Page 1

Specifications subject to change without notice

Edition

EN

The device may only be mounted and started

Operating, assembly and maintenance instructions

BR 31a Rack-and-pinion Actuator,

SRP and DAP

1. General

These instructions are intended to support the user in the

assembly, maintenance, and repair of BR 31a Rack-and-

Fig. 1 - Rack-and-pinion actuator

0. Contents

1. General 1

2. Design, principle of operation, and dimensions 1

3. Actuator designation and nameplate 1

4. Operating conditions 2

4.1 Design 2

4.2 Warnings 2

4.3 Operating media 3

4.4 Supply pressure 3

4.5 Operating temperatures 3

4.6 Response time 3

4.7 Rotation and travel limitation 3

4.8 Lubrication 3

4.9 Coating and corrosion protection 3

4.10 Function and direction of rotation 4

4.11 Fail-safe position 4

5. Actuator design und mounting instructions 4

5.1 Principle of operation 4

5.2 Important safety instructions 5

5.3 Control and connections 5

5.4 Mounting accessories 5

5.5 Mounting the actuator onto valves 6

5.6 Changing the direction of action/fail-safe position 6

5.7 Alternative mounting options 6

6. Maintenance and assembly instructions 7

6.1 Fourth generation of rack-and-pinion actuators

(version manufactured from 2000)

6.2 Third generation rack-and-pinion actuators 13

7. Storage instructions 18

8. Customer inquiries 18

1 of 18

pinion Actuators.

Before operating the unit, please read this manual thor ough l y

and retain it for future reference.

Technical specifications, as a result of further development of

valves mentioned in these instructions are subject to

alteration without notice.

The text and illustrations do not necessarily display the scope

of supply or any ordering of spare parts.

Drawings and graphics are not to scale. Customer-specific

designs not in accordance with our standard product range

are not shown.

Parts subject to wear are not covered by the warranty.

up by skilled staff who are familiar with the

assembly, start-up, and operation of this

product.

In these maintenance and assembly instructions, the term

skilled staff refers to individuals who are able to judge the

responsibilities assigned to them as well as recognize

potential hazards due to their specialized training,

knowledge, and experience as well as their special

knowledge of the relevant standards.

These instructions apply to the actuator only. In addition,

refer to the instructio ns of the moun ted valv e.

2. Design, principle of operation, and dimensions

Design, principle of operation, and dimensions including all

further details and technical data can be found in the Data

Sheet <TB 31a>.

3. Actuator designation and nameplate

The actuator type, size, operating pressure, output torque,

direction of rotation, fail-safe action, operating temperature,

and type of attachment are determined by the actuator

designation.

: August 2017 Maintenance EB 31a-01_

Page 2

Specifications subject to change without notice

Edition

EN

• Maxi mum per mis si ble pr ess ur e (fixed)

6 Always 10 bar for BR 31a

• Pr inciple of opera tion (variable)

7 Actuator function: Single-acting/double-acting

8 Direction of action : CW = Clockwise

CCW = Counterclockwise

9 Schematic diagram of the spring function with the air

connection. Schematic diagram of NAMUR interface

with identification for ports 2 and 4

• Exact type designation (variable)

10 Series: BR 31a

11 Type: SRP / DAP

12 Actuator size: 6 to 10000

13 Spring design ation: 2,5 to 6 (bar)

• Opening angle (fixed, depending on actuator size)

14 0-90° +5/-15°; 0-120°+/+5/-15°; 0-180° +5/-15°;

• Article number (variable)

15 Pfeiffer article number

• Version acc. to EN (fixed, depending on actuator size)

Example: F07-Y-D-17

16 Flange F07

17 Spigot ( Y )

18 Diagonal square drive ( D )

19 Square drive, width across flats 17

• Torques (variable)

20 Specification of the actuator torque depending on

supply pressure.

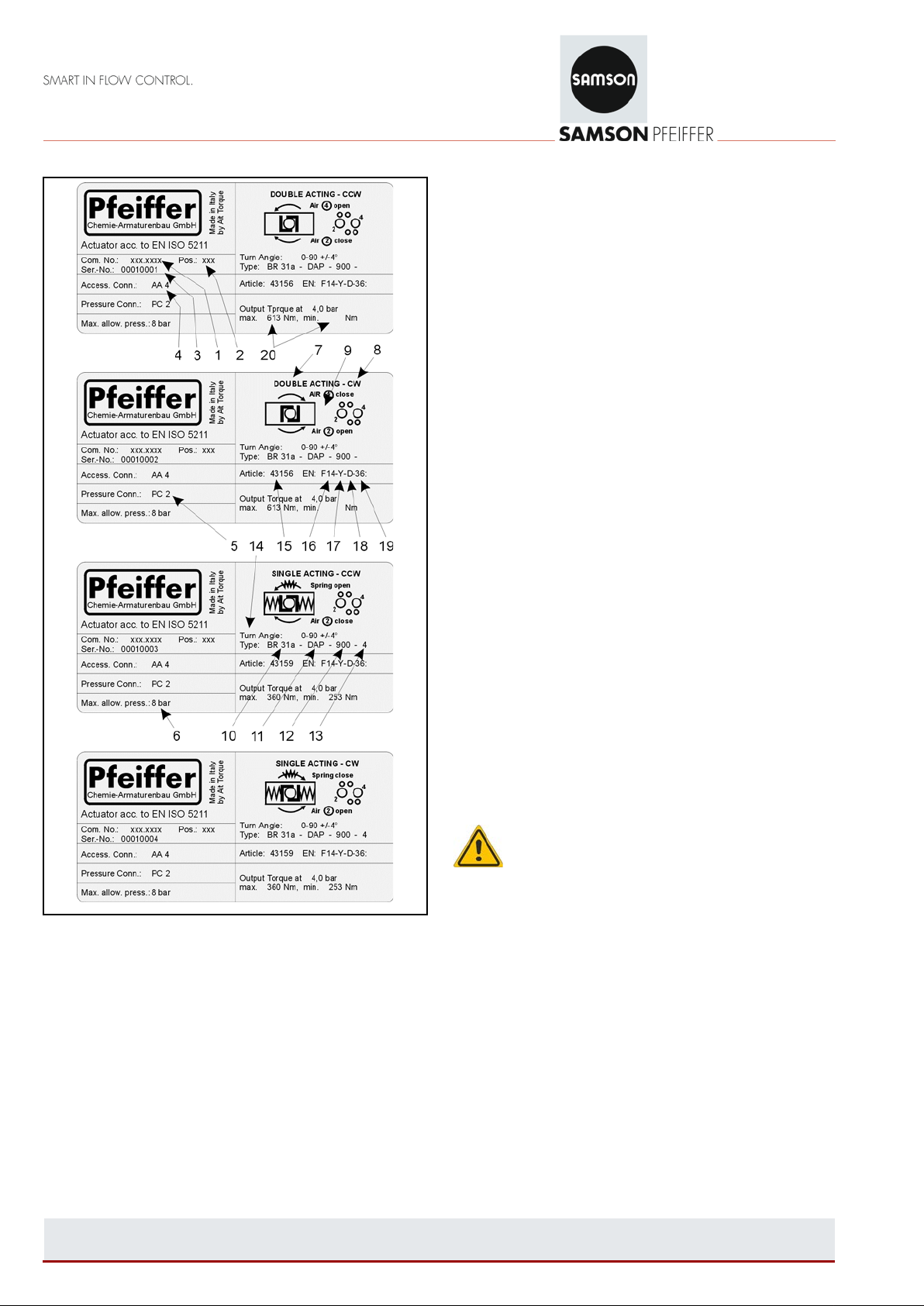

Fig. 2 – Name plates

Rack-and-pinion actuators have nameplates, which show the

following information:

• Unique identification (variabel)

1 Order number

2 Position number in the order

3 Serial number (automatically assigned)

• Connection for accessories (fixed, depending on

actuator size)

4 AA1 to AA5 (VDE/VDI actuator size 1 to 4)

• Pressure connection (fixed, depending on actuator size)

5 PC1 = G 1/8“ PC3 = G 3/8“

PC2 = G 1/4“ PC4 = G 1/2“

2 of 18

4. Operating conditions

4.1 Operating conditions

The rack-and-pinion actuator is suitable for use in closed and

open environments without additional weather protection.

