Page 1

Instruction Manual

Model No’s PH60/PH60-1/PH60-C

PI Control

Programmable Thermostatic

Radiator Valve Control Head

Page 2

PH60 INSTRUCTION MANUAL

2

PRODUCT COMPLIANCE

This product complies with the essential requirements of the

following EC Directives:

•

Electro-Magnetic Compatibility directive 2004/108/EC

•

Low Voltage Directive 2006/95/EEC

•

EC Marking directive 93/68/EEC

SAFETY INFORMATION

These instructions are applicable to the SALUS Controls model

stated on the front cover of this manual only, and must not be

used with any other make or model.

These instructions should be followed along with any other

statutory obligations - if you are in any doubt, please contact

the SALUS Controls technical helpline.

Please leave these instructions with the end user where they

should be kept in a safe place for future reference.

Page 3

INTRODUCTION

A Thermostatic Radiator Valve (TRV) is a self-regulating valve fitted

to hot water heating system radiators. The TRV controls the

temperature of a room by regulating the flow of hot water to the

radiator.

The PH60 from SALUS Controls is a stylish and accurate TRV

programmable control head designed for independent control of

central heating radiators. It is fitted to a new or existing TRV, and

works by controlling the radiator temperature according to a series

of programmed settings.

The PH60 is fitted with an easy to read Liquid Crystal Display (LCD)

and a five key operating panel, which is coupled with a unique,

smart design that makes the PH60 easy to programme and operate.

PI Control

The SALUS PH60 is a PI (Time Proportional & Integral) control product

as defined in the Building Regulations, which makes the heating

system operate up to 15% more efficient and provides close,

accurate control. Please note there is no span on the PH60 PI.

Features

•

PI Control for accuaracy

and efficiency

•

LCD with Backlight

•

Stylish Casing

•

Simple to Install

•

6 Control Modes

•

Temporary Override Function

•

Built in Start-up Programmes

•

Limescale Protection feature

•

7 day Independent Programming

PH60 INSTRUCTION MANUAL

3

PH60-1

PH60

PH60C

Page 4

INSTALLATION

Please read the important safety information at the start

of this manual before you begin to install the device.The

PH60 is easily installed – whether fitted as part of a new

installation, or in place of an existing TRV control head.

Battery Installation and Replacement

After Installation

After completing installation and powering up the PH60 for the first

time the controller will go through an adaptation procedure to check

that the valve has been installed correctly. The PH60 will behave in the

following way:

PH60 INSTRUCTION MANUAL

4

Push button to

gain access to

battery

compartment.

Please insert

batteries

correctly as

indicated.

Installation of the batteries is a straightforward

operation. Remove end cap from the PH60 body as

shown in this picture, and insert the batteries,

please make sure that the batteries are correctly

inserted.

About Valve Compatibility

An adapter for valves from the following manufactuers:

Heimeier, Junkers, Landy + Gyr, Honeywell-braukmann,

Oventrop M30X1.5 is not required.

For Danfoss valves RA-Series, you may require the

following adapter (supplied). Slide the adapter onto

the valve completely and tighten the screw.

The PH60 is attached to the valve body by screwing the

locking collar at the base of the controller onto the

threaded section of the TRV body, as shown in this

picture. The locking collar only needs to be tightened

by hand – do not use a spanner or pipe grips as you

may damage the PH60, TRV or both.

Page 5

PH60 INSTRUCTION MANUAL

5

Display Comments

All the indicators on the display and the backlight

will be turned on for two seconds.

The internal firmware version will then be displayed for

one second (the numbers displayed may be different to

the one shown here, depending on the firmware

revision of the individual PH60 controller)

The PH60 will then enter ADAPTATION mode. If there

are no problems with the battery or gear assembly, the

display will be as shown in this example. The flashing

indicator shows the motor is operating and retracting

the control pin.

Once the control pin is fully retracted, the display stops

flashing and the display will indicate the valve is open.

Install the TRV to the valve. To move to the next stage,

press any key.

The flashing indicator shows the motor is operating and

extending the control pin to close the valve.

Once closed, the display will change as shown in this

example. The flashing indicator shows the motor is

operating and retracting the control pin again. If this

final stage is completed successfully, the PH60 will enter

NORMAL mode

When entering NORMAL mode for the first time or after

a RESET), the time and day are set to 00:00 and 1. They

are flashing to prompt you to set them to the correct

values – to do this, please follow the ‘Time Setting

Mode’ procedure on page 18.

