Installation & Operating Procedures

Opal SS6

Series

SOLID STATE REDUCED VOLTAGE STARTER

FOR 3 PHASE INDUCTION MOTORS

OPAL SS6 Reduced Voltage St art ers

Opal SS6 SERIES

REDUCED VOLTAGE

SOLID STATE STARTERS

FOR 3 PHASE INDUCTION MOTORS

INSTALLATION & OPERATING PROCE DURE

Revision 1.08 - 07/2011

OPAL SS6 Reduced Voltage St art ers

FOR YOUR SAFETY

Only qualified personnel should install this equipment, after first reading and

understanding all the information in this manual. All instructions should be strictly

adhered to. The user should consult SAF Drives Inc. or a SAF OPAL Starters

supplier for clarification of the contents of this manual should any doubt or

questions arise.

The installation of this equipment must be conducted in accordance with all

national, regional and local electrical codes.

All drawings and technical representations included in this manual are for typical

installations and should not in any way be considered for specific applications or

modifications. Consult SAF OPAL Starters for supplemental instructions.

SAF Drives Inc. accepts no liability for any consequences resulting from

inappropriate, negligent or incorrect installation, application or adjustment of this

equipment.

The contents of this manual are believed to be correct at the time of printing. In

following with our commitment to the ongoing development and improvement of

our products SAF OPAL Starters reserves the right to change the specification of

this product and/or the content of this instruction manual without notice.

OPAL SS6 Reduced Voltage St art ers

TABLE OF CONTENTS

1.0 DESCRIPTION ......................................................................................................... 1

1.1 OVERVIEW .................................................................................................................... 1

1.1.1 STANDARD FEATURES ............................................................................................. 1

1.1.2 OPTIONAL FEATURES .............................................................................................. 2

1.2 APPLICATION NOTES ................................................................................................... 2

1.2.1 OPERATION MODES ................................................................................................. 2

1.2.2 CHOOSING STARTING MODE .................................................................................. 3

1.2.3 MOTOR AND LOAD TYPES ....................................................................................... 4

1.2.4 STARTING AC MOTORS I N PARALL EL .................................................................... 5

2.0 SPECIFICATIONS .................................................................................................... 6

2.1 POW ER RATING ............................................................................................................ 6

2.2 MAXI MUM RAT INGS ...................................................................................................... 6

2.3 SERVICE CONDITIONS ................................................................................................. 6

2.4 FUSE SIZING ................................................................................................................. 7

2.5 DIMENSIONS ................................................................................................................. 8

2.5.1 STANDARD UNIT ....................................................................................................... 8

2.5.2 REVERSING UNITS ................................................................................................... 9

2.6 SCR INSTALLATION SPECIF ICATIONS .......................................................................10

2.6.1 SCR TIGHTENING PROCEDURE .............................................................................10

3.0 CARD FUNCTIONS ................................................................................................ 12

3.1 CARD LAYOUT ..............................................................................................................12

3.2 ANNUNCIATION ............................................................................................................13

3.2.1 LED INDICATIONS ....................................................................................................13

3.2.2 NEON INDICATIONS .................................................................................................13

3.3 ADJUSTMENTS .............................................................................................................13

3.3.1 POTENTIOMETERS ..................................................................................................13

3.3.2 LINK SELECTION ......................................................................................................14

3.3.3 PUSHBUTTON AND SWITCHES ..............................................................................14

3.4 TERMINALS...................................................................................................................14

3.4.1 CUSTOMER TERMINALS..........................................................................................14

3.4.2 TERMINALS FOR INTERNAL USE ............................................................................15

3.5.1 OVER TEMPERATURE .............................................................................................15

3.5.2 MOTOR OVERLOAD .................................................................................................15

3.5.3 PHASE LOSS ............................................................................................................15

4.0 INSTALLATION AND START-UP .......................................................................... 16

4.1 INSPECTION .................................................................................................................16

4.2 SAFETY PRECAUTIONS ..............................................................................................16

4.5.1 BEFORE POWER-UP ................................................................................................17

4.5.2 WITH POW ER ON .....................................................................................................18

4.5.3 HEAVY DUTY CURRENT CALIBRAT ION TABLE .....................................................19

OPAL SS6 Reduced Voltage St art ers

5.0 OPAL OPTION CARDS .......................................................................................... 20

5.1 SOFT STOP ...................................................................................................................20

5.2 SOLID STATE REVERSING ..........................................................................................21

5.3 UP-TO-SPEED, SHEAR PIN, AND ENERGY SAVER ...................................................22

5.3.1 UP-TO-SPEED AND SCR BY-PASS ..........................................................................22

5.3.2 SHEAR PIN PROTECTION ........................................................................................23

5.3.3 ENERGY SAVER .......................................................................................................23

5.3.4 EXTENDED OVERLOAD ...........................................................................................23

5.4 SHORTED SCR DETECTION........................................................................................24

5.5 LINEAR ACCEL/DECEL OPTION ..................................................................................25

5.5.1 POTENTIOMETERS ..................................................................................................25

5.5.2 LINK SELECTION ......................................................................................................26

5.5.3 TERMINALS ...............................................................................................................26

5.5.4 START-UP .................................................................................................................26

6.0 TYPICAL CONNECTIONS ..................................................................................... 27

6.1 OPAL WITH 2-WIRE CONTROL A ND EXTERNAL RESET ..........................................28

6.2 OPAL WITH 3-WIRE CONTROL, OPTIONAL RUN AND READY P ILOT LIGHT ..........29

6.3 OPAL WITH SOFT STO P ..............................................................................................30

6.4 OPAL WITH SOLID STAT E REVERSI NG .....................................................................31

6.5 OPAL WITH BYPASS CONTACTOR FOR NEMA 4 OR 12 125A AND BELOW ...........32

6.6 OPAL WITH BYPASS CONTACTOR FOR NEMA 4 OR 12 200A AND ABOVE ............33

6.7 OPAL W ITH SHORTED SCR OPTION ..........................................................................34

6.8 OPAL W ITH LINEAR ACCEL/DECEL CARD .................................................................35

7.0 SPARE PARTS ...................................................................................................... 36

7.1 STANDARD UNIT ..........................................................................................................36

7.2 OPTION CARDS ............................................................................................................36

8.0 TROUBLESHOOTING ........................................................................................... 37

OPAL SS6 Reduced Voltage St art ers

1.0 DESCRIPTION

1.1 OVERVIEW

The OPAL series is a line of solid state reduced voltage starters for use with 3ø induction

motors. This series also includes various optional features that can be easily appended.

A solid state starter provides a step-less, thus smooth current ramp to the motor. This

characteristic elimi nates current surges and mechanical torque trans ients. Since these units

are solid state, we now eliminate the maintenance of moving contacts which are involved in

almost any other method of starting an AC induction motor.