4.2 Warnings:

• Referring to the Machinery Directive 2006/46/EU, the

actuators can be classified as “partly completed

machinery” (see declaration of incorporation).

As a result, the actuator cannot put into service until the

machinery and/or the system, into which the actuator is to

be incorporated, has been declared in conformity with the

provisions of the Directive 2006/42/EU.

• Actuators are designed, produced, and classifi ed

according to the ATEX Directive 2014/34/EU.

The use of the actuators in potentially explosive

atmosphere zones must comply with the ATEX

classification indicated on the actuator nameplate and

according to the ATEX safety regulations.

• It is important that the actuator is used only within the

working limits permitted in the technical specifications.

: August 2017 Maintenance EB 31a-01_

Page 3

Specifications subject to change without notice

Edition

EN

Manufacturer

Lubricant

Tennex

TS 2066/2

• Do not operate the actuator outside the temperature

limits: this could damage internal and external

components (disassembly of single-acting actuators may

be dangerous).

• Do not operate the actuator outside the pressure limits:

this could damage internal parts as well as cause damage

to the housing and end caps.

• D o not use the actuator in corrosive environments with

insufficient protection: this could damage internal and

external parts.

• D o not disassem ble ind iv idua l sprin g cartridges; this may

result in personal injury. If maintenance to springs is

necessary, send them to Pfeiffer.

• C lose and disco nne ct all air su pply lines and ma ke sure

that pneumatic connections are vented during

maintenance and when mounting the actuator onto the

valve.

• Do not disassemble the actuator or remove the end caps

while the actuator is pressurized.

• The actuators are designed to be used only on valves.

• Bef ore mou ntin g the actuator onto the valve, make sure

that the direction of rotation and the position indicator are

in the correct position.

• If the actuator is incorporated into a system or must be

used in safety devices or circuits, the operator must

ensure that the national and local safety laws and

regulations are observed.

4.3 Operating media:

Dry or lubricated air or inert gases, provided that they are

compatible with the actuator’s internal parts and lubricant

used.

Note: The operating media must have a dew point

equal to -20 C (-4°F) or at least 10°C below the

ambient temperature. The maximum particle size

contained into the operating media must not

exceed 30 μm.

Note: For operation at low and high temperatures,

special lubricant is required. Please contact

Pfeiffer. A low or high temperature can slightly

influence the torque of the actuator.

4.6 Response time:

Refer to the corresponding data sheets for the response

times.

Note: The response time depends on several

factors, e.g. supply pressure, supply capa city of

the operating medium (pipe diameter, flow

capacity of pneumatic accessories), valve type, valve torque

and characteristics, applied safet y factor, o perat ing fr equ enc y

and temperature etc.).

4.7 Rotation and travel li m itation:

Refer to the data sheet for the travel of the rack-and-pinion

actuators:

Standard actuator: 90° rotating angle, with end stop

setting at 0° and 90°, +5/–15°

adjustable

120° actuator: 120° rotating angle with end stop

setting at 0° and 120°, +5/–15°

adjustable

180° actuator: 180° rotating angle with end stop

setting at 0° and 180°, +5/–15°

adjustable

4.8 Lubrication:

The actuators are delivered ready lubricated for the service

life of the actuator under normal operating conditions. The

standard lubricant is approved for the temperature range from

-40°C (-40°F) to +80 C (+176°F).

For low (SLT) and high (HT) temperatures, a special lubricant

is required. Contact Pfeiffer in this case.

4.4 Supply pressure:

The maximum supply pressure is 10 bar (145 psi).

For double-acting and single-acting actuators, the operating

pressure range is 2.5 bar (36 psi) to 10 bar (145 psi).

4.5 Operating temperatures:

• Standard actuator:

from -40°C (-40°F) to +80°C (+176°F).

• Low-temperature version SLT with silicone O-rings:

from -55°C (-67°F) to +80°C (+176°F).

• High-temperature version HT with FPM O-rings:

from -15°C (+5°F) to +150°C (+300°F).

3 of 18

: August 2017 Maintenance EB 31a-01_

Table 1 - Lubricant recommendation

4.9 Coating and corrosion protection:

All actuators are protected against corrosion under normal

weather conditions. The different types of coating are

described in the data sheet

Note: Before mounting the actuator in a corrosive

environment, make sure that the correct type of

corrosion protection has been chosen.

Page 4

Specifications subject to change without notice

Edition

EN

4.10 Function and direction of rotation:

The actuator is a pneumatic component for remote actuation

of valves. For the actuation (90°, 120° or 180° rotation), there

are different actuator versions:

• Direct mounting of a solenoid valve (5/2 or 5/3-way for

double acting, 3/2-way for single acting) for connecting to

ports 2 and 4.

• Hook-up (to ports 2 and 4) with a separate control unit.

• The standard direction of rotation is the clockwise

direction to close a mounted valve. The counterclockwise

direction for double-acting actuators is achieved by

applying air pressure to port 2.

• For actuat ors mar ked “CCW”, the direction of rotation to

close the valve is counterclockwise, the clockwise

direction of rotation (CW) is achieved by applying air

pressure to port 2.

4.11 Fail-safe position:

• Fail-close: clockwise (SRP only)

• Fail-open: counterclockwise (SRP only)

