SAF Opal Pro MS6 Series, MS6-30, MS6-80, MS6-125, MS6-250 Installation & Operating Procedures

...Page 1

Installation & Operating Procedures

Opal Pro MS6

Series

SOLID STATE REDUCED VOLTAGE STARTER

FOR 3 PHASE INDUCTION MOTORS

Page 2

Opal Pro MS6 SERIES

SOLID STATE REDUCED VOLTAGE

STARTER

FOR 3 PHASE INDUCTION MOTORS

Revision 1.08 - 01/2011

Page 3

MS6 REDUCED VOLTAGE STARTER

Page 2

Page 4

MS6 REDUCED VOLTAGE STARTER

FOR YOUR SAFETY

Only qualified personnel should install this equipment, after first reading

and understanding all the information in this manual. All instructions should

be strictly adhered to. The user should consult SAF Drives Inc. or a SAF

OPAL Starters supplier for clarification of the contents of this manual should

any doubt or questions arise.

The installation of this equipment must be conducted in accordance with all

national, regional and local electrical codes.

All drawings and technical representations included in this manual are for

typical installations and should not in any way be considered for specific

applications or modifications. Consult SAF OPAL Starters for supplemental

instructions.

SAF Drives Inc. accepts no liability for any consequences resulting from

inappropriate, negligent or incorrect installation, application or adjustment of

this equipment.

The contents of this manual are believed to be correct at the time of

printing. In following with our commitment to the ongoing development and

improvement of our products SAF OPAL Starters reserves the right to

change the specification of this product and/or the content of this instruction

manual without notice.

Page 3

Page 5

MS6 REDUCED VOLTAGE STARTER

Page 4

Page 6

MS6 REDUCED VOLTAGE STARTER

TABLE OF CONTENTS

1 MS6 GENERAL DESCRIPTION................................................................................................. 7

1.1 OVERVIEW................................................................................................................................................................7

1.1.1 STANDARD FEATURES ...................................................................................................................................7

1.1.2 OPTIONAL FEATURES....................................................................................................................................8

1.2 APPLICATION NOTES ............................................................................................................................................8

1.2.1 OPERATION MODES........................................................................................................................................ 8

1.2.2 CHOOSING STARTING MODE.......................................................................................................................8

1.2.3 MOTOR AND LOAD TYPES............................................................................................................................9

1.2.4 STARTING AC MOTORS IN PARALLEL .....................................................................................................9

2 SPECIFICATIONS ......................................................................................................................10

2.1 POWER RATING.....................................................................................................................................................10

2.2 MAXIMUM RATINGS............................................................................................................ ................................10

2.3 SERVICE CONDITIONS ........................................................................................................................................10

2.4 FUSE SIZING............................................................................................................................................................11

2.5 DIMENSIONS...........................................................................................................................................................12

2.5.1 STANDARD UNIT.............................................................................................................................................12

2.5.2 REVERSING UNIT (OR STANDARD UNIT WITH DC INJECTION).....................................................12

3 TERMINALS................................................................................................................................ 13

4 KEY PAD OPERATION.............................................................................................................15

5 INSTALLATION AND START-UP........................................................................................... 16

5.1 INSPECTION............................................................................................................................................................16

5.2 SAFETY PRECAUTIONS.......................................................................................................................................16

5.3 MOUNTING GUIDELINES....................................................................................................................................16

5.4 WIRING GUIDELINES...........................................................................................................................................17

5.5 START-UP.................................................................................................................................................................18

5.5.1 BEFORE POWER-UP.......................................................................................................................................18

5.5.2 WITH POWER ON ...........................................................................................................................................18

6 FAULTS......................................................................................................................................... 19

FAULT (DISPLAY)....................................................................................................................................................19

Page 5

Page 7

MS6 REDUCED VOLTAGE STARTER

7 FEATURES................................................................................................................................... 20

7.1 SOFT STOP...............................................................................................................................................................20

7.2 SCR BY-PASS...........................................................................................................................................................20

7.3 SHEAR PIN PROTECTION ...................................................................................................................................20

7.4 SLOW SPEED FWD/REV (JOG) ...........................................................................................................................20

7.5 SHORTED SCR DETECTION ...............................................................................................................................21

7.6 SOLID STATE FULL SPEED REVERSING........................................................................................................21

7.7 DC INJECTION BRAKING....................................................................................................................................22

8 PARAMETERS ............................................................................................................................ 23

9 SPARES......................................................................................................................................... 28

9.1 SPARE PARTS..........................................................................................................................................................28

9.2 SCR INSTALLATION PROCEDURE...................................................................................................................28

10 CONNECTION DRAWINGS ................................................................................................... 29

10.1 TWO WIRE CONTROL.......................................................................................................................................29

10.3 THREE WIRE REVERSING...............................................................................................................................31

10.4 THREE WIRE WITH BY-PASS..........................................................................................................................32

10.5 THREE WIRE CONTROL WITH SHORTED SCR DETECTION................................................................33

10.6 DCI FOR 80 AMP UNITS AND BELOW...........................................................................................................34

10.7 DCI FOR 125 AMP UNITS AND ABOVE..........................................................................................................35

10.8 INTEGRATED BY-PASS .....................................................................................................................................36

Page 6

Page 8

MS6 REDUCED VOLTAGE STARTER

1 MS6 GENERAL DESCRIPTION

1.1 OVERVIEW

The Opal Pro series is a processor controlled line of solid state reduced voltage starters for use

with 3 phase induction motors. This series also includes various communication options,

which can be easily added to connect to standard industrial networks.

A solid state starter provides a step-less, smooth current ramp to the motor. This characteristic

eliminates current surges and mechanical torque transients. Since these units are solid state, we

now eliminate the maintenance of moving contacts, which are involved in almost any other

method of starting an AC induction motor.

1.1.1 STANDARD FEATURES

• 200 – 600 VAC 3 phase universal voltage, 50/60Hz with no adjustment

• Single control card through out Opal Pro range

• Current regulated closed loop

• Dual operation modes to match any application:

Constant Current mode for light loads or limited power supplies

Current Ramp mode for high inertia or heavy loads

• Soft stop

• Jog Speed:

14% of full speed forward

20% of full speed reverse

• Two or three wire control

• 120 VAC control inputs for:

Start

Stop

Jog

Reverse

Reset

Enable

• Keypad and LCD display for starter setup and diagnostics

• Single phase protection

• Phase rotation insensitive

• Instantaneous over-current trip

• Class 10, 15, 20, or 30 electronic motor overload

• Shorted SCR Fault output

• Shear pin Fault

• Dry contact relay outputs for:

Fault

By-pass

Shorted SCR

Running

Reverse

Page 7

Page 9

MS6 REDUCED VOLTAGE STARTER

1.1.2 OPTIONAL FEATURES

• By-Pass Contactor

Once the motor has reached operational speed, the by-pass contactor is closed. This

shorts the SCR’s which eliminates the voltage drop across the SCR’s, in turn being more

efficient and ridding excess heat.

