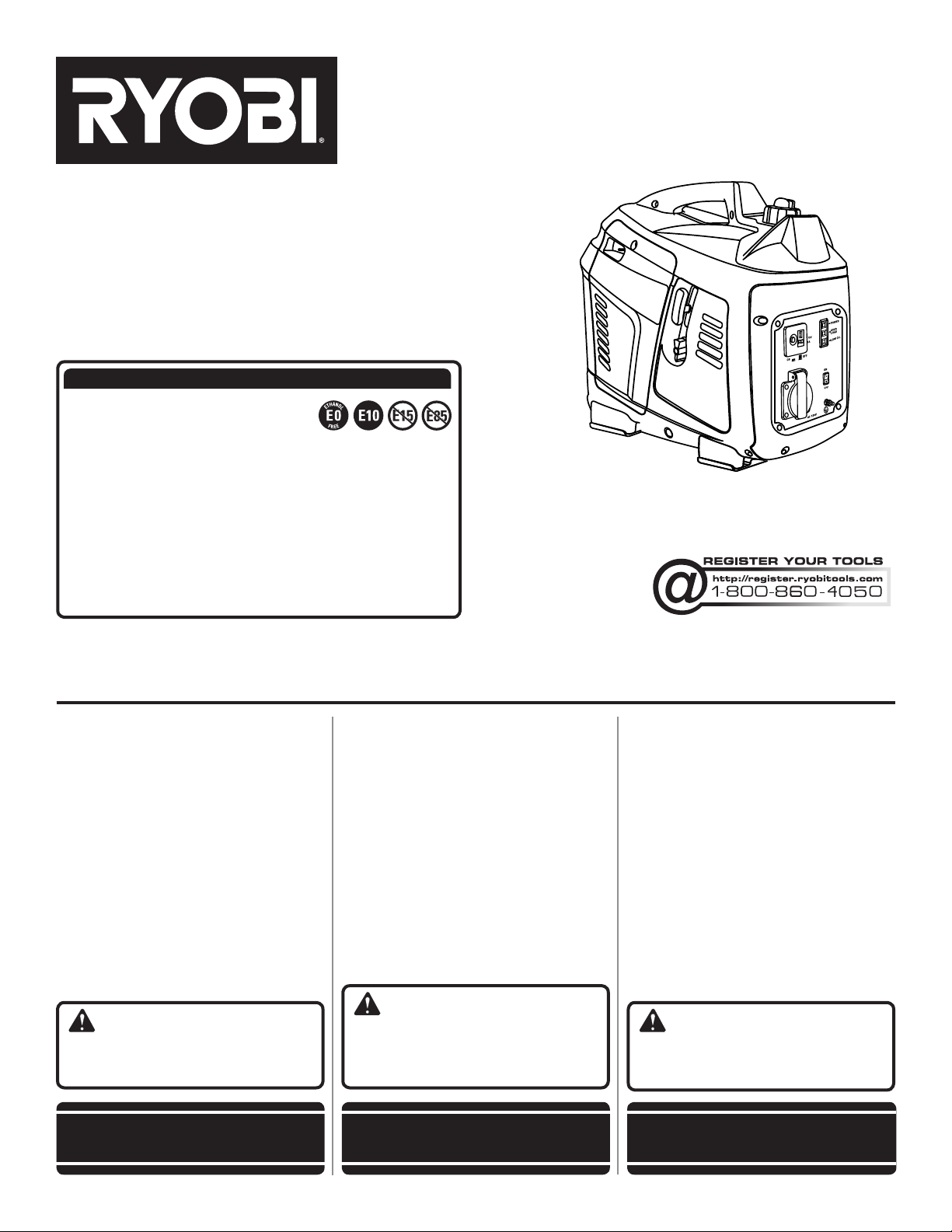

Page 1

OPERATOR’S MANUAL

DIGITAL INVERTER GENERATOR

GÉNÉRATRICE NUMÉRIQUE D’INVERSEUR

GENERADOR DEL INVERSOR DE DIGITACES

RYi1000

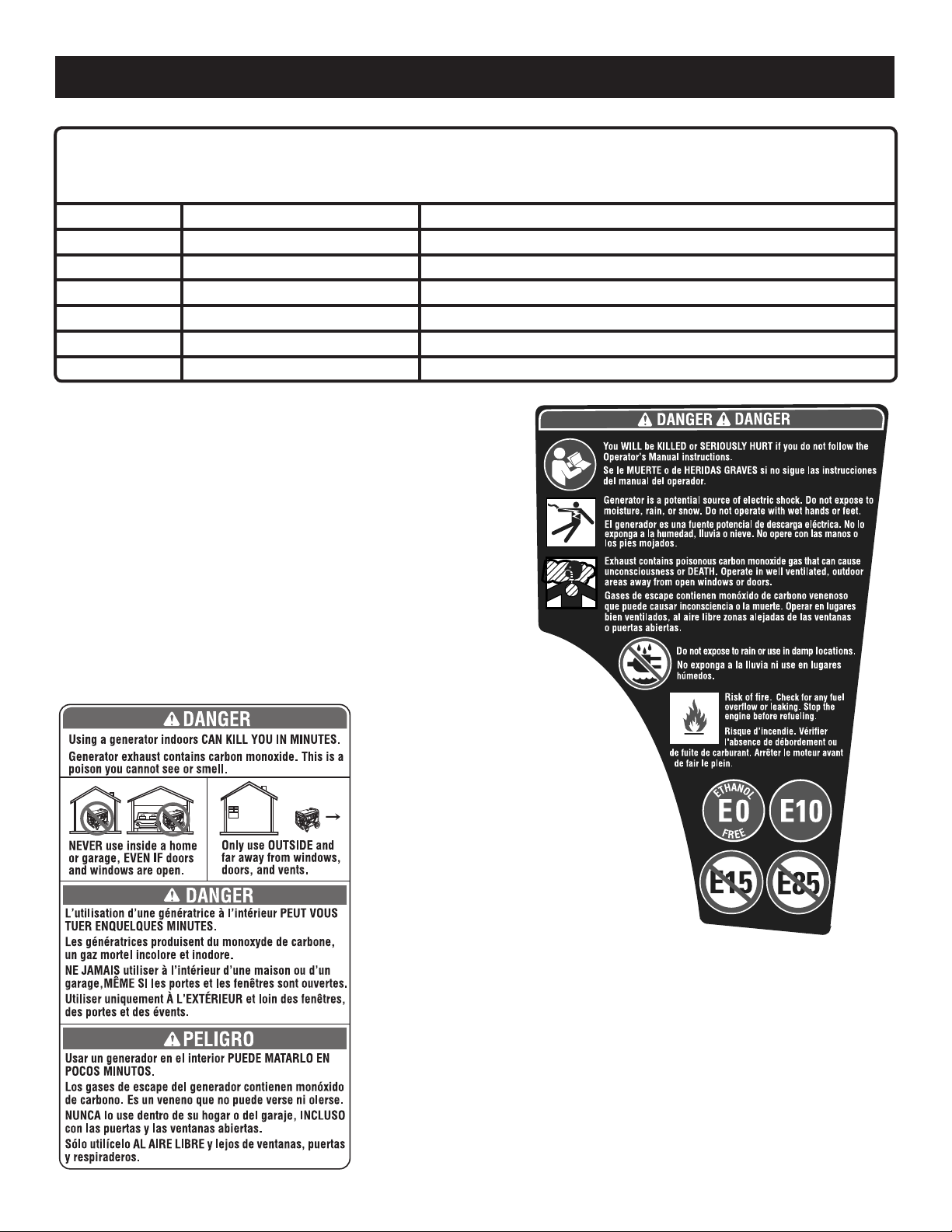

NOTICE AVIS AVISO

Do not use E15 or E85 fuel (or fuel

containing greater than 10% ethanol)

in this product. It is a violation of federal law and will damage the unit and void your warranty.

Ne pas utiliser d’essence E15 ou E85 (ou un carburant

contenant plus de 10 % d’éthanol) dans ce produit. Une

telle utilisation représente une violation de la loi fédérale et

endommagera l’appareil et annulera la garantie.

No utilice combustibles E15 o E85 (ni combustibles que

contengan más de 10 % de etanol) con este producto. Esto

constituye una violación a la ley federal, dañará la unidad

y anulará la garantía.

