Series 240

Pneumatic Control Valve Type 3241-1 and Type 3241-7

Globe Valve Type 3241

Application

Control valve for process engineering and industrial

applications

Nominal size DN 15 to DN 300

Nominal pressure PN 10 to PN 40

Temperatures –196 to 450 °C

Type 3241 Globe Valve operated with:

Type 3271 Pneumatic Actuator (Type 3241-1 Control Valve)

•

or

Type 3277 PneumaticActuator(Type 3241-7 Control Valve)

•

Valve body made of:

Cast iron

•

Spheroidal graphite iron

•

Cast steel, cast stainless steel or cast cold-resisting steel

•

Forged steel or forged stainless steel

•

Special materials

•

Undivided valve bonnet up to DN 150

Valve plug with:

• Metal sealing

• Soft sealing

The modular design of the control valves allows them to be

equipped with various accessories:

Positioners, solenoid valves and other accessories according to

IEC 60534-6 and NAMUR recommendation. See Information

Sheet T 8350 EN for details.

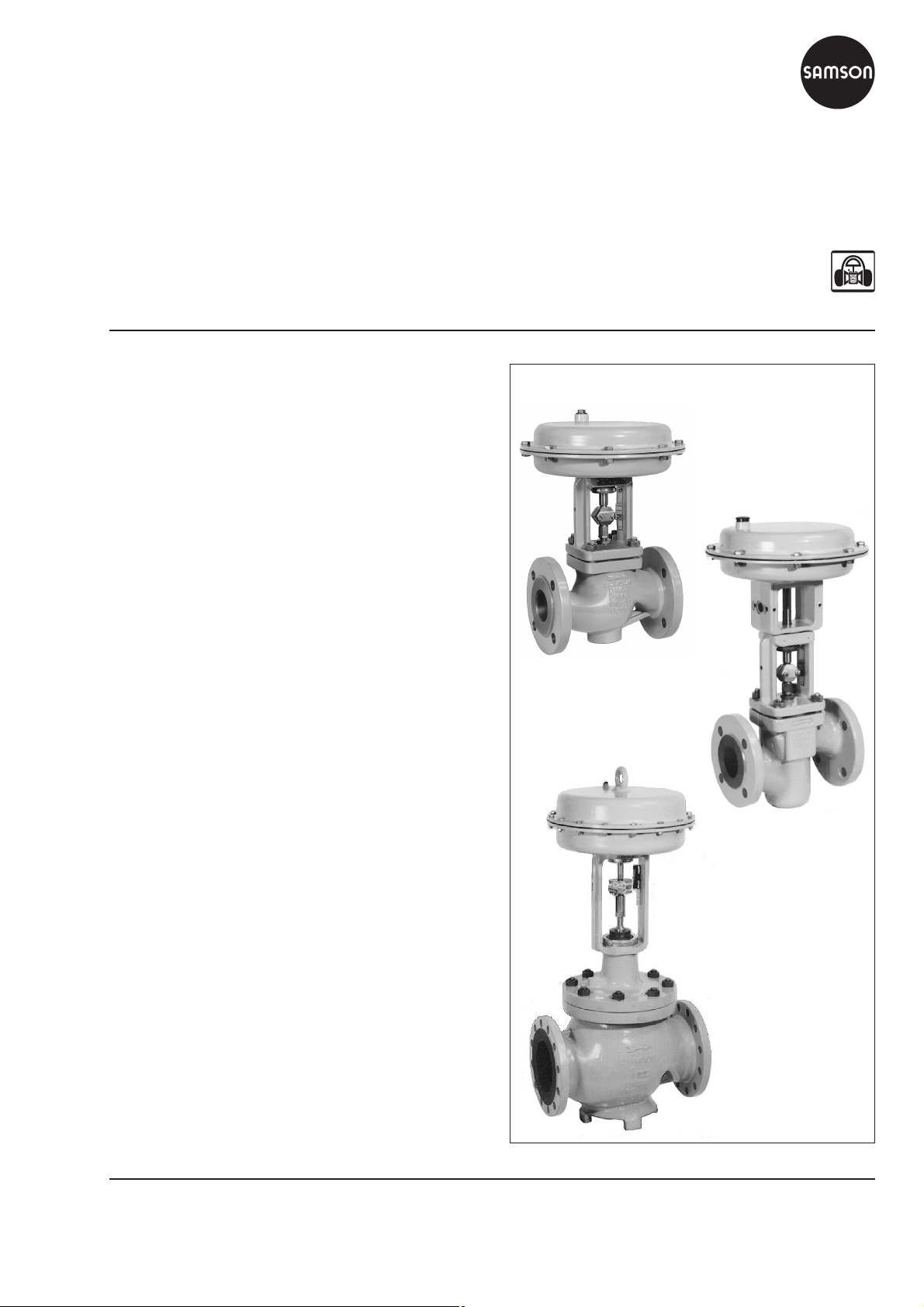

Fig. 1 · Type 3241-1

DN 15 to 150

Versions

Standard version fortemperaturesranging from –10 to220°C

–

Type 3241-1 (Figs. 1 and 3) · DN 15 to 300

with Type 3271 Pneumatic Actuator (see T 8310-1/-2 EN)

