Page 1

TCFG series

Tantalum capacitors

Chip tantalum capacitors with

open-function built-in

TCFG series

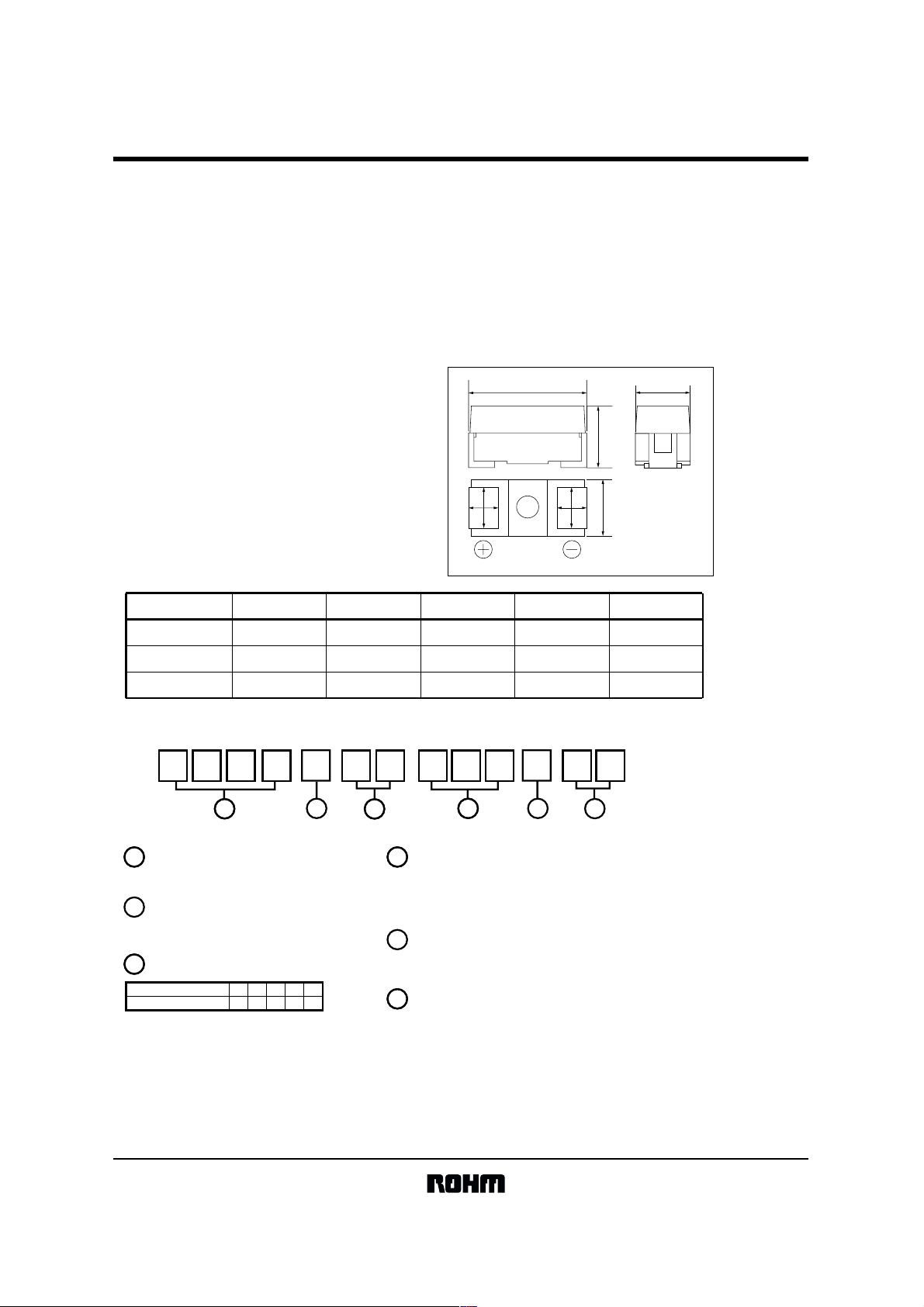

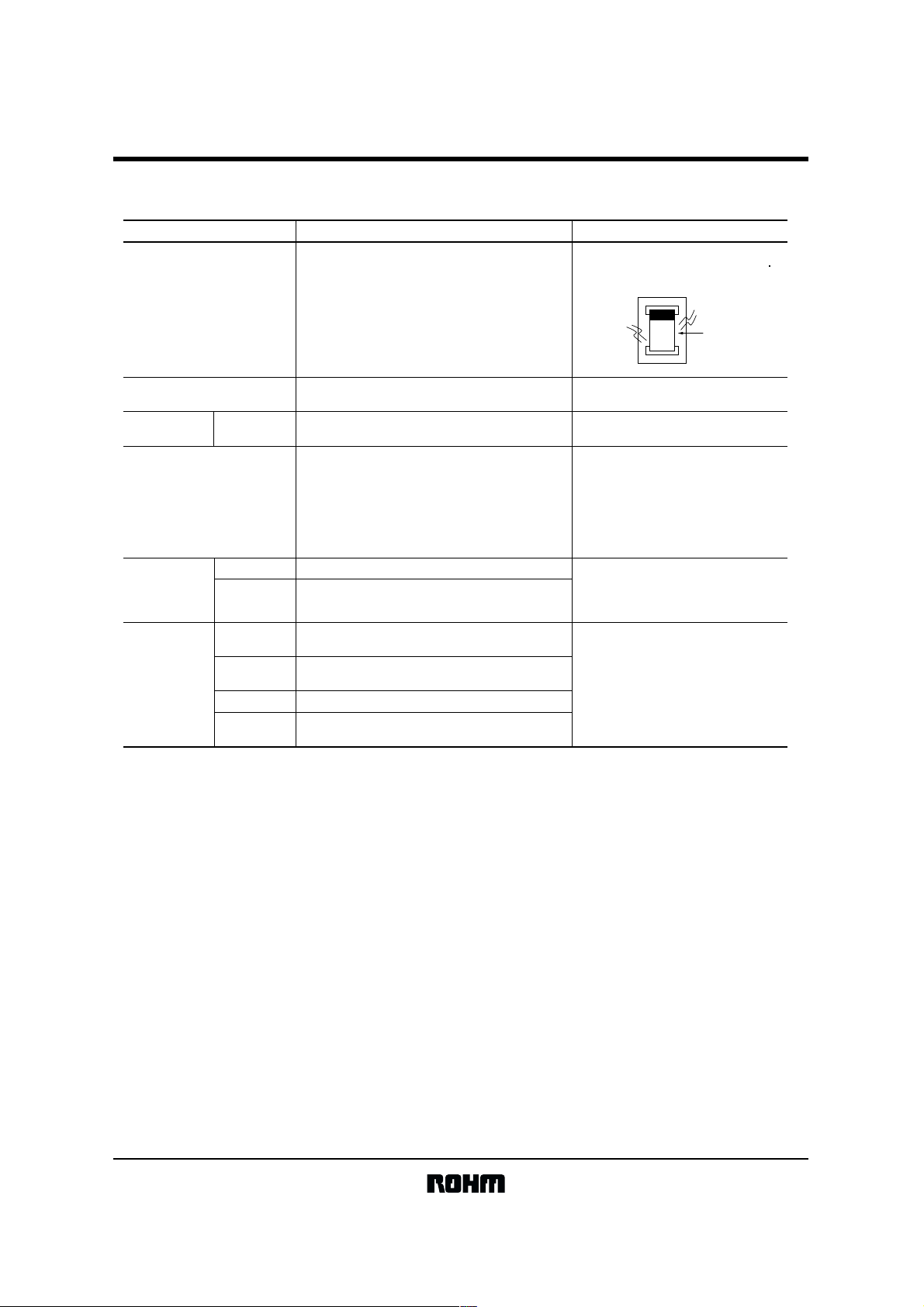

!!!!Features !!!!External dimensions (Units : mm)

1) Safety design by open functiom built - in.

2) Wide capacitance range

3) Screening by thermal shock.

L

H

W

2

S

2

W

S

W

1

Max.

W

1

Case code L W

P (2012) 2.0 0.2 1.25 0.2 0.9 0.2 Max.1.20 0.45 0.3

A (3216) 3.2 0.2 1.6 0.2 1.2 0.2 1.6 0.2 0.8 0.3

B (3528) 3.5 0.2 2.8 0.2 1.9 0.2 1.9 0.2 0.8 0.3

+

−

+

−

+

−

1

+

−

+

−

+

−

W

2

+

−

+

−

+

−

HS

+

−

+

−

T C

11

Series name

TC/TCFG

2

Case code

TC…………M,P,A

TCFG……P,A,B

3

Rated voltage

Rataed voltage

CODE

161

(V)

4

6.30J101A161C20

0G

A0J

2

1D

3

4

5

1

Capacitance