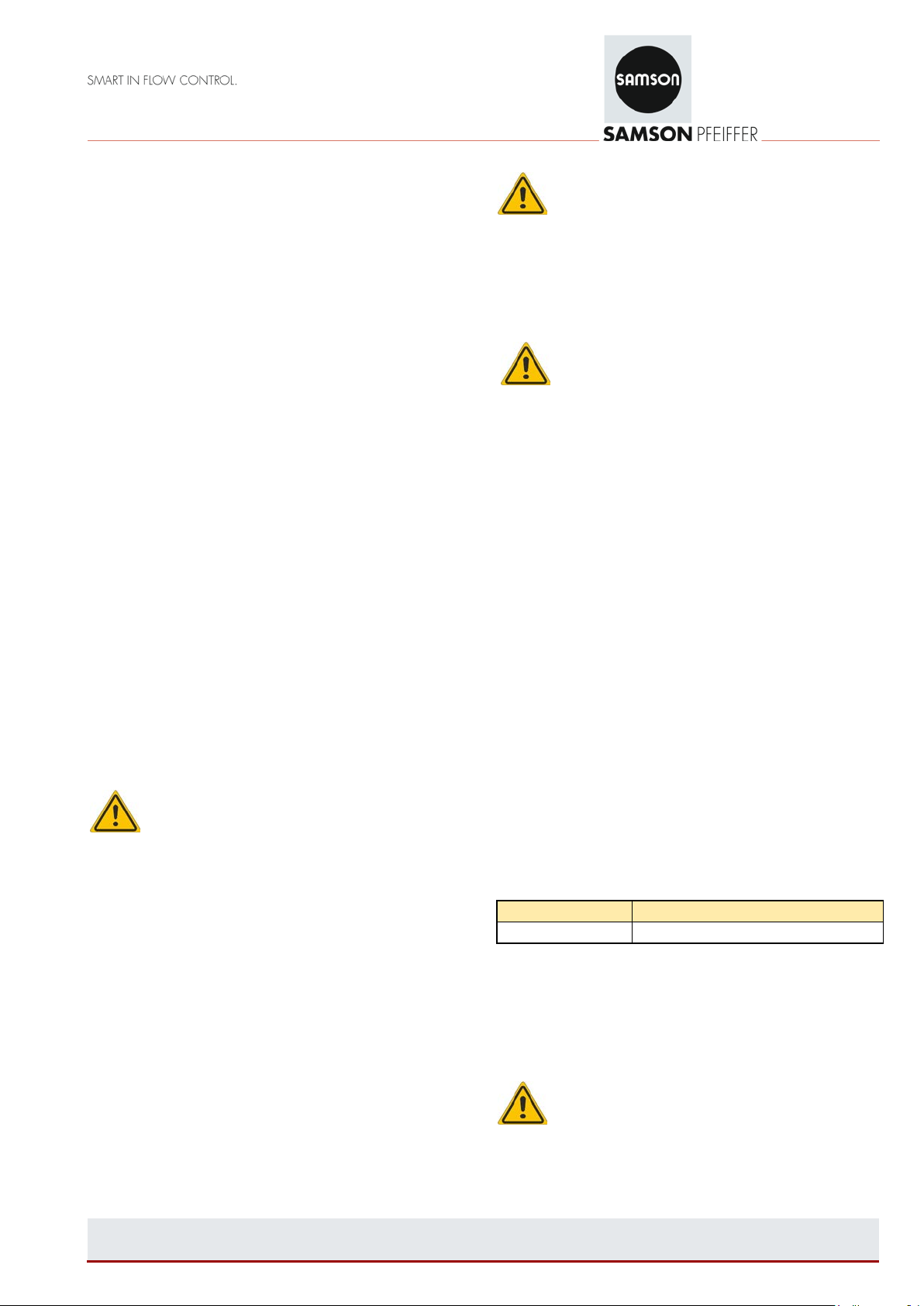

Fig. 4 - CCW direction

If the shaft of the actuator is to turn in a clockwise direction

when the valve opens, the pistons must be installed in the

opposite way to the standard version (see Fig. 4).

The shaft turns from the start position OPEN to the end

position CLOSED in clockwise direction (SRP only). The

actuator is delivered in the start position.

Fig. 3 - CW direction

The standard version of the Series 31a Actuators is mounted

in the direction of the media flow.

When pressure is applied to port 2, the shaft turns from the

start position CLOSED to the end position OPEN in the

counterclockwise direction.

In case of pressure loss at port 2, the shaft turns clockwise to

the start position CLOSED (SRP only). The actuator is

delivered in the start position.

Note: If mounted diagonal to the media flow, make

sure that the position indicator is set correctly (turn

90°, see mounting instructions

4 of 18

5. Actuator design und mounting instructions

The BR 31a Actuator operates with a 90° (optionally 120° or

180°) angle of rotation to open and close different types of

valves

Note: All the necessary technical information to

correctly mount the actuator onto a valve, e.g.

dimensions, output torque, air volume, travel

adjustment, response time, operating temperature, and

direction of rotation are clearly stated on the nameplate, in

the catalog and/or data sheets.

Read the technical information carefully before proceeding

with mounting the actuator.

5.1 Principle of operation:

• Double-acting actuator (standard direction of rotation)

