SAF 50S15, 90S18 Owner's Manual

Owner’s Manual

XL-KP11695BM-en-DE Rev. A

Translation of the original owner's

manual

SAF fifth wheel kingpin 50S15 - 90S18

1.1 Dear customer,

This operating manual will help you to familiarise yourself with the SAFHOLLAND product and use it for its proper use.

The operating manual contains important instructions on how to operate

the product safely, properly and economically. Adherence to it helps

prevent hazards, faults and reduce down times and increase the reliability

and service life of the product. Read the operating manual through

carefully and follow the instructions accurately.

It must be ensured that all personnel with responsibility for performing

tasks on the vehicle are able to consult the operating manual at all times.

The operating manual must be kept in the glove compartment in the

driver's cabin of the towing vehicle at all times.

1.1 Copyright

This operating manual is classified as in accordance with the law on unfair

competition.

All rights reserved by

SAF-HOLLAND GmbH

Hauptstraße 26

D-63856 Bessenbach

This operating manual contains text and drawings that without the express

permission of the manufacturer cannot be either fully or partly

• duplicated,

• distributed or

• in any other way disclosed.

Any breach or infringement will result in liability for damages.

2

XL-KP11695BM-en-DE Rev. A · 02.2015 · Errors and changes excluded · © SAF–HOLLAND

en

Table of Contents

1 Product data.................................................................................. 4

1.1 Product description ................................................................... 4

1.2 Product identification ................................................................ 4

1.3 Type designation ....................................................................... 6

2 Ordering spare parts..................................................................... 11

3 General information..................................................................... 11

3.1 Liability ..................................................................................... 11

3.2 Warranty and general terms and conditions of business ............ 12

3.3 Environmental protection .......................................................... 12

4 Safety............................................................................................. 12

4.1 Target group ............................................................................. 12

4.2 Proper use ................................................................................ 13

4.3 Improper use ............................................................................ 13

4.4 Safety instructions and symbols used ........................................ 13

4.5 Marking used for sections of text .............................................. 14

4.6 General safety instructions ........................................................ 14

5 Installation..................................................................................... 16

5.1 General instructions for installation ........................................... 16

5.2 D Value/fifth wheel kingpin ....................................................... 17

5.3 Welding the flange ................................................................... 19

5.4 Installation of the fifth wheel kingpin ........................................ 21

5.5 Screw home the fifth wheel kingpin .......................................... 23

6 Implementation............................................................................. 23

7 Inspection...................................................................................... 24

7.1 General test instructions ........................................................... 24

7.2 Before each journey .................................................................. 25

7.3 Test schedule ............................................................................ 25

7.4 Wear check ............................................................................... 26

7.5 Lubricate ................................................................................... 28

8 Maintenance.................................................................................. 29

8.1 General maintenance instructions ............................................. 29

8.2 Torques .................................................................................... 29

Table of Contents

3

XL-KP11695BM-en-DE Rev. A · 02.2015 · Errors and changes excluded · © SAF–HOLLAND

en

1 Product data

1.1 Product description

The fifth wheel kingpin consists of:

• Pin

• Flange

• Screws

is the connecting shaft between the fifth wheel installed on the tractor

and that installed on the articulated trailer (trailer). The flange is welded to

the bolster plate. The kingpins comply with the applicable standards in

terms of their dimensions beneath the bolster plate.