Page 6

At the start of the adaptation procedure, the controller will

check the battery and gear assembly; if there are any problems,

the following screens will be displayed:

Display Error

This example shows the battery voltage is low.

This example shows the gear assembly is not installed.

If there is a problem during the adaptation procedure, the

controller will stop and restart the process. If the problem still

exists, an error code will be displayed;

Error Code Description

Er1 Stroke too short. During the ‘P2’ adaptation stage the pin

stopped extending before reaching its minimum controllable point.

Er2 Stroke too long. During the ‘P2’ adaptation stage the pin did not stop

extending after reaching its maximum controllable point.

Er3 Unequal stroke. The measured strokes during stages

‘P2’ and ‘P3’ are not equal (this is normally caused

by weak batteries).

Er4 Operation over time. The motor has been operating

for over 100 seconds before reaching the end point.

PH60 INSTRUCTION MANUAL

6

Page 7

PH60 INSTRUCTION MANUAL

7

An example of an error message is shown below:

Display Error Description

Error 2 (Er2 – stroke too long) occurred

during the adaptation process.

Pressing any key will restart

the adaptation process.

It is also possible to enter ADAPTATION mode manually if the PH60 is

in NORMAL mode. This is done by pressing the SET key until ‘AdAP’ is

shown on the display. Releasing the SET key will start the adaptation

process. If an error is displayed during the manually selected

adaptation, pressing any key or waiting 8 seconds without a key press

will return the PH60 to NORMAL mode.

