Saeco New Royal HD 8930 Service Manual

Service Manual

Revision 01 December 2012

Service

Co ee Machine

HD 8930

New Royal

Table of contents Page

1. Introduction

1.1. Documentation required 1

1.2. Tools and equipment required 1

1.3. Material 1

1.4. Safety warnings 1

1.5

Service Policy

2

1.6. External machine parts 3

1.6. Internal machine parts 4

2. Technical speci cations

2.1. Technical speci cations 1

2.2 Speci cation for the measurement of the co ee

products temperature.

2

2.3.

Machine parameters and performance

3

3. User instructions

3.1. Customer and programming menu 1

3.2. Machine indications 3

3.3. Operation, cleaning and maintenance 4

4. Operating logic

4.1. Water circuit 1

4.2. Frother unit valve assembly 2

4.3. Cappuccino maker assembly 2

4.4. Relief valve 3

4.5. Co ee cycle 4

4.6. Single microswitch 5

4.7 Temperature sensor 5

Table of contents Page

4.8. Water level detection (water tank) 6

4.9. Descaling request 6

4.10. Water lter 7

5. Troubleshooting

5.1. Test mode 1

5.2. Diagnostics mode 5

5.3 Error messages 7

6. Standard checks

6.1. Repair schedule 1

6.2. Service schedule 1

6.3. Final test 2

7. Disassembly

7.1. Outer elements 1

7.2. Co ee grinder 1

7.3. Grinder blades 2

7.4. Co ee grinder motor 3

7.5. Doser hatch, coil and microswitch 3

7.6. Doser hopper 3

7.7. Co ee boiler and steam boiler 4

7.8. Boiler pin 4

7.9. Co ee pump and steam pump 4

7.10. Flow meter 5

All parts of this document are the property of Saeco International Group.

All rights reserved. This document and all the information herein is provided without liability deriving from any errors or omissions. Furthermore, no part may be reproduced,

used or collected, except where express authorization has been provided in writing or through a contractual agreement.

Published by Saeco International Group Subject to modi cation EN 4219 400 013

2011-July-08

PartsGuru.com

Saeco parts, repairs & tech support, contact:

For

Services Unlimited, Inc./ Parts Guru

209 Walnut street, Lansdale, PA 19446

215-361-7000 - email: sales@partsguru.com

Online store: www.shop.partsguru.com

Services Unlimited, Inc./ Parts Guru 209

Walnut street, Lansdale, PA 19446

215-361-7000 - email: sales@partsguru.com

Online store: www.shop.partsguru.com

Having problems steaming Milk hot?

Use Milk flow restrictor Click Here to order to steam Milk Hotter

Eliminate Milk Carafe. They are expensive and need frequent refilling, intense cleaning

and replacement of damaged or lost rubber connectors. Use of Milk flow restrictor with

15" Silicone tube Order part # 26151-S15

The restrictor is used on frothers that draw milk from a Milk container. Cannot be used

for straight Pannarello frothers.

Extensive Calcium deposits are seen in almost every espresso machine

we open for repairs.

Filter cartridges are preventative, expensive & ineffective as descaler.

The Brita filter installed on the kitchen faucet works better.

Calcium sediment inside the machine causes the following problems:

(1) reduces internal flow of water with full or partial clogging.

(2) generates back pressure in the Hydraulic system & causes internal leaks.

(3) reduces pump pressure, reduced flow of coffee & internal leakage reduces

programmed coffee in the cup (4) Error codes "Fill water" or Ventilate will display.

This will shut the machine down & force expensive repairs.

Descaling is best done manually, every two or three months.

Order Best descaler (#DSC-6) from our online store for effective & authentic Descaling

Learn about our New FULLY AUTOMATIC espresso maker GAMEA REVO for better tasting &

hot Espresso & steaming of milk at the touch of your finger tip

Return in 30 days for Full refund if not satisfied. Standard 1-year

warranty for labor & electrical parts

Extended 3-year warranty for purchase with one Kg. bag of

espresso Beans every month package.

NEW MACHINE AT AFFORDABLE PRICE EVERY COFFEE

LOVER CAN ENJOY.

Fully automatic home espresso machine with LED display

1- Convenient to operate

2- Easy to Program drinks

3- Easy access to brew group for cleaning

4- Easy to maintain

Trade in for any Jura,

YOU WILL BE HAPPY YOU DID.

Delonghi or Gaggia espresso machine.

It is worth it

"Gamea Revo"

As Good As it Gets

Have questions? E-mail inquiries. sales@partsguru.com

Table of contents Page

7.11. Gear motor 5

7.12. Relief valve 6

7.13. Solenoid valve assembly 6

7.14. Steam pipe assembly 7

7.15. Dispenser assembly 7

7.16. Power board 7

7.17. Display, keypads and control board 8

7.18. Fitting and removing Oetiker clamps 9

8. Notes

9. Water circuit diagram

10 Electrical diagram

Saeco International Group Rev. 01 NEW ROYAL

PartsGuru.com

For

Saeco parts, repairs & tech support, contact:

Services Unlimited, Inc./ Parts Guru

209 Walnut street, Lansdale, PA 19446

215-361-7000 - email: sales@partsguru.com

Online store: www.shop.partsguru.com

Saeco International Group Rev. 01 NEW ROYAL

PartsGuru.com

Saeco parts, repairs & tech support, contact:

For

Services Unlimited, Inc./ Parts Guru

209 Walnut street, Lansdale, PA 19446

215-361-7000 - email: sales@partsguru.com

Online store: www.shop.partsguru.com

NEW ROYAL 01 INTRODUCTION

Saeco International Group Rev. 01 Page / 04

1.1. Documentation required

The following documentation is needed for repair procedures:

• Instruction booklet for specifi

c model.

• Technical documentation for specifi c model (diagrams, exploded view, sympton cure and

service manual).