pF Code : 1st two digits represent significant figures, 3rd

digit represent multiplier (number of zeros to follow)

Capacitance Tolerance

M :

±20%

Taping

8: Tape width (8mm)

R:Anode is on the opposite side of the sprocket hole

6

0

4 5

K :

±10%

M 8 R

6

+

−

+

−

+

−

1/15

Page 2

TCFG series

Tantalum capacitors

!!!!Capacitance range

TCFG series

Raited voltage (V.DC)

µF

4

0G

6.3

0J

10

1A

16

1C

20

1D

1.0 P,A A

1.5 A

2.2 P,A

3.3 P,A

4.7 P,A P,A P,A,B A,B

6.8 P,A

10 P,A

15 P,A,B P,A,B A,B

22 P,A,B A,B

33 A,B A,B

47 A,B

68

100

∗

Pleasecontactusaboutthisproduct.

typical example

Valtge code

P

P P,A A,B

B

B

P

P

P,A

P,A,B

B

B

B

Capacitance

P

P,A

A,B

A,B

∗

A,B

B

B

A

A,B

A,B

B

B

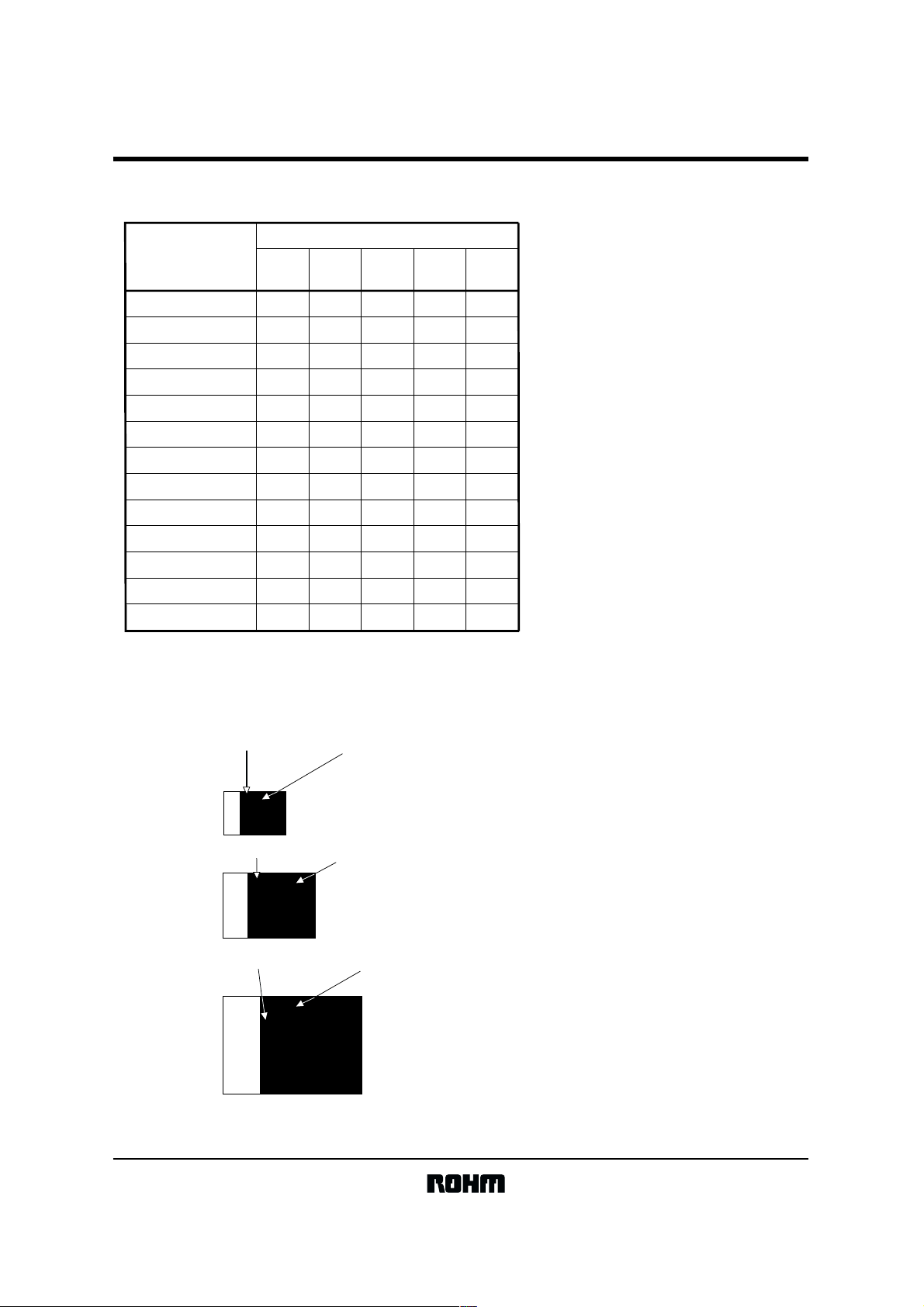

P case

(2012)

