Page 1

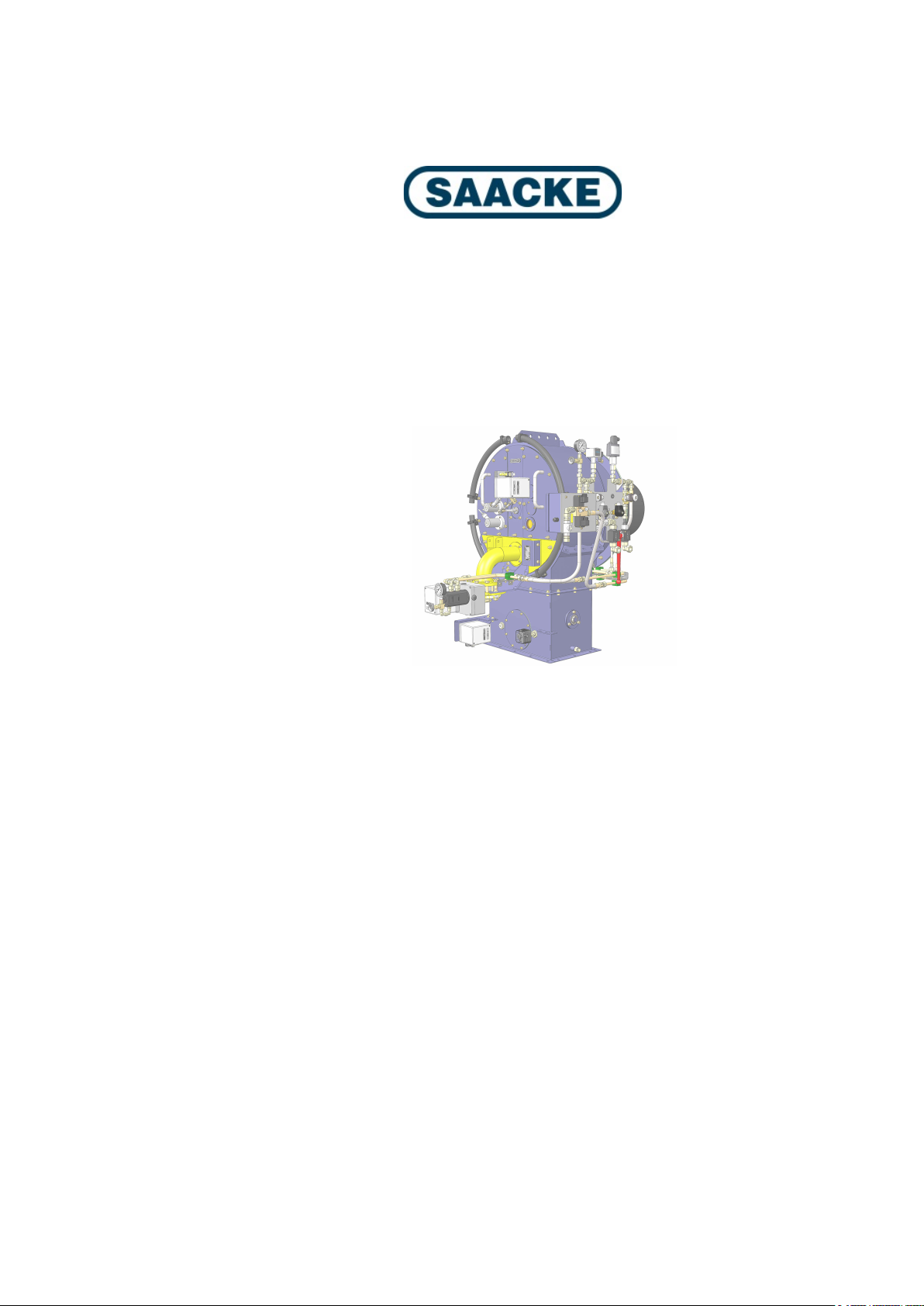

TEMINOX®

GL

Operating Instructions

Duoblock Burner

2021-06-22

BA-TEMINOX-GL-Duo2021-02

Page 2

The reproduction, distribution and utilization of this

the communication of its contents

to others without express authorization is prohibited.

Offenders will be held liable for the payment of

damages. All rights reserved in the event of the grant of

Copyright reserved

Technical Documentation SAACKE

Original Manual

document as well as

a patent, utility model or design.

Page 3

Technology with a Future

ch and development, ensure

Power of innovation, technical

perfection and reliability of all products

account for SAACKE’s technological

leadership. Competent project

management, comprehensive

service network stand for customer

proximity and partnership with a

guaranteed future within the industrial

worldwide -

For more than 80 years SAACKE has set

standards in economic, eco-friendly and

easy-to-service burner technology.

First-rate engineering and continuous

optimization of products and systems,

supported by extensive in-house

resear

requirements and sustain flexibility.

operational advice, and a worldwide

thermal market.

Page 4

Contents

TEMINOX®

GL

0 Contents

0 Contents ............................................................................................................................... 4

1 Safety .................................................................................................................................... 7

1.1 Documentation is a part of the product! ................................................................................................... 7

1.2 Symbols .................................................................................................................................................... 7

1.3 Safety in General ...................................................................................................................................... 8

1.4 Limit Values .............................................................................................................................................. 8

1.5 Authorized Use ......................................................................................................................................... 9

1.6 Limitation of Liability ................................................................................................................................. 9

1.7 Qualified Staff ......................................................................................................................................... 10

1.8 Transport and Interim Storage at Installation Site .................................................................................. 10

1.9 Danger from Hot Surfaces ...................................................................................................................... 10

1.10 Electrical Hazards................................................................................................................................... 11

1.11 Emergency Procedures .......................................................................................................................... 11

1.12 Explosion Protection in Potentially Explosive Atmospheres (ATEX) ..................................................... 11

1.13 Emergency Operation (Applies to Marine Plants Only).......................................................................... 11

1.14 Protective Clothing ................................................................................................................................. 11

2 Transport, Storage and Packing ....................................................................................... 12

2.1 Lifting Lugs ............................................................................................................................................. 12

2.2 Safety Instructions for Transport ............................................................................................................ 13

2.3 Checking the Delivery ............................................................................................................................ 13

2.4 Reporting Transport Damage ................................................................................................................. 13

2.5 Instructions for Storage .......................................................................................................................... 13

2.6 Disposal of the Packaging ...................................................................................................................... 14

2.7 Disposal of the Product .......................................................................................................................... 14

3 Design and Function ......................................................................................................... 15

4 Construction of the Refractory Brickwork ....................................................................... 20

4.1 Burner Head Variant C01 / C03 ............................................................................................................. 21

4.2 Burner Head Variant C02 ....................................................................................................................... 22

5 Mounting Instructions ....................................................................................................... 23

5.1 Mounting the Burner ............................................................................................................................... 23

5.2 Connecting Lines and Fittings ................................................................................................................ 25

6 Electrical Connections of the Burner ............................................................................... 27

7 Operation ............................................................................................................................ 28

7.1 Preparing the Heat Generator ................................................................................................................ 28

7.2 Preparing the Burner .............................................................................................................................. 28

7.3 Starting the Burner ................................................................................................................................. 28

Technical Documentation

4 / 78

BA-TEMINOX-GL-Duo2021-02 2021-06-22

Page 5

TEMINOX®

GL Contents

7.4 Controlled Operation .............................................................................................................................. 28

7.5 Switching Off the Burner ........................................................................................................................ 28

7.6 Service Interruption due to Fault ............................................................................................................ 29

8 Functional Schematic ........................................................................................................ 30

9 Maintenance / Cleaning ..................................................................................................... 34

9.1 General Information ................................................................................................................................ 34

9.2 Preparing Maintenance Work ................................................................................................................. 35

9.2.1 Periodical Maintenance (Fault not Acute) ............................................................................... 35

9.2.2 Maintenance after a Fault has Interrupted the Operation ....................................................... 36

9.3 Maintenance Intervals ............................................................................................................................ 36

9.4 Maintenance of General Components.................................................................................................... 37

9.4.1 Checking Supply Pressures .................................................................................................... 39

9.4.2 Cleaning the Flame Scanner / Performing a Function Test .................................................... 40

9.4.2.1 SAACKE FLUS 06 UV / FLS 09 UV ................................................................... 40

9.4.2.2 F 200 K2 ............................................................................................................. 41

9.4.3 Checking the Air Pressure Monitor ......................................................................................... 42

9.4.4 Checking the Protective Grating of the Fan ............................................................................ 43

9.4.5 Lubricating the Bearings of the Fan Motors (>75 kW Fan Output) ......................................... 43

9.4.6 Checking the Force Transmitter .............................................................................................. 43

9.4.7 Checking the Ignition Cables and Plug-and-Socket Connections .......................................... 43

9.4.8 Checking the Ignition Systems ZAP(ZDAP) and ZA0(ZDA0) ................................................. 44

9.5 Maintenance of Components Relevant to the Oil Operation Mode ........................................................ 45

9.5.1 Cleaning the Dirt Trap ............................................................................................................. 46

9.5.2 Checking the Fuel Lines Outside the Burner .......................................................................... 46

9.6 Maintenance of Components Relevant Especially to the Gas Operation .............................................. 47

9.7 After Completion of the Maintenance Work ........................................................................................... 47

10 Troubleshooting ................................................................................................................ 48

10.1 Troubleshooting (Gas Operation) ........................................................................................................... 48

10.2 Troubleshooting (Oil Operation) ............................................................................................................. 52

