FLUS 06 UV / FLS 09 UV

Operating Instructions

Flame Detection System

2014-03-05

1-8254-8054b-02

Combustion and Energy Systems

The reproduction, distribution and utilization of this

document as well as the communication of its contents

to others without express authorization is prohibited.

Offenders will be held liable for the payment of

f the grant of

Copyright reserved

Technical Documentation SAACKE

Original Manual

damages. All rights reserved in the event o

a patent, utility model or design.

Technology with a Future

rate engineering and continuous

research and development, ensure

Power of innovation, technical

perfection and reliability of all products

account for SAACKE’s technological

ship. Competent project

management, comprehensive

operational advice, and a worldwide

service network stand for customer

proximity and partnership with a

guaranteed future within the industrial

SAACKE worldwide -

For more than 80 years SAACKE has set

standards in economic, eco-friendly and

easy-to-service burner technology.

Firstoptimization of products and systems,

supported by extensive in-house

requirements and sustain flex ibility.

leader

thermal market.

Combustion and Energy Systems

Contents

FLUS 06 UV / FLS 09 UV

0 Contents

0 Contents ............................................................................................................................... 4

1 About this Document ........................................................................................................... 5

2 Safety .................................................................................................................................... 6

2.1 Documentation is a part of the product! .............................................................................................. 6

2.2 Symbols ............................................................................................................................................... 6

2.3 Safety in General ................................................................................................................................. 7

2.4 Intended Use ....................................................................................................................................... 7

2.5 Limitation of Liability ............................................................................................................................ 7

2.6 Qualified Staff ...................................................................................................................................... 7

2.7 Electrical Hazards ............................................................................................................................... 8

2.8 Dangers from Ambient Conditions ...................................................................................................... 8

3 Transport, Storage and Packing ......................................................................................... 9

3.1 Checking the Delivery ......................................................................................................................... 9

3.2 Reporting Transport Damage .............................................................................................................. 9

3.3 Instructions for Storage ....................................................................................................................... 9

3.4 Disposal of the Packaging ................................................................................................................... 9

3.5 Disposal of the Product ....................................................................................................................... 9

4 Scope of Delivery ............................................................................................................... 10

5 Design and Function ......................................................................................................... 11

5.1 Flame Scanner FLS 09 UV ............................................................................................................... 11

5.2 Flame Monitor FLUS 06 UV .............................................................................................................. 12

6 Installation .......................................................................................................................... 15

7 Maintenance ....................................................................................................................... 16

7.1 Cleaning the FLS 09 UV Flame Scanner / Running the Shut-off Check .......................................... 16

7.2 Flame Monitor FLUS 06 UV .............................................................................................................. 18

8 Troubleshooting ................................................................................................................ 19

9 Repair ................................................................................................................................. 20

10 Technical Data ................................................................................................................... 21

10.1 Flame Scanner FLS 09 UV ............................................................................................................... 21

10.2 Flame Monitor FLUS 06 UV .............................................................................................................. 23

4 / 26

Technical Documentation

1-8254-8054b-02 2014-03-05

FLUS 06 UV / FLS 09 UV

About this Document

1 About this Document

This document describes the SAACKE flame detection system FLUS 06 UV /

FLS 09 UV. It provides detailed information on function, installation and

maintenance of the flame detection system.

Please read this document and the safety instructions it contains carefully before

working with the flame detection system.

The initial commissioning of the flame detection system may be performed during

commissioning of the burner by personnel specially trained for this purpose only.

Further information on initial commissioning can therefore be found in the separate

service manual for the flame detection system and in the commissioning

instructions for your burner.

2014-03-05

Technical Documentation

1-8254-8054b-02 5 / 26

Safety

FLUS 06 UV / FLS 09 UV

2 Safety

2.1 Documentation is a part of the product!

This document is an integral part of the product. It must be retained for the entire

service life of the product. Make this document available to the staff responsible for

the work described in it. Add any updates you receive later from SAACKE to the

document.

Help us improve this documentation!

We appreciate any feedback that improves the quality of our documentation. You

will find our address on the back of this document.

2.2 Symbols

Especially important information in this docum ent is hi ghligh ted b y the

corresponding symbols:

Warning!