1.1.1 STANDARD FEATURES

- 200-600 VAC 3ø Universal voltage, 50/60Hz with no adjustments

- Single controller card throughout the OPAL range

- Current regulated, closed loop

- Dual operation modes to match any application:

Constant Current mode for light loads or limited power supplies

Current Ramp mode for high inertia or heavy loads

- LED and NEON status and diagnostics

- Prevents starting with any phase missing

- Phase rotation insensitive

- Instantaneous electronic over-current trip

- Class 20 electronic motor overload

- Overload capacity:

500 % for 35 seconds

115 % continuous

- Form C dry fault contact

- N/O dry run contact

- Simple user set-up and current calibration by rotary switch

- Two or three wire control

Page 1

OPAL SS6 Reduced Voltage Starters

1.1.2 OPTIONAL FEATURES

- Solid State Reversing

Through the addition of 4 Silicon Controlled Rectifiers ( SCR's ) and a reversing card,

smooth motor reversing is achieved without having to stop the motor.

- Soft Stop

Motor deceleration is controlled to eliminate water hammer effect on pump applications.

- By-Pass Contactor

Once the motor has reached operational speed, the by-pass contactor is closed. This shorts

the SCR's which eliminates the voltage drop across the SCR's, in turn being more efficient

and ridding excess heat.

- Up-To-Speed Contact / Shear Pin Protection / Energy Saver

- Shorted SCR Sensor and Protection

Sensor detects shorted SCR and trips circuit breaker or contactor upstream.

- Linear Accel\Decel Card

Provides linear accel and decel independent of load with the use of speed feedback

- DC Injection Braking

Through the addition of 4 SCR's and a DC Injection card, adjustable braking of an AC motor

is performed. More information is provided in the OP-STOP, DC INJECTION manual.

- External Reset Push Button

- Start, Stop, Reverse Push Buttons

- NEMA 4 or NEMA 12 Enclosures

1.2 APPLICATION NOTES

1.2.1 OPERATION MODES

1.2.1.1 Constant Current Mode

Applications

*Compressors

*Empty Mixers

*Empty Crushers

*Chippers

*Pumps/Fans

*Centrifuges

Page 2

OPAL SS6 Reduced Voltage St art ers

1.2.1.2 Current Ramp Mode

Applications

* Conveyors

* Extruders

* Mixers

* Stamping

Machines

* Cranes

* Shredders

*Hammer Mills

1.2.2 CHOOSING STARTING MODE

With any induction motor the design is such that starting currents and torques are very high.

Across the line starting for a basic NEMA B design motor creates an in-rush current of

600% or more of the nameplate rating. Often these levels are so high that they cause

problems with mechanical or auxiliary electrical. An example of this is the high starting

torques which cause belt slip and high currents, creating large voltage dips. The basis of

choosing the correct starting mode is determining the problem to be solved.

Torque Reduction on heavy loads is accomplished by using the Current Ramp Mode.

The idea is to reduce starting current to just above the level which will produce enough

torque to get the motor to move. This is commonly referred to as "break-away torque". As

the current ramps up from this point, the torque also increases as time passes. If at the

initiation of start, the motor torque is less than the load, the motor will remain stalled until

the torque ramps to a sufficient level for acceleration.

Soft Startin g for light loads or reducin g starting current are accomplished by using the

Constant Current Mode.

On some applications the starting time is still too fast in the current ramp mode because the

load is too light. In this application it is best to select the constant current mode which will

allow the acceleration torque to be better controlled, actually kept constant.

If the available current is limited and causes significant voltage drops, the constant current

mode will allow flexibility in setting the current draw. Remember that the current level must

be great enough to provide acceleration torque and this level is determined by the load. For

all other applications, or if in doubt, select the Current Ramp Mode.

Page 3

OPAL SS6 Reduced Voltage Starters

1.2.3 MOTOR AND LOAD TYPES

1.2.3.1 Squirrel Cage Motors

Squirrel cage motors, with a single winding and of any NEMA design may be connected to

the OPAL starter.

1.2.3.2 Wound Rotor Motors

Wound Rotor Induction Motors (WRIM) and solid state starters make an excellent

combination for frequent starting, jogging, plug-stopping and reversing applications. These

WRIM motors use multiple steps of resistors to provide various speed torque characteristics.

This allows a high starting torque characteristic while providing low starting current when

compared to NEMA B designs.

One disadvantage has been the high maintenance costs of the resistor and shorting contactor

bank. The use of an OPAL allows an improvement to this arrangement by allowing the

current to be limited without use of the multiple steps. Usually the load characteristic is such

that this starting may be accomplished with only one or two starting steps. By eliminating

several contactors a major savings is realised that often pays for the installation cost.

The common method is to add only one step of resistance at 20% (Rotor volts divided by

Rotor Amps times 20%). This resistance value will provide relatively high starting torque

and the OPAL will be used to limit the current. As little as 200% of mot or full load current

can provide 100% starting torque unlike squirrel cage NEMA B motors which would require

500% current. The resistor bank may be shorted with a contactor at fu ll speed to reduce t he

slip and eliminate the watt losses in the resistors.

Page 4

OPAL SS6 Reduced Voltage St art ers

1.2.3.3 Other Types of AC Motors

OPAL starters may also be used to start 2-speed motors with multiple windings or

connections. Proper contactor selection and sequencing is required for the specific motor.

1.2.3.4 Resistive and Inductive Loads

The TRU-START is well suited for use as a phase controller or current regulator on resistive

or inductive loads such as heaters. When applied with a Temperature PI controller, the TRUSTART will maintain smooth control to avoid the overheating associated with on/off type

controllers. Improved temperature accuracy and longer heater elem ent life can be expected

over standard control methods.

1.2.4 STARTING AC MOTORS IN PARALLEL

OPAL SS6 starters can be used to start motors in parallel but they must have individual

overload devices added.

When the paralleled motors are also connected to the same load, mechanically or through the

material, then load sharing must be considered.

When the motors are mechanically tied, the load sharing is determined by how closely the

motor characteristics are to each other. It is important to keep the motors exactly t he same.

Even changing the manufacturers of the motors can cause some variations in load sharing.

The OPAL size is determined by the total of the motor current ratings.