• Solid State Full Speed Reversing

Through the addition of 4 SCR’s and a reversing card, smooth motor reversing is

achieved without having to stop the motor.

• DC Injection Braking

Through the addition of SCR’s and a DC injection card, adjustable electric braking of the

AC motor is performed.

• Various communication options, which will allow connection to standard industrial

networks

• NEMA 4 or NEMA 12 enclosures

1.2 APPLICATION NOTES

1.2.1 OPERATION MODES

With any induction motor the design is such that starting currents and torques are very high.

Across the line starting for a basic NEMA B design motor creates an in-rush current of 600%

or more of the nameplate rating. Often these levels are so high that they cause problems with

mechanical or auxiliary electrical. An example of this is the high starting torques which cause

belt slip and high currents, creating large voltage dips. The basis of choosing the correct

starting mode is determining the problem to be solved.

1.2.2 CHOOSING STARTING MODE

Constant Current Mode

Soft Starting for light loads or reducing starting current are accomplished by using the Constant

Current Mode.

On some applications the starting time is still too fast in the current ramp mode because the

load is too light. In this application it is best to select the constant current mode which will

allow the acceleration torque to be better controlled, actually kept constant.

If the available current is limited and causes significant voltage drops, the constant current

mode will allow flexibility in setting the current draw. Remember that the current level must be

great enough to provide acceleration torque and this level is determined by the load.

For all other applications, or if in doubt, select the Current Ramp Mode.

Current Ramp Mode

Torque Reduction on heavy loads is accomplished by using the Current Ramp Mode.

The idea is to reduce starting current to just above the level, which will produce enough torque

to get the motor to move. This is commonly referred to as "break-away torque". As the current

ramps up from this point, the torque also increases as time passes. If at the initiation of start,

the motor torque is less than the load, the motor will remain stalled until the torque ramps to a

sufficient level for acceleration.

Page 8

Page 10

MS6 REDUCED VOLTAGE STARTER

1.2.3 MOTOR AND LOAD TYPES

Squirrel Cage Motors

Squirrel cage motors, with a single winding and of any NEMA design may be connected to the

Opal Pro starter.

Wound Rotor Motors

Wound Rotor Induction Motors (WRIM) and solid state starters make an excellent combination

for frequent starting, jogging, plug-stopping and reversing applications. These WRIM motors

use multiple steps of resistors to provide various speed torque characteristics. This allows a

high starting torque characteristic while providing low starting current when compared to

NEMA B designs.

One disadvantage has been the high maintenance costs of the resistor and shorting contactor

bank. The use of an Opal Pro allows an improvement to this arrangement by allowing the

current to be limited without use of the multiple steps. Usually the load characteristic is such

that this starting may be accomplished with only one or two starting steps. By eliminating

several contactors a major savings is realized that often pays for the installation cost.

The common method is to add only one step of resistance at 20% (Rotor volts divided by Rotor

Amps times 20%). This resistance value will provide relatively high starting torque and the

Opal Pro will be used to limit the current. As little as 200% of motor full load current can

provide 100% starting torque unlike squirrel cage NEMA B motors which would require 500%

current. The resistor bank may be shorted with a contactor at full speed to reduce the slip and

eliminate the watt losses in the resistors.

Other Types of AC Motors

Opal Pro starters may also be used to start 2-speed motors with multiple windings or

connections. Proper contactor selection and sequencing is required for the specific motor.

Resistive and Inductive Loads

The Opal Pro MS6 is well suited for use as a phase controller or current regulator on resistive

or inductive loads such as heaters. When applied with a Temperature PI controller, the Opal

Pro MS6 will maintain smooth control to avoid the overheating associated with on/off type

controllers. Improved temperature accuracy and longer heater element life can be expected

over standard control methods.

1.2.4 STARTING AC MOTORS IN PARALLEL

Opal Pro MS6 starters can be used to start motors in parallel but they must have individual

overload devices added.

When the paralleled motors are also connected to the same load, mechanically or through the

material, then load sharing must be considered.

When the motors are mechanically tied, the load sharing is determined by how closely the

motor characteristics are to each other. It is important to keep the motors exactly the same.

Even changing the manufacturers of the motors can cause some variations in load sharing. The

Opal Pro size is determined by the total of the motor current ratings.

Page 9

Page 11

MS6 REDUCED VOLTAGE STARTER

2 SPECIFICATIONS

2.1 POWER RATING

Power 3 phase, 200-600 VAC, 50/60Hz

Control 115VAC 50Hz or 120VAC 60Hz

Rating See Section 2.2

All models have 1600V PIV SCR’s

Digital Inputs 120VAC, 2mA

Digital Outputs Relay contacts rated at 0.2A, 120VAC

By-Pass Output Relay contact rated at 5A, 120VAC

Analog Input 0 – 10Vdc

Analog Output 0 – 5Vdc, 5mA max

Protection Short circuit by HRC fuses or circuit breaker (supplied upon request)