–

Type 3241-7 (Fig. 2) · DN 15 to 150

with Type 3277 Pneumatic Actuator for integral positioner

attachment (see T 8310-1 EN)

Additional versions with:

–

Welding ends

–

Adjustable packing · See Information Sheet T 8000-1 EN

–

Flow divider or AC-1/AC-2 Trim for noise reduction · See

Data Sheets T 8081 EN and T 8082 EN

–

Perforated plug · On request

–

Valve plug with pressure balancing · See Technical data

–

Extension bonnet or bellows seal · See Technical data

–

Heating jacket · On request

–

Stainless steel actuator · See T 8310-1 EN

–

Additional handwheel · See Data Sheet T 8310-1/-2 EN

Associated Information Sheets T 8000-x EN

Associated Data Sheets for

Pneumatic Actuators T 8310-1/-2 EN

Fig. 2 · Type 3241-7

DN 15 to 80,

forged steel

Fig. 3 · Type 3241-1

Edition October 2011

DN 200

³

Data Sheet T 8015 EN

Type 3241 DWA · Version for PSA plants (pressure swing

–

adsorption) · See T 8012-1 EN and T 8015-1 EN

Typetested version · For application in heating systems (see

–

Data Sheet T 8016 EN), DIN/DVGW-tested version for gas

(see Data Sheet T 8020 EN), liquid fuels and liquefied

petroleum gas intheliquidphase (see Data SheetT8022 EN)