A case

(3216)

B case

(3528)

j J

- -

AA

Valtge code

j 106

YAA

Valtge code

10

16V

YAA

Capacitance

Capacitance

2/15

Page 3

TCFG series

Tantalum capacitors

!!!!Characteristics

Item Performance

Operating temperature −55˚

Max. operating temperature

at rated voltage

Rated voltage (V. DC)

Derated voltage (V. DC)

Surge voltage (V. DC)

Leakage current Less than or equal to the larger of 0.5

Capacitance range 1.0 ~ 100

tan

δ

Impedance

Resistance to

solder heat

Open function

operation

Temperature

cycle

Resistance to

humidity

(steady state)

P case

A case

B case 3.3

Appearance

∆C / C

tan

δ

Appearance

L.C

∆C / C

tan

δ

Appearance

∆C / C

tan

δ

C

~ +125˚

C

+85˚

C

2016106.34

13

106.342.5

26201385.2

0.01CV. Details are given in Table 1,

"Standard Product List".

µ

F

1

µ

F to 4.7µF : 0.08 max.

6.8

µ

F to 15µF : 0.10 max.

1

µ

F max.: 0.04 max.

1.5

µ

F to 22µF : 0.06 max.

33

µ

F to 47µF : 0.08 max.

µ

F to 47µF : 0.06 max.

68

µ

F to 100µF : 0.08 max.

27.5Ω max.P case

20.0Ω max.A case

15.0Ω max.B case

No noticeable irregularities, and the

markings must be easy to read.

Must satisfy the initial specified value.L.C

A B case within ± 5%

P case within ± 10%

P case 1.5 times or less or initial specified tolerance.

A B case must satisfy the initial specified value.

320˚

C

for 20s or less

No noticeable irregularities, and the

markings must be easy to read.

Must satisfy the initial specified value.

P case = Within 150% of initial limit.

P case within ± 10%

A B case within ± 5%

P case 1.5 times or less or initial specified tolerance.

A B case must satisfy the initial specified value.

No noticeable irregularities, and the

markings must be easy to read.

Must satisfy the initial specified value.L.C

P case within ± 20%

A B case within ± 10%

P case 1.5 times or less or initial specified tolerance.

A B case must satisfy the initial specified value.

µ

A or

Test methods / conditions

(based on JIS C 5102, 5143)

at 125˚

C

Measured value 60s after application

of rated voltage.

Measured frequency: 120 ± 12Hz

Measured voltage: 0.5Vrms + 1.5V. DC

Measured circuit: equivalent series

circuit

Measured frequency: 120 ± 12Hz

Measured voltage: 0.5Vrms + 1.5V. DC

Measured circuit: equivalent series

circuit

Measured frequency: 100 ± 10Hz

Measured voltage: 0.5Vrms max.

Measured circuit: equivalent series

circuit

Direct immersion into solder bath

Solder bath temperature: 260 ± 5˚

Immersion time: 5s

Immersion cycles: 1 time

Direct immersion into solder bath

(320 ± 5˚

The four cycles in the table below are

repeated five times in succession.

Measured after being left for 500

± 12hrs. at 60 ± 2˚

RH, then 1 to 2 hrs. at normal room

temperature and humidity.

C

)

Temperature Time

−55 ± 3˚

125 ± 2˚

C

C

C

and 90 to 95%

1

Room temperature

2

3

Room temperature

4

C

30 ± 3mins.

3mins. max.

30 ± 3mins.

3mins. max.

3/15

Page 4

TCFG series

Tantalum capacitors

Temperature

characteristics

Surge

resistance

Hightemperature

load

Terminal

strength

Item Performance

Temperature

∆C / C

tanδ

L.C −

Temperature +85°C

∆C / C

tanδ Must satisfy the initial specified value.

L.C Less than or equal to the larger of 5µA or 0.1CV.

Temperature +125°C

∆C / C

tanδ

L.C Less than or equal to the larger of 6.3µA or

Appearance

∆C / C

tanδ

Appearance No noticeable irregularities, and the

L. C Must satisfy the initial specified value.

∆C / C Within ± 10%

tanδ

Capacitance Value must be stable during measurement.

Appearance No noticeable irregularities.

−55°C

P case within +0% and −15% of the value before testing.

B case within +10% and −0% of the value before testing.

A

P case within 1.5 times of the value before testing.

A B case must satisfy the initial specified value.

P case within +0% and −15% of the value before testing.

B case within +0% and −10% of the value before testing.

A

P case within +20% and −0% of the value before testing.

A B case within +15% and −0% of the value before testing.

P case within 1.5 times of the value before testing.

A B case must satisfy the initial specified value.

0.125CV.

A B case no noticeable irregularities, and the

markings must be easy to read.

Must satisfy the initial specified value.L.C

P case within ± 10%

A B case within ± 5%

P case within 1.5 times of the value before testing.

A B case must satisfy the initial specified value.

markings must be easy to read.

P case within 1.5 times of the value before testing.

A B case must satisfy the initial specified value.

Test methods / conditions

(based on JIS C 5102,5143)

Apply the rated surge voltage for

30 ± 5s at intervals of 5 ± .05mins.

1000 times, with the temperature at

85 ± 2°C.

Temp.

Series Resistance

Applied voltage

Test time

meusure made after pieces shall be left for

1 to 2 hrs under room temp. and room

humidity after test.

Apply pressure to the device using the

specified tool for 5s so that the center

deflection is 1mm (see below).

: 85 ± 2°C

: 3Ωmax.