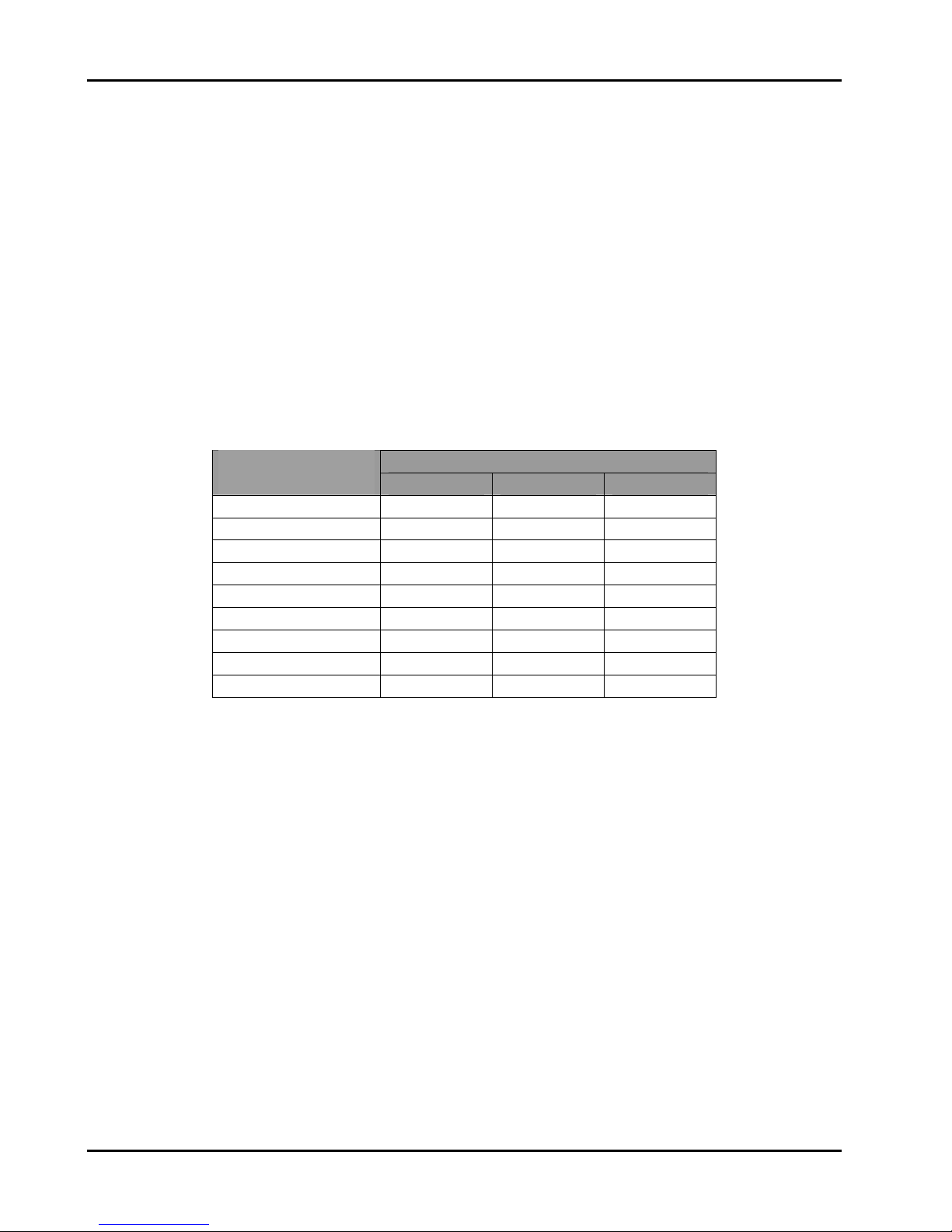

2.2 MAXIMUM RATINGS

HORSE POWER OPAL PRO

MODEL

MS6-30 10 25 30

MS6-50 20 40 50

MS6-80 30 60 75

MS6-125 40 100 125

MS6-250 100 200 250

MS6-420 175 350 420

MS6-500 200 400 500

MS6-600 200 500 600

MS6-800 300 600 800

* HP Rating for estimate only. Size by motor FLA

230VAC 460VAC 575VAC

2.3 SERVICE CONDITIONS

Elevation For altitudes in excess of 1000 meters (3300 feet) above sea level, all

assemblies must be de-rated 1% for every 100 meters (330 feet) above

Ambient Temperature Do not install in areas where the ambient temperature falls below

0°C(32°F) or exceeds 40°C(104°F)