ANSI version · See Data Sheet T 8012 EN

–

Versions with dimensions according to Japanese Industry

–

Standard (JIS) · Details on request

Principle of operation

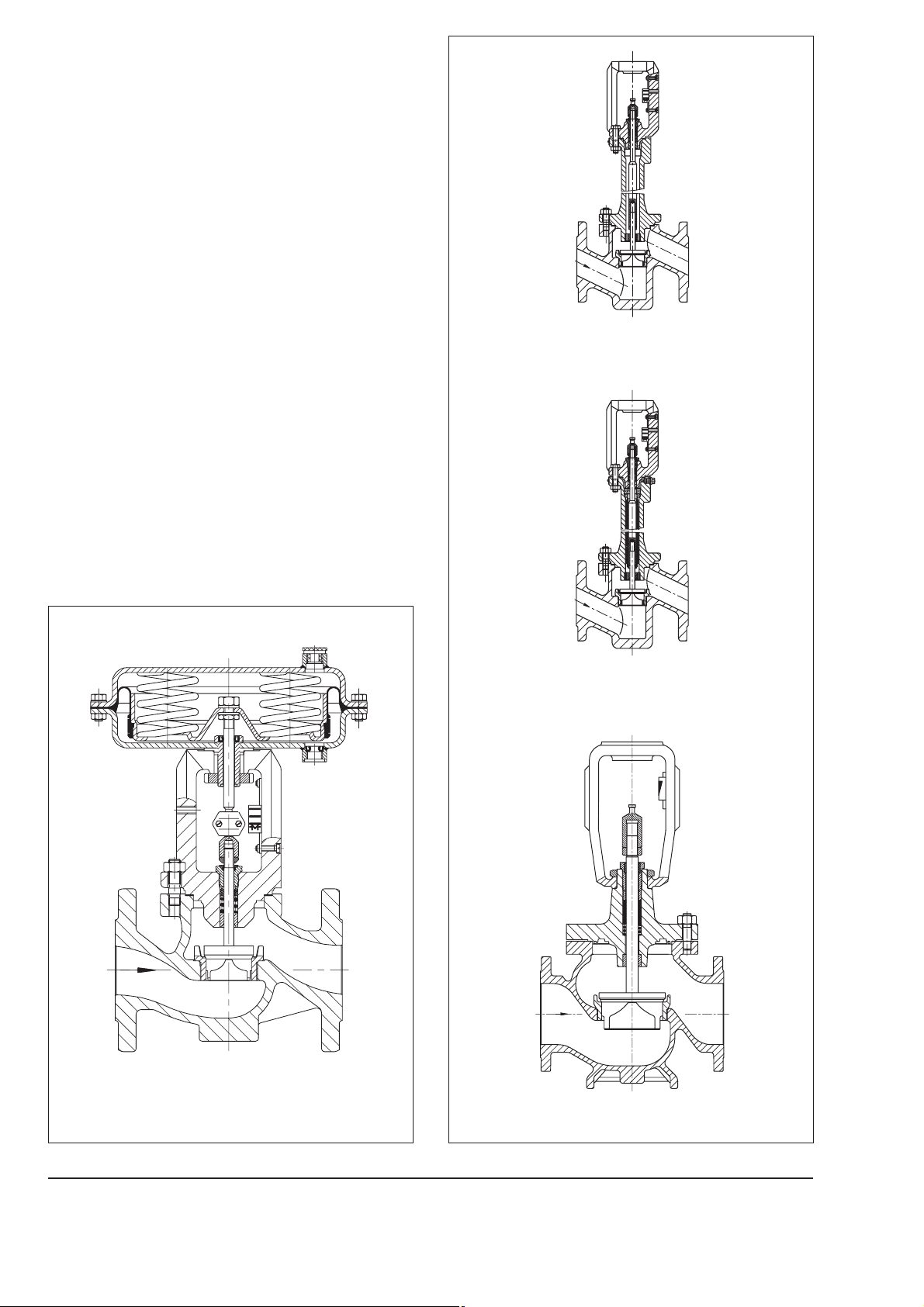

The process medium flows through the valve in the direction

indicated by the arrow. The position of the valve plug

determines the cross-sectional areabetweenthe seat and plug.

Fail-safe positions

Depending on howthe compression springs arearranged in the

actuator (see Data Sheets T 8310-1 EN and T 8310-2 EN for

details), the control valve has two different fail-safe positions

which become effective upon supply air failure:

Actuator stem extends (FA)

The actuator springs close the valve when the supply air fails.

Actuator stem retracts (FE)

The actuator springs open the valve when the supply air fails.

Differential pressures

Permissible differential pressures are listed in Information Sheet

T 8000-4 EN.

Fig. 5 · Type 3241 Valve, forged steel version

DN 15 to 80 with extension bonnet

Note

Figs. 4 to 6 show configuration examples.

Fig. 6 · Type 3241 Valve, forged steel version

DN 15 to 80 with metal bellows seal

Fig. 4 · Type 3241-1 Control Valve

DN 15 to 150 with Type 3271 Pneumatic Actuator

2

Fig. 7 · Type 3241 Control Valve, DN 200 to 300

T 8015 EN

Table 1 · Technical data for Type 3241

Nominal size DN 15 to 250 15 to 150 15 to 300 15 · 25 · 40 · 50 · 80

Stainless

cast steel

1.4308

Forged steel

1.0460

Material

Nominal

pressure

Cast iron

EN-JL1040

PN

10 · 16 16 · 25 10 · 16 · 25 · 40

Sph. graphite

iron

EN-JS1049

Cast steel

1.0619

Stainless

cast steel

1.4408

Cast steel

1.6220

Flanges All DIN versions

End connections

Welding ends –

DIN EN 12627 Fig. 2 only for

DN 25, 40, 50, 80, 100, 150, 200, 250, 300

Seat/plug sealing Metal sealing · Soft sealing · High-performance metal sealing

Characteristic Equal percentage · Linear

Rangeability 50 : 1 for DN 15 to 50 · 30 : 1 for DN 65 to 150 · 50 : 1 for DN 200 and higher