1.2. Tools and equipment required

As well as the standard equipment, the following is required:

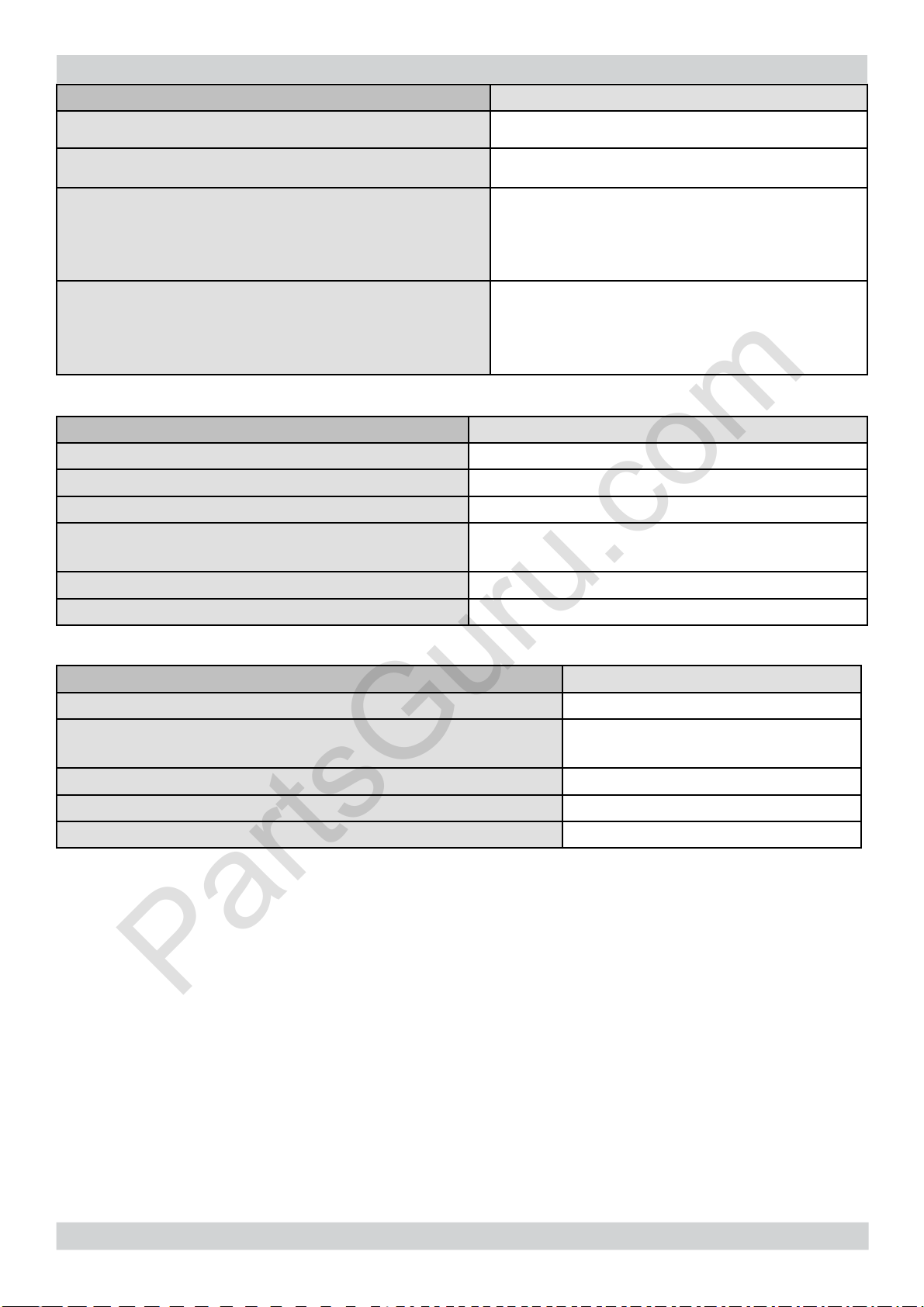

Qty. Description Notes

1 Screwdriver Torx T 8 - T 10 - T 20

1 Screwdriver Cross-head

1 Pliers for Oetiker clamps

1 CC -A - Vdc tester

1 Digital thermometer Scale limit > 150°C

1 SSC (Saeco Service Center) Programmer

(for programming and diagnostics mode)

1.3. Material

Description Notes

Thermal paste Heating element > 200°C

Descaler Saeco descaler

Grease solvent Personal choice

Silicone grease Safe to use with food

1.4. Safety warnings

We recommend you consult this Service Manual of the machine before performing any maintenance work.

Observe all applicable standards relating to the repair of electrical appliances.

Always disconnect the power plug from the mains before beginning repair work.

Simply turning off the main machine power switch is not an adequate safety precaution.

This domestic appl

iance is rated as insulation class I.

On completion of the repair work, insulation and dielectric rigidity tests must be performed.

01

PartsGuru.com

NEW ROYAL 01 INTRODUCTION

Saeco International Group Rev. 01 Page / 04

02

Components Assembly use Single components available

COFFEE

GRINDER

Only for OOW repairs

YES, to consult the specifi c exploded-view of the

machine or of the Coffee Grinder on website

BREWING

UNIT

Only for OOW repairs

YES, to consult the specifi c exploded-view of the

machine or of the Brewing unit on website

BOILER Only for OOW repairs

YES, to consult the specifi c exploded-view of the

machine on website

GEAR

MOTOR

Only for OOW repairs

YES, to consult the specifi c exploded-view of the

machine on website

FILTER

HOLDER

Only for OOW repairs

YES, to consult the specifi c exploded-view of the

machine on website

MILK

CARAFE

Only for OOW repairs

YES, to consult the specifi c exploded-view of the

machine on website

THERMAL

CARAFE

Only for OOW repairs

YES, to consult the specifi c exploded-view of the

Thermal Carafe on website

MILK ISLAND Only for OOW repairs

YES, to consult the specifi c exploded-view of the

Milk Island on website

List of principal assembly present in all our coffee machines

1.5 Service POLICY grid as used for coffee machine

For IN WARRANTY repairs is mandatory to use the single components (not the assembly) avail-

able in the exploded views of the coffee machines or of the specifi c components. If you fi

nd the

information “SEE THE EXPLODED VIEW E........” in the assembly description fi eld, it means that

the single components of the assembly are available in the other pages of the exploded view. It’s

possible to use the assembly only if there is a specifi c Symptom Cure that include this possibility

or when the single components are not available for the order.