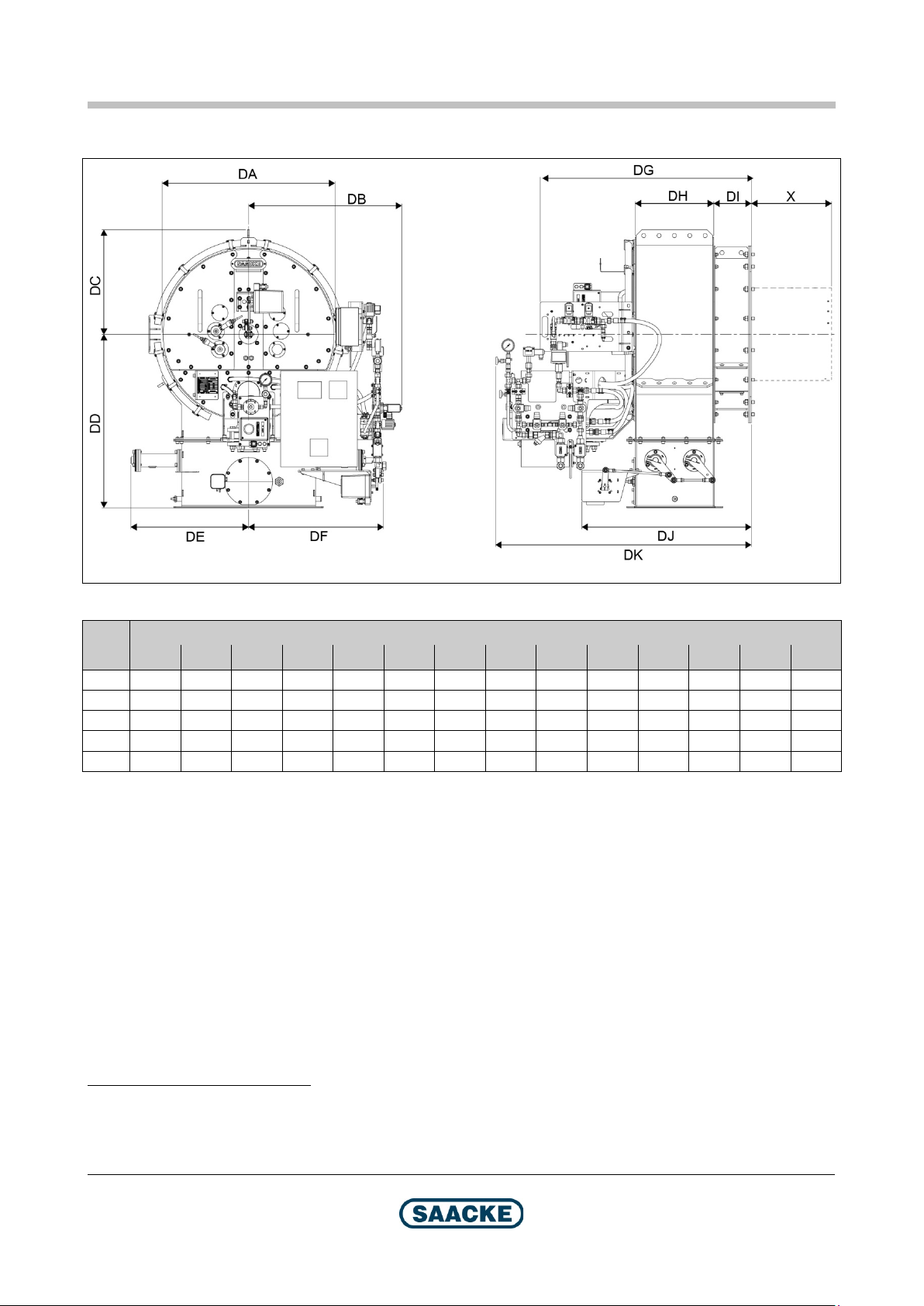

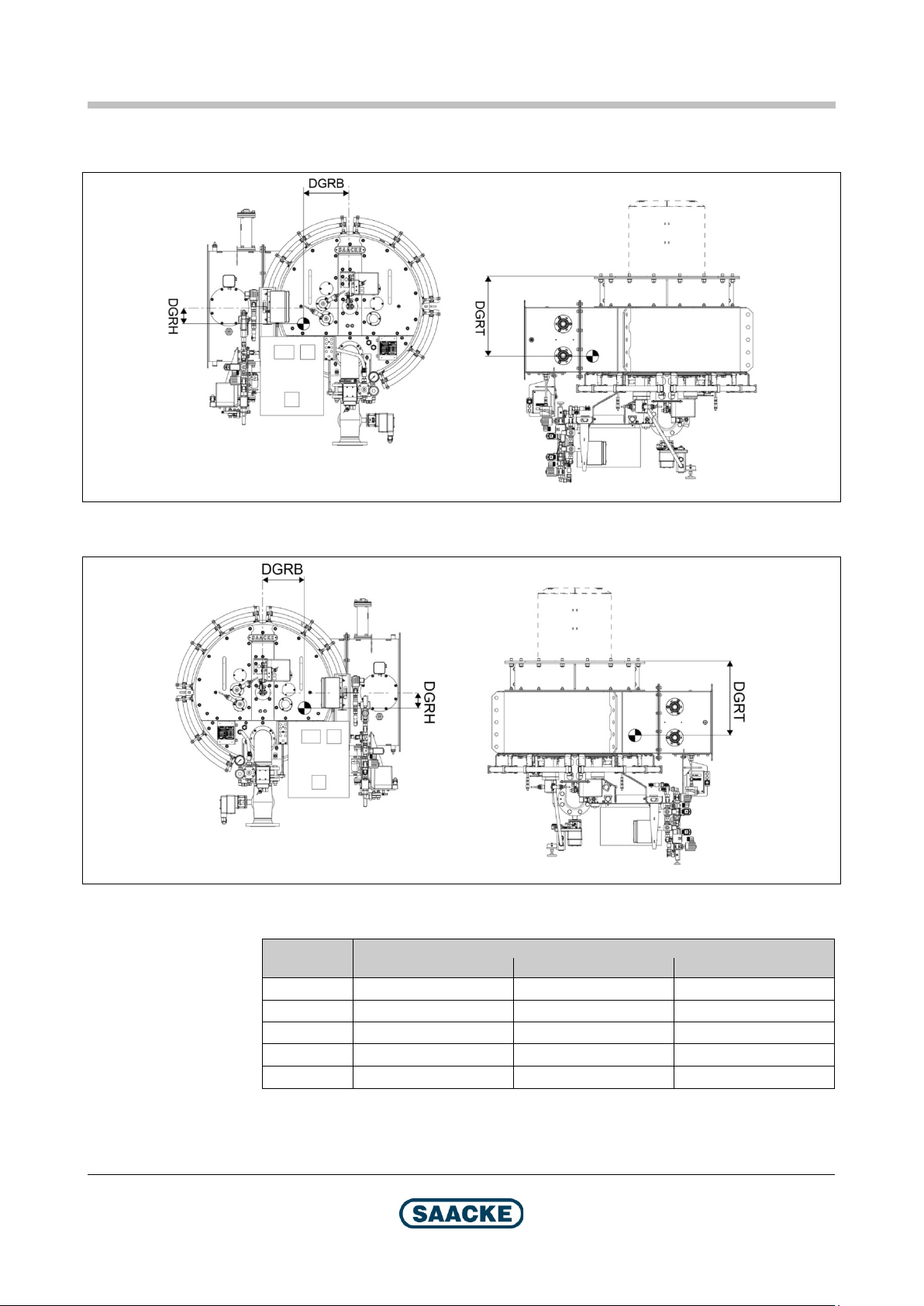

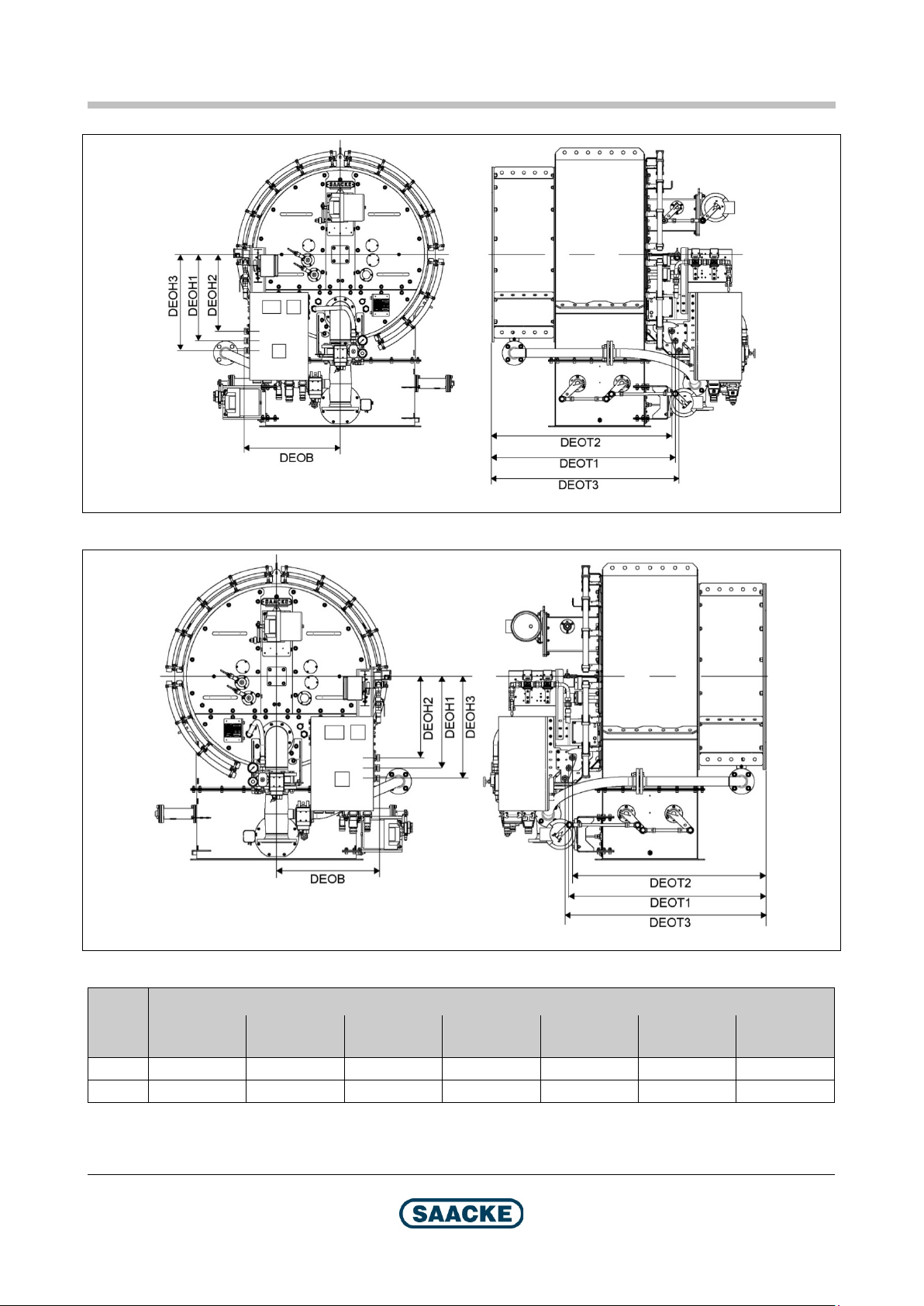

11 Dimensions / Types ........................................................................................................... 55

11.1 Arrangement of the Ignition Medium and Fuel Fittings .......................................................................... 55

11.2 Basic Dimensions ................................................................................................................................... 58

11.3 Weight .................................................................................................................................................... 59

11.3.1 Mixing System ......................................................................................................................... 59

11.3.2 Integrated Burner Control System (Optional) ......................................................................... 59

11.3.3 Motor Control (Optional) ......................................................................................................... 59

11.4 Center of Gravity .................................................................................................................................... 60

11.5 Position of the Fuel Inlets ....................................................................................................................... 61

11.6 Position of the Air Inlet Connection ........................................................................................................ 65

11.7 Burner Mounting Plate ............................................................................................................................ 66

Technical Documentation

2021-06-22

BA-TEMINOX-GL-Duo2021-02 5 / 78

Page 6

Conte

nts TEMINOX®

GL

11.8 Minimum Distances ................................................................................................................................ 68

11.8.1 All Duoblock Burners .............................................................................................................. 68

11.8.2 “Outer” Ignition and Fuel Fittings ............................................................................................ 69

11.8.3 “Inner” Ignition and Fuel Fittings ............................................................................................. 70

11.9 Connection Dimensions ......................................................................................................................... 71

11.10 Tightening Torque for Mounting Screws ................................................................................................ 72

12 Technical Data ................................................................................................................... 73

12.1 Capacity and Turndown Ratio ................................................................................................................ 73

12.2 Requirements for Fuels and Further Media ........................................................................................... 74

12.3 Distances of Fuel Supply System Components ..................................................................................... 75

12.4 Electrical Data ........................................................................................................................................ 75

12.5 Permitted Mounting Positions ................................................................................................................. 76

12.6 Acoustic Emissions................................................................................................................................. 77

6 / 78

Technical Documentation

BA-TEMINOX-GL-Duo2021-02 2021-06-22

Page 7

TEMINOX®

GL

Safety

1 Safety

1.1 Documentation is a part of the product!

This document is an integral part of the product. It must be retained for the entire

service life of the product. Make this document available to the staff responsible for

the work described in it. Add any updates you receive later from SAACKE to the

document.

Help us improve this documentation!

We appreciate any feedback that improves the quality of our documentation. You

will find our address on the back of this document.

1.2 Symbols

Especially important information in this document is highlighted by the

corresponding symbols:

Warning!

The industrial safety symbol identifies safety instructions whose purpose is to

prevent physical injury or death. Follow these safety instructions carefully and be

especially cautious during the work/procedures they refer to.

Warning! Risk of death from electric shock!

The electricity symbol identifies safety instructions whose purpose is to prevent

physical injury or death from electric shock. Follow these safety instructions

carefully and be especially cautious during the work/procedures they refer to.

Caution!

The caution symbol identifies all safety warnings whose purpose is to prevent

damage or destruction of the product and/or other plant components.

2021-06-22

Note

This points to information or notes that are especially useful.

Technical Documentation

BA-TEMINOX-GL-Duo2021-02 7 / 78

Page 8

Safety

TEMINOX®

GL

1.3 Safety in General

The "Safety" chapter gives you an overview of the safety aspects you must pay

attention to in order to work with the product safely. Any individual who assembles,

installs, mounts, commissions, operates and/or does maintenance on the product

described must read and follow the instructions in this chapter carefully to avoid

physical injury and material damage. Your safety is at stake.

In addition to these general safety instructions you will find specific safety

instructions in the product documentation related to individual actions or

procedures.

Only if you follow all of the safety instructions will you be able to provide the best

possible protection for yourself, your colleagues and the environment by ensuring

that the product functions safely and reliably.

In addition to this, it is imperative that you comply with the accident prevention and

safety regulations of the country you are working in.

1.4 Limit Values

The following products (apart from the burner) are considered as further

subsystems of a plant:

Heat generator / air supply system / flue gas system

Fuel supply system

Burner control system

Other plant components that are not part of the burner (e.g. sound absorbing

These subsystems are required to operate the plant but they are not an integral

part of the burner described in the present document and may vary depending on

the plant. For this reason, the present burner documentation does not include any

concrete contents on the other subsystems of the plant.

system, emissions-reducing systems)

We assume that the burner and the other subsystems are properly mounted and

electrically connected before they are commissioned and that the supply of the

burner with the fuel agreed on in the contract is ensured. We also assume that the

other subsystems comply with the relevant standards/regulations, that they are

compatible with the burner and have been tested for proper operation.

The burner must be integrated into a coherent plant environment. For instructions

on integrating the burner into a coherent plant environment, please refer to the

chapters "Furnace Dimensions" and "Burner Selection" in the planning

documentation. For any information required for mounting the burner, connecting

the burner to the electric system and for the construction of the refractory

brickwork, please refer to the planning documentation and to the operating

instructions.

The plant authorities must ensure compliance with the country-specific accident

prevention and safety regulations. They must also ensure that the work

environment (e.g. boiler house) complies with the regulations. We recommend that

the plant authorities compile operating instructions for the entire work environment.

The present document and all other manufacturer´s documentation for the plant

components should be used as a basis for these operating instructions.

Technical Documentation

8 / 78

BA-TEMINOX-GL-Duo2021-02 2021-06-22

Page 9

TEMINOX®

GL

Safety

1.5 Authorized Use

The burner is exclusively designed to generate heat within the performance data

specified in the Technical Data by combusting the fuel specified on the rating plate.

The burner must be integrated into a coherent plant environment (fuel supply

system, heat generator etc.) (refer to chapter 1.4).

The energy generated by the burner, must be taken off, also during

commissioning.

To ensure proper operation of the burner, the pressure at the installation site must

not be negative relative to the atmosphere. The suction opening of the fan must be

free to ensure that it can draw in sufficient air.

Before the burner may be used for controlled operation, it must be commissioned

(with regard to its combustion performance). Only commissioning experts (refer to

"Qualified Staff") are permitted to commission the burner.

The commissioning expert is responsible for achieving proper combustion at all of

the firing rates and for ensuring that all the safety equipment (monitors etc.) are set

correctly. He/she must record all the values set in an approval and measurement

report and make it available to the plant authorities.

The settings made during commissioning must not be changed later on. Exception:

If the operating conditions change at a time following commissioning (e.g. due to

changed fuel properties or the plant environment), a commissioning expert must

check the settings and adjust them, if required. Again, the values set must be

recorded in an approval and measurement report.

The burner is fitted with safety equipment and has been tested for safety and

accepted. It may be operated only if the entire safety equipment has been adjusted

correctly and is in operation. The following is considered as safety equipment:

safety interlock circuits and all the associated components, all the other monitors

as well as construction-related protective measures such as safety fencing and

warning signs.

It is prohibited to modify or disable safety equipment unless the documentation

explicitly instructs you to disable and/or dismount such equipment temporarily. If

this should be required, e.g. for maintenance, the safety equipment must be

mounted and/or enabled again before the burner is taken into operation again. As

a rule, warning signs must never be covered or removed.

Unauthorized reconstruction and modification of the burner is prohibited. Only

original spare parts may be used! The use of third-party accessories must explicitly

be approved by SAACKE.

Comply with the instructions and regulations in the documentation in all the phases

of life of the burner. This applies especially to the burner maintenance (adhering to

the intervals for inspection and maintenance and for replacing safety-related

components).

To ensure operability, safety and economic efficiency, the plant must be inspected

by the manufacturer and/or authorized and trained personnel once a year. A

service agreement is recommended. SAACKE Service is at your disposal for more

detailed information.

1.6 Limitation of Liability

Any use deviating from the conditions specified above is considered as

unauthorized.

2021-06-22

SAACKE does not assume liability for damage resulting from unauthorized use.

Such use is at the risk of the operator/plant authorities.

Technical Documentation

BA-TEMINOX-GL-Duo2021-02 9 / 78

Page 10

Safety

TEMINOX®

GL

1.7 Qualified Staff

Warning!

Risk of injury and property damage due to improper operation!

The plant authorities must ensure that only qualified and authorized personnel uses

the product.

In terms of the present documentation, the term qualified staff refers to persons

who have been trained in handling the described product and are authorized by the

plant authorities to mount, commission, operate and/or service the product.

The burner may only be commissioned by personnel especially trained and

certified to do so for the burner and the plant components concerned

("commissioning experts“). SAACKE will provide the training and certification for

the burner; either SAACKE or the respective manufacturer will provide the training

and certification for the other plant components.

1.8 Transport and Interim Storage at Installation Site

Risk of injuries if the burner falls over

If the burner falls over, it can cause serious injuries!

Always follow the transport and storage instructions.

1.9 Danger from Hot Surfaces

Warning! Risk of burns from hot surfaces!

If the burner is operated with preheated air, steam or preheated oil, the following

safety measures must be taken to avoid injury:

Burners operating with preheated air are designed to be insulated.

Protect all accessible surfaces with insulation (for instance, in the form of mineral

insulation), so that the surface temperature does not exceed 50 °C (in

accordance with DIN EN 563) and/or protect all accessible surfaces with a

protection plate.

Burners and associated components operated with steam or preheated oil that

were not insulated ex works upon delivery must also be insulated appropriately.

Nevertheless, ensure that all hazardous areas are equipped with clearly visible

warning signs to draw the personnel's attention to the risk of injury arising from

contact with hot surfaces.

Wear appropriate protective clothing when performing any work on the burner and

always comply with national accident prevention and safety regulations.

Warning! Risk of burns from hot surfaces!

The FGR line must be insulated at burners that are operated with recirculated flue

gas.

10 / 78

Technical Documentation

BA-TEMINOX-GL-Duo2021-02 2021-06-22

Page 11

TEMINOX®

GL

Safety

1.10 Electrical Hazards

Warning! Risk of death from electric shock!

Damaged lagging or live components that are not covered correctly present a risk

of death from electric shock!

Warning! Risk of death from electric shock!

Carelessness can lead to an electric shock.

This is why when you work with electrical equipment, you must always first:

1. Disconnect each piece of equipment from the mains.

2. Secure it to prevent it from being switched back on.

3. Check that the equipment is de-energized.

4. Ground the equipment and short-circuit it.

5. Cover other components/equipment nearby that are energized.

6 Secure the danger zone, for example by blocking it off and/or putting up a

1.11 Emergency Procedures

conspicuous danger sign that no one can overlook.

In the case of danger:

Press the "Emergency stop button" of the plant and cut off the fuel supply!

1.12 Explosion Protection in Potentially Explosive Atmospheres (ATEX)

If the product is to be used in potentially explosive atmospheres, the plant

authorities must ensure that the product is integrated into an appropriate explosion

protection concept in compliance with directive 1999/92/EC.

1.13 Emergency Operation (Applies to Marine Plants Only)

SAACKE burners used in marine plants feature an emergency operation function

to meet the requirements of the corresponding classification societies. For more

information, please refer to the emergency operation documents that are part of

the plant documentation.

1.14 Protective Clothing

Warning!

When performing any work, always wear appropriate protective clothing that

complies with the accident prevention and safety regulations of the country you are

working in.

Transport

2021-06-22

Technical Documentation

BA-TEMINOX-GL-Duo2021-02 11 / 78

Page 12

Transport, Storage and Packing

TEMINOX®

GL

TMX029

2 Transport, Storage and Packing

The burner is delivered screwed onto a transport rack and secured with holding

straps.

Remove the transport rack before mounting the burner onto the heat generator.

2.1 Lifting Lugs

12 / 78

Fig. 1: Lifting lugs

Note

Observe the information on weight and center of gravity in chapter "Dimensions /

Types".

Technical Documentation

BA-TEMINOX-GL-Duo2021-02 2021-06-22

Page 13

TEMINOX®

GL

Transport, Storage and Packing

2.2 Safety Instructions for Transport

Warning! Risk of accidents during transport!

There is the risk of accidents during burner transport due to the heavy weight.

Do not stand under suspended loads.

Always use the appropriate aids when loading the burner (e.g. forklift or

crane).

Warning! Risk of injuries from hoists too weak for the load!

Hoists or lifting equipment that are too weak for the load can tear.

Always select hoists or lifting equipment with sufficient load bearing capacity.

Use only tested and reliable hoists and lifting equipment, such as:

– Shackles, e.g. according to DIN 82101.

– Sling chains, e.g. according to DIN 5687 Product Grade 8

Caution!

The improper use of means of transport and tools (e.g. forklift or crane) bears the

risk of damaging the burner or burner components.

2.3 Checking the Delivery

SAACKE products are packed and checked before they leave the factory.

When the product is delivered, first check whether the packaging is intact. This

would be the first indication that it has been transported correctly.

Check the product for transport damage.

2.4 Reporting Transport Damage

If damage has occurred during transport, follow these procedures:

Record the transport damage on the freight documents and take a

photograph and/or make a sketch of it.

Have the person responsible for the delivery (for example the truck driver)

confirm that the damage was noticed by signing the freight documents.

Report the transport damage right away to SAACKE or whichever company

supplied the product.

2.5 Instructions for Storage

Only store the burner on the pallet or in the crate that it was delivered on/in.

Store the burner on safe and firm ground.

Keep all components, especially electrical, pneumatic and hydraulic components,

dry, free of dust and at their correct temperature during storage. The relative

humidity must be below 80 %.

2021-06-22

Protect the burner with appropriate covering in the case of a long period of

inactivity. Preserve all metal surfaces.

Technical Documentation

BA-TEMINOX-GL-Duo2021-02 13 / 78

Page 14

Transport, Storage and Packing

GL

2.6 Disposal of the Packaging

Dispose of all packaging correctly and ecologically.

When you do it, comply with the waste disposal regulations of the country in which

you are working.

2.7 Disposal of the Product

At the end of its service life the product must be disposed of correctly and

ecologically.

When you do it, comply with the waste disposal regulations of the country in which

you are working.