Heating jacket

Up to DN 100 PN 25

DN 125 PN 16

³

Temperature ranges in °C · Permissible operating pressures acc. to pressure-temperature diagrams (see Information Sheet T 8000-2 EN)

Body without extension bonnet –10 to 220 °C

Short

–10…300 °C –10…350 °C –10…400 °C1)–50…450 °C –50...300 °C –50...300 °C –10…400 °C1)–50...450 °C

Long

Short

–10…300 °C –10…350 °C –10…400 °C1)–50…450 °C –50...300 °C –50...300 °C –10…400 °C1)–50…450 °C

Long

– –196...450 °C – –196...300°C – –196…450 °C

– –196...450 °C – –196...300 °C – –196…450 °C

Body

with

Valve

plug

Extension

bonnet

Bellows

seal

Standard

Balanced

Metal sealing –196 to 450 °C

Soft sealing –196 to 220 °C

with PTFE ring –50 to 220 °C · Lower temperatures on request

w. graphite ring 220 to 450 °C

Stainless

forged steel

1.4571

–

Leakage class according to IEC 60534-4

Metal sealing Standard: IV · High-performance metal sealing: V

Valve

plug

Balanced

1)

Down to –50 °C at p

Soft sealing VI

Metal sealing Standard: IV · With PTFE or graphite pressure-balancing ring

Special version: V · High-performance metal sealing (only with PTFE balancing ring) on request

75 % PN (acc. to AD W10)

£

max

Table 2 · Materials

Standard version

Forged

steel

1.0460

1.0460 1.4401

1.4006/

1.4008

1.4006

(1.4404)/

1.4008

Valve body

Valve bonnet

2)

Seat

2)

Plug

Plug sealing

1)

Cast iron

EN-JL1040

1.0460/

EN-JL1040

Sph. graphite

iron

EN-JS1049

1.0460/1.0619

Cast steel

1.0619

1.4006/1.4008

1.4006 (1.4404)/1.4008

Stainless

cast steel

1.4408

1.4408/

1.4401

1.4404/

1.4409

1.4404/

1.4409

Cast steel

1.6220

1.0566

1.6220

1.4006/

1.4008

1.4006

(1.4404)/

1.4008

Stainless

cast steel

1.4308

1.4308

1.4301

1.4301/

1.4308

1.4301/

1.4308

Sealing ring for soft sealing: PTFE with glass fiber

Sealing ring for balanced plug: PTFE with carbon or graphite ring –

Guide bushing 1.4104 1.4571 1.4571 1.4301 1.4104 1.4571

3)

Packing

V-ring packing PTFE with carbon · Spring: 1.4310

Body gasket Metal/graphite

Extension bonnet

1.0460 1.4401 1.0566 1.4301 1.0460 1.4401

Bellows seal

Intermediate piece 1.0460 1.4401 1.0566 1.4301 1.0460 1.4401

Metal bellows 1.4571

4)

1.4541 1.4571

Heating jacket – 1.4404

Stainless

forged steel

1.4571

1.4404/

1.4409

1.4404/

1.4409

4)

1)

Special materials for applications with sea water: 1.4538, duplex 1.4470; nickel-based alloy: 9.4610; other special materials on request.

2)

All seats and metal-seated plug also with Stellite facing; for£DN 100 plug up to seat bore 38 made of solid Stellite available.