1.2 Product identification

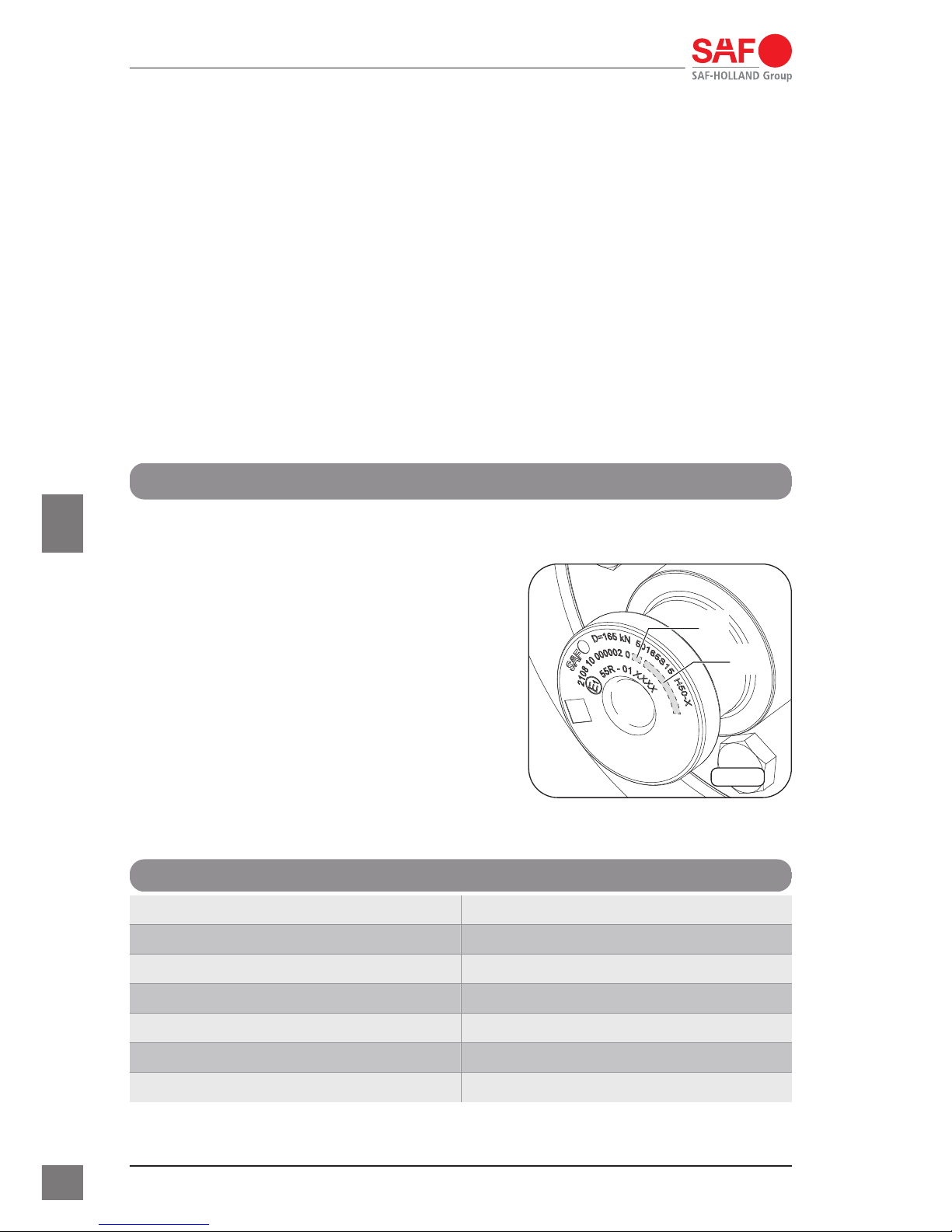

Pin

Please have the exact part number of the product ready when ordering

spare parts.

The details of the pin are engraved on

the top and bottom –Arrow–, Fig. 1. The

“D-value” is given in kilonewton .

Pin details

Technical designation Value/detail

Manufacturer/brand SAF

permitted D-value: D = 165 kN

Design: 50165S15

Class: H50–X

Part number: 2108 10 0000002 0

Revision: *1

KP-0001

*1

*2

Fig. 1 · Pin example 50S15

1 Product data

4

XL-KP11695BM-en-DE Rev. A · 02.2015 · Errors and changes excluded · © SAF–HOLLAND