PartsGuru.com

Saeco parts, repairs & tech support, contact:

For

Services Unlimited, Inc./ Parts Guru

209 Walnut street, Lansdale, PA 19446

215-361-7000 - email: sales@partsguru.com

Online store: www.shop.partsguru.com

NEW ROYAL 01 INTRODUCTION

Saeco International Group Rev. 01 Page / 04

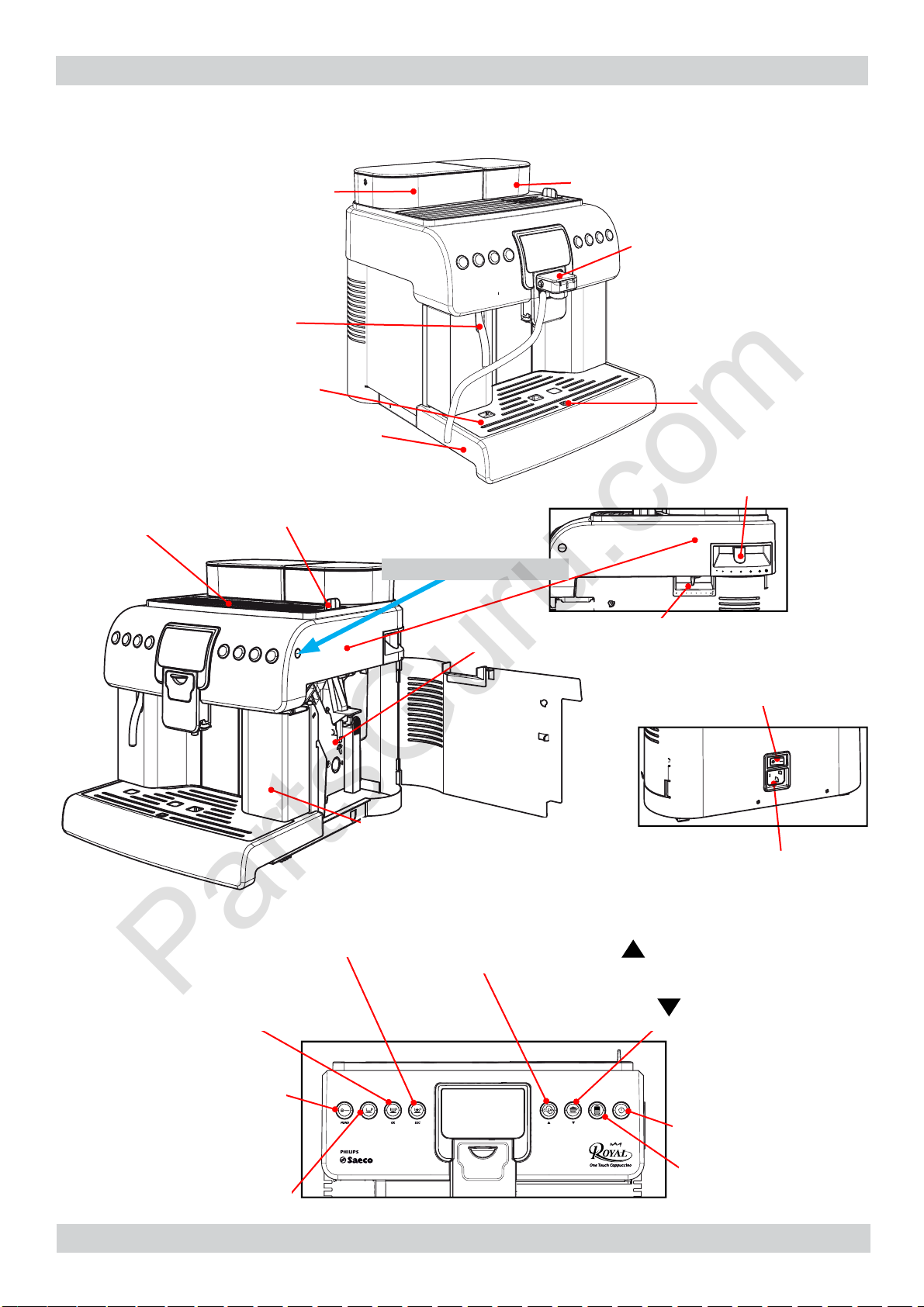

1.6. External machine parts

03

Grille

Water tank

Cappuccino maker (removable)

Coffee bean hopper

Hot water dispensing pipe

Full tray fl oating indica-

tor

Drip tray

Brewing unit

Pre-ground coffee compartment

Dreg drawer

Service hatch

Cup heater plate

Grinding adjustment

Coffee dose adjustment

MENU OK ESC

Cappuccino maker “Clean” button or used to scroll

through the menu (Page Up )

Special Drinks selection button or used to exit the

menu (ESC)

ON/OFF button

Cappuccino dispensing button or used to scroll through

the menu (Page Down

)

Coffee dispensing button or used to confi rm selection (OK)