TEMINOX®

14 / 78

Technical Documentation

BA-TEMINOX-GL-Duo2021-02 2021-06-22

Page 15

TEMINOX®

GL

Design and Function

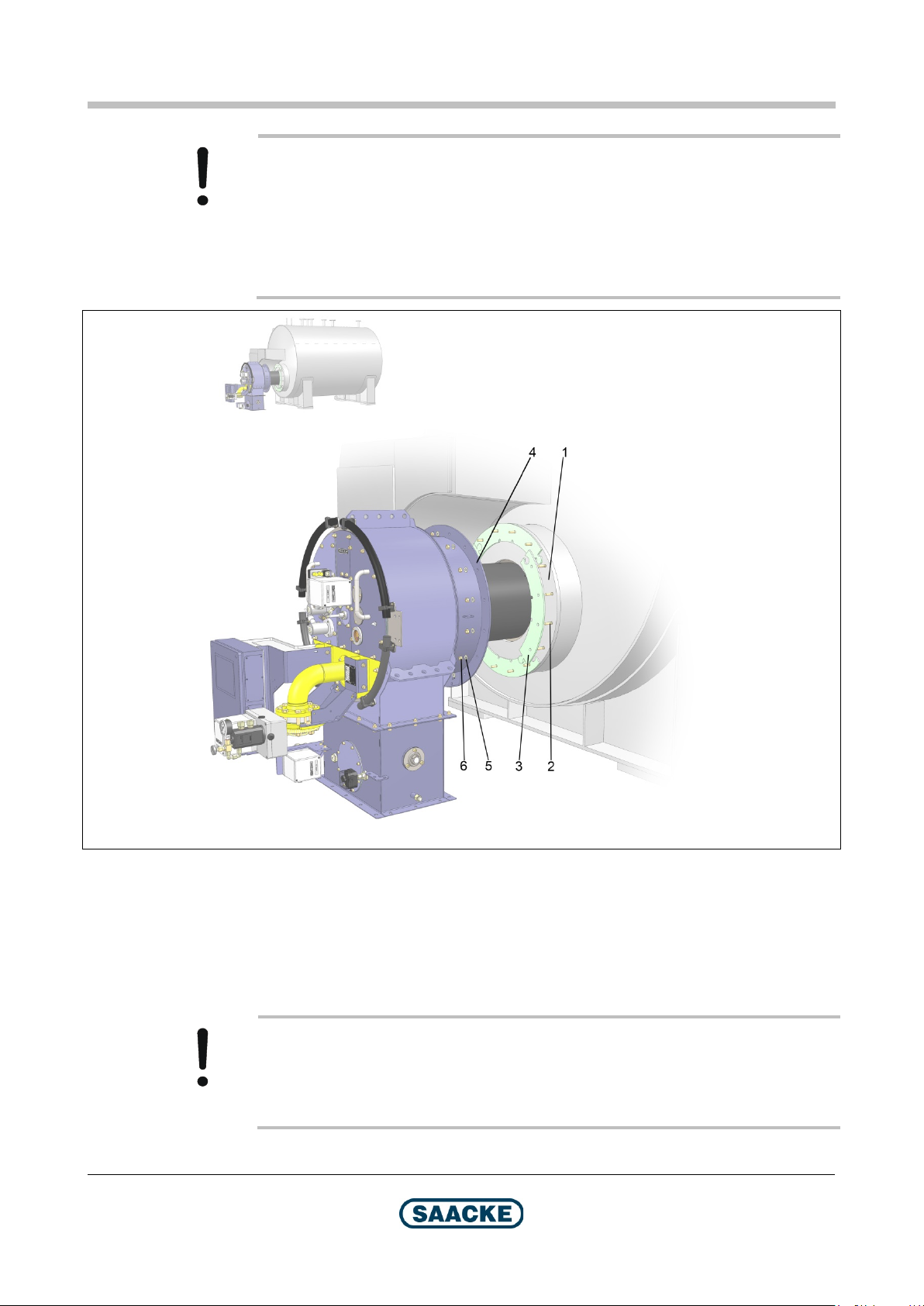

TMX192

3 Design and Function

Note

A burner with standard equipment is shown. The equipment may vary depending

on the plant. As several burner head variants are possible, the presentation of the

burner head may differ.

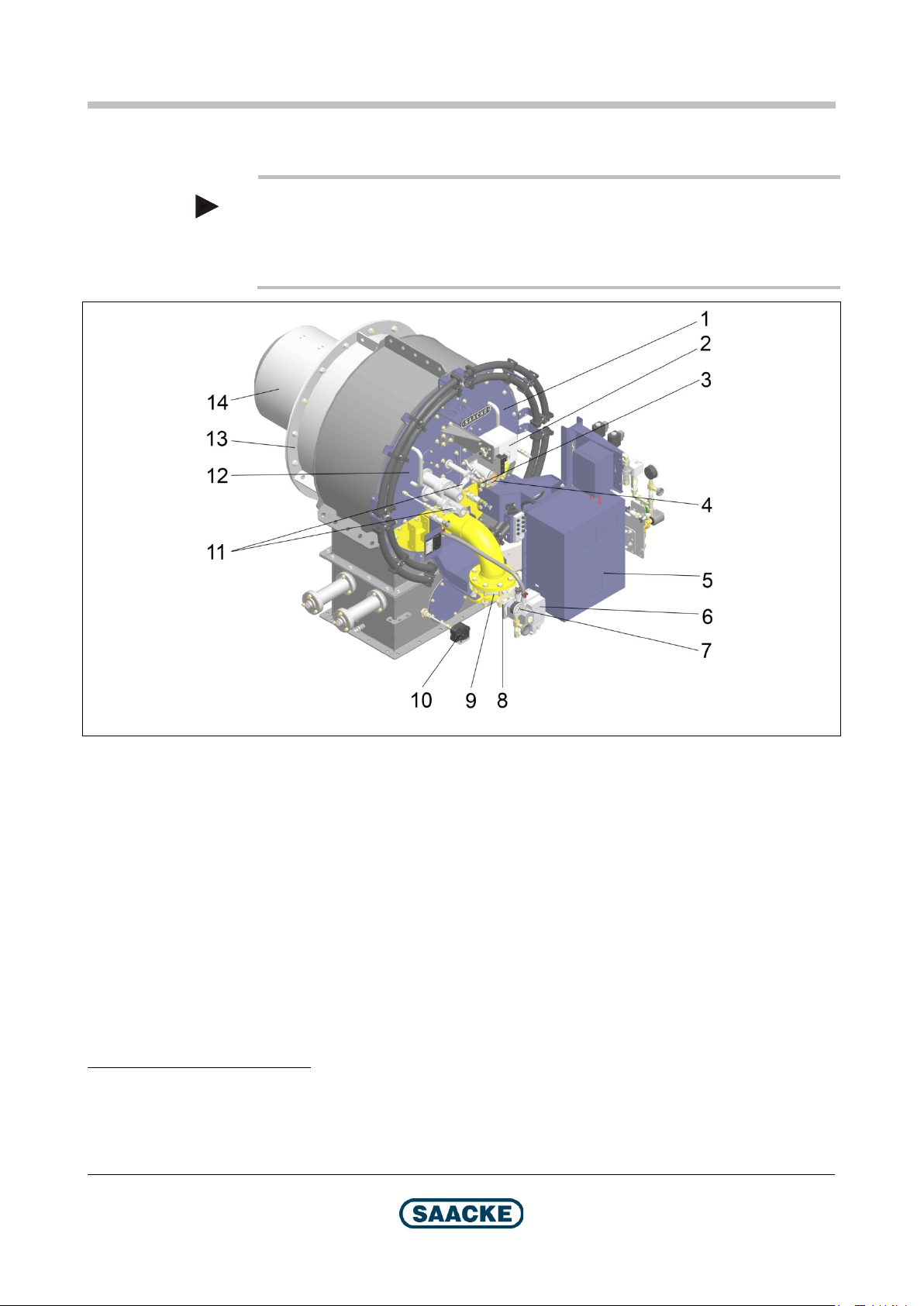

Fig. 2: Burner components (1)

1 Right-hand maintenance cover

2 Servomotor for stabilizing disk retract mechanism

3 Driving linkage for stabilizing disk retract mechanism

4 Inspection glass

5 Component connection box / control box for optional integrated burner control system

6 Servomotor for oil flow controller / gas control damper

7 Return line pressure gauge (with manual shut-off fitting)

8 Power transmitter for oil flow controller / gas control damper

9 Gas control damper

10 Pressure monitor (L) for combustion air

11 Flame scanner (here: optional variant with 2 flame scanners)

12 Left-hand maintenance cover

13 Flange

14 Burner head

1

2

1

With TEMINOX G burners with burner head variant C02, a manual stabilizing disk retract mechanism is

installed as the standard. The servomotor is only available as an option for this variant.

2

Only TEMINOX GL (dual-fuel burner)

Technical Documentation

2021-06-22

BA-TEMINOX-GL-Duo2021-02 15 / 78

Page 16

Design and Functi

on TEMINOX®

GL

TMX193

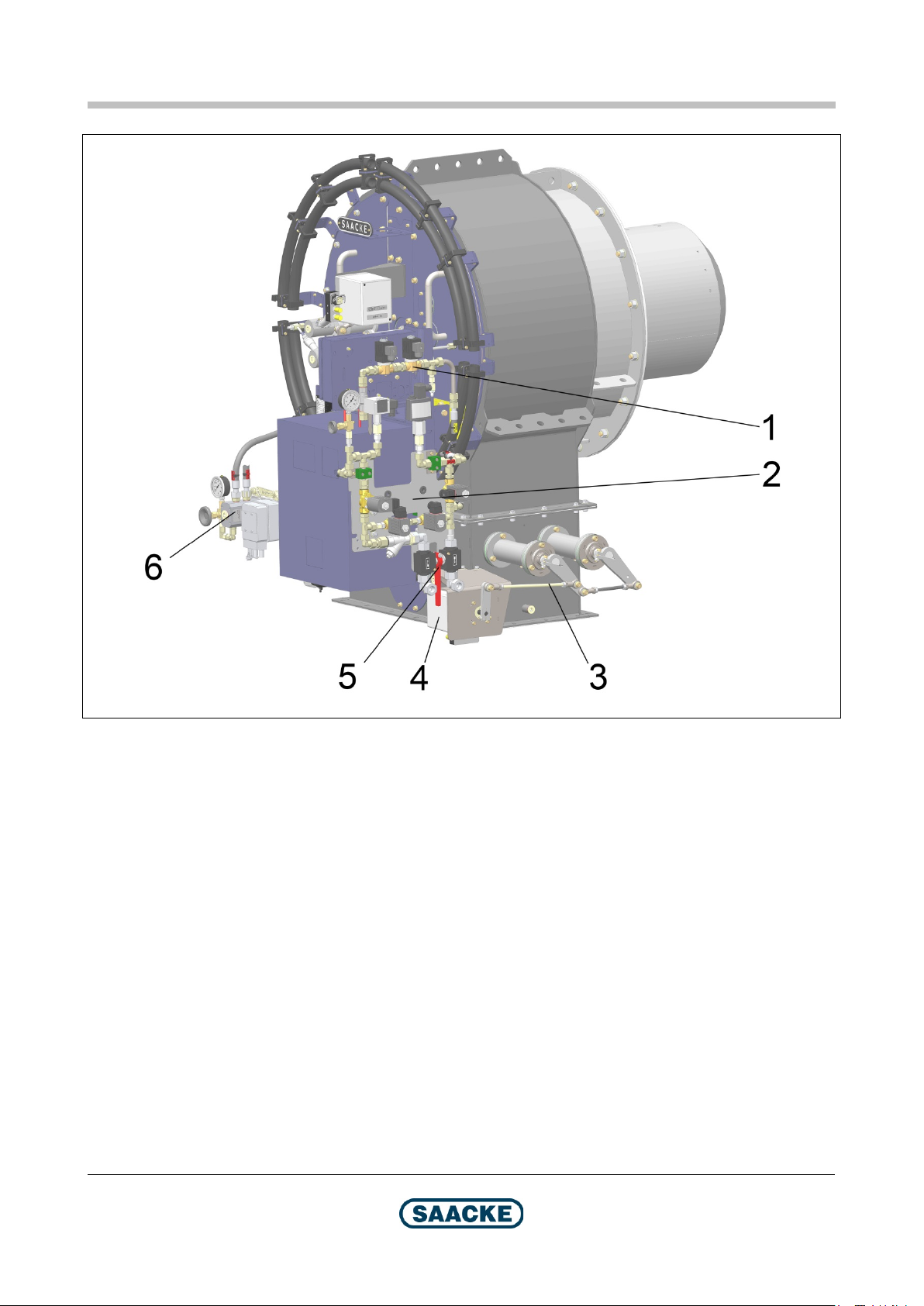

Fig. 3: Burner components (2)