: rated voltage

: P case 1000

A B case 2000

20

50

F (Direction of force)

R230

(Units: mm)

1

+36

− 0

hrs

+73

− 0

hrs

45 45

4/15

Page 5

TCFG series

Tantalum capacitors

Item Performance

Adhesion Terminals must not detach. With the device mounted on the printed

External dimensions Refer to "External dimensions" Measure using slide calipers that meet

Markings Resistance to

solvents

Solderability

Inspect the solder cover of

the terminals using a solder

immersion test

Marking must be easy to read. Immerse in isopropyl alcohol for

At least 3 / 4 of the surface of the immersed

terminals must be covered with new solder.

circuit board, apply a force of 0.5kg f

from each side for a period of 10 ± 1s.

the requirements of JIS B7507 Class 2.

30 ± 5s.

Immersion speed: 25 ± 2.5mm / s

Pre-processing (accelerated aging):

leave for 1hr over boiling distilled water.

Solder temperature: 235 ± 5°C

Immersion time: 2 ± 0.5s

Solder type: H63A

Flux: rosin 25%, IPA 75%

Test conditions

Device

C105

YAA

Printed circuit board

Force

Resistance to

vibration

polarity

withstanding

voltage

Capacitance

Appearance No noticeable irregularities.

AppearanceReverse

L.C Must be less than or equal to twice the initial

∆C / C Within ± 10% of the value before the test.

tanδ Must be less than or equal to 1.5 times the

Value must be stable during measurement.

No noticeable irregularities, and the markings

must be easy to read.

specified value.

initial specified value.

Vibrate in the X / Y axis at frequencies of

10~55~10Hz / minute for two hours

each, with a total vibration amplitude of

1.5mm.

Apply either 0.1 times the rated voltage,

or 3V, whichever is smaller, via a series

resister of 3Ωmax. and 0.1Ωmin. at a

temperature of 85 ± 2°C.

5/15

Page 6

TCFG series

Tantalum capacitors

!!!!Table 1Standard list, TCFG series

6/15

Page 7

TCFG series

Tantalum capacitors

(P : 2012 A : 3216 B : 3528)

Part No.

TCF GP 0G 225

TCF GP 0G 335

TCF GP 0G 475

TCF GA 0G 475

TCF GP 0G 685

TCF GA 0G 685

TCF GP 0G 106

TCF GA 0G 106

TCF GP 0G 156

TCF GA 0G 156

TCF GB 0G 156

TCF GA 0G 226

TCF GB 0G 226

TCF GA 0G 336

TCF GB 0G 336

TCF GA 0G 476

TCF GB 0G 476

TCF GB 0G 686

TCF GB 0G 107

TCF GP 0J 155

TCF GP 0J 225

TCF GP 0J 335

TCF GA 0J 335

TCF GP 0J 475

TCF GA 0J 475

TCF GP 0J 685

TCF GA 0J 685

TCF GP 0J 106

TCF GA 0J 106

TCF GB 0J 106

TCF GA 0J 156

TCF GB 0J 156

TCF GA 0J 226

TCF GB 0J 226

TCF GA 0J 336

TCF GB 0J 336

TCF GB 0J 476

TCF GB 0J 686

Rated

voltage

at 85°C

Tolerance

(M : ±20%, K : ±10%)

Derated

voltage

at 125°C

(V)

4 2.5 5.2 2.2 ±20,10 0.5 8 P

4 2.5 5.2 3.3 ±20,10 0.5 8

4 2.5 5.2 4.7 ±20,10 0.5

4 2.5 5.2

4 2.5 5.2

4 2.5 5.2

4 2.5 5.2

4 2.5 5.2

4 2.5 5.2

4 2.5 5.2

4

4

4

4

4

4

4

4

4

6.3 4 8 1.5

6.3 4 8 2.2

6.3 4 8 3.3

6.3 4 8

6.3 4 8

6.3 4 8

6.3 4 8

6.3 4 8

6.3 4 8

6.3 4 8

6.3

6.3

6.3

6.3

6.3

6.3

6.3

6.3

6.3

(V)

2.5 5.2

2.5 5.2

2.5 5.2

2.5 5.2

2.5 5.2

2.5 5.2

2.5 5.2

2.5 5.2

2.5 5.2

Surge

voltage

at 85°C

48

48

48

48

48

48

48

48

48

Capacitance

(V)

Leakage

Tolerance

(µF)

4.7 0.5

6.8

6.8 0.5

10

10 0.5

15

15

15 0.6

22

22

33

33 1.3

47

47 1.9

68 2.7

100 4.0

3.3 0.5

4.7

4.7 0.5

6.8

6.8 0.5

10

10 0.6

10 0.6

15

15 0.9

22 1.4

22

33 2.1

33

47 3.0

68 4.3

(%)

±20,10

±20,10

±20,10

±20,10

±20,10

±20,10

±20,10

±20,10

±20,10

±20,10

±20,10

±20,10

±20,10

±20,10 6

±20,10 8

±20,10

±20,10

±20,10

±20,10

±20,10

±20,10

±20,10

±20,10

±20,10

±20,10

±20,10

±20,10

±20,10

±20,10

±20,10

±20,10

±20,10

±20,10

±20,10

±20,10

current

at 25°C

1WV.60s

(µA)

0.5

0.5

0.6

0.6

0.9

0.9

1.3

1.9

0.5

0.5

0.5

0.5

0.5

0.6

0.9

1.4

2.1

DF

120Hz

25°C

(%)

8

6

10

6

10

6

10

6

6

6

6

8

6

8

8

8

8

8

6

8

6

10

6

10

6

6

6

6

6

6

8

6

6

8

Case

code

P

P

A

P

A

P

A

P

A

B

A

B

A

B

A

B

B

B

P

P

P

A

P

A

P

A

P

A

B

A

B

A

B

A

B

B

B

7/15

Page 8

TCFG series

Tantalum capacitors

(P : 2012 A : 3216 B : 3528)

Case

code

P

A

P

A

P

A

P

A

B

A

B

A

B

A

B

B

B

B

P

A

A

A

A

B

A

B

A

B

B

B

B

A

Part No.