Pre-ground coffee button or (MENU) to

access programming mode

Espresso dispensing button

Latte macchiato dispensing button

Power cable connector

Main switch 0/I

IRDA for SW programation

Services Unlimited, Inc./ Parts Guru

PartsGuru.com

NEW ROYAL 01 INTRODUCTION

Saeco International Group Rev. 01 Page / 04

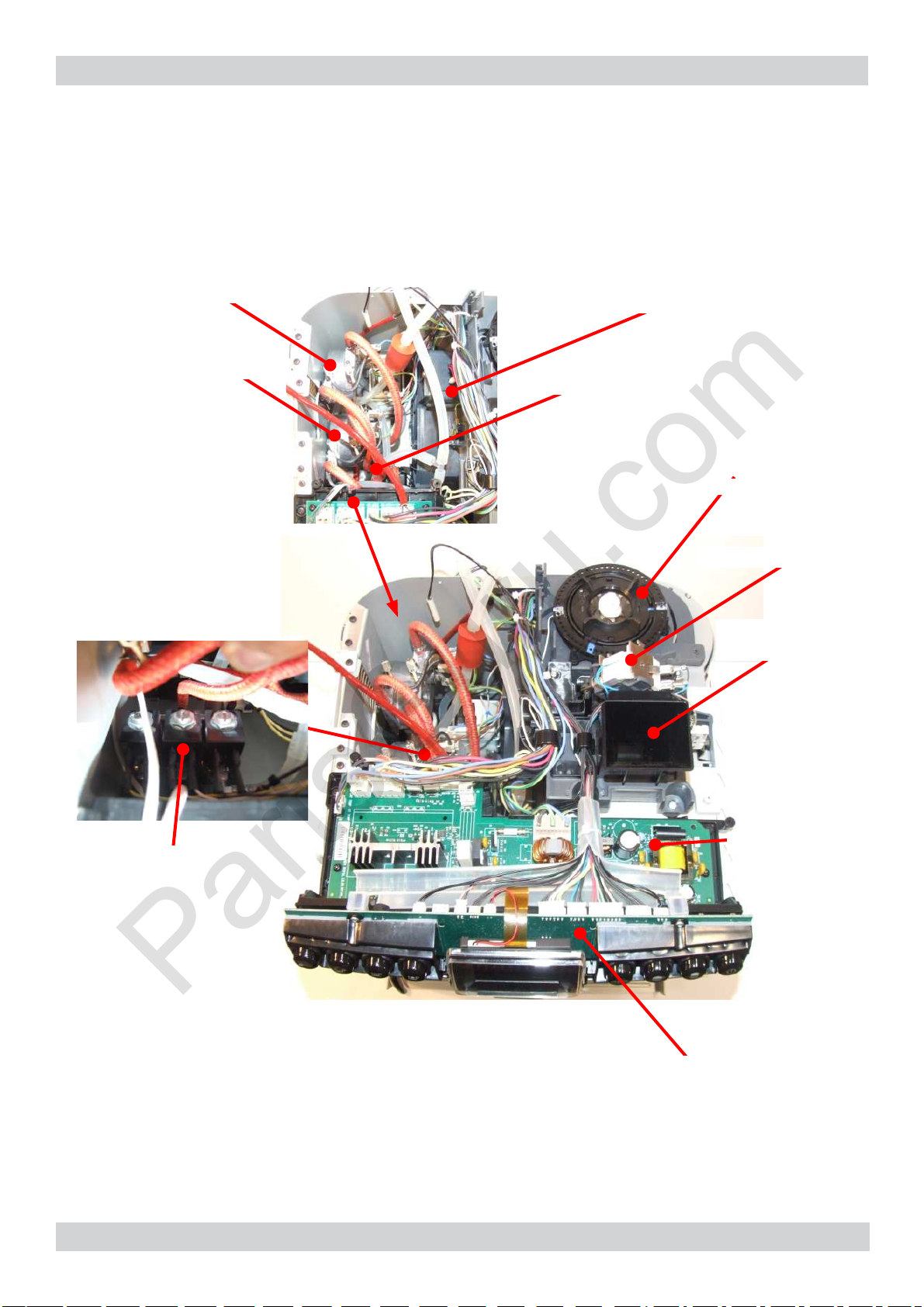

1.7. Internal machine parts

04

Coffee grinding assembly

Ground coffee hopper

Power board

Control board

Doser assembly

Coffee boiler

Gear motor assembly

Relief valve assembly

Steam boiler

Solenoid valve assembly

Services Unlimited, Inc./ Parts Guru

PartsGuru.com

Saeco International Group Rev. 01 NEW ROYAL

Services Unlimited, Inc./ Parts Guru

PartsGuru.com

For

Saeco parts, repairs & tech support, contact:

Services Unlimited, Inc./ Parts Guru

209 Walnut street, Lansdale, PA 19446

215-361-7000 - email: sales@partsguru.com

Online store: www.shop.partsguru.com

NEW ROYAL 02 TECHNICAL SPECIFICATIONS

Saeco International Group Rev. 01 Page / 03

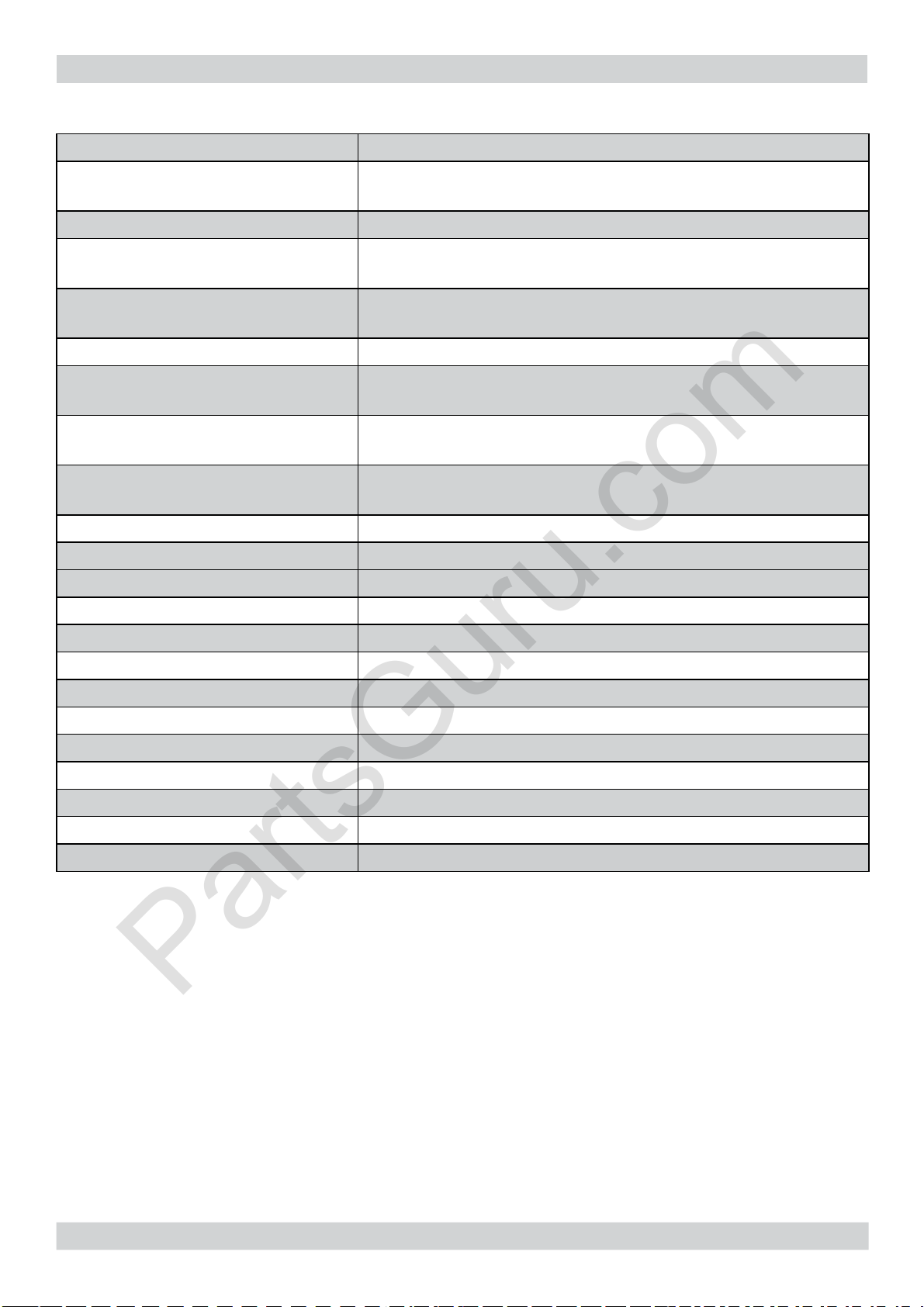

2.1. Technical specifi cations

Power supply and output: 240 V~ 50 Hz 1500 W - 230 V~ 50/60 Hz 1400 W

Temperature monitoring:

(NTC) variable resistor sensor - transmits the value to the

electronic card

Safety system: 2 thermostats at 190°C one shot

Cof

fee heat exchanger output:

Stainless steel

(230 V~) 1300 W for coffee dispensing

Steam heat exchanger output:

Stainless steel

(230 V~) 1300 W for water/steam dispensing

Gear motor: 2 rotation directions; power supply 24VC

Coffee pump

Ulka Type EP5/S GW approx. 13-15 bar with reciprocating

piston and thermal switch 120°C 48 W, 230V, 50 Hz,

Steam pump

Ulka HF with reciprocating piston 230V, 50 Hz and thermal

switch 120°C - 22W

Overpressure valve:

(multi-way valve)

Opening at approx. 19-23 bar

Water fi lter: In tank

Coffee grinder: Direct current motor with conical steel grinder blades

Power consumption: During heating phase- approx. 5.6 A

Consumption in Standby < 0.3 W

Dimensions: W x H x D in mm: 336x380x450

Weight: 16 kg

Water tank capacity: 2.2 l

Coffee bean hopper capacity: 320 g. of coffee beans

Dreg drawer capacity: 19 (18+1)

Heat exchanger capacity: Approx. 10 cc

Water circuit fi lling time: Approx. 50 sec Max. on fi rst fi lling cycle including rinsing

Heating time: Approx. 25 sec. Max. in stand-by

Grinding time: Approx. 4-7 sec.

01

Services Unlimited, Inc./ Parts Guru

PartsGuru.com

NEW ROYAL 02 TECHNICAL SPECIFICATIONS

Saeco International Group Rev. 01 Page / 03

02

2.2. Specifi cation for the measurement of the coffee products temperature.

The temper

ature is infl uenced by the fl ow from the dispenser and stratifi

cation of temperatures in

the glass. In order to consider these phenomena and to introduce measures that allow comparisons in controlled conditions, below guidelines must be followed:

Conditions:

a) Water temperature in tank: 23°C (+/-2°C).

b) It must be used a plastic cup (see picture N°1).

c) It must be used a thermocouple thermometer (e.g. type K - see picture N°2).

d) The coffee machine is tested without any change of parameters or calibrations, which may

affect the temperature of products, so the measurement of temperature must be done with

machine in default factory setting.

Procedure:

1. The temperature must be measured in the cup, immediately after dispensing. Cup has to be

placed on a non-metal surface using a thermocouple thermometer.

2. The temperature in the cup is measured by immersing the probe of the thermometer up to

touch the bottom.The probe then must be moved in a circular motion for 5/6 rotations. At the

of the rotations, stop in the center of the cup.

3. The highest temperature measured during the rotations is the value we are searching for, and

that must be reported;

4. Test measurement: from end of dispensing to the end of rotations must be completed within 12

seconds.

Limits of acceptability

The acceptance limits are divided by features and products and are the following:

Espresso Coffee Italy Q.ty 25/40 gr.

Temperature of 1st product 69°C ≤ 85°C

Temperature of 2nd product 72°C ≤ 85°C

Coffee Q.ty 70/120 gr.