en

Technical designation Value/detail

Manufacturing site and serial number: *2

Approval number: E1 55R – 01 XXXX

Data-Matrix-Code □: contains documentation and

manufacturing data, which are

centrally stored at SAF-HOLLAND

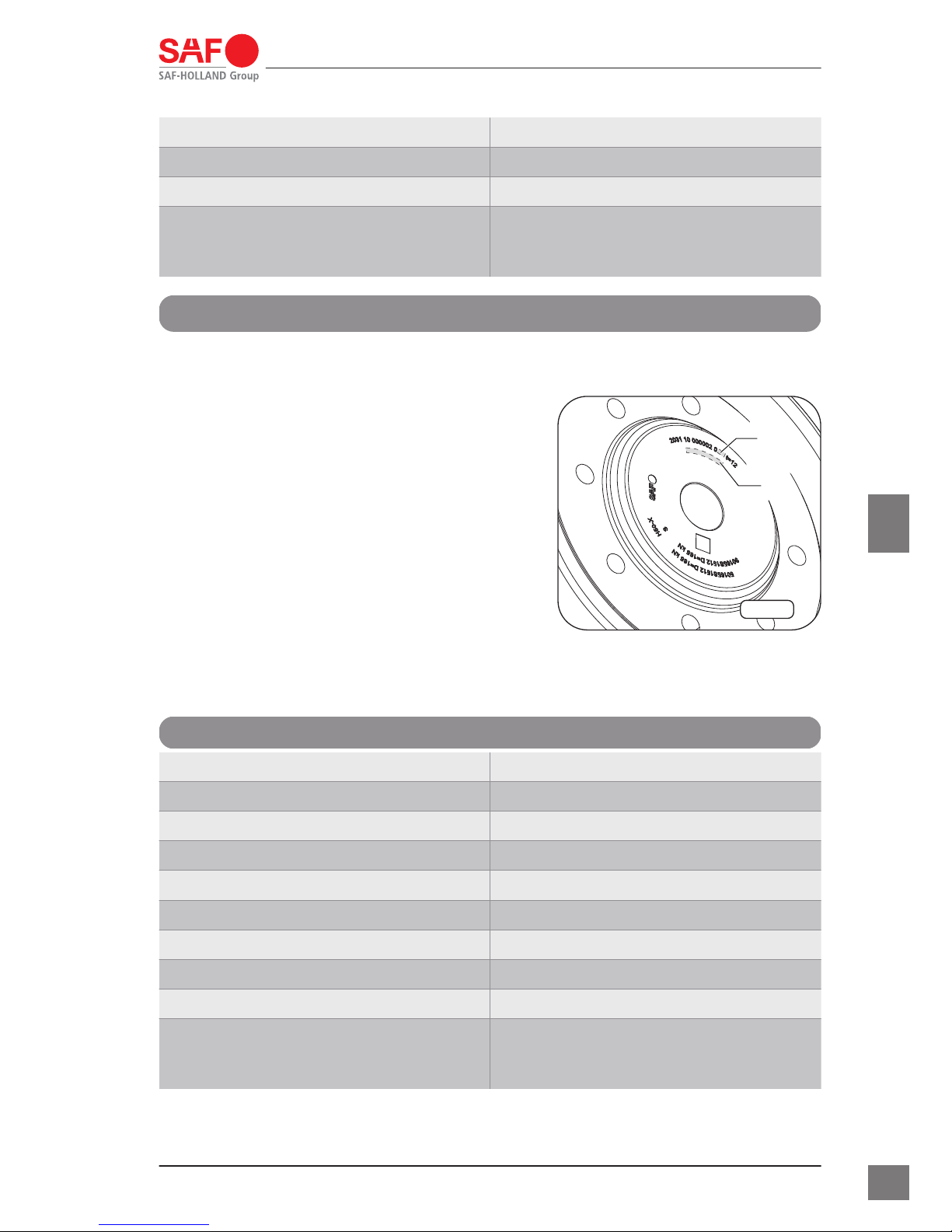

Flange

Please have the exact part number of the product ready when ordering

spare parts.

The details of the flange are engraved on

the inside –Arrow–, Fig. 2. The “D-value”

is given in kilonewton .

Flange details

Technical designation Value/detail

Manufacturer/brand SAF

permitted D-value: D = 165 kN

Design: 50165S1512 and 90165S1512

Class: H50–X or S

Part number: 2031 10 0000002 0

Revision: *1

Manufacturing site and serial number: *2

Trailer bolster plate thickness: t = 12

Data-Matrix-Code □: contains documentation and

manufacturing data, which are

centrally stored at SAF-HOLLAND

KP-0002

*1

*2

Fig. 2 · Flange example 50S15 or

90S15

1 Product data

5

XL-KP11695BM-en-DE Rev. A · 02.2015 · Errors and changes excluded · © SAF–HOLLAND