1 Ignition valves (here: manual shut-off fitting in open position)

2 Oil fittings block (see separate figure)

3 Driving linkage for air control dampers

4 Servomotor for air control dampers

5 Manual shut-off fitting supply line / return line (mechanically coupled) (here: open position)

6 Oil flow controller

16 / 78

Technical Documentation

BA-TEMINOX-GL-Duo2021-02 2021-06-22

Page 17

TEMINOX®

GL

Design and Function

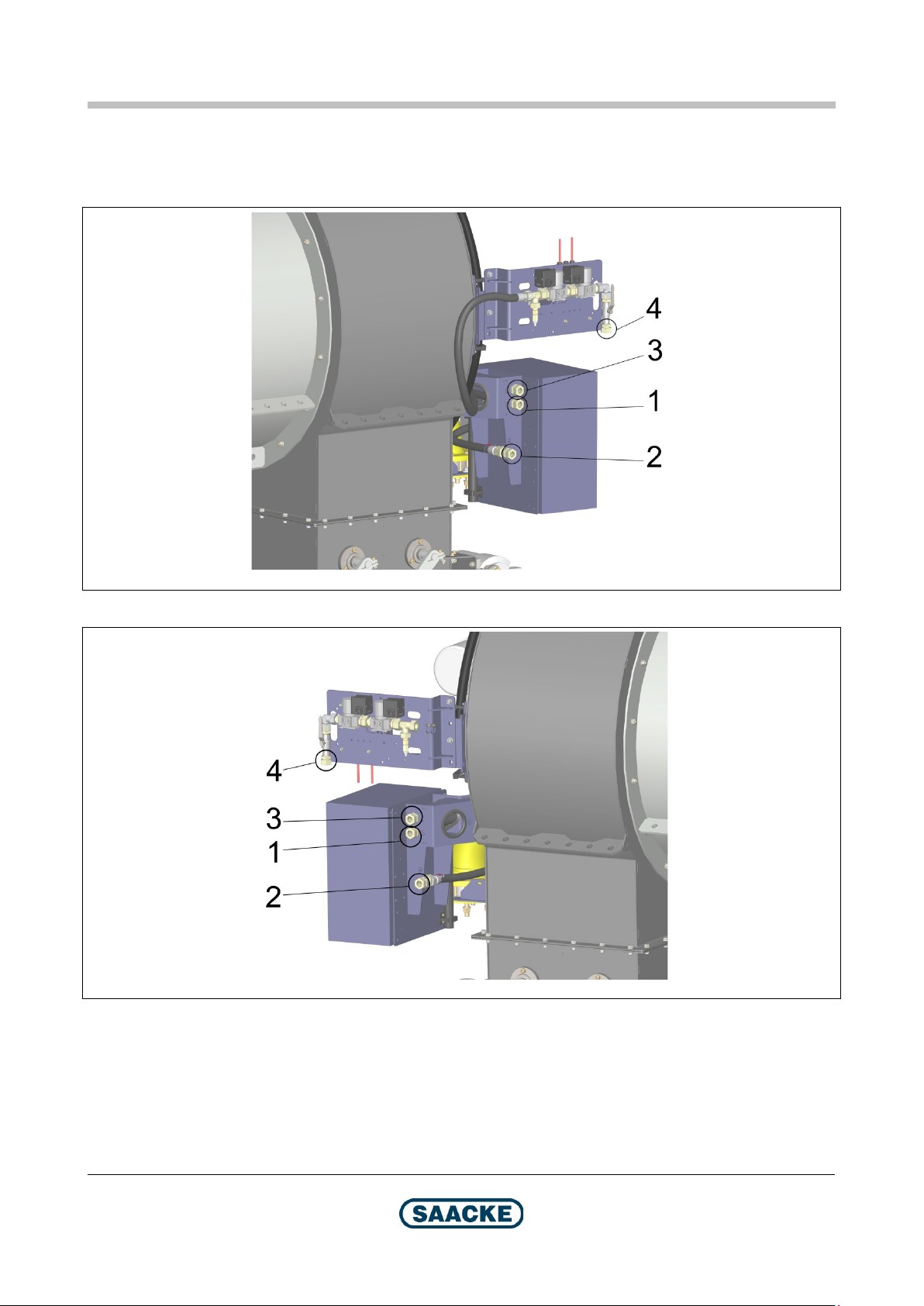

TMX254

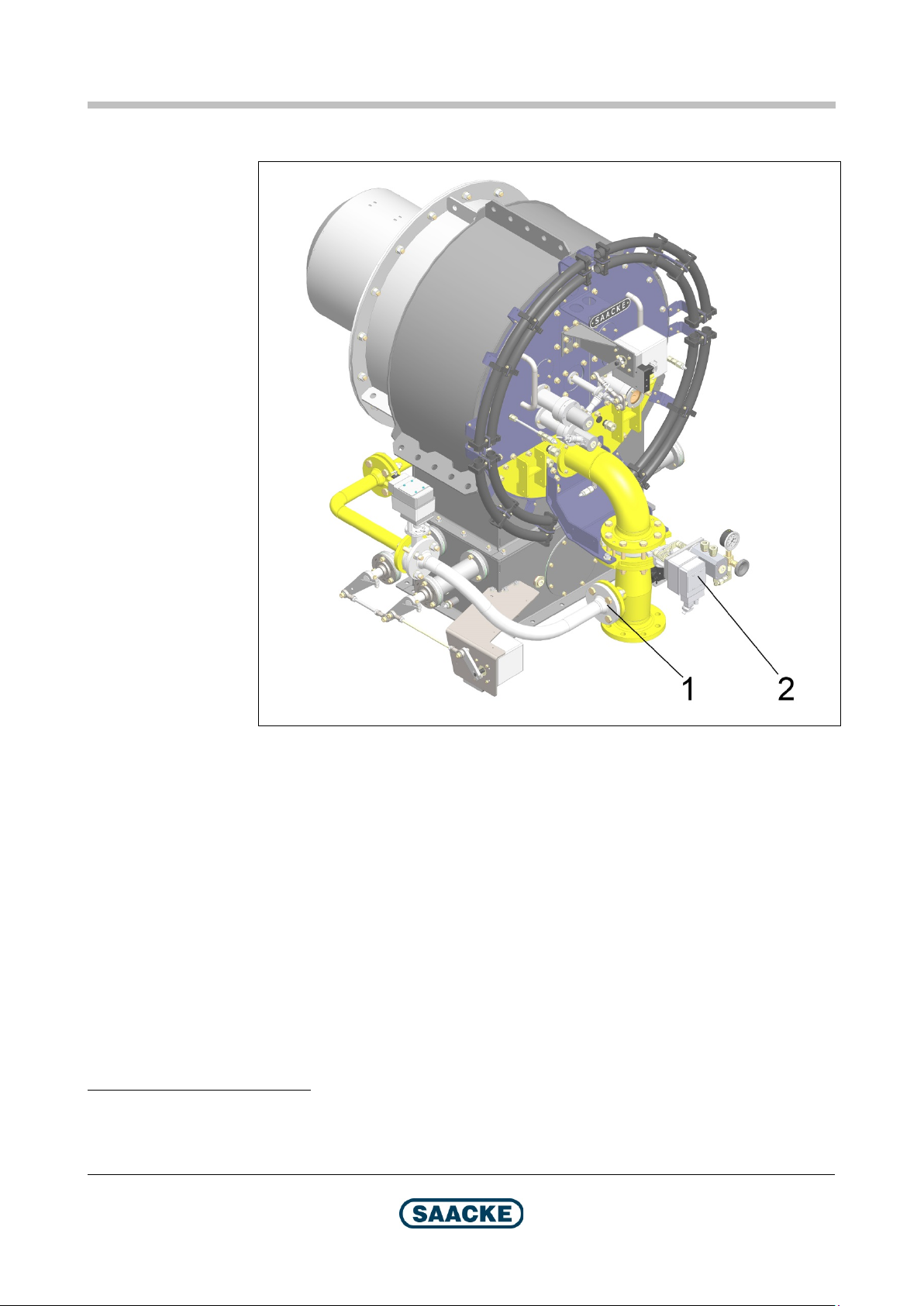

Burner with Controlled Primary Gas (optional3)

Fig. 4: Burner with controlled primary gas4

1 Primary gas control damper

2 Servomotor for primary gas control damper

3

Standard with burner head variant C03

4

Oil fittings and component connection box are hidden for a better overview

2021-06-22

Technical Documentation

BA-TEMINOX-GL-Duo2021-02 17 / 78

Page 18

Desig

n and Function TEMINOX®

GL

TMX015

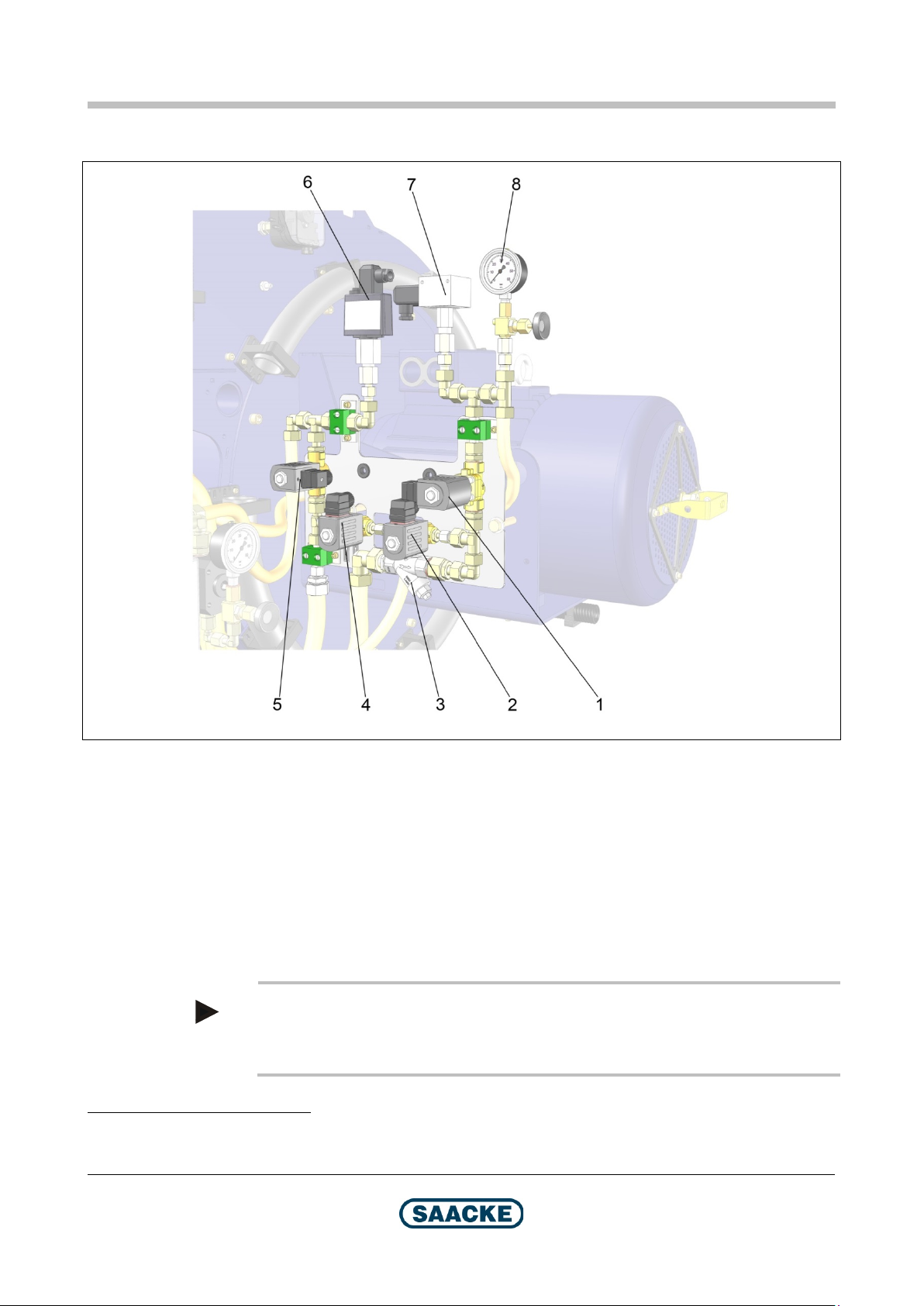

Oil Fittings Block

Fig. 5: Oil fittings block5

1 Rapid shut-off valve supply line

2 Rapid shut-off valve control line supply line

3 Dirt trap

4 Rapid shut-off valve control line return line

5 Rapid shut-off valve return line

6 Pressure monitor (H)

7 Pressure monitor (L)

8 Pressure gauge for supply flow pressure (with manual shut-off fitting)

Not illustrated: Manual shut-off fitting supply line / return line (see figures above)

Note

Depending on the arrangement of the ignition medium and fuel fittings, the oil

fittings block can have a laterally inversed design.

5

The example shows a monoblock burner, the duoblock burner has a similar design

Technical Documentation

18 / 78

BA-TEMINOX-GL-Duo2021-02 2021-06-22

Page 19

TEMINOX®

GL

Design and Function

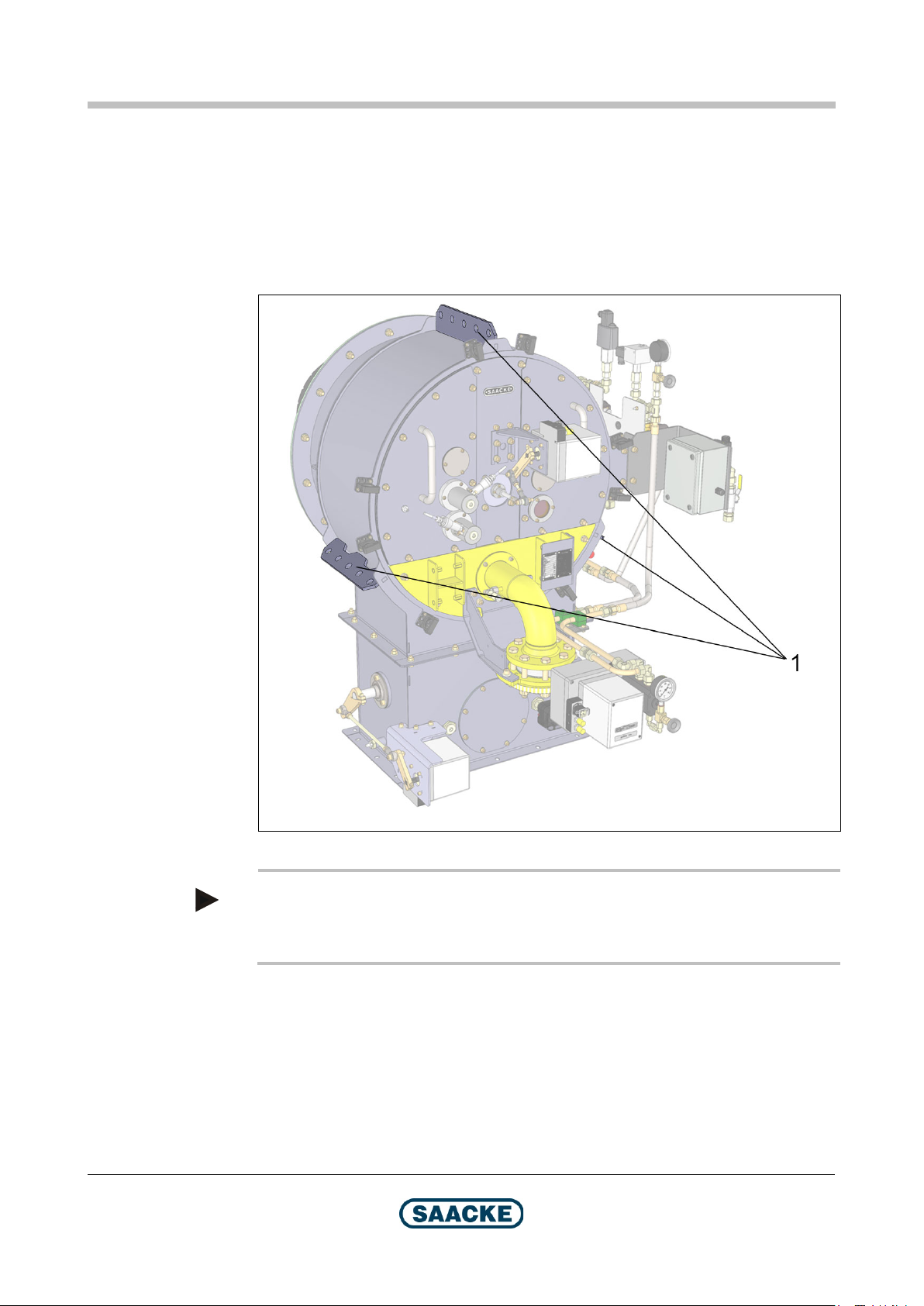

TMX194

Position of the Rating Plate and the Plate for Variant Designation

2021-06-22

Fig. 6: Position of the rating plate and the plate for variant designation

1 Rating plate and plate for variant designation

Technical Documentation

BA-TEMINOX-GL-Duo2021-02 19 / 78

Page 20

Construction of the Refractory Brickwork

TEMINOX®

GL

4 Construction of the Refractory Brickwork

Before the burner can be mounted on the heat generator, refractory brickwork must

be constructed in keeping with the specifications in the present chapter.

The fireproof material for the refractory brickwork should have a AL

content of

2O3

at least 60 % and a spalling resistance of at least 15.

Warning!

The refractory brickwork must be parallel to the burner mounting plate and at right

angle to the center line of the burner, as shown in the figure.

With this burner head variant

please continue with chapter “Burner Head Variant C01 / C03”.

With this burner head variant

please continue with chapter “Burner Head Variant C02”.