The industrial safety symbol identifies safety instructions whose purpose is to

prevent physical injury or death. Follow these safety instructions carefully and be

especially cautious during the work/procedures they refer to.

Warning! Risk of death from electric shock!

The electricity symbol identifies safety instructions whose purpose is to prevent

physical injury or death from electric shock. Follow these safety instructions

carefully and be especially cautious during the work/procedures they refer to.

Caution!

The caution symbol identifies all safety warnings whose purpose is to prevent

damage or destruction of the product and/or other plant components.

6 / 26

Note

This points to information or notes that are especially useful.

Technical Documentation

1-8254-8054b-02 2014-03-05

FLUS 06 UV / FLS 09 UV

2.3 Safety in General

The "Safety" chapter gives you an overview of the safety aspects you must pay

attention to in order to work with the product safely. Any individual who assembles,

installs, mounts, commissions, operates and/or does maintenance on the product

described must read and follow the instructions in this chapter carefully to avoid

physical injury and material damage. Your saf et y is at stak e.

In addition to these general safety instructions you will find specific safety

instructions in the product documentation related to individual actions or

procedures.

Only if you follow all of the safety instructions will you be able to provide the best

possible protection for yourself, your colleagues and the environment by ensuring

that the product functions safely and reliably.

In addition to this, it is imperative that you comply with the accident prevention and

safety regulations of the country you are working in.

2.4 Intended Use

The product supplied must only be used in a coherent plant configuration. A plant

configuration is coherent if the product supplied is the equivalent of the plant

component it replaces or it is used according to the manufacturer's specifications.

You can verify this by checking the technical data given in this document.

Safety

2.5 Limitation of Liability

SAACKE shall not be held liable for damage resulting from any use of the product

other than its intended one, from ignoring the documentation or from operation by

inadequately qualified staff. The risk in this case lies with the operator / plant

authorities alone.

2.6 Qualified Staff

Warning!

Risk of physical injury and damage from incorrect operation!

The plant authorities must ensure that only qualified and authorized staff works

with the product.

Qualified staff in the context of this documentation are individ uals w ho ha ve the

training that enables them to handle the product described and are authorized by

the plant authorities to assemble, install, mount, commission, operate and/or do

maintenance on the product.

2014-03-05

Technical Documentation

1-8254-8054b-02 7 / 26

Safety

FLUS 06 UV / FLS 09 UV

2.7 Electrical Hazards

Warning! Risk of death from electric shock!

Damaged lagging or live components that are not covered correctly present a risk

of death from electric shock!

Warning! Risk of death from electric shock!

Carelessness can lead to an electric shock.

This is why when you work with electrical equipment, you must always first:

1. Disconnect each piece of equipment from the mains.

2. Secure it to prevent it from being switched back on.

3. Check that the equipment is de-energized.

4. Ground the equipment and short-circuit it.

5. Cover other components/equipment nearby that are energized.

6 Secure the danger zone, for example by blocking it off and/or putting up a

conspicuous danger sign that no one can overlook.

2.8 Dangers from Ambient Conditions

Warning!

The risk in the event of an external fire and load from traffic, wind and earthquake

must be evaluated separately depending on the installation situation and the setup

location of the pressure device.

Transport

8 / 26

Technical Documentation

1-8254-8054b-02 2014-03-05

FLUS 06 UV / FLS 09 UV

Transport, Storage and Packing

3 Transport, Storage and Packing

3.1 Checking the Delivery

SAACKE products are packed and checked before they leave the factory.

When the product is delivered, first check whether the packaging is intact. This

would be the first indication that it has been transported correctly.

Check the product for transport damage.

3.2 Reporting Transport D amage

If damage has occurred during transport, follow these procedures:

Record the transport damage on the freight documents and take a

photograph and/or make a sketch of it.

Have the person responsible for the delivery (for example the truck driver)

confirm that the damage was noticed by signing the freight documents.

Report the transport damage right away to SAACKE or whichever company

supplied the product.

3.3 Instructions for Storage

Only store the product in its undamaged original packaging.

Keep all components, especially electrical, pneumatic and hydraulic components,

dry, free of dust and at their correct temperature during storage. The relative

humidity must be below 80%.

