Installation & Operating Procedures

Opal LT

Series

RVS-AX Analogue Soft Starter

8-170A, 220V-600V

Manufactured By SOLCON

Supplied By

R

R

V

V

S--

S

A

A

X

X

AAnnaalloogguuee SSoofftt SSttaarrtteerr

88--117700AA,, 222200--660000V

Innssttrruuccttiioonn

I

Ver. 3.2.04

V

Maannuuaall

M

1

Table of Contents

Page Subject

3 Starter Selection

4 Installation Notes

5 Wiring

6 Starter Settings

7 Motor Protection

8 Start-up Procedure

9 Technical Specification

10 Dimensions

Safety

• Read this manual carefully before operating the equipment and follow its instructions.

• Installation, operation and maintenance should be in strict accordance with this

manual, national codes and good practice. Installation or operation not performed in

strict accordance with these instructions will void manufacturer's warranty.

• Disconnect all power inputs before servicing the soft-starter and/or the motor.

• After installation, check and verify that no parts (bolts, washers, etc) have fallen into

the starter.

Attention

1. This product was designed and tested for compliance with IEC947-4-2 for class A equipment.

2. Use of the product in domestic environments may cause radio interference, in which case the user may

be required to employ additional mitigation methods.

3. Utilization category is AC-53a or AC53b. Form1.

4. For further information, see Technical Specification.

Warnings

• Internal components and P.C.B's are at Mains potential when the RVS-AX is

connected to mains. This voltage is extremely dangerous and may cause death or

severe injury if contacted.

• When RVS-AX is connected to Mains, even if start signal has not been issued, full

voltage may appear on motor's terminals. Therefore, for isolation purposes it is

required to connect an isolating device (C/B, switch, line contactor, etc) upstream to

the RVS-AX.

• Starter must be properly grounded to ensure correct operation and safety.

• Check that Power Factor capacitors are not connected to the output side of the soft

starter

The company reserves the right to make any improvements or modifications to its products without prior notice.

2

Starter Selection

The RVS-AX electronic soft starter incorporates six

thyristors to start a three-phase squirrel cage induction

motor. By supplying a slowly increasing voltage, it

provides soft start and smooth stepless acceleration,

while drawing the minimum current necessary to start

the motor.

A Soft Stop feature can be enabled when the RampDown potentiometer is adjusted. When used, upon stop

signal (open contact terminals 1 and 2), motor's voltage

is slowly reduced to zero.