Page 8

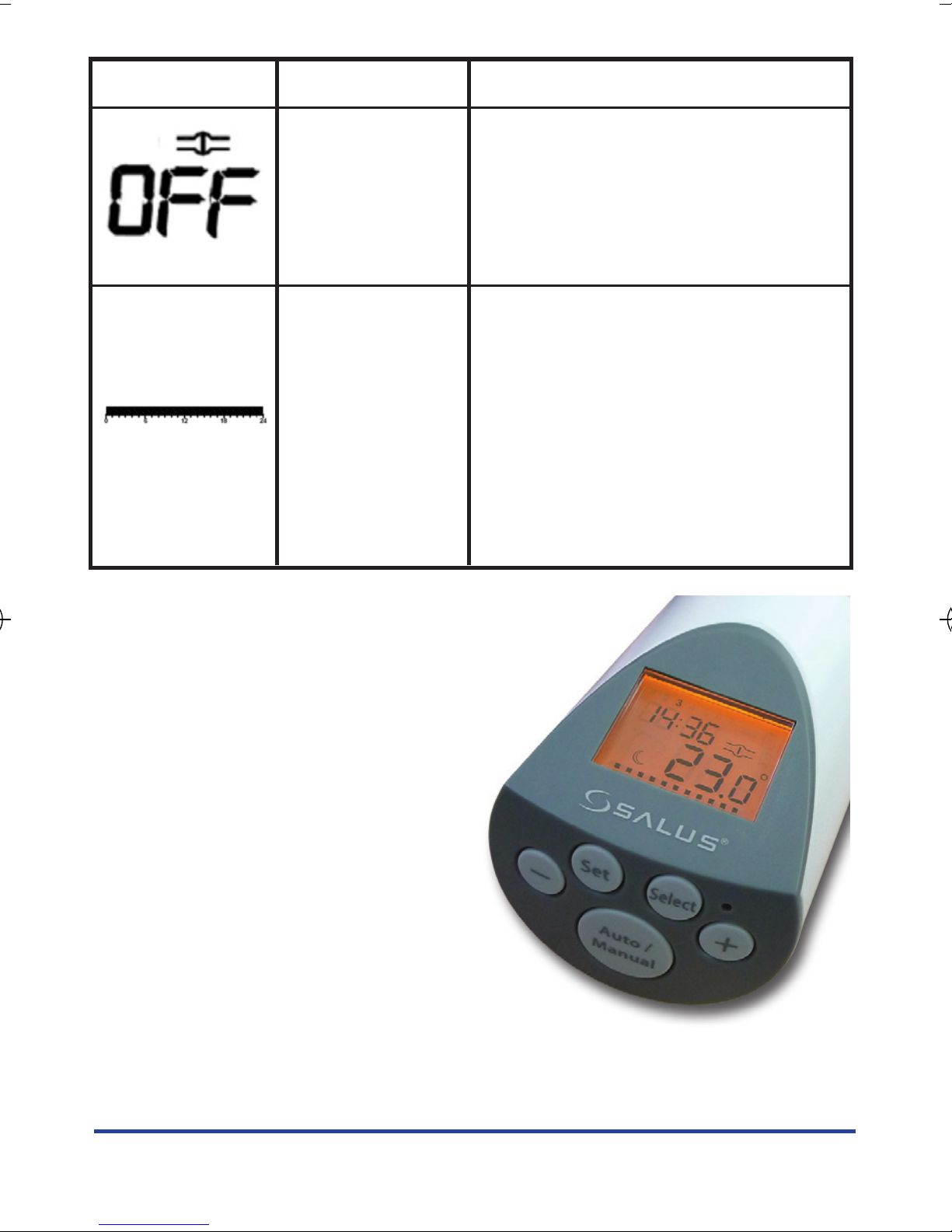

USER INTERFACE AND CONTROLS

The status and operation of the

PH60 can be clearly seen on the

backlit Liquid Crystal Display

(LCD) - this display allows the

user to see at a glance the current

status of the valve controller.

The display consists of a combination of symbols and

alphanumeric displays. The status indicator symbols and their

meanings are shown in the following table:

User Control Function Summary

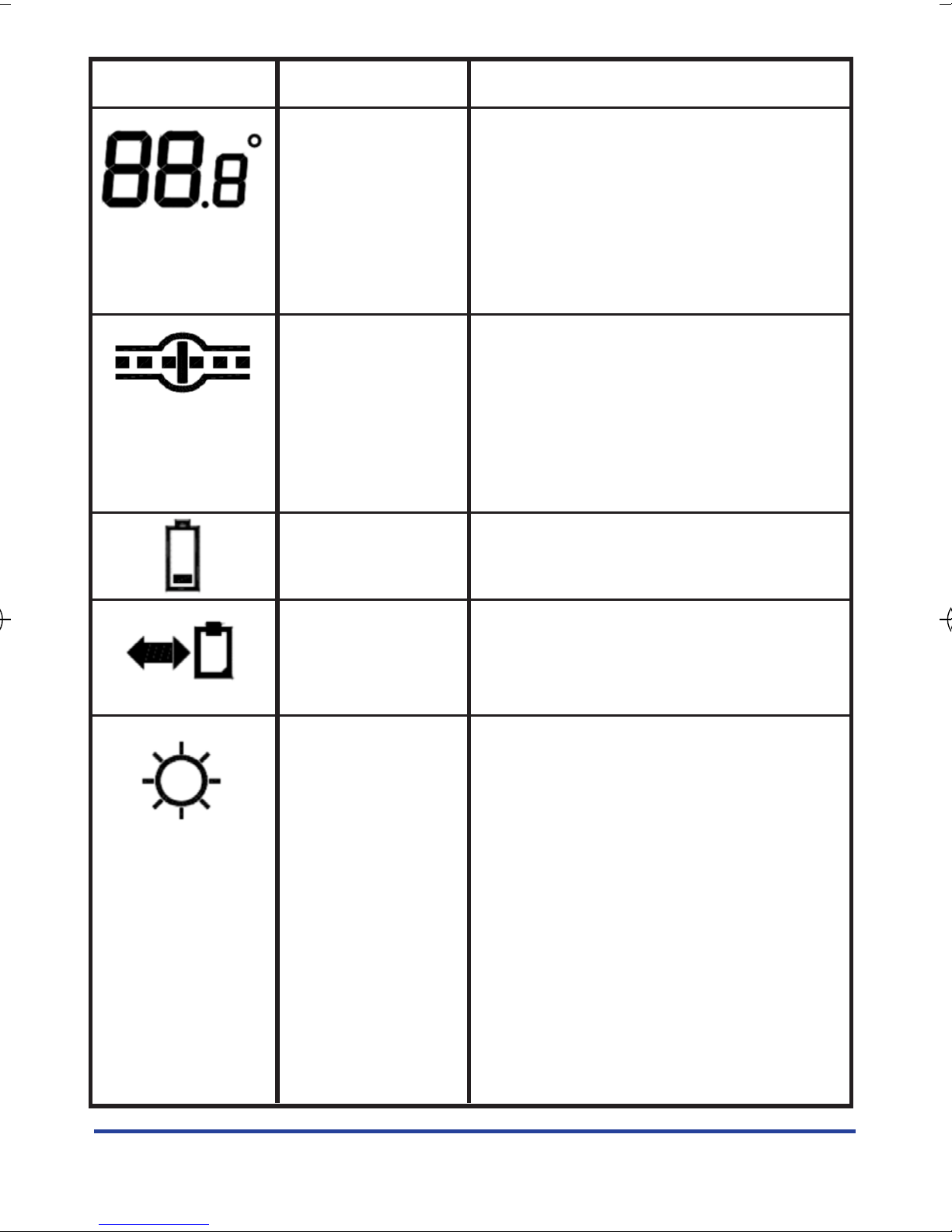

Indicator Description Function

1 2 3 4 5 6 7 Day of Week In NORMAL mode indicates

Indicator the current day of the week.