3.4 Disposal of the Packaging

Dispose of all packaging correctly and ecologically.

When you do it, comply with the waste disposal regu la tions of the country in which

3.5 Disposal of the Produc t

you are working.

At the end of its service life the product must be disposed of correctly and

ecologically.

When you do it, comply with the waste disposal regu la tions of the countr y in which

you are working.

2014-03-05

Technical Documentation

1-8254-8054b-02 9 / 26

Scope of Delivery

FLUS 06 UV / FLS 09 UV

4 Scope of Delivery

Flame scanner FLS 09 UV with connection cable (3m)

Optional: Mount for the flame scanner

Flame monitor FLUS 06 UV

10 / 26

Technical Documentation

1-8254-8054b-02 2014-03-05

FLUS 06 UV / FLS 09 UV

Design and Function

H022

5 Design and Function

The flame detection system monitors the burner flame of a firing plant. If a flameout occurs, a safe operating state (“Flame OFF”) is generated which shuts off the

fuel supply to the burner.

The flame detection system SAACKE FLUS 06 UV / FLS 09 UV consists of the

flame scanner FLS 09 UV and the flame monitor FLUS 06 UV.

5.1 Flame Scanner FLS 09 UV

Fig. 1: Flame scanner FLS 09 UV with connection cable

The flame scanner uses its lens to perceive the pulsating UV radiation of the

burner flame and converts it into an electrical signal variable.

Display and operating controls

There are no display or operating controls on the flame scanner. The signal of the

flame scanner is visualised on the flame monitor.

Variants

FLS 09 UV flame scanners are available in two lengths (FLS 09 UV-5 and

FLS 09 UV-5L; dimensions see chapter “Technical Data”).

Technical Documentation

2014-03-05

1-8254-8054b-02 11 / 26

Design and Function

FLUS 06 UV / FLS 09 UV

H025

H024

5.2 Flame Monitor FLUS 06 UV

Fig. 2: Flame monitor FLUS 06 UV (as of Revision 3)

Fig. 3: Flame monitor FLUS 06 UV (up to Revision 2)

12 / 26

The flame monitor processes the electrical signal variable that it receives from the

flame scanner and outputs a status message for the flame signal by means of

LEDs and potential-free contacts.

The flame monitor is self-monitored, i.e. it processes the input signals from the

flame scanner via two separate, alternately controlled channels whose output

levels are continuously compared with anticoincidence.

Technical Documentation

1-8254-8054b-02 2014-03-05

FLUS 06 UV / FLS 09 UV

Design and Function

H016

H015

Display and operating controls

Fig. 4: Front panel of flame monitor (as of Revision 3)

Fig. 5: Front panel of flame monitor (up to Revision 2)

2014-03-05

Technical Documentation

1-8254-8054b-02 13 / 26

Design and Function

FLUS 06 UV / FLS 09 UV

H017

Fig. 6: Detail: LEDs on the front panel

When the operating voltage has been switched on on the control cabinet, the flame

monitor is ready for operation after about 10 seconds.

In the initial state (“Flame OFF”) the red LED1 is lit.

If the flame is detected when the burner has ignited, the red LED1 goes out.

Instead the green LED2 is lit (“Flame ON”).

Note

The green LED2 flickers with the rhythm of the self-monitoring, this is not a fault

message.

The green LED3 and LED4 are used to indicate the flame intensity:

If the flame signal is weak, only LED3 is lit.

If the flame signal is strong, LED3 and LED4 are lit.

Note

The position and alignment of the flame scanner, which is set during

commissioning, are decisive for the intensity of the flame signal.

14 / 26

Technical Documentation

1-8254-8054b-02 2014-03-05

FLUS 06 UV /

FLS 09 UV Installation

6 Installation

The flame scanner is mounted on the burner. The flame scanner must be aligned

in such a way that

it perceives the first third of the flame during burner operation

it reliably detects the flame in the entire capacity range of the burner

This was already taken into account for SAACKE burners during the design phase.

The position of the flame scanner(s) has therefore already been specified in the

design. Only the insertion depth and the alignment of the flame scanner (lens)

must be optimised specifically for the plant during commissioning of the burner.