20 / 78

Technical Documentation

BA-TEMINOX-GL-Duo2021-02 2021-06-22

Page 21

TEMINOX®

GL

Construction of the Refractory Brickwork

TMX053

W

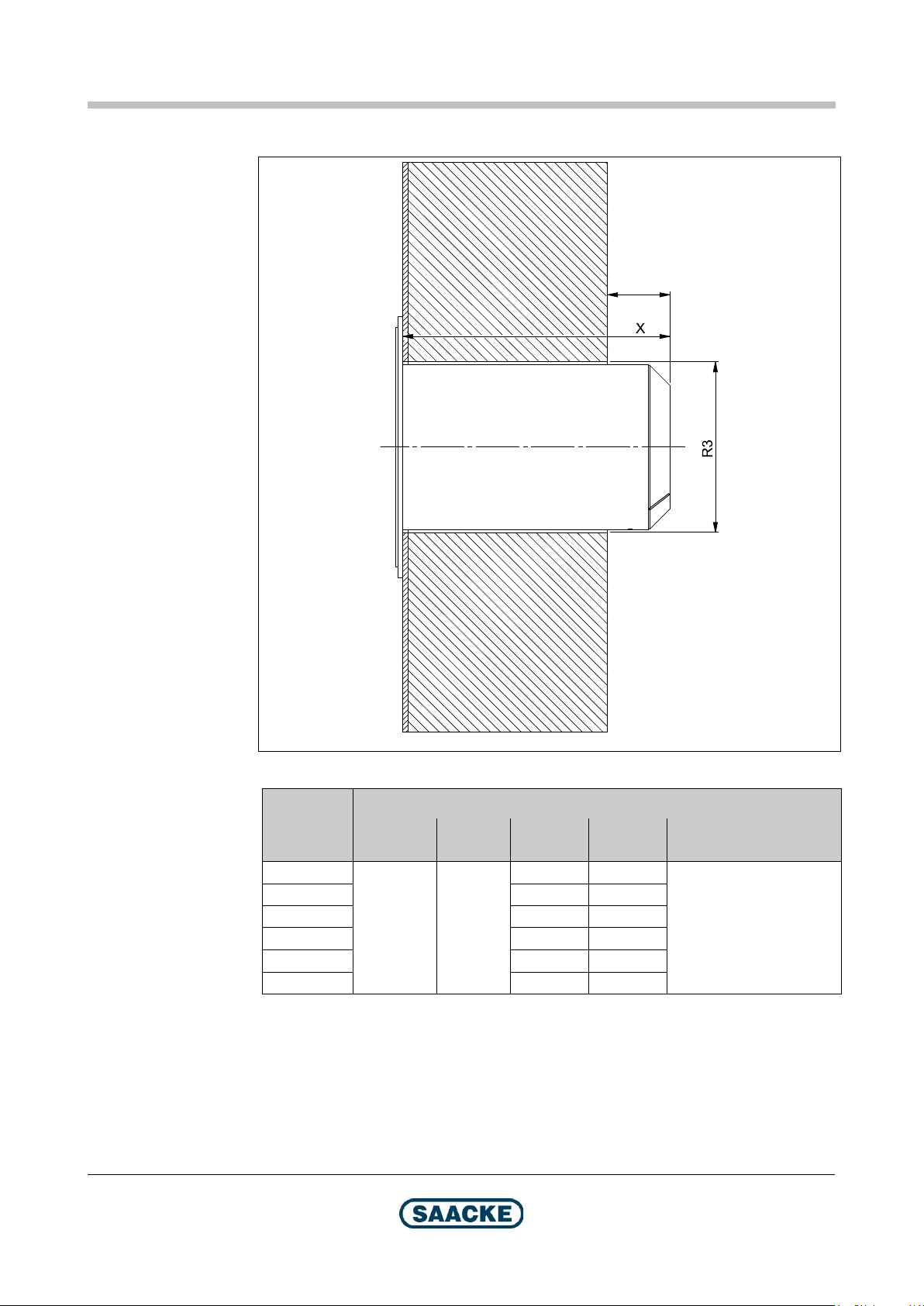

4.1 Burner Head Variant C01 / C03

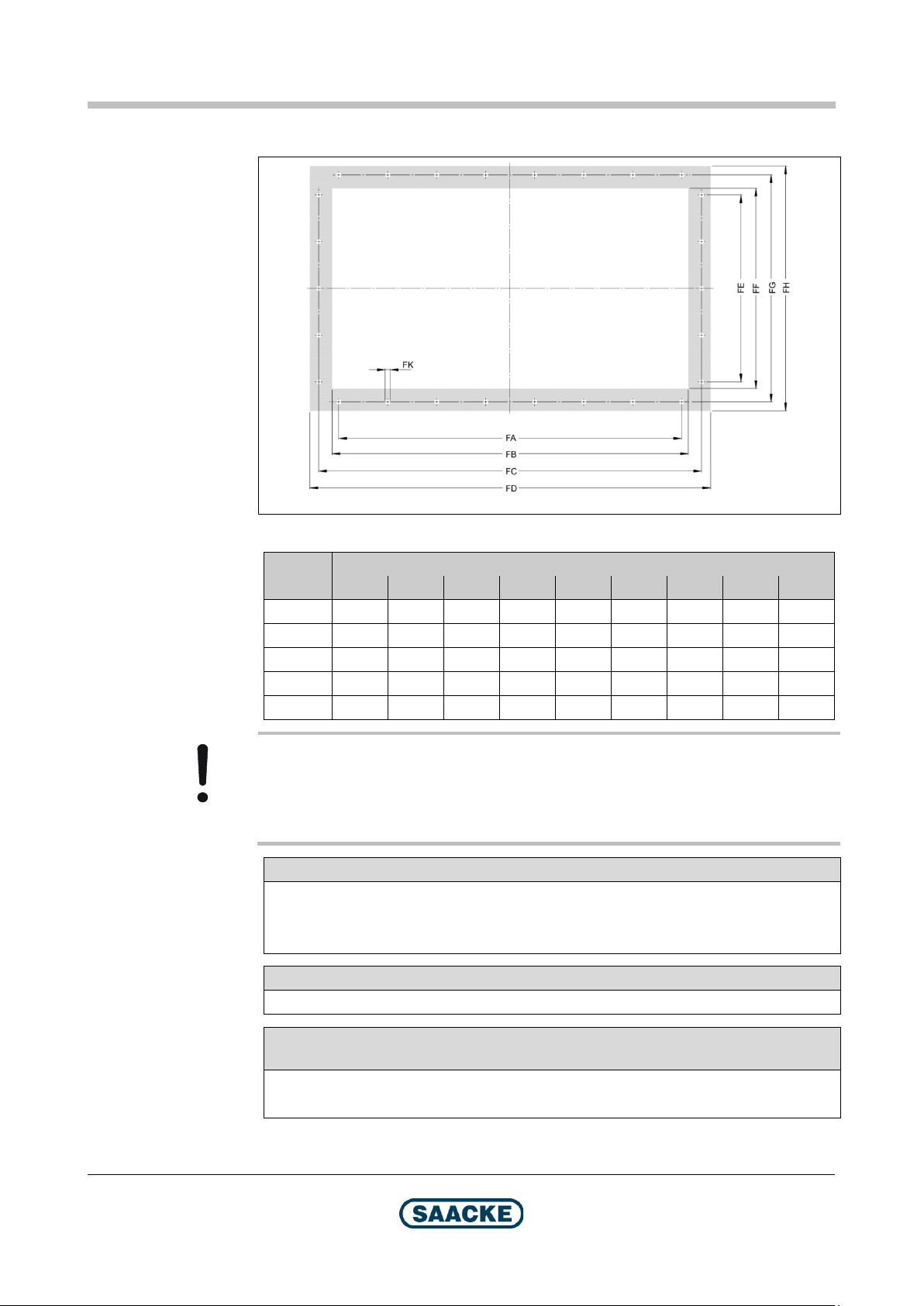

Fig. 7: Refractory brickwork

Dimensions in mm

Burner size

W

Corrugated tube W Plain tube

50

70 475 470

100 480 475

140 480 475

200 480 475

280 495 490

≥130

≥130

and

≤160

X

Monoblock

burners

475 -

X

Duoblock

burners

R3

See chapter “Dimensions /

Types”, section “Burner

Mounting Plate”, dimension

MBP1 (monoblock burners) /

DBP1 (duoblock burners)

Technical Documentation

2021-06-22

BA-TEMINOX-GL-Duo2021-02 21 / 78

Page 22

Construction of the Refractory Brickwork

GL

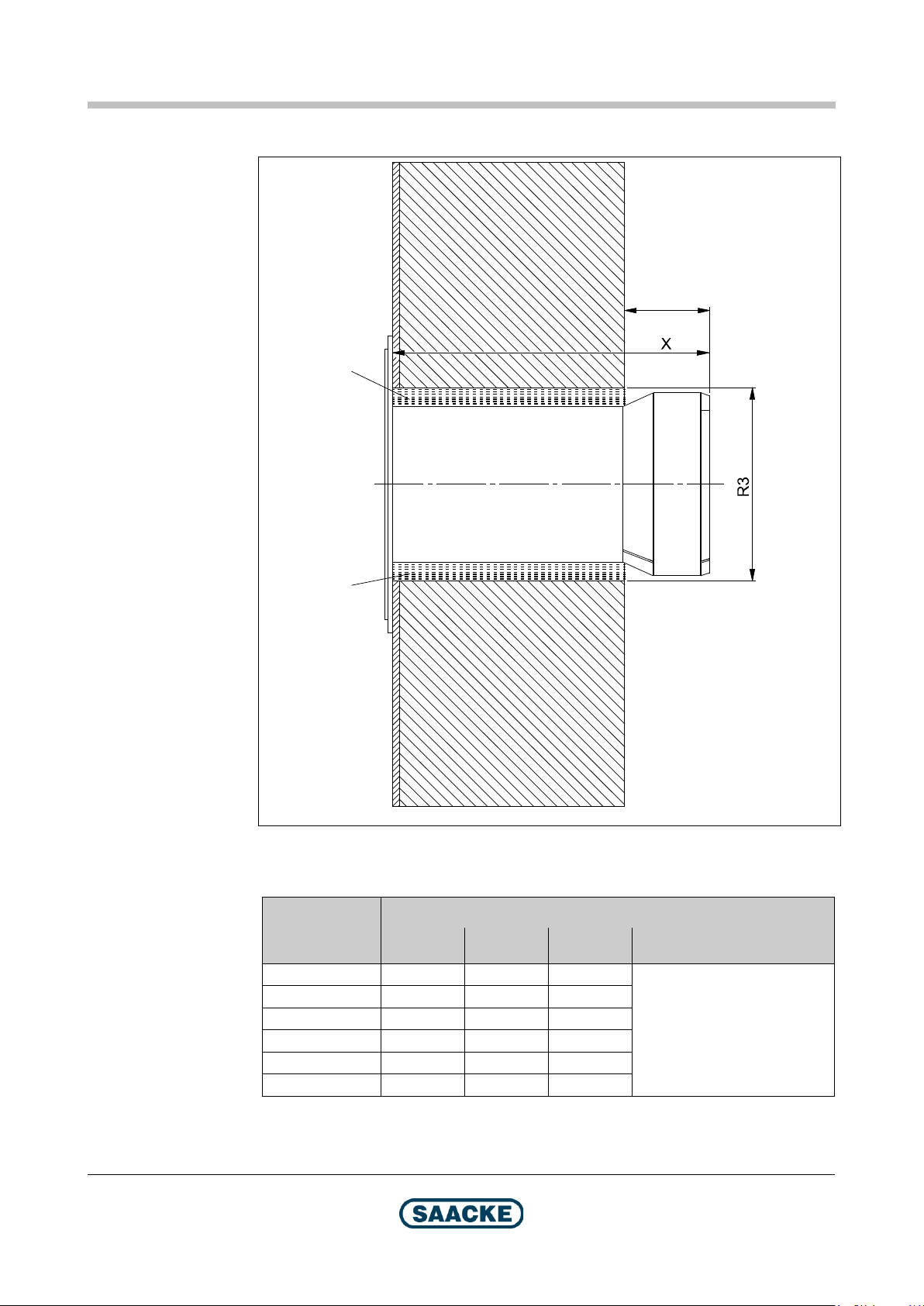

4.2 Burner Head Variant C02

TMX043

X

burners

X

burners

W

1

1

TEMINOX®

Fig. 8: Refractory brickwork

1 Ceramic fibre mat (see chapter “Mounting Instructions”)

Dimensions in mm

Burner size

50 110 470 -

70 130 490 485

100 145 510 505

140 165 525 520

200 190 550 545

280 215 575 570

W

Monoblock

Duoblock

R3

See chapter “Dimensions / Types”,

section “Burner Mounting Plate”,

dimensions

MBP1 (monoblock burners) /

DBP1 (duoblock burners)

Transport

Technical Documentation

22 / 78

BA-TEMINOX-GL-Duo2021-02 2021-06-22

Page 23

TEMINOX®

GL Mounting Instructions

5 Mounting Instructions

Warning! Risk of injury and property damage due to the weight of the burner

and the fan!

For all the work described in the following, always follow the instructions and safety

instructions in the chapter "Transport, Storage and Packaging" before starting with

any of the tasks described here!

Caution! Faulty mounting of the burner possible!

The correct construction of the refractory brickwork (refer to the chapter entitled

"Construction of the Refractory Brickwork") is a requirement for mounting the

burner.

Note

Observe section “Burner Mounting Plate” (chapter “Dimensions / Types“).

Caution!

There may still be a small amount of oil from the pressure test in the oil-carrying

lines. Keep an oil drip tray ready during mounting and dispose of any oil correctly

and ecologically.

Warning! Health hazard due to ceramic fiber material!

Sealing cords and fiber plates for sealing contain ceramic high-temperature mineral

fibers, which may be a health hazard in the case of direct contact or if fiber dust is

inhaled. When handling sealing cords or fiber plates, wear appropriate protective

clothing (overall that fits loosely on your throat and wrists, gloves, safety goggles

with side shields, FFP2 respirators).

Caution!

The heat generator is subject to thermal expansion. Therefore flexible connectors

must be fitted between all fixed lines and ducts and the burner. When connecting

the flexible connectors, note the direction of the expansion.

5.1 Mounting the Burner

Note

With this burner head variant

please wind the supplied ceramic fiber mat around the thinner, cylindrical part of

the burner head before installing the burner (see chapter “Construction of the

Refractory Brickwork”)

2021-06-22

Technical Documentation

BA-TEMINOX-GL-Duo2021-02 23 / 78

Page 24

Mounting Instructions

TEMINOX®

GL

TMX049

Caution! Faulty mounting of the burner possible!

Take into consideration the entry position of the combustion air when mounting the

burner: In the figure, position 0° is shown as an example. This position differs

depending on the plant configuration!

In addition, please have in mind that that gas connection module must always be

in position 0°, independent of the plant configuration.

24 / 78

Fig. 9: Mounting the burner

1 Burner mounting plate

2 Stud screw

3 Gasket (fiber plate)

4 Flange (burner)

5 Washer

6 Hexagonal nut

Caution!

Sealing cord and ceramic fiber plates shrink by up to 15 % during commissioning

due to the effects of the temperature. Therefore retighten all of the mounting

screws after the burner has been commissioned.

Technical Documentation

BA-TEMINOX-GL-Duo2021-02 2021-06-22

Page 25

TEMINOX®

GL Mounting Instructions

5.2 Connecting Lines and Fittings

After mounting the burner, connect the lines and fittings intended for your plant to

the burner. The corresponding connection dimensions can be found in the chapter

entitled "Dimensions / Types".

More detailed information on the plant-specific arrangement of the burner, the

fittings, the lines and the burner control system, as well as on the materials, which

you must use, can be found in the plant drawing and in the circuit diagram in your

operator's manual.

In principle, you should comply with the following installation instructions:

Install all fuel lines, the air duct

linkage in such a way that…

they are not in the way during operation and maintenance of the burner.

they can withstand the mechanical, chemical and thermal stresses which

occur during operation.

no electrical faults occur.

This also applies to the corresponding interfaces to the burner.

Make sure that all flange connections and tubes are mounted torsion free.

6

, the FGR line6, the electrical cabling and the

Protect the flange surfaces against damage during mounting.

Tighten all the screws in a crosswise pattern.

Caution!

Mounting errors must not be eliminated by forcibly tightening the flange or tube

connection.

Install flexible tubes, which are used as a connection between tubes and the

burner, according to the installation instructions which you can find in your

operator's manual.

Install suitable supports for the fittings and tubes. Structurally, the burner has not

been designed to support fittings and tubes!

Install the lines and fittings stress and vibration free. Depending on the plant

configuration, it may be necessary to install compensators.

For duoblock burners: Install an expansion joint between the fan and the inlet for

combustion air in the burner.

Caution!

If possible, only install the fuel lines in the pressure area horizontally (ascending in

the direction of flow) or vertically to prevent air and/or gas accumulation.

6 If installed

2021-06-22

Technical Documentation

BA-TEMINOX-GL-Duo2021-02 25 / 78

Page 26

Mounting Instructions

TEMINOX®

GL

Burners which are intended for operation with steam as atomizing medium and/or preheated

air as combustion air:

Follow the instructions in the Safety chapter, section "Danger from Hot Surfaces",

for all steam and air lines.

Insulate the steam and air lines.

Use electric leads that are suitable for the high temperatures.

Wartung / R eini gung Tra ns pot

Ensure that the lines are laid at a sufficient distance from the burner.

Grounding

Warning!

The entire fuel supply system and the burner must be reliably grounded. All flange

connections must be connected so they are electrically conductive. Measure the

resistance to ensure this is actually true (result <1 Ω).

26 / 78

Technical Documentation

BA-TEMINOX-GL-Duo2021-02 2021-06-22

Page 27

TEMINOX®

GL

Electrical Connections of the Burner

6 Electrical Connections of the Burner

The plant-specific “Electrical Documentation” can be found in the Operator's

Manual for your plant.

2021-06-22

Technical Documentation

BA-TEMINOX-GL-Duo2021-02 27 / 78

Page 28

Operation

TEMINOX®

GL

7 Operation

7.1 Preparing the Heat Generator

Prepare the heat generator (e. g. boiler, combustion chamber) for operation. Heed

the instructions for the heat generator in the manufacturer's documentation.

7.2 Preparing the Burner

Supply the burner with the fuel and the ignition medium

the fuel supply system in the manufacturer's documentation.

7.3 Starting the Burner

Select the fuel and switch the burner on. Follow the instructions in the

manufacturer's documentation for the burner control system.

Wait until the end of the purge phase.

Monitor the sequence of operations and the ignition cycle.

7

. Heed the instructions for

If a fault is signaled: Refer to chapter 7.6.

Starting the heat generator (when the plant is cold)

Start the heat generator when the plant is cold. Heed the instructions for the heat

generator in the manufacturer's documentation.

7.4 Controlled Operation

Controlled operation is performed automatically. No manual operation is required.

Exception: Firing rate controller is set to "Manual". Follow the instructions in the

manufacturer's documentation on the burner control system.

If a fault is signaled: Refer to chapter 7.6.

In case of danger:

Press the "Emergency Stop button" of the plant and interrupt the fuel supply!

7.5 Switching Off the Burner

Run the burner to low-load position. Follow the instructions in the manufacturer's

documentation for the burner control system.

Switch off the burner. Follow the instructions in the manufacturer's documentation

for the burner control system.

7

For burners with ignition medium

28 / 78

Technical Documentation

BA-TEMINOX-GL-Duo2021-02 2021-06-22

Page 29

TEMINOX®

GL

Operation

For Maintenance

Also follow the instructions in the chapter entitled "Maintenance/Cleaning" in the

operating instructions.

For Prolonged Shutdown Time

Interrupt the fuel supply and the supply with the ignition medium as well

example manual shut-off valves in the supply system). Follow the instructions in

the manufacturer's documentation for the corresponding supply systems.

7.6 Service Interruption due to Fault

Note

This section describes only the steps relevant for the burner. Follow the

instructions in the manufacturer's documentation on the fuel supply system and

burner control system as well as the other subsystems in the plant.

8

(for

For Immediate Restart without Troubleshooting and Elimination of Faults:

Acknowledge the fault. Follow the instructions in the manufacturer's documentation

for the burner control system.

Reset the burner control system. Follow the instructions in the manufacturer's

documentation for the burner control system.

Follow the instructions in chapters 7.3 to 7.4.

If Troubleshooting is Necessary:

Secure the burner to prevent it from being restarted.

Interrupt the fuel supply and the supply with the ignition medium

instructions in the manufacturer's documentation for the corresponding supply

systems.

9

. Follow the

Eliminate the fault (refer to the chapter "Troubleshooting" and

"Maintenance/Cleaning" in the operating instructions). If in doubt, contact the

service personnel.

Acknowledge the fault. Follow the instructions in the manufacturer's documentation

for the burner control system.

Reset the burner control system. Follow the instructions in the manufacturer's

documentation for the burner control system.

Follow the instructions in chapters 7.1 to 7.4.