In PROGRAMME mode indicates

the day being programmed.

In PROGRAMME COPY mode

indicates the source and

destination day.

Time Indicator In NORMAL mode indicates the

current time. In PROGRAMME

mode indicates the

programme time.

PH60 INSTRUCTION MANUAL

8

Page 9

PH60 INSTRUCTION MANUAL

9

Indicator Description Function

Temperature In NORMAL mode indicates the

Indicator room temperature. In

PROGRAMME mode indicates

the set temperature. In

TEMPERATURE mode indicates

the set temperature.

Valve Status A ‘water flow’ animation is

Indicator shown when the valve is opened.

A ‘closed valve’ animation is

shown when the valve is closed.

Indicator flashes when the

valve is opening.

Low Battery Indicator flashes when the

Indicator battery voltage is low.

Programme In PROGRAMME COPY mode

Copy Indicator shows the source and

destination day.

Comfort In AUTO mode indicates the set

Temperature temperature is ‘Comfort’.

Mode Indicator In MANUAL mode indicates the

set temperature is ‘Comfort’.

In PROGRAMME SETTING

mode indicates the set

temperature selected for the

hour is ‘Comfort’.

Page 10

PH60 INSTRUCTION MANUAL

10

Indicator Description Function

Econ In AUTO mode indicates the set

Temperature temperature is ‘Econ’.

Mode Indicator In MANUAL mode indicates the

set temperature is ‘Econ’.

In PROGRAMME SETTING mode

indicates the set temperature

selected for the hour is ‘Econ’.

Party In NORMAL mode indicates

Temperature the set temperature is ‘Party’.

Mode In MANUAL mode indicates the

Indicator set temperature is ‘Party’.

Holiday In NORMAL mode indicates

Temperature the set temperature is ‘Holiday’.

Mode In MANUAL mode indicates the

Indicator set temperature is ‘Holiday’.

Frost Protection In NORMAL mode indicates the

Temperature set temperature is ‘Frost

Mode Indicator Protection’. In MANUAL mode

indicates the set temperature

is ‘Frost Protection’.

Page 11

Indicator Description Function

‘OFF’ Mode Indicates the PH60 is operating

Indicator in ‘OFF’ mode - a special manual

control mode that closes the

TRV regardless of the room

temperature or set temperature.

Programme In NORMAL mode indicates the

Profile Indicator controller is running in AUTO

(Programme) control mode.

In PROGRAMME mode indicates

the profile of the selected day.

In the PROGRAMME COPY mode

it indicates the program profile

of the source day.

There are few user controls for

the PH60, making the controller

very easy to operate. These

controls are shown below,

along with a description of each

of their functions.

PH60 INSTRUCTION MANUAL

11

Page 12

User control function summary:

Key / Operation Functions

+ Increases or changes the selected setting.

- Decreases or changes the selected setting.

SET Enters Menu or confirms a menu selection

SELECT Selects item when in SET mode

AUTO/MANUAL In NORMAL mode, press to choose the AUTO

programme, or any of the MANUAL control modes.

Reset Button Press and hold for more than one second to reset the

controller to default (original factory) settings.

OPERATION

The PH60 is configured and

adjusted by the use of five

touch sensitive buttons.

PH60 INSTRUCTION MANUAL

12

Page 13

PH60 INSTRUCTION MANUAL

13

Normal Mode

NORMAL mode is the default operating mode of the PH60.

This is a typical NORMAL operating mode display.

• The time is midnight, and the day is 1 (Monday)

• The room temperature is 23 ºC

• The valve animation shows that the TRV is open

• The profile indicator at the bottom of the display

shows the PH60 is in AUTO mode

• The ‘Econ’ indicator shows the PH60 set

temperature mode is ‘Econ’

Auto and Manual Control Modes

When the PH60 is operating in AUTO mode, TRV control is

based on the programme currently set. In MANUAL mode, the

set temperature is fixed depending on which set temperature

mode (Off, Comfort, Econ, Party, Holiday or Frost) has been

selected. The temperature mode indicator and programme

profile indicator show what mode the PH60 is operating in:

Page 14

Display Operation

In this example, the PH60 is set to operate

in ‘Comfort’ mode.