3)

Other packings on request (refer to T 8000-1 EN)

4)

Other materials on request

3 T 8015 EN

Table 3 · KVScoefficients

Table 3a · Overview (with Flow Divider St I (K

K

VS

KVSI

KVSII

KVSIII

Seat Ø [mm] 3 6 12 24 31 38 48 63 80 63 80 100 110 130 125 150 200 250 300

Travel [mm] 15 30 60 120

0.1

0.16

0.4 0.63 1.0 1.6 2.5 4.0 6.3 10 16 25 40 60 80 63 100 160 200 260 250 360 630

0.25

– 1.45 2.2 3.6 5.7 9 14.5 22 36 54 72 57 90 144 180 234 225 320 560

– 8 13 20 32 48 63 50 80 125 160 210 200 290 500 800 –

– 7.5 – 20 30 – – 47 75 120 – – 190 270 480 750 –

I), St II (KVSII) or St III (KVSIII))

VS

1000*1500

900*1350

* Not available with valve body made of cast iron (EN-JL1040)

Terms for control valve sizing according to IEC 60534, Parts 2-1 and 2-2: F

= 0.95, XT= 0.75

L

Table 3b · Versions without flow divider · Areas highlighted in gray indicate versions also with pressure balancing

0.1

K

0.16

VS

DN

15 •••••••

20 ••••••••

25 •••••••••

32 •••••••••

40 ••••••••••

50 •••••••••••

65 • • • With 19 mm overtravel (not with bellows seal)

80 •••• •

100 •••

125 •••

150 ••• •

200 •• •••

250 •• ••••*

300 • •••••

0.4 0.63 1.0 1.6 2.5 4.0 6.3 10 16 25 40 60 80 63 100 160 200 260 250 360 630 1000 1500

0.25

*

*

Table 3c · Versions with Flow Divider St I (KVSI) · Areas highlighted in gray indicate versions also with pressure balancing

KVSI – 1.45 2.2 3.6 5.7 9 14.5 22 36 54 72 57 90 144 180 234 225 320 560 900 1350

DN

15 •••

20 •••

25 •••

32 •••

40 ••••

50 •••••

65 •••

80 ••••

100 •••

125 •••

150 ••• •

200 •••

250 ••••*

300 •••••

* DN 250 with KVSI = 900 not available with valve body made of cast iron (EN-JL1040)

4 T 8015 EN

Table 3d · Versions with Flow Divider St II (KVSII) · Areas highlighted in gray indicate versions also with pressure balancing

KVSII – 8 13 20 32 48 – 50 80 125 160 210 200 290 500 800 1200

DN

15

20

25

32 • •

40 •••

50 •••

65 •••

80 •••

100 •••

125 ••

150 ••• •

200 •• ••

250 •• •••

300 • ••••

Table 3e · Versions with Flow Divider St III (KVSIII) · Areas highlighted in gray indicate versions also with pressure balancing

KVSIII – 7.5 – 20 30 – – 47 75 120 – – 190 270 480 750 –

DN

15

20

25

32

40

50 •

65 • •

80 • •

100 •

125 •

150 •••

200 •• ••

250 ••• •••

300 • ••••

1)

Not with bellows seal

1)