8

For burners with ignition medium

9

For burners with ignition medium

2021-06-22

Technical Documentation

BA-TEMINOX-GL-Duo2021-02 29 / 78

Page 30

Functional Schematic

TEMINOX®

GL

TMX217

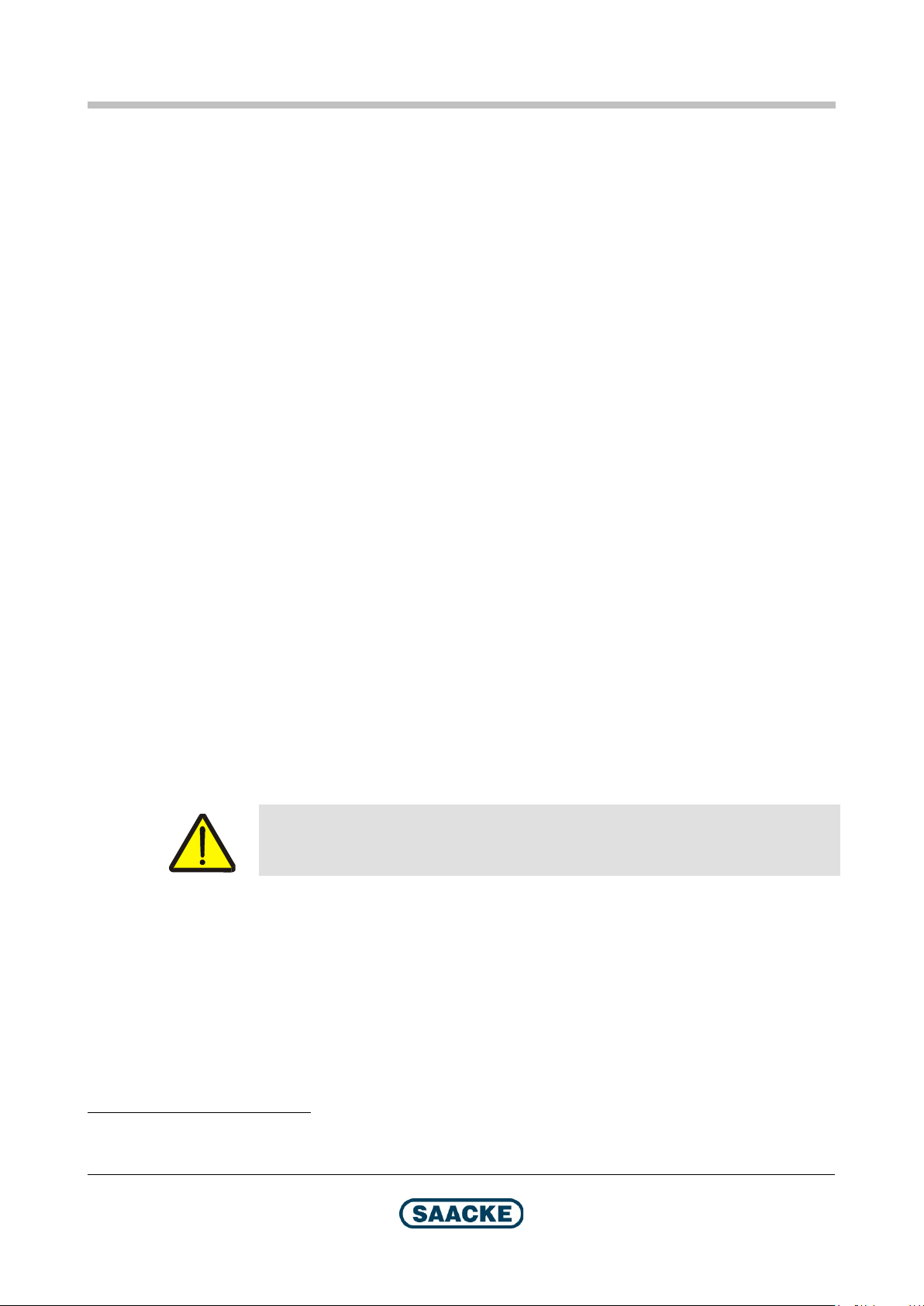

8 Functional Schematic

Fig. 10: Functional schematic for gas operation

Technical Documentation

30 / 78

BA-TEMINOX-GL-Duo2021-02 2021-06-22

Page 31

TEMINOX®

GL Functional Schematic

Device number

A --- Main fuel inlet (gas)

B --- Combustion air inlet

C --- Heat generator

1a/1b 10 A 1 / External11

2 28 F 2 / External11 Gas pressure monitor (L)

3 28 F 3 / External11 Gas pressure monitor (H)

4 External Emergency stop button for fuel supply system

5a ---

5b ---

6 --- Stabilizing disk retract mechanism

7 40 B 1 Flame scanner

8* --- Manual shut-off fitting

9* 2 Y 1 Rapid shut-off valve 1 for ignition medium

10* 2 Y 2 Rapid shut-off valve 2 for ignition medium

11 2 T 1 Ignition transformer

12 --- Combustion air fan

13 17 F 2 Pressure monitor (L) for combustion air

14 --- Air control dampers

15 External Speed pickup (optional)

16** --- Flue gas actuator for “Mini-Rezi“

* For sizes 50 and 70, ignition is direct and electrical in both oil operation and gas

operation. Therefore these components are not installed on these burners.

10

Designation

Rapid shut-off valves 1 and 2 (double solenoid valve) for main

fuel gas

TEMINOX GL: Drive unit oil / gas

TEMINOX G: Gas control damper

Burner head variant C03: Gas control damper for controlled

primary gas

Burner head variant C01: Optional gas control damper for

controlled primary gas

Burner head variant C02: Not installed

** Optional component

10

Cp. Electrical Documentation

11

Depending on the order, this component may be part of the gas valve train or part of the burner. If it has

been ordered as part of the gas valve train, it will be connected externally.

Technical Documentation

2021-06-22

BA-TEMINOX-GL-Duo2021-02 31 / 78

Page 32

Functional Schematic

TEMINOX®

GL

TMX169

Fig. 11: Functional schematic for oil operation

32 / 78

Technical Documentation

BA-TEMINOX-GL-Duo2021-02 2021-06-22

Page 33

TEMINOX®

Wartung / R eini gung Tra ns pot

GL Functional Schematic

Device

number

A --- Main fuel inlet (oil)

B --- Combustion air inlet

C --- Heat generator

D --- Main fuel outlet (oil)

1a --- Manual shut-off fitting – supply line13

1b --- Manual shut-off fitting – return line13

2 --- Dirt trap

3 3 Y 3 Rapid shut-off valve – supply line

* --- Arrow imprinted on valve

4 --- Pressure gauge – supply line

5 17 F 3 Oil pressure monitor (L) – supply line

6 --- Flexible tubes – supply line / control line / return line

7 40 B 1 Flame scanner

8 --- Oil gun

9 --- Stabilizing disk retract mechanism

10 --- Pressure gauge – return line

11 ---

12 18 F 4 Oil pressure monitor (H) – return line

13 3 Y 4 Rapid shut-off valve – return line

* --- Arrow imprinted on valve

14 3 Y 2 Rapid shut-off valve (open when de-energized) – control line

15 3 Y 1 Rapid shut-off valve – control line

16 --- Combustion air fan

17 17 F 2 Pressure monitor (L) for combustion air

18 --- Air control dampers

19 2 T 1 Ignition transformer

20 External Speed pickup (optional)

16** --- Flue gas actuator for “Mini-Rezi“

** Optional component

Designation

12

TEMINOX GL: Drive unit oil / gas

TEMINOX L: Oil flow controller

12

Cp. Electrical Documentation

13

The manual shut-off fittings for the supply line and the return line are coupled mechanically

Technical Documentation

2021-06-22

BA-TEMINOX-GL-Duo2021-02 33 / 78

Page 34

Maintenance / Cleaning

TEMINOX®

GL

9 Maintenance / Cleaning

Note

A burner with standard equipment is shown. The equipment may vary depending

on the plant. As several burner head variants are possible, the presentation of the

burner head may differ.

9.1 General Information

The chapter entitled "Maintenance / Cleaning" contains mandatory instructions for

the inspection and maintenance of the burner as well as for the replacement of

components.

Before and during maintenance activities, always follow the instructions in the

chapter on "Safety" and comply with the national regulations in respect of personal

and environmental protection as well as the accident prevention regulations.

The tasks described in this context may only be performed by personnel explicitly

authorized to do so by the plant authorities. The plant authorities must ensure that

the personnel is qualified to perform the described tasks correctly. It is crucial that

these persons are capable of detecting potential hazards in due time and of

preventing them. SAACKE Service is at your disposal for more detailed information

on training courses. You will find our contact data on the rear of this document.

Persons performing tasks on the electric system must have specialized knowledge.

For this reason, tasks involving the electric system may be performed by

electricians only.

Tasks identified by the term "Service Personnel" may influence the proper

operation of the burner and the quality of the combustion considerably. For this

reason, only personnel with product-specific and task-related specialized

knowledge with access to the equipment required to perform the tasks (e.g.

measuring instruments) may perform the related tasks. SAACKE ensures the

smooth course of service tasks of this kind by taking internal qualification

measures and a persistent quality management. In addition, SAACKE also offers

plant authority training courses. SAACKE Service is at your disposal for more

detailed information on this topic as well. You will find our contact data on the rear

of this document.

34 / 78

Caution!

If a burner component is defective, it must be replaced. Please observe that only

service personnel is permitted to replace some of the security-related parts.

Only original spare parts may be used for replacing components within the scope

of maintenance work. For more detailed information, please refer to the chapter

entitled "Safety".

Repairs may only be performed by specialized staff explicitly authorized to do so

by the manufacturer. SAACKE Service is at your disposal for more detailed

information.

Technical Documentation

BA-TEMINOX-GL-Duo2021-02 2021-06-22

Page 35

TEMINOX®

GL

Maintenance / Cleaning

Note

The other subsystems of the plant (e.g. heat generator, fuel supply system, refer to

the chapter entitled "Safety") are required to operate the plant but they are not an

integral part of the burner described in the present document and may vary

depending on the plant. For this reason, the present burner documentation does not

include any concrete contents on the other subsystems of the plant.

Observe the instructions in the manufacturer's documentation on the other

subsystems to ensure safe operation of the plant.

9.2 Preparing Maintenance Work

9.2.1 Periodical Maintenance (Fault not Acute)

Agree the terms with the plant manager before starting any maintenance work.

Ensure that the shut-down of the plant for maintenance purposes does not cause

faults or damage to other plants or plant components.

Note

The following instructions apply to all the maintenance tasks.

Exception: Tasks, for which it is explicitly pointed out that they can only be

performed on the running system.

Run the burner to the low-load position.

Switch the burner and the burner control system off.

Disconnect the power supply to the plant and safeguard it against restarting.

Warning!

Risk of electrocution and danger through inadvertent restarting of the burner!

Disconnecting from the mains includes the following:

Switching off the main switch of the plant

Or switching off the automatic cut-outs of the plant

Or removing the fuse links (all phases).

Ensuring that the system cannot be turned on again means:

Placing the turned off main switch in the 0-position

Or placing a clearly visible warning sign on the automatic cut-outs or on the fuse

bottom part.

Cut off the fuel supply. Heed the instructions for the fuel supply system in the

manufacturer's documentation.

Let the burner cool off.

2021-06-22

Technical Documentation

BA-TEMINOX-GL-Duo2021-02 35 / 78

Page 36

Maintenance / Cleaning

TEMINOX®

GL

Take the following measures before working on fuel-carrying components:

Warning! Danger through open fire!

Ensure that there isn't any open fire on the plant while maintenance work is being

performed. Do not use any open fire (not even a lighter or a welding apparatus)

during maintenance!

Professionally remove the residual fuel in the lines.

Dispose of the fuel ecologically.

9.2.2 Maintenance after a Fault has Interrupted the Operation

Proceed as described in the chapter entitled "Operation", section "Operation

Interruption due to Fault".

9.3 Maintenance Intervals

The following recommended, average maintenance intervals are based on normal

operating conditions and periodical use with interrupted operation (Installation

Category B according to DIN 31052).

Particular operating conditions may necessitate correspondingly shorter

maintenance intervals. Particular operating conditions are, for example:

A higher concentration of impurities of the fuel

Special environmental factors, e.g. salty or particularly dusty air, high air

humidity, extreme temperatures

Continuous operation

Caution!

Immediately repair damaged surface coating to avoid corrosion.

Remedy immediately defects detected in the burner.

Note

It is possible that, in the manufacturer´s documentation for a component,

maintenance intervals or steps are listed that deviate from the information stated in

this chapter. In this case, the information stated in this chapter shall prevail.

Note

If your burner is equipped with a component that is not explicitly named in this

chapter, the information stated in the manufacturer´s documentation for the

component shall apply.

