Page 1

Triple Play Access Concentrator

SAGEM 3P@C

4450E

Next Generation DSLAM

SAGEM 3P@C

HARDWARE INSTALLATION MANUAL

Issue November 2004

S

3P@C Installation Manual

Page 0-0 Reproduction and communication in any form prohibited without the written permission of SAGEM SA

Page 2

Triple Play Access Concentrator

SAGEM 3P@C

4450E

Next Generation DSLAM

SAGEM 3P@C

HARDWARE INSTALLATION MANUAL

Issue November 2004

S

3P@C Installation Manual

Page 0-1 Reproduction and communication in any form prohibited without the written permission of SAGEM SA

Page 3

SAGEM 3P@C

WARNING

The information in this document covers a version of the system designated SAGEM 3P@C 4450E. It is subject to

technical changes.

The different versions of the manual will follow changes to the equipment.

3P@C Installation Manual

Page 0-2 Reproduction and communication in any form prohibited without the written permission of SAGEM SA

Page 4

SAGEM 3P@C

RECORD OF AMENDMENTS

(Each new edition supersedes the previous edition)

EDITION N° DATE PURPOSE OF UPDATES PAGES

1 November 2004 Creation of the document All pages

FOREWORD

You have just acquired a product which has been developed using the very latest

technologies and SAGEM

products.

SA know-how. SAGEM thanks you for your confidence in their

3P@C Installation Manual

Page 0-3 Reproduction and communication in any form prohibited without the written permission of SAGEM SA

Page 5

TABLE OF CONTENTS

Use Guide to This Manual 13

Part I 16

1. Overview of the 3P@C 4450E IP-DSLAM 1-1

1.1. S

YSTEM OVERVIEW 1-1

1.2. R

1.3. S

1.4. H

EPRESENTATIVE NETWORKING APPLICATIONS 1-1

YSTEM COMPOSITION 1-2

ARDWARE FEATURES 1-3

2. 3P@C 4450E Hardware Structure 2-1

2.1. S

HELF CONFIGURATION 2-1

2.1.1. Structure of the General Chassis 2-1

2.1.2. 10U Chassis 2-3

2.1.3. Fan Module 2-4

2.1.4. Air Deflector Frame 2-4

2.2. F

2.3. SMUB

ULL CONFIGURATION OF THE CABINET 2-6

AND SERVICE BOARDS 2-7

2.3.1. Service Processor Unit Board (SMUB) 2-7

2.3.2. VDSL Unit Board (VDUB) 2-10

2.3.3. ADSL Unit Board (ADUB) 2-11

2.3.4. ADSL Unit Card (ADUC) 2-13

2.4. P

OWER DISTRIBUTION SYSTEM 2-14

2.4.1. Overview 2-14

2.4.2. Functional Features 2-14

2.5. O

PTIONAL UPLINK INTERFACE MODULES 2-15

2.5.1. 1-port Gigabit Long-wave Optical Interface Module (DS-1GLX) 2-15

2.5.2. 1-port Gigabit Short-wave Optical Interface Module (DS-1GSX) 2-17

2.5.3. 2-port 100M Multi-mode Optical Interface Module (DS-2FMM) 2-18

2.5.4. 2-port 100M Single-mode Optical Interface Module (DS-2FSM) 2-19

2.5.5. 4-port 100M Electrical Interface Module (DS-4TXB) 2-21

2.5.6. VAS Card (DS-4ITX) 2-22

2.6. R

OUTE TRANSFER UNIT (RTU) 2-23

3. Installation Preparation 3-1

3.1. E

NVIRONMENTAL REQUIREMENTS 3-1

3.1.1. Temperature and Humidity Requirements 3-1

3.1.2. Cleanness Requirements 3-1

3.1.3. Floor Requirements 3-1

3P@C Installation Manual

Page 0-4 Reproduction and communication in any form prohibited without the written permission of SAGEM SA

Page 6

SAGEM 3P@C

3.1.4. Heat Dissipation Requirements 3-2

3.1.5. Power Supply Requirements 3-2

3.1.6. Grounding Requirements 3-2

3.1.7. Anti-interference Requirements 3-4

3.1.8. Other Requirements 3-4

3.2. S

AFETY REQUIREMENTS 3-5

3.2.1. Basic Safety Requirements 3-5

3.2.2. Antistatic Requirements 3-5

3.2.3. Avoiding Laser Damage 3-6

3.2.4. Lightning Protection Requirements 3-6

3.2.5. Anti-seismic Design Requirements 3-7

3.2.6. Fireproof Design Requirements 3-7

3.2.7. Precautions for Equipment Handling 3-7

3.3. I

3.4. P

NSTALLATION TOOLS AND MATERIALS 3-7

RODUCT CONFIGURATION LIST 3-8

3.4.1. Basic Configuration of the Product 3-8

3.4.2. Optional Components 3-8

3.5. U

NPACKING FOR ACCEPTANCE 3-9

3.5.1. Preparation 3-9

3.5.2. Unpacking 3-10

3.5.3. Goods Acceptance 3-14

4. Equipment Installation and Connection 4-1

4.1. C

ABINET INSTALLATION 4-1

4.1.1. Installation on the Cement Floor 4-2

4.1.2. Installation on the Antistatic Floor 4-8

4.1.3. Installing the Cabinet Guide Rails 4-14

4.2. I

NSTALLING THE EQUIPMENT 4-15

4.2.1. Installing the 10U Chassis 4-15

4.2.2. Installing the Fan Module 4-16

4.2.3. Installing the Air Deflector Frame 4-19

4.3. C

ONNECTING THE POWER AND GROUNDING CABLES 4-21

4.3.1. Connecting the Power Cables of the Equipment 4-21

4.3.2. Connecting the Power Cable of the Fans 4-22

4.3.3. Connecting the Grounding Cables 4-22

4.3.4. Equipment Power Supply Test 4-23

4.4. I

NSTALLING THE SERVICE PROCESSOR UNIT BOARD (SMUB) 4-23

4.4.1. Installing the Uplink Interface Modules 4-23

4.4.2. Installing the RTU 4-25

3P@C Installation Manual

Page 0-5 Reproduction and communication in any form prohibited without the written permission of SAGEM SA

Page 7

SAGEM 3P@C

4.4.3. Installing the SMUB 4-27

4.4.4. Connecting the Ethernet Interfaces of SMUB 4-28

4.4.5. Connecting the Optical Interfaces of SMUB 4-30

4.5. I

4.6. I

4.7. C

4.8. C

NSTALLING THE SUBSCRIBER SERVICE CARDS 4-31

NSTALLING THE DUMMY PANELS 4-31

ONNECTING THE SUBSCRIBER CABLES 4-32

ONNECTING THE CONSOLE CABLE 4-37

5. Suggestions to Ethernet Cabling 5-1

5.1. R

5.2. R

5.3. S

5.4. S

5.5. O

5.6. I

EQUIREMENTS FOR CABLE TYPES 5-1

EQUIREMENTS FOR CABLING LENGTH 5-1

PACING REQUIREMENTS FOR INDOOR CABLING 5-1

EVERAL FORBIDDEN OVERHEAD CABLING METHODS 5-3

THER REQUIREMENTS FOR OUTDOOR CABLING 5-4

NSTALLING EXTERNAL LIGHTNING ARRESTER 5-4

6. System Configuration and Management 6-1

6.1. E

6.2. S

QUIPMENT POWER-ON 6-1

ETTING UP THE CONFIGURATION ENVIRONMENT 6-1

6.2.1. Local Configuration via the Console Interface 6-1

6.2.2. Remote Configuration via Telnet 6-3

6.3. C

OMMAND LINE SYSTEM 6-4

6.3.1. Command Mode 6-4

6.3.2. Common Commands 6-4

6.3.3. Online Help of Command Line 6-5

6.3.4. Command Line Edit Feature 6-6

6.4. S

YSTEM MANAGEMENT 6-6

6.4.1. Storage Media and File Type 6-6

6.4.2. Program File Management 6-7

6.4.3. Configuration File Management 6-7

Part II 8

7. System Maintenance 7-1

7.1. S

YSTEM UPGRADE 7-1

7.1.1. Storage Media and File Type 7-1

7.1.2. Sequence of System Upgrade 7-1

7.1.3. Upgrading the System File 7-1

7.1.4. Upgrading the Master System Control Board 7-10

7.1.5. Upgrading the Standby System Control Board 7-12

7.2. M

ANAGING THE CONFIGURATION FILE 7-12

7.2.1. Type and Format of Configuration File 7-12

3P@C Installation Manual

Page 0-6 Reproduction and communication in any form prohibited without the written permission of SAGEM SA

Page 8

SAGEM 3P@C

7.2.2. Backuping the Configuration File 7-13

7.2.3. Loading the Configuration File 7-14

7.2.4. Erasing the Configuration File 7-14

7.3. Q

UERYING THE MAINTENANCE INFORMATION 7-14

7.3.1. Querying the Current Software Version 7-14

7.3.2. Viewing the Current Configuration 7-15

7.3.3. Querying the Port Status 7-15

7.3.4. Querying the VLAN Status 7-16

7.3.5. Viewing FIB Table 7-17

7.3.6. Viewing the ARP Table 7-17

7.3.7. Viewing the Route Information 7-18

7.3.8. Querying the System Running Time 7-18

7.4. H

ANDLING PASSWORD LOSS 7-18

8. Port Maintenance 8-1

8.1. C

8.2. C

HECKING THE OPTICAL INTERFACE 8-1

HECKING THE STATUS OF THE USER PORT 8-2

8.2.1. Querying the ADSL Port Status 8-2

8.2.2. Querying the VDSL Port Status 8-5

9. Card Maintenance 9-1

9.1. M

AINTENANCE FOR SYSTEM CONTROL BOARD 9-1

9.1.1. Check 9-1

9.1.2. Hot Plugging 9-2

9.1.3. Master/Standby Switchover 9-2

9.1.4. Reset 9-4

9.1.5. Replacing System Control Board 9-4

9.2. M

AINTENANCE FOR SERVICE BOARD 9-6

9.2.1. Check 9-6

9.2.2. Hot Plugging 9-7

9.2.3. Reset 9-8

9.2.4. Replacing Service Board 9-8

10. Power Distribution System Maintenance 1

10.1. C

HECKING AIR-BREAK SWITCH 1

11. Line Provisioning & Maintenance 11-1

11.1. M

AINTENANCE FOR AIR FILTER 11-1

11.1.1. Checking Air Filter 11-1

11.1.2. Cleaning and Replacing Air Filter 11-1

11.2. M

AINTENANCE FOR FAN SHELF 11-2

11.2.1. Checking Fan Shelf 11-2

3P@C Installation Manual

Page 0-7 Reproduction and communication in any form prohibited without the written permission of SAGEM SA

Page 9

SAGEM 3P@C

11.2.2. Replacing Fan Shelf 11-2

12. Line Commissioning and Maintenance 12-1

12.1. C

12.1.1. ADSL Technical Parameters 12-1

12.1.2. ADSL Line Commissioning 12-5

12.1.3. ADSL Line Maintenance 12-12

OMMISSIONING AND MAINTENANCE OF ADSL SUBSCRIBER LINE 12-1

12.2. C

OMMISSIONING AND MAINTENANCE OF THE VDSL SUBSCRIBER LINE 12-17

12.2.1. VDSL Technical Parameters 12-17

12.2.2. VDSL Line Commissioning 12-19

12.2.3. VDSL Line Maintenance 12-22

13. Fault Analysis and Solution 13-1

13.1. P

ROBLEM LOCATION & INFORMATION COLLECTION 13-1

13.1.1. General Check 13-1

13.1.2. Layer-2 Check 13-1

13.1.3. Layer-3 Check 13-2

13.1.4. Service Check 13-2

13.2. U

NSTABLE SERVICE DUE TO WRONG MAKING OF NETWORK CABLES 13-2

13.2.1. Common Causes 13-2

13.2.2. Processing Procedure 13-3

13.2.3. Typical Cases 13-3

14. Operation Instructions for the Auxiliary Devices 14-1

14.1. U

SE OF AC/DC CONVERTER 14-1

Appendix 14-1

LIST OF FIGURES

Figure 1-1 Triple Play services in Next Generation Networks .................................................................................. 1-1

Figure 2-1 General chassis of 3P@C 4450E ........................................................................................................... 2-1

Figure 2-2 Rear view of the general chassis of 3P@C 4450E ................................................................................. 2-2

Figure 2-3 Front view of the 10U chassis ................................................................................................................. 2-3