Page 5

OPAL SS6 Reduced Voltage Starters

2.0 SPECIFICATIONS

2.1 POWER RATING

POWER 3ø, 200-600VAC, 50/60 Hz

CONTROL 115 VAC@50 Hz or 120 VAC@60 Hz, 12VA (fans are extra)

RATING See Section 2.2

All models have 1600V PIV SCR's

CONTACTS Run and fault relay contacts rated at 0.2A, 115VAC

PROTECTION Short circuit by HRC fuses or circuit breaker (supplied upon request)

Voltage surge protection by MOV's across the SCR's

2.2 MAXIMUM RATINGS

OPAL

MODEL

SS6-15 5 10 15

SS6-30 10 25 30

SS6-50 20 40 50

SS6-80 30 60 75

SS6-125 50 100 125

SS6-200 75 150 200

SS6-360 150 300 350

SS6-500 200 400 500

SS6-600 250 500 600

230V 460V 575V

HORESEPOWER

Page 6

SS6-800 300 600 800

2.3 SERVICE CONDITIO NS

ELEVATION For altitudes in excess of 2000 meters / 6600 feet above sea level, all

assemblies must be derated 1% for every 100 meters / 330 feet above

AMBIENT Do not install in areas where ambient temperature falls below

TEMPERATURE 0°C / 32°F or exceeds 40 °C / 104°F

HP

J FUSE AMPS

OPAL SS6 Reduced Voltage St art ers

2.4 FUSE SIZING

OPAL

MODEL

SS6-15

SS6-30

SS6-50

SS6-80

SS6-125

MOTOR

FLC

5

10

15

20

25

30

34

0

52

60

65

75

100

125

460V 575V FAST ACTING TME DELAYED

3

7.5

10

15

20

--

25

30

40

-50

60

75

100

5

10

15

20

25

30

30

40

50

60

--

75

100

125

15

25

40

50

60

70

70

80

100

125

150

150

200

250

10

15

25

30

40

50

50

60

80

90

90

100

150

175

SS6-200

SS6-360

SS6-500

150

180

200

250

300

360

400

500

125

150

--

200

250

300

--

400

150

--

200

250

300

--

400

500

300

400

400

500

600

--

--

--

200

250

300

350

400

500

500

600

Page 7

OPAL SS6 Reduced Voltage Starters

2.5 DIMENSIONS

This is a general guideline for dimensions as they may change slightly based on different

options used.

2.5.1 STANDARD UNIT

OPAL

MODEL

SS6-15

SS6-30

SS6-50

SS6-80

SS6-125

SS6-200

Height × Width × Depth

CHASSIS NEMA 1 NEMA 12

33cm × 22cm × 15cm

13" × 8.5" × 6"

41cm × 22cm × 15cm

16" × 8.5" × 6"

43cm × 27cm × 19cm

17" × 10.5" × 7.5"

43cm × 27cm × 22cm

17" × 10.5" × 8.5"

53cm × 27cm × 24cm

21" × 10.5" × 9.5"

34cm × 52cm × 27cm

13.5" × 20.5" × 10.5"

33cm × 22cm × 18cm

13" × 8.5" × 7"

41cm × 22cm × 18cm

16" × 8.5" × 7"

43cm × 30cm × 27cm

17" × 12" × 10.5"

43cm × 30cm × 27cm

17" × 12" × 10.5"

53cm × 30cm × 27cm

21" × 12" × 10.5"

76cm × 61cm × 41cm

30" × 24" × 16"

33cm × 22cm × 18cm

13" × 8.5" × 7"

61cm × 50cm × 30cm

24" × 20" × 12"

43cm × 30cm × 27cm

17" × 12" × 10.5"

43cm × 30cm × 27cm

17" × 12" × 10.5"

53cm × 30cm × 27cm

21" × 12" × 10.5"

122cm × 91cm × 41cm

48" × 36" × 16"

Page 8

SS6-360

SS6-500

SS6-600

SS6-800

48cm × 56cm × 28cm

19" × 22" × 11"

50cm × 64cm × 34cm

19.5" × 25" × 13.5"

50cm × 64cm × 34cm

19.5" × 25" × 13.5"

65cm × 71cm × 42cm

25.5" × 28" × 16.5"

91cm × 76cm × 41cm

36" × 30" × 16"

107cm × 91cm × 41cm

42" × 36" × 16"

107cm × 91cm × 41cm

42" × 36" × 16"

122cm × 91cm × 51cm

48" × 36" × 20"

122cm × 91cm × 41cm

48" × 36" × 16"

152cm × 122cm × 41cm

60" × 48" × 16"

152cm × 122cm × 41cm

60" × 48" × 16"

152cm × 152cm × 51cm

60" × 60" × 20"

OPAL SS6 Reduced Voltage St art ers

2.5.2 REVERSING UNITS

OPAL

MODEL

SS6-15R

SS6-30R

SS6-50R

SS6-80R

SS6-125R

SS6-200R

Height × Width × Depth

CHASSIS NEMA 1 NEMA 12

33cm × 22cm × 17cm

13" × 8.5" × 6.5"

41cm × 22cm × 17cm

16" × 8.5" × 6.5"

43cm × 27cm × 20cm

17" × 10.5" × 8"

43cm × 27cm × 22cm

17" × 10.5" × 8.5"

53cm × 27cm × 24cm

21" × 10.5" × 9.5"

34cm × 52cm × 28cm

13.5" × 20.5" × 11"

33cm × 22cm × 18cm

13" × 8.5" × 7"

41cm × 22cm × 18cm

16" × 8.5" × 7"

43cm × 30cm × 27cm

17" × 12" × 10.5"

43cm × 30cm × 27cm

17" × 12" × 10.5"

53cm × 30cm × 27cm

21" × 12" × 10.5"

91cm × 76cm × 41cm

36" × 30" × 16"

33cm × 22cm × 18cm

13" × 8.5" × 7"

61cm × 50cm × 30cm

24" × 20" × 12"

43cm × 30cm × 27cm

17" × 12" × 10.5"

43cm × 30cm × 27cm

17" × 12" × 10.5"

53cm × 30cm × 27cm

21" × 12" × 10.5"

122cm × 91cm × 41cm

48" × 36" × 16"

SS6-360R

SS6-500R

SS6-600R

SS6-800R

48cm × 56cm × 29cm

19" × 22" × 11.5"

50cm × 64cm × 36cm

19.5" × 25" × 14"

50cm × 64cm × 36cm

19.5" × 25" × 14"

65cm × 71cm × 42cm

25.5" × 28" × 16.5"

122cm × 76cm × 41cm

48" × 30" × 16"

122cm × 91cm × 41cm

42" × 36" × 16"

122cm × 91cm × 41cm

42" × 36" × 16"

152cm × 91cm × 51cm

60" × 36" × 20"

122cm × 91cm × 41cm

48" × 36" × 16"

152cm × 122cm × 41cm

60" × 48" × 16"

152cm × 122cm × 41cm

60" × 48" × 16"

183cm × 152cm × 51cm

72" × 60" × 20"

Page 9

OPAL SS6 Reduced Voltage Starters

2.6 SCR INSTALLATION SPECI FICATIONS

2.6.1 SCR TIGHTENING PROCEDURE

2.6.1.1 Clean both heat sink and SCR surfaces.

2.6.1.2 Apply a thin layer of joint compound (Noalox) to both SCR surfaces.

2.6.1.3 Observe correct SCR polarity.

2.6.1.4 Install SCR so that roll pins engage dimples on both sides of the SCR.

2.6.1.5 Tighten clamp bolts evenly until finger-tight.

2.6.1.6 Tighten each bolt according to table below (based on number of spring bars

and size of bars).

