Saito FG-61TS User Manual

|

FG-61TS Instruction Manual |

|

|

|

|

|

|

|

ver. Dec, 2018 |

||||

|

|

|

|

|

|

|

|

|

|

|

|||

Specifications |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Bore |

Φ37.2mm x 2 |

Stroke |

28mm x 2 |

|

Disp. |

60.9cc |

|

|

Applications |

Gasoline 50 class |

|

|

|

Weight (Approx. |

Mainbody : 2,090g / Mu er :100g / Ignition:170g |

|

Practical speed |

Approx.1,500-7,400rpm |

Max on ground |

Approx. 6,200-7,400rpm |

|

||||||

Propeller |

D21”~23” x P10”xP11 |

Plug |

CM-6 |

|

Battery for ignition system |

|

Voltage:6-8.4V, greater than 1,000mA |

|

|

||||

|

Limit gauge (0.1t)for |

tappet adjustment 1pc |

Spanner for tappet adjusting lock nut 1pc |

Carburetor adjustment bar |

1pc |

|

|||||||

Standard |

Spark plug[CM-6](Attached to the engine) 2pcs |

Mu er set |

|

|

|

1set |

Choke bar |

1pc |

|||||

accessories |

Ignition system w/sensor |

1set |

Mu er bracket |

|

|

|

1set |

Plug wrench |

1pc |

||||

|

Stand o mount |

|

1set |

Anti-loosening nut |

|

|

1pc |

Hexagonal wrench |

1set |

||||

Optional parts |

Filter with weight [G36-154] |

Durable tube for Gasoline (1m) [G36-155] |

|

|

|

|

|||||||

Aluminum spinner nut [57T-30] |

Tappet adjusting kit [120S-161] |

Digital tachometer [G17-167] |

|

|

|||||||||

|

|

|

|||||||||||

1. Fuel

●The fuel is mixture of commercial regular gasoline and reliable oil for 2-stroke engines. ●[Example of oil recommendation]

Klotz KL-200 Original Techniplate Morgans Cool Power 'Blue' Synthetic Lubricant etc.

●Be sure to use the mixture “gasoline : oil =15~20 : 1” by volume ratio. (Ex. 1000ml of gasoline should be mixed with more than 50ml of oil ). ●In Break-in process, use 15:1 mixed fuel to ensure the best lubrication for initial run.

●Any damage caused by the fuel used, in which the oil ratio is lower than 20:1 ratio, is not warranted. ●Do not use gasoline ethanol mixed. It may cause not only power loss but also corrosion inside the engine.