Page 10

Page 12

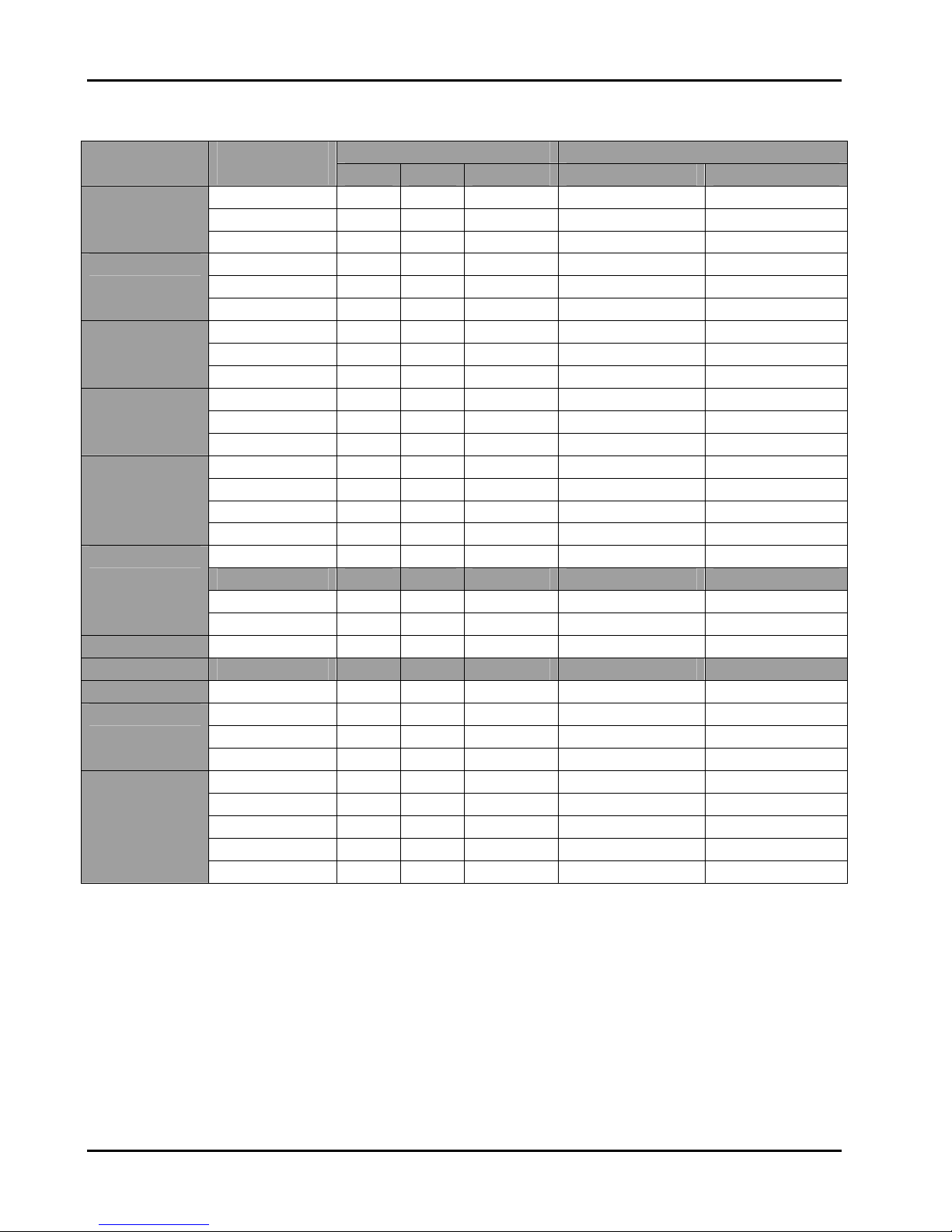

2.4 FUSE SIZING

MS6 REDUCED VOLTAGE STARTER

MODEL

MS6-30

MS6-50

MS6-80

MS6-125

MS6-250

MS6-420

MS6-500

MS6-600

MS6-800

MS6-1000

MOTOR

FLC

240V 460V 575V FAST ACTING TIME DELAY

HP J FUSE AMPS OPAL PRO

20 --- 15 20 50 30

25 10 20 25 60 40

30 --- 25 30 70 50

37 15 --- --- 70 50

40 --- 30 40 80 60

50 20 40 50 100 80

60 25 --- 60 125 90

65 --- 50 --- 150 100

75 30 60 75 150 125

90 --- 75 --- 200 150

100 40 --- 100 200 150

125 50 100 125 250 200

150 60 125 150 300 225

180 75 150 --- 400 250

200 --- --- 200 400 300

250 100 200 250 500 350

300 125 250 300 600 450

L FUSE AMPS

360 150 300 --- 600 500

400 --- --- 400 600 600

500 200 400 500 800 600

L FUSE AMPS

600 250 500 600 900 800

700 300 --- 700 1000 1000

720 --- 600 --- 1100 1000

800 --- --- 800 1200 1200

840 --- 700 --- 1400 1200

850 350 --- --- 1400 1200

900 --- --- 900 1500 1200

960 --- 800 --- 1500 1600

1000 --- --- 1000 1600 1600

Page 11

Page 13

MS6 REDUCED VOLTAGE STARTER

2.5 DIMENSIONS

2.5.1 STANDARD UNIT

DIMENSIONS MODEL

HEIGHT WIDTH DEPTH WEIGHT

MS6-30-N1 43.2cm(17”) 30.5cm(12”) 26.75cm(10.5”) 13.6kg(30 lbs.)

MS6-50-N1 43.2cm(17”) 30.5cm(12”) 26.75cm(10.5”) 13.6kg(30 lbs.)

MS6-80-N1 43.2cm(17”) 30.5cm(12”) 26.75cm(10.5”) 13.6kg(30 lbs.)

MS6-125-CH 38cm(15”) 38cm(15”) 29.25cm(11.5”) 18.2kg(40 lbs.)

MS6-250-CH 38cm(15”) 38cm(15”) 29.25cm(11.5”) 18.2kg(40 lbs.)

MS6-420-CH 49.5cm(19.5”) 38cm(15”) 29.25cm(11.5”) 22.6kg(50 lbs.)

MS6-500-CH 49.5cm(19.5”) 45.75cm(18”) 33cm(13”) 42.2kg(93 lbs.)

MS6-600-CH 49.5cm(19.5”) 45.75cm(18”) 33cm(13”) 42.2kg(93 lbs.)

MS6-800-CH 68.6cm(27”) 61cm(24”) 38.1cm(15”) 56.7kg(125 lbs.)

MS6-1000-CH 68.6cm(27”) 61cm(24”) 38.1cm(15”) 56.7kg(125 lbs.)

2.5.2 REVERSING UNIT (or STANDARD UNIT WITH DC INJECTION)

DIMENSIONS MODEL

HEIGHT WIDTH DEPTH WEIGHT

MS6R-30-N1 43.2cm(17”) 30.5cm(12”) 26.75cm(10.5”) 13.6kg(30 lbs.)

MS6R-50-N1 43.2cm(17”) 30.5cm(12”) 26.75cm(10.5”) 13.6kg(30 lbs.)

MS6R-80-N1 43.2cm(17”) 30.5cm(12”) 26.75cm(10.5”) 13.6kg(30 lbs.)

MS6R-125-CH 62cm(24.5”) 38cm(15”) 29.25cm(11.5”) 27kg(60 lbs.)

MS6R-250-CH 62cm(24.5”) 38cm(15”) 29.25cm(11.5”) 27kg(60 lbs.)

MS6R-420-CH 83cm(32.5”) 38cm(15”) 29.25cm(11.5”) 34kg(75 lbs.)

MS6R-500-CH 83cm(32.5”) 45.75cm(18”) 33cm(13”) 63kg(140 lbs.)

MS6R-600-CH 83cm(32.5”) 45.75cm(18”) 33cm(13”) 63kg(140 lbs.)

MS6R-800-CH 113cm(44.5”) 61cm(24”) 38.1cm(15”) 85kg(188 lbs.)

MS6R-1000-CH 113cm(44.5”) 61cm(24”) 38.1cm(15”) 85kg(188 lbs.)

Page 12

Page 14

MS6 REDUCED VOLTAGE STARTER

3 TERMINALS

CONTROL POWER INPUT

1

Control Power Line 1 (120VAC ± 10%)

2 Control Power Neutral

120VAC INPUT LOGIC

3 Start Input – 120VAC Momentary normally open switch for 3

4 Stop Input(three wire control) / DCI or

Soft Stop Enable(two wire control) 120VAC

5 Jog Input – 120VAC Maintained normally open switch used

6 Reverse Input – 120VAC Maintained normally open switch used

7 Reset Input – 120VAC Momentary normally open switch use to

8 Enable Input – 120VAC Maintained normally open switch used

9 Input Neutral Neutral for 120VAC control signals

Power for the control card and also for

the cooling fans on units below 500A

wire control. Maintained normally open

switch for 2 wire control

Momentary normally closed switch for 3

wire control. Maintained normally open

switch used to enable or disable a

selected stop mode in 2 wire control.

to activate jog function

to activate reverse function (if installed).

If activated along with JOG the unit will

run in reverse jog mode

reset a fault

to enable unit operation. Unit will not

run if this input is not active. If opened

while running the unit will coast to a

stop no matter what stopping method is

choosen. If this input is active and all 3

incoming phases are valid a green

indicator will be illuminated on the

keypad.

Page 13

Page 15

MS6 REDUCED VOLTAGE STARTER

DRY CONTACT RELAY OUTPUTS

10 Fault Relay Common

11 Fault Relay N.C.

12 Fault Relay N.O.

13 Bypass Relay Common

14 Bypass Relay N.O.

15 Shorted SCR Relay Common

16 Shorted SCR Relay N.C.

17 Shorted SCR Relay N.O.

18 Run Relay Common

19 Run Relay N.O.

20 Reverse Relay Common

21 Reverse Relay N.O.

ANALOG I/O (not isolated)

22 Analog Input ( 0 to 10VDC)

23 Analog Common

24 Analog Output (0 to 5VDC, max 5mA)

25 Analog Common

The fault relay is energized in a NO

Fault condition. In a fault condition or

a case of power loss the relay will deenergize and the contacts will go to

there normal condition indicating a

fault.

This relay is used to control a by-pass

contactor either directly or indirectly if

the coil current of the by-pass contactor

is to large (>5amps). This relay will

energize once the Opal Pro has phased

full on and the motor current has

dropped below 110% of the nameplate

current.

This relay is energized when a shorted

SCR is detected and should be used to

trip a shunt trip breaker.