Fig. 5

Fig. 6

: August 2017 Maintenance EB 31a-01_

Page 5

Specifications subject to change without notice

Edition

EN

Screw

M5

M6

M8

M10

M12

M14

M16

M20

M24

M30

Tightening

in NM

5

6

10

11

23

25

48

52

82

86

132

138

200

210

390

410

675

705

1340

1400

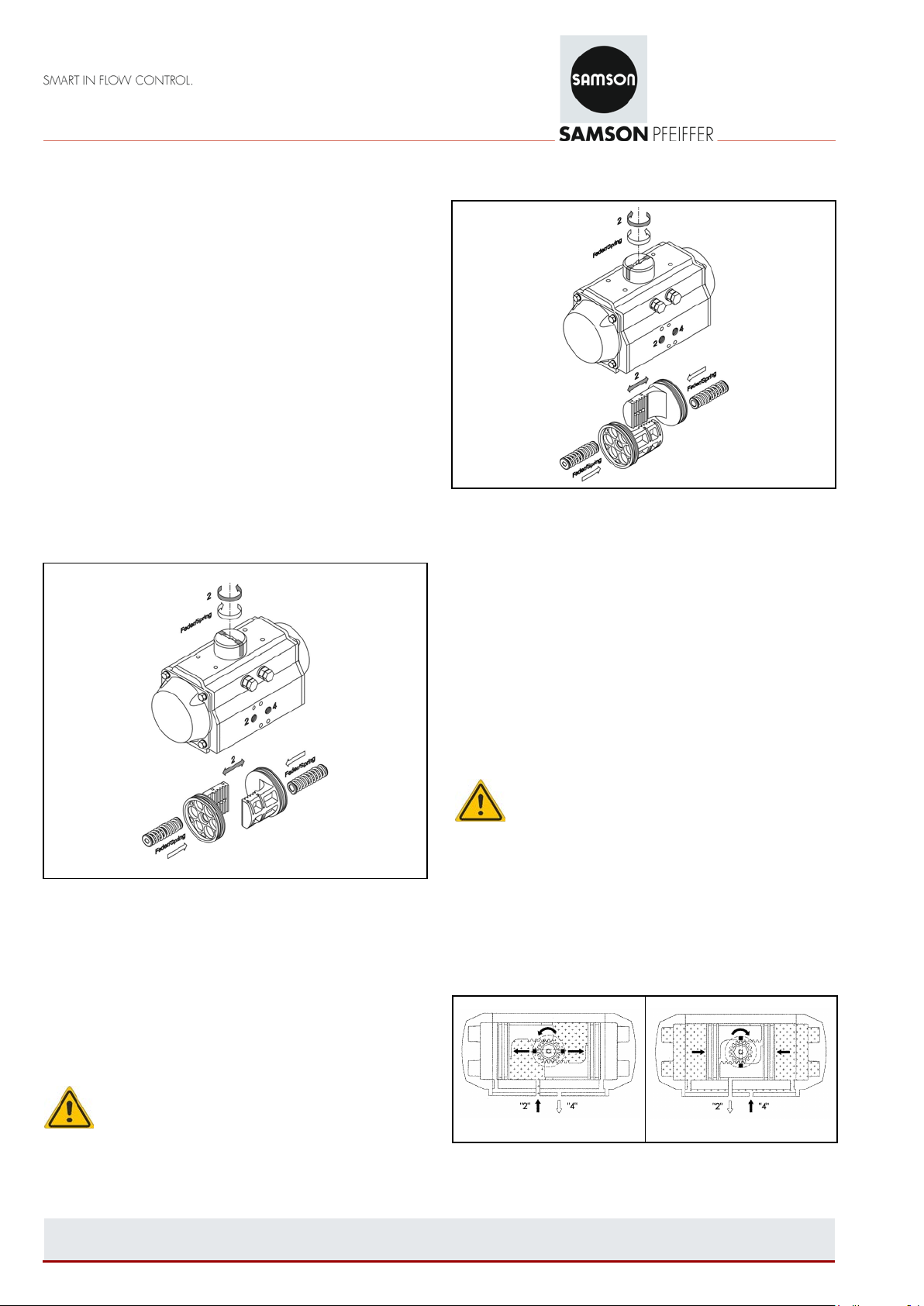

Air supplied to port 2 (Fig. 5) forces the pistons apart and

towards the end positions. Air is vented at port 4. This is

based on a clockwise direction of rotation.

Air supplied to port 4 (Fig. 6) forces the pistons together. Air

is vented at port 2. This is based on a clockwise direction of

rotation.

• Single-a cting actuat or (standard direction of rotation)

Fig. 7

Fig. 8

Air supplied to port 2 (Fig. 7) forces the pistons apart and

towards the end positions. The springs are compressed. Air is

vented at port 4. This is based on a clockwise direction of

rotation.

A loss of air pressure at port 2 (Fig. 8) allows the pistons to

return to the start position. Air is vented at port 2. This is

based on a clockwise direction of rotation.

5.3 Control and connecti o ns:

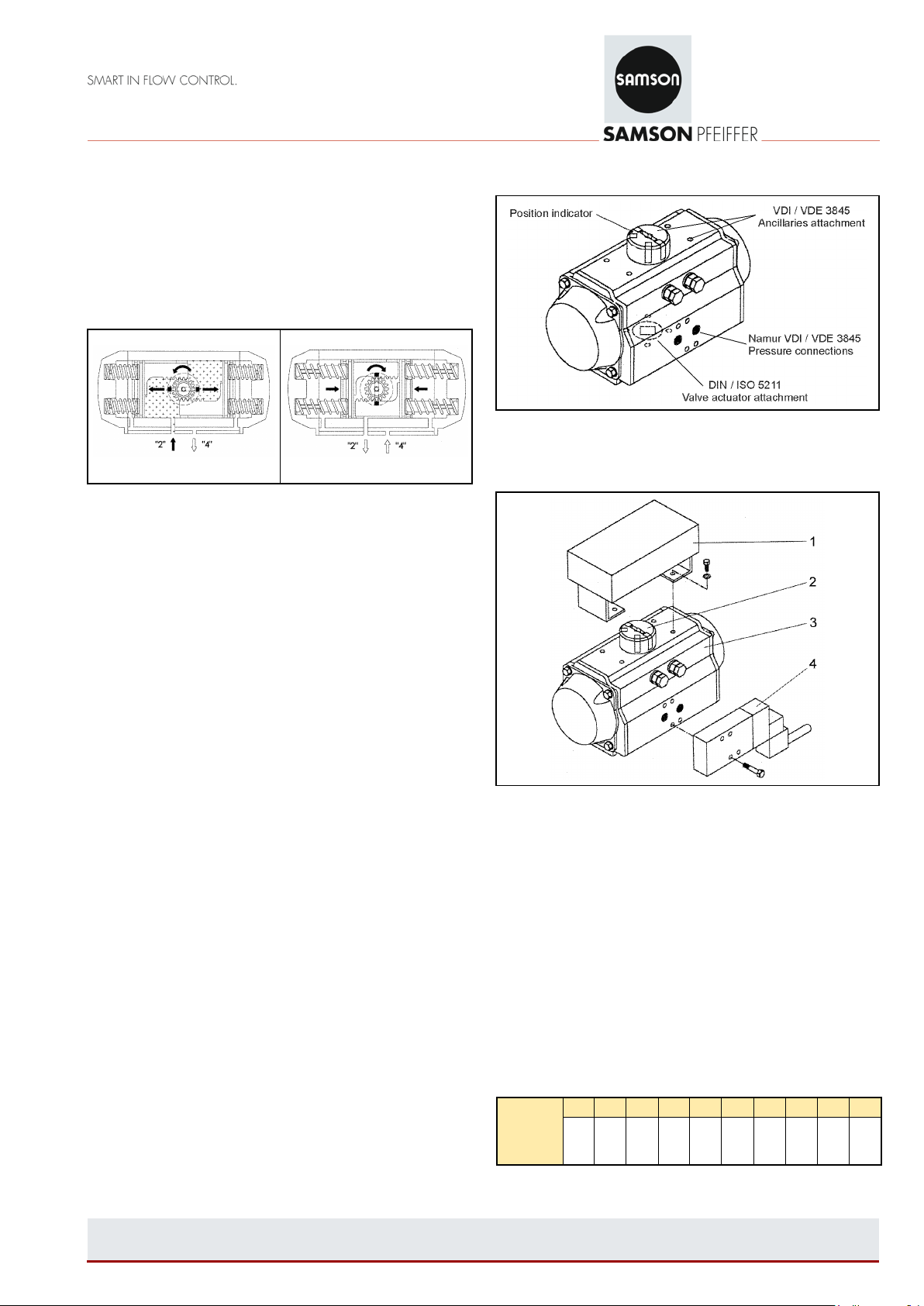

Fig. 9 – Connections

5.4 Mounting accessories

5.2 Important safety instr u ctions

• For safety reasons, the actuator must not be pressurized

when mounting the actuator onto the valve. Risk of injury.

• When connecting the air pressure to the actuator, it is

important that all connecting parts are clean and free from

dirt, especially the thread connections, pipe screw fittings,

and gaskets.

• When fitting accessories to the actuator, make sure that

the emergency operator control of the solenoid valve and

the top end of the shaft are easily accessible for possible

manual operation of the actuator.

• Before mounting the actuator onto the valve, make sure

that the actuator is correctly aligned based on the direction

of rotation required.

• For single-acting actuators, make sure dan ger ou s and/or

corrosive substances in the working environment cannot

enter the spring chambers through the use of suitable

filters and/or solenoid valves.

• Remove plugs from the actuator’s pneumatic connections

during installation and operation. Protect any unused

pneumatic connections of actuators.

5 of 18

Fig. 10 - Mounting accessories

• Mounting the solenoid valve:

Before mounting the solenoid valve, check that the

actuator is in the initial posit ion (closed position, pistons

retracted). For standard mounting and clockwise rotation

(closing): The groove on the shaft or position indicator (2)

must be in the closed position, at a right angle to the

longitudinal axis of the actuator. Mount the solenoid valve

(4) onto the actuator (3) using the suitable screws (see

Table 2 for max. tightening torque).