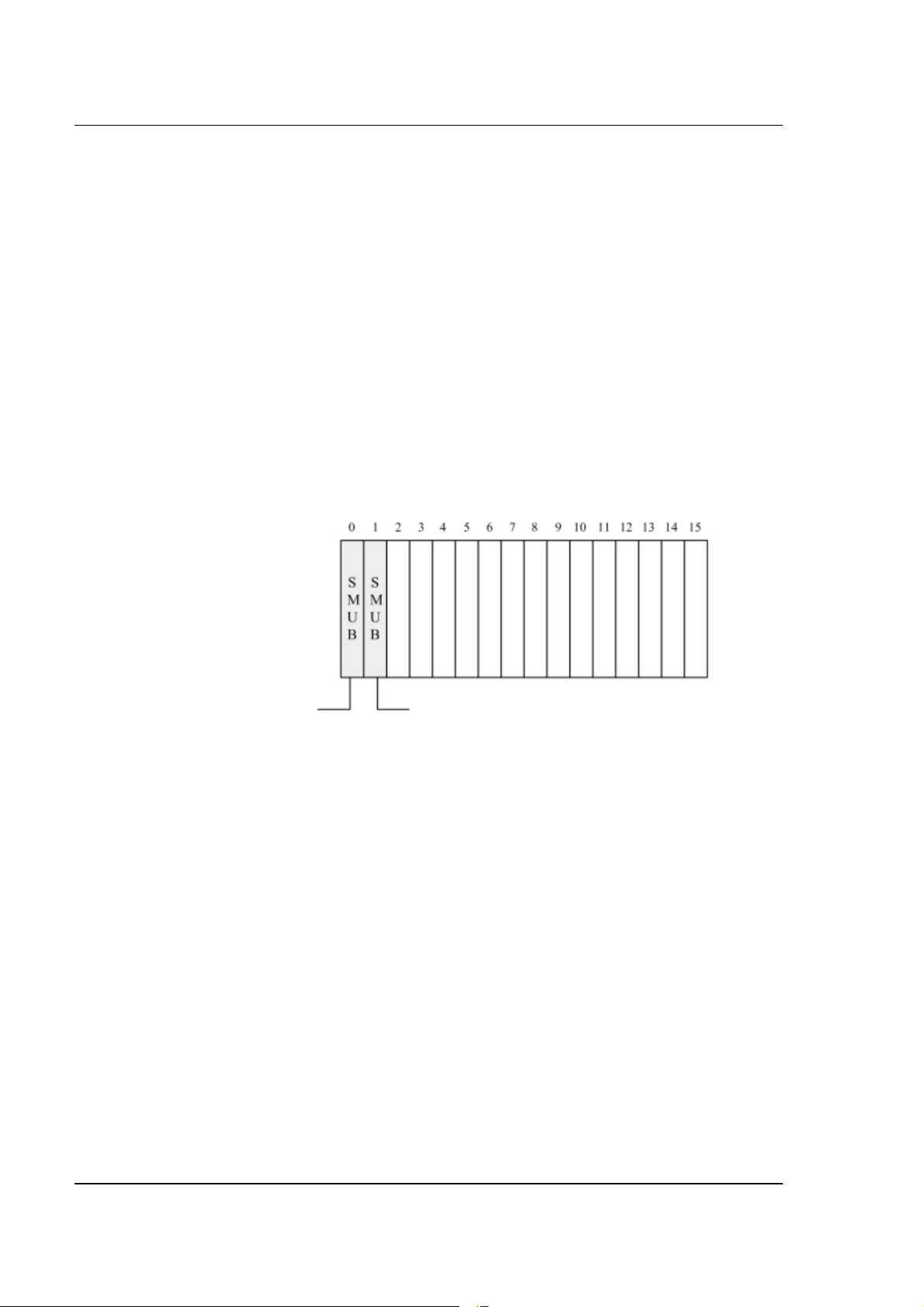

Figure 2-4 Slots for the SMUB and service boards .................................................................................................. 2-3

Figure 2-5 Front view of the fan module ................................................................................................................... 2-4

Figure 2-6 Outside view of the radiator fans............................................................................................................. 2-4

Figure 2-7 Sectional view of the air deflector frame ................................................................................................. 2-4

Figure 2-8 Heat dissipation of a single system ......................................................................................................... 2-5

Figure 2-9 Air ducts inside the cabinet ..................................................................................................................... 2-5

Figure 2-10 Full configuration of 3P@C 4450E........................................................................................................ 2-6

Figure 2-11 Slots of the SMUB ................................................................................................................................. 2-7

Figure 2-12 Front view of the SMUB ........................................................................................................................ 2-8

3P@C Installation Manual

Page 0-8 Reproduction and communication in any form prohibited without the written permission of SAGEM SA

Page 10

SAGEM 3P@C

Figure 2-13 Slots of the VDUB ............................................................................................................................... 2-10

Figure 2-14 Front view of the VDSL ....................................................................................................................... 2-10

Figure 2-15 Slots of the ADUB ............................................................................................................................... 2-12

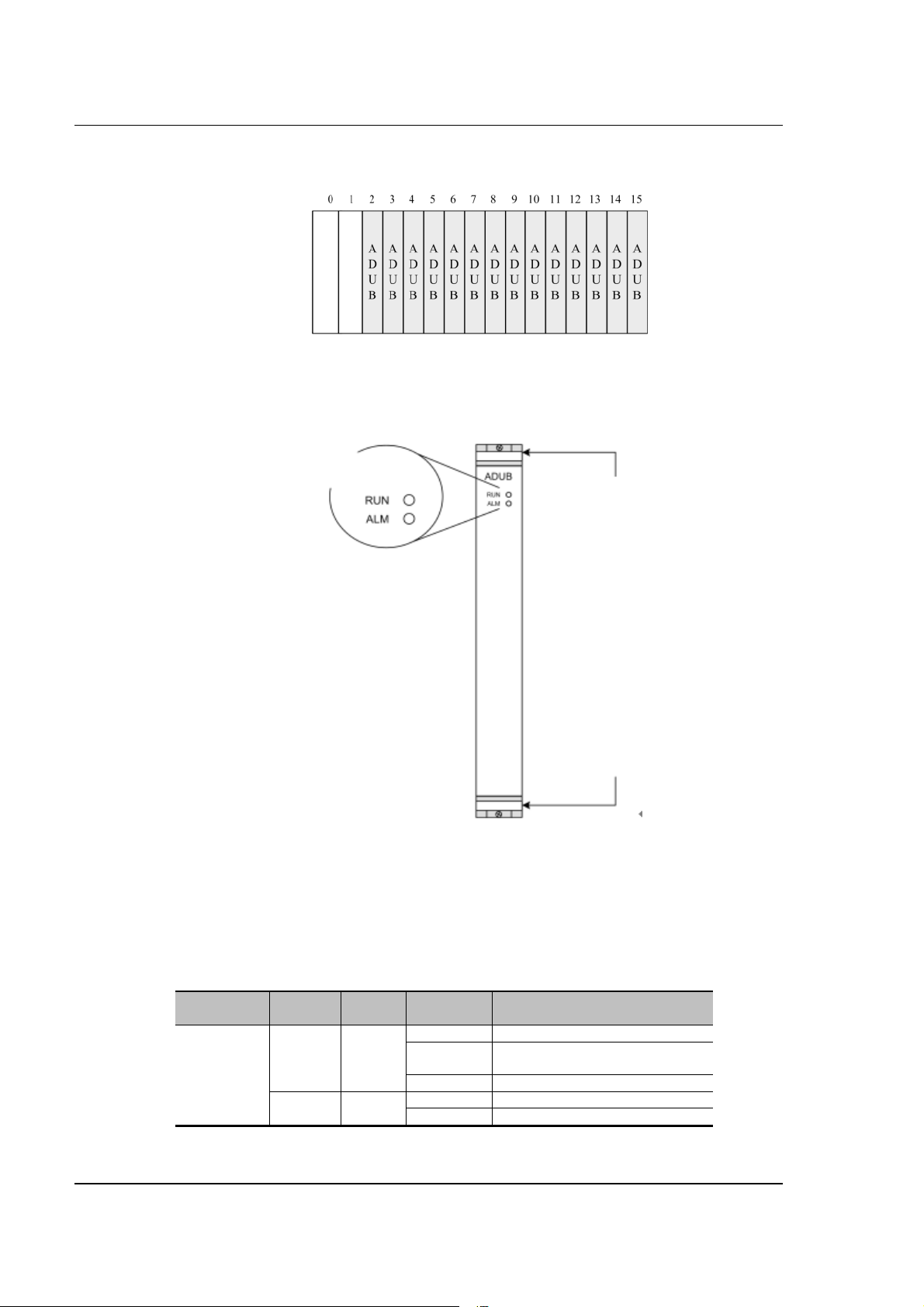

Figure 2-16 Front view of the ADUB....................................................................................................................... 2-12

Figure 2-17 Slots of the ADUC ............................................................................................................................... 2-13

Figure 2-18 Front view of the ADUC....................................................................................................................... 2-13

Figure 2-19 Connection relations............................................................................................................................ 2-14

Figure 2-20 Front view of the DS-1GLX module .................................................................................................... 2-16

Figure 2-21 Front view of the DS-1GSX module .................................................................................................... 2-17

Figure 2-22 Front view of the DS-2FMM module ................................................................................................... 2-18

Figure 2-23 Front view of the DS-2FSM module .................................................................................................... 2-20

Figure 2-24 Front view of the DS-4TXB module..................................................................................................... 2-21

Figure 2-25 Front view of the DS-4ITX module ...................................................................................................... 2-22

Figure 3-1 Recommended power sockets ................................................................................................................ 3-3

Figure 3-2 Appearance of the packing box............................................................................................................. 3-10

Figure 3-3 Packing structure of the equipment inside the packing box.................................................................. 3-11

Figure 3-4 Appearance of the cabinet packing box ................................................................................................ 3-12

Figure 3-5 Draw out the packing box backward from the reverse direction ........................................................... 3-13

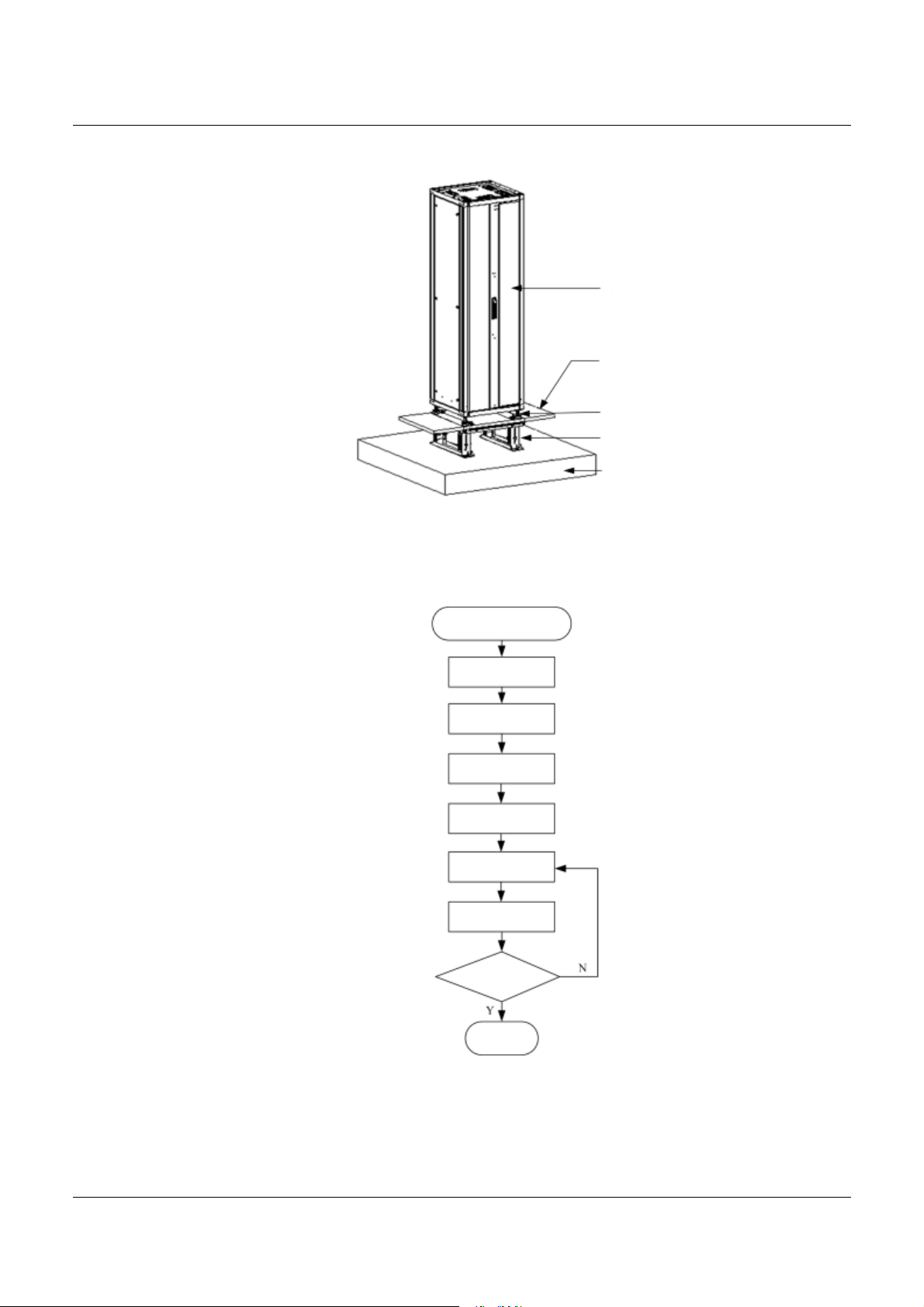

Figure 4-1 Cabinet installation flow chart ................................................................................................................. 4-1