FLOTTANTE NEUTRE / NEUTRAL DE FLOTACIÓN

MANUEL D’UTILISATION

MANUAL DEL OPERADOR

NEUTRAL FLOATING

TABLE OF CONTENTS

Important Safety Instructions ............3-4

Specific Safety Rules ...........................4

Symbols ............................................5-7

Electrical ...........................................8-9

Features ........................................10-11

Assembly ...........................................11

Operation ......................................12-15

Maintenance .................................15-17

Troubleshooting .................................18

Warranty ........................................19-21

Parts Ordering / Service ....... Back Page

WARNING: To reduce the

risk of injury, the user must read and

understand the operator’s manual before

using this product.

SAVE THIS MANUAL FOR

FUTURE REFERENCE

TABLE DES MATIÈRES

Instructions importantes

concernant la sécurité ......................3-4

Règles de sécurité particulières ........... 4

Symboles ..........................................5-7

Caractéristiques électriques .............8-9

Caractéristiques ............................10-11

Assemblage .......................................11

Utilisation ......................................12-15

Entretien ........................................15-17

Dépannage ......................................... 18

Garantie ........................................19-21

Commande de pièces /

réparation ............................Páge arrière

AVERTISSEMENT : Pour

réduire les risques de blessures,

l’utilisateur doit lire et veiller à bien

comprendre le manuel d’utilisation avant

d’employer ce produit.

CONSERVER CE MANUEL

POUR FUTURE RÉFÉRENCE

ÍNDICE DE CONTENIDO

Instrucciones de seguridad

importantes .......................................3-4

Reglas de seguridad específicas .........4

Símbolos ...........................................5-7

Aspectos eléctricos ..........................8-9

Características ..............................10-11

Armado ..............................................11

Funcionamiento ............................12-15

Mantenimiento ..............................15-17

Corrección de problemas ..................18

Garantía ........................................19-21

Pedidos de piezas/

servicio ............................ Pág. posterior

ADVERTENCIA: Para reducir

el riesgo de lesiones, el usuario debe leer

y comprender el manual del operador

antes de usar este producto.

GUARDE ESTE MANUAL

PARA FUTURAS CONSULTAS

Page 2

See this fold-out section for all of the figures referenced

in the operator’s manual.

Consulter l’encart à volets afin d’examiner toutes les

figures mentionnées dans le manuel d’utilisation.

Consulte esta sección desplegable para ver todas las

figuras a las que se hace referencia en el manual del

operador.