• Mounting the limit switch box:

Fit the limit switch box and bracket (1) onto the actuator

(3) using suitable screws (see Table 2 for max. tightening

torque).

torque

Table 2 - Tightening torque

bis

bis

bis

bis

bis

bis

bis

bis

bis

bis

: August 2017 Maintenance EB 31a-01_

Page 6

Specifications subject to change without notice

Edition

EN

5.5 Mounting the actuator onto valves:

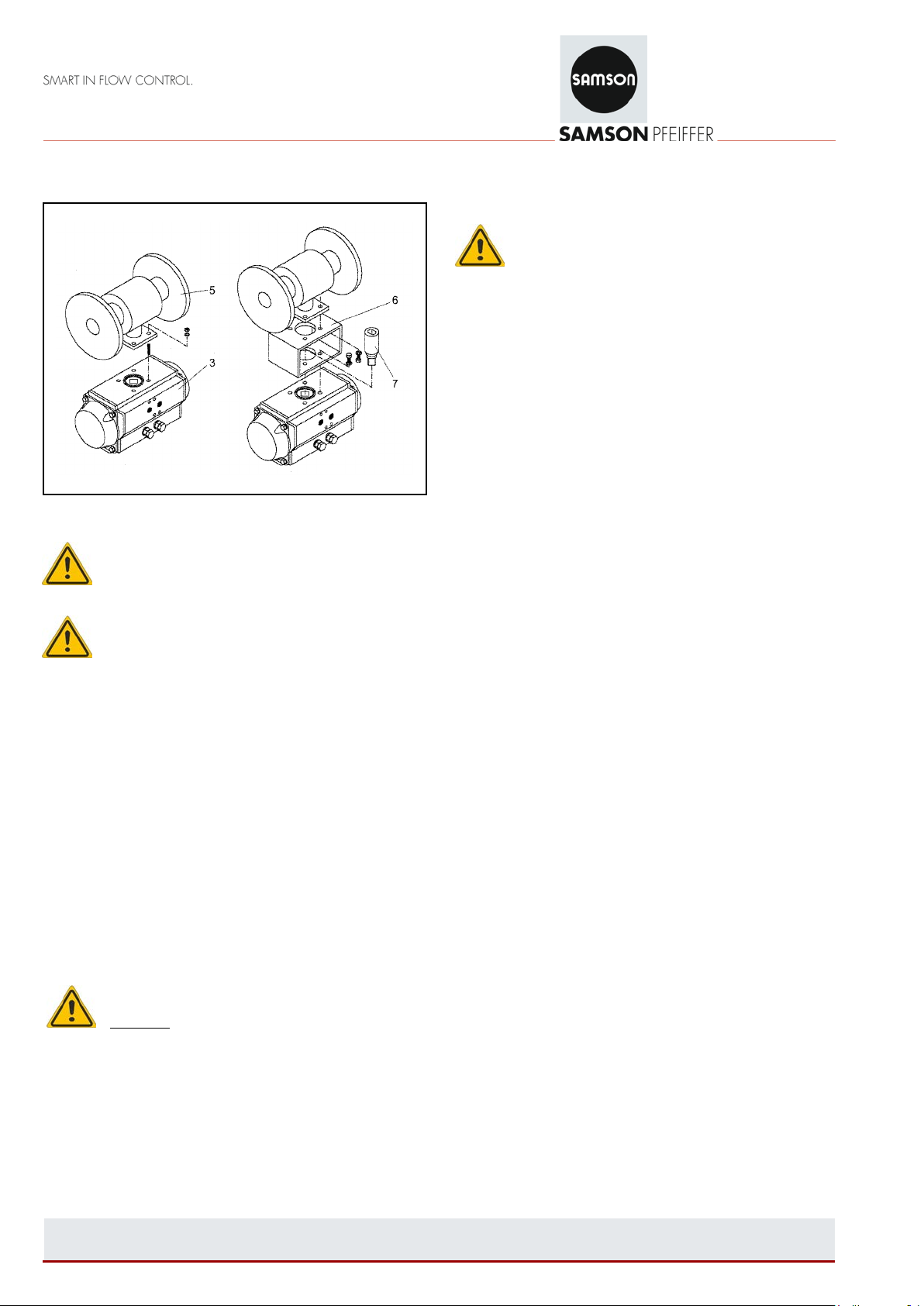

Fig. 11 - Mounting the actuator onto valves

Note: Before mounting the actuator onto a valve,

ensure that the actuator turns in the required

direction of rotation and that the valve and actuator

are correctly aligned with each other.

Caution: When mounting a single-acting actuator

(with spring) with a defined fail-safe position,

ensure upon pneumatic or electric power failure

that the direction of rotation is according to your application.

(clockwise to close).

Mount the actuator ( 3 ) onto the valve ( 5 ). The actuator

must be in the initial position (CLOSED position).

There are two different mounting versions:

• Direct mounting:

Insert either the square drive, flat head drive or key drive

of the valve shaft directly into the actuator shaft. Fasten

them using the ISO flange onto the actuator. See Table 2

for max. tightening torque.

• Mounting using a bracket:

Mount the bracket (6) onto the valve (5) and place the

coupling (7) onto the actuator shaft.

Note: Make sure that the position indicator of the

coupling corresponds with the switching position of

the valve.

Place the actuator onto the shaft and fasten the unit. See

Table 2 for max. tightening torque.

6 of 18

5.6 Changing the direction of action/fail-safe position

Note: For the exact procedure for disassembly and

assembly, refer to section 6 (maintenance and

assembly instructions).

• Move the actuator to the fail-safe position to release the

spring compression.

• Remove the screws ( 24 ) (see Fig. 15).

• Pull the position indicator ( 19 ) off the end of the shaft. If

necessary, use a screwdriver to lever it off.

• Remove both adjusting screws ( 2 ) with washers ( 4 ) and

lock nuts ( 3 ) (see Fig. 16).

• Remove the O-ring ( 11 ).

• Unscrew the screws ( 13 ) of the end caps (see Fig. 17).

• Remove end caps ( 22 und 23 ) from the housing.

• For single-acting actuators, remove the spring cartridges

( 17 ).

• Remove the gaskets ( 14 ) of the end caps.

• C lamp the hou sing ( 29 ) in a vise or similar. Turn the

shaft ( 30 ) until the pistons ( 25 ) are released

(see Fig. 18).

• Turn both pistons ( 25 ) in axial direction by 180° and

reassemble.

• Press both pistons ( 25 ) simultaneously into the housing

( 29 ) until they engage and turn the housing until the

travel end position is reached.

• Check that the pistons are in the end position. Turn the

shaft 4° over the center line (0°) (see Fig. 25).

• For single-acting actuators, insert the spring cartridges

into the end caps (see Fig. 27).

• Insert the gasket ( 14 ) into the groove of both end caps.

• Mount the end caps on the housing ( 29 ).

• Tighten the screws ( 13 ) by hand. Observe the tightening

sequence (see Fig. 28).

• Insert the adjusting screws ( 2 ), lock nuts ( 3 ), washers

( 4 ), and O-rings ( 11 ).

• Screw the adjusting screws ( 2 ) into the housing.

• Observe the end position setting.

• Place the position indicator ( 19 ) onto the shaft. Make

sure that it is in the correct position (see Fig. 30).

• Tighten screw ( 24 ).