* Note: SMALL clamps are 4.25 inches / 10.5 cm and LARGE clamps are 5 inches / 12.5 cm.

CLAMP SIZE SPRING BARS

BOLT TURNS PAST

FINGER TIGHT

SMALL 1 0.75

SMALL 2 1

LARGE 3 1.75

LARGE 4 1.75

Page 10

OPAL SS6 Reduced Voltage St art ers

Page 11

OPAL SS6 Reduced Voltage Starters

3.0 CARD FUNCTIONS

3.1 CARD LAYOUT

Page 12

CA392 - OPAL CONTROLLER CARD

OVER

TEMP

On when unit is faulted because of an open Over

Temperature switch at the OT terminal

MOTOR

OVRLD

When lit an IOC (instantaneous over-current) or

an inverse time overload fault exists

Should be lit during stop and extinguished when the motor is

up to speed. This represents the status of SCR 1 and 2

Indicates voltage is present on L1

Should be lit during stop and extinguished when the motor is

up to speed. This represents the status of SCR 3 and 4

Indicates voltage is present on L2

Should be lit during stop and extinguished when the motor is

SETTING

Adjusts the time of the current ramping

CW rotation decreases the time

Adjusts the starting current or breakaway

CW increases the torque (current)

OPAL SS6 Reduced Voltage St art ers

3.2 ANNUNCIATION

3.2.1 LED INDICATIONS

LED NAME COLOUR DESCRIPTION

LD1

RED

LD2 READY GREEN This LED is illuminated when there are no faults

LD3 RUN GREEN Indication of run commanded to starter

LD4

RED

LD5 +15V GREEN Illuminated when +15V power supply is okay

3.2.2 NEON INDICATIONS

NEON NAME DESCRIPTION

NE1 SCR 1,2

NE2 L1 ON

NE3 SCR 3,4

NE4 L2 ON

NE5 SCR 5,6

up to speed. This represents the status of SCR 5 and 6

NE6 L3 ON Indicates voltage is present on L3

3.3 ADJUSTMENTS

3.3.1 POTENTIOMETERS

POT NAME RANGE

RV1 RATE 2-3 SEC 50%

RV2 STEP 150-350%

DEFAULT

50%

DESCRIPTION

torque

Page 13

Shipped from factory with no jumper

RV1 has no bearing

This selects current ramp mode which is

BURDEN

Calibrates current for nameplate rating of motor

115 VAC supplied to this input will enable the unit

Common Fault relay contact. The relay is energized

when a fault exists

Normally open Fault relay contact

Normally closed Fault relay contact

Dry run contact for external use or sealing contact for

start pushbutton with three wire control

115 VAC control voltage input

250 VAC

A contact closure across these terminals will reset

For local panel door use, low voltage control.

OPAL SS6 Reduced Voltage Starters

3.3.2 LINK SELECTION

LINK NAME POSITION DESCRIPTION

With no jumper present, heavy duty mode

selected

Selects constant current mode

dependent on RV1

JP1 DUTY

JP3 RATE

NO

JUMPER

OFF

ON

*Note : JP2 does not exist on this version

3.3.3 PUSHBUTTON AND SWITCHES

SWITCH NAME DESCRIPTION

SW1 RESET Resets IOC or inverse time overload fault

SW2

SELECT

Refer to current table on starter or Section 4.5.3.

3.4 TERMINALS

3.4.1 CUSTOMER TERMINALS

TERMINAL NO. DESCRIPTION

1

to run

2

3

TB

4

5 115 VAC supplied for control logic

6,7

AC AC1, N

TB1 RESET

AC1, N AC1 input is protected with internal fuse, 3A

any faults that exist.

Page 14

This two pin connector is for an over temperature switch on

units with fans and must be shorted if an OT switch is not used

OPAL SS6 Reduced Voltage St art ers

3.4.2 TERMINALS FOR INTERNAL USE

TERMINAL DESCRIPTION

OT

FAN Fused 115 VAC for fan connection

SCR1-6 Gate lead connections for SCR firing

OPT Provided for ribbon cable link to SAF's OPAL option cards

3.5 FAULTS

Any OPAL fault energizes the fault relay and shuts down the starter. Whenever any fault exists, the

READY LED will be off indicating the starter won't run. Once the fault is cleared, READY will be

illuminated if no other faults exist. Terminal TB-2 to 3 will be open when no fault exists and closed

during a fault condition, TB2 to 4 is vice versa.

3.5.1 OVER TEMPERATURE

OPAL units with fans have over temperature switches fastened to the heatsink(s). This switch or

switches in series, are connected in the OT terminal on the control card. Units without fans have

a jumper installed. In the case where there is a fan failure or fan blockage and the heatsink

temperature exceeds 85°C / 185°F ± 5°C / 41°F, the over temperature switch opens, faulting the

OPAL. This fault is indicated by LD1, OVERTEMP. When the heatsink cools enough, creating

switch closure, the OVER TEMP LED will extinguish.

3.5.2 MOTOR OVERLOAD

This fault has two conditions, instantaneous over current (IOC) or inverse timed overload. Both

of these faults are indicated by LD4, MOTOR OVRLD. If started into a short, the OPAL should

trip on an IOC dependent upon the impedance of the incoming lines. This condition is resettable

instantly by the RESET button. The inverse time overload is a class 20 overload that simulates

the heating of the motor.

This electronic circuitry begins to integrate whenever the current to the motor exceeds 115% of

the current setup with SW2. This current calibration switch should be setup to the name plate

current rating of the motor. Once the overload circuitry reaches the trip level, the unit faults and

shuts down. This trip is allowed to be cleared with the RESET button after a time period of

approximately 5-7 minutes. This time allows for the motor to cool before restarting.

3.5.3 PHASE LOSS

If any of the incoming lines are not present before starting the OPAL will be faulted. Each line is

indicated by a corresponding neon lamp. Once the missing phase(s) is/are present and no other

faults exist, the unit will be ready to run.

Page 15

CAUTION

machinery, touch motor terminals or control equipment pa rts.

OPAL SS6 Reduced Voltage Starters

4.0 INST A LLATION A ND ST A RT-UP

4.1 INSPECTION

The OPAL has been packaged to protect it from damage caused by normal handling during

shipment; however mishandling may cause damage to the OPAL. Unpack the unit as soon as

it is received and check for any shipping or storage damages.

If damage is found, notify the carrier. Any damage claim must be filed by the customer since

all shipments are F.O.B. SAF plant unless otherwise specified.

If the OPAL is not installed when received, store it in a clean, dry, well ventilated area, free

from heat, humidity, oil, dust, and metal particles.

4.2 SAFETY PRECAUTIONS

Equipment is at line voltage when AC power is connected.

Pressing "STOP" pushbutton does not remove AC mains potential.

All phases must be disconne cted before it is safe to work on

The electrical code requires all equipment, starter, motor, operator station, etc. to be

grounded properly.