The flame scanner is already correctly connected to the flame monitor ex works.

The flame monitor is also already connected in the component connection box.

2014-03-05

Technical Documentation

1-8254-8054b-02 15 / 26

Maintenance

FLUS 06 UV / FLS 09 UV

7 Maintenance

7.1 Cleaning the FLS 09 UV Flame Scanner / Running the Shut-off Check

The lens of the flame scanner must be cleaned at specific intervals depending on

the operating conditions of the firing plant.

To do this, the flame scanner must be removed.

We recommend checking the “Flame fault safety shut-off” safety function (shut-off

check) at the same time. Before you start, carefully read the operational sequence

description of the shut-off check.

Note

The shut-off check can only be run while the burner is in operation.

If you would like to clean the lens only, without running the shut-off check, switch

the burner off before you remove the flame scanner.

The sequence including the shut-off check is described below.

Warning!

Plant operation without “Flame monitoring” safety function!

During the shut-off check you are instructed to remove the flame scanner during

operation.

Remember: While the flame scanner is removed, the flame is not monitored, i.e.

the “Flame monitoring” safety function is inactive during this time.

Therefore do the steps described below carefully and quickly.

Warning! Risk of injuries from parti cles in the air!

When removing the flame scanner, air containing particles may escape. We

recommend wearing safety goggles.

Caution!

The shut-off check will trigger a safety shut-off! Get clearance from the plant

manager before starting the check.

16 / 26

Technical Documentation

1-8254-8054b-02 2014-03-05

FLUS 06 UV / FL

S 09 UV Maintenance

TX080

Fig. 7: Flame scanner with mount

1 Flame scanner

2 Mount (made of polycarbonate, transparent)

3 Clamping screw

4 Position screw (on the burner)

5 Mounting screw

6 Adapter (on the burner, example)

If the flame scanner monitors the ignition flame:

Start the burner and wait until the ignition flame is burning.

If the flame scanner monitors the main flame:

Run the burner to the low-load position.

Unscrew the two mounting screws (5).

Caution!

The position screws (4) and the clamping screw (3) stay screwed in!

Pull out the flame scanner with its mount.

Warning!

Plant operation without the “Flame monitoring” safety function!

While the flame scanner is removed, the flame is no longer monitored, i.e. the

“Flame monitoring” safety function is inactive during this time.

Cover the lens. When doing so, be sure not to soil or scratch the lens.

This must trigger a safety shut-off within one second at the latest.

2014-03-05

Technical Documentation

1-8254-8054b-02 17 / 26

Maintenance

FLUS 06 UV / FLS 09 UV

Warning!

Plant operation without the “Flame monitoring” safety function!

If no safety shut-off is triggered during the shut-off check, press the emergency

stop button on the plant.

Observe the chapter entitled “Troubleshooting”.

Only restart the plant when you are sure that the flame detection system is

functioning properly.

Check whether the lens is dirty. Clean it if required.

Caution!

The lens is made of glass. Take care not to scratch the lens. Use only cleaning

materials that do not damage the surface of the lens.

Mount the flame scanner (including the mount).

Reset the burner at the burner control system.

7.2 Flame Monitor FLUS 06 UV

The flame monitor is maintenance-free.

If the front panel is dirty...

Clean it with a clean cloth and one of the cleansers listed below.

Then wipe it off with a clean cloth.