en

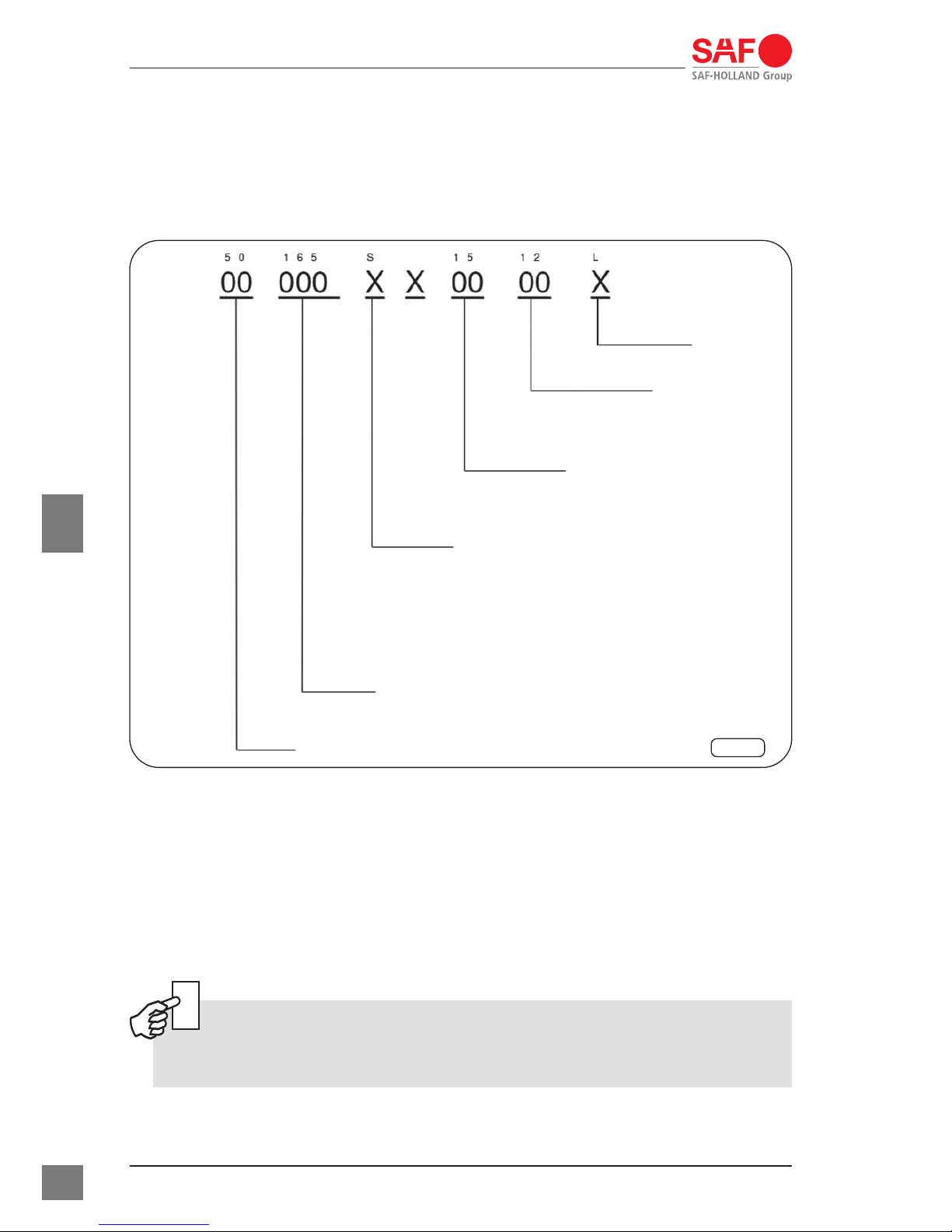

1.3 Type designation

marking

Following example is a description of the type marking Fig. 3. The letters

are marked with “X” and the numbers are marked with “0”.

KP-0011

2

3

4

5

6

( )

1

Fig. 3 · Explanation of the marking

1 Size:

• 50 = 2 inches

• 90 = 3.5 inches

2 D-value:

• 165 = 165 kN

• 320 = 320 kN

Note:

The D-value was not considered for the type approval.

3 Fastenings:

• S = with screws

1 Product data

6

XL-KP11695BM-en-DE Rev. A · 02.2015 · Errors and changes excluded · © SAF–HOLLAND

en

• M = with nuts

4 Circle diameter of part:

• 15 = 150 mm

• 18 = 180 mm

5 Semi-trailer bolster plate thickness:

• 06 = 6 mm

• 08 = 8 mm

• 10 = 10 mm

• 12 = 12 mm

• 16 = 16 mm

6 Marking of special types:

• L = steering

Note:

The thickness of the semi-trailer bolster plate is not considered

for the type approval.