36 / 78

Technical Documentation

BA-TEMINOX-GL-Duo2021-02 2021-06-22

Page 37

TEMINOX®

GL

Maintenance / Cleaning

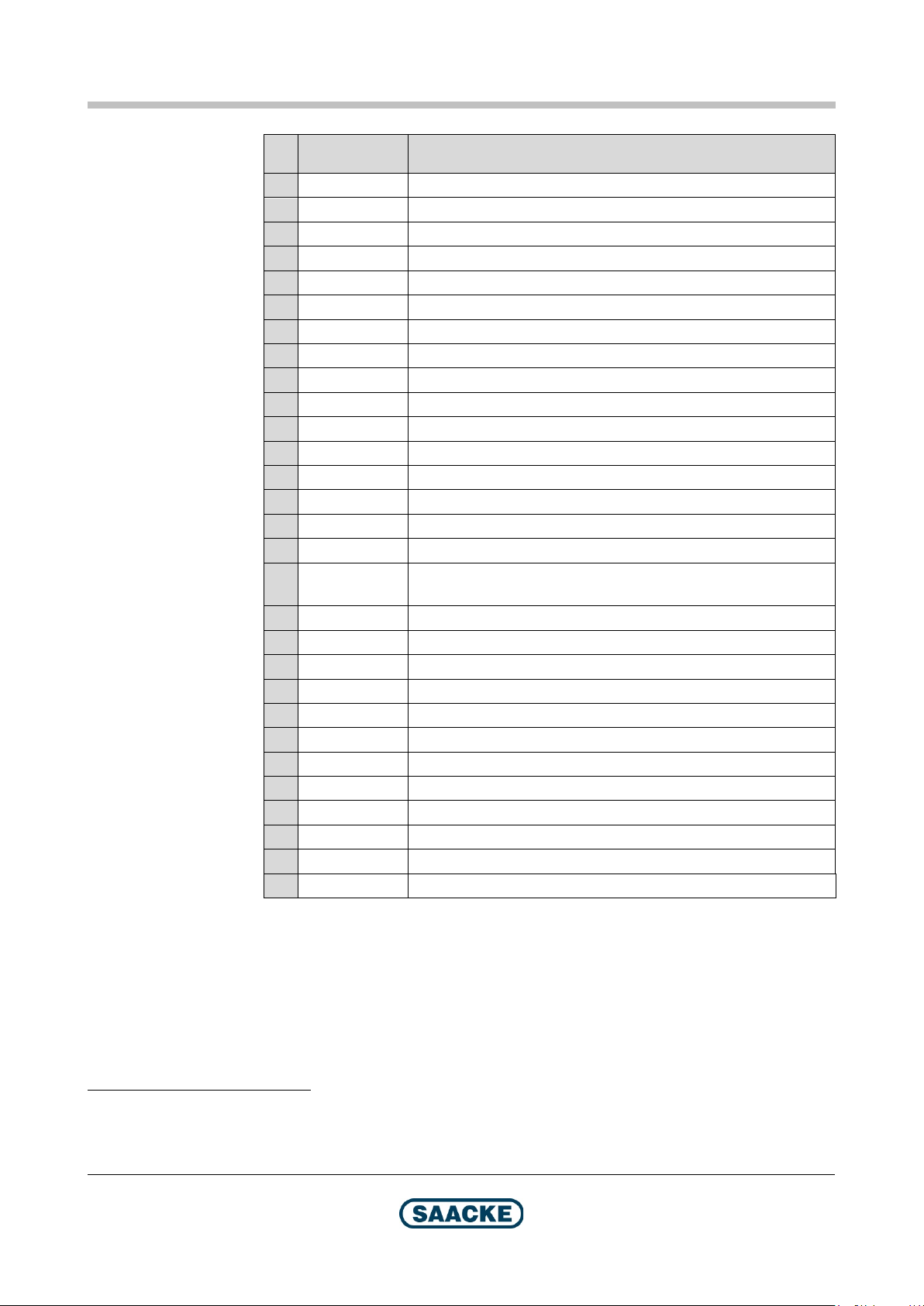

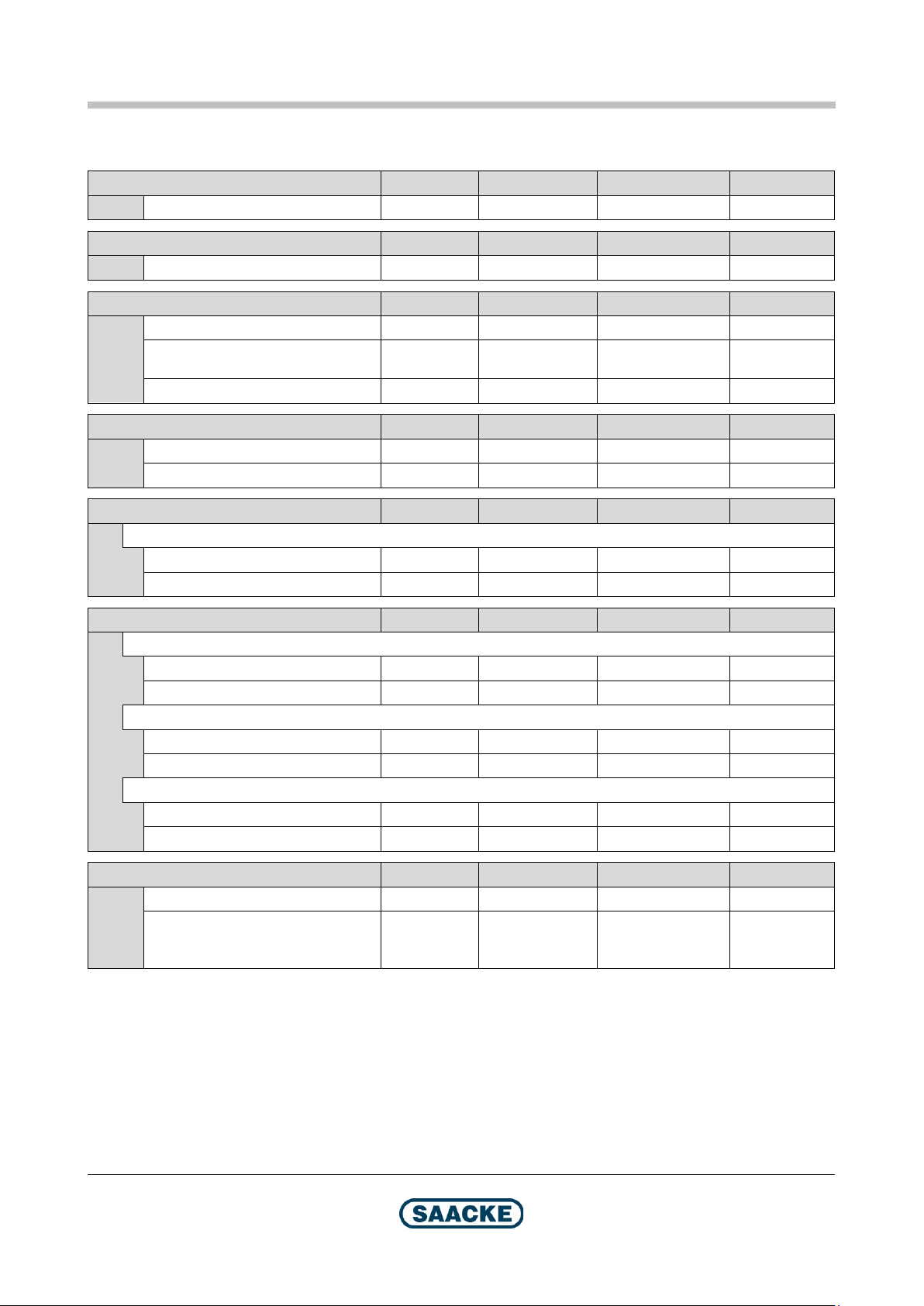

Categorization of Maintenance Intervals

Tasks marked with the term “Recommendation” are relevant for optimum

burner availability. These are non-binding recommendations.

Tasks marked with the term “Obligation” are relevant for safety. These

intervals are binding.

Besides long-standing empirical values, all intervals are based on the

specifications in the documentation of the respective component manufacturer and

on recommendations of BDH / European Control Manufacturers' Association

error

9.4 Maintenance of General Components

General

Check the plant for proper operation

(e.g. visual inspection, check for smells,

listen for noise), monitor operation and fault

messages, remove escaped lubricants.

Check the supply pressures of combustion

air, ignition medium

compare them to the approval and

measurement report.

Check the driving linkage of the actuators

and all the other detachable connections of

the moving components and connectors.

Check emission values (O2, CO, NOx and

smoke spot number).

Check whether security-related

components have reached their rated

service life and, if so, inform the plant

authorities.

Check the flow paths of the combustion air,

fuel and ignition medium

any deposits.

Flame detection system

FLUS 06 UV / FLS 09 UV, SAACKE

Clean flame scanner 6 months Plant authorities Recommendation 9.4.2.1

Check function 6 months Plant authorities Recommendation 9.4.2.1

Clean flame scanner 6 months Plant authorities Recommendation 9.4.2.2

Check function 6 months Plant authorities Recommendation 9.4.2.2

Check alignment, flame signal and

Replace 10 years Service personnel Obligation ---

Check alignment, flame signal and

temperature

Replace the flame scanner 10 years Service personnel Obligation ---

Replace the flame monitor 10 years Service personnel Obligation ---

Flame scanner F 200 K2, Lamtec

temperature

14

From size 100

(afecor).

14

and main fuel and

14

for wear, remove

Interval Who? Category Chapter

Periodically Plant authorities Recommendation -

Periodically Plant authorities Recommendation 9.4.1

1 year Service personnel Recommendation ---

1 year Service personnel Recommendation ---

1 year Service personnel Recommendation ---

1 year Service personnel Recommendation ---

Interval Who? Category Chapter

3 years Service personnel Recommendation ---

3 years Service personnel Recommendation ---

Technical Documentation

2021-06-22

BA-TEMINOX-GL-Duo2021-02 37 / 78

Page 38

Maintenance / Cleaning

TEMINOX®

GL

Air pressure monitor

DL 50A / DL 150A, Kromschröder

Check 1 year Plant authorities Recommendation Chapter 9.4.3

Check measurement section 3 years Service personnel Recommendation ---

Replace 10 years Service personnel Obligation ---

Servomotor

D 006-100 / FSM 006-100, SAACKE

Replace 10 years Service personnel Recommendation ---

Fan (monoblock burner only)

Make “Lammers”

Check the protective gratings of the fan

Air control dampers

Force transmitter (TEMINOX GL only)

Replace lever and linkage 5 years Service personnel Recommendation ---

Mixing system (parts in contact with fire)

Ignition system “integrated ignition device”

(TEMINOX G and GL, from size 100, if no

“separate igniter” is installed)

Check 3 years Service personnel Recommendation ---

intake opening and the silencer, remove

coarse dirt as required

Replace bearings of the fan motor

(<75 kW fan output)

Lubricate bearings of the fan motor

(>75 kW fan output)

Check 2 years Service personnel Recommendation ---

Check 6 months Plant authorities Obligation 9.4.6

Check 1 year Service personnel Recommendation ---

Replace 5 years Service personnel Recommendation ---

Ignition transformer

Check cable and plug-and-socket

connection

Replace cable and plug-and-socket

connection

Replace ignition transformer 10 years Service personnel Recommendation ---

Ignition electrodes

Check 1 year Service personnel Recommendation ---

Replace (incl. cable and plug-andsocket connection)

Ignition gas guns

Interval Who? Category Chapter

Interval Who? Category Chapter

Interval Who? Category Chapter

Periodically Plant authorities Recommendation 9.4.4

20,000 hours Service personnel Obligation ---

4000 hours Plant authorities Obligation 9.4.5

Interval Who? Category Chapter

Interval Who? Category Chapter

Interval Who? Category Chapter

Interval Who? Category Chapter

1 year Plant authorities Recommendation 9.4.7

5 years Service personnel Recommendation ---

3 years Service personnel Recommendation ---

38 / 78

Technical Documentation

BA-TEMINOX-GL-Duo2021-02 2021-06-22

Page 39

TEMINOX®

GL

Maintenance / Cleaning

Ignition system “separate igniter”

Igniter ZAP(ZDAP) and ZA0(ZDA0), Hegwein

Check 6 months Plant authorities Recommendation 9.4.8

Replace ignition electrodes 3 years Service personnel Recommendation ---

Replace ignition system 10 years

Rapid shut-off valve for ignition medium

(G and GL, from size 100 or if an igniter is

available)

6027 A, Bürkert

Check 1 year Service personnel Recommendation ---

Replace 10 years Service personnel Obligation ---

MVD 505/5 and/or MVD 503/5, Dungs

Check 1 year Service personnel Recommendation ---

Replace 10 years Service personnel Obligation ---

Pressure controller for ignition medium

(G and GL, from size 100 or if an igniter is

available)

FRS 503, Dungs

Check 1 year Service personnel Recommendation ---

Replace 15 years Service personnel Obligation ---

Fuel lines within the burner

Check 1 year Service personnel Recommendation ---

Replace the flexible tubes 5 years Service personnel Obligation ---

Flue gas actuator for “Mini-Rezi“ (optional for

monoblock burners)

Check 1 year Service personnel Recommendation ---

Interval Who? Category Chapter

250,000

switching cycles

Interval Who? Category Chapter

Interval Who? Category Chapter

Interval Who? Category Chapter

Interval Who? Category Chapter

Service personnel Obligation ---

9.4.1 Checking Supply Pressures

Note

This check can be performed only while the burner is in operation.

Check the supply pressures of the combustion air (for duoblock burners), the

ignition medium

15

and the main fuel.

Compare these values with the values documented in the approval and

measurement report.

If you detect deviations: Make sure that the supply routes are free. Contact the

service personnel if you cannot find the cause for the deviation.

15

From size 95 (monoblock burner) / 100 (duoblock burner)

Technical Documentation

2021-06-22

BA-TEMINOX-GL-Duo2021-02 39 / 78

Page 40

Maintenance / Cleaning

TEMINOX®

GL

TX080

9.4.2 Cleaning the Flame Scanner / Performing a Function Test

Warning!

Risk of injuries resulting from incorrect operation or incorrect settings!

Follow the instructions in the manufacturer's documentation on the flame detection

system.

Warning! Risk of injuries due to air containing particles!

When dismounting the flame scanner, air containing particles may escape. We

recommend wearing safety goggles.

Note

This check can be performed only while the burner is in operation.

Caution!

The check will trigger a safety shut-off! Agree the terms with the plant manager

before starting the check.

9.4.2.1 SAACKE FLUS 06 UV / FLS 09 UV

Run the burner to low-load position.

Fig. 12: Flame scanner with mount

1 Flame scanner

2 Mount (made of polycarbonate, transparent)

3 Clamping screw

4 Position screw

5 Mounting screw

6 Adapter on the burner, example

40 / 78

Technical Documentation

BA-TEMINOX-GL-Duo2021-02 2021-06-22

Page 41

TEMINOX®

GL

Maintenance / Cleaning

H009

Dismount the flame scanner as follows:

Screw out the two mounting screws.

Caution!

The position screw and the clamping screw stay screwed in!

Pull out the flame scanner with its mount.

Cover the lens. When doing so, be sure not to soil or scratch the lens.

This must trigger a safety shut-off.

Warning!

If a safety shut-off was not triggered, actuate the emergency stop button of the

plant and contact the service personnel. Do not restart the plant until the case has

been checked by the service personnel.

Clean the lens of the flame scanner using a soft cloth.

Mount the flame scanner (including the mount).

To facilitate installation, there is a mark on the part of the flame scanner which

protrudes out of the burner. This designation is opposite the lens, i.e. it must point

away from the furnace.

Fig. 13: The lens and marking of the flame scanner

1 Lens

2 Marking (opposite to the lens)

Retighten the two mounting screws.

Reset the burner on the burner control system.

9.4.2.2 F 200 K2

2021-06-22

Refer to the manufacturer's documentation on the flame scanner for the

instructions.

Technical Documentation

BA-TEMINOX-GL-Duo2021-02 41 / 78

Page 42

Maintenance / Cleaning

TEMINOX®

GL

A001a

9.4.3 Checking the Air Pressure Monitor

Note

This check can be performed only while the burner is in operation.

Caution!

The check will trigger a safety shut-off! Agree the terms with the plant manager

before starting the check.

Fig. 14: Air pressure monitor (figure without cover), pressure connector on the rear

is not shown

1 Pressure connector 1

2 Measuring point

3 Test button

4 Adjusting screw with scale

5 Pressure connector 2 (not visible)

Run the burner to low-load position.

Press the test button.

This must trigger a safety shut-off.

If a safety shut-off was triggered, the check was successful. Reset the burner on

the burner control system.

Warning!

If a safety shut-off was not triggered, actuate the emergency stop button of the

plant and contact the service personnel. Do not restart the plant until the case has

been checked by the service personnel.

42 / 78

Technical Documentation

BA-TEMINOX-GL-Duo2021-02 2021-06-22

Page 43

TEMINOX®

GL Maintenanc

e / Cleaning

TMX057

9.4.4 Checking the Protective Grating of the Fan

The fan can only draw in sufficient air when the intake opening is unobstructed.

Check that the intake opening of the fan is unobstructed.

Remove coarse dirt from the protective grating of the fan.

Note

With duoblock burners, the fan is not included in the scope of delivery of the

burner. Observe the manufacturer's documentation on the fan.

9.4.5 Lubricating the Bearings of the Fan Motors (>75 kW Fan Output)

Refer to the manufacturer's documentation on the fan for the instructions.

9.4.6 Checking the Force Transmitter

Check if the linkages and levers of the force transmitter are worn or damaged. If

they are worn or damaged: Contact the service personnel.

Caution! Risk of damage to components!

Do not lubricate the joints of the power transmitter.

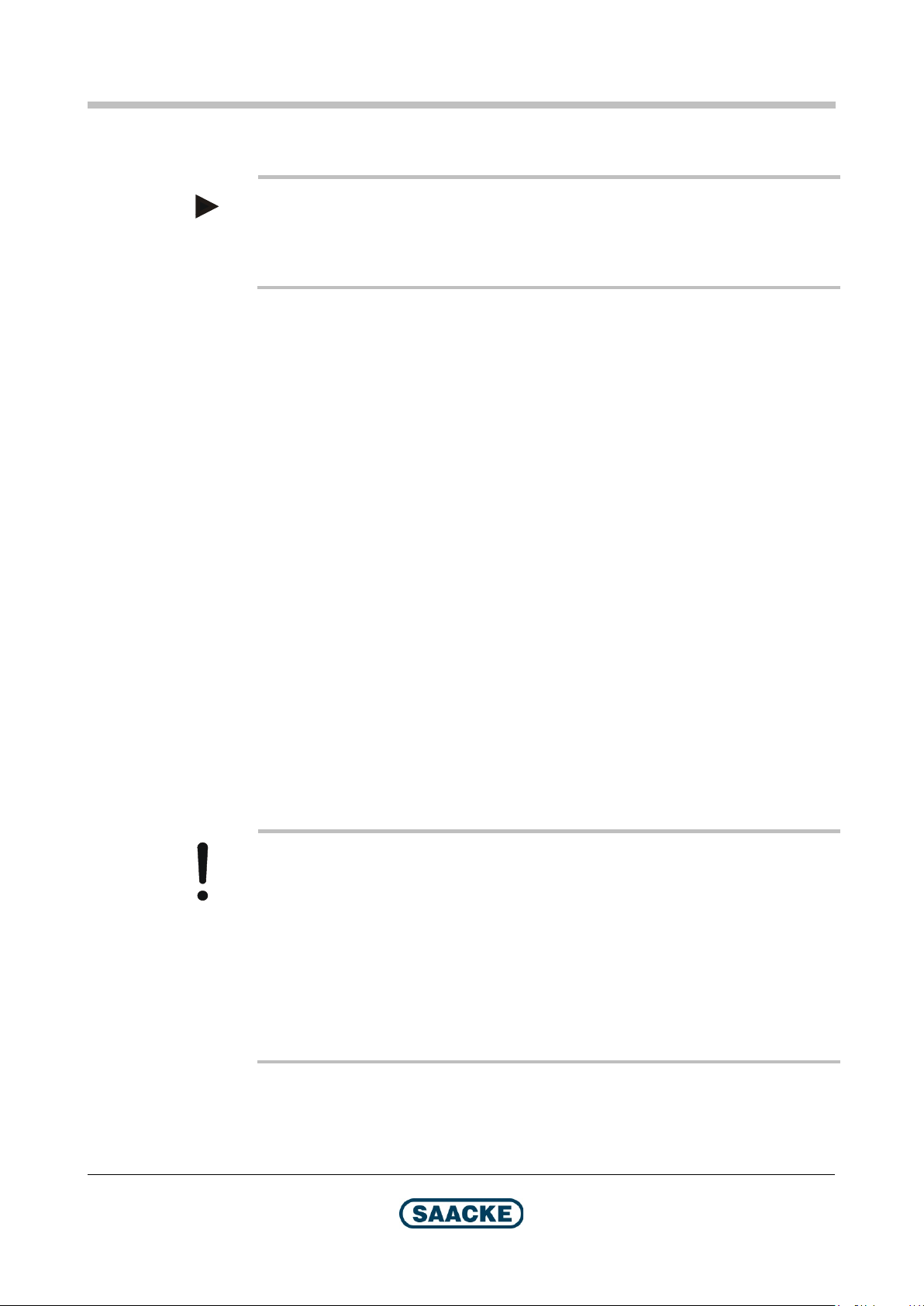

9.4.7 Checking the Ignition Cables and Plug-and-Socket Connections

Warning! Risk of death by electric shock!

The tasks described in the present section may be performed by electricians only.

2021-06-22

Fig. 15: Position of the ignition transformer (monoblock burner)

Technical Documentation

BA-TEMINOX-GL-Duo2021-02 43 / 78

Page 44

Maintenance / Cleaning

TEMINOX®

GL

TMX056

Fig. 16: Position of the ignition transformer (duoblock burner)

Open the control box for the ignition transformer (1).

Check the plug-and-socket connections for external damage.

Check the parts of the ignition cable that are accessible without opening the burner

for external damage.