This relay is energized when the unit is

running

This relay is energized when the unit is

running is the reverse mode

Page 14

Page 16

MS6 REDUCED VOLTAGE STARTER

4 KEY PAD OPERATION

Actual Mode This is the mode that the unit will be in on power up. If the u nit is healthy the actual

motor current will be displayed in Amps. If the unit is faulted the fault will be

displayed in text format. If the unit is faulted and the user enters any of the other

display modes the unit will automatically return to this mode and display the fault

every 15 seconds. If the “MENU” key is pressed in this mode the user will enter the

Group mode. If you are in the Group Mode you can return to the Actual Mode by

pressing the “MENU” key.

Group Mode This mode allows the user to scroll through the different parameter groups using the

up and down arrow keys. This mode can be accessed from either the Actual Mode

or Parameter Mode by pressing the “MENU” key. If the “ENTER” key is pressed in

this mode you will enter the Parameter mode and be able to view the parameters of

the current group that is being displayed.

Parameter Mode This mode allows the user to view and modify the individual parameters in a

particular group. The parameters can be scrolled through using the up and down

arrow keys. If a parameter is to be modified the “ENTER” key must be pressed and

the parameter value will now blink. At this point it is possible to chang e the

parameter setting using the up and down arrow keys. When the desired setting is

reached the “ENTER” key should be pressed again and the blinking of the parameter

will now stop and the new parameter setting will be saved. To return to the Group

mode the “MENU” key should be pressed.

Reset Key This key will reset any fault as long as the fault has no longer exists.

Local/Remote Key This key switches the unit between local and remote control. Local or Remote mode

is displayed via LED. In local the unit can be started from the keypad. In local

mode the start and stop commands from the terminal strip or communication module

are ignored. In Remote mode, the terminal strip becomes active.

Start Stop Key

Red LED This LED will be illuminated during a fault condition or during initial power-up

Green LED This LED will be illuminated when the starter is ready to be started. This includes

This key is used to start and stop the motor in local mode. You still need the En able

signal at the terminal strip.

the ENABLE signal being active and also having valid three phase power.

Page 15

Page 17

MS6 REDUCED VOLTAGE STARTER

5 INSTALLATION AND START-UP

5.1 INSPECTION

• The Opal Pro has been packaged to protect it from damage caused by normal handling

during shipment, however mishandling may cause damage to the Opal Pro. Unpack the unit

as soon as it is received and check for any shipping or storage damages.

• If damage is found, notify the carrier. Any damage claim must be filed by the customer

since all shipments are F.O.B. Manufacturers plant unless otherwise specified.

• If the Opal Pro is not installed when received, store it in a clean, dry, well ventilated area,

free from heat, humidity, oil, dust, and metal particles.

5.2 SAFETY PRECAUTIONS

CAUTION

Equipment is at line voltage when AC power is connected.

Pressing "STOP" pushbutton does not remove AC mains potential.

All phases must be disconnected before it is safe to work on machinery, touch motor terminals or

control equipment parts.

• The electrical code requires all equipment, starter, motor, operator station, etc. to be

grounded properly.

• An incoming circuit breaker or disconnect switch must be locked open before wiring or

servicing this starter, motor, or other related equipment. This equipment must be installed

and serviced only by qualified personnel, familiar with this starter.

• The user is responsible for ensuring that proper short circuit protection is provided by either

a circuit breaker or HRC fuses.

5.3 MOUNTING GUIDELINES

• Standard Nema 1 Opal Pro Starters must be installed indoors in a well ventilated area, free

from heat, humidity, oil, dust and metal particles.

• One foot of clearance must be kept all around in a natural cooled unit. The equipment must

be mounted away from any heat source. See Section 2 for additional specifications.

• Be aware that the heatsink may reach 70° C / 158°F during normal operation. Do not

install the starter in contact with any material that cannot accept this temperature.

• The starter must be mounted vertically and where it will not experience excessive shock or

vibration.

Page 16

Page 18

MS6 REDUCED VOLTAGE STARTER

5.4 WIRING GUIDELINES

• The electrical code requires that an approved circuit disconnecting device be installed in the

incoming AC supply circuit. Mounted in a location readily accessible to personnel

installing or servicing this equipment.

• Power factor correcting capacitors MUST NOT be connected to the OPAL output. If

desired, they may be added ahead of the starter. Capacitors can be connected before

starting or after the motor has reached full speed.

• In-line contactors are not required; however they can be used on the line side or the motor

side without detriment to the starter. It is recommended that the contactor be sequenced to

open and close under no-load conditions to prolong the life of the contacts.

• Size the power wiring as per local code. On long wire runs it is recommended to use a

larger wire size.

• All three phases of the incoming power wires must pass through the same hole in the

enclosure. This rule also applies to all phases of the outgoing or motor wires.

• If an electro-mechanical brake is used in the system, it must be powered from the line side

of the starter, to ensure full voltage to the brake.

Page 17

Page 19

MS6 REDUCED VOLTAGE STARTER

5.5 START-UP

5.5.1 BEFORE POWER-UP

• Ensure that all electrical connections are completed as shown on the schematics, and that

connections are properly tightened. Including a solid ground connection.

5.5.2 WITH POWER ON

• Check 120VAC control voltage to terminals 1 & 2 of the Opal Pro

• Set parameter 1001 to the control scheme desired

• Set parameter 1002 to the ramp time desired (set to 0 for constant current mode)

• Set parameter 1003 to step current required (set to required current for constant current

mode)

• Set group 11 parameters for desired stopping method and setup

• Set parameter 1301 to motor full load current as read from the motor nameplate

• Set parameter 1302 to the motor nameplate voltage

• Set parameter 1303 to the motor nameplate service factor

• Set group 14 parameters if a communication module is installed on the Opal Pro

• Set group 15 parameters for the desired fault conditions

• Check for the red LED on the keypad to be NOT illuminated (if it is illuminated there is a

fault which will be shown on the LCD display of the keypad)

• Check for the green LED on the keypad to be illuminated (if it is not, the ENABLE signal

(terminal 8) is missing or there is a problem with the incoming 3 phase power)

• Once start has been initiated the motor must start rotating immediately, it must not stall. If

it does not rotate immediately the step current (parameter 1003) must be increased

• Parameter 1002 can be adjusted to extend or decrease the acceleration time. The actual

motor accelerating time depends on the motor current as well as the mechanical load. The

acceleration time entered is the amount of time it will take for the current to increase from

the step setting to 500% of the nameplate current

Page 18

Page 20

6 FAULTS

Fault (display) Description

IOC Instantaneous Over Current

MTR OVRLD Motor Thermal Overload (calculated)