Type overview

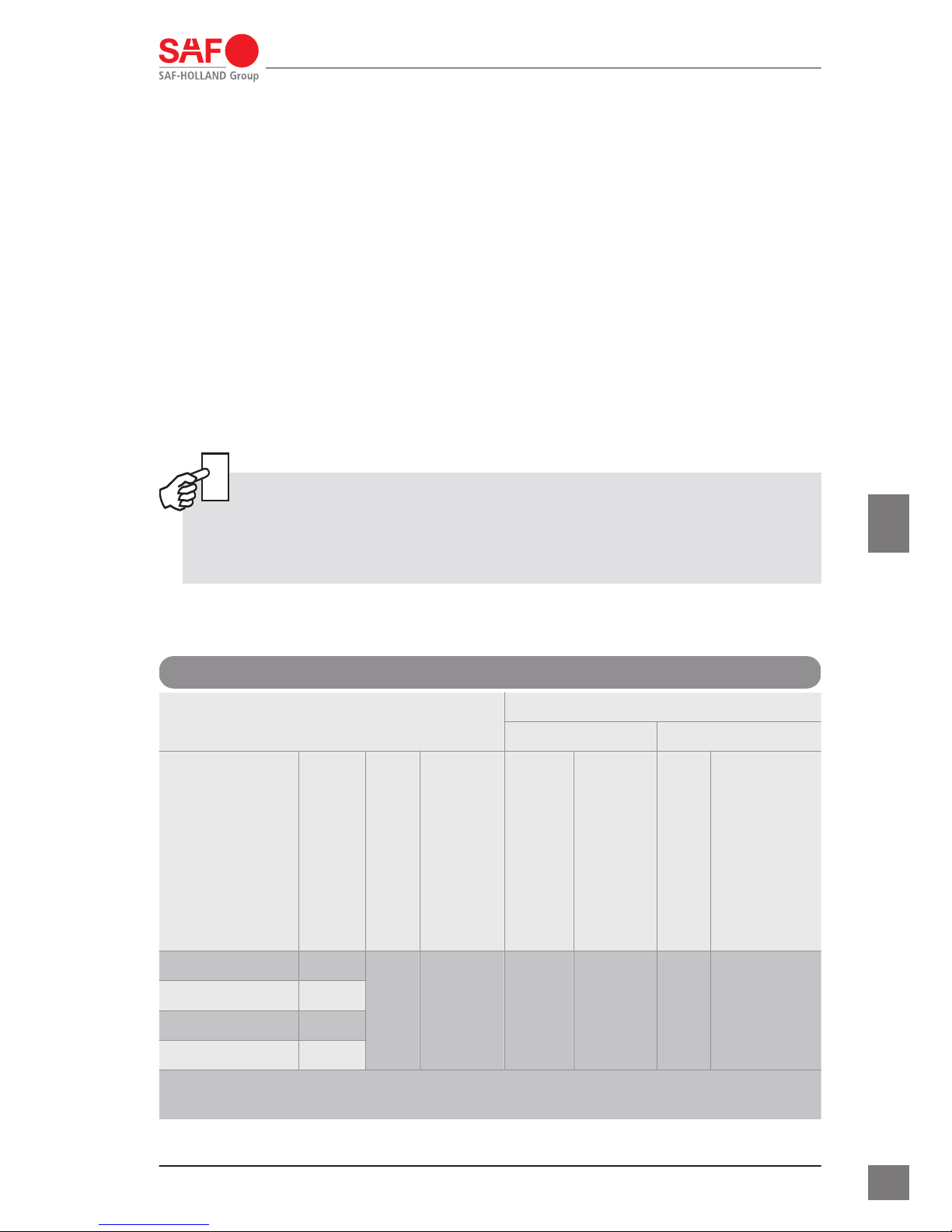

Type 50S15

Type 50S15

Installation with flange design

+GF+ HOLLAND

Design

Trailer plate thickness

in mm

D-value in kN

ECE approval no.

D-value in kN

type

D-value in kN

type

50165S1512 12

165

E1 55R–

01 2289

162.4 101 109 165 65

50165S1510 10

50165S1508 8

50165S1506 6

The pins of SAF type 50S15 can be installed with the corresponding flange

designs of +GF+ and HOLLAND.

1 Product data

7

XL-KP11695BM-en-DE Rev. A · 02.2015 · Errors and changes excluded · © SAF–HOLLAND

en

Type 50S15L

Type 50S15L

Installation with

flange design

+GF+

Design

Trailer plate thickness

in mm

D-value in kN

ECE approval no.

D-value in kN

type

50165S1512L 12

165

E1 55R–01

2422

162.4 101 10950165S1510L 10

50165S1508L 8

The pins of SAF type 50S15L can be installed with the corresponding flange

designs of +GF+.