TCF GP 1A 105

TCF GP 1A 155

TCF GA 1A 155

TCF GP 1A 255

TCF GA 1A 225

TCF GP 1A 335

TCF GA 1A 335

TCF GP 1A 475

TCF GA 1A 475

TCF GB 1A 475

TCF GB 1A 685

TCF GB 1A 106

TCF GA 1A 156

TCF GB 1A 156

TCF GB 1A 226

TCF GB 1A 336

TCF GB 1A 476

TCF GP 1C 105

TCF GA 1C 105

TCF GA 1C 155

TCF GA 1C 225

TCF GA 1C 335

TCF GB 1C 335

TCF GA 1C 475

TCF GB 1C 475

TCF GA 1C 685

TCF GB 1C 685

TCF GB 1C 106

TCF GB 1C 156

TCF GB 1C 226

TCF GA 1D 105

Rated

voltage

at 85°C

Tolerance

(M : ±20%, K : ±10%)

Derated

voltage

at 125°C

(V)

10 6.3 13 1.0

10 6.3 13

10 6.3 13

10 6.3 13

10 6.3 13

10 6.3 13

10 6.3 13

10 6.3 13

10

10 6.3

10

10

10

10

10

10

10

10

10

16 1.0

16

16

16

16

16

16

16

16

16

16

16

16 10

20 13 26 1.0

(V)

6.3 13

6.3

6.3

6.3

6.3

6.3

6.3

6.3

6.3

6.3

10

10

10

10

10

10

10

10

10

10

10

10

Surge

voltage

at 85°C

(V)

13

13

13

13

13

13

13

13

13

13

20

20

20

20

20

20

20

20

20

20

20

20

20

Capacitance

(µF)

1.5

1.5

2.2

2.2

3.3

3.3

4.7

4.7

4.7

6.8TCF GA 1A 685

6.8

10TCF GA 1A 106

10

15

15

22

33

47

1.0

1.5

2.2

3.3

3.3

4.7

4.7

6.8

6.8

10

15

22

Leakage

Tolerance

(%)

±20,10 0.5 8 P

±20,10 0.5 8

±20,10 0.5

±20,10

±20,10

±20,10

±20,10

±20,10

±20,10

±20,10

±20,10

±20,10

±20,10

±20,10

±20,10

±20,10

±20,10 6

±20,10 6

±20,10

±20,10

±20,10

±20,10

±20,10

±20,10

±20,10

±20,10

±20,10

±20,10

±20,10

±20,10

±20,10

±20,10

±20,10

current

at 25°C

1WV.60s

(µA)

0.5

0.5

0.5

0.5

0.5

0.5

0.5

0.7

0.7

1.0

1.0

1.5

1.5

2.2

3.3

4.7

0.5

0.5

0.5

0.5

0.5

0.5

0.8

0.8

1.1

1.1

1.6

2.4

3.5

0.5

DF

120Hz

25°C

(%)

