Saito FG-17 User Manual

Instructions for SAITO

FG-17(AAC) 4-Stroke Gasoline Single Engine

Thanks for buying SAITO FG-17 4-stroke gasoline engine exclusively for

model airplanes.

In order to avoid misuse, please be sure to read well the

instructions carefully. If there should be any deficiency,

inconvenience, etc. concerning the manufacture, our

company will repair them with responsibility. Any failure or

trouble caused by unnecessary disassembly, modification, or

other uses than those provided in the instruction manuals is

not subject to the warranty, however.

Moreover, all responsibilities for the use of the engine, and other obligations

and responsibilities based on laws, regulations, etc. are borne by the purchaser

and the user, and SAITO SEISAKUSHO CO., LTD. is exempt from any

responsibilities.

SAITO FG-17 is a 4-stroke gasoline engine exclusively for model airplanes

which is designed with emphasis on high performance, durability, and weight

saving. Its parts are modified to adapt to the gasoline engine based on FA-100

glow engine, equipped with carburetor with a pump, ignition system and

small-size spark plug matched to our engine. Moreover for the airplane on

which FA-100 is installed, FG-17 can be replaced easily with minimal change

such as fuel tank and lines to gasoline-resistant ones.

Features of the gasoline engine

・ Fuel efficient. ・ Low cost of fuel. ・ Easy to install “smoke system” (by using muffler pressure or crank pressure)

・ The airframe could not be soiled easily.

Features of FG-17

Cylinder The cylinder head is integrated with the cylinder in order to prevent distortion, save weight and improve cooling effectiveness. Hard

chromium is plated the cylinder without using liners for higher durability.

Piston High-silicon-containing aluminum piston equipped with compression ring for higher performance.

Connecting rod Robust with forged high-strength aluminum. As a measure for gasoline engine, phosphor bronze busing is pressed into the big end to

improve heat resistance.

Crankshaft Robust with forged chromium molybdenum steel and supported by two ball bearings.

Cam gear Placed in the front for compactification.

Cam High output type, high cam specification.

Combustion chamber Volumetric efficiency and com

Propeller nut Designed to have double nuts preventing loosening and fall-off for safety.

Exhaust sound Sound quality similar to the exhaust sound of the real airplane. And as calm as a glow engine.

Carburetor Self-designed and developed carburetor with a pump for small-seize 4-stroke gasoline engines.

Ignition system A new designed battery type electronic ignition and the electronic spark advancing system.

Starting method Forward rotation (CCW) can be manually started due to automatic spark advancing system. (Using a starter is still recommended for safety)

Fuel With the same composite fuel as two cycle gasoline engine which contains 5% of oil content.

Flight pattern Since there

Spark plug Small-size spark plug dedicated for our 4-stroke engine, of which screw size is the same as that of glow plug (UNEF1/4-32)

are no worries about the inclination of oil, all acrobatic flights are possible.

bustion efficiency are improved by adoption of a vent roof type combustion chamber.

Specifications

Bore

Weight (approx.)

Practical Speed

Propeller

Fuel

Fuel consumption

Battery for ignition system

Accessories

φ29.0mm

Main body : 610g / Muffler : 60g / Ignition system : 113g / Engine mount set : 155g

Approx. 2,000-9,500rpm

14"x8", 15"x6", 16"x6"

Regular gasoline : Oil (2-stroke oil) =20:1 (Volume ratio)

Approx 15cc/min (At full throttle, approx 8,800rpm)

*Fuel flow varies depends upon prop load. More fuel flow with larger load and less fuel flow with smaller load.

Voltage:6-8V higher than 1,000mA is recommended

1. Limit gauge (0.1t) for tappet adjustment

2. Spanner for tappet adjusting lock nut

3. Hexagonal wrench set

4. Ignition system (with sensor attached)

5. Spark plug [SAITO SP-1] (attached)

6. Plug wrench

7. Muffler complete

8. Engine mount set

Stroke 26.0mm Stroke volume 17.2cc

Applications 4-stroke 90 class

Static thrust Approx. 3-4kgf

1 pc.