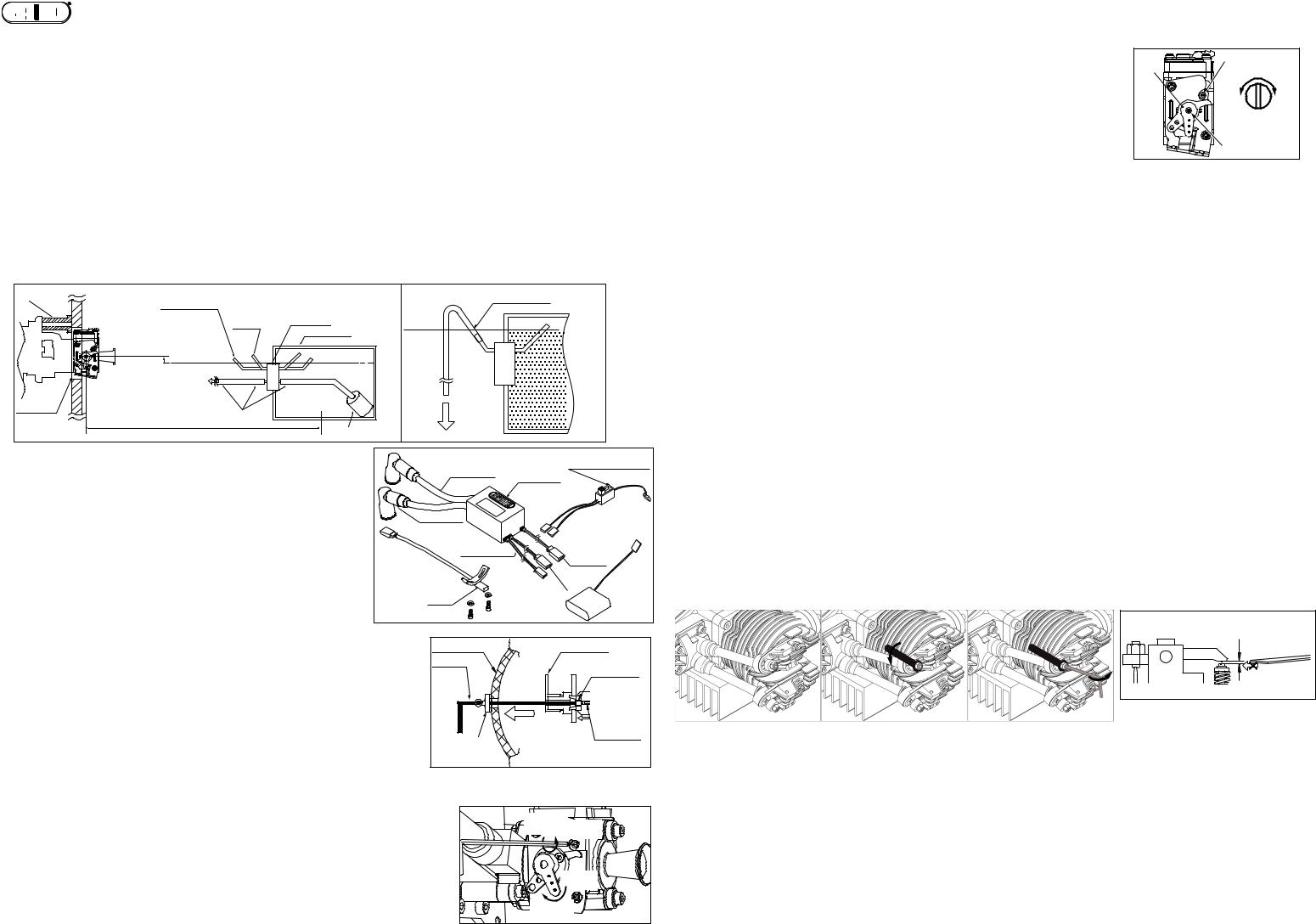

Stand o mount |

Firewall |

|

Vent line |

Fuel filler line |

|

||

|

Gasoline-compatible |

|

|

|

|

Fuel |

|

|

Vent line |

tank stopper |

|

|

Level |

||

|

Set the center of the carb |

Fuel tank |

|

|

|

|

|

|

slightly above the fuel level |

|

|

|

Fuel supply to carburetor |

|

|

Hollow out |

Gasoline-compatible tubing |

|

|

|

|

|

|

|

Close as possible |

Filter with weight |

To Outside of the plane |

2. Ignition |

|

|

Switch(morethan3A) |

●Ignition arrangementPlace the main unit as far from other electrical devices |

(1)Plugcord |

|

|

as possible. |

Mainunit |

|

|

|

|

||

(1) Plug cord(meshed high tension cord) |

|

|

|

2 cords compatible for left/right cylinder. Insert the cap deeply into the plug |

|

|

|

to make sure it will not come o . |

Plugcap |

|

Recommendedbattery |

(2) Sensor cord |

|

|

Voltage:6-8.4V |

Connect with the cord from the sensor attached to the engine. |

|

|

Capacity:1,000mA~ |

|

|

|

|

(3) Battery cord (black / red cord) |

(2)Sensorcord |

|

(3)Battery |

Use a fully charged battery that has adequate spec. (6-8.4V, more than |

|

|

cord |

|

|

|

|

1000mA is recommended.). Between the battery and main unit, make sure |

(4)Tachometercord |

|

|

to set a heavy duty switch whose capacity is higher than 3A. |

|

||

Sensor |

|

|

|

(4)Tachometer cord |

|

|

|

Connect the digital tachometer (Option). Otherwise the connector is |

|

|

|

3. Method of choke(No need when you use starter) |

|

|

|

Choking is the means by which fuel is fed to the engine when you start it by hand flipping. |

Cowling |

Throttle lever |

|

Thus it is unnecessary when using starter. Starting with a electric starter is recommended |

Choke bar |

|

Choke bar for insert |

for safety. |

|

|

|

|

|

M3.5 screw |

|

●In advance, make a thin hole in the cowling to insert the choke bar / slow needle adjust- |

|

|

Throttle valve |

ment bar. |

|

|

|

|

|

(Move to the left) |

|

●During choking, be sure to turn o the ignition switch. |

|

|

|

●As shown in the fig, pass the choke bar (with M3.5 thread on its tip) through the hole in the |

|

|

|

cowling. Then turn the bar to insert into the M3.5 internal thread at the center of the |

Temporary fixed |

|

Slow needle |

throttle lever. |

|

|

|

●Fully close the throttle and pull the choke bar and fix it with a clip or clamp as shown in the |

by a clip |

|

|

|

|

|

|

fig so that it may not go back to the previous position. |

|

|

|

●Grasp the prop by hand and turn it several times in the direction of normal operation |

|

|

|

(CCW) until the carburetor generates hissing-like sound. After hearing this sound for about |

|

|

|

5 times, quickly flip the prop approximately 10 times. |

|

|

|

●Remove the choke bar. Then power on the ignition system and flip the prop quickly to |

|

For CCW |

needleMain |

start the engine. If the engine doesn’t start, repeat the choking procedure. |

|

Make rich |

|

4. Break-in MOST IMPORTANT!! |

|

|

|

●Prop-recommendation : Mejzlik-22x10. |

|

|

|

●Use 15:1 fuel:oil ratio for break-in. |

|

|

Throttle |

●Never make the fuel mixture lean during Break-in. It could cause seizure even during idling or |