An incoming circuit breaker or disconnect switch must be locked open before wiring or

servicing this starter, motor, or other related equipment. This equipment must be installed

and serviced only by qualified personnel, familiar with this starter.

The user is responsible for ensuring that proper short circuit protection is provided by either

a circuit breaker or HRC fuses.

4.3 MOUNTING GUIDELINES

Standard Nema 1 OPAL Starters must be installed indoors in a well ventilated area, free

from heat, humidity, oil, dust and metal particles.

One foot of clearance must be kept all around in a natural cooled unit. The equipment must

be mounted away from any heat source. See Section 2 for additional specifications.

Be aware that the heatsink may reach 70° C / 158°F during normal operation. Do not install

the starter in contact with any material that can not accept this temperature.

The starter must be mounted vertically and where it will not experience excessive shock or

vibration.

Page 16

OPAL SS6 Reduced Voltage St art ers

4.4 WIRING GUIDELINES

The electrical code requires that an approved circuit disconnecting device be installed in the

incoming AC supply, mounted in a location readily accessible to personnel installing or servicing

this equipment.

Power factor correcting capacitors MUST NOT be connected to the OPAL output. If desired, they

must be added ahead of the starter. Cap acitors can be connected before startin g or after the motor

has reached full speed. It is recommended that the Up-to-Speed option card be used to connect the

capacitors after full speed has been reached.

In-line contactors are not required; however they can be used on the line side or the motor side

without detriment to the starter. It is recommended that the contactor be sequenced to open and

close under no-load conditions to prolong the life of the contacts.

Size the power wiring as per local code. On long wire runs it is recommended to use a larger wire

size.

All three phases of the incoming power wires must pass through the same hole in the enclosure.

This rule also applies to all phases of the outgoing or motor wires.

If an electro-mechanical brake is used in the system, it must be powered from the line side of the

starter, to ensure full voltage to the brake.

For short-circuit fuse protection, we suggest referencing the table in Section 2.

4.5 START-UP

4.5.1 BEFORE POWER-UP

4.5.1.1 Ensure that all electrical connections are completed as shown on the schematics, and

that connections are properly tightened.

4.5.1.2 Read motor full load current from the nameplate and rotate SW2 to match the motor

full load current, according to the label attached or the current chart in Section 4.5.3.

4.5.1.3 Check 120 VAC control voltage to the OPAL unit.

4.5.1.4 Set RV1 and RV2 to mid-position, for 15 sec ramp time and 250% starting current.

4.5.1.5 Check link positions. The factory settings are current ramp mode and no jumper for

heavy duty.

Page 17

OPAL SS6 Reduced Voltage Starters

4.5.2 WITH POWER ON

4.5.2.1 With the motor connected and power on, all neon lamps should be illuminated and

no faults should exist.

4.5.2.2 Once start has been initiated the motor must start rotating immediately, it must not

stall. Increase the starting current if necessary by rotating RV2, STEP, clockwise.

4.5.2.3 The RATE could be re-adjusted to extend or decrease the accelerating time. To

speed up the acceleration rate, turn RV1 clockwise. The actual motor accelerating

time depends on the motor current as well as the mechanical load. This setting has

no effect when constant current mode has been selected. Refer to diagram below.

4.5.2.4 The RATE adjusts the time from the STEP setting to 500% of motor full load

current.

4.5.2.5 Some readjustments may be required when the motor is started to suit specific

applications.

Page 18

OPAL SS6 Reduced Voltage St art ers

4.5.3 HEAVY DUTY CURRENT CALIBRATION TABLE

SW2

OPAL MODEL (SS6 -)

POSITION

15 30 50 80 125 200 360 500 600 800

0 1 12 24 47 77 103 150 286 420 494

1 2 13 26 50 80 109 164 300 432 514

2 3 15 28 52 84 116 178 315 444 535

3 4 16 30 54 87 122 192 330 456 555

4 5 17 32 56 90 129 206 343 468 576

5 6 19 34 58 93 135 220 357 480 596

6 7 20 36 61 96 142 234 372 492 616

7 8 22 38 63 100 148 248 386 504 637

8 9 23 40 65 103 155 262 400 516 657

9 10 24 42 67 106 161 276 415 528 678

A 11 6 44 69 109 168 290 429 540 698

B 12 27 46 72 112 174 304 443 552 718

C 13 29 48 74 116 181 318 458 564 739

D 14 30 51 76 119 187 332 472 576 759

E 15 31 53 78 122 194 346 486 588 780

F 16 33 55 80 125 200 360 500 600 800

Page 19

OPAL SS6 Reduced Voltage Starters

5.0 OPAL OPTION CARDS

Re fer to Section 6 for typica l connections of any of the options listed in this se c tion.

5.1 SOFT STOP

CA390 - SOFT STOP CARD

This option has been designed to provide a controlled stop, to eliminate the water hammering effect

a ss ociated with fluid pumping applications.

The Soft St op card w ork s in the opposite fashion as t he OPAL start ing. W hen stop is commanded,

t he OPAL out put voltage drops t o a level set by STEP, RV2, and begins to ramp down following a

rate set by t he pot enti ometer D ECEL, RV 1, The OPA L wi l l remai n on unti l t he mot or t ermi nal

v o l tag e h as d ec reased t o a s et vo ltage l evel, at w h i c h tim e th e starter s w i tc h es o ff. T he maximum

ramp ti me i s l i mi t ed t o a maxi mum 15-20 seconds. T hi s i s the ti me that t he r el ay i n t he OPA L

controller card, CA392, is maintained ene rgize d.

The ma jority of AC induction motors expe rience a region of instability when phased back or volta ge

i s reduced. T he STEP potentiomet er shoul d be adj usted to a l evel , w hi ch is j ust bel ow this poi nt.

Fully counter-clockwise provides little decrease in voltage step when stop is commanded.

Clockwise rotation of RV1 slows the ramp down from this point.

T h e v olt ag e l ev el ju mp er , J1 , set at L O c eases st ar t er o perat i o n at 1 5 % v o ltag e w hi le at H 1 , t he

OPAL stops a t 20% line voltage.

Terminals 1 and 2 on t his option car d are prov ided to w ir e an ex ternal selector swit ch to enable or

di sable t he sof t st op mode. W hen terminal s 1 and 2 of T B 1 are shor ted, t he OPA L will coast t o a

res t when stop is commanded.