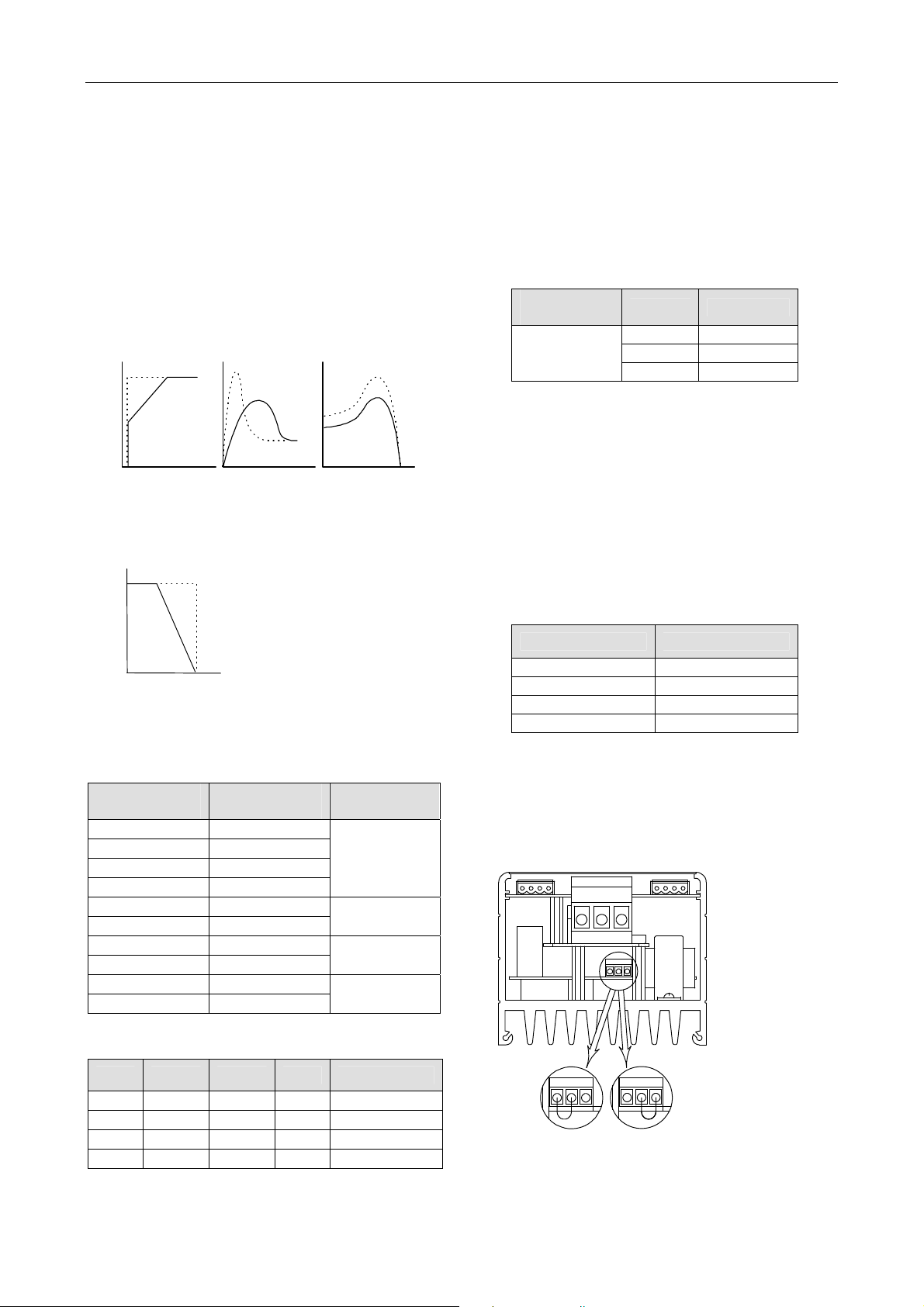

Soft-Start Characteristics

I%U%

100

50

10

400

100

CurrentVoltage

Soft-Stop Characteristics

100

U%

The Soft-Stop characteristic

may be used for controlled

50

deceleration of pumps and high

friction loads.

10

Voltage

RVS-AX ratings and Frame sizes

Max. Motor

FLA (Amp)

Starter Type

FLC (Amp.)

8 RVS-AX 8

17 RVS-AX 17

31 RVS-AX 31

44 RVS-AX 44

58 RVS-AX 58

72 RVS-AX 72

85 RVS-AX 85

105 RVS-AX 105

145 RVS-AX 145

170 RVS-AX 170

Dimensions (mm) & Weights (Kg)

Size Width Height Depth Weights (Kg)

A1 120 232 105

A2 129 275 185

A3 129 380 185

A4 172 380 195

M%

100

Torque

Frame Size

(Aluminum)

A1

A2

A3

A4

2.6

5

8.4

11.8

The starter should be selected in accordance with the

following criteria:

1. Motor Current & Starting Conditions

Select the starter according to motor's Full Load

Ampere (FLA) - as indicated on its nameplate (even if

the motor will not be fully loaded).

The RVS-AX is designed to operate under the

following maximum conditions:

Ambient

Temp.

40° C

I start Acc. Time

300% In 30 Sec

350% In 20 Sec

400% In 5 Sec

Max. Starts per Hour: four (4) starts per hour at

maximum ratings and up to 10

starts per hour at light load

applications (consult factory).

: For very frequent starts (inching applications)

Note

the inching current should be considered as the

Full Load Current (FLC) – consult factory.

2. Mains Voltage

Each starter is factory set for one of the following

levels according to the Ordering Information.

Voltage Tolerance

380 - 415 V +10 -15 %

440 V +10 -15 %

460 - 500 V * +10 -15 %

575 - 600 V +10 -15 %

Frequency: 50 / 60 Hz.