Figure 4-2 Equipment installation space .................................................................................................................. 4-2

Figure 4-3 Flow of cabinet installation on the cement floor ...................................................................................... 4-3

Figure 4-4 Mounting hole positions for a single cabinet ........................................................................................... 4-4

Figure 4-5 Mounting hole positions for two cabinets ................................................................................................ 4-4

Figure 4-6 Installation sequence of the pressure plate assembly ............................................................................ 4-6

Figure 4-7 Completion of the installation of a single cabinet .................................................................................... 4-6

Figure 4-8 The connecting boards before combining two cabinets side by side...................................................... 4-7

Figure 4-9 The connecting boards after combining two cabinets side by side......................................................... 4-7

Figure 4-10 Effect after the installation of two combined cabinets ........................................................................... 4-7

Figure 4-11 Appearance of the A600 series support................................................................................................ 4-8

Figure 4-12 Completion of the installation of a single cabinet .................................................................................. 4-9

Figure 4-13 Flow of the cabinet installation on the antistatic floor............................................................................ 4-9

Figure 4-14 Cabinet marking template ................................................................................................................... 4-10

Figure 4-15 Connection positions of the mounting holes for the support and the antistatic floor .......................... 4-11

Figure 4-16 Assembly chart of the pressure plate assembly ................................................................................. 4-12

Figure 4-17 Positions of the bolts to be fastened ................................................................................................... 4-13

Figure 4-18 Completion of the installation of two combined cabinets .................................................................... 4-14

Figure 4-19 Guide rail ............................................................................................................................................. 4-15

Figure 4-20 Front view of the guide rails installed .................................................................................................. 4-15

3P@C Installation Manual

Page 0-9 Reproduction and communication in any form prohibited without the written permission of SAGEM SA

Page 11

SAGEM 3P@C

Figure 4-21 Fixing the hangers onto the 10U chassis............................................................................................ 4-16

Figure 4-22 Insert the 10U chassis into the rack and fix it ..................................................................................... 4-16

Figure 4-23 Install the fan supports ........................................................................................................................ 4-17

Figure 4-24 Install the fan module .......................................................................................................................... 4-17

Figure 4-25 Operate the puller adapter .................................................................................................................. 4-18

Figure 4-26 Install the air deflector frame ............................................................................................................... 4-19

Figure 4-27 Completion of the installation of a single general chassis .................................................................. 4-20

Figure 4-28 Installation of the -48V DC power cables ............................................................................................ 4-21

Figure 4-29 Power cable connection of the fans .................................................................................................... 4-22

Figure 4-30 Panel view of the SUMB...................................................................................................................... 4-23

Figure 4-31 Insert the pins of the uplink interface module into the socket of the SMUB........................................ 4-24

Figure 4-32 Fix the uplink interface module with screws........................................................................................ 4-25

Figure 4-33 Installation position of the RTU ........................................................................................................... 4-25

Figure 4-34 Insert the pins of the RTU into the socket of the SMUB ..................................................................... 4-26

Figure 4-35 Fix the RTU with screws...................................................................................................................... 4-26

Figure 4-36 Rear view of the RTU installed with screws and nuts ......................................................................... 4-27

Figure 4-37 Installation of the SMUB...................................................................................................................... 4-27

Figure 4-38 RJ-45 connector .................................................................................................................................. 4-28

Figure 4-39 Illustration of making a straight-through cable .................................................................................... 4-29

Figure 4-40 Illustration of making a crossover cable .............................................................................................. 4-29

Figure 4-41 Ethernet interface connection of the SMUB ........................................................................................ 4-30

Figure 4-42 SC optical connector ........................................................................................................................... 4-30

Figure 4-43 Uplink optical interface connection...................................................................................................... 4-31

Figure 4-44 Install a dummy panel ......................................................................................................................... 4-32

Figure 4-45 Installation of the LU and LC subscriber cables on the backplane ..................................................... 4-33

Figure 4-46 Pinouts of the LU subscriber cable ..................................................................................................... 4-33

Figure 4-47 Pinouts of the LC telephone line ......................................................................................................... 4-34

Figure 4-48 Cable bending and binding ................................................................................................................. 4-36

Figure 4-49 Single binding...................................................................................................................................... 4-37

Figure 4-50 Double binding .................................................................................................................................... 4-37

Figure 4-51 Console interface connection .............................................................................................................. 4-38

Figure 4-52 Input the connection name and select an icon for it............................................................................ 4-38

Figure 4-53 Select the connecting serial port ......................................................................................................... 4-39

Figure 4-54 Communication parameter setting ...................................................................................................... 4-39

Figure 4-55 Select the terminal emulation type ...................................................................................................... 4-40

Figure 5-1 Requirements for cabling length ............................................................................................................. 5-1

Figure 5-2 Parallel and crossed net spacing ............................................................................................................ 5-3

Figure 5-3 Direct overhead cabling between two buildings without any protection (1) ............................................ 5-3

3P@C Installation Manual

Page 0-10 Reproduction and communication in any form prohibited without the written permission of SAGEM SA

Page 12

SAGEM 3P@C

Figure 5-4 Direct overhead cabling between two buildings without any protection (2) ............................................ 5-3

Figure 5-5 Direct overhead cabling between two buildings without any protection (3) ............................................ 5-3

Figure 5-6 Direct overhead cabling from the outdoors of the top of a buildings to the bottom floor without any

protection ........................................................................................................................................................... 5-4

Figure 5-7 Connection of the external lightning arrester .......................................................................................... 5-4

Figure 6-1 Remote management of 3P@C 4450E via Telnet.................................................................................. 6-3

Figure 7-1 Connecting the console cables ............................................................................................................... 7-5

Figure 7-2 hoosing the file to be sent ....................................................................................................................... 7-8

Figure 7-3 File transfer interface............................................................................................................................... 7-8

Figure 7-4 Connection mode .................................................................................................................................... 7-9

Figure 11-1 Schematic diagram of pulled handle operation ................................................................................... 11-3

Figure 11-2 Installation of fan support .................................................................................................................... 11-4

Figure 11-3 Installation of fan module .................................................................................................................... 11-4

Figure 12-1 Frequency range of ADSL................................................................................................................... 12-1

Figure 12-2 The pass-band characteristics of the ADSL voice splitter................................................................... 12-2

Figure 12-3 ADSL distribution................................................................................................................................. 12-6

Figure 12-4 Connection of splitters......................................................................................................................... 12-9

Figure 12-5 VDSL frequency range ...................................................................................................................... 12-17

Figure 12-6 VDSL distribution............................................................................................................................... 12-19

Figure 12-7 Connection of splitters....................................................................................................................... 12-21

Figure 12-8 Networking diagram .......................................................................................................................... 12-24

LIST OF TABLES

Table 1-1 Boards, cards and uplink interface modules provided by 3P@C 4450E ................................................. 1-2

Table 1-2 Name, quantity and type of the interfaces supported by 3P@C 4450E................................................... 1-3

Table 1-3 Performance indexes of the 3P@C 4400

Table 2-1 General chassis composition of 3P@C 4450E ........................................................................................ 2-1

Table 2-2 Interface features of the SMUB ................................................................................................................ 2-8

Table 2-3 Type of uplink interface modules.............................................................................................................. 2-8

Table 2-4 Status definitions of the LED indicators on the SMUB ............................................................................. 2-9

Table 2-5 Status definitions of the LED indicators on the front panel of VDUB ..................................................... 2-11

Table 2-6 Status definitions of the LED indicators on the front panel of ADUB ..................................................... 2-12

Table 2-7Status definitions of the LED indicators on the front panel of ADUC ...................................................... 2-14

E

............................................................................................... 1-3

Table 2-8 Types of uplink interface modules .......................................................................................................... 2-15

Table 2-9 Status definitions of the LINK and ACT LEDs on the DS-1GLX module ............................................... 2-16

Table 2-10 Gigabit long-wave optical interface features of the DS-1GLX module ................................................. 2-16

Table 2-11 Status definitions of the LINK and ACT LEDs on the DS-1GSX module ............................................. 2-17

Table 2-12 Interface features of the DS-1GSX module.......................................................................................... 2-18

3P@C Installation Manual

Page 0-11 Reproduction and communication in any form prohibited without the written permission of SAGEM SA

Page 13

SAGEM 3P@C

Table 2-13 Status definitions of the LINK and ACT LEDs on the DS-2FMM module ............................................ 2-19

Table 2-14 Interface features of the DS-2FMM module ......................................................................................... 2-19

Table 2-15 Status definitions of the LINK and ACT LEDs on the DS-2FSM module ............................................. 2-20

Table 2-16 Interface features of the DS-2FSM module.......................................................................................... 2-20

Table 2-17 Status definitions of the LINK and ACT LEDs on the DS-4TXB module............................................. 2-21

Table 2-18 Interface features of the DS-4TXB module .......................................................................................... 2-21

Table 2-19 Status definitions of the LINK and ACT LEDs on the DS-4ITX module ............................................... 2-22

Table 2-20 Interface features of the DS-4ITX module............................................................................................ 2-23

Table 2-21 Structure of the RTU............................................................................................................................. 2-23

Table 4-1 Pinouts of the RJ-45 MDI interface ........................................................................................................ 4-28

Table 4-2 Pinouts of the RJ-45 MDIX interface ...................................................................................................... 4-28

Table 4-3 Pinouts of the LU subscriber cable......................................................................................................... 4-33

Table 4-4 Pinouts of the LC telephone line ............................................................................................................ 4-35

Table 5-1 Requirements of spacing between Ethernet cables and cables of other electric devices ....................... 5-2

Table 5-2 Requirements of spacing between the Ethernet cables on the wall and other pipelines ......................... 5-2

Table 6-1 Description of the read-only mode and the configuration mode .............................................................. 6-4

Table 6-2 Commands in the read-only mode ........................................................................................................... 6-4

Table 6-3 Common commands in the configuration mode....................................................................................... 6-5

Table 6-4 Line edit commands in the command line ................................................................................................ 6-6

Table 6-5 Correspondence between file types and command line parameters of 3P@C 4450E............................ 6-6

Table 7-1 Bootrom command ................................................................................................................................... 7-3

Table 7-2 Upgrade submenu in the network port ..................................................................................................... 7-3

Table 7-3 Relevant parameters downloaded by the network port of system control board ..................................... 7-4

Table 9-1 Description of LED status of the system control board SMUB ................................................................. 9-1

Table 9-2 Description of the indicator of the VDUB service board ........................................................................... 9-6

Table 12-1 ADSL parameter setting table .............................................................................................................. 12-3

Table 12-2 ADSL subscriber line length attenuation table ..................................................................................... 12-4

Table 12-3 ADSL line attenuation per kilometer within different frequency bands................................................. 12-4

Table 12-4 ADSL line connection parameters ........................................................................................................ 12-6

Table 12-5 DC loop resistance for subscriber lines with different core diameters per kilometer ........................... 12-8

Table 12-6 Line test reference table ....................................................................................................................... 12-8

Table 12-7 ADSL service line reference table ...................................................................................................... 12-10

Table 12-8 Broadband service user information record table .............................................................................. 12-11

Table 12-9 ADSL setting parameters and connection parameter record table .................................................... 12-11

Table 12-10 The minimum SNR value for the rates (for reference) ..................................................................... 12-18

Table 12-11 DC resistance reference value of common lines.............................................................................. 12-20

Table 12-12 VDSL setting parameters and connection parameter record table .................................................. 12-22

3P@C Installation Manual

Page 0-12 Reproduction and communication in any form prohibited without the written permission of SAGEM SA

Page 14

SAGEM 3P@C

USE GUIDE TO THIS MANUAL

Target Readers

This manual is intended for system administrators responsible for the installation and maintenance of the 3P@C

4450E IP-DSLAM (“3P@C 4450E”). Readers should have the following knowledge:

Local Area Networks (LANs)

Ethernet Concepts

Ethernet Switching and Bridging Concepts

Routing Concepts

Simple Network Management Protocol (SNMP)

Contents

This manual describes the installation and maintenance of 3P@C 4450E, including its features, components,

component functions as well as equipment connections and maintenance.