Page 20

OPAL SS6 Reduced Voltage St art ers

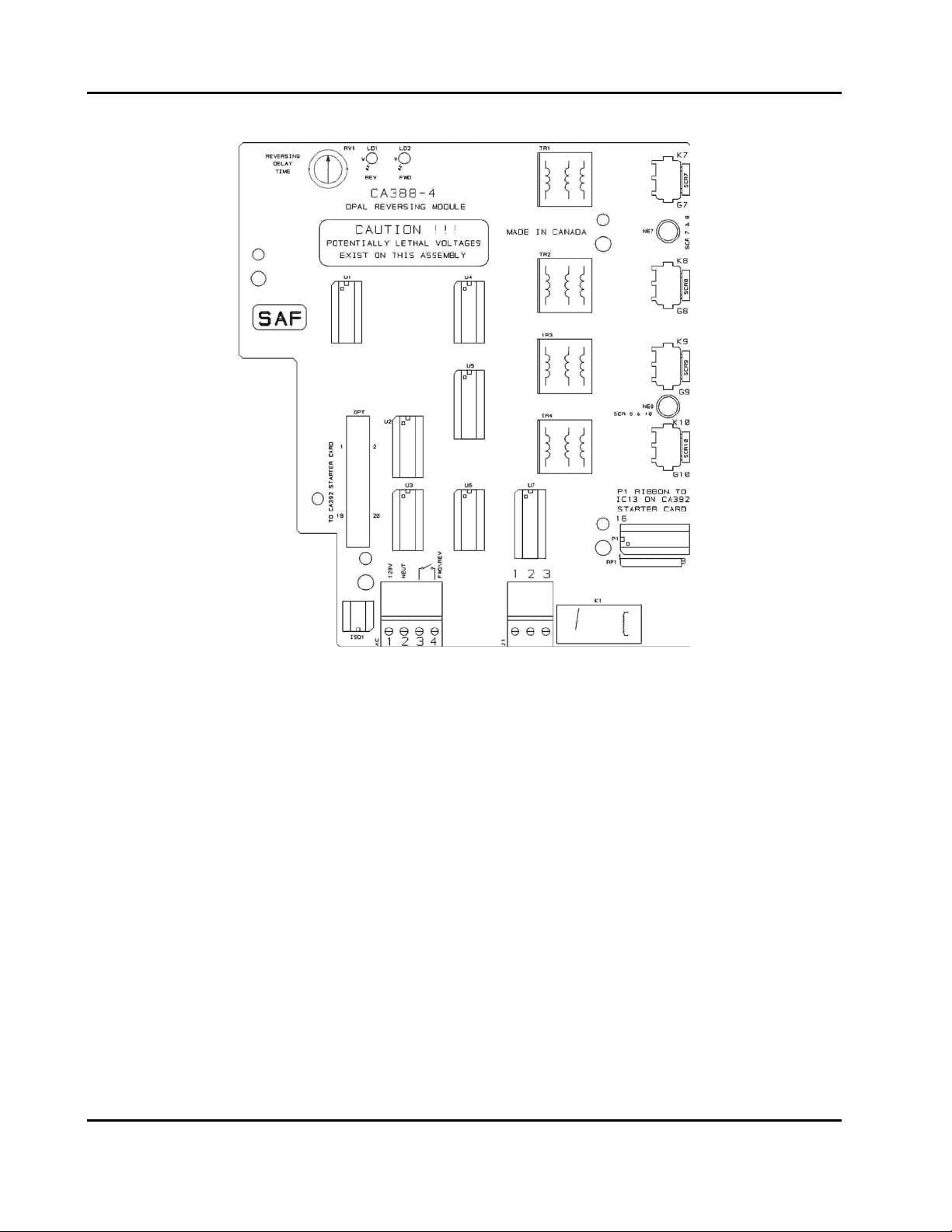

5.2 SOLID STATE REVERSING

CA388 - SOLID STATE REVERSING CARD

This option provides a smooth, current controlled, motor rotation reversal without any current surge

or torque jerk. Motor stopping is not required. Additions to the OPAL include a reversing card,

CA388, plus four additional SCR's.

Terminal block AC, terminals 1 and 2 are to be connected to 115 VAC control voltage. An external

switch or contact must be connected to AC, terminals 3 and 4 of this card. The forward brid ge is

selected with the switch closed. With the switch open the starter will fire the reverse bridge.

Terminal block J1 is a form C dry contact rated at 0.2A, 115 VAC for an indication of the direction

selected and by-pass contactor sequencing for a reverse/by-pass combination. The red LED, LD1

indicates the reverse selection and the green LED, LD2 annunciates that the forward bridge is

chosen.

A REVERSING DELAY TIME potentiometer, RV1, sets the time the OPAL remains off when

switching directions, from 1 to 10 seconds. Clockwise rotation increases dwell time. The factory

default setting is 1 second.

When the motor is running and the forward/reverse switch changes states, the OPAL turns all SCR's

off. After an adjustable time delay set up by RV1, the OPAL is switched back on, triggering a

different set of SCR's. This effectively switches two output lines, decelerates the motor down to

zero speed, and continues to accelerate it to full speed in the opposite direction. The motor reversal

is performed under complete current control via the RAMP and STEP potentiometers on the

CA392.

Page 21

OPAL SS6 Reduced Voltage Starters

5.3 UP-TO-SPEED, SHEAR PIN, AND ENERGY SAVER

5.3.1 UP-TO-SPEED AND SCR BY-PASS

A three pole contactor used in conjunction with the Up-To-Speed contact eliminates the

SCR losses by shorting them out after the motor has reached full speed. This feature is a tru e

Watt Saver modification and permits the use of the OPAL in a NEMA 4 or NEMA 12

enclosure. The by-pass contactor is switched on only after the motor has reached fu ll speed

and as such sees only motor full load current. At stop, the by-pass contactor is opened while

the SCR's are triggered fully on, limiting the power contacts opening voltage. The SCR's are

then switched off without having any voltage surge.

When a by-pass contactor is used in conjunction with reversing, the FWD/REV contacts of

the CA388 must be connected in series for proper sequencing of the contactor(s).

When the motor reaches full speed, the Up-To-Speed relay is energized and the red UP-TOSPEED LED, LD3 is illuminated. A form C dry relay contact rated at 1A, 120VAC, is

provided on J1 terminals 1, 2 and 3 for by-pass sequencing. Large contactors require a

control relay to handle the high in rush current to the coil.

Page 22

CA391 - MULTI OPTION CARD

OPAL SS6 Reduced Voltage St art ers

5.3.2 SHEAR PIN PROTECTION

This feature has been designed to provide motor jam protection, similar to a mechanical

shear pin.

Once the motor has reached full speed, indicated by LD3 being on, the OPAL will trip if the

motor current increases to 300%. The red SHEAR TRIP LED, LD2 will indicate this trip and

is resettable via the red RESET pushbutton on the option card. Link JP2 enabl es or disables

this optional feature.

5.3.3 ENERGY SAVER

This option is designed to phase back the SCR's under light load, and keep them fully phased

on under medium to full load. This optional feature is intended for use on small motors in

applications where the motor runs under no load for an extensive time but can not be

switched off. The energy save is not effective on motors over 25 HP. The OPAL starter is

designed for repeated starting and stopping. The most efficient operation is to switch the

motor off when ever possible.

Link JP1 enables or disables this optional feature. The red ENERGY SAVE LED, LD1 will

come on to announce that this feature is active. To calibrate this feature, turn RV1, PHASE

BACK ADJUST pot clockwise until the motor starts to become unstable. Once this occurs,

turn the pot slightly counter-clockwise until the motor is again stable. Energy save is not

operational with the use of a bypass contactor.