Temperature of 1st product 69°C ≤ 85°C

Temperature of 2nd product 72°C ≤ 85°C

Picture 1

Picture 2

Services Unlimited, Inc./ Parts Guru

PartsGuru.com

NEW ROYAL 02 TECHNICAL SPECIFICATIONS

Saeco International Group Rev. 01 Page / 03

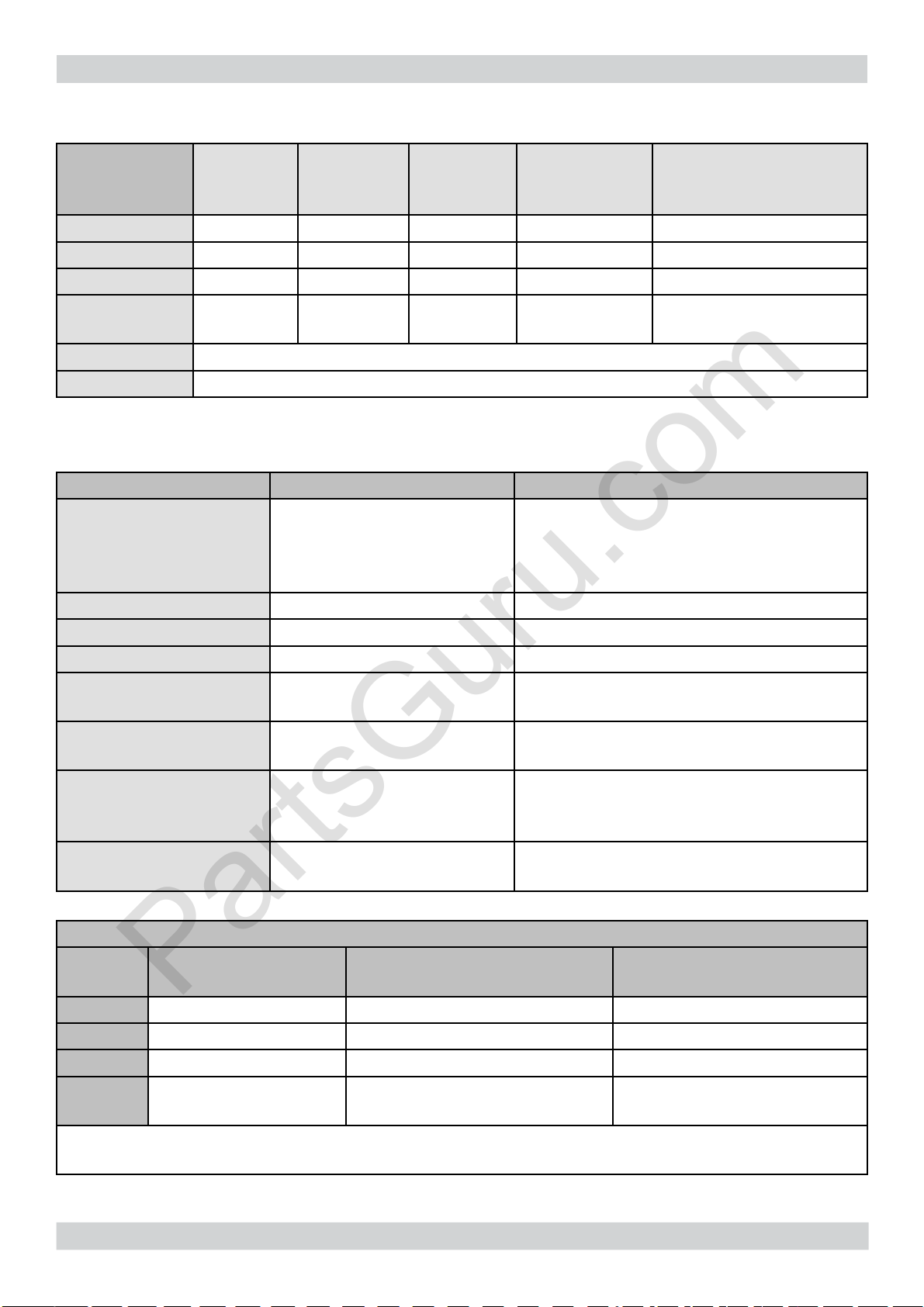

2.3. Machine parameters and performance

PRODUCT

QUANTITY

Minimum

quantity

(Puls.)

Default

quantity

(Puls.)

Maximum

quantity

(Puls.)

User pro-

grammable

Programm. by

Production / Service

Espresso 90 130 - 170 * 200 Yes No

Coffee 100 200 -280* 600 Yes No

Long coffee 70 330 - 440 * 600 Yes No

American

coffee

300 - 600 Yes No

Pre-ground Yes

Hot water Continues for 400 pulses

* Depends on the language selected by the user

RINSE Initial rinse Final rinse

When performed When the machine is

switched on and the boiler

temperature is ≤ 50°C

When the machine is switched off elec-

tronically, manually or automatically after

30', if at least one coffee has been dis-

pensed, before switching off

No. of pulses 130 100

Stopping option Yes, by pressing any key Yes, by pressing any key

User disable option No No

Production/Service de-

partment disable option

No No

No. of pulses user ad-

justment option

No No

No. of pulses Produc-

tion/Service department

adjustment option

No No

Pulse range

(Min. – Max.)

No No

03

Descaling cycle frequency

Hard-

ness

Water hardness Without water fi lter With water fi lter

1 Soft (up to 7°dH) 240 litres (480,000 pulses) 480 litres (960,000 pulses)

2 Medium (7° - 14°dH) 120 litres (240,000 pulses) 240 litres (480,000 pulses)

3 Hard (15° - 21°dH) 60 litres (120,000 pulses) 120 litres (240,000 pulses)

4 Very hard

(over 21°dH)

30 litres (60,000 pulses) 60 litres (120,000 pulses)

The default water hardness level is 4. Each litre of water corresponds to approximately

2,000 pulses.

Services Unlimited, Inc./ Parts Guru

PartsGuru.com

NEW ROYAL 02 TECHNICAL SPECIFICATIONS

Saeco International Group Rev. 01 Page / 03

WATER TANK Description

Water reserve (pulses) 200

Water reserve modifi able by Production/Service

departments

No

"Fill tank" alarm Yes

"No tray" alarm No

Water mains No

DREG DRAWER Description and values

Time-out for dreg drawer

5 sec.

Warning to empty dreg drawer after

Yes, after 15 lots of dregs

Empty dreg drawer blocking alarm after

(double coffee is the last beverage

dispensed)

18 lots of dregs

(19 lots of dregs)

Reset dreg counter

The dreg drawer must be emptied only

when prompted by the machine ensuring

the machine is switched on and removing

the drawer for more than 5 seconds.