6

8

6

8

6

8

6

6

6

6

6

6

6

6

6

8

4

6

6

6

6

6

6

6

6

6

6

6

4

8/15

Page 9

TCFG series

Tantalum capacitors

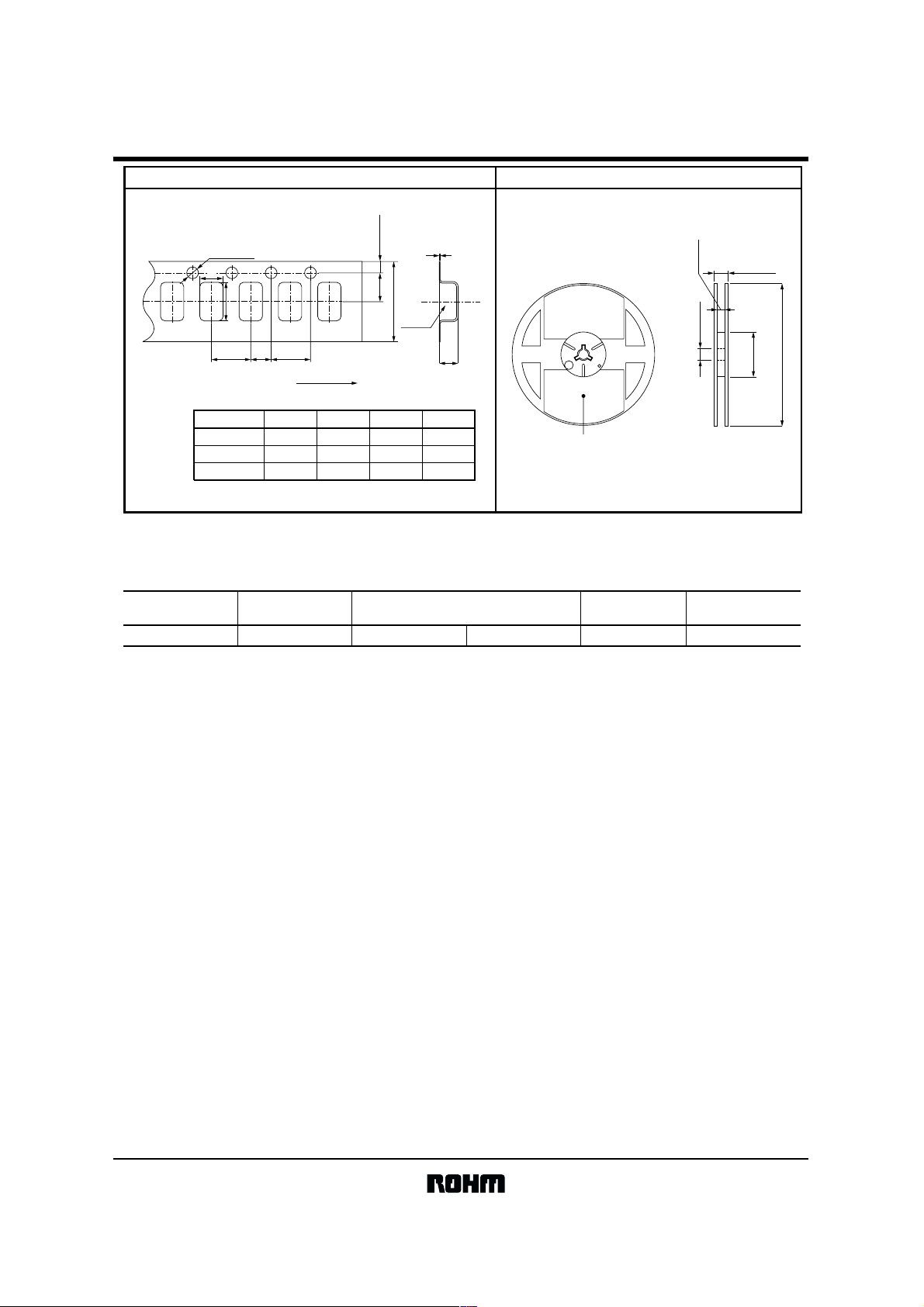

Taping Reel

TCFG Plastic reel

+ 0.1

φ1.5

− 0

A

4.0 ± 0.1B4.0 ± 0.1

2.0 ± 0.05

Pull-out direction

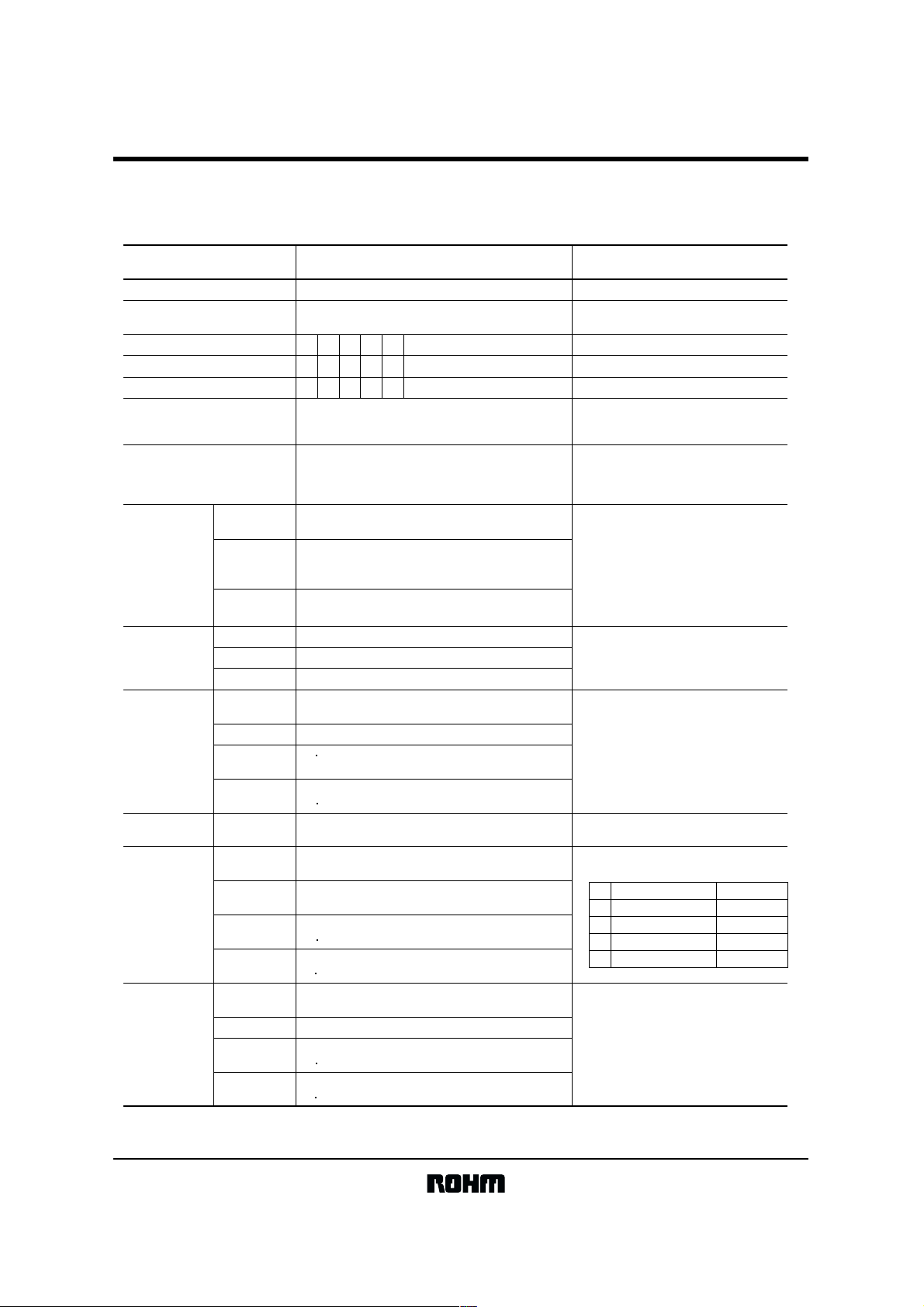

Case code A ± 0.1 B ± 0.1 t1 ± 0.05 t2 ± 0.1

P (2012) 1.55 2.3 0.25 1.5

A (3216) 1.9 3.5 0.25 1.9

B (3528) 3.3 3.8 0.25 2.2

Some emboss tapes have the center hole

on its bottom.

1.75 ± 0.1

3.5 ± 0.05

8.0 ± 0.3

Product

!!!!Packaging style

Part No. Package type Packaging style

TCFG

Taping Plastic taping φ180 mm reel

t

1

11.4 ± 1.0

9.0 ± 0.3

φ13 ± 0.2

t

2

Label position

EIAJ ETX - 7001comformed

0

0

− 3

+ 1

φ60

φ180

Symbol

R 2,000

Basic ordering unit (pcs)

9/15

Page 10

TCFG series

Tantalum capacitors

!!!! Electrical characteristics and operation notes

(1) Soldering conditions (soldering temperature and soldering time)

Reflow

TCFG

170

Preheat

280

TCFG

160

(°C)

150

TEMPERATURE

140

130

0 60 90 120 150 180

(sec)

TIME

Fig.1 Reflow (Infrared Ray, Hot Plate, Hot Air)

270

260

250

(°C)

240

230

220

TEMPERATURE

210

200

0 2 4 6 8 10 12 14 16

TIME

(sec)

Fig.2 Flow

(Dipping wave soldering)

TCFG

260

(°C)

240

TEMPERATURE

220

200

0 10203040506070

TIME

(sec)

340

320

(°C)

300

TEMPERATURE

280

0 5 10 15 20 25

TIME (

sec)

Fig.3 Hand soldering

(soldering gun output:

30W or less)

TCFG

(2) Leakage current-to-voltage ratio

1

0.1

LEALKAGE CURRENT RATIO DCL / DCL

0.01

0 20 40 60 80 100

% OF RATED VOLTAGE (

Fig.4

VR)

10/15

Page 11

TCFG series

Tantalum capacitors

(3) Derating voltage as function of temperature

100

)

R

90

(V

80

70

60

PERCENT OF 85°C RVDC1

50

75 85 95 105 115 125

TEMPERATURE

(°C)

Fig.5

(4) Reliability

The malfunction rate of tantalum solid state electrolytic capacitors varies considerably depending on the conditions of

usage (ambient temperature, applied voltage, circuit resistance).