5.7 Alternative mounting opti o n s:

• Alternative mounting options

(in clockwise direction to open)

: August 2017 Maintenance EB 31a-01_

Page 7

Specifications subject to change without notice

Edition

EN

Actuator

DAP/SRP

d

in mm

SW 1

in mm

SW 2

in mm

SW 3

in mm

SW 4

in mm

15

14

10

10 8 3

30

16

10

10

10

3

60

22

13

13

10 4 100

25

13

13

10 4 150

26

17

17

13 5 220

36

19

19

13 6 300

38

19

19

17 6 450

45

22

22

17 6 600

48

22

22

19

6

900

52

24

24

19 8 1200

58

30

30

22

10

2000

68

30

30

24

10

3000

80

36

36

22

12

4000

85

46

46

24

17

5000

90

46

46

24

17

10000

102

24

60

Allen 14

-

Fig. 12 - Clockwise direction to close

• Val v e mounted with an actu ator :

(in clockwise direction to open)

6.1 Fourth generation of rack-and-pinion

actuators (version manufactured from 2000)

6.1.1 Screw sizes

Table 3 - Dimensions

Fig. 13 - Clockwise direction to open

6. Maintenance and assembly instructions

With the information stated below, Pfeiffer provides the end

user with all the required information necessary for

maintenance. Under normal operating conditions, the

actuator requires only periodic checks to ensure proper

functioning.

Spare part kits for maintenance are available to replace all

seals and bearings. Maintenance may be necessary between

500,000 and 1,000,000 cycles, depending on the operating

and/or environmental conditio ns.

7 of 18

: August 2017 Maintenance EB 31a-01_

Fig. 14 - Screw sizes (depending on actuator version)

Page 8

Specifications subject to change without notice

Edition

EN

Item

Qty.

Description

Material

Item

Qty.

Description

Material

1 1 Cam (end position adjustment)

GS400-15

16 2 O-ring (piston)

NBR

2 2 Adjusting screw

A2-70

17

4 - 12

Spring cartridge

SiCr spring steel

3

2

Lock nut

A2-70

18 1 Spring clip

C 75

4

2

Washer

A2

19 1 Position indicator

PP + 30% GF

5 2 Bearing (piston back)

Nylon 46

20 1 Shaft seal (bottom)

NBR

6 1 Shaft bearing bushing (top)

PA 46

21 1 Shaft seal (top)

NBR

7 1 Shaft bearing bushing (bottom)

PA 46

22 1 Right end cap

GD-AlSi8.5Cu3.5Fe

8 2 Thrust bearing

Nylon 46

23 1 Left end cap

GD-AlSi8.5Cu3.5Fe

9 2 Plug (to seal air port)

NBR

24 1 Screw (position indicator)

A2-70

10 1 Thrust washer

1.4301

25

2

Piston

GD-AlSi8.5Cu3.5Fe

11 2 O-ring (adjusting screw)

NBR

26 1 Nameplate

Polyester aluminium

12 2 Piston guide

Nylon 66 + 30% GF

27 2 Nameplate (end cap)

Polyester aluminium

13

8/12/16

Screw (end cap)

A2-70

28

1

Spigot

EN AW 6063

14 2 Gasket (end cap)

NBR

29

1

Housing

EN AW 6063

15 2 Bearing (piston head)

POM

30

1

Shaft

C22

Fig. 15 - Detailed drawing of Series 31a Actuator, version manufactured from 2010

Table 4 - Parts list

8 of 18

: August 2017 Maintenance EB 31a-01_

Page 9

Specifications subject to change without notice

Edition

EN

6.1.2 Disassembly of the actuator:

When the actuator must be disassembled for maintenance

purposes, first remove the actuator from the valve.

Note: Before disassembly, it is important to check

that the actuator is not pressurized and the

compression is relieved from the actuator springs

(end position).

Always use caution and check that ports 2 and 4 are vented

and that all accessories are removed.

Before disassembling a single-acting actuator, make sure that

the actuator is in the start position and the pistons fully

retracted.

• Removing the position indicator

(see Fig. 16)

◦ Remove screw ( 24 ).

◦ Lift position indicator ( 19 ) from shaft. If necessary,

use a screwdriver to lever it off.

• Removing the adjusting screws:

(actuator versions manufactured up to 2006) (see Fig. 17)

◦ Remove both adjusting screws ( 2 ) with the washers

( 4 ) and lock nuts ( 3 ).

◦ Remove O-rings ( 11 ) and replace them when

replacing spare parts.

• Remov i ng adjusting scr e ws:

(actuator versions manufactured from 2006) (see Fig. 17)

◦ Remove lock nuts ( 3 ) together with washers ( 4 ).

◦ Remove O-rings ( 11 ) and renew them when

replacing spare parts

◦ Unthread both adjusting screws ( 2 ) and continue

unscrewing until their stopping point. Before

continuing with the final disassembly, remove the end

caps ( 22 and 23 ) and the pistons ( 25 ) since the

adjusting screws can only be removed from the inside

of the housing. The instructions for dismantling the

end caps and pistons are described below.

• Removing the end caps

(see Fig. 18)

For sizes 900 to 3000, the end caps ( 22 and 23 ) are

symmetric.

◦ Remove the screws ( 13 ) in the sequence a-b-c-d

(see Fig. 18).

Note: When disassembli ng a single-acting

actuator, loosen the screws of the end caps ( 22

and 23 ) in alternating sequence.

If there is still noticable force after 4 or 5 turns on all end cap

screws, this may indicate a damaged spring cartridge, and

any further disassembly should be discontinued. Further

disassambly of the end caps may result in injury.

Return the actuator to Pfeiffer for further maintenance.

◦ For single-acting actuators, remove spring cartridge

( 17 ).

◦ Remove gasket ( 14 ) and renew it when replacing

spare parts.

Fig. 16

Fig. 17

Fig. 18

9 of 18

: August 2017 Maintenance EB 31a-01_

Page 10

Specifications subject to change without notice

Edition

EN

• Removing the pistons:

(see Fig. 19)

◦ Clamp the housing ( 29 ) in a vise or similar device.

Turn the shaft ( 30 ) until the pistons ( 25 ) are

accessible.

Note:

Do not apply air pressure to remove the pistons

from the housing (projectile impact).

◦ Carefully remove the piston O-rings ( 16 ) using a

screwdriver. Remove the piston bearing ( 5 ) and

piston bearing ( 15 ).

Renew gasket ( 14 ) when replacing spare parts.

• Remov i ng the shaft

(see Fig. 20)

◦ Use pliers for circlips to carefully remove the spring

clip ( 18 ). Remove the thrust bearing ( 8 ) and thrust

washer ( 10 ).

◦ Push down on the top of the shaft ( 30 ) until it is

possible to remove the cam ( 1 ) and the internal thrust

bearing ( 8 ). Pull the shaft ( 30 ) all the way out of the

housing.

If the shaft cannot be removed by hand, gently tap the

top of the shaft with a plastic mallet to drive it out.

◦ Remove the top and bottom shaft bearings ( 6 and 7 )

as well as top and bottom shaft seals ( 20 and 21 ).

◦ Renew the bearing bushings ( 6 and 7 ), internal and

external thrust bearing ( 8 ) as well as the seals ( 20

and 21 ) when replacing all the spare parts.

Note: Thoroughly clean all dismantled parts as well

as any parts that have not been renewed and

check them for wear.

6.1.3 Actuator assembly:

Note: Before assembly, ensure that all parts are

clean and in perfect condition. Use the grease

recommended by Pfeiffer (Table 1).

• Shaft assembly

(see Fig. 21, Fig. 22a and Fig. 22b)

◦ Mount the top and bottom bearing bushings ( 6 and 7 )

followed by the top and bottom shaft seals ( 20 and

21 ) onto the shaft.