STANDBY Description and values

Inlet time (min. – max.) 15 minutes - 180 minutes

Inlet time (default) 30 minutes

Inlet time programmed by user Yes

Inlet time programmed by Production/

Service

Yes

Boiler temperature during Standby Boiler OFF

Cup heater during Standby Cup heater OFF

04

Services Unlimited, Inc./ Parts Guru

PartsGuru.com

For

Services Unlimited, Inc./ Parts Guru

209 Walnut street, Lansdale, PA 19446

215-361-7000 - email: sales@partsguru.com

Online store: www.shop.partsguru.com

Saeco parts, repairs & tech support, contact:

Saeco International Group Rev. 01 NEW ROYAL

Services Unlimited, Inc./ Parts Guru

PartsGuru.com

For

Saeco parts, repairs & tech support, contact:

Services Unlimited, Inc./ Parts Guru

209 Walnut street, Lansdale, PA 19446

215-361-7000 - email: sales@partsguru.com

Online store: www.shop.partsguru.com

NEW ROYAL 03 USER INSTRUCTIONS

Saeco International Group Rev. 01 Page / 04

MENU OK ESC

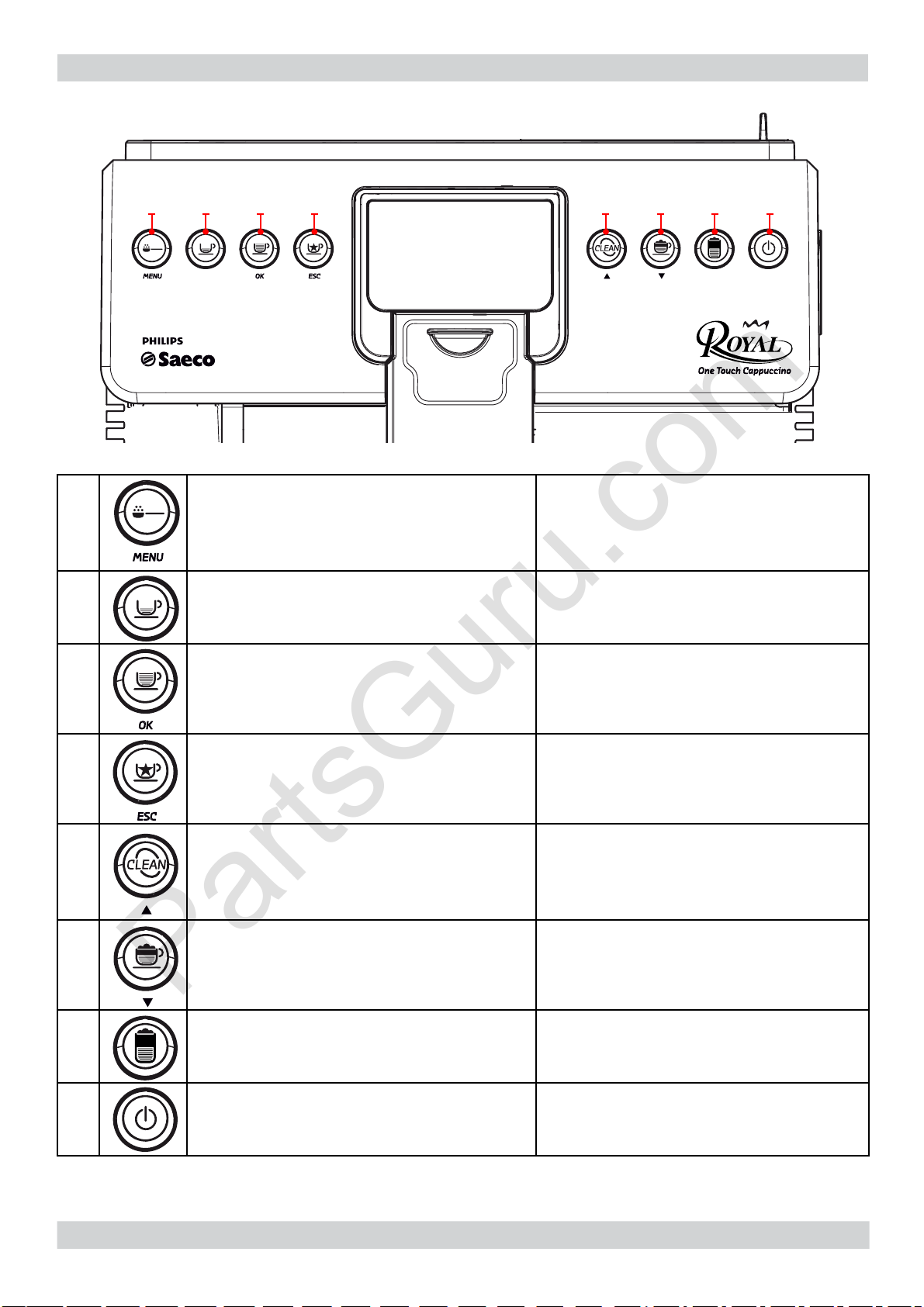

3.1. Customer and programming menu

01

1

Pre-ground selection button - MENU

This button is used to select the possibility to

dispense the coffee with

pre-ground coffee.

2nd function - Press for 5 seconds to access

the machine programming menu.

2

Espresso dispensing button

3

Coffee button - OK

The button is used to select

the type of coffee dispensing.

2nd function - Press to select the heading

shown on the display.

4

Special Drinks selection button - ESC

The button is used to access the l

ist of special

drinks the machine can dispense.

2nd function - Press to exit the selected

page and/or exit the programming mode and/

or stop the drink dispensing.

4

CLEAN button (washing) - Page UP

The button is used to carry out a cleaning cycle

of the cappuccino maker by dispensing steam

(for more details refer to the specifi

c paragraph).

2nd function - Press to scroll the selection in

the page upwards.

6

Cappuccino dispensing button - Page DOWN

The button is used to select cappuccino dispensing.

2nd function - Press to scroll the selection in

the page downwards.