5 T 8015 EN

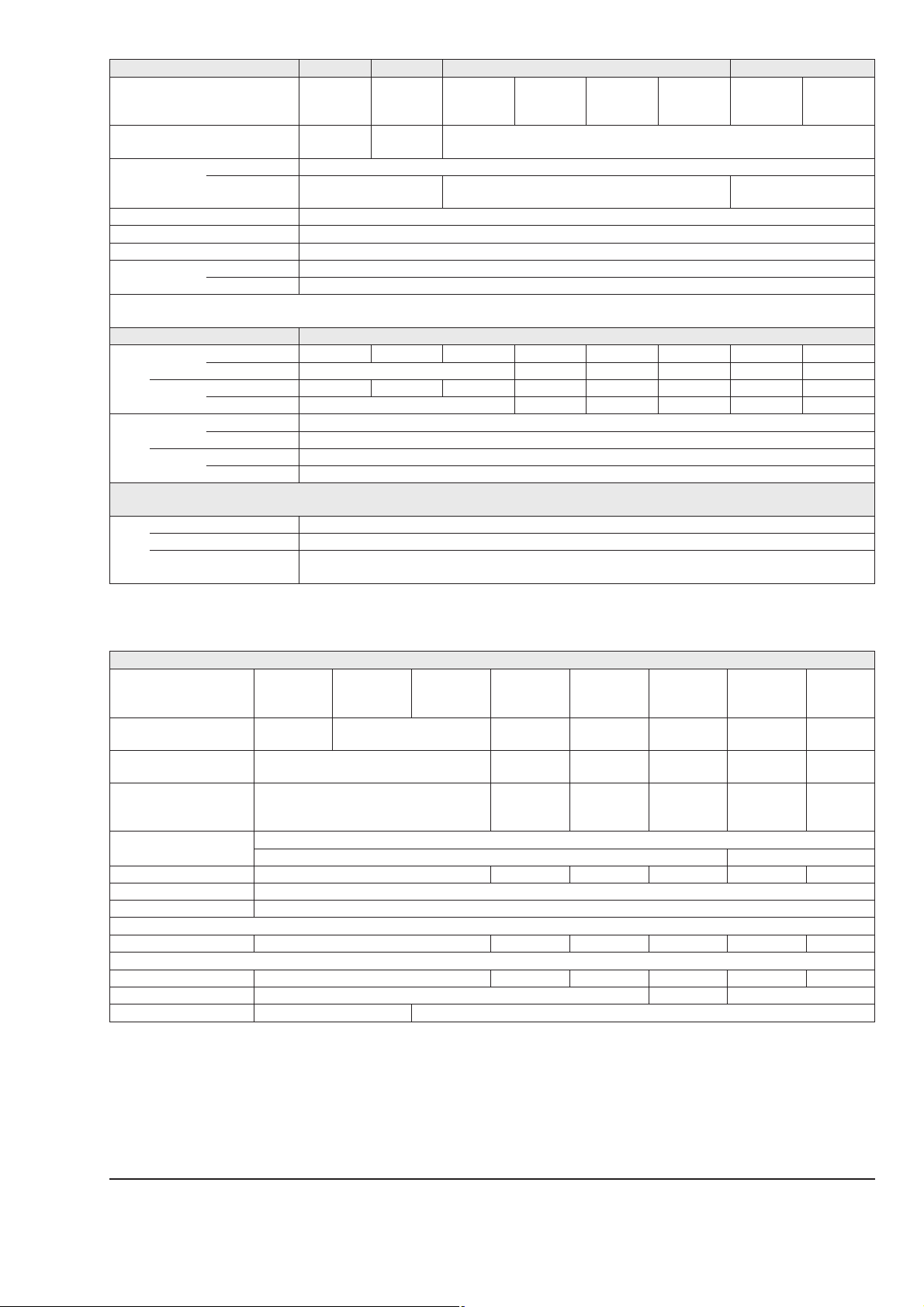

Table 4 · Dimensions in mm for standard version of Type 3241-1 and Type 3241-7 with flanges or welding ends

250

250-

Valve

Length L

700 cm²

2)

H1

for

actuators

£

1400-60 cm²

1400-120 cm²

2800 cm²

H2 for

1)

Valve in DN 250-60 with 60 mm valve travel; DN 250-120 with 120 mm valve travel, not in cast iron

2)

H1 increases by 170 mm for valves with KVS250, 360 or 630 and 60 mm rated travel operating with overtravel.

3)

Version in PN 10/16: 148 mm

Cast steel 44 72 98 118 144

Forged steel 53 – 70 – 92 98 – 128 –

15 20 25 32 40 50 65 80 100 125 150 200

DN

130 150 160 180 200 230 290 310 350 400 480 600 730 730 730 850

mm

220 260 350 363 390 –

– 815 815 870 – 1185

– 902 902 955 1104 1334

– 902 902 955 1104 1334

3)

175 245 260 270 310 350

cast

iron

60

1)

250-

120

300

1)

2)

Actuator

Diaphragm

D

Æ

cm²

mm

H (700 cm² and larger

inc. lifting ring)

H3

1)