Approved cleansers: Ethyl alcohol, household cleanser, isopropanol, window

cleaner

Not approved cleansers: Solvents (dichloromethane, ether, chloroform), acetone,

butanone, acids, undiluted alkalis

18 / 26

Technical Documentation

1-8254-8054b-02 2014-03-05

FLUS 06 UV / FLS 09 UV

Troubleshooting

8 Troubleshooting

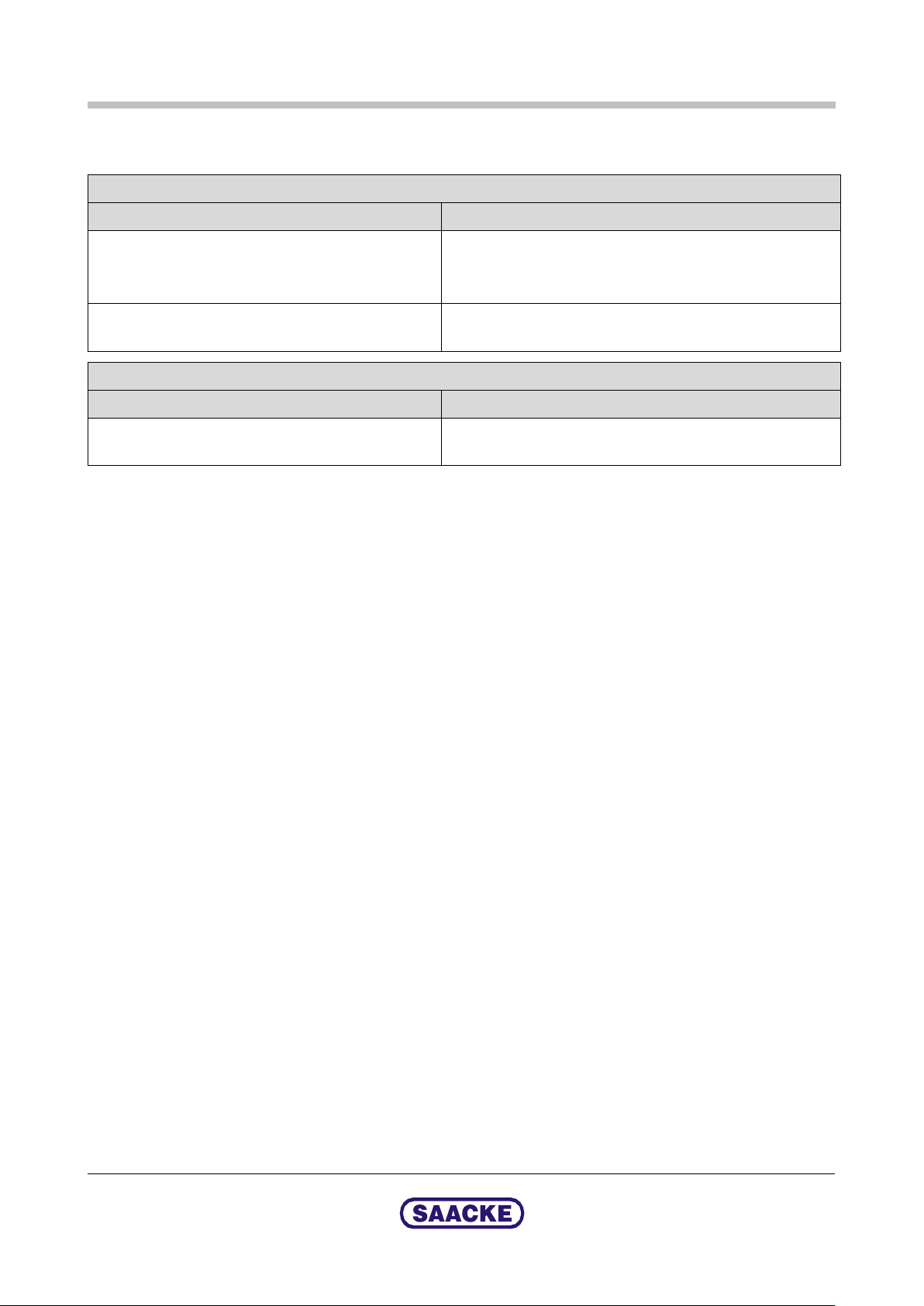

Fault message “Flame fault” during operation

Possible cause Measures

Flame not correct (various causes possible)

Follow the operating instructions for the burner.

If in doubt: Contact SAACKE Service (address on back

of the document).

Flame scanner / flame monitor defective

Shut-off check not successful

Possible cause Measures

Flame scanner / flame monitor defective

Contact SAACKE Service (address on back of the

document).

Contact SAACKE Service (address on back of the

document).

2014-03-05

Technical Documentation

1-8254-8054b-02 19 / 26

Repair

FLUS 06 UV / FLS 09 UV

9 Repair

Warning!