It briefly describes some software configuration information. For a detailed description of the commands and

configuration operations, please refer to the 3P@C 4450E IP-DSLAM Software Configuration Manual and the

3P@C 4450E IP-DSLAM Command Reference.

The 3P@C 4450E IP DSLAM User Manual consists of three parts:

Part I

It introduces the structure, installation, connection and basic configuration of the 3P@C 4450E , specifically

including the following contents:

Chapter

Title

Contents

Chapter 1

Product Overview

Introduces the functions, features and system components of 3P@C 4450E

Chapter 2

Product Structure

Describes the integrated equipment structure of 3P@C 4450E as well as the components and functions of its parts or modules

Chapter 3

Installation Preparation

Describes the installation environment and safety requirements, installation tools, materials, product configuration and

unpacking inspection of 3P@C 4450E

I Hardware Installation

I I

Chapter 4

Equipment Installation and Connection

Describes the installation and cable connection of cabinets, chassis and modules of 3P@C 4450E

Chapter 5

Ethernet Cabling Suggestions

3P@C Installation Manual

Page 0-13 Reproduction and communication in any form prohibited without the written permission of SAGEM SA

Page 15

SAGEM 3P@C

Gives suggestions on the FE interface cabling in practical engineering

Chapter 6

System Configuration and Management

Introduces the setup of the configuration environment, the command line system and the management mode of the related

programs and files in the system

Part II

II Maintenance

IIII

It introduces the maintenance methods and related knowledge of he 3P@C 4450E , specifically including

the following contents:

Chapter

Title

Contents

Chapter 7

System Maintenance

Describes system upgrade, configuration file management, common maintenance information view and handling of password

loss

Chapter 8

Port Maintenance

Describes optical interface detection and subscriber port status check

Chapter 9

Card Maintenance

Describes the maintenance of SMUB and service boards such as VDUB/ADUB/ADUC

Chapter 10

Power Distribution System Maintenance

Describes the check and handling of air switches

Chapter 11

Accessories Maintenance

Describes the maintenance of dust filters and fan frames

Chapter 12

Line Provisioning & Maintenance

Describes the provisioning and maintenance of ADSL and VDSL lines

Chapter 13

Fault Analysis and Solution

Describes the fault location and information collection methods and the handling in the case of service interruption from time to

time due to incorrect making of the network cables

Chapter 14

Operation Instructions for the Auxiliary Devices

Describes the usage of the HD4825 DC/AC converter

3P@C Installation Manual

Page 0-14 Reproduction and communication in any form prohibited without the written permission of SAGEM SA

Page 16

SAGEM 3P@C

Appendix Common Troubleshooting & Relevant Knowledge

It introduces the common troubleshooting and related knowledge of he 3P@C 4450E , specifically

including the following contents:

Appendix A

Diagnosis of Common Faults

Lists some common faults of 3P@C 4450E and the possible causes and solutions

Appendix B

Glossary

Explains some terminologies involved in this manual

Appendix C

Fiber-related Knowledge

Gives the related knowledge about optical fibers

Conventions

Conventions for icons are listed as follows:

Icon

Description

Warning

Notifies users that improper operation may cause damage to human body or equipment, service disruption or data loss during

the process of installation and service configuration.

Note

This icon alerts users to some precautions.

prompt

This icon provides some text-related information and some guidance for users, and helps users understand the text better.

Technical Support

SAGEM establishes a complete hierarchical service system consisting of 3 levels, namely, the

headquarter, area and local technical support centers. It provides all-weather and full-time telephone

hotline services. Any time when users have problems on our product and network operation, feel free to

contact us by local service support hotlines. Visit www.sagem.com to find out the local service support

hotlines, to see the latest products and to download needed technical documents.

3P@C Installation Manual

Page 0-15 Reproduction and communication in any form prohibited without the written permission of SAGEM SA

Page 17

SAGEM 3P@C

PART I

Hardware Installation

I

I I

3P@C Installation Manual

Page 0-16 Reproduction and communication in any form prohibited without the written permission of SAGEM SA

Page 18

CHAPTER 1

1. Overview of the 3P@C 4450E IP-DSLAM

This chapter describes the typical networking models, features and performance indexes of the 3P@C 4400E.

1.1. System Overview

As the heart of Next Generation network architecture, SAGEM 3P@C 4450E and 4048E are high-performance

IP-DSLAM platforms that enable to deliver a wide variety of services such as broadband internet, voice over

packet, LAN to LAN connections, video multicast streaming, leased lines and VPN, on any subscriber line.

Thanks to their flexible, modular and scalable design, SAGEM 3P@C systems can provide all services simply by

the composition of relevant units in the same carrier-class platform.

NG-DSLAM

SAGEM 3P@C supports any combinations of ADSL, ADSL2/2+ or VDSL user interfaces in several types of

high-density configurations : mini-shelf and large shelves.

Thanks to its internal architecture, the SAGEM 3P@C is able to concentrate user streams and switch them to

several network interfaces, managing traffic parameters in order to guarantee QoS requirements. Subtending

interfaces can be used to create star and daisy-chain extensions, offering a high scalability in order to reach

remote users.

A wide variety of Fast Ethernet, Giga Ethernet, Packet over SDH and even ATM uplink interfaces allows the

connection to Next Generation IP and Ethernet networks. Enhanced video services can be delivered over

ADSL2+ or ADSL connections, such as TV broadcast, Video on Demand and Pay Per View, using SAGEM

3P@C multicast and IGMP capabilities. Connecting to ISP network, SAGEM 3P@C can support B-RAS features

such as PPP session processing, tunnelling and termination, user authentication, IP address management and

dynamic routing.

Management

SAGEM IONOS NMS management platform is designed for the provisionning, monitoring and supervision of the

whole SAGEM 3P@C product family. This powerful NMS allows network-wide visibility and provides userfriendly graphical features. In addition, IONOS NMS enhances operational efficiency with its powerful

client/server architecture.

Scalable range

SAGEM 3P@C is a complete range of access equipment, scaling from small sized configurations to large central

office nodes.

SAGEM 3P@C 4450E is dedicated to high density CO, connecting up to 448 DSL users per subrack, whereas

SAGEM 3P@C 4048E is designed for small CO or remote sites connecting up to 48 ADSL users.

The micro-DSLAM is targeted to specific applications, such as Multi-Tenant Unit (MTU) and remote area.

Thanks to its stackable design, up to 192 users can be connected as the need for broadband connections grows.

The 3P@C 4048E can be installed as a stand alone unit connected to a switched network or as an extension of

3P@C 4450E in subtending mode.

3P@C Installation Manual

Page 1-1 Reproduction and communication in any form prohibited without the written permission of SAGEM SA

Page 19

Page 20

SAGEM 3P@C

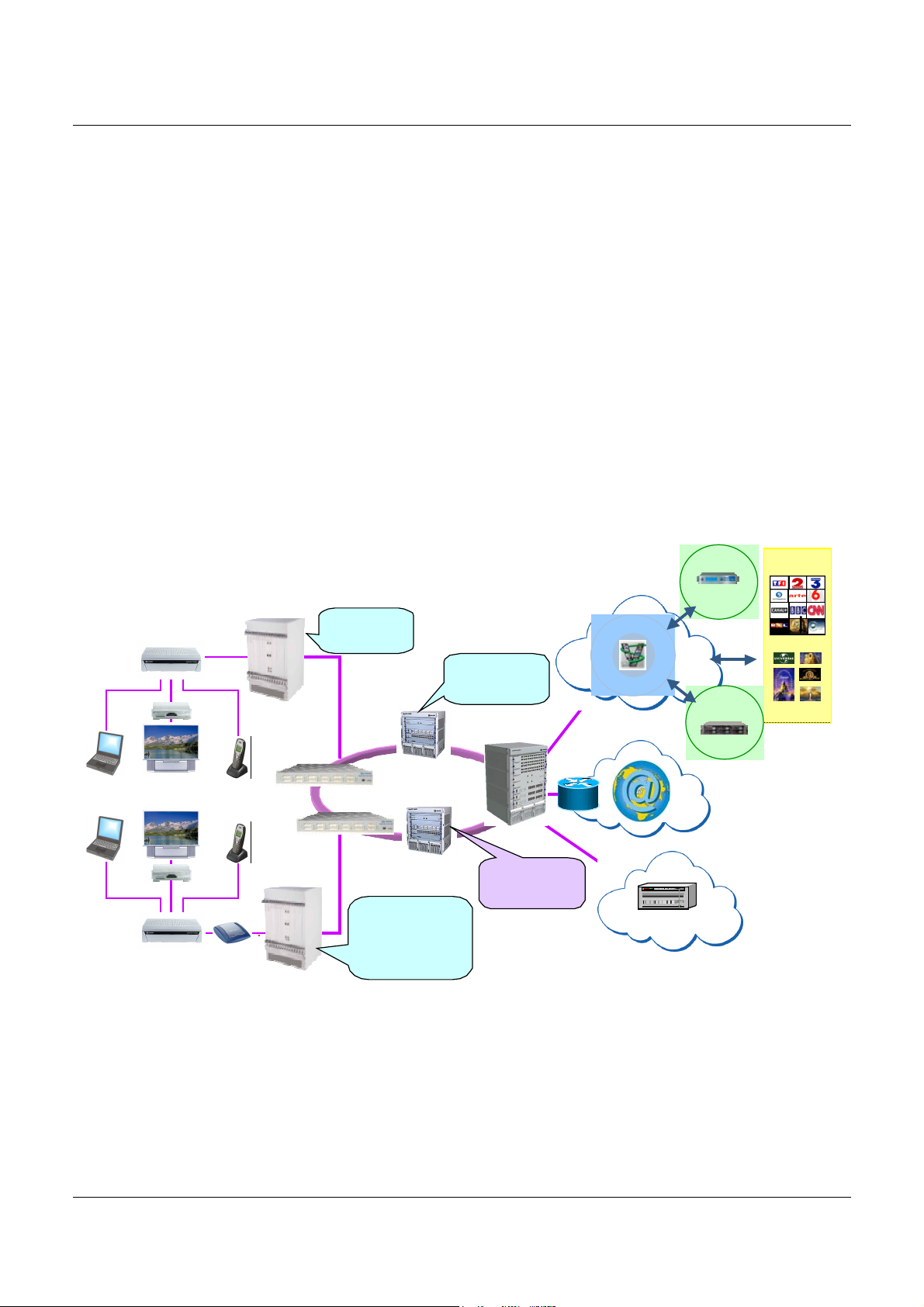

1.2. Representative Networking Applications

SAGEM is in a unique position to assist it’s customers with the design and implementation of next-generation

service offerings using Ethernet based broadband technology. SAGEM 3P@C solutions provide incumbent and

competitive carriers with Internet access, Voice over IP(VoIP), broadcast video(IPTV), Video on Demand (VoD),

Pay-Per-View, music channels and interactive television.

SAGEM 3P@C approach has shown reduced Cost of Ownership through Ethernet-based IP broadband

technology. Applying this technology to a solution customized for each customer can provide them with the

technological and competitive advantage needed for continued success in the broadband service market.

SAGEM 3P@C delivers an IP based broadband access solution that meets customer’s current needs as well as

their future needs for multi-service offerings. Our products are currently supporting all current service offerings

such as residential and commercial Internet access, Internet access through other ISPs, and LAN-to-LAN

connectivity.

SAGEM is able to build up Triple Play end to end solutions using F@st residential gateways and CPE, 3P@C

IP-DSLAM, GigaP@C MAN Ethernet switches or Ethernet over SDH equipment, and B-RAS, Video Streamers

and Voice Gateways and Softswitches.

RGW F @st 3202

STB

STB

RGW F @st 3190

3P@C 4400E

Giga P@C F 5610

GigaP@C F 5610

F@st 908

Mono-vc Multi-VLAN

3P@C 440 0E

Multicast I P

IGMP S nooping

Proxy

GigaP@C B6 805

MAN Ethernet

Ens ur e mu lt ic as t

service only to

authenticated users

Provide multicast

wire-speed

forwarding

IG MP Snoo ping

GigaP@C B6805

Mu lticas t IP

PIM Routing

Gi ga P@C B6 808

L2/L 3 switches

MPLS/VPLS

RIP/OSPF

Service Platform

Streaming Server

Internet

Soft Switch or VoIP Gateway

Live TV

Live Video

VoD

VOD Ser vers

Content

Providers

Liv e Cont e nt Pro vide rs

VO D C onten t

Provide rs

Figure 1-1 Triple Play services in Next Generation Networks

3P@C Installation Manual

Page 1-1 Reproduction and communication in any form prohibited without the written permission of SAGEM SA

Page 21

SAGEM 3P@C

1.3. System Composition

The 3P@C 4450E is composed of the following parts:

General chassis: It consists of a 10U chassis, a backplane, a fan module, a fan mounting

support and an air deflector frame.