|

lever |

|

|

|

||

low speed running. |

|

For CW |

|

●Before starting the engine, open the main needle Approx. 3 turns open (CCW) from fully closed. |

|

||

Open |

|

||

●Start the engine (using a starter is recommended for safety). |

Throttle |

Main needle |

|

●Run for about 30 seconds at low speed to warm up. |

|

|

|

lever |

|

|

|

●Open the throttle gradually up to over half open. In the meantime turn the main needle CCW. |

|

|

|

Continue to turn the main needle CCW until the RPM declines, keeping the throttle opened over |

|

|

|

half. |

|

CCW |

CW |

●If opening main needle doesn’t drop RPM, then open the slow needle too. |

|

Rich |

Lean |

●Run in this very rich condition for 1 liter of fuel. |

|

|

|

5. Adjustment of carburetor after initial break-in. |

|

Slow needle |

|

Needle reference position (Set after initial break-in)

●Start the engine after adjusting the needle to the following reference value. ●Main needle Approx.2.5~3 turns CCW from fully closed

●Slow needle Approx. 4~5 turns CCW from fully closed (Then throttle should be fully closed) ●Actually, the best position of the needles vary depending on the prop, temperature, humidity and so on. Please adjust as necessary after observing the engine performance during flight.

Peak adjustment

●After starting the engine, warm up for approx. 30 seconds at low speed. ●Achieve the peak at full throttle.

→Turn the main needle CW gradually to the position where the RPM is greatest (the peak). Continuing to turn the needle CW past the peak could lead to seizure so turn it slowly and carefully. If the RPM suddenly decreases after passing the peak, instantly turn the main needle CCW to again increase the RPM. Otherwise it could damage the engine seriously.

●Once achieving peak RPM, return the throttle to low speed. Make a note of the position of main needle at the peak at that time. ( How many turns you did CW based on the reference value. )

Slow needle Adjustment

●After achieving peak RPM, next is slow needle adjustment. Open the throttle from low RPM to full throttle quickly.

●Turn the slow needle CCW slightly if the engine hesitates for a moment or stalls before the engine reaches max RPM because the mixture is too lean.

●Turn the slow needle CW slightly if the engine is slow to reach peak RPM (full throttle set) because the mixture is too rich.

●Adjust the slow needle as above until the RPM follows the throttle movement smoothly. The important point is to adjust the slow needle AFTER the main needle has been adjusted to its peak.

●Now break-in at ground level is done. Adjust tappets by the method described later.

Pre-flight / Flight adjustment

●When the slow needle adjustment is done, check the response by revving up from low speed to full throttle quickly several times. ●Open the throttle fully and turn the main needle CCW approx. 60 90 degrees from the peak position. This is to make the fuel mixture

richer in the air where the RPM get higher than on the ground.

●After all adjustments are made, fly your aircraft and fine tune the engine according to the situation. Basically tuning should be done with the main needle. Readjustment of the slow needle is rarely needed if the first adjustment of the slow needle has been done successfully.

7. Tappet adjustment

The valve clearance should be checked and adjusted after break-in and every time after two hours while the engine is cold. Before adjusting

tappet gaps, tighten up the screws around cylinders etc. |

3. Once the gap is set, tighten the |

4. Turn the prop by hand to check if the |

||

1. Remove the spark plug and rocker |

2. Loosen the lock nut and adjust |

|||

lock nut and attach the plug and |

compression is enough. If the gap is less |

|||

arm covers of a cylinder. Then |

the gap by hexagonal wrench |

covers. Then do the same |

than 0, the valve is always opened |

|

turn the prop CCW by hand to |

until you get the correct gap for |

adjustment for the other cylinder. |

slightly and lose compression. Then |

|

place the piston at TDC of |

both of intake & exhaust. |

|

adjust again. |

|

compression stroke. |

|

|

|

|

Correct Gap |

Close to “0” with no limit |

Limit gauge |

(0.1mm) |

Must not be inserted |

Note:

●As it uses oil-mixed fuel, the plane may sometimes get dirty from the exhaust.

●Use a reliable and well-balanced prop. Otherwise it may cause an abnormal vibration and could result in a serious accident. ●During operation, all engine screws can loosen due to metal heat expansion. Check and tighten occasionally.

●When the exhaust valve gets dull by carbon or sludge especially in cold atmosphere, remove the rocker cover and apply some anti-rust spray to the exhaust valve to help the valve to move smoothly.

●Pay attention to the surroundings so as not to disturb others by noise and exhaust. ●Always keep spectators stand behind the engine when operating the engine.

●As exhaust smoke is harmful, be careful not to breathe in or otherwise expose yourself to its harmful e ects.

●Pay attention not to touch the rotating propeller when starting engine, and move to rear side of the aircraft once the engine is started. ●All responsibilities for the use of the engine, and other obligations and responsibilities based on laws, regulations, etc. are borne by the

purchaser and the user, and SAITO SEISAKUSHO CO., LTD. is exempt from any responsibilities.

Loading...

Loading...