Type 3271

Type 3277 –

120 240 350 700 1400-60 1400-120 2800

168 240 280 390 530 534 770

70 62 82 200 287 490 630

110 190

610 650

H5 Type 3277 88 101 –

Thread

a

Type 3271

Type 3277 –

Type 3271

G ¼ (¼ NPT) G

M30x1.5

a2 Type 3277 – G

1)

Minimum clearance required to remove the actuator

3

3

(

NPT) G ¾ (¾ NPT) G 1 (1 NPT)

8

8

3

3

(

NPT) –

8

8

M60x1.5 M100x2

Table 5 · Weights in kg for standard version of Type 3241-1 and Type 3241-7

Valve

Weight without actuator

in kg

15 20 25 32 40 50 65 80 100 125 150 200

DN

5 6 7 11 12 15 24 30 42 80 120 396 468 608 872

250

cast iron

250

-60/

-120

300

Actuator

Type

3271

Type

3277

Without

handwheel

W. handwheel

80 mm travel

£

W. handwheel

160 mm travel

£

Without

handwheel

handwheel

cm²

With

120 240 350 700 1400-60 1400-120 2800

3 5 8 22 70 175 450

– 9 13 27 175 300 575

– 425 700

5 9 12 26

–

– 131731

6 T 8015 EN

Table 6a · Dimensions and weights for Type 3241 with extension bonnet or bellows seal DN 15 to 150 - without actuator

Nominal size

Height

H4

Weight

in kg

Short ext. bonnet

or bellows seal

Long ext. bonnet

or bellows seal

Short/with

bellows

Long/long with

bellows

15 20 25 32 40 50 65 80 100 125 150

DN

408 408 450 635 644 671

710 712 754 883 885 912

8 9 10 17 18 21 32 38 60 105 150

12 13 14 21 22 25 26 42 68 113 158

Table 6b · Dimensions and weights for Type 3241 with extension bonnet or bellows seal DN 200 to 300 - without actuator

Version with Extension bonnet Bellows seal

Actuator cm² 1400-60 1400-120 2800 1400-60 1400-120 2800

DN 200 1260

Height H4

in mm

DN 250

Travel =

60 mm

120 mm

DN 300 1683 1832 2055 2203

DN 200 440 485

Weight

in kg

DN 250

2)

DN 300 950 1020

1)

Also for DN 250 in cast iron (EN-JL1040)

2)

For cast iron (EN-JL1040) minus 140 kg

1494

–

1)

1579

1728

666 711

1345

1)

1579

1728

1467

1924

–

1)

2009

2158

1552

1)

2009

2158

Table 6c · Dimensions in mm for Type 3241 with heating jacket - Not for valves with body materials EN-JL1040 or EN-JS1049

Nominal size DN 25 40/50 80 100 150 200 to 300

a 110 140 180 200 265

b 1520355080

c 140 170 215 255 130

On request

d 190 190 230 320 355

Dimensions in mm

H3

H

H1

ØD

a

H5

a2

H2

L

Type 3241-1 · DN 15 to 150 Type 3241-1 · DN 200 to 300

Type 3241-7 · DN 15 to 150

7 T 8015 EN

Type 3241 with extension bonnet or metal bellows seal

Type 3241 with heating jacket

a

DN 15 to 150 DN 200 to 300

Ordering text

Globe valve Type 3241, DN … PN ...

Valve body material According to Table 2

End connections Flanges or welding ends

Seat and plug Metal sealing/soft sealing/

high-performance metal sealing

Characteristic Equal percentage or linear

Pneumatic actuator Type 3271 or Type 3277

Fail-safe position Valve CLOSED or OPEN

Process medium Density and temperature

Maximum flow rate in kg/h or m³/h

Pressure p

and p2in bar (absolute pressure)

1

Accessories Positioner and/or limit switch

Bellows seal version

with heating jacket

d

c

Flange DN 15 or 25, PN 25, DIN 2635

a

b

c

Specifications subject to change without notice.

SAMSON AG · MESS- UND REGELTECHNIK

Weismüllerstraße 3 · 60314 Frankfurt am Main · Germany

Phone: +49 69 4009-0 · Fax: +49 69 4009-1507

Internet: http://www.samson.de

T 8015 EN

2011-10

Loading...

Loading...