Interface: Multiple uplink interfaces can be provided, including 100M electrical/optical

interfaces, gigabit optical interfaces and ATM interfaces.

Slots: Each 10U chassis provides 16 slots, where 2 are SMUB slots and 14 are service

board/card slots.

Power supply: The -48 V DC power supply is adopted. To connect to the 220 V AC power

supply, it is necessary to use the primary power supply system.

3P@C 4450E is installed in the 19-inch standard cabinet with the height of 2.2 m.

Based on the high-performance ASIC, 3P@C 4450E adopts modular structure design to provide abundant uplink

interface modules for your choice. See 1-1 for the specific module types. Each 3P@C 4450E consists of a 10U

chassis, a fan module, an air deflector frame and a fan frame support. Up to 16 boards/cards can be installed in

each 3P@C 4450E chassis. Among them, up to 2 SMUBs and 14 VDSL or ADSL service boards/cards can be

installed. Each SMUB can provide 2 gigabit optical interfaces/4 100M optical interfaces/8 100M electrical

interfaces/2 155M ATM interfaces. Each VDUB can provide 24 VDSL data interfaces, and the integrated

equipment supports up to 336 VDSL interfaces. Each ADUB can provide 32 ADSL interfaces, and the integrated

equipment supports up to 448 ADSL interfaces. See Table 1-2 for descriptions of the specific interface types.

You may select the appropriate boards, cards and uplink interface modules as required.

Table 1-1 Boards, cards and uplink interface modules provided by 3P@C 4450E

Module model Name of the card/uplink interface

module

SMUB Service processor unit board

VDUB VDSL service board

ADUB, ADUC ADSL unit board/card

RTU Route Transfer Unit

DS-1GLX 1-port gigabit long-wave single-mode

interface board

DS-1GSX 1-port gigabit short-wave multi-mode

interface board

DS-4TXB 4-port 100M interface board

DS-4ITX Value-added service card

DS-2FMM 2-port 100M multi-mode interface board

DS-2FSM 2-port 100M single-mode interface board

DS-A155SM 1-port 155M long-wave single-mode ATM

interface board

DS-A155MM 1-port 155M short-wave multi-mode ATM

interface board

3P@C Installation Manual

Page 1-2 Reproduction and communication in any form prohibited without the written permission of SAGEM SA

Page 22

Table 1-2 Name, quantity and type of the interfaces supported by 3P@C 4450E

SAGEM 3P@C

Interface name Quantity Interface

type

Gigabit optical interface (1000BaseSX/LX interface)

100M optical interface (100Base-FX

interface)

100M electrical interface

(10/100Base-TX interface)

ATM interface (155M single-/multimode ATM interface)

Console interface 1 × 2 RJ-45 Console

VDSL interface 24 × 14 European

ADSL interface 32 × 14 European

2 × 2 SC Uplink

4 × 2 SC Uplink

(8 + 1) × 2 RJ-45 Uplink

2 × 2 SC Uplink

connector

connector

Description

interface

interface

interface

interface

interface

Subscriber

interfaces

Subscriber

interfaces

For the detailed description of 3P@C 4450E structure,

please refer to Chapter 2.

prompt

1.4. Hardware Features

Table 1-3 lists the detailed performance indexes of the 3P@C 4450E.

Table 1-3 Performance indexes of the 3P@C 4400

Physical performance 3P@C 4450E

Dimensions of the 10U chassis

(Height × Width × Depth)

Dimensions of the fan module (Height

× Width × Depth)

Dimensions of the air deflector frame

(Height × Width × Depth)

17 kg when empty (containing a 10U chassis, a backplane, a fan module, a fan mounting

Weight

Working

environment

Power supply DC: -40.5V ~ -57V

Power consumption 1,200 W (1,200 W in full configuration mode)

support and an air deflector frame)

41 kg when fully populated (containing a 10U chassis, a backplane, a fan module, a fan

mounting support, an air deflector frame and 16 boards)

Temperature -5 °C ~ 50 °C

Humidity 5% ~ 95%, non-condensing

441.7 mm × 426.5 mm × 389.2 mm

44 mm × 434.6 mm × 360.1 mm

86.1 mm × 434.6 mm × 371.5 mm

E

3P@C Installation Manual

Page 1-3 Reproduction and communication in any form prohibited without the written permission of SAGEM SA

Page 23

SAGEM 3P@C

Physical performance 3P@C 4450E

Uplink ports 100M electrical and optical interfaces, gigabit optical interfaces

Port

configuration

Service ports VDSL and ADSL ports

Slot 16, among which, 2 SMUB slots and 14 service board/card slots

Hot plug Supported

Hot backup Redundancy hot backup for core partsError

tolerance

design

Negotiation function Full-duplex auto-negotiation

Basic

performance

Status

indication

Max. cable

length

Electromagnetic compatibility EMS feature: Complying with the standards of EN 55024 , ETSI

Security specifications Complying with the standards of EN 60950, UL 60950,

CPU

detection

Packet transfer rate

( L2/L3)

Forwarding mode Store-and-forwarding

Port status Communication status and LINK status

Universal status Power status, system status & hot-swap display

10/100Base-TX 100 meters Categories-3/4/5 shielded/unshielded twisted pairs

100Base-FX 62.5/125µm multi-mode fiber (max. 2km), 9µm single-mode fiber

1000Base-SX 62.5/125 µm multi-mode fiber (max. 275m), 50/125 µm multi-

1000Base-LX 9µm single-mode fiber (max.10km)

100Base-FX

interface

1000Base-SX

interface

1000Base-LX

interface

and ATM interfaces. All optical interfaces support single-mode

and multi-mode interface types, and the 100M optical interfaces

support the Trunk function

CPU detection

Wire speed

(max. 15km)

mode fiber (max. 550m)

EN 300 386, CISPR 24, GB/T 17626, GB/T 17618 and IEC

61000-4

CAN/CSA-C22.2 NO. 60950, GB 4943, IEC 60950, and AS/NZS

60950

SC

SC

SC

Interface type

DS-A155MM (155M

multi-mode ATM)

interface

DS-A155SM (155M

single-mode ATM)

interface

Console interface RJ-45

10/100Base-TX

interface

SC

SC

RJ-45

3P@C Installation Manual

Page 1-4 Reproduction and communication in any form prohibited without the written permission of SAGEM SA

This page intentionally left blank

Page 24

CHAPTER 2

2. 3P@C 4450E Hardware Structure

This chapter describes hardware structure of the 3P@C 4450E, including the whole-equipment

configurations and the description of each service module.

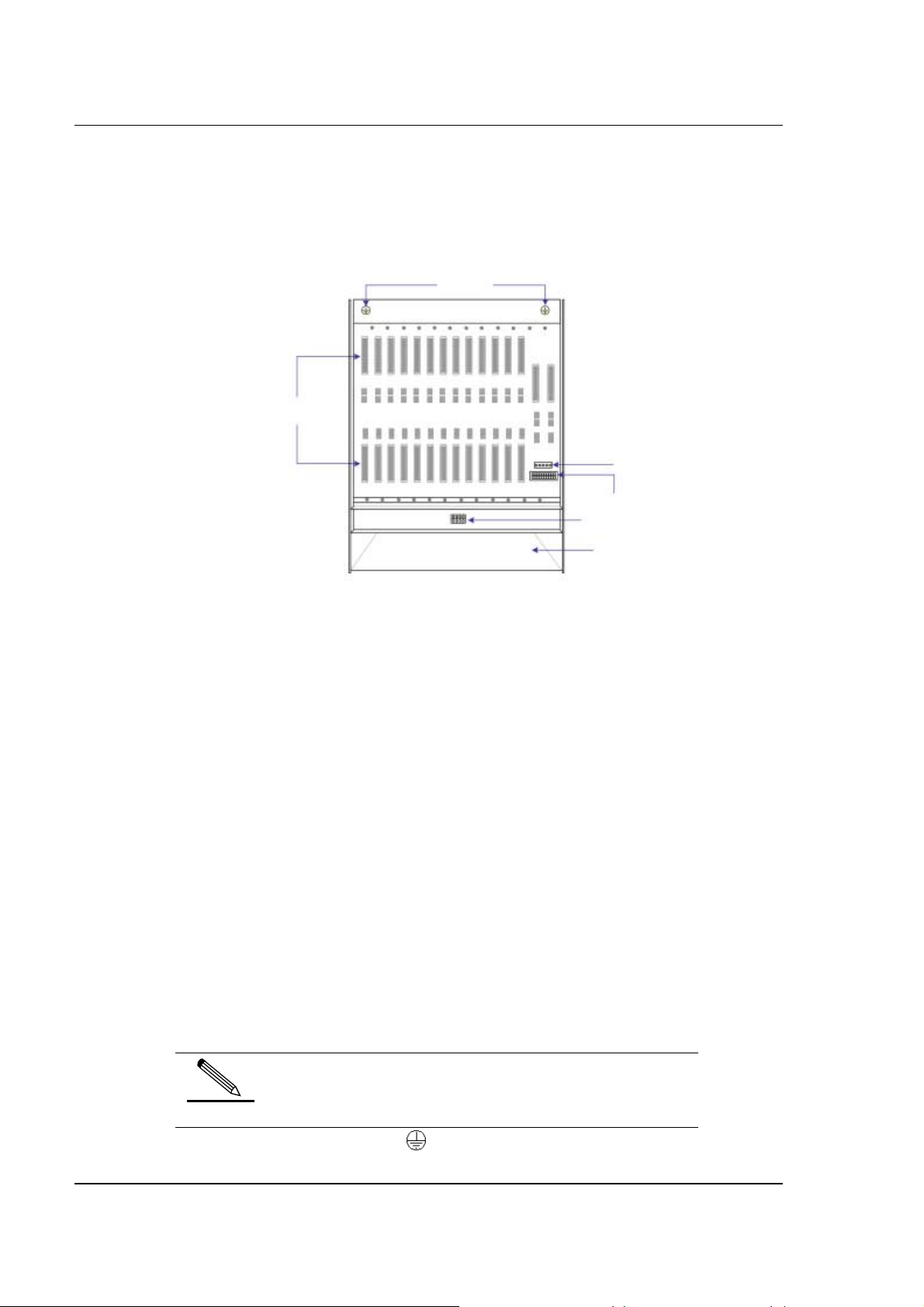

2.1. Shelf Configuration

2.1.1. Structure of the General Chassis

The general chassis of 3P@C 4450E is called 3P@C 4450E-IPDSLAM-10U general chassis kit. It

contains a 10U chassis, a backplane, a fan module, a fan mounting support and an air deflector frame.

Its outside view is shown in Figure 2-1.

Figure 2-1 General chassis of 3P@C 4450E

10U chassis

Fan module

Air deflector

frame

The general chassis composition of 3P@C 4450E is described in Table 2-1:

Table 2-1 General chassis composition of 3P@C 4450E

Name Height Composition Application

Slots 0 ~ 1 For SMUB10U chassis 10U

Slots 2 ~ 15 For ADUB, ADUC or VDUB

Fan

module

Air deflector

frame

1U 6 fans inside For system cooling

2U Slant spacer

inside

Air ducts (inlet from the front and

outlet from the rear)

3P@C Installation Manual

Page 2-1 Reproduction and communication in any form prohibited without the written permission of

SAGEM SA

Page 25

SAGEM 3P@C

3P@C 4450E provides the uplink interface and the Console port on the SMUB. The rest subscriber

line outlets are set on the backplane, that is, the rear leading-out mode is adopted. Therefore, all the

subscriber line interfaces and power supply interfaces are provided on the rear of 3P@C 4450E, as

shown in Figure 2-2:

Figure 2-2 Rear view of the general chassis of 3P@C 4450E

Grounding

socket

DIN

connector

Power interfac e

of the fans

Power interface of

the equipment

Power interface of

the fan module

Air outlet of the air

deflector frame

Viewed from the rear, the general chassis of 3P@C 4450E consists of the following parts:

DIN connector: Subscriber line interface

Equipment power supply interface: -48 V DC power supply interface

Fan power supply interface: Connects with the fan module power socket to supply

power to the fan

Fan module power socket: Connects with the fan power supply interface to supply

power to the fan

Grounding socket: Equipment grounding

Outlet of the air deflector frame: Hot air outlet of the switch below when multiple sets

of equipment are working

The DIN connectors are used for the subscriber line interfaces in two rows (upper and lower). Each

DSL service board needs 2 groups of subscriber lines. One group is the LU line that corresponds to

the connector in the upper row and is connected to the subscriber line, and the other group is the LC

line that corresponds to the connector in the lower row and is connected to the PSTN switch. The slots

correspond to the types of the service boards inserted in the chassis front to support subscribers of

different quantities. For the definition and connection method of subscriber lines, refer to the contents

in Section 4.7.