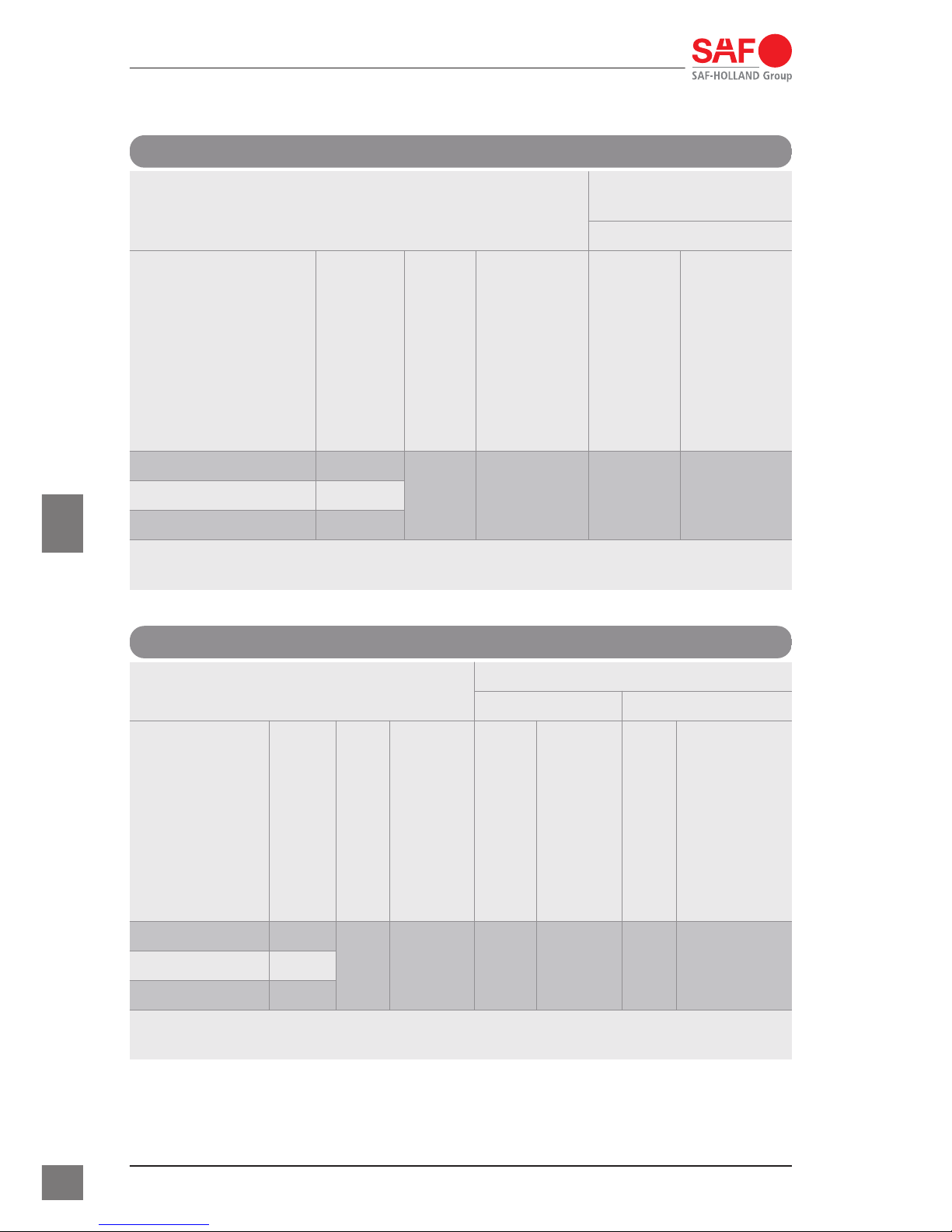

Type 90S15

Type 90S15

Installation with flange design

+GF+ HOLLAND

Design

Trailer plate thickness

in mm

D-value in kN

ECE approval no.

D-value in kN

type

D-value in kN

type

90165S1512 12

165

E1 55R–

01 2371

162.4 101 169 165 6790165S1510 10

90165S1508 8

The pins of SAF type 90S15 can be installed with the corresponding flange

designs of +GF+ and HOLLAND.

1 Product data

8

XL-KP11695BM-en-DE Rev. A · 02.2015 · Errors and changes excluded · © SAF–HOLLAND

en

Type 90S15L

Type 90S15L

Installation with

flange design

+GF+

Design

Trailer plate thickness

in mm

D-value in kN

ECE approval no.

D-value in kN

type

90165S1512L 12

165

E1 55R–01

2421

162.4 101 16990165S1510L 10

90165S1508L 8

The pins of SAF type 90S15L can be installed with the corresponding flange

designs of +GF+.