PHASE LOSS Incoming Phase Loss

SHEAR PIN Excessive Motor Current While Running

SHORTED SCR Shorted SCR Fault

HEAT SINK OT Heat Sink Over Temperature

COMM FLT Communication Fault

POWERING UP Power Up Sequence

MS6 REDUCED VOLTAGE STARTER

- Current has reached a value of 1000% of stack size

- Usually a short circuit on the output or misfiring of SCR’s

- This fault cannot be disabled

- motor has been drawing over 100% of motor nameplate current

for a specified amount of time based on the class of overload

selected in group 15 parameter 2

- after this fault has occurred the Opal Pro will not allow a reset

for approx. 6 minutes (this is to allow the motor to cool down)

- this fault can be disabled in group 15 parameter 2

- one of the incoming phases is missing or abnormally low

- phase voltages can be read in group 1 parameters 2, 3, and 4

- this fault will not be triggered until the motor is commanded to

start

- this fault cannot be disabled

- if the Opal Pro is phased fully on and the motor is up to speed

this fault will be triggered if the current goes above 300%

- this fault can be disabled in group 15 parameter 1

- this fault will not be triggered until the motor is commanded to

start

- this fault cannot be disabled

- One of three temperature switches mounted on the heat sink has

been triggered

- These switches trigger at approx. 85 degrees Celsius

- The switches are only mounted on units which include fans

- This fault cannot be disabled

- a loss of communication between the Opal Pro and the master

device has been detected based on a watch dog bit that is sent

back an forth

- this fault is disabled when no communication cards are installed

on the Opal Pro

- this fault can also be disabled in group 15 parameter 3

- the time delay for the watch dog bit can be set in group 15

parameter 4

- the Opal Pro will be faulted for the first 6 seconds after the

120VAC control power is applied

- this allows time for everything to initialize and then a fault reset

is automatically applied at the end of the 6 seconds

Page 19

Page 21

MS6 REDUCED VOLTAGE STARTER

7 FEATURES

7.1 SOFT STOP

• This provides a controlled stopping method to eliminate the water hammering effect

associated with fluid pumping applications.

• The Opal Pro operates in the opposite fashion of starting. When stop is initiated the Opal

Pro output voltage is reduced to the point set by parameter 1102 and then ramps down

based on a rate set in parameter 1103. The Opal Pro will remain on for the amount of time

set in parameter 1103. If two wire control is used then terminal 4 is a soft stop enable input

and when de-activated will turn the Opal Pro off during a soft stop.

7.2 SCR BY-PASS

• A three pole contactor used in conjunction with the by-pass contact eliminates the SCR

losses by shorting them out after the motor has reached full speed. This feature is a true

Watt Saver modification and permits the use of the Opal Pro in a NEMA 4 or NEMA 12

enclosure. The by-pass contactor is switched on only after the motor has reached full

speed and as such sees only motor full load current. At stop, the by-pass contactor is

opened while the SCR's are triggered fully on, limiting the power contacts opening voltage.

The SCR's are then switched off without having any voltage surge.

• When a by-pass contactor is used in conjunction with reversing, the REV contact must be

used to drive a slave relay that inter-locks the two by-pass contactors to ensure proper

sequencing of the contactors.

• This option requires by-pass lugs which are an add on option to the standard Opal Pro

7.3 SHEAR PIN PROTECTION

• This feature has been designed to provide motor jam protection, similar to a mechanical

shear pin.

• Once the motor has reached full speed, the MicroOpal will trip if the motor current

increases to 300%. Parameter 1501 enables or disables this feature.

7.4 SLOW SPEED FWD/REV (JOG)

• This provides the ability to run an AC motor at 14% speed in the forward direction or 20%

in the reverse direction without any added SCR’s.

• To jog in the forward direction the jog input (terminal 5) must be activated

• To jog in the reverse direction the jog input (terminal 5) and the rev input (terminal 6) must

be activated.

• Current draw is abnormally high during jog mode therefore it must only be used for very

short amount of time to avoid overload trips and excessive motor heating.

Page 20

Page 22

MS6 REDUCED VOLTAGE STARTER

7.5 SHORTED SCR DETECTION

• This option provides protection against the unlikely event of a shorted Silicon Controlled

Rectifier (SCR).

• The state of the SCR’s are checked every time a start or jog command is initiated. An SCR

that shorts while the Opal Pro is running will not be identified until the next time the Opal

Pro attempts to start or jog.

• This fault should be used in conjunction with a shunt trip circuit breaker or an in-line

contactor.

• In the event of a shorted SCR, it is not sufficient to merely trip the starter. The incoming 3

phase power must be removed. The danger associated with a shorted SCR is that even when

the starter is not running, current may pass freely through the motor.

• If a shorted SCR is detected, the Shorted SCR relay is energized. The form C relay

contacts on terminals 15, 16 and 17, are provided for means of opening the circuit breaker

or contactor used.

• When a shorted SCR fault occurs you will have to use an ohm meter to find out which SCR

is shorted. This can be done by turning all the power off and using an ohm meter to

measure the resistance between L1 and T1. The resistance should be greater than

10Kohms. If it is a short either SCR 1 or 2 is bad. Repeat this for L2 and T2, which will

check SCR’s 3 and 4. Then finally check L3 and T3, which will check SCR’s 5 and 6.

7.6 SOLID STATE FULL SPEED REVERSING

• This option provides a smooth, current controlled, motor rotation reversal without any

current surge or torque jerk. Motor stopping is not required. Additions to the Opal Pro

include a reversing card, CA531, plus four additional SCR's.

• With the reverse input (terminal 6) enabled the starter will fire the reverse bridge.

• Terminals 20 and 21 dry contact used to indicate the direction selected and by-pass

contactor sequencing for a reverse/by-pass combination.

• When the motor is running and the forward/reverse switch changes states, the Mirco Opal

turns all SCR's off. After a time delay, the Opal Pro is switched back on, triggering a

different set of SCR's. This effectively switches two output lines, decelerates the motor

down to zero speed, and continues to accelerate it to full speed in the opposite direction.

The motor reversal is performed under complete current control via the RAMP (parameter

1002) and STEP (parameter 1003) settings.

• If a CA531 card is not present on the Opal Pro the reverse command will be ignored for

normal running but will still be active for jog reversing.

Page 21

Page 23

MS6 REDUCED VOLTAGE STARTER

7.7 DC INJECTION BRAKING

• DC injection braking provides smooth braking for AC induction motors.

• DC injection offers adjustable braking because it is current controlled.

• Unlike a mechanical brake, an electrical brake will never wear out.

• The brake operates by injecting DC current in two phases of the motor to rapidly decelerate

it to zero speed.

• When stop is commanded the Opal Pro shuts off for 2 seconds to allow the voltage across

the motor to drop. The DC injection current is then applied at a level set in parameter 1104

for the amount of time set in parameter 1105. It does not provide zero speed sensing,

although if two wire control is used terminal 4 can be used to disable the DC injection

(activated = enabled).