1 pc.

1 set

1 pc.

1 pc.

1 pc.

1 set.

1 set.

-1-

e

s

s

E.C

4-O4.2

M12 ~1.0

104.522.5

127

23.5

40

Outside dimension

56 25

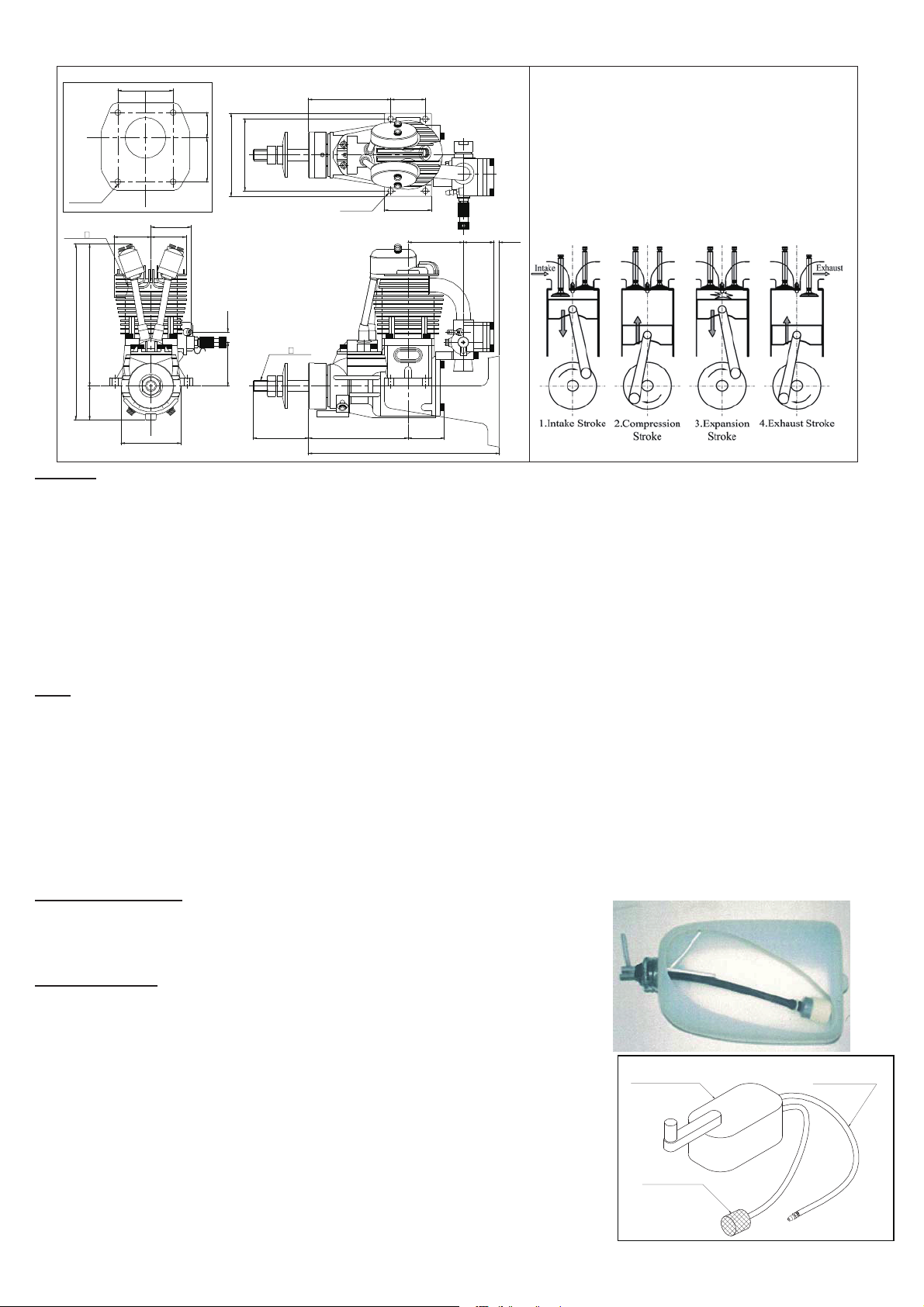

Mechanism of 4-StrokeEngin

The 4-Stroke engine provides 4 individual piston

18.331.7

60

52

movements as illustrated below. The “Stroke” means the

piston movement from the Top Dead Center to the Bottom

Dead Center. In the 4-Stroke engine, one cycle of operation

in change of gas state inside the cylinder and valve

E.C

4-O4.2

28

23

31 7.4

M8 ~1.25

34

35

21.5

movement are completed at every 4 strokes of piston that is

every 2 revolutions of the crankshaft. Formally the engine is

calledthe 4-strokeone-cycle engine.

2.5

36 68.5 26

127.5

Fig.1

42.6

1.Propeller

Depending on the airframe, pleaseadopt the standard size in thedata anduse a reliableproduct which isgenerally onthe market. (Carbon made prop isrecommended)

Since a large-diameter prop is used, please maintain sufficient balance. Since an imbalanced prop is vibratory and dangerous with lowered performance, please maintain

balance with a balancer. Moreover, a cracked prop isdangerous.Please be sure tocheck any timeand replace it with a new oneifit’s cracked.

*Prop andfuel consumption

Ifthe loadis large (thediameter & pitch of the prop islarge)forthe engine characteristics, the air-fuelmix

tureshould be rich.Thusthemainneedle hasto be opened. That is,

