumstances is permitted solely under the conditions stated below. Sub-

licensing is not allowed; section 10 makes it unnecessary.

3. Protecting Users‘ Legal Rights From Anti-Circumvention Law.

No covered work shall be deemed part of an effective technological measure under any applicable

law fullling obligations under article 11 of the WIPO copyright treaty adopted on 20 December

1996, or similar laws prohibiting or restricting circumvention of such measures.

When you convey a covered work, you waive any legal power to forbid circumvention of technolog-

ical measures to the extent such circumvention is effected by exercising rights under this License with

respect to the covered work, and you disclaim any intention to limit operation or modication of the

work as a means of enforcing, against the work‘s users, your or third parties‘ legal rights to forbid

circumvention of technological measures.

4. Conveying Verbatim Copies.

You may convey verbatim copies of the Program‘s source code as you receive it, in any medium,

provided that you conspicuously and appropriately publish on each copy an appropriate copyright

notice; keep intact all notices stating that this License and any non-permissive terms added in accord

with section 7 apply to the code; keep intact all notices of the absence of any warranty; and give all

recipients a copy of this License along with the Program.

You may charge any price or no price for each copy that you convey, and you may offer support or

warranty protection for a fee.

5. Conveying Modied Source Versions.

You may convey a work based on the Program, or the modications to produce it from the Program,

in the form of source code under the terms of section 4, provided that you also meet all of these conditions:

a) The work must carry prominent notices stating that you modied it, and giving a relevant date.

b) The work must carry prominent notices stating that it is released under this License and any con-

ditions added under section 7. This requirement modies the requirement in section 4 to “keep

intact all notices”.

c) You must license the entire work, as a whole, under this License to anyone who comes into pos-

session of a copy. This License will therefore apply, along with any applicable section 7 additional terms, to the whole of the work, and all its parts, regardless of how they are packaged.

This License gives no permission to license the work in any other way, but it does not invalidate

such permission if you have separately received it.

32 EB 6611-2 EN

Annex

Page 33

d) If the work has interactive user interfaces, each must display Appropriate Legal Notices; howev-

er, if the Program has interactive interfaces that do not display Appropriate Legal Notices, your

work need not make them do so.

A compilation of a covered work with other separate and independent works, which are not by their

nature extensions of the covered work, and which are not combined with it such as to form a larger

program, in or on a volume of a storage or distribution medium, is called an “aggregate” if the

compilation and its resulting copyright are not used to limit the access or legal rights of the compilation‘s users beyond what the individual works permit. Inclusion of a covered work in an aggregate

does not cause this License to apply to the other parts of the aggregate.

6. Conveying Non-Source Forms.

You may convey a covered work in object code form under the terms of sections 4 and 5, provided

that you also convey the machine-readable Corresponding Source under the terms of this License, in

one of these ways:

a) Convey the object code in, or embodied in, a physical product (including a physical distribution

medium), accompanied by the Corresponding Source xed on a durable physical medium customarily used for software interchange.

b) Convey the object code in, or embodied in, a physical product (including a physical distribution

medium), accompanied by a written offer, valid for at least three years and valid for as long as

you offer spare parts or customer support for that product model, to give anyone who possesses

the object code either (1) a copy of the Corresponding Source for all the software in the product

that is covered by this License, on a durable physical medium customarily used for software interchange, for a price no more than your reasonable cost of physically performing this conveying of source, or (2) access to copy the Corresponding Source from a network server at no

charge.

c) Convey individual copies of the object code with a copy of the written offer to provide the Cor-

responding Source. This alternative is allowed only occasionally and noncommercially, and only

if you received the object code with such an offer, in accord with subsection 6b.

d) Convey the object code by offering access from a designated place (gratis or for a charge), and

offer equivalent access to the Corresponding Source in the same way through the same place at

no further charge. You need not require recipients to copy the Corresponding Source along with

the object code. If the place to copy the object code is a network server, the Corresponding

Source may be on a different server (operated by you or a third party) that supports equivalent

copying facilities, provided you maintain clear directions next to the object code saying where

to nd the Corresponding Source. Regardless of what server hosts the Corresponding Source,

you remain obligated to ensure that it is available for as long as needed to satisfy these requirements.