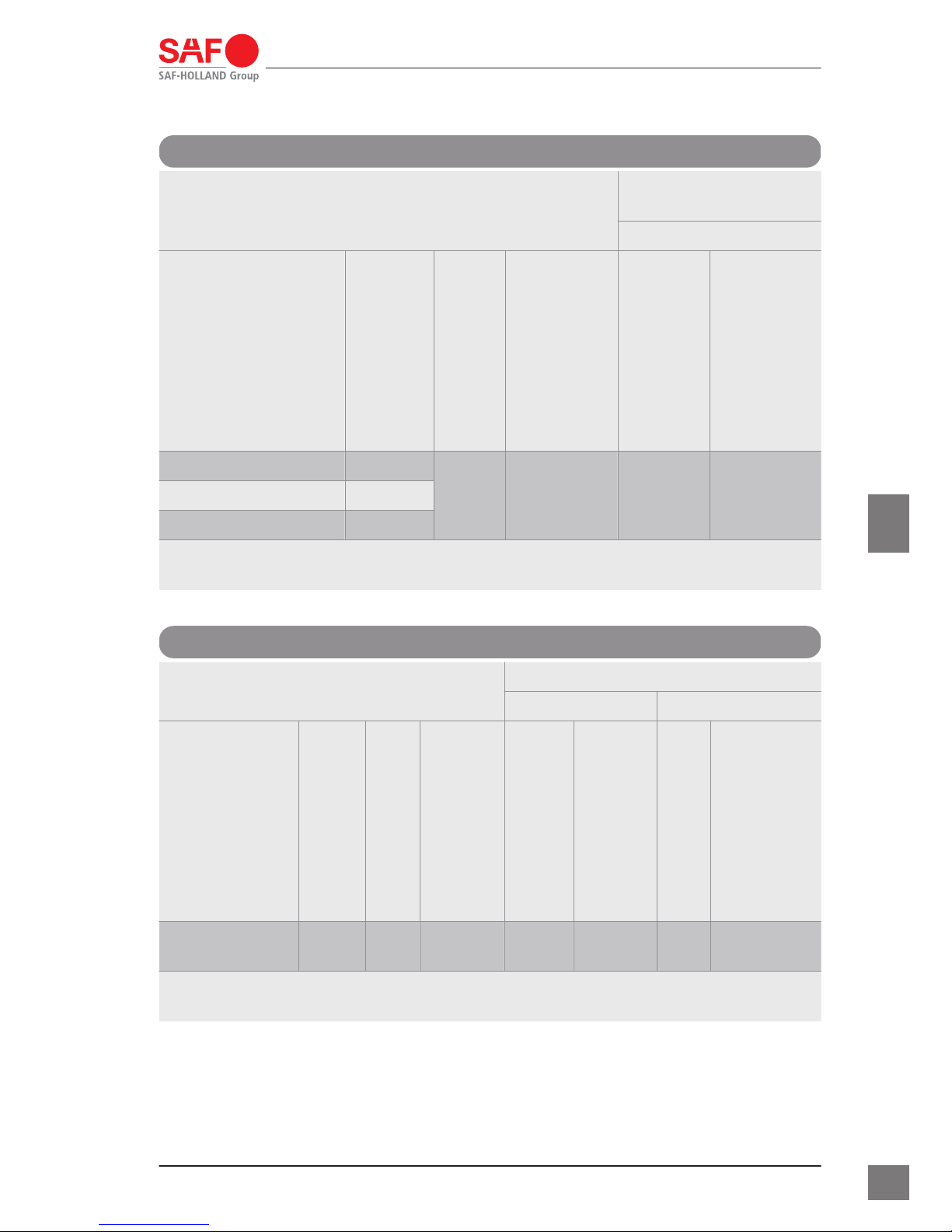

Type 50S18

Type 50S18

Installation with flange design

+GF+ HOLLAND

Design

Trailer plate thickness

in mm

D-value in kN

ECE approval no.

D-value in kN

type

D-value in kN

type

50165S1816 16 165

E1 55R–

01 2418

162.4 102 022 165 66

The pins of SAF type 50S18 can be installed with the corresponding flange

designs of +GF+ and HOLLAND.

1 Product data

9

XL-KP11695BM-en-DE Rev. A · 02.2015 · Errors and changes excluded · © SAF–HOLLAND

en

Type 50S18L

Type 50S18L

Installation with

flange design

+GF+

Design

Trailer plate thickness

in mm

D-value in kN

ECE approval no.