The temperature mode indicator will flash if

temporary override mode has been selected.

In this example, the PH60 is set

to operate in ‘Econ’ mode.

When operating in MANUAL mode, programmes are not used

– the profile indicator is not displayed, and the set temperature

is fixed to the temperature selected by the user.

The images below show the PH60 operation in MANUAL mode

with the set temperature in ‘Comfort’, ‘Econ’, ‘Party’, ‘Holiday’

and ‘Frost’ modes:

Changing Control Mode

Pressing the AUTO/MANUAL key when the PH60 is in

NORMAL mode will allow you to change between automatic

control and the six manual control modes. Pressing the + or –

keys allow you to change the set temperature:

PH60 INSTRUCTION MANUAL

14

Page 15

Display Operation

Press the AUTO/MANUAL key once and the

PH60 will display ‘SEt’ and the current

control mode.

Press and hold the SET key or wait for 8

seconds to return to NORMAL mode

without making any changes.

Press the AUTO/MANUAL key again (or the

SELECT key) to change the control mode.

Use the AUTO/MANUAL key to scroll

through the control modes (Auto

Manual Comfort Manual Econ

Manual Party Manual Holiday

Manual Frost Manual Off Auto).

Press the SET key or wait for 8 seconds to

return to NORMAL mode and the PH60

will start to operate in the new mode.

When choosing the control mode, you can

use the + or – keys to change the

set temperature setting.

You cannot adjust the set temperature

if ‘Off’ mode has been selected.

Pressing the + or – key in NORMAL mode will

allow you to review the current set

temperature. ‘SEt’ and the set temperature

will be displayed until the key is released.

If the + or – key is held for more than

two seconds, the display will flash once

and change to setting mode.

PH60 INSTRUCTION MANUAL

15

Page 16

Accessing the Menus

To access the Mode screens, press the SET key as indicated in

the table below:

Display Operation

Press and hold the SET key for one second

to enter the time setting mode. The display

will change to show ‘CLOC’.

Press and hold the SET key for four seconds

to enter the programme setting mode.

The display will change to show ‘Pro’.

Press and hold the SET key for 7 seconds

to enter the programme copy mode.

The display will change to show ‘Pro’

and the copy icon.

Press and hold the SET key for 10 seconds

to enter the option setting mode. The

display will change to show ‘OPn’.

Press and hold the SET key for 13 seconds

to enter the adaptation mode. The display

will change to show ‘AdAP’.

Press and hold the SET key for 16 seconds to return

the PH60 to NORMAL mode.

PH60 INSTRUCTION MANUAL

16

Page 17

PH60 INSTRUCTION MANUAL

17

Time Setting Mode

The Time Setting mode allows the setting of the day and time

– these are the only items displayed on the screen.

• Initially, the hour will be flashing;

press the + or – keys to change

the setting.

• Press the SELECT key to select

the minutes; press the + or – keys

to change the setting.

• Press the SELECT key to select the

day; press the + or – keys to

change the setting.

Pressing the SET key, or not pressing any keys for 30 seconds

will return the PH60 to NORMAL mode.

Programme Setting Mode

The PH60 offers great versatility with its programming options,

allowing the user to programme the controller to operate on a

7 day individual, 5/2 or 7 day control cycle. The controller has

a default set of Programmes that have been designed to meet

the needs of most users:

Page 18

Day of Week Factory Preset Programme

Monday

Tuesday

Wednesday

Thursday

Friday

Saturday

Sunday

In the examples shown above, the time between 0600 to 2200 will

represent a ‘Comfort’ setting ( High set point temperature) The blank

areas will represent an Econ setting ( Low set point temperature)

Please note, Econ temperature cannot be set higher than Comfort

temperature setting.

PH60 INSTRUCTION MANUAL

18

The table below reflects a 24hr day.

Page 19

PH60 INSTRUCTION MANUAL

19

All the set temperatures are adjustable in 0.5 ºC steps.

‘Comfort’ and ‘Econ’ are used in programmes.

If these default programmes are not suitable for your particular

situation, reprogramming the PH60 with your own settings is

a very straightforward operation.