For ADUB/ADUC, each slot supports 32 subscribers.

For VDUB, each slot supports 24 subscribers.

The 3P@C 4450E rear also provides an equipment power supply interface, a fan power supply

interface and a fan module power supply socket.

Here the -48 V DC power supply is adopted for 3P@C

4450E.

prompt

In addition, two grounding sockets marked with are provided on the upper part of the rear panel for

equipment grounding.

3P@C Installation Manual

Page 2-2 Reproduction and communication in any form prohibited without the written permission of SAGEM SA

Page 26

SAGEM 3P@C

2.1.2.

2.1.2. 10U Chassis

2.1.2.2.1.2.

The 10U chassis is adopted for 3P@C 4450E. Altogether 2 SMUBs and 14 ADSL/VDSL service

boards can be installed at the same time, as shown in the following figure:

Figure 2-3 Front view of the 10U chassis

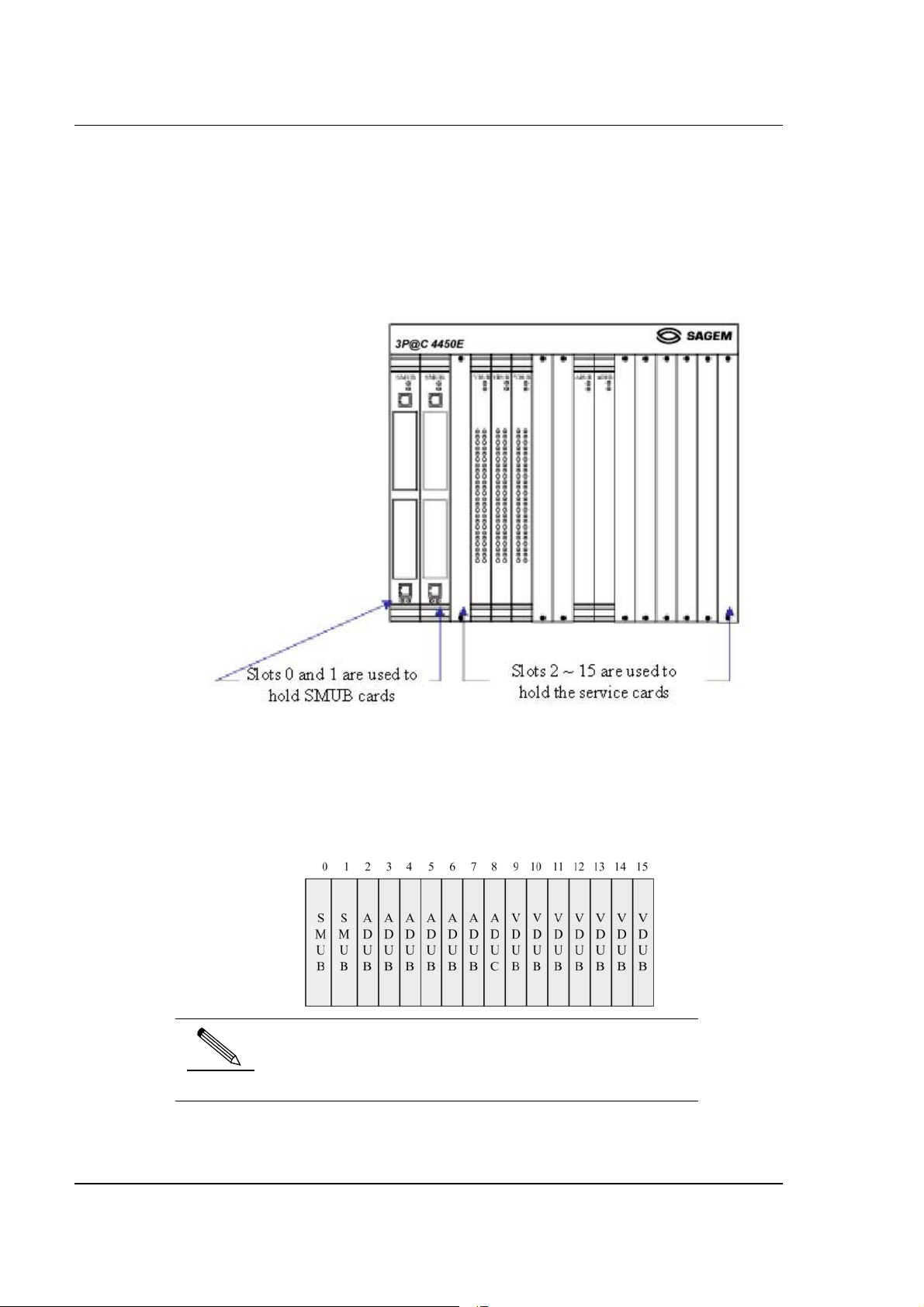

Each 10U chassis provides 16 slots which are numbered 0 ~ 15 from left to right. The former 2 slots

(slots 0 ~ 1) with a width of 1.4 inch each are used to insert the SMUBs. SMUBs can be inserted in

both slots at the same time, or only one SMUB is inserted either in slot 0 or in slot 1. The latter 14 slots

(slots 2 ~ 15) with a width of 1 inch and a depth of 340 mm each are used to insert VDUB or

ADUB/ADUC. Descriptions of the slots for the SMUB and the service boards are shown in Figure 2-4.

Figure 2-4 Slots for the SMUB and service boards

1. The service board slots support the interchange of VDSL

and ADSL service boards.

prompt

2. Please install dummy panels in the slots not inserted with

any boards.

3P@C Installation Manual

Page 2-3 Reproduction and communication in any form prohibited without the written permission of SAGEM SA

Page 27

SAGEM 3P@C

2.1.3.

2.1.3. Fan Module

2.1.3.2.1.3.

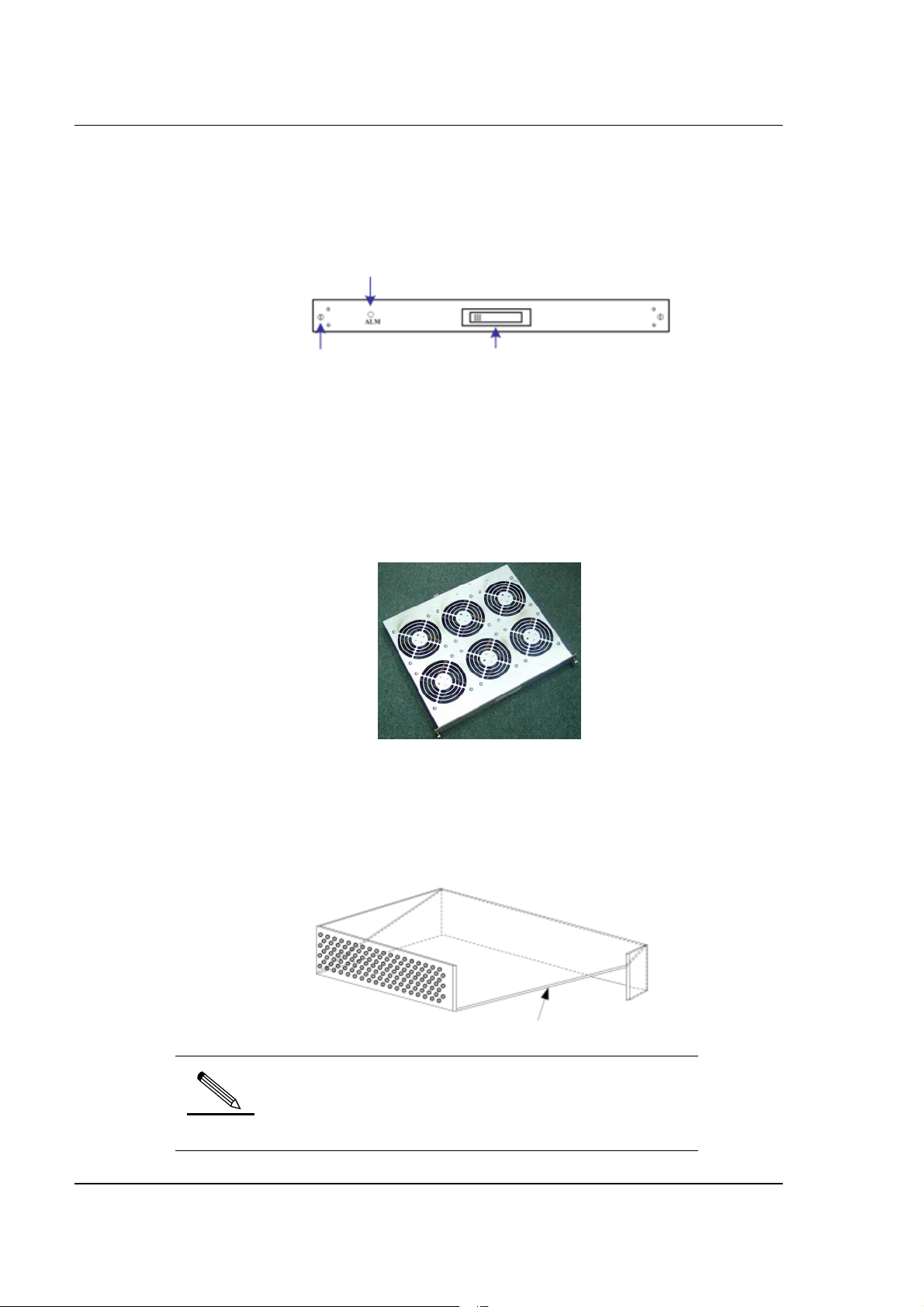

In the lower part of the 10U chassis is a 1U fan module, as shown in the following figure:

Figure 2-5 Front view of the fan module

Alarm LED

Screw Hidden puller adapter

Viewed from the front, the fan module consists of the following parts:

Screw: Used to fix the fan module.

Alarm indicator: Used for giving out failure alarm of the fan module

Hidden puller adapter: Usually closed. When removing the fan module, it can be

used to pull out the fan module. For the specific operations, refer to the related

contents in Section 4.2.2.

Each fan module provides 6 radiator fans, as shown in Figure 2-6:

Figure 2-6 Outside view of the radiator fans

2.1.4.

2.1.4. Air Deflector Frame

2.1.4.2.1.4.

Below the fan module is a 2U air deflector frame with the front inlet and rear outlet design and isolated

in the middle by a spacer. The sectional view of the air deflector frame is shown in the following figure:

Figure 2-7 Sectional view of the air deflector frame

Spacer

When the switch is operating, the cold air is drawn in above

the spacer. If multiple switches are operating at the same

time, the hot air coming out from the lower switch are

prompt

3P@C Installation Manual

Page 2-4 Reproduction and communication in any form prohibited without the written permission of SAGEM SA

exhausted below the spacer via the rear of the air deflector

frame.