* Starter’s rated 460-500VAC can be field modified

for system voltage of 220-240V, by placing the

internal Jumper J3 as shown below.

220 to 240V 460 to 500V

WVU

123

J3

123123

3

Installation Notes

Prior to Installation

Check that Motor's Full Load Ampere (FLA) is lower

than or equal to starters Full Load Current (FLC) and

that Mains voltage is as indicated on the front panel.

Mounting

• The starter must be mounted vertically. Allow

sufficient space above and below the starter for

suitable airflow.

• It is recommended to mount the starter directly on

the rear metal plate of the switchgear for better

heat dissipation.

• Do not mount the starter near heat sources.

• Protect the starter from dust and corrosive

atmospheres.

Temperature Range and Heat Dissipation

The starter is rated to operate over a temperature range

of –10

ºC (14ºF) to +40ºC (104ºF).

Relative non-condensed humidity inside the enclosure

should not exceed 93%.

The heat dissipation during continuous operation is

Approx. 0.4 x In (in watts).

Example: When motor's current is 100 Amp, heat

dissipation will be approx. 40 watts.

Internal enclosure heating can be reduced using

additional ventilation.

Additional Ventilation

RVS-AX

General purpose enclosure

with filter on the air inlet and

Fan on air outlet.

RVS-AX

Fan, creating air circulation

Voltage Spike Protection

Voltage spikes can cause malfunction of the starter and

damage the SCRs. When expected, use suitable

protection such as Metal Oxide Varistors (consult

factory for further details).

Short Circuit Protection

The RVS-AX should be protected against a short

circuit by Thyristor Protection fuses.

The recommended I

2

t values are:

RVS-AX type I²t (A²S) Ferraz Fuses

RVS-AX 8 400 6,6 URS 35

RVS-AX 17 2,000 6,6 URS 45

RVS-AX 31 3,000 6,6 URS 63

RVS-AX 44 6,000 6,6 URB 100

RVS-AX 58 12,000 6,6 URB 150

RVS-AX 72 18,000 6,6 URB 160

RVS-AX 85 40,000 6,6 URD 200

RVS-AX 105 60,000 6,6 URD 250

RVS-AX 145 100,000 6,6 URD 355

RVS-AX 170 140,000 6,6 URD 400

Caution

Power factor correction capacitors must not be

installed on starter's Load side. When required,

Install capacitors on the Line side.

Warning

When Mains voltage is connected to the starter,

even if start signal has not been initiated, full

voltage may appear on the starter’s load

terminals. Therefore, for isolation purposes it is

required to connect an isolating device (C/B,

switch, line contactor, etc) upstream to the RVSAX (on the Line Side).

Built-in Bypass

The RVS-AX incorporates

internal bypass relays

allowing current flow

through the thyristors only

C/T

C/T

during starting process. At

the end of the starting

process, the built-in relays

X 3

bypass the thyristors and

carry the current to the

Motor.

Upon stop signal, or in

RVS-AX

M

case of fault, all three

bypass relays will open and stop the motor.

When Ramp-Down potentiometer is set to allow softStop process, upon stop command, the bypass relays

will open immediately and the current will flow

through the thyristors. The voltage will then be

reduced slowly and smoothly to zero.

4

Wiring

Block and Connection Diagram

Reduced Voltage Starter

Reset

Start

Stop N

1234

NOTE:

The RVS-AX incorporates an internal control

voltage transformer connected to phases L1&L3, in

case of phase loss of L1 or L3 the starter will stop the

motor. In case of phase loss for L2 the phase loss fault

will trip the starter only if Terminal 3 – Neutral, is

used).

Connection Diagram

L1

L2

L3

Neutral

Q1

I>I> I>

1

2

L

L

/

/

1

3

T1/U

M

On

Ramp-Up/Down

Run

Overload

Phase Loss

Over Tem p.

3

L

/

5

x 3

T2/V

W1V1U1

1L 2L 3L

RVS -AX

T2/V T3/W

T1/U

RVS-AX

T3/W

Moto r FLC

50% 100%

Initial Voltage

10% 50%

Current Limit

100% 40 0%

Ramp-Up

230 Sec.

Ramp-Down

30 Sec.0.2

End of

Acceleration Fault

56 78

S1

Start / Stop

1 2

R1A

End Of

Acceleration

Neutral

Not Used

3

4

Ground

R2A

R1C

765

Fault

R2C

8

Stop / Start ......................................... Terminals 1 - 2

By voltage free contact (Dry contact)

Close: Start command.