ii

Page 3

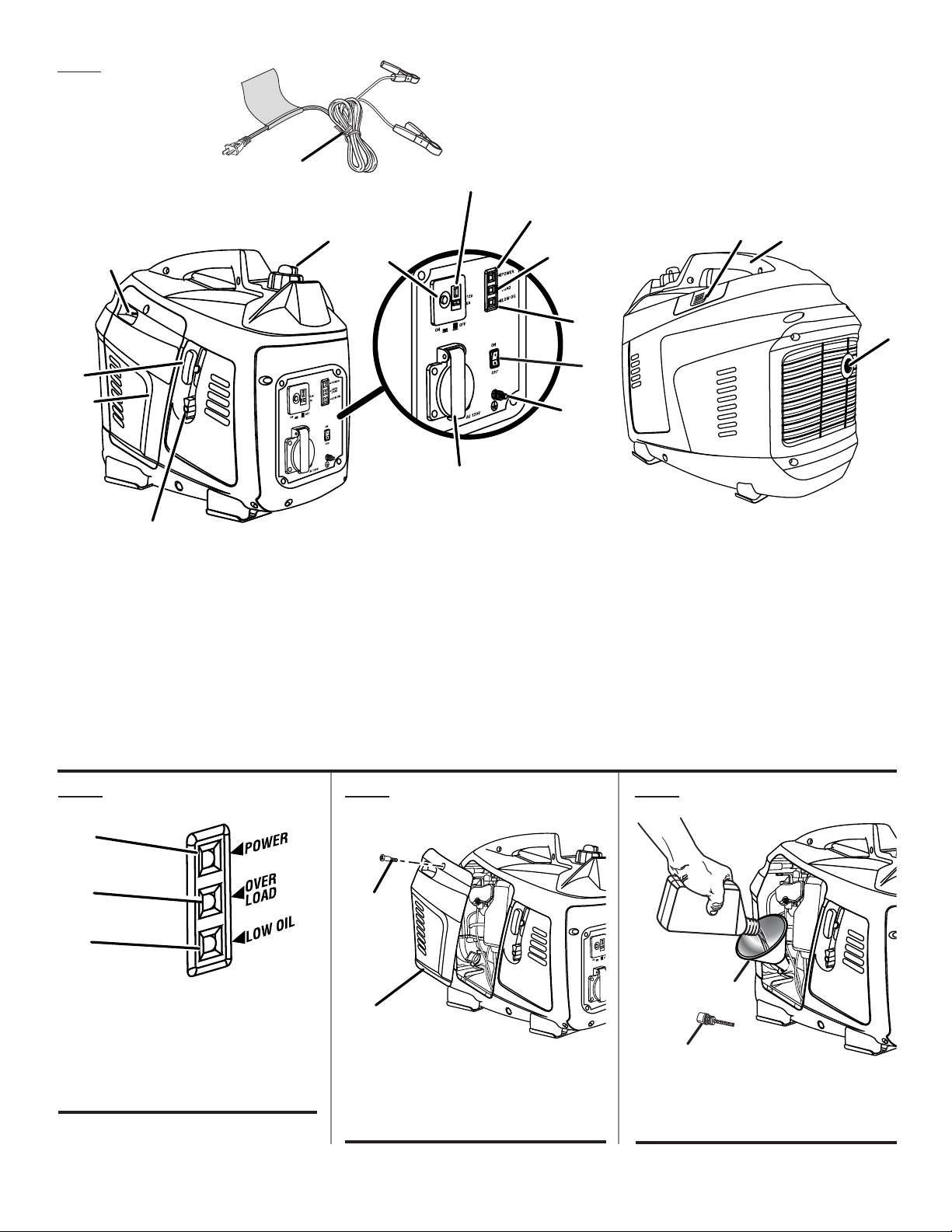

Fig. 1

H

J

M

E

D

I

L

O

P

C

B

A

A - On/off switch (commutateur marche/arrêt,

interruptor de encendido y apagado)

B - Engine maintenance cover (couvercle

pour l’entretien du moteur, cubierta de

mantenimiento del motor)

C - Starter grip and rope (poignée du lanceur et

corde, mango del arrancador y cuerda)

D - Choke lever (levier d’étrangleur, palanca del

anegador)

E - Vented fuel cap (bouchon de carburant

exhalé, tapa del tanque ventilación)

F - 120 volt AC 15 amp receptacles (prises 120 V

c.a. 15 A, 120 V de ca 15 A receptáculos)

K

N

G

F

G - Ground terminal (borne de terre, terminal de

conexión a tierra)

H - Battery charging cable (câble du charge pile,

cable para cargar la batería)

I - DC circuit breaker (disjoncteur d.c., disyuntor

de circuito de d.c)

J - 12 Volt DC receptacle (prise de 12 V c.c,

receptáculo de 12 V cc)

K - Low oil indicator (l’indicateur de bas niveau

d’huile, luz de bajo nivel de lubricante)

L

- Overload indicator (indicateur de surcharge,

indicador de sobrecarga)

Q

M- Power indicator (voyant d’alimentation,

indicador de potencia)

N - Auto idle (mode de marche au ralenti

automatique, ralentí automático)

O - Spark plug cover (couvercle de la bougie,

cubierta de la bujía)

P - Carry handle (poignée de transport, mango

de acarreo)

Q - Muffler with spark arrestor screen (silencieux

avec écran pare-étincelles, silenciador con

pantalla parachispas)

Fig. 2 Fig. 4Fig. 3

A

B

C

A - Power indicator (power indicator, power

indicator)

B - Overload indicator (indicateur de surcharge,

indicador de sobrecarga)

C - Low oil indicator (l’indicateur de bas niveau

d’huile, luz de bajo nivel de lubricante)

B

A

A - Engine maintenance cover (couvercle

pour l’entretien du moteur, cubierta de

mantenimiento del motor)

B - Screw (vis, tornillo)

B

A

A - Oil cap/dipstick (bouchon/ jauge d’huile,

tapa de relleno de aceite/varilla medidora de

aceite)

B - Funnel (entonnoir, embudo)

iii

Page 4