Page 28

SAGEM 3P@C

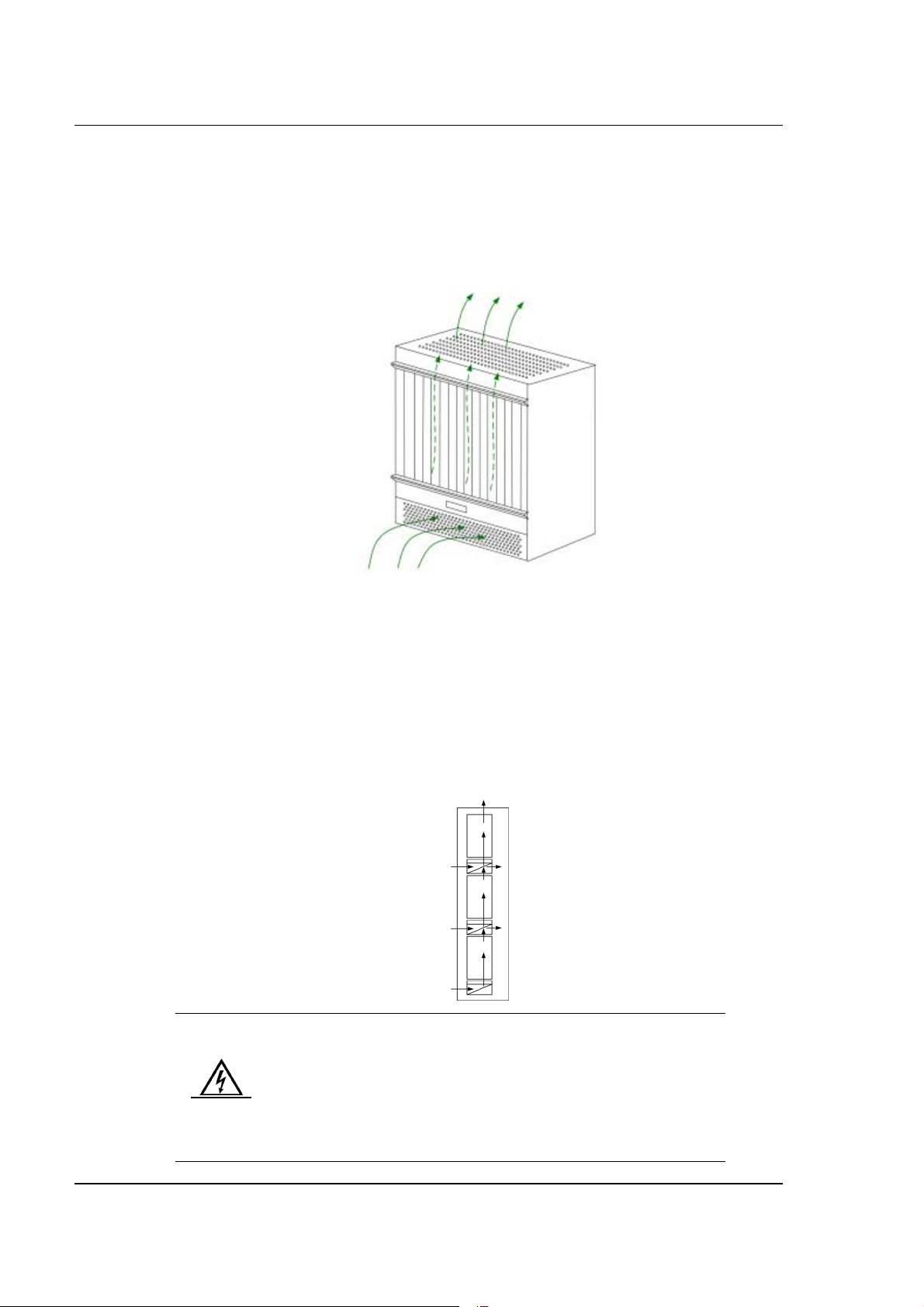

To satisfy the requirement for long-term equipment operating temperature, the general chassis design

of 3P@C 4450E fully considers the system heat dissipation. When a single device is operating, the

heat dissipation of the system is shown in Figure 2-8, where, the air is led in from the lower part and

led out from the upper part in the chassis front. The air outlet is on the top of the switch.

Figure 2-8 Heat dissipation of a single system

Hot air is discharged

Cold air comes in

On the air deflector frame is a fan module with 6 radiator fans built in. When the fans are started, the

cold air is drawn in from the inlet on the front of the air deflector frame, then goes upward in the

cabinet. It passes by the switch, and takes away the heat of the switch, and finally goes out from the

top of the switch.

When multiple switches operate at the same time, the hot air in the lower switch are let out from the

top of the switch, and exhausted via the rear outlet of the air deflector frame above it. The following

figure shows the air ducts in the cabinet in the case that multiple switches are operating at the same

time.

Figure 2-9 Air ducts inside the cabinet

The radiator fans are used for cooling and heat dissipation to

improve the temperature features of the system and ensure the

normal operation of the switch. Make sure these ventilation

holes are not blocked and enough space is reserved on two

Warning

sides of the equipment for air circulation, ventilation and heat

dissipation. Otherwise, if the components in the equipment are

overheated, the system would not work normally or even the

components would be damaged by overheat.

3P@C Installation Manual

Page 2-5 Reproduction and communication in any form prohibited without the written permission of SAGEM SA

Page 29

SAGEM 3P@C

2.2.

2.2. Full Configuration of the Cabinet

2.2.2.2.

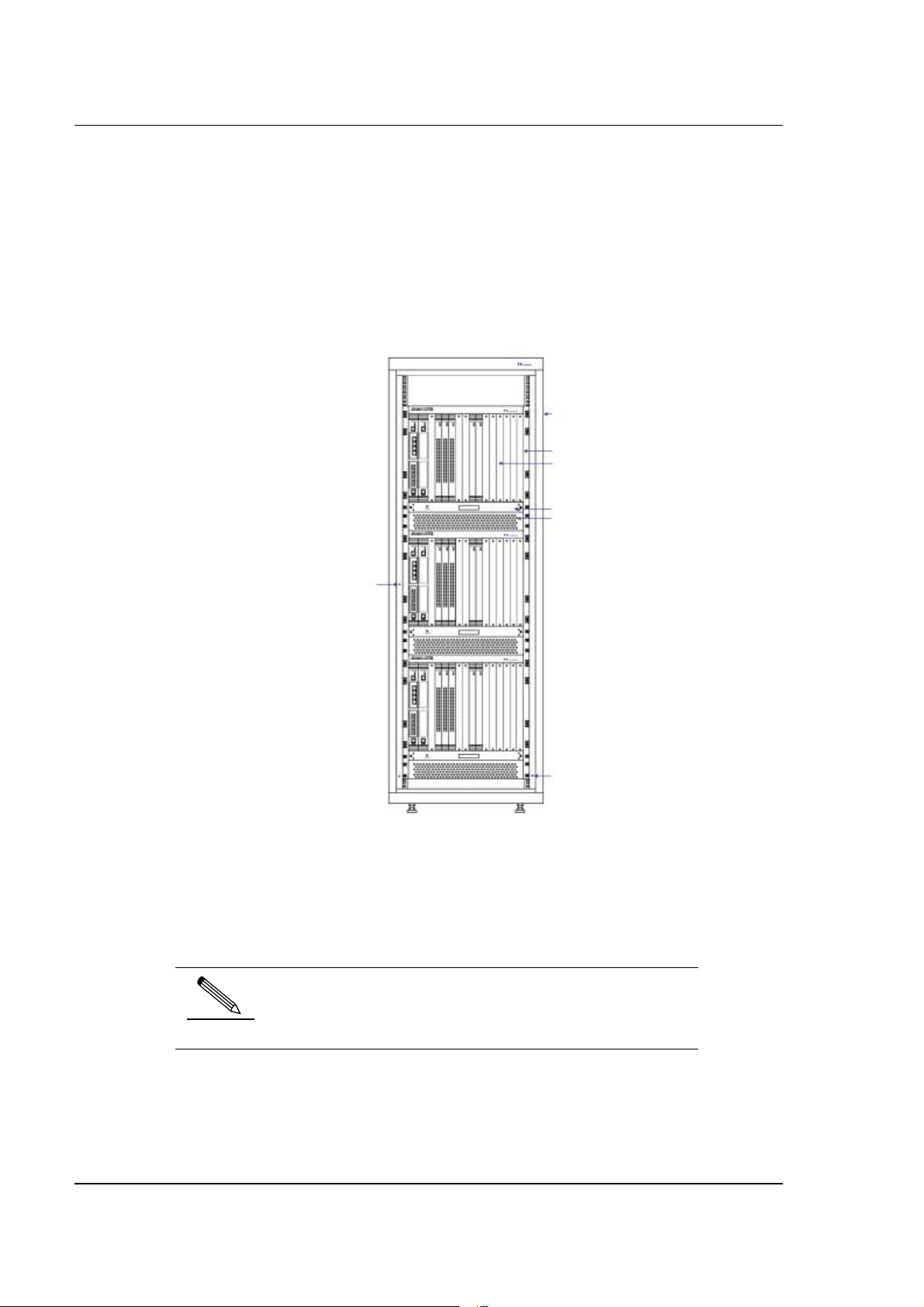

In the full configuration mode, 3 sets of 3P@C 4450E can be installed in a 19-inch standard cabinet

with the height of 2.2 m, as shown in Figure 2-10:

Figure 2-10 Full configuration of 3P@C 4450E

2.2 m cabinet

10U chassis

Service f unction

modules

1U fan module

2U air deflector

frame

ESD socket

Grounding

post

In the full configuration mode, the 3P@C 4450E system comprises 6 major parts: A standard 19-inch

cabinet with the height of 2.2 m, a 10U chassis, a 1U fan module, 2U air deflector frame, service

functional modules (including SMUB and ADSL/VDSL service boards) and the -48 V DC power

distribution system.

1. The -48 V DC power distribution system is on the rear of

the integrated equipment.

prompt

2. To connect to the 220 V AC power supply, it is necessary

to use the primary power supply system.

3P@C Installation Manual

Page 2-6 Reproduction and communication in any form prohibited without the written permission of SAGEM SA

Page 30

SAGEM 3P@C

2.3.

2.3. SMUB and Service Boards

2.3.2.3.

2.3.1.

2.3.1. Service Processor Unit Board (SMUB)

2.3.1.2.3.1.

1.1.1.1 Structure of the SMUB

As the control center of 3P@C 4450E, the SMUB is responsible for the data exchange and control

management of the system and it provides uplink interfaces for the ADSL and VDSL subscribers to

access the network.

The single-SMUB or dual-SMUB operating mode can be adopted for 3P@C 4450E. When the singleSMUB operating mode is adopted, SMUB can be inserted in slot 0 or 1 of the 10U chassis. Hot

backup can be implemented in the system when the dual-SMUB operating mode is adopted, in which,

two SMUBs can be inserted in slot 0 and slot 1 of the 10U chassis respectively. The SMUB in slot 0

serves as the active one, and the SMUB in slot 1 serves as the standby one, as shown in the following

figure:

Figure 2-11 Slots of the SMUB

Active

SMUB

Only the active SMUB is active at one time. The equipment can be managed only via the Console

interface on the active SMUB, and the Console interface on the standby SMUB is suspended.

The rear view of the SMUB is shown in Figure 2-12:

Standby

SMUB

3P@C Installation Manual

Page 2-7 Reproduction and communication in any form prohibited without the written permission of SAGEM SA

Page 31

Figure 2-12 Front view of the SMUB

System running

state LED

10/100 Base-TX

Uplink interface

SAGEM 3P@C

Upper puller

adapter

Console

interface

Uplink interface

extended slot

Lower puller

adapter

1.1.1.2

1.1.1.2 Interface features of the SMUB

1.1.1.21.1.1.2

Table 2-2 Interface features of the SMUB

Interface

name

Console

interface

Ethernet

uplink

interface

1.1.1.3

1.1.1.3 Extended slots of the SMUB

1.1.1.31.1.1.3

Quant

ity

Interface

type

Interface

attributes

Description

1 RJ-45 RS-232C Located at the uppermost of the

SMUB, the Console interface can

be used to manage and configure

3P@C 4450E via the command

line interface.

1 RJ-45 10/100Base

-TX

Located at the lowermost of the

SMUB, it is used to connect the

VDSL and ADSL subscribers to the

IP network.

The SMUB provides 2 extended slots for installing uplink interface modules. 3P@C 4450E supports

the following uplink interface modules:

Table 2-3 Type of uplink interface modules

Module type Name Description Interface

type

DS-1GLX 1-port gigabit long-

wave optical

interface module

DS-1GSX 1-port gigabit short-

wave optical

interface module

Providing 1 long-wave optical

uplink interface of 1G rate

Providing 1 short-wave optical

uplink interface of 1G rate

SC

SC

3P@C Installation Manual

Page 2-8 Reproduction and communication in any form prohibited without the written permission of SAGEM SA

Page 32

SAGEM 3P@C

Module type Name Description Interface

type

DS-2FSM 2-port 100M single-

mode optical

interface module

DS-2FMM 2-port 100M multi-

mode optical

interface module

DS-A155SM 1-port long-wave

single-mode ATM

optical interface

module

DS-A155MM 1-port short-wave

multi-mode ATM

optical interface

module

DS-4TXB 4-port 100M

electrical interface

module

DS-4ITX Value-added

service card

For the detailed description of uplink interface modules,

please refer to Section 2.5.

prompt

Providing 2 100Base-FX

uplink single-mode optical

interfaces

Providing 2 100Base-FX

uplink multi-mode optical

interfaces

Providing 1 155M long-wave

single-mode uplink ATM

optical interface

Providing 1 155M short-wave

multi-mode uplink ATM optical

interface

Providing 4 10/100Base-TX

uplink electrical interfaces

Providing 4 10/100Base-TX

uplink electrical interfaces

SC

SC

SC

SC

RJ-45

RJ-45

1.1.1.4

1.1.1.4 Indicators of the SMUB

1.1.1.41.1.1.4

The front panel of SMUB provides LEDs for indicating the system operating status and the Ethernet

interface working status. The administrator can judge the system operation status according to the

display of these LEDs so as to diagnose the network fault in time, reduce the operation loss and

improve work efficiency. Descriptions of the LED indicators are given in Table 2-4:

Table 2-4 Status definitions of the LED indicators on the SMUB

LED Identific

ation

System

running

status

indicator

Ethernet

interface

working

status

indicators

ALM Red

LINK Green

ACT Green

Color Status Description

Off The system does not operateRUN Green

FlashingThe system operates normally.