D-value in kN

type

50165S1816L 16 165

E1 55R–01

2428

162.4 102 022

The pins of SAF type 50S185L can be installed with the corresponding flange

designs of +GF+.

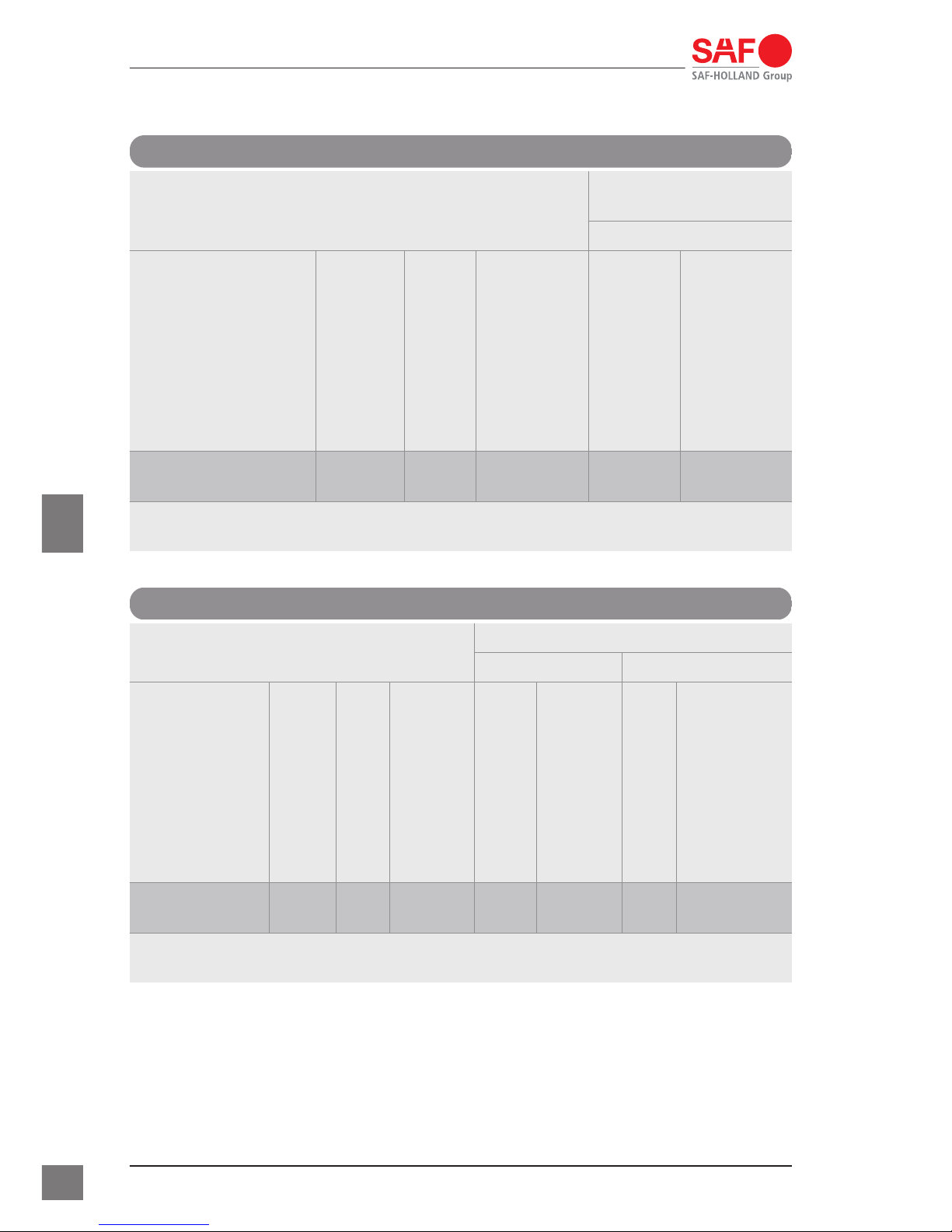

Type 90S18

Type 90S18

Installation with flange design

+GF+ HOLLAND

Design

Trailer plate thickness

in mm

D-value in kN

ECE approval no.

D-value in kN

type

D-value in kN

type

90320S1816 16 320

E1 55R–

01 2426

320 102 021 200 63

The pins of SAF type 90S18 can be installed with the corresponding flange

designs of +GF+ and HOLLAND.

1 Product data

10

XL-KP11695BM-en-DE Rev. A · 02.2015 · Errors and changes excluded · © SAF–HOLLAND

en

Loading...

Loading...