7

Latte Macchiato dispensing button

8

ON/OFF button

MENU

1 2 3 4 5 6 7 8

Services Unlimited, Inc./ Parts Guru

PartsGuru.com

NEW ROYAL 03 USER INSTRUCTIONS

Saeco International Group Rev. 01 Page / 04

02

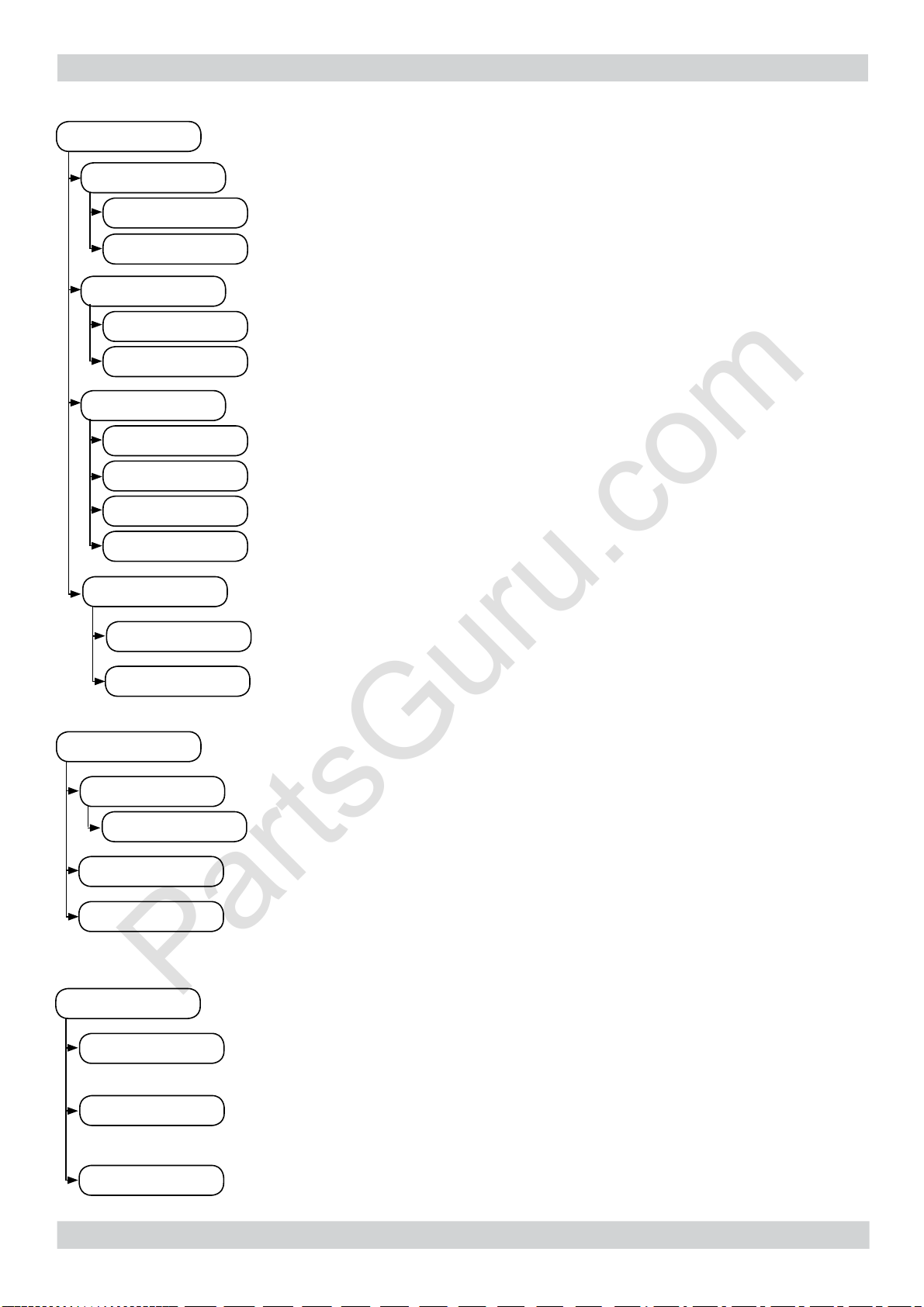

DISPLAY MENU

This function is used to set the menu language and the display brightness

This setting is vital for correctly setting the parameters of the appliance for the user's country

The currently selected language is shown. The language can be changed using the special commands

To set the correct brightness on the display

To set the correct contrast on the display

DISPLAY MENU

BRIGHTNESS

CONTRAST

LANGUAGE

ENGLISH

MACHINE MENU Used to customize the machine's operational settings

ON

OFF

To change the appliance operating settings

This function permits activating/deactivating audible warnings

This function is used to set the time since the last beverage dispensing when the machine will go onto

standb

y. The default time setting is 30 min.

After the set time the machine will go onto standby.

To reactivate the machine, press any button.

After running function diagnosis and the heating phase, the machine is again ready for use

To enable buzzers

When the machine is switched on all the boilers (coffee/steam) come on to allow the immediate

preparation of all beverages.

When the appliance is switched on, only the coffee boiler is activated. The appliance consumes less

power but takes longer to dispense milk beverages

To disable buzzers

This function governs activation of the boilers in the appliance for energy saving

GENERAL MENU

SOUND

ECOMODE

GENERAL STANDBY

OFF

ON

OFF

ON

15 MINUTES

30 MINUTES

60 MINUTES

180 MINUTES

This function is used to enable/disable the cup heater on the top of the machine

To disable the cup heater

To enable the cup heater

CUP HEATER

WATER MENU

This menu is used to set the parameters for correct water management

To change the setting of the hardness of the water in the appliance, adjusting it to the one used, so it

will request descaling at the right time

To activate the fi lter after it has been installed or replaced.

To activate/deactivate the water fi lter replacement warning. When this function is active the appliance

warns the user when the water fi lter needs to be changed.

OFF: Warning disabled ON: Warning enabled

(this value is set automatically when the fi lter is activated)

WATER MENU

ACTIV. FILTER

HARDNESS

ENABL. FILTER

Services Unlimited, Inc./ Parts Guru

PartsGuru.com

Loading...

Loading...