Open: Stop command.

Warning

Do not apply voltage to terminals 1 - 2.

Neutral......................................................Terminal 3

Neutral wire (when used) is required only for operation

of the Phase Loss Protection (Phase Loss can not be

detected when Neutral is not connected to Terminal 3).

See detailed description in “Phase Loss” explanation.

Open terminal – not connected ................Terminal 4

End of Acceleration (E.O.A) .......... Terminals 5 - 6

Voltage free, N.O., 8A / 250VAC, 2000VA max.

The contact closes after the time adjusted on the

"Ramp-Up" potentiometer. The contact returns to its

original position on stop signal, on fault condition,

upon voltage outage and at the beginning of Soft Stop.

Use of E.O.A. Contact

This contact can be used for:

• Activating a valve after a compressor has reached

full speed

• Loading a conveyor after the motor has reached

full speed.

Fault contact .................................... Terminals 7 - 8

Voltage free, N.O., 8A / 250VAC, 2000VA max.

The contact closes upon operation of any fault. The

contact returns to its original position (after the fault

has been removed) upon reset, or upon disconnection

the Mains voltage.

Warning

Do not use the Fault contact to trip an upstream

contactor. When the Fault contact trips the

upstream contactor, Mains voltage will be

disconnected, thus resetting the starter and the

motor will restart instantaneously upon voltage

restoration (see Fault Resetting).

Warning

Start/Stop with a maintained contact!

When the line contactor is operated by a

maintained

contact, in case of Mains failure, the

motor will be automatically restarted upon

voltage restoration.

When resetting after a fault with the Reset

button, the motor will restart upon fault reset.

It is therefore recommended not to connect the

fault relay to the line contactor.

5

Starter Settings

Front Panel Layout

°

°

°

°°

50% 100%

°

°

°

°°

10% 50%

°

°°

°°

100% 400%

°

°

°

°°

230 Sec.

°

°

°

°°

0.2 30 Sec.

FLC - Full Load Current (Motor FLC)

The adjustment allows easy setting of the RVS-AX

current level, automatically adjusting current based

functions (Overload, Current Limit, etc).

Set FLC potentiometer according to the following

equation:

FLC ×=

FLC

Where:

Motor FLA is the motor's Full Load Current rating as

shown on its nameplate.

FLC is the starter Full Load Current as shown on its

label.

Example:

When starting a 27A motor using RVS-AX 31:

27

FLC% =×=

31

Therefore set the FLC% to a

reading of 87% (see Ex.)

Initial Voltage

Determines the initial voltage

to the motor (torque is directly

proportional to the square of

the voltage).

Range: 10-50% of nominal

voltage.

This adjustment also

determines the inrush current

and mechanical shock.

Too high of a setting may cause high initial mechanical

shock and high inrush current (even if Current Limit is

set low, as the Initial Voltage setting over-rides the

Current Limit setting).

Too low of a setting may result in prolonged time until

motor starts revolving. The motor should start

revolving immediately

FLC %

Initial Voltage

Current Limi t

Ramp-Up

Ramp-Down

FLAMotor

100

87% 100

50% 100%

after Start signal.

°

°

°

°°

U%

100%

50%

10%

230Sec.

87 %

FLC %

Current Limit

Determines motor's highest

current during starting.

Range is 100-400% of FLC (as

set on starter's FLC adjustment).

I%

600%

400%

Too high of a setting will allow

higher currents to be drawn from

100%

Mains, resulting in faster

acceleration.

Too low of a setting may prevent the motor from

completing the acceleration process and reaching full

speed.

Generally, this setting should be set to the highest

acceptable value in order to prevent stalling.

Caution

Starting Current should not exceed the allowable

conditions as shown in page 3.

Ramp-up Time

Determines motor's voltage rampup time from initial to full

100%

U%

voltage.

Range: 2-30 sec.