• If braking is released before the motor stops, the motor will coast to rest. If the braking

remains on after the motor stops, the DC supply will provide a holding brake.

Page 22

Page 24

MS6 REDUCED VOLTAGE STARTER

8 PARAMETERS

GROUP

1 Actual Values

101 Current of the motor in Amps Read Only

102 Line 1 to line 2 volts Read Only

103 Line 1 to line 3 volts Read Only

104 Line 2 to line 3 volts Read Only

105 DI1-DI5 Status right most bit: Start

106 Analog input 1 value Read Only

107 Relay Status right most bit: Run relay

108 Analog output 1 value Read Only

2 Version Info

201 Stack size in Amps Read Only

202 Communication Module Type Read Only

203 Firmware version Read Only

PARAMETER DESCRIPTION RANGE ACCESS

Read Only

Stop

Jog

Reverse

Reset

Read Only

By-Pass relay

Shorted SCR relay

Reverse relay

Fault relay

Page 23

Page 25

MS6 REDUCED VOLTAGE STARTER

10 Start Control

1001 Start \ Stop control

- 2 wire means that you have a single maintained start

contact

- 3 wire means that you have a momentary normally open

start contact and a momentary normally closed stop

contact

- Comm module means the start command will come from

an external device through the communication module

installed

1002 Ramp

- this is the time that it will take for the current reference to

increase from the Step value (parameter 1003) to 500%

of the motor name plate current (entered in parameter

1301)

- a setting of “0 seconds” will cause the Opal to operate in

constant current mode, this means the current reference

will be set at the Step value (parameter 1003) and will not

change

1003 Step Current

- this is the amount of current (in percent of motor

nameplate current entered in parameter 1301) that will

initially be applied to the motor before the current

reference begins to ramp up to 500%

- this value is usually set as low as possible but still high

enough so that the motor begins to rotate and soon and

the start command is applied

- if the Ramp time is set to 0 (parameter 1002) then this is

the value of current (in percent of motor nameplate

current entered in parameter 1301) that the Opal will be

limited to constantly

1004 IREF (Current Reference)

- Internal means the current reference is generated

internally from the ramp and step parameters

- Analog In means that the current reference will b e tak en

from the analog input (0 to 10Vdc = to 0 to 500% of

nameplate current)

- Comm module means the current reference will be taken

from the communication link (0 to 1000 = 0 to 500% of

nameplate current)

1005 Phase Angle

- Internal means the phase angle reference is generated

internally from the current loop

- Analog In means that the phase angle reference will be

taken from the analog input (0 to 10Vdc = to min to max

phase angle)

- Comm module means the phase angle reference will be

taken from the communication link (0 to 1000 = min to

max phase angle)

- Note that when using a phase angle reference from the

analog input or communication link the Opal Pro makes

no attempt to limit current

2-Wire

3-Wire

Comm Module

0 – 60 seconds Read\Write

20% - 400% Read\Write

Internal

Analog In

Comm Module

Internal

Analog In

Comm Module

Read\Write

Read\Write

Read\Write

Page 24

Page 26

MS6 REDUCED VOLTAGE STARTER

1006 Jog Accelerating Current Limit

- This is the current limit that will be used when in the jog

mode

- When jog is initiated the current will ramp up to this

value in 1 second and remain here for the amount of time

specified in parameter 1008.

1007 Jog Current Limit

- This is the current limit that will be used in jog mode after

the acceleration time has elapsed

1008 Jog Ramp

- This is the amount of time that the starter will regulate the

accelerating current set in parameter 1006 in jog mode

before dropping to the current limit set in parameter

1007

-a value of zero will cause the starter to go directly to

regulating the current set in parameter 1007

0% - 400% Read\Write

0% - 400% Read\Write

0 – 5 seconds Read\Write

11 Stop Control

1101 Stop Mode

- Coast means that the Opal will inhibit firing of the

SCR’s as soon as the stop command is received

- Soft Stop means that the Opal will ramp down the

current in the amount of time specified in parameter

1102

1102 Sft Stop Step

- This is the amount of motor voltage that the output

will step down to when a stop is commanded. If this

value is set to high the motor will go through a state of

instability.

1103 Sft Stop Rmp

- This is the amount of time that it will take to ramp the

voltage down from the step voltage to 35% of the

motor voltage

1104 DCI Current

- this is the amount of current that will be regulated during

DC Injection stopping (represented as a percentage of

nameplate current)

1105 DCI Time

- this is the amount of time that the Opal will DC inject for

Coast

Soft Stop

DC Injection

50% – 85% Read\Write

2 – 60 seconds Read\Write

100% – 300% Read\Write

1 – 60 seconds Read\Write

Read\Write

Page 25

Page 27

MS6 REDUCED VOLTAGE STARTER

12 Analog I/O

1201 Analog Output

- This parameter designates what signal will be sent o ut the analog

output

- Current reference means the current reference that the Opal is

currently using (0-5volts = 0 – 615% motor nameplate current)

- Current feedback means that the actual motor current will be sent

(0-5volts = 0-615% motor nameplate current)

- Overload level means that the present calculated thermal capacity

will be sent (0-5volts = 0-100% of capacity)

- Phase Angle means that the current phase angle will be sent (0-

5volts = 0-180 degrees)

13 Motor Data

1301 Motor Amps

- this should be the name plate full load amps of the motor

1302 Motor Volts

- this should be the name plate voltage of the motor

1303 Service Factor

- this should be the name plate service factor of the motor

14 Communications

1401 Modbus Slave Node

- This is the slave node that the Opal will be seen as

- This parameter is only accessible if a Modbus Slave card is

installed in the Opal

1402 MB Slv Baud Rate

- This is the baud rate that the MB Slave card will attempt to

communicate

- This parameter is only accessible if a Modbus Slave card is

installed in the Opal

1403 DeviceNet MacID

- This is the DeviceNet MacID that the Opal will be seen as

- This parameter is only accessible of a DeviceNet Slave card is

installed in the Opal

1404 DeviceNet Slv Baud Rate

- This is the baud rate that the DeviceNet Slave card will attempt to

communicate

- This parameter is only accessible of a DeviceNet Slave card is

installed in the Opal

1405 DH+ Station Address

- This is the station ad dress that the Opal will be seen as

- This parameter is only accessible if a DH+ card is installed

1406 DH+ Baud Rate

- This is the baud rate that the DH+ card will communicate at

- This parameter is only accessible if a DH+ card is installed

Current Reference

Current Feedback

Overload Level

Phase Angle

5 – 1100 Amps Read\Write

240 – 600 Volts Read\Write

1.00 – 1.30 Read\Write

1 – 7 Read\Write

300 Kbaud

1200 Kbaud

2400 Kbaud

4800 Kbaud

9600 Kbaud

19200 Kbaud

38400 Kbaud

57600 Kbaud

0 – 31 Read\Write

125 Kbaud

250 Kbaud

500 Kbaud

1 - 32 Read\Write

57.6 Kbaud

115.2 Kbaud

230.4 Kbaud

Read\Write

Read\Write

Read\Write

Page 26

Page 28

15 Faults

1501 Shear Pin Flt

- Enables and disables the shear pin fault

- The shear pin fault is automatically disabled during jog

1502 MOL Flt

- Sets up the class of overload that will be used

- Can also disable the overload

1503 Overload Level

- Represents has a percentage the amount of overload that has

accumulated

- Once this level reaches 100% the Opal will trip on a MOL FLT

- this level will increase based on the class set in parameter 1502 any

time that the current feedback is above the name plate current

(parameter 1301) multiplied by the service factor (parameter 1303)