even if the revolution is low, the fuel consumption is high. Conversely, when the load is small and the revolution is high, thefuel consumption is lowered because the main

needle can be closed.

In order to decrease the fuel consumption and prolong the engine life, a propeller should be used whose revolution is maximized when the throttle-valve is fully opened,

while using an airframe which enables all flights with about 90% of the output of the propeller.In thiscase, the throttle valve wil

l be further throttled duringhorizontal flight.

Onthe contrary, anairframe which can only deliverperformance in fullyopen condition willsufferworsening fuelconsumptionand life.

2.Fuel

The fuel is mixture of commercial regular gasoline and reliable oil for 2-stroke. (In addition, unleaded high-octane gasoline is not necessarily required for our engine.)

[Exampleofoil]

・ Klotz KL-200 Original Techniplate

・ Deluxe Materials PowerModel 2T-S etc.

For themixtureratio, please be sure to use “gasoline : oil = 20 : 1” or richer by volume ratio. Any damage caused by the fuelused,in which the oil ratio is lower than 20:1

ratio,isnotwarranted.

Since gasoline is a dangerous material, be careful of its storage, use, and transport enough. (The evaporative emission and exhaust smoke of gasoline have a harmful effect

. Also, if gasoline is leaked, there is danger of fire etc.) Please note that we takes no responsibility for accidents, health damages, etc which occur during

on a human

body

storage, useand transport of gasoline.