EB 6611-2 EN 33

Annex

Page 34

e) Convey the object code using peer-to-peer transmission, provided you inform other peers where

the object code and Corresponding Source of the work are being offered to the general public

at no charge under subsection 6d.

A separable portion of the object code, whose source code is excluded from the Corresponding

Source as a System Library, need not be included in conveying the object code work.

A “User Product” is either (1) a “consumer product”, which means any tangible personal property

which is normally used for personal, family, or household purposes, or (2) anything designed or

sold for incorporation into a dwelling. In determining whether a product is a consumer product,

doubtful cases shall be resolved in favor of coverage. For a particular product received by a particular user, “normally used” refers to a typical or common use of that class of product, regardless of the

status of the particular user or of the way in which the particular user actually uses, or expects or is

expected to use, the product. A product is a consumer product regardless of whether the product has

substantial commercial, industrial or non-consumer uses, unless such uses represent the only signicant mode of use of the product.

“Installation Information” for a User Product means any methods, procedures, authorization keys, or

other information required to install and execute modied versions of a covered work in that User

Product from a modied version of its Corresponding Source. The information must sufce to ensure

that the continued functioning of the modied object code is in no case prevented or interfered with

solely because modication has been made.

If you convey an object code work under this section in, or with, or specically for use in, a User

Product, and the conveying occurs as part of a transaction in which the right of possession and use

of the User Product is transferred to the recipient in perpetuity or for a xed term (regardless of how

the transaction is characterized), the Corresponding Source conveyed under this section must be accompanied by the Installation Information. But this requirement does not apply if neither you nor any

third party retains the ability to install modied object code on the User Product (for example, the

work has been installed in ROM).

The requirement to provide Installation Information does not include a requirement to continue to

provide support service, warranty, or updates for a work that has been modied or installed by the

recipient, or for the User Product in which it has been modied or installed. Access to a network

may be denied when the modication itself materially and adversely affects the operation of the net-

work or violates the rules and protocols for communication across the network.

Corresponding Source conveyed, and Installation Information provided, in accord with this section

must be in a format that is publicly documented (and with an implementation available to the public

in source code form), and must require no special password or key for unpacking, reading or copying.

34 EB 6611-2 EN

Annex

Page 35

7. Additional Terms.

“Additional permissions” are terms that supplement the terms of this License by making exceptions

from one or more of its conditions. Additional permissions that are applicable to the entire Program

shall be treated as though they were included in this License, to the extent that they are valid under

applicable law. If additional permissions apply only to part of the Program, that part may be used

separately under those permissions, but the entire Program remains governed by this License without

regard to the additional permissions.

When you convey a copy of a covered work, you may at your option remove any additional permissions from that copy, or from any part of it. (Additional permissions may be written to require

their own removal in certain cases when you modify the work.) You may place additional permissions on material, added by you to a covered work, for which you have or can give appropriate

copyright permission.

Notwithstanding any other provision of this License, for material you add to a covered work, you

may (if authorized by the copyright holders of that material) supplement the terms of this License

with terms:

a) Disclaiming warranty or limiting liability differently from the terms of sections 15 and 16 of this

License; or

b) Requiring preservation of specied reasonable legal notices or author attributions in that materi-

al or in the Appropriate Legal Notices displayed by works containing it; or

c) Prohibiting misrepresentation of the origin of that material, or requiring that modied versions of

such material be marked in reasonable ways as different from the original version; or

d) Limiting the use for publicity purposes of names of licensors or authors of the material; or

e) Declining to grant rights under trademark law for use of some trade names, trademarks, or ser-

vice marks; or

f) Requiring indemnication of licensors and authors of that material by anyone who conveys the

material (or modied versions of it) with contractual assumptions of liability to the recipient, for

any liability that these contractual assumptions directly impose on those licensors and authors.

All other non-permissive additional terms are considered “further restrictions” within the meaning of

section 10. If the Program as you received it, or any part of it, contains a notice stating that it is governed by this License along with a term that is a further restriction, you may remove that term. If a license document contains a further restriction but permits relicensing or conveying under this License,

you may add to a covered work material governed by the terms of that license document, provided

that the further restriction does not survive such relicensing or conveying.