Both the flame scanner and the flame monitor are safety-related components. If

they are defective, they must not be repaired, they must be replaced.

The casings of the flame scanner and flame monitor must not be opened.

Use only original spare parts as replacements. SAACKE Service is at your disposal

for more detailed information. You will find our contact address on the back of this

document.

After replacing the flame scanner and/or the flame monitor, run at least one shutoff check for safety reasons.

20 / 26

Technical Documentation

1-8254-8054b-02 2014-03-05

FLUS 06

UV / FLS 09 UV Technical Data

H013

(Shield)

FLS 09 UV-5L

FLS 09 UV-5

10 Technical Data

10.1 Flame Scanner FLS 09 UV

2014-03-05

Fig. 8: Dimensions of flame scanner

Technical Documentation

1-8254-8054b-02 21 / 26

Technical Data

FLUS 06 UV / FLS 09 UV

Weight 400 g

Ambient conditions (transport) -20 to +70°C

Maximum humidity 80% at 35°C

Ambient conditions (operation) -10 to +60°C

Maximum humidity 80% at 35°C

Viewing angle

Protection class IP65

Detectable spectral radiation range 215 – 360 nm

Detectable pulsation frequency 10 – 200 Hz

Installation position any

Connection cable

Stranded hookup wire SABIX D315 FRNC special (6-core), 6 x 1 x 0.5 mm²

(AWG20), length 3 m

Extension up to maximum 100m possible

The PK (pink) wire of the connection cable must not be extended.