Off The system operates normally

ON System alarm. This LED flashes

once when the equipment is started

and conducts self-check. It does

not indicate any alarm at this time

Solid

on

Off The port is not connected

FlashingData are being received/transmitted

Off No data are being

The corresponding LED is solid on

after a stable connection is set up

at the port

on the port

received/transmitted on the port

3P@C Installation Manual

Page 2-9 Reproduction and communication in any form prohibited without the written permission of SAGEM SA

Page 33

SAGEM 3P@C

2.3.2.

2.3.2. VDSL Unit Board (VDUB)

2.3.2.2.3.2.

1.1.1.5

1.1.1.5 Structure of the VDUB

1.1.1.51.1.1.5

VDUB is the VDSL office end access service board of 3P@C 4450E. Each VDUB provides 24 VDSL

subscriber interfaces. The subscriber interface is connected to the DIN connector on the backplane,

thus implementing data transmission via the existing data switching line (such as telephone line) and

separation of data transmission from voice transmission.

The VDUB features high security and supports IEEE 802.1Q VLAN to provide secure isolation for

each subscriber. In addition, it supports the port locking function to prevent illegal subscribers from

accessing the network.

VDUB adopts the -48 V power supply with an allowable voltage ranging from -36 V to -72 V. It

supports hot plugging, and can identify the rack slots, thus facilitating the management and

maintenance.

When used in 3P@C 4450E, the VDUBs can be inserted in slots 2 ~ 15 of the 10U chassis, as shown

in the following figure:

Figure 2-13 Slots of the VDUB

The front view of the VDUB is shown in the following figure:

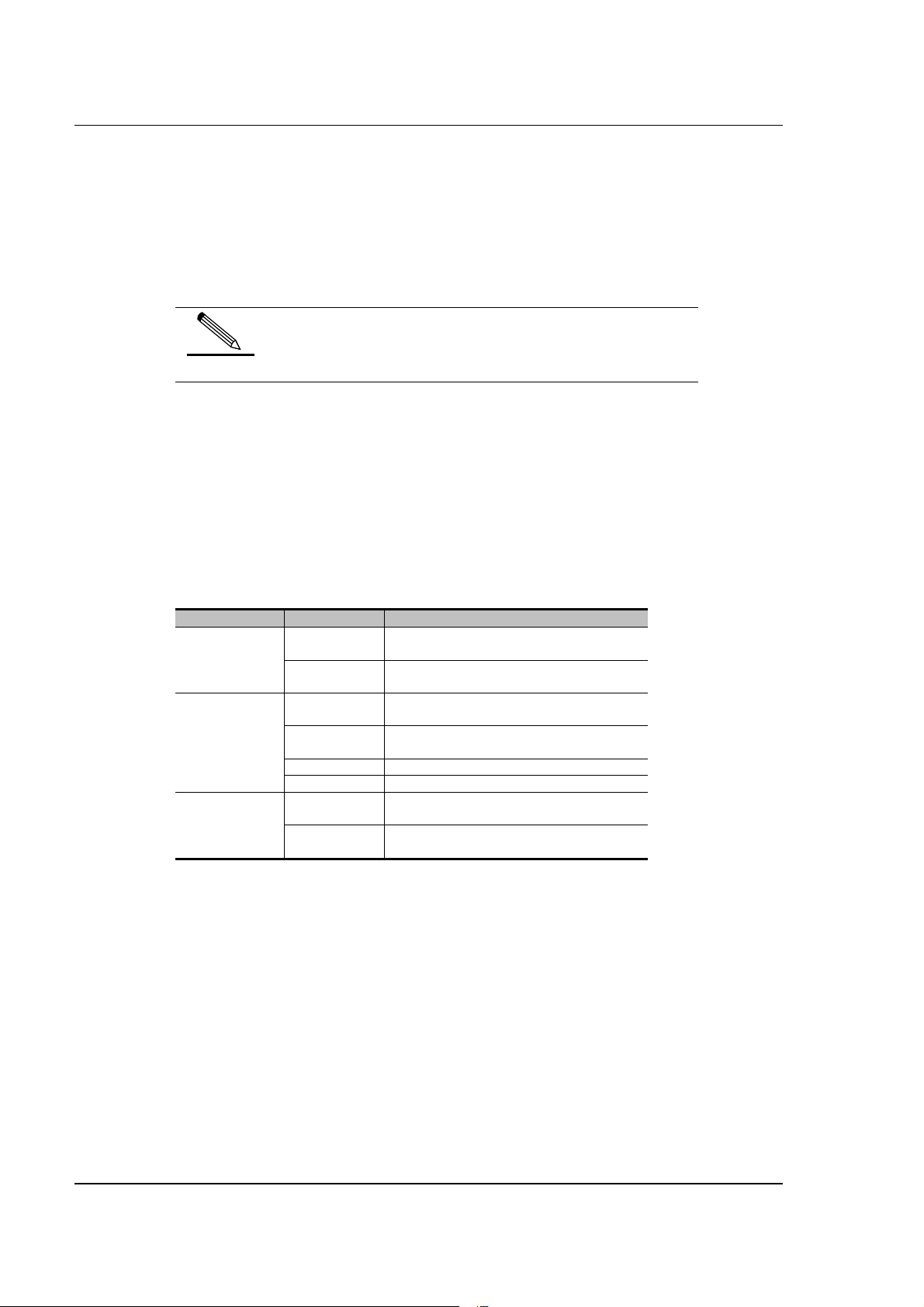

Figure 2-14 Front view of the VDSL

VDUB running

state LED

Lower puller adapter

The front panel of VDUB provides two groups of LEDs, as follows:

Upper puller

adapter

Subscriber interface

working state LED

VDUB running status indicators RUN and ALM, which are in the upper part of the

3P@C Installation Manual

Page 2-10 Reproduction and communication in any form prohibited without the written permission of SAGEM SA

Page 34

VDUB.

VDSL subscriber interface working status indicators, which are in the middle of the

VDUB. The VDUB provides 24 VDSL subscriber interfaces. The working status of

each interface is shown by two indicators, LINK and ACT.

1.1.1.6

1.1.1.6 Indicators of the VDUB

1.1.1.61.1.1.6

Descriptions of the LED indicators on the front panel of VDUB are given in Table 2-5:

Table 2-5 Status definitions of the LED indicators on the front panel of VDUB

SAGEM 3P@C

LED Identific

ation

VDUB

running

status

indicator

VDSL

subscriber

interface

working

status

indicators

2.3.3.

2.3.3. ADSL Unit Board (ADUB)

2.3.3.2.3.3.

1.1.1.7

1.1.1.7 Structure of the ADUB

1.1.1.71.1.1.7

RUN Green

ALM Red

LINK Green

ACT Green

Color Status Description

On The system is powered on

Off The system is powered off or

abnormal

Flashing The VDUB operates normally

Off The VDUB operates normally

ON VDUB alarm

Solid on The corresponding LED is solid

on after a stable connection is

set up at the subscriber interface

Off The subscriber interface is not

connected with any subscriber

Flashing Data are being

received/transmitted on the

subscriber interface

Off No data are being

received/transmitted on the

subscriber interface

The ADUB is used to provide ADSL data access services. Each ADUB provides 32 ADSL subscriber

interfaces. The subscriber interface is connected to the DIN connector on the backplane, thus

implementing data transmission via the existing data switching line (such as telephone line) and

separation of data transmission from voice transmission.

The ADUB features high security and supports IEEE 802.1Q VLAN to provide secure isolation for

each subscriber. In addition, it supports the port locking function to prevent illegal subscribers from

accessing the network.

ADUB adopts the -48 V DC power supply with an allowable voltage ranging from -44 V DC to -60 V

DC. It supports hot plugging, and can identify the rack slots, thus facilitating the management and

maintenance.

When used in 3P@C 4450E, the ADUBs can be inserted in slots 2 ~ 15 of the 10U chassis, as shown

in Figure 2-15:

3P@C Installation Manual

Page 2-11 Reproduction and communication in any form prohibited without the written permission of SAGEM SA

Page 35

Figure 2-15 Slots of the ADUB

The front view of the ADUB is shown in the following figure:

Figure 2-16 Front view of the ADUB

ADUB running

state LED

SAGEM 3P@C

Upper puller

adapter

Lower puller

adapter

1.1.1.8

1.1.1.8 Indicators of the ADUB

1.1.1.81.1.1.8

The front panel of ADUB provides LED indicators showing the ADUB running status. Descriptions of

the LEDS are given in the following table.

Table 2-6 Status definitions of the LED indicators on the front panel of ADUB

LED Identific

ation

ADUB

running

status

indicator

RUN Green

ALM Red

Color Status Description

On The system is powered on

Off The system is powered off or

abnormal

Flashing The ADUB operates normally

Off The ADUB operates normally

ON ADUB alarm

3P@C Installation Manual

Page 2-12 Reproduction and communication in any form prohibited without the written permission of SAGEM SA

Page 36

SAGEM 3P@C

2.3.4.

2.3.4. ADSL Unit Card (ADUC)

2.3.4.2.3.4.

1.1.1.9

1.1.1.9 Structure of the ADUC

1.1.1.91.1.1.9

In addition to the same functions and features as the ADUB, the ADUC also has a line capture relay

that can be used together with the ADSL special-purpose test device to provide the wiring function.

When used in 3P@C 4450E, the ADUCs can be inserted in slots 2 ~ 15 of the 10U chassis, as shown

in the following figure:

Figure 2-17 Slots of the ADUC

The rear view of the ADUC is shown in Figure 2-18:

Figure 2-18 Front view of the ADUC

ADUC running

state LEDa

Upper puller

adapter

Lower puller

adapter

1.1.1.10

1.1.1.10 Indicators of the ADUC

1.1.1.101.1.1.10

The front panel of ADUC provides LED indicators showing the ADUC running status. Descriptions of

the LEDS are given in the following table.

3P@C Installation Manual

Page 2-13 Reproduction and communication in any form prohibited without the written permission of SAGEM SA

Page 37

SAGEM 3P@C

Table 2-7Status definitions of the LED indicators on the front panel of ADUC

LED Identific

ation

ADUC

running

status

indicator

2.4.

2.4. Power Distribution System

2.4.2.4.

2.4.1.

2.4.1. Overview

2.4.1.2.4.1.

The DC distribution unit of 3P@C 4450E adopts the -48 V DC power supply. It is 4U high and is fixed

to the upper part of the equipment rack rear. The -48 V DC input power is divided into 4 tributaries

whose outputs are controlled by air switches separately. Their connection relations are shown in

Figure 2-19:

Figure 2-19 Connection relations

RUN Green

ALM Red

Color Status Description

On The system is powered on

Off The system is powered off or

abnormal

Flashing The ADUC operates normally

Off The ADUC operates normally

ON ADUC alarm

2.4.2.

2.4.2. Functional Features

2.4.2.2.4.2.

Input requirements

1. -48 V single input.

2. -48 V input range: -36 ~ -72 V DC.

3. -48 V total input power: 3,300 W.

Output requirements

1. The -48 V power is output to 4 channels that are led out by wiring terminals and controlled by air

switches.

2. The rated current of the air switch is 32 A.

3P@C Installation Manual

Page 2-14 Reproduction and communication in any form prohibited without the written permission of SAGEM SA

Page 38

3. The output power of each -48 V output is 1,200 W.

Cable selection

SAGEM 3P@C

The -48V input cable and the BGND and PGND external connection cables are

The four -48V output cables and the BGND and PGND internal connection cables

2

16mm

blue, black and yellow-green power cables respectively.

are 6mm

2

blue, black and yellow-green power cables respectively.

For the connection of DC power supplies, refer to Section

4.3. To connect to the 220 V AC power supply, it is

prompt

2.5.

2.5. Optional Uplink Interface Modules

2.5.2.5.

necessary to use the primary power supply system.

The modular structure is adopted for 3P@C 4450E. Each 10U chassis has 16 slots, the former two of

which are for inserting the SMUB boards. The SMUB provides multiple optional types of uplink