9.4.8 Checking the Ignition Systems ZAP(ZDAP) and ZA0(ZDA0)

Refer to the manufacturer's documentation on the igniter for the instructions.

44 / 78

Technical Documentation

BA-TEMINOX-GL-Duo2021-02 2021-06-22

Page 45

TEMINOX®

GL

Maintenance / Cleaning

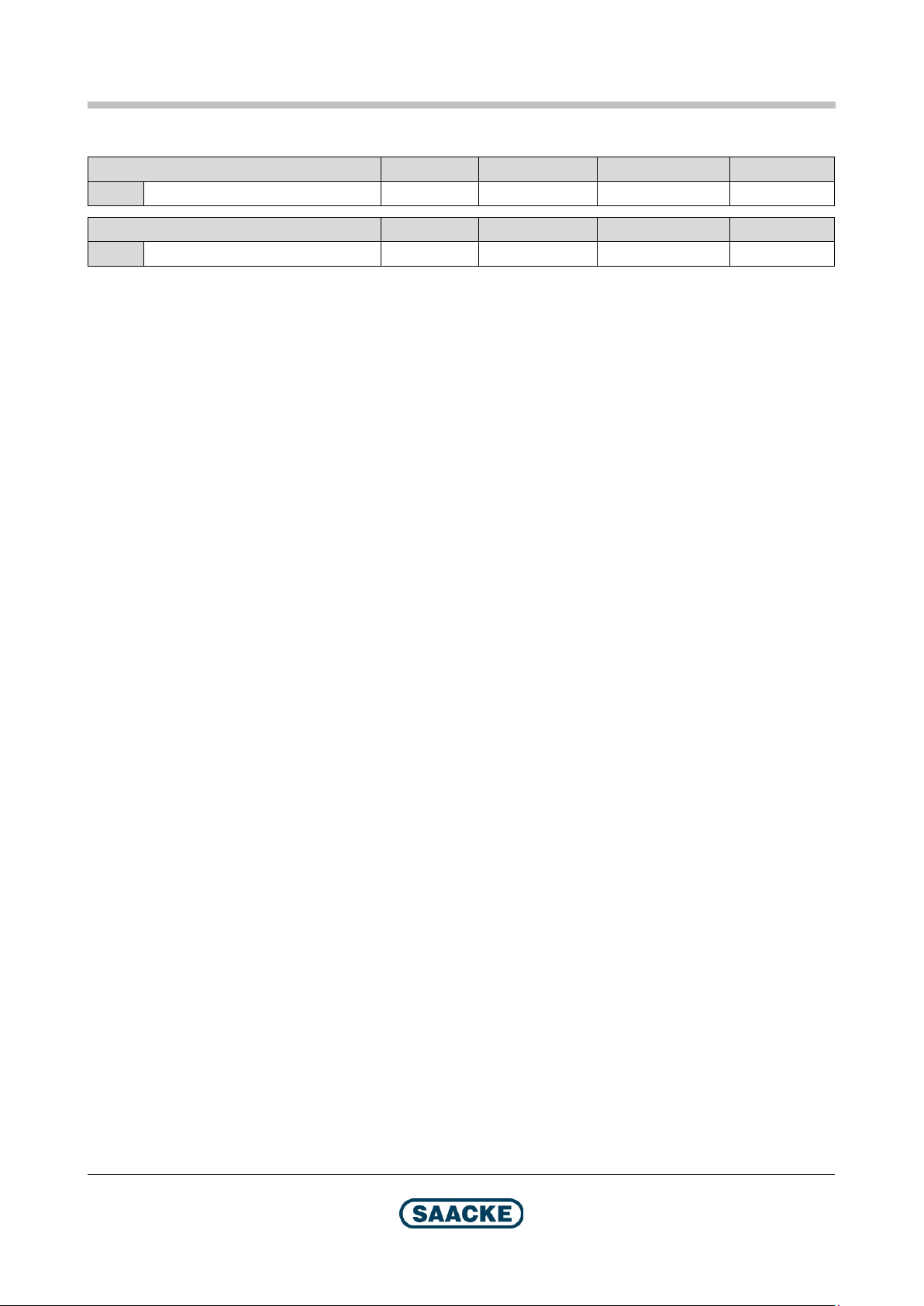

9.5 Maintenance of Components Relevant to the Oil Operation Mode

Manual shut-off fitting supply line / return line

Check 1 year Service personnel Recommendation ---

Dirt trap

Clean 1 year Plant authorities Recommendation Chapter 9.5.1

Oil gun

Check 1 year Service personnel Recommendation ---

Fuel lines outside the burner

Replace the flexible tubes 5 years Service personnel Obligation ---

Rapid shut-off valves

Pressure monitor

Oil flow controller

Replace nozzle plate, vortex plate and

seals of the gun

Replace the oil gun 10 years Service personnel Obligation ---

Check 1 year Plant authorities Recommendation Chapter 9.5.2

5406-A13 / 6027-A10 / 6027-A03 / 6027-B02, Bürkert

Check 1 year Service personnel Recommendation ---

Replace 10 years Service personnel Obligation ---

DWR 40-206, Fema / Honeywell

Check 1 year Service personnel Recommendation ---

Replace 10 years Service personnel Obligation ---

DSF 146 F001, Sauter

Check 1 year Service personnel Recommendation ---

Replace 5 years Service personnel Obligation ---

DWR 6-205, DWR 625-205, Fema / Honeywell

Check 1 year Service personnel Recommendation ---

Replace 10 years Service personnel Obligation ---

Check 1 year Service personnel Recommendation ---

Replace the seal 2 years /

Interval Who? Category Chapter

Interval Who? Category Chapter

Interval Who? Category Chapter

3 years Service personnel Recommendation ---

Interval Who? Category Chapter

Interval Who? Category Chapter

Interval Who? Category Chapter

Interval Who? Category Chapter

12,000

operating hours

Service personnel Recommendation ---

2021-06-22

Technical Documentation

BA-TEMINOX-GL-Duo2021-02 45 / 78

Page 46

Maintenance / Cleaning

TEMINOX®

GL

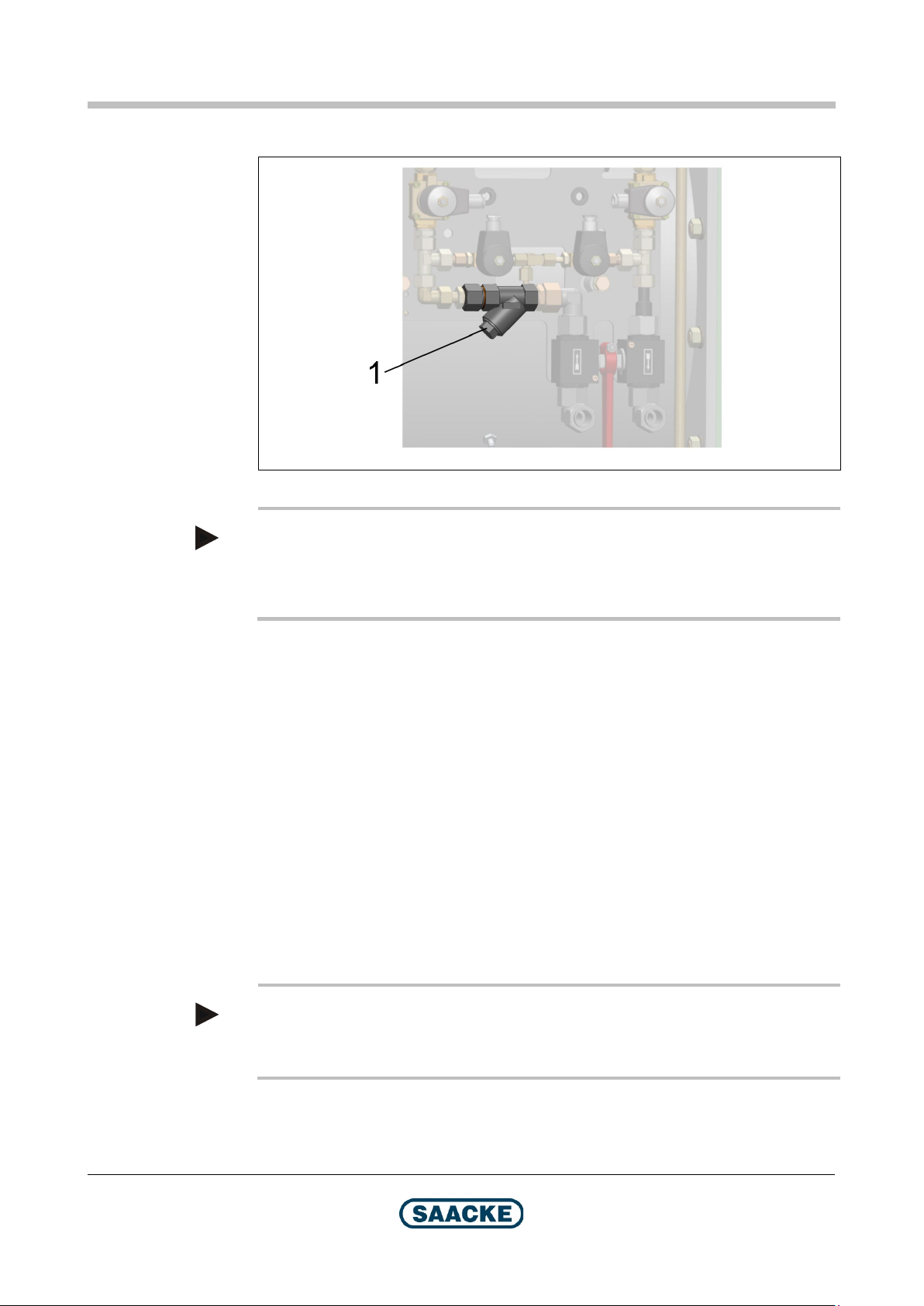

T102

9.5.1 Cleaning the Dirt Trap

Fig. 17: Dirt trap (example)

Note

Fuel may escape when performing the tasks described below. For this reason,

place an oil drip tray underneath the dirt trap and dispose of any fuel that has

escaped professionally and in an ecologically compatible manner.

Remove the screw (1). Use a size 24 open wrench for this purpose.

Remove the strainer of the dirt trap.

Clean the strainer.

Re-install the strainer.

Tighten the screw (1) again.

9.5.2 Checking the Fuel Lines Outside the Burner

Check the flexible tubes for external damage.

Check whether fuel has escaped in the area around the flexible tubes.

If fuel has escaped:

Immediately switch the burner off.

Find the leak and repair it, if possible.

46 / 78

Note

It might be necessary to replace the flexible tube. In this case, contact the service

personnel.

Dispose of any leakage oil correctly and in an environmentally friendly manner.

Technical Documentation

BA-TEMINOX-GL-Duo2021-02 2021-06-22

Page 47

TEMINOX®

GL

Maintenance / Cleaning

9.6 Maintenance of Components Relevant Especially to the Gas Operation

Gas guns

Check 1 year Service personnel Recommendation ---

Gas control damper(s)

Check 1 year Service personnel Recommendation ---

Interval Who? Category Chapter

Interval Who? Category Chapter

9.7 After Completion of the Maintenance Work

Prepare the burner, the heat generator and the further subsystems of the plant for

operation once you have completed the maintenance work.

Restart the burner.

Transpot

2021-06-22

Technical Documentation

BA-TEMINOX-GL-Duo2021-02 47 / 78

Page 48

Troubleshooting

TEMINOX®

GL

10 Troubleshooting

Note

If problems arise that cannot be solved with the help of the following descriptions,

please contact SAACKE Service.

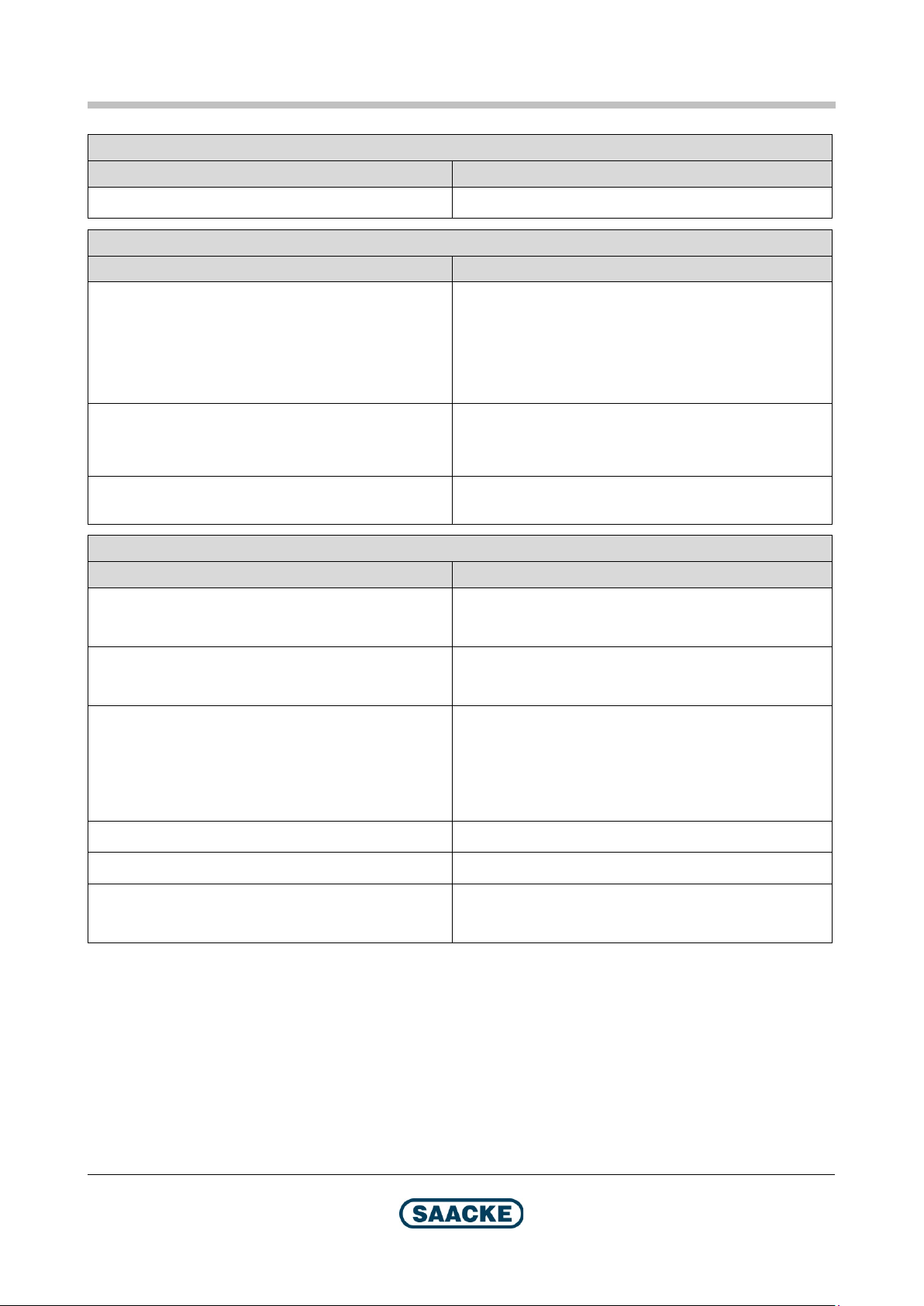

10.1 Troubleshooting (Gas Operation)

Burner does not start

Possible cause Measures

Control voltage not available

Fuel has not been preselected

Burner still locked by the burner control system after

the safety shut-off

General safety interlock circuit of the plant

interrupted; causes e.g.

– Low water

– Flue gas damper of the heat generator not open

Note

For burner sizes 50 and 70, ignition is direct and electrical in both oil operation and

gas operation. The data related to ignition media and ignition flame therefore does

not apply to these sizes.

Unlock the burner at the burner control system.

Manually driven flue gas damper:

Open flue gas damper.

Flue gas damper driven by the plant control system:

Check the mechanical path of the flue gas damper

If this does not solve the problem, check the

Provide for a supply with control voltage.

Preselect fuel.

Feed in boiler water.

and remove any obstacles.

manufacturer's documentation for solutions or revert

to the service personnel responsible for the heat

generator or try to solve the problem via the plant

control system.

– Emergency stop button of the plant was actuated

– The safety manostat / thermostat of the heat

Boiler control circuit interrupted

48 / 78

generator has triggered a fault and is locked

Technical Documentation

BA-TEMINOX-GL-Duo2021-02 2021-06-22

Ensure that the button was actuated accidentally or

that the reason for the emergency stop has been

eliminated.

Reset the emergency stop button of the plant.

Reset the safety manostat / thermostat. Refer to the

manufacturer's documentation on the heat

generator.

Check the control circuit, if in doubt, revert to the

service personnel.

Page 49

TEMINOX®

GL

Troubleshooting

Burner does not start

Possible cause Measures

Gas safety interlock circuit interrupted, causes e.g.

– Fuel not available or insufficient pressure

Check whether the available gas pressure

corresponds to the plant configuration.

Refer to the manufacturer's documentation on the

fuel supply system.

– Gas pressure monitor in the fuel supply system

incorrectly set or defective

Combustion air fan does not start or triggers a fault during operation

Possible cause Measures

Voltage for drive motor not available

Motor circuit breaker has triggered a fault

Fuse defective

Impeller blocked mechanically