It is recommended to set RampUp Time to the minimum

acceptable value (approx. 5 Sec).

230Sec.

Notes:

1. Setting Current Limit low will extend Ramp-Up

Time.

2.

When motor reaches full speed before voltage

reaches nominal, Ramp-Up Time adjustment

is overridden, causing voltage to quickly ramp

up to nominal.

Ramp-Down time (Soft-stop)

Used to control deceleration of

high friction loads. When Ramp-

100%

U%

Down potentiometer is set, upon

stop signal the starter output

voltage is gradually ramped

down.

Range: 0.2-30 sec. When "Ramp-

0.2

30 sec

down Time" is set to minimum, the motor will stop

immediately.

6

Motor Protection

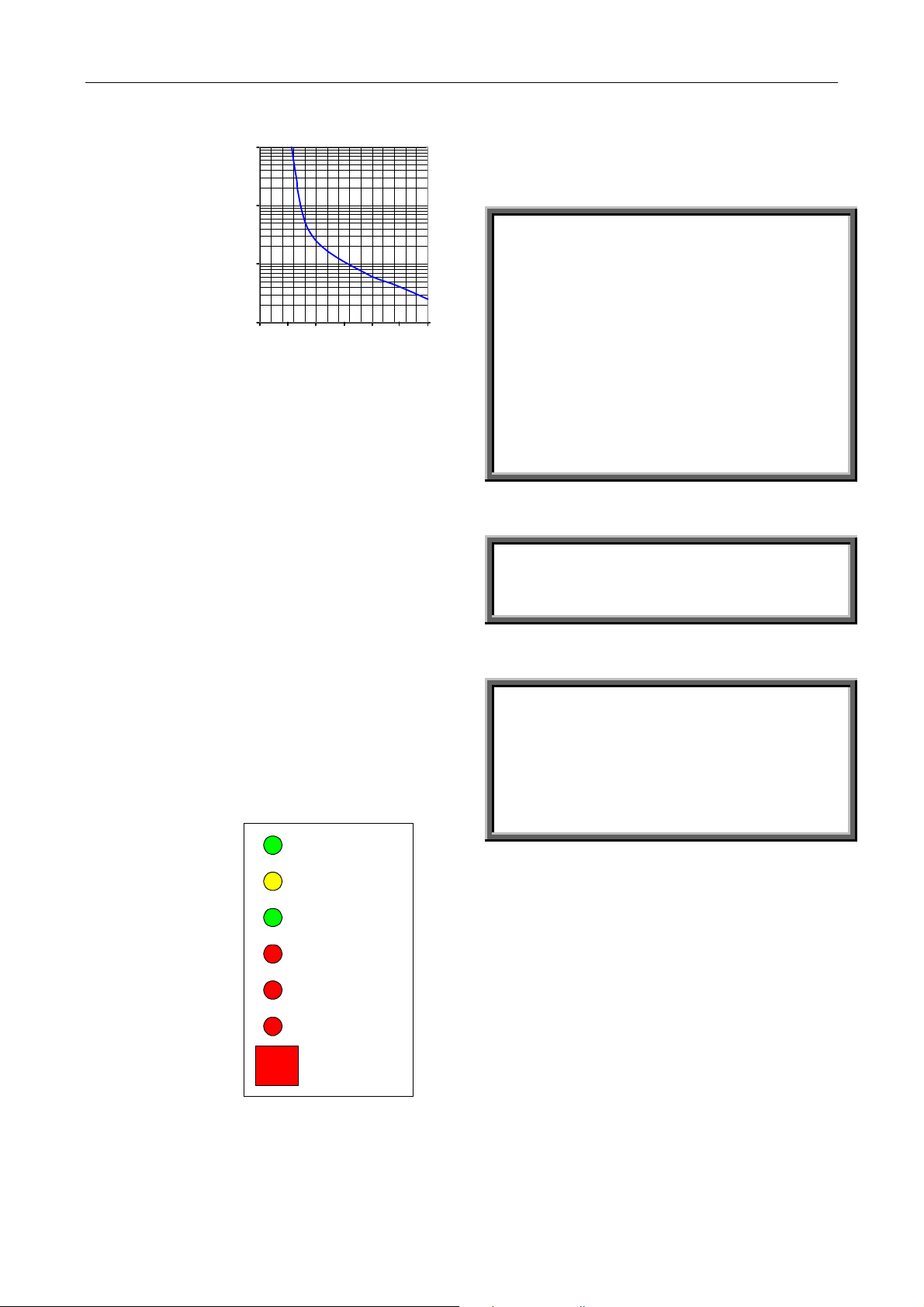

Electronic Overload

The built-in inverse

time electronic

overload becomes

operational after

end of acceleration

process. Trip

current is factory set

to 115% of Motor

Full Load Current

(from the setting on

Motor FLC

potentiometer),

E.g. In order to

increase the O/L trip point; increase FLC setting above

the calculated level. Trip time varies from 60 sec. at

150% of n

c

urrent.

ominal current to 2 sec. at 600% of nominal

Phase Loss

The protection becomes operational when the starter is

energized; it protects the motor from single phasing. It

will trip the starter wh

r more than 1 sec.

fo

When phase loss occurs during starting or when motor

is not loaded, it may happen that motor will st

without acc

urate indication of the Phase Loss LED.

Note: Phase loss protection operates

erminal 3 is connected to Neutral.

T

Fault Logic, Alarm an

Upon operation of

any protection, the

starter locks in a

fault mode,

disabling thyristors

firing. The proper

fault indication

LED lights and the

Fault contact closes.

To reset the starter,

after the fault has

been removed, press

Reset button on

starter's front panel

or discon

oltage.

v

nect Mains

1000

100

Seconds

10

1

024

I(Load)/In

531

en one or two phases are missing

only when

d Reset Circuits

On

Ramp Up / Down

Run

Overload

Phase Loss

Over Temp.

Reset

6

op

Heatsink Over temperature Protection

A thermal sensor mounted on the heatsink trips the

starter when its heatsink temperature rises above 85ºC.

Warning

The Over-temperature Protection is designed to

operate under normal conditions and will operate

incase abnormal conditions occur:

• Incorrect starter selection

• Too frequent starting at max. conditions

Repeated starting under fault conditions

•

Extended low overload

•

Insufficient ventilation

•

Other abnormal conditions

•

Note- In case of frequent starting the internal

thyristors may overheat before the heatsink reaches

its over-temperature protection of 85

causing component malfunction.

ºC, thus

Caution

When starter is operated by a maintained contact,

resetting the fault will start the motor immediately.

Warning

Do not use the Fault contact to trip an upstream

contactor. When the Fault Contact closes on fault

and trips the upstream contactor, Mains voltage

will be disconnected, thus resetting the RVS-AX

and the motor will restart instantaneously (see

Fault Resetting).

7

Startup Procedure

1. Set FLC (Motor Full Load Current) -

according to

2.

Calculation:

3.

Set other potentiometers according to system

requirements (see next column for examples)

4.

Connect Mains voltage to starter Line

terminals.

5.

Start the motor, if it begins revolving shortly

after start signal proceed to Para. 5. If not,

increase Initial Voltage setting until motor

starts to turn shortly after start signal.

When initial inrush current and mechanical

shock are too high, decrease Initial Voltage

setting and proceed to Para 6.

6.

Motor begins to turn. If speed smoothly

accelerates to nominal proceed to Para 6. If

current during acceleration is too high,

slightly decrease Current Limit setting. If

motor speed does not increase to nominal,

increase Current Limit setting.

7.

Disconnect the start command (open

Terminals 1 and 2) and wait until the motor

stops.

8.

Slightly increase Initial Voltage and Current

Limit adjustments to allow for load variations.

9.

Start the motor again and verify that

acceleration process to full speed is as

required.

10.

If acceleration time is too short, increase

Ramp-Up time setting.

When Soft stop is required, set Ramp-Down

Potentiometer to the required time (minimum

deceleration time is recommended).

Check that soft stopping process is as required.

If Ramp Down potentiometer is not in the minimum

setting. Emergency stop may be performed by

disconnecting the mains voltage.

Motor FLA

FLC ×=

Note:

100

LCStarter F

Examples of Starting Curves

Light Loads - Pumps, Etc.