Formula for calculating malfunction rate

λp = λb × (π

E × πSR × πQ × πCV)

λp

: Malfunction rate stemming from operation

λb

: Basic malfunction rate

π

E : Environmental factors

π

SR : Series resistance

π

Q : Level of malfunction rate

π

CV : Capacitance

For details on how to calculate the malfunction rate stemming from operation, see the tantalum solid state electrolytic

capacitors column in MIL-HDBK-217.

Malfunction rate as function of operating Malfunction rate as function of circuit resistance (Ω/V)

temperature and rated voltage

1.0

0.5

0.3

0.2

0.1

0.06

0.03

0.02

FAILURE RATE COEFFICIENT

0.01

Applied Voltage

Ratio =

Rated Voltage

20 40 60 85

OPERATING TEMPERATURE

1.0

0.7

0.5

0.3

0.1

(°C)

Fig.6

85°C

Rated Voltage

(V.DC) (V.DC) (V.DC) (V.DC)

4

6.3

10

16

20

Surge Voltage

Category Voltage Surge Voltage

5.2

8

13

20

26

6.0

4.0

(π)

2.0

1.0

0.8

0.6

RESISTANCE COEFFICIENT

0.4

0.1 0.2 0.60.4 3.01.0 2.0

RESISTANCE OF CIRCUIT

Fig.7

2.5

6.3

10

13

125°C

3.4

4

5

9

12

16

(Ω / V)

11/15

Page 12

TCFG series

Tantalum capacitors

(5) External temperature vs. fuse blowout (6) Power vs. fuse blowout characteristics / Product sur face temperature

360

350

340

330

320

310

300

290

280

EXTERNAL TEMPERATURE (°C)

270

260

1 10 100

TIME

No failed

(sec)

Fig.8

P case (2012)

A case (3216)

B case (3528)

Failed

Half failed

Note: Solder the chip at 300°C or less. If it is soldered using

a temperature higher than 300°C, open function built-in may operate.

(7) Maximum power dissipation

Warming of the capacitor due to ripple voltage balances with warming caused by Joule heating and by radiated heat.

Maximum allowable warming of the capacitor is to 5°C above ambient temperature. When warming exceeds 5°C, it can

damage the dielectric and cause a short circuit.

Power dissipation (P) = I

2

$ R

Ripple current

P : As shown in table at right

R : Equivalent series resistance

Notes:

1. Please be aware that when case size is changed, maximum allowable power dissipation is reduced.

2. Maximum power dissipation varies depending on the package. Be sure to use a case which will keep warming within

the limits shown in the table below.

Allowable power dissipation (W) and maximum temperature rising

100

90

80

70

(sec)

60

50

40

30

OPERATING TIME

20

10

0

024

No operating area

P case (2012)

A case (3216)

B case (3528)

Open-function charcteristic

Surface temp.

curve of the products

Operating area

681097531

ELECTRIC POWER

Fig.9

300

250

200

150

SURFACE TEMP. OF THE PRODUCT (°C)

(W)

Case

Ambient

temp.

+25°C +55°C +85°C +125°C

0.025P case (2012) 0.022 0.020 0.010

0.070A case (3216) 0.063 0.056 0.028

0.080B case (3528) 0.072 0.064 0.032

5Max. temp. rise 5 5 2

12/15

Page 13

TCFG series

Tantalum capacitors

(8) Impedance frequency characteristics (9) ESR frequency characteristics

100000

10000

1000

(Ω)

100

10

IMPEDANCE

1

1 100 10k 1M 500M100M

FREQUENCY

Fig.10

(10) Temperature characteristics

10

6

(%)

2

0

−2

CAP CHANGE

−6

CAP 120Hz

10V−1µF P case (2012)

4V−4.7µF A case (3216)

4V−33µF B case (3528)

A105

P case (2012)

G475

A case (3216)

C105

A case (3216)