After entering the Programme Setting mode, the programme

settings are adjusted as follows:

The PH60 has 5 preset set temperature modes:

No Programme Description

1 Comfort A warm, comfortable setting.

Adjustable between 7 – 30 ºC

2 Econ A lower setting than ‘Comfort’ to save energy.

Adjustable between 7 – 30 ºC

3 Party An alternative comfortable setting, similar to

‘Comfort’. Adjustable between 15 – 30 ºC

4 Holiday A low setting used when the house is not occupied

for a long period. Adjustable between 7 – 15 ºC

5 Frost An even lower setting than ‘Holiday’, just high

enough to stop pipes freezing.

Adjustable between 4 – 7 ºC

Page 20

Display Operation

Initially, day 1 (Monday) will be displayed. The

clock hour will be flashing, along with a flashing

cursor on the profile indicator at the bottom of

the display.

Press SELECT to change the programme time. In

this example, the time has changed to 11:00, and

the set temperature is using the ‘Comfort’

programme, set at 21 ºC

To change the set temperature, press the + key to

change the temperature mode to ‘Comfort’, or

the – key to change to ‘Econ’. The set time will

then advance by 1 hour.

Press the SET key to advance to the next day. The sequence

is 1 – 2 – 3 – 4 – 5 – 6 – 7 – (1 – 5) – (6 – 7) – (1 – 7). Press

SET again to return to NORMAL mode. (1 – 5), (6 – 7) and

(1 – 7) are called day groups – all the days included are

programmed together. The programming method is the

same as single day programming.

If the programme settings of the involved days are

different, the temperature indicator, set temperature, and

programme profile are not displayed. If the + or – keys are

pressed to change the programme all the days of the

displayed day group will be reset to the default programme

setting. The temperature indicator, set temperature and

programme profile will then be displayed to allow you to

continue adjusting the programme settings.

If no keys are pressed for 30 seconds, the PH60 will automatically

return to NORMAL mode.

PH60 INSTRUCTION MANUAL

20

Page 21

PH60 INSTRUCTION MANUAL

21

Programme Copy Mode

The PH60 programme copy mode allows the user to copy one

day’s programme settings to another day.

If no keys are pressed for 30 seconds, the copy will be cancelled

andthe PH60 will automatically return to NORMAL mode.

Display Operation

On entering programme copy mode, day 1 (Monday) is

displayed and flashing. The programme copy indicator

is also displayed with an animated pointer pointing

towards the clipboard.

Press the + or – keys to select and copy other days,

then press the SET key to go to the next screen.

Initially, the same day that was chosen as the source is

also set as the destination. Press the + or – keys to select

other days as the destination. Press the SET key to

complete the copy operation and return to

NORMAL mode.

Groups of days can be selected as the destination, so

that several days can be programmed together. This

example shows that all the weekdays have been set as

the copy destination.

Page 22

PH60 INSTRUCTION MANUAL

22

Option Setting Mode

There are 5 user option modes available: Language, Stroke

Position, Open Window Detection Sensitivity, Temperature

Offset and Limescale Protection:

Display Operation

The first option is Language. "LAnG" for English.

"SPrA" for German. The current language setting

is displayed.

The default language setting for the PH60 is English

(‘EnG’). Pressing the + or – keys will allow you to

change the setting. Pressing the SET key will confirm

the choice and move to the next screen.

This is adjusted and set automatically in adaptive

mode, see AdAP page 5. There is no change required.

The third option is the Open Window Detection

Sensitivity. ‘OPEn’ and the current sensitivity time

setting is displayed.

Pressing the + or – keys will allow you to change the

setting to the options of 0, 1, 2 or 3. (0 turns off the

option, 1 – 3 indicates low to high sensitivity).

Pressing the SET key will confirm the choice and move

to the next screen.

Page 23

Display Operation

The fourth option is the Temperature Offset. ‘OFS’ and

the current offset temperature setting is displayed.

Pressing the + or – keys will allow you to change

the setting between – 3.5 to + 3.5 ºC in 0.5 ºC

steps. Pressing the SET key will confirm the choice

and move to the next screen.

The fifth option is the Limescale Protection. ‘LInE’ and

the current setting is displayed.

Pressing the + or – keys will allow you to change

the setting to the options of ‘YES’ or ‘NO’. Pressing the

SET key will confirm the choice and return the

PH60 to NORMAL mode.

PH60 INSTRUCTION MANUAL

23

If no keys are pressed for 30 seconds, the PH60 will

automatically return to NORMAL mode.

Page 24

PH60 INSTRUCTION MANUAL

24

Adaptation Mode

It is possible to enter ADAPTATION

mode manually if the PH60 is in

NORMAL mode. This is done by

pressing the SET key until ‘AdAP’ is

shown on the display.