EB 6611-2 EN 35

Annex

Page 36

If you add terms to a covered work in accord with this section, you must place, in the relevant source

les, a statement of the additional terms that apply to those les, or a notice indicating where to nd

the applicable terms.

Additional terms, permissive or non-permissive, may be stated in the form of a separately written li-

cense, or stated as exceptions; the above requirements apply either way.

8. Termination.

You may not propagate or modify a covered work except as expressly provided under this License.

Any attempt otherwise to propagate or modify it is void, and will automatically terminate your rights

under this License (including any patent licenses granted under the third paragraph of section 11).

However, if you cease all violation of this License, then your license from a particular copyright holder is reinstated (a) provisionally, unless and until the copyright holder explicitly and nally terminates your license, and (b) permanently, if the copyright holder fails to notify you of the violation by

some reasonable means prior to 60 days after the cessation.

Moreover, your license from a particular copyright holder is reinstated permanently if the copyright

holder noties you of the violation by some reasonable means, this is the rst time you have received

notice of violation of this License (for any work) from that copyright holder, and you cure the violation prior to 30 days after your receipt of the notice.

Termination of your rights under this section does not terminate the licenses of parties who have received copies or rights from you under this License. If your rights have been terminated and not permanently reinstated, you do not qualify to receive new licenses for the same material under section

10.

9. Acceptance Not Required for Having Copies.

You are not required to accept this License in order to receive or run a copy of the Program. Ancil-

lary propagation of a covered work occurring solely as a consequence of using peer-to-peer transmission to receive a copy likewise does not require acceptance. However, nothing other than this License grants you permission to propagate or modify any covered work. These actions infringe copyright if you do not accept this License. Therefore, by modifying or propagating a covered work, you

indicate your acceptance of this License to do so.

10. Automatic Licensing of Downstream Recipients.

Each time you convey a covered work, the recipient automatically receives a license from the origi-

nal licensors, to run, modify and propagate that work, subject to this License. You are not responsible for enforcing compliance by third parties with this License.

An “entity transaction” is a transaction transferring control of an organization, or substantially all

assets of one, or subdividing an organization, or merging organizations. If propagation of a covered work results from an entity transaction, each party to that transaction who receives a copy of

36 EB 6611-2 EN

Annex

Page 37

the work also receives whatever licenses to the work the party‘s predecessor in interest had or could

give under the previous paragraph, plus a right to possession of the Corresponding Source of the

work from the predecessor in interest, if the predecessor has it or can get it with reasonable efforts.

You may not impose any further restrictions on the exercise of the rights granted or afrmed under

this License. For example, you may not impose a license fee, royalty, or other charge for exercise of

rights granted under this License, and you may not initiate litigation (including a cross-claim or

counterclaim in a lawsuit) alleging that any patent claim is infringed by making, using, selling, offering for sale, or importing the Program or any portion of it.

11. Patents.

A “contributor” is a copyright holder who authorizes use under this License of the Program or a

work on which the Program is based. The work thus licensed is called the contributor‘s “contributor

version”.

A contributor‘s “essential patent claims” are all patent claims owned or controlled by the contributor,

whether already acquired or hereafter acquired, that would be infringed by some manner, permitted

by this License, of making, using, or selling its contributor version, but do not include claims that

would be infringed only as a consequence of further modication of the contributor version. For purposes of this denition, “control” includes the right to grant patent sublicenses in a manner consistent

with the requirements of this License.

Each contributor grants you a non-exclusive, worldwide, royalty-free patent license under the con-

tributor‘s essential patent claims, to make, use, sell, offer for sale, import and otherwise run, modify

and propagate the contents of its contributor version.

In the following three paragraphs, a “patent license” is any express agreement or commitment, however denominated, not to enforce a patent (such as an express permission to practice a patent or

covenant not to sue for patent infringement). To “grant” such a patent license to a party means to

make such an agreement or commitment not to enforce a patent against the party.

If you convey a covered work, knowingly relying on a patent license, and the Corresponding Source

of the work is not available for anyone to copy, free of charge and under the terms of this License,

through a publicly available network server or other readily accessible means, then you must either

(1) cause the Corresponding Source to be so available, or (2) arrange to deprive yourself of the