5.3.4 EXTENDED OVERLOAD

With a high inertia load such as a chipper, a Class 20 overload may not allow enough time

for the motor to reach full speed without nuisance overload tripping.

In such a scenario an extended overload option can be implemented. This allows the motor

500% current for a longer period of time. This option only affects the overload when the

motor is started.

The extended overload is not a factory option and must be specifically requested. Consult

factory for more details.

Page 23

OPAL SS6 Reduced Voltage Starters

5.4 SHORTED SCR DETECTION

CA395 - SHORTED SCR CARD

This option provides protection against the unlikely event of a shorted Silicon Controlled Rectifier

(SCR). This card only functions when the OPAL is not running and should be used in conjunction

with a shunt trip circuit breaker or an in-line contactor.

In the event of a shorted SCR, it is not sufficient to merely trip the starter. The incoming 3ø power

must be removed. The danger associated with a shorted SCR is that even when the starter is not

running, current may pass freely through the motor.

If a shorted SCR is detected, the Shorted SCR relay is energized. The form C relay contact rated at 1

Amp, 120 VAC on terminals 1, 2 and 3 of J1, is provided for means of opening the circuit breaker

or contactor used. Large contactors require a control relay to handle the high in rush current to the

coil. A red LED, LD1 will illuminate during this condition of a shorted device.

The CA395 will indicate a shorted SCR if the motor is not connected. In reversing applications, two

shorted SCR cards must be used. When using an OPAL with an integral DC Injection option, the

DCI contact from the OP-STOP must be used in conjunction with the shorted SCR contact to

eliminate erroneous trips during DC injection.

Page 24

Sets up speed feedback for the regulator by adjusting voltage at TP1

OPAL SS6 Reduced Voltage St art ers

5.5 LINEAR ACCEL/DECEL OPTI O N

CA385 - LINEAR ACCEL/DECEL CARD

This option card combined with a 60 tooth magnetic pulse pick-up or a tachometer provides

linear acceleration and deceleration independent of load. The ramp reference can be via

internal ramp generator or an auxi liary reference. A form C dry contact indicating when the

unit is running is available for external use and illuminated via LD1.

5.5.1 POTENTIOMETERS

POT NAME DESCRIPTION

RV1 STAB Adjustment for stability of the ramping transition

RV2

TACH

SCALE

RV3 DECEL Adjusts decel time of ramp, 5 - 50 seconds, CW increases time

RV4 ACCEL Adjusts accel time of ramp, 5 - 50 seconds, CW increases time

(below JP2), CW decreases voltage at TP1

For internal ramp set TP1 for -9.2V or less at full speed

For aux ref set TP1 = maximum reference -0.667 or slightly less at

full speed

Page 25

PULSE

FEEDBACK

Common point for pulse pick up feedback

and auxiliary reference

Input for auxiliary reference when JP1 is at AUX

Range is 0 - 15V maximum

ramp reference or auxiliary input reaches 0V

FEEDBACK

Scaled by resistor at J3

Scaling resistor for tach feedback

OPAL SS6 Reduced Voltage Starters

5.5.2 LINK SELECTION

LINK NAME DESCRIPTION

AUX Reference from auxiliary input

JP1

INT Internal reference from ramp generator

PULSE Feedback from magnetic pick-up input on J1

JP2

TACH Feedback from tachometer input on J2

5.5.3 TERMINALS

TERMINAL

NO. NAME DESCRIPTION

1

2 COMMON

J1

3 AUX REF

4 NO Normally open starter status contact

5 NC Normally closed starter status contact

6 COM

J2

J3 CAL R

5.5.4 START-UP

TACH

Connection point for pulse pick up feedback

Common of ramp status form C contacts

Energized when unit started and de-energized when

Input for tachometer feedback

Resistor should be 1 Watt or greater

CAL R = (max. tach volts -13.4) ÷ 12 in kilo-ohms

5.5.4.1 STEP (RV2) should be set at 0 and the RATE jumper (JP3) must be OFF or

removed on the CA392 control card. Ensure SW2 is in correct position.

5.5.4.2 Set JP1 and JP2 on CA385 at settings for your application. If tach feedback is being

used, install resistor as per above procedure in TERMINALS.

5.5.4.3 Set all pots to 50%.

5.5.4.4 Start unit and adjust speed feedback according to the procedure in the table

POTENTIOMETERS, RV2 description when at full speed. If accel or decel is too

slow adjust appropriate pot. If motor does not seem to get up to full speed, reduce

the level at TP1 by turning RV2 clock-wise.

Page 26

OPAL SS6 Reduced Voltage St art ers

6.0 TYPICAL CONNECTIONS

Listed in this section are diagrams containing typical single option connections. Notice that

multi-option connections are possible, meaning a combination of a starter with two or more

options attached. The only connection difference between the various sized OPAL power

units, other than the obvious sizes and ratings of devices, is the location of the current

transformers. This should be of no concern because any modification involving this

configuration should be done at the factory or be consulted by SAF Drives Inc.