Releasing the SET key will start the adaptation process. If an

error is displayed during the manually selected adaptation,

pressing any key or waiting 8 seconds without a key press will

return the PH60 to NORMAL mode.

Page 25

PH60 INSTRUCTION MANUAL

25

OTHER FUNCTIONS AND CONTROLS

Valve Status Indication

The status of the TRV is displayed on the PH60 is shown by the

valve status indicator:

Display Status

When the TRV is closed, the PH60 will display

a ‘closed valve’ indicator.

When the TRV is open, the PH60 will display

a ‘water flow’ animation.

When the TRV is operating, the PH60 will display

a flashing valve indicator.

Page 26

PH60 INSTRUCTION MANUAL

26

Backlight

The backlight of the PH60 is switched on automatically

whenever any of the keys are pressed. The backlight will

remain illuminated for 10 seconds after the last key press. The

backlight does not operate if the PH60 is in ADAPTATION

mode, or if the battery is low.

Limescale Protection

If the TRV is not operated for long periods, limescale deposits

can build up in the valve and prevent correct operation. The

PH60 has an inbuilt limescale protection mode to prevent this

problem.

When limescale protection mode is enabled, the PH60 will

operate the TRV at least once a day.

At 13:00 every day, if the valve has not been operated in the

last 24 hours the PH60 will open and close the valve once. This

will be indicated on the display as shown:

When enabled, limescale protection will continue to

operate even if the ‘Off’ programme has been selected.

Page 27

Open Window Detection

If a door or window is opened, this may cause a sudden drop

in the room temperature and cause the TRV to be opened by

the controller. This drop in room temperature is usually

temporary, and in this situation it is usually better to turn off

the heating.

When Open Window detection is enabled, the PH60 will

automatically monitor the room temperature. If the

temperature falls quickly (within a user selectable setting of

1.0, 1.5 or 2.5 ºC) the PH60 will enter Open Window mode and

close the TRV. If the room temperature stops falling (or starts

to rise) the Open Window mode will stop and reset the

detection state.

When Open Window mode is operating, it will be indicated on

the display as shown below:

The Open Window state is automatically cancelled after 15

minutes, or if any key is pressed.

PH60 INSTRUCTION MANUAL

27

Page 28

PH60 INSTRUCTION MANUAL

28

Reset Button

The Reset Button is provided as a way to restore the PH60 to its

default factory settings. Pressing this button will delete any

previously entered settings.

The default factory settings for the PH60 are:

Function Default Setting

Operating Mode Adaptation mode

Clock 00:00, 1

Programme Reset to default

Control Mode Auto

Room Temperature Depends on current room temperature

Room Temperature Offset 0.0 ºC

Set Temperature Depends on current programme

‘Comfort’ Set Temperature 21 ºC

‘Econ’ Set Temperature 16 ºC

‘Party’ Set Temperature 21 ºC

‘Holiday’ Set Temperature 10 ºC

‘Frost’ Set Temperature 5 ºC

Backlight Off

Keylock Disabled

Span 0.5 ºC

Window Open Detection Sensitivity 2 (medium)

Temperature Offset 0.0 ºC

Limescale Protection Enabled

Battery Low Warning Based on current battery condition

Valve Status Open (after completion of adaptation)

Page 29

Keylock

The PH60 keypad can be locked to prevent any accidental

changing of the controller settings.

The keylock mode can be turned on when the PH60 is in

NORMAL mode by pressing and holding the SELECT key for

three seconds. Once active, pressing any key will show ‘LOC’ on

the display, as shown below:

If you are unable to change any of the

controller settings, check that the

keylock mode is not turned on. To

disable the keylock, press and holding

the SELECT key again for three seconds.

Temporary Override Mode

When the PH60 is in AUTO mode, the user can temporarily

override the current set temperature. This override will remain

active until the next programmed set temperature becomes

active.

When Temporary Override mode is set,

the TEMPERATURE mode indicator

(‘Comfort’ or ‘Econ’) will flash. To end

the temporary override, press the

AUTO/MANUAL key and reselect the

AUTO mode.

PH60 INSTRUCTION MANUAL

29

Page 30

PH60 INSTRUCTION MANUAL

30

Low Battery Detection

The PH60 constantly monitors battery voltage. When battery

voltage falls below a preset point, the low battery indicator will

be shown on the display as shown below:

The low battery indicator will continue

to be displayed until the battery

voltage returns to normal levels. The

display backlight will not operate

when the battery level is low. When

the low battery indicator is displayed,

you should replace the batteries as

soon as possible.