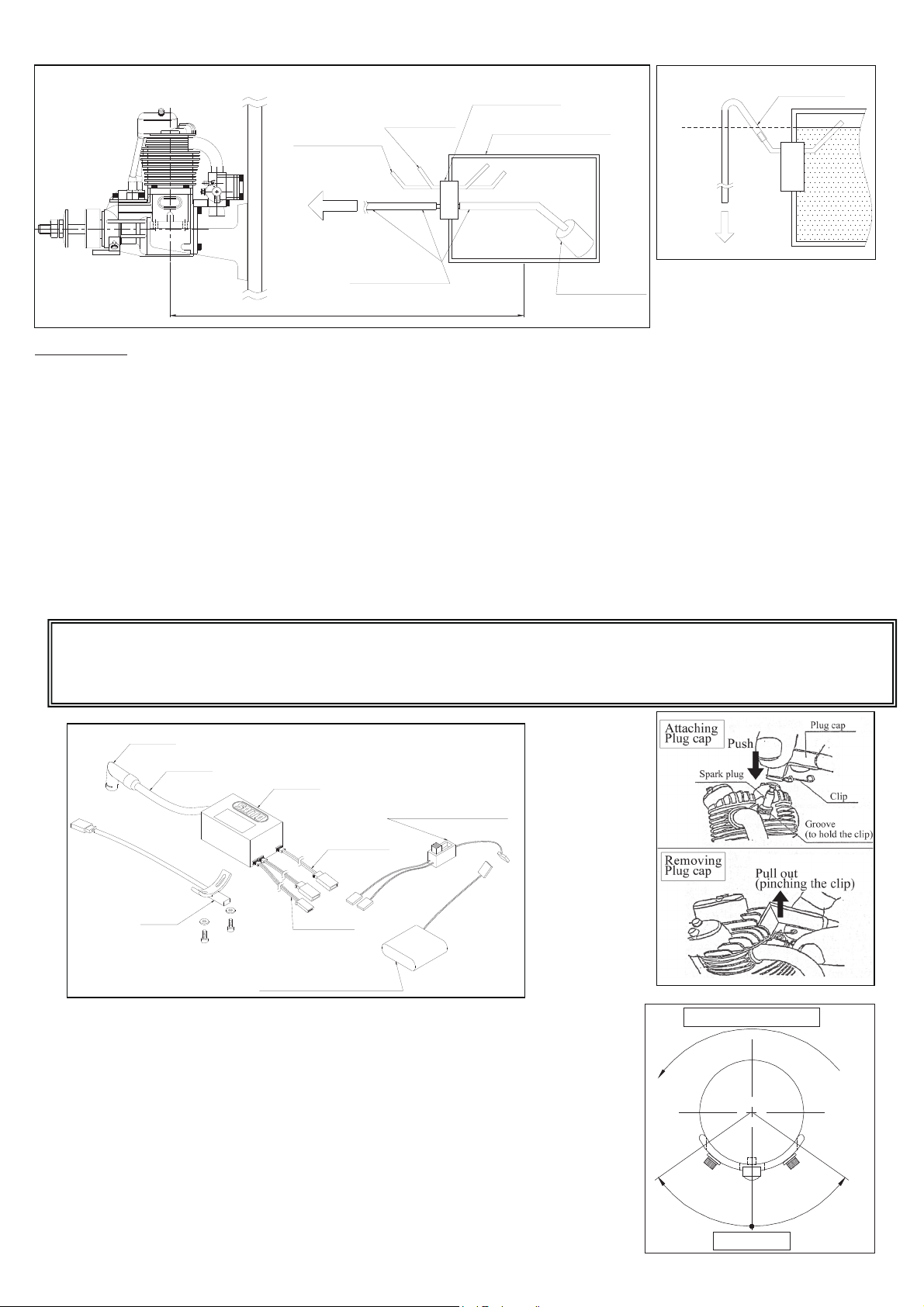

3.Fuel Filter and fuel pump

Since commercial gasoline has many impurities, please be sure to use a reliable filter for the admission port of the

gasolinefuelpump (Fig.2) orthefilter with weightinthe fueltank as thefollowingpictureshows.

Without using a filter, the performanceof the carburetoris not delivered,resultingin failures.

4. Fuel tank and piping

For the capacity (about 200cc-250cc), refer to the dataand select the best of commercial product. Please be sure to

use a filter with weight. To avoid entrain any impurities to the carb, piping with “Fuel feeding pipe” and “Air

inhalation pipe” (Fig.3)is recommended.

*Please be sure to use “gasoline-proof” products for the tank lid rubber, piping, and tubing. Some of the

products for glow fuel can’t be used for gasoline. Please check carefully if there’re any clack of the

piping,tubing, connection, and tank. All of theconnection partshould be bound by thin Nylon strapor

wire to avoid fuel leakage or

air induction to thefuel line. (If there are any leakages, the performance

ofthe engine decreasesdramatically.)

* The tank should be placed within the range of 200mm from the engine center to the tank center.