◦ Apply grease to the top and bottom of the shaft as

shown in Fig. 21.

◦ Guide the shaft ( 30 ) partially into the housing ( 29 )

◦ Mount the cam ( 1 ) in the required position, in relation

to the top and bottom position of the shaft as well in

relation to the direction of rotation of the actuator (see

Fig. 22).

◦ Place the internal thrust bearing ( 8 ) onto the shaft

( 30 ). Guide the shaft completely into the housing.

◦ Mount the external thrust bearing ( 8 ), thrust washer

( 10 ), and spring clip ( 18 ) (using pliers).

Fig. 19

Fig. 20

Fig. 21

10 of 18

: August 2017 Maintenance EB 31a-01_

Page 11

Specifications subject to change without notice

Edition

EN

Fig. 22a

Fig. 23

Fig. 24

Fig. 22a

Note: For actuators from 2006:

The adjusting screws ( 2 ) of this act uator ver sio n

are mounted from the inside, into the actuator

housing. This step must carried out before the piston and end

caps are mounted.

• Mounting the pistons

(see Fig. 23, Fig. 24, Fig. 25a, Fig. 25b, and Fig. 26)

◦ Mount the the piston O-ring ( 16 ), piston bearing ( 5 ),

and piston bearing ( 15 ).

◦ Apply grease to the bearing surface of the piston ( 25 )

inside the housing ( 29 ) and the piston rack teeth.

◦ Either clamp the top end of the shaft in a vise or hold

the shaft stationary with the corresponding counterpar t

and place the housing ( 29 ) in a horizontal position

(see Fig. 23).

◦ Make sure that the cam ( 1 ) is in the correct position

(see Fig. 24).

◦ For the standard direction of rotation (clockwise to

close), turn the housing ( 29 ) by 40° to 45°

counterclockwise (view from below) or clockwise (view

from top), depending on which way the shaft is held

(see Fig 25a and Fig. 25b).

◦ Press both pistons ( 25 ) simultaneously into the

housing ( 29 ) until the pistons are engaged and turn

the housing clockwise or counterclockwise (see

above) until the travel end is reached.

◦ Check the pistons in the end position and turn the

shaft 4° over the middle line (0°) (see Fig. 26).

11 of 18

Fig. 25a

Fig. 25b

Fig. 26

: August 2017 Maintenance EB 31a-01_

Page 12

Specifications subject to change without notice

Edition

EN

• Mounting the end caps

(see Fig. 27, Fig. 28 and Fig. 29)

For actuator sizes 900 to 3000, the end caps ( 22 and 23 )

and spring cartridges ( 17 ) are symmetric (Figs. 27, 28

and 29).

◦ Bearing surface of the housing.

◦ For single-acting actuators, insert the correct number

of spring cartridges (according to table) into the end

caps (see Figs. 27 and 28).

◦ Fit gaskets ( 14 ) into the grooves of both end caps.

◦ Mount the end caps onto the housing ( 29 ), making

sure that the gaskets are seated properly in the

grooves.

◦ Tighten the screws ( 13 ) by hand. Tighten according

to the sequence indicated in Fig. 29.

• Mounting the adjusting screws

(actuator versions manufactured up to 2006) (see Fig. 30)

◦ Insert adjusting screws ( 2 ), lock nuts ( 3 ), washers

( 4 ) and O-rings ( 11 ).

◦ Screw the adjusting screws ( 2 ) into the housing.

• Mounting the adjusting screws

(actuator versions manufactured from 2006) (see Fig. 30)

◦ Both adjusting screws ( 2 ) must be screwed into the

housing before the pistons and end caps are

mounted because they can only be inserted from the

inside of the actuator.

◦ Insert the O-rings ( 11 ).

◦ Place the lock nuts ( 3 ) and washers ( 4 ) onto the

adjusting screws.

• Adjusting the end position on the standard actuator

(in clockwise direction to close)

◦ 0° (closed) end position adjustment for an actuator in

the closed position: turn the screw ( 2 ) on the right

(view from the top) either clockwise or

counterclockwise until the required position is

achieved.

To secure this position, tighten the lock nut ( 4 ).

◦ 90° (open) end position adjustment for an actuator in

the open position: turn the screw ( 2 ) on the left

(view from the top) either clockwise or

counterclockwise until the required position is

achieved.

To secure this position, tighten the lock nut ( 4 ).

Fig. 28

Fig. 29

Fig. 27

12 of 18

: August 2017 Maintenance EB 31a-01_

Fig. 30

Page 13

Specifications subject to change without notice

Edition

EN

• Mounting the position indicator

(see Fig. 31)

◦ Place the position indicator ( 19 ) on the shaft, making

sure that it is in the correct position.

◦ Tighten screw ( 24 ).

Fig. 31

The actuator assembly is now completed.

Fig. 32

6.2 Third generation rack-and-pinion actuators

6.2.1 Actuator disassembly

Note: Before disassembly, it is important to check

that the actuator is not pressurized and all

accessories (e.g. solenoid valv es or limit sw itche s)

have been removed.

Refer to the detailed drawing of actuator (Fig. 39).

• Removing the cam or position indicator (if fitted)

(see Fig. 32)

◦ Open the spring clip ( 18 ) using a suitable pair of

pliers.

Note:

Make sure that the spring clip is not stretched too

far.

◦ Use a tool (e.g. screwdriver) to lift the cam up slightly.

• O-ring replacement on angle adjusting screw OPEN

(see Fig. 33)

◦ Undo nut ( 12 ) using a socket w r ench.

◦ Unthread the adjusting screw ( 10 ) and remove the

washer ( 11a ) and O-ring ( 11 ). This must be done on

both sides.

◦ After renewing the O-ring ( 11 ), slightly tighten the nut

(without locking) to tighten the adjusting screw with O ring and washer.

◦ The two adjusting screws are first to be locked

properly once the final assembly has been completed

and on adjusting the piston.

13 of 18

Fig. 33

Fig. 34

• Removing the end caps

(see Fig. 34)

◦ Unscrew the screws ( 13 ) in the sequence shown in

Fig. 34. For Type SRP (single-acting), remove the

compression springs ( 17 ) as well.

◦ Renew gasket ( 14 ).

: August 2017 Maintenance EB 31a-01_

Page 14

Specifications subject to change without notice

Edition

EN

• O-ring replacement (with stop screw OPEN)

• (see Fig. 35)

◦ Undo nut ( 12 ) using a socket w r ench.

◦ Unthread the adjusting screw ( 10a ) and remove t he

washer ( 11a ) and O-ring ( 11 ). This must be done on

both sides.

◦ After renewing the O-ring ( 11 ), slightly tighten the nut

(without locking) to tighten the adjusting screw with O ring and washer.

◦ The two adjusting screws are first to be locked

properly once the final assembly has been completed

and on adjusting the piston.

• Removing the piston

(see Fig. 36)

◦ After removing the end caps, hold the housing ( 1 )

stationary (possibly in a vise) and turn the shafts until

the the pistons on both sides are released.

◦ Remove both the pistons on both sides.

◦ Use a flat, blunt tool (e.g. screwdriver) to remove the

O-ring ( 16 ), piston head bearing ( 15 ), and piston

back bearing ( 5 ).