The PH60 will also monitor the maximum motor speed

achieved when the valve is being operated. If the motor speed

is too low, the PH60 will assume that the battery is low or there

is some problem with the valve actuator.

In this situation, the PH60 will stop

normal operation and enter battery

protection mode, as shown in the

image. The PH60 will set the TRV to a

half open position – the valve will stay

in this condition until the PH60 is reset

by the user.

Page 31

Off Mode

The PH60 has a special manual control mode (‘Off’ mode) that

will close the TRV regardless of the room temperature or set

temperature.

Off mode is generally used when heating is not needed, for

example in the summer. When Off mode is operating, it will

be indicated on the display as shown below:

If limescale protection is enabled, it will still be active in Off

mode. Open Window mode is disabled if the PH60 is operating

in Off mode.

PH60 INSTRUCTION MANUAL

31

Page 32

PH60 INSTRUCTION MANUAL

32

ENERGY TIP

One way to set and use your heating system is to find the

lowest temperature setting that you are comfortable with in

each room, and then leave it set at this temperature. You can

do this by setting the PH60 to a low temperature, (for example

17 °C) and then increasing the setting by one degree each day

until you are comfortable with the room temperature - you

won’t have to adjust the thermostat further, as adjustment

above this setting will waste energy - a 1 °C increase in

temperature is equal to 3% of your heating costs.

MAINTENANCE

The PH60 programmable TRV controller requires no special

maintenance. Periodically, the outer casing can be wiped clean

using a dry cloth (please DO NOT use solvents, polishes,

detergents or abrasive cleaners, as these can damage the

controller).

There are no user serviceable parts within the unit; any

servicing or repairs should only be carried out by Salus Controls

or their appointed agents.

Should the PH60 TRV controller fail to

function correctly, check:

• The batteries are the correct type, fitted correctly

and are not exhausted - fit new batteries if in doubt.

• Heating system is switched on.

• If the PH60 is still not functioning correctly,

press the Reset Button.

Page 33

PRODUCT SPECIFICATION

Model: PH60

Type: Electronic programmable

thermostat for radiator

valve control.

Clock

Display Modes: 24 hour clock with Day

of Week display.

Tolerance: ±60 seconds per month

Programming

Programming Modes: User selectable for 7 day individual,

5/2 or 7 day options

Hourly programming to ‘Comfort’

or ‘Econ’ set points

Group programming function

Override Facility: User selectable programme

override facility.

Temperature

Scale: Celsius

Tolerance: Less than ± 0.5 ºC at 25 ºC

Display Range: 0.0 ºC to 40.0 ºC

Display Resolution: 0.5 ºC

PH60 INSTRUCTION MANUAL

33

Page 34

Control Modes

Operating Modes: Auto (program) or Manual

(in manual mode, user can select

one of 6 preset temperature modes)

Programme Range Step

Off N/A N/A

Comfort 7 – 30 ºC 0.5 ºC

Econ 7 – 30 ºC 0.5 ºC

Party 15 – 30 ºC 0.5 ºC

Holiday 7 – 15 ºC 0.5 ºC

Frost 4 – 7 ºC 0.5 ºC

Power Supply

Power Source: 2 x AA (LR6) alkaline batteries

Battery Life: Approximately 1 year

Memory and Operating Backup

Memory Backup: Electrically Erasable Programmable

Read Only Memory (EEPROM)

Environment

Operating Temperature: 0 ºC to + 50 ºC

Storage Temperature: - 20 ºC to + 60 ºC

PH60 INSTRUCTION MANUAL

34

Page 35

Salus Controls warrants that this product will be free from any defect

in materials or workmanship, and shall perform in accordance with its

specification, for a period of two years from the date of purchase. Salus

Controls sole liability for breach of this warranty will be (at its option)

to repair or replace the defective product.

PH60 Warranty

Customer Name: ....................................................................

Customer Address: .................................................................

...............................................................................................

Post Code: ..................... Tel No: ............................................

Email: .....................................................................................

Engineers Company: ..............................................................

Tel No: ...................................................................................

Email: .....................................................................................

Intallation Date: .....................................................................

Engineers Name: ....................................................................

Engineers Signature: ..............................................................

Page 36

Email: sales@salus-tech.com Tel: 01226 323961

Email: tech@salus-tech.com Tel: 01226 323961

Sales

:

Technical

:

SALUS Controls plc, Salus House, Dodworth Business Park South,

Whinby Road, Dodworth, Barnsley S75 3SP

salus-tech.

15/05/2013 Ver013

Loading...

Loading...