Approx. ± 5° to the optical axis

22 / 26

Technical Documentation

1-8254-8054b-02 2014-03-05

FLUS 06 UV / FLS 09 UV

Technical Data

H030

H014

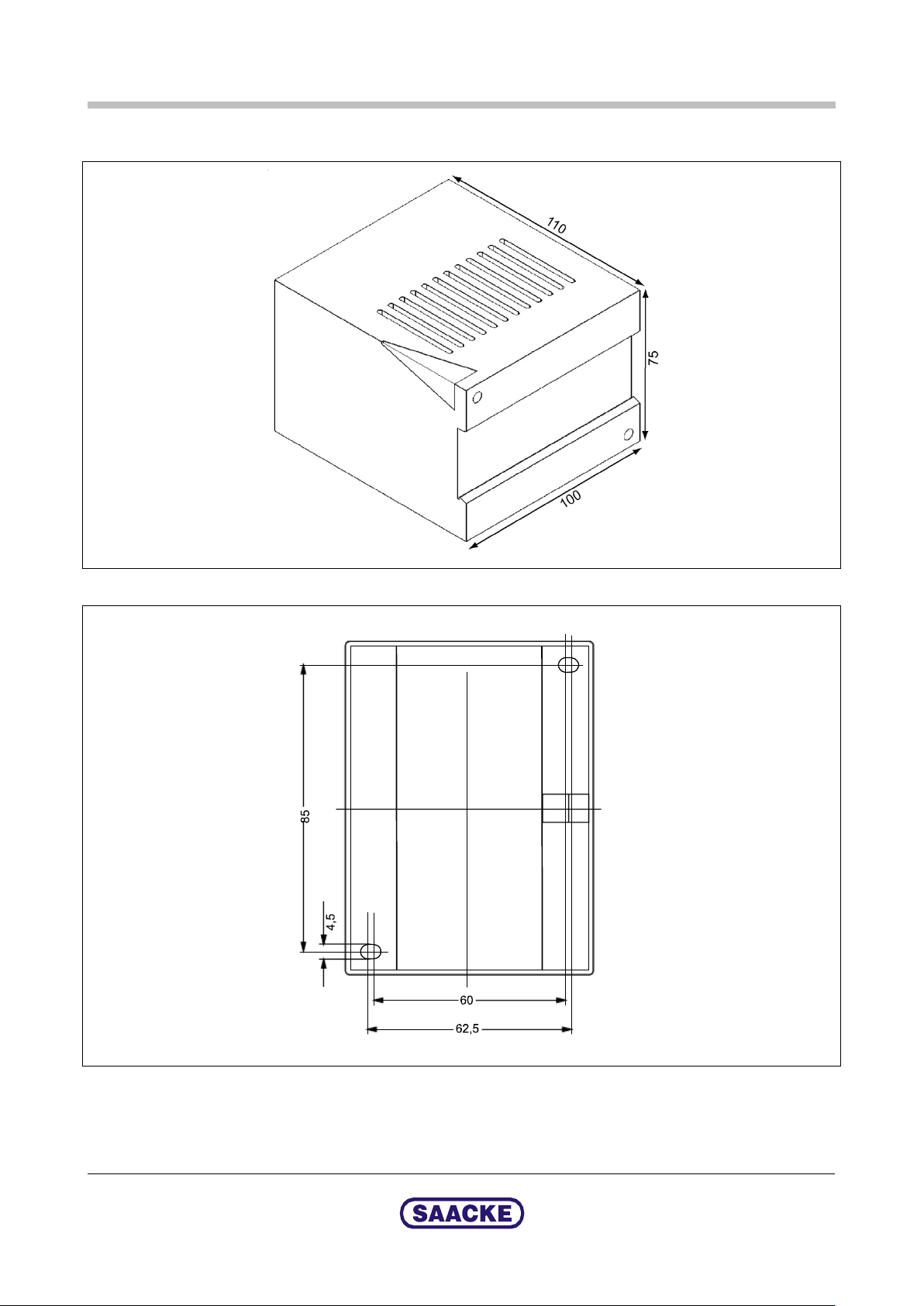

10.2 Flame Monitor FLUS 06 UV

Fig. 9: Dimensions of flame monitor (1)

2014-03-05

Fig. 10: Dimensions of flame monitor (2), view from below

Technical Documentation

1-8254-8054b-02 23 / 26

Technical Data

FLUS 06 UV / FLS 09 UV

1

Weight 500 g

Ambient conditions (transport) -20 to +70°C

Maximum humidity 80% at 35°C

Ambient conditions (operation) -10 to +60°C

Maximum humidity 80% at 35°C

Installation type In the control cabinet / control panel or control box

Mounting type On top-hat rail, alternatively via mounting holes

Installation position Any

Protection class Up to Revision 2: IP20

As of Revision 3: IP20 if plug inserted

Safety time

Operating voltage 230 V AC (-15 % to +10 %),

Power consumption approx. 5 VA

Safe output contact

for safety function

(potential-free, open when deenergised)

≤ 1 s

115 V AC (-15 % to +10 %) optional,

50 or 60 Hz

Terminals 11 and 12

Permitted switching voltage Min. 6 V AC / 6 V DC

Max. 250 V AC / 30 V DC

Permitted switching current Min. 1 mA (with contact limit

Switching power Max. 15 W DC

load 50 mA)

Max. 0. 5 A

Max. 125 VA AC

(when cos

ϕ = 0.4)

Non-safe output contact

for indication function

(potential-free, open when deenergised)

Measurement output for flame

intensity

Feed to flame scanner Voltage 22 – 37 V DC

1

Must be fused externally. The fuse is not included in the scope of delivery

Terminals 9 and 10

Permitted switching voltage Min. 6 V AC / 6 V DC

Max. 250 V AC / 30 V DC

Permitted switching current Min. 40 mA

Max. 0.5 A

Fuse

Terminals 7 and 8

Output current 0 – 20 mA (direct current)

Max. resistance

No-load direct voltage 22 – 26 V DC

Intrinsic error

Short-circuit current 30 mA (max. 1 min)

0.5 A

500

± 2%

Ω

24 / 26

Technical Documentation

1-8254-8054b-02 2014-03-05

For local contacts please see www.saacke.com

a

SAACKE GmbH

Suedweststrasse 13

28237 Bremen

Germany

Tel.: +49 421 6495-0

Fax: +49 421 6495-5224

info@saacke.de

www.saacke.com

SAACKE Service:

Industrial Solutions

Supportline: +800-1002001

or +49 421 6495-5201

spares-industrial@saacke.com

service-industrial@saacke.com

Marine Systems

Hotline Germany: +49 421 6495-5229

Hotline Worldwide: +1 954 767 0309

spares-marine@saacke.com

service-marine@saacke.com

Loading...

Loading...