Current limit - set to 300%

Initial Voltage - set to 30%

Ramp-up time - set to 5 sec.

U%

100%

50%

30%

10%

5

600%

400%

300%

100%

t

I%

t

Upon start, the voltage quickly increases to the Initial

Voltage value (30% Un) and then gradually ramps-up

to nominal.

The current will simultaneously increase to peak

current value, which can be the Current Limit setting or

less, before smoothly decreasing to the operating

current. The motor will accelerate to full speed quickly

and smoothly.

High inertia loads – Crushers, Centrifuges, Mixers Etc.

Current Limit - set to 350%

Initial Voltage - set to 50%

Ramp-Up time - set to 5 sec.

100%

50%

10%

U%

20

t

600%

350%

100%

I%

20

t

Upon Start the voltage and current increase until

current reaches Current Limit value. The voltage

remains at this value until motor reaches nominal

speed, where current starts to decrease, voltage

continues to ramp-up to nominal. At this time, the

motor should have smoothly accelerated to full speed.

8

Technical Specification

Environment

Supply voltage Three phase, line to line,

380 – 415 Vac +10% -15%

460 – 500 Vac +10% -15% *

575 – 600 Vac +10% -15%

Frequency 50 / 60 Hz

Load

Three-Phase, Three-Wire, Squirrel Cage

Induction Motor

Degree of protection IP 20

Altitude 1000 m above sea level Consult factory for derating

Adjustments

FLC (Full Load Current) 50% - 100%

Starting Torque (Initial Voltage) 10-50 % of full voltage

Current limit 100 % - 400% of nominal current

Ramp Up Time (soft start) 2 - 30 sec.

Ramp Down Time (Soft Stop) 0.2 - 30 sec.

Protection

Electronic Overload Inverse time (I2t), factory preset at 115% of FLC, active only during Run.

Phase Loss Trips when one phase is missing (When Neutral is connected)

Heatsink Over temperature Trips when the heatsink temperature exceeds 85ºC.

Reset buttons To reset the starter, after the fault has been removed.

Indications

Indication lights (LEDs)

Overload – Red Inverse time electronic overload becomes

Phase loss – Red Lights when one or two phases are missing for

Over temperature – Red Lights on and trips the starter when the heatsink

ON - Green Lights when three phases are connected to the

Ramp Up / Ramp Down – Yellow Lights upon start signal or during soft stopping.

RUN – Green Lights upon end of starting. When the internal

Temperatures

Operating -10° to 40°C

Storage -20° to 70°C

Relative humidity 93 % - non condensed

EMC

Immunity to radio electric interference EN 1000-4-3 level 3 Conforming to EN 60947-4-2

Electrostatic discharge EN 1000-4-2 level 3 Conforming to EN 60947-4-2

Immunity to electrical transients EN 1000-4-4 level 4 Conforming to EN 60947-4-2

Shock waves of voltage / current EN 1000-4-5 level 3 Conforming to EN 60947-4-2

Radiated and conducted emissions EN 1000-4-6 level 3

Radio frequency emissions According to EN 55011 class A Conforming to EN 60947-4-2

Mechanical

Shock resistance 8 gn Conforming to EN 60947-4-2

Vibration resistance 2 gn Conforming to EN 60947-4-2

Output relay

End of Acceleration Contact N.O.

Rated operating current 5 A, 250 V - Size A1

8 A, 250 V – Size A2

* 460 – 500 Vac is applicable for 220 – 240 Vac

by changing the position of the internal jumper –

J3. As shown in page 3.

RVS-AX.

bypass relays close.

operational after the End Of Acceleration process

(see page 7).

more than 1 sec.

temperature rises above 85ºC.

9

Dimensions

\\SOLSRV1\Data\Catalogs and Marketing materials\Instruction Manuals\RVS-AX Instruction Manual 4-5-03.doc

18 Neville Street, Unit C

New Hamburg, ON N3A 4G7

Tel: 519-662-6489

Fax: 1-866-280-5247

www.safdrives.com

www.opalstarters.com

email: answers@opalstarters.com

(Replies given within 24 hours)

Loading...

Loading...