◦ Check that both pistons are free of dirt particles,

especially at the gears. Renew the O-ring, piston head

bearing ( 15 ), and piston back bearing ( 5 ).

• Removing the shaft and bearing bushings

(see Fig. 37 and Fig. 38)

◦ Remove the spring clip ( 18 ) using pliers for circlip s

and the thrust washer ( 8 ).

◦ Push the shaft from the top downward out of the

housing (see Fig. 37).

◦ Remove the top and bottom bearing bushings ( 6 and

7 ) as shown in Fig. 38.

Fig. 36

Fig. 37

Fig. 35

14 of 18

: August 2017 Maintenance EB 31a-01_

Fig. 38

Page 15

Specifications subject to change without notice

Edition

EN

Item

Qty.

Description

Material

Item

Qty.

Description

Material

1

1

Housing

AlMgSi0,5 F25

12

4

Lock nut

X5 CrNi 18 10

2

2

Piston

GD-AlSi8 Cu3

13 8 Screw (end cap)

X5 CrNi 18 10

3

2

End cap

GD-AlSi8 Cu3

13a

8

Washer

X5 CrNi 18 10

4

1

Shaft

C22

14 2 Gasket (end cap)

Buna N

5 2 Bearing (piston back)

PA 4.6

15 2 Bearing (piston head)

PA 4.6

6 1 Shaft bearing bushing (top)

PA 4.6

16 2 O-ring (piston)

Buna N

7 1 Shaft bearing bushing (bottom)

PA 4.6

17

12

Spring cartridge

54 Si Cr6

8 1 Thrust washer

PA 4.6

18 1 Spring clip (pinion)

C75

8a 1 Support screw

X5 CrNi 18 10

19 1 Position indicator

PA

9 2 Air port screw

Buna N

20 1 Screw/washer

X5 CrNi 18 10

10 2 Adjusting screw (OPEN)

X5 CrNi 18 10

21 1 O-ring (pinion top)

Buna N

10a 2 Adjusting screw (CLOSED)

X5 CrNi 18 10

22 1 O-ring (pinion bottom)

Buna N

11 4 O-ring (adjusting screw)

Buna N

24 2 Guide piston

PPA

11a

4

Washer

X5 CrNi 18 10

25 1 Centering ring

PA

Fig. 39 - Detailed drawing of BR 31a Actuator, third generation

Table 5 - List of parts

15 of 18

: August 2017 Maintenance EB 31a-01_

Page 16

Specifications subject to change without notice

Edition

EN

6.2.2 Actuator reassembly after replacement of parts

• Mounting the actuator shaft and bearing bushings

(see Fig. 40, Fig. 41, Fig. 42, and Fig. 43)

◦ Apply grease to the shaft as shown in Fig. 40.

◦ Push the top bearing bushing ( 6 ) onto the shaft ( 4 ).

◦ Apply grease to the surface of the bearing bushing

( 7 ) and the shaft ( 4 ) as shown in Fig. 41.

◦ Apply grease to the surface of the bearing bushing

( 7 ) and mount the bushing as shown in Fig. 42.

◦ Use the special tool (available from Pfeiffer) to hold

the bearing bushing ( 7 ) stationary while pressing in

the shaft ( 4 ).

We recommend clamping the tool into a vise as shown

in Fig. 43.

After mounting the shaft, place the thrust washer ( 19 )

on the top shaft end. Mount the spring clip ( 18 ) using

pliers for circlips.

Fig. 40

Fig. 43

• Mounting the pistons

(see Fig. 44a, Fig. 44b, and Fig 45)

◦ Apply grease to the inside running surface of the

housing ( 1 ).

◦ Clamp the flattened section of shaft in a vise and

position the housing in the horizontal position.

◦ Align the tooth profile vertically as shown in Fig. 44a

and push the two pistons into the housing.

To obtain a counterclockwise rotation to close the

valve, install the pistons turned by 180° (see Fig. 44a).

◦ Turn the housing by 15° to 20° counterclockwise as

shown in Fig. 44b.

Fig. 41

Fig. 42

16 of 18

: August 2017 Maintenance EB 31a-01_

Fig. 44a

Fig. 44b

Page 17

Specifications subject to change without notice

Edition

EN

◦ Push and turn the housing onto the pistons clockwise

until the end of travel is reached. Check that the

internal angle adjusting screw does not reduce the

travel. This is not necessary if it is to be 90° to 95°.

◦ The shaft clearance is 3° to 5° more than 0°

(see Fig. 45).

Fig. 46

• Adjusting the opening angle for 0° position CLOSED

◦ To adjust, turn the adjusting screw ( 10a ) until the

required position is reached and lock this position with

the nut ( 12 ) using a socket wrench. While locking in

position, hold the adjusting screw stationary with an

Allen key.

◦ To ensure that both pistons stop at the same time, turn

the adjusting screw at the other piston until you feel

resistance and they stop at the shaft.

Lock the adjusting screw in the same position with the

lock nut ( 12 ).

◦ The initial position CLOSED has now been adjusted.

• Mounting the end caps and compression springs

(see Fig. 46 and Fig. 47)

◦ Apply grease to the housing.

◦ Insert the correct number of compre ssion springs

( 17 ) specified in Fig. 46 and according to the pattern

shown in Fig. 46.

◦ Fit on the end caps ( 3 ) and check to ensure that the

gaskets ( 14 ) are seated properly.

◦ Insert the screws ( 13 ) without screwing them tight.

Tighten them according to the sequence shown in

Fig. 47.

• Adjusting the switching position to 90° position OPEN

(see Fig. 48)

◦ External adjustment can only be made after the

actuator assembly is completed with the pistons

extended as far as they will go on the outside of the

housing as shown in Fig. 48.

◦ In double-acting actuators, this can be done by turning

the shaft. When the actuator has been mounted onto

the valve, apply the control pressure to move it to this

switching position.

Once you have adjusted the switching position on one

side, turn the screw on the other side as far as it will

go and lock this position.

17 of 18

Fig. 45

◦ For single-acting actuators (SRP), apply the control

pressure to move the actuator to the switching

position. Check this position, readjust, and move the

actuator to the position again until the required

position is reached.

◦ Lock the adjusting screw, while using an Allen key to

hold the screw stationary and lock it with a special key

(available from Pfeiffer).

The actuator assembly is now completed.

Fig. 47

Fig. 48

: August 2017 Maintenance EB 31a-01_

Page 18

Specifications subject to change without notice

Edition

EN

PDF=166

7. Storage instructions

lf the actuators are not for immediate use, the following

measures must be taken:

• Store them in dry environment at normal ambient

temperature.

• We recommend to leave the actuators in their original

packaging.

• Do not remove the plastics plugs on the air supply ports 2

and 4.

8. Customer inquiries

(please specify the following details)

Type of actuator: BR31a Typ DAP oder Typ SRP

Size: 15, 30, 60, 100, 150, 220, 300, 450,

600, 900, 1200, 2000, 3000, 4000,

5000 oder 10000

Number of springs: only with single-acting Type SRP

Fail-safe position: Clockwise or counterclockise rotation

of springs (only with single-acting

Type SRP)

Supply pressure: .... bar

Operating range: Number of springs or nominal signal

range

VDI/VDE bracket: To mount positioner or indicating

devices

18 of 18

: August 2017 Maintenance EB 31a-01_

Loading...

Loading...