- this level will decrease any time that the current feedback is below

that level

- if this level reaches 100% and the drive trips, a reset will not be

allowed until this level has decreased to 15%

1504 Comm Flt

- this will enable or disable the communication fault if a

communication module is present

- a communication fault is detected by monitoring a watch dog bit

that the Opal sends out to the master device which has to be

inverted and sent back with in a specific amount of time (parameter

1505)

1505 Comm Flt Time

- this is the time used to determine a communication fault

MS6 REDUCED VOLTAGE STARTER

Enable

Disable

Disable

Class 10

Class 15

Class 20

Class 30

Read Only

Enable

Disable

0.1 – 5.0

seconds

Read\Write

Read\Write

Read\Write

Read\Write

Page 27

Page 29

MS6 REDUCED VOLTAGE STARTER

9 SPARES

9.1 SPARE PARTS

Model SCR Current

Transformer

Control

Card

Stack ID

Card

MOV

MS6-30 N10SP03(61A SCR) T261123 (1500:1) CA530 CA532(30) O210050

MS6-50 N10SP06(90A SCR) T261123 (1500:1) CA530 CA532(50) O210050

MS6-80 N10SP16(140A SCR) T262320 (2500:1) CA530 CA532(80) O210050

MS6-125 N728352(300A SCR) T262320 (2500:1) CA530 CA532(125) O210050

MS6-250 N728452(580A SCR) T262320 (2500:1) CA530 CA532(250) O210050

MS6-420 N718602(720A SCR) T265320 (5000:1) CA530 CA532(420) O210050

MS6-500 N718133(1100A SCR) T268320 (8500:1) CA530 CA532(500) O210050

MS6-600 N718153(1200A SCR) T268320 (8500:1) CA530 CA532(600) O210050

MS6-800 N718552(1500A SCR) T261321 (10000:1) CA530 CA532(800) O210050

9.2 SCR INSTALLATION PROCEDURE

• Clean both heat sink and SCR surfaces.

• Apply a thin layer of joint compound (Noalox) to both SCR surfaces.

• Observe correct SCR polarity.

• Install SCR so that roll pins engage dimples on both sides of the SCR.

• Tighten clamp bolts evenly until finger-tight.

• Tighten each bolt according to table below (based on number of spring bars and size of

bars).

Note: SMALL clamps are 10.5cm(4.25inches) and LARGE clamps are 12.5cm(5inches)

CLAMP SIZE SPRING BARS BOLT TURNS PAST

FINGER TIGHT

SMALL 1 0.75

SMALL 2 1

LARGE 3 1.75

LARGE 4 1.75

Page 28

Page 30

10 CONNECTION DRAWINGS

10.1 TWO WIRE CONTROL

MS6 REDUCED VOLTAGE STARTER

Enable must be closed

for starter to operate

Page 29

Page 31

MS6 REDUCED VOLTAGE STARTER

10.2 THREE WIRE CONTROL

Enable must be closed

for starter to operate

Page 30

Page 32

10.3 THREE WIRE REVERSING

MS6 REDUCED VOLTAGE STARTER

Enable must be closed

for starter to operate

Page 31

Page 33

MS6 REDUCED VOLTAGE STARTER

10.4 THREE WIRE WITH BY-PASS

Page 32

Enable must be closed

for starter to operate

Page 34

MS6 REDUCED VOLTAGE STARTER

10.5 THREE WIRE CONTROL WITH SHORTED SCR DETECTION

Enable must be closed

for starter to operate

Page 33

Page 35

MS6 REDUCED VOLTAGE STARTER

10.6 DCI FOR 80 AMP UNITS AND BELOW

Enable must be closed

for starter to operate

Page 34

Page 36

10.7 DCI FOR 125 AMP UNITS AND ABOVE

MS6 REDUCED VOLTAGE STARTER

Enable must be closed

for starter to operate

Page 35

Page 37

MS6 REDUCED VOLTAGE STARTER

10.8 INTEGRATED BY-PASS

MOTOR

INDUCTION3 PHASE

T1

MS6B

BPM

T2

BPM

T3

BPM

232224

25

COM

COM

ANALOG IN

ANALOG OUT

G6G4 K5 G5 K6

K4

TO SCR GATE S

21

REV

RUN

18 2019

17

SCR

SHORTED

1514 16

BYPASS RELAY

TERMINALS 2 AND 9 ARE NOT INTERNALLY CONNECTED.

3 TO 9 BE DIFFERENT THAN THE 120VAC SUPPLY USED

THEREFORE IF DESIRED THE 120VAC SUPPLY FOR TERMINALS

FOR TERMINAL 1 AND 2

%%UNOTE:

SCR2

MOV1

SCR1

CT1

L1

FU1

SCR4

MOV2

SCR3

CT2

L2

FU2

SCR6

MOV3

SCR5

CT3

G1K1 K3G2K2 G3

CA532

CT1 CT2 CT3

L3

FU3

GND

BYPASS

131110 12

137

FAULT

CA530

98

NEUTRAL

ENABLE

7

RESET

65

REV.

JOG

43

STOP

NEUTRAL

AC

1

FU4

1

START

2

26

ENABLE

RESET

REVERSE

JOG

STOP

START

BPR

FOR 200A AND ABOVE CONTACTORS.

- BYPASS RELAY MUST BE USED

%%UNOTE:

BYPASS

CONTACTOR

38

BPR BPM

50/60HZ.

200-600V

PROTECTED

3PH.

Page 36

R

50VA MIN.

PROTECTED

115VAC/50HZ

120VAC/60HZ.

Page 38

www.safdrives.com

email: answers@opalstarters.com

(Replies given within 24 hours)

18 Neville Street, Unit C

New Hamburg, ON N3A 4G7

Tel: 519-662-6489

Fax: 1-866-280-5247

www.opalstarters.com

Loading...

Loading...