When performing an acrobat

witha large change in fuel level or thatrequiring anexcessive movement

ofthrottle, thetank must be placed at apositionclose tothe engineasmuch as possible.

*When provide “Air inhalation pipe” as Fig.3, arranging the tube above the fuel level (Fig.4) is the

effective way offuelleakage prevention.

-2-

Filter with weight (tank is not included)

Gasoline-proof

Pump

Filter with weight

Gasoline-proof tube

Fig.2

Fire wall

Fuel feeding pipe

to Carb nipple

Air inhalation

pipe

Rubber cap for

gasoline-resistant

Fuel tank

(200-250cc in capacity)

Fuel level

to Outside of

the fuselage

Fig.4

above

Fuel level

Air inhalation

pipe

Fig.3

Engine center

5. Ignition system

Gasoline-proof tube

Within 200mm (close as possible)

(Fig.5)

Filter with weight

Center of fuel tank

The ignition system is designed to match our 4-stroke engines with automatic advancing system.

However this ignition system is designed to be an anti-noise product, please isolate it completely from the receiver, servo, and battery to avoid a radio-interference trouble.

Moreover, it is desirable to utilize a noise filter (line filter). Especially, each switch (for Ignition and for Receiver) should be isolated and set far from each ones.

The function of each cord;

(1) Plug cord (meshed high tension cord)

The tip of the plug cap is designed exclusively for SAITO SP-1 Plug. When you put on the plug cap, insert it to the plug until the clip fits the groove on the plug (Fig.6;

then you will hear clicky sound) to avoid coming off during flight. And then pull the plug cap to

make sure that it won’t come off.

When you put off, pinch the clip and pull up the plug cap (Fig.7).

(2) Sensor cord (black /red/white cord)

Connect with the cord from the sensor attached to the engine.

(3) Battery cord (black/red cord)

Please use the fully charged battery that has adequate spec. (6-8V, more than 1000mA is recommended.). Between the battery and main body, make sure to set an

ignition switch whose capacity is higher than 3A.

Noise check (required)

Caution: A gasoline engine generates a noise which has an adverse effect on RC adjustment unlike a glow engine. Please be sure to carry out a noise check each time

while the engine is running before the flight. Since a noise which occurs during flight may lead to a large-scale accident, please carry out a noise check without fail.

As a simple method, after starting engine you can check by removing the antenna of the transmitter and operate it about 50m away from the airplane. If there is no

malfunction, it is normal. Moreover, it is preferable to obtain advices from an expert of gasoline units.

Plug cap

Plug cord

Main unit

Switch (not included)

Capacity: more than 3A

Battery cord

Sensor

Fig.5

Sensor cord

Battery

Voltage: 6-8V

Capacity: 1,000mA or higher

*Sensor position and Power / Starting easiness;

The ignition sensor can be moved to CW (advance the spark timing) or CCW (delay the timing) as Fig.8 shows.

At the factory default the sensor is fixed on the center (neutral) position. The

reason is related to the methods of engine

starting.

・With an electric starter…You can start wherever the sensor is fixed.

So you can set the sensor as the rpm reaches maximum speed.

・By hand flip (Manual start)…Starting easiness depends on the sensor position.

The factory default is set as you can start by hand flip and also get highest rpm in that range as possible.

If you prefer easiness of hand starting, move the sensor to CCW direction to delay the spark timing. But then the

maximum rpm will slightly decline.

If you prefer power (highest rpm), move the sensor to CW direction. But then you can't start by hand flip but only with

starter.

In addition by the feature of the ignition system, it heats up with engine running. When

you restart the engine by hand

flip, you should open the throttle valve slightly while it's hot. And it's better to enlarge the choke without wetting the plug.

For safety we recommend to use an electric starter.

Fig.6

Fig.7

CW

Fig.8

View from front

Advance

Spark timing

Neutral Position

Prop rotation

Delay

Spark timing

Hand start

(CCW)

C

C

W

easy area

-3-

Loading...

Loading...