C335

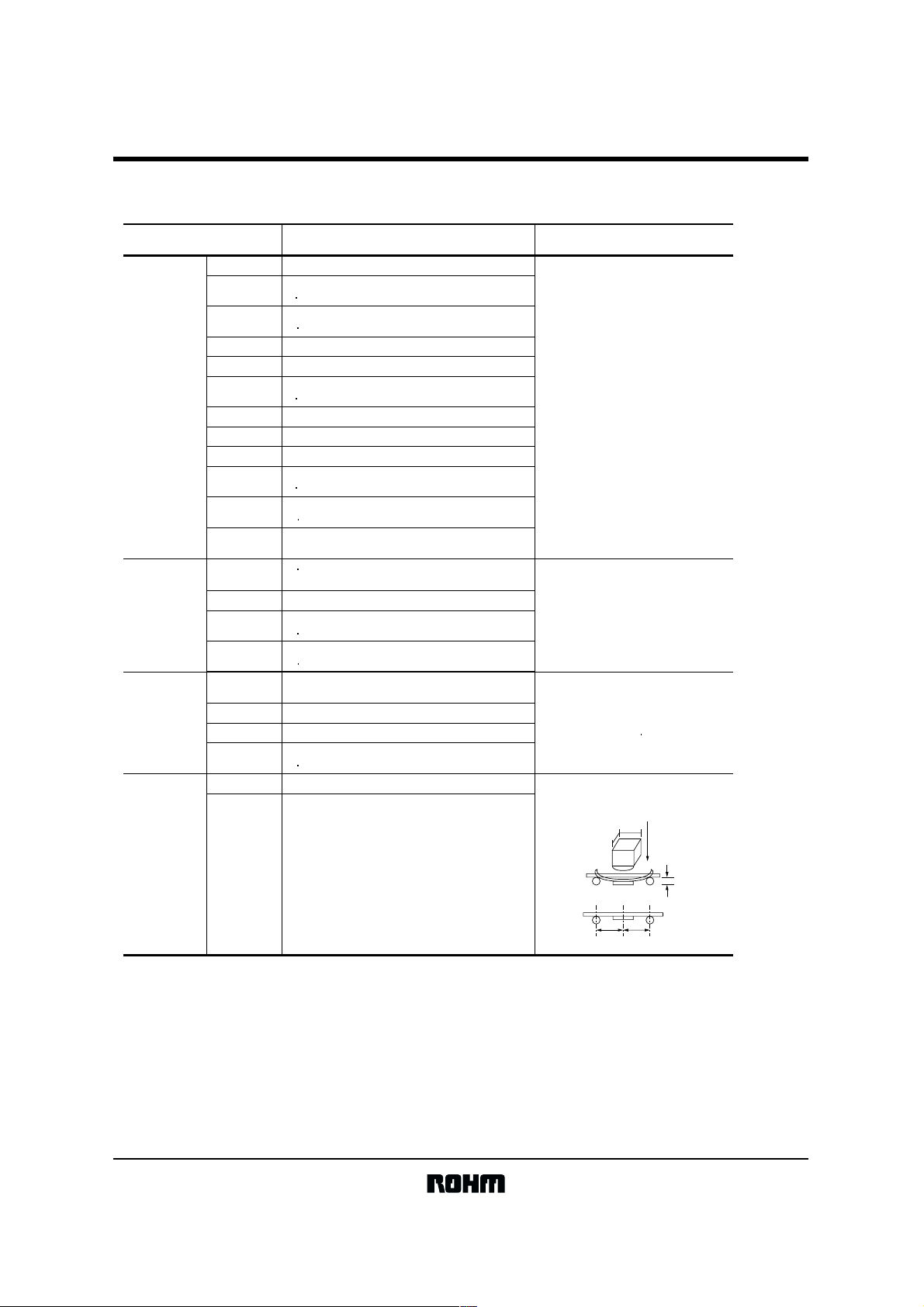

B case (3528)

(Hz)

100

10

(Ω)

ESR

1

0.1

1 100 10k 1M 500M100M

FREQUENCY

A105

P case (2012)

G475

A case (3216)

C105

A case (3216)

C335

B case (3528)

(Hz)

Fig.11

DF 120Hz

10V−1µF P case (2012)

4V−4.7µF A case (3216)

4V−33µF B case (3528)

DF (%)

5

4

3

2

1

−10

−55 25

TEMPERATURE

Fig.12

85 125

(°C)

0

−55 25

TEMPERATURE (°C)

Fig.13

85 125

1000

100

(nA)

LC

10

0

−55 25

LC 1WV

10V−1µF P case (2012)

4V−4.7µF A case (3216)

4V−33µF B case (3528)

TEMPERATURE

Fig.14

85 125

(°C)

13/15

Page 14

TCFG series

Tantalum capacitors

Inrush current

Beware of inrush current.

Inrush currents are inversely proportional to ESR. Large inrush currents can cause component failure.

100

10

1

INRUSH CURRENT (A)

0.1

0.1 1 10 100

33µF

33µF

15µF

4.7µF

Vpp = 10V limit = 20A

Pulse Width = 500µsec.

Power OP Amp Slew Rate = 10V / 6µs

Tantalum capacitor

Aluminum electrolyte

100µF

4.7µF

47µF

22µF

ESRΩ (100kHz)

Fig.16 Maximum inrush current and ESR

Inrush current can be limited by means of a protective resistor.

100

10

I (A)

V

I =

0.476

R

C

1

I =

0.476 + R

V

SAMPLE 16V-3.3µF NEC

Pulse width = 500µsec

Slew rate = 10V-6µc

R = 0Ω

Current limit = 20A

0.25

0.5

1.0

2.0

5.0

0.1

0.1 1 10 100

Fig.17 Imax change due to protective resistor R

V (V)

(11) Ultrasonic cleaning

Carry out cleaning under the mildest conditions possible. The internal element of a tantalum capacitor are larger than

those of a transistor or diode, so it is not as resistant to ultrasonic waves.

Example : water

Propagation speed 1500m / s

Solvent density 1g / cm

Frequency and wavelength

Frequency Wavelength

20kHz 7.5cm

28kHz 5.3cm

50kHz 3.0cm

3

Precautions

14/15

Page 15

TCFG series

Tantalum capacitors

1) Do not allow solvent to come to a boil (kinetic energy increases).

$ Ultrasonic output 0.5W / cm

$ Use a solvent with a high boiling point.

$ Lower solvent temperature.

2) Ultrasonic cleaning frequency

28 kHz or less

3) Keep cleaning time as short as possible.

4) Move item being cleaned.

Standing waves caused by the ultrasonic waves can cause stress to build up in part of the item being cleaned.

Reference

Kinetic energy = 2 x π x frequency x

2

or less

2 x ultrasonic output

propagation speed x solvent density

15/15

Page 16

Appendix

No technical content pages of this document may be reproduced in any form or transmitted by any

means without prior permission of ROHM CO.,LTD.

The contents described herein are subject to change without notice. The specifications for the

product described in this document are for reference only. Upon actual use, therefore, please request

that specifications to be separately delivered.

Application circuit diagrams and circuit constants contained herein are shown as examples of standard

use and operation. Please pay careful attention to the peripheral conditions when designing circuits

and deciding upon circuit constants in the set.

Any data, including, but not limited to application circuit diagrams information, described herein

are intended only as illustrations of such devices and not as the specifications for such devices. ROHM

CO.,LTD. disclaims any warranty that any use of such devices shall be free from infringement of any

third party's intellectual property rights or other proprietary rights, and further, assumes no liability of

whatsoever nature in the event of any such infringement, or arising from or connected with or related

to the use of such devices.

Upon the sale of any such devices, other than for buyer's right to use such devices itself, resell or

otherwise dispose of the same, no express or implied right or license to practice or commercially

exploit any intellectual property rights or other proprietary rights owned or controlled by

ROHM CO., LTD. is granted to any such buyer.

Products listed in this document use silicon as a basic material.

Products listed in this document are no antiradiation design.

Notes

The products listed in this document are designed to be used with ordinary electronic equipment or devices

(such as audio visual equipment, office-automation equipment, communications devices, electrical

appliances and electronic toys).

Should you intend to use these products with equipment or devices which require an extremely high level of

reliability and the malfunction of with would directly endanger human life (such as medical instruments,

transportation equipment, aerospace machinery, nuclear-reactor controllers, fuel controllers and other

safety devices), please be sure to consult with our sales representative in advance.

About Export Control Order in Japan

Products described herein are the objects of controlled goods in Annex 1 (Item 16) of Export Trade Control

Order in Japan.

In case of export from Japan, please confirm if it applies to "objective" criteria or an "informed" (by MITI clause)

on the basis of "catch all controls for Non-Proliferation of Weapons of Mass Destruction.

Appendix1-Rev1.0

Loading...

Loading...