Page 27

OPAL SS6 Reduced Voltage Starters

6.1 OPAL WITH 2-WIRE CONTROL AND EXTE RNAL RE S E T

Page 28

OPAL SS6 Reduced Voltage St art ers

6.2 OPAL WITH 3-WIRE CONTROL, O P TIONAL RUN AND READY PILOT LIGHT

Page 29

OPAL SS6 Reduced Voltage Starters

6.3 OPAL WITH SOFT STOP

Page 30

OPAL SS6 Reduced Voltage St art ers

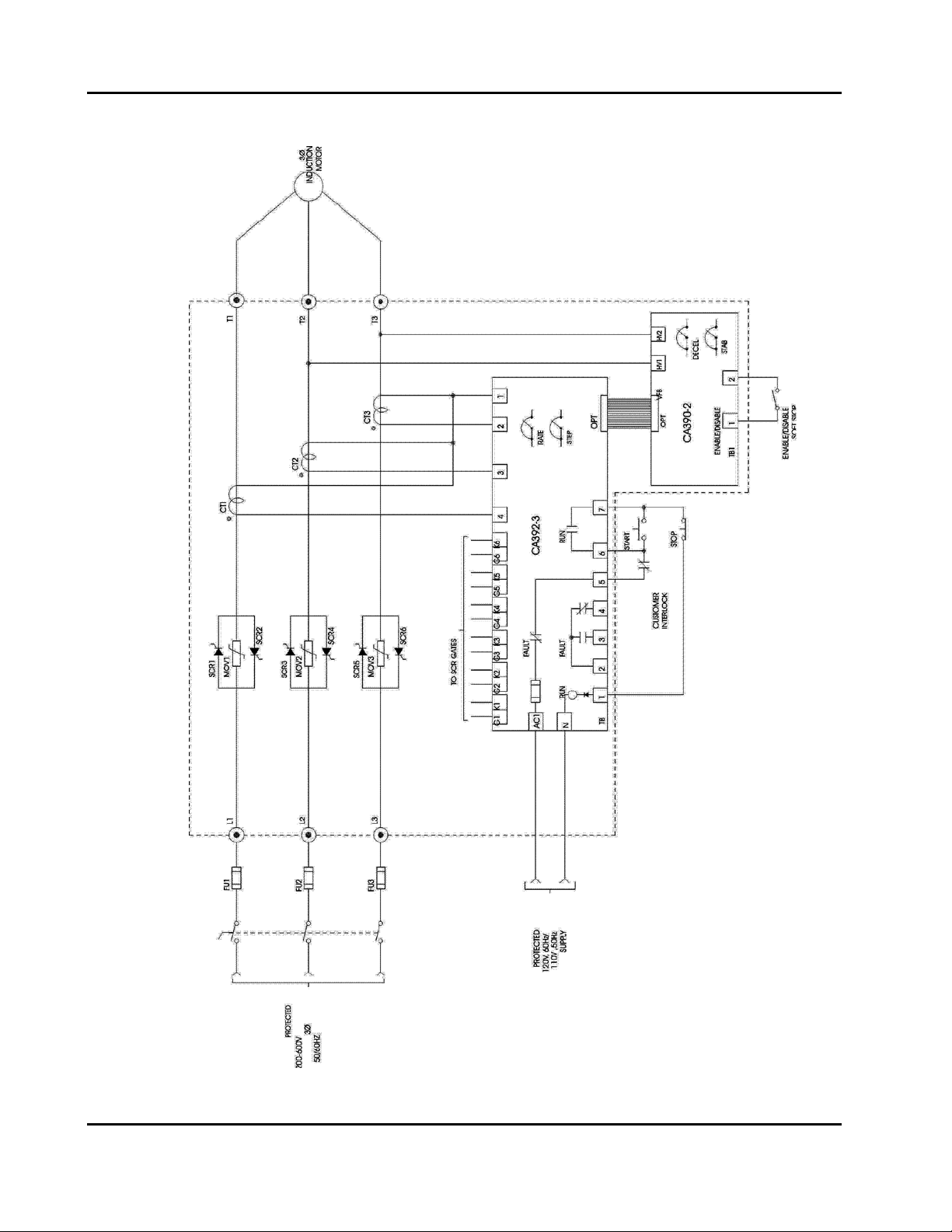

6.4 OPAL WITH SOLID STATE REV E RS ING

Page 31

OPAL SS6 Reduced Voltage Starters

6.5 OPAL WITH BYPASS CONTACTOR FOR NE MA 4 O R 1 2 125A AND BELOW

Page 32

OPAL SS6 Reduced Voltage St art ers

6.6 OPAL WITH BYPASS CONTACTOR FOR NE MA 4 O R 1 2 200A AND ABOVE

Page 33

OPAL SS6 Reduced Voltage Starters

6.7 OPAL WITH SHORTED SCR OPTION

Page 34

OPAL SS6 Reduced Voltage St art ers

6.8 OPAL WITH LINEAR ACCEL/DECE L CARD

Page 35

C/T

NO.

MULTI

SOLID STATE

SOFT

SHORTED

LINEAR

OPTION

CARD

OPAL SS6 Reduced Voltage Starters

7.0 SPARE PARTS

7.1 STANDARD UNIT

OPAL

MODEL

C/T

RATIO

PART

SCR

PART NO.

MOV PART

NO.

CONROL

CARD

SS6-15 1500:1 T261122 N10SP03 O210050 CA392

SS6-30 1500:1 T261122 N10SP03 O210050 CA392

SS6-50 1500:1 T261122 N10SP06 O210050 CA392

SS6-80 2500:1 T262320 N10SP16 O210050 CA392

SS6-125 2500:1 T262320 N20SP06 O210050 CA392

SS6-200 2500:1 T262320 N728452 O210050 CA392

SS6-360 5000:1 T265320 N718133 O210050 CA392

SS6-500 8500:1 T268320 N718552 O210050 CA392

SS6-600 8500:1 T268320 --- O210050 CA392

SS6-800 10000:1 T261321 --- O210050 CA392

Page 36

7.2 OPTION CARDS

DESCRIPTION

OPTION

CA391 CA388 CA390 CA395 CA385

REVERSING

STOP

SCR

ACCEL/DECEL

Fan failure

Replace fan

Fan blockage

Clear blockage

Replace jumper, units without fans

only

READY (LD2)

not lit

Does not start &

doesn't illuminate

Shorted motor or output

Check motor and output

SW2 not calibrated for

motor

Refer to current calibration chart on

unit

Burden pack not installed

or not installed correctly

Install burden pack and/or correctly

Confirm SW2 is setup for the motor

connected

RAMP and STEP setup or

necessary

Check control voltage and FU1 on

control card

Motor runs in

direction

Measure continuity between line and

Motor not connected

Connect motor

Neons 2, 4, or 6

not lit

Motor sounds

starting

Confirm good connections and all gate

card are secure

try CONSTANT CURRENT mode

Incoming lines must be connected to

OPAL SS6 Reduced Voltage St art ers

8.0 TROUBLESHOOTING

PROBLEM POSSIBLE CAUSE CORRECTION

OVER TEMP

(LD1) lit

Jumper missing from OT

Fault present Refer to section 3.5 FAULTS

RUN (LD3)

Control wiring

MOTOR OVRLD

(LD4) lit

Motor overload

SW2 setup may be wrong

trips before motor

is up to speed

extended overload

+15V (LD5) not lit Control voltage not present

wrong

Neons 1, 3, or 5

Phase reversal

Shorted SCR

not lit at stop

Refer to section 6 TYPICAL

CONNECTIONS and check wiring

Increase RV1 and RV2, refer to

section 4

Interchange any two incoming or

motor leads

output terminals

3ø supply Check incoming line voltage

rough when

Loose connections or gate

leads

Lightly loaded

Motor starts

similar to

across the line

Incorrect line, terminal and

bypass connections

leads to SCR's and the CA392 control

Decrease STEP and RAMP or maybe

L1, L2, L3

Motor must be connected to T1, T2,T3

Bypass contactor must be connected to

BPM L1-3, BPM T1-T3

Page 37

OPAL SS6 Reduced Voltage Starters

Page 38

SAF Drives Inc. www.safdrives.com

18 Neville Street, Unit C www.opalstarters.com

Tel: 519-662-6489 Email: answers@opalstarters.com

Fax: 1-866-280-5247 Toll Free: 1-800-3-ASK-SAF

18 Neville Street, Unit C

New Hamburg, ON N3A 4G7

Tel: 519-662-6489

Fax: 1-866-280-5247

www.safdrives.com

www.opalstarters.com

email: answers@opalstarters.com

(Replies given within 24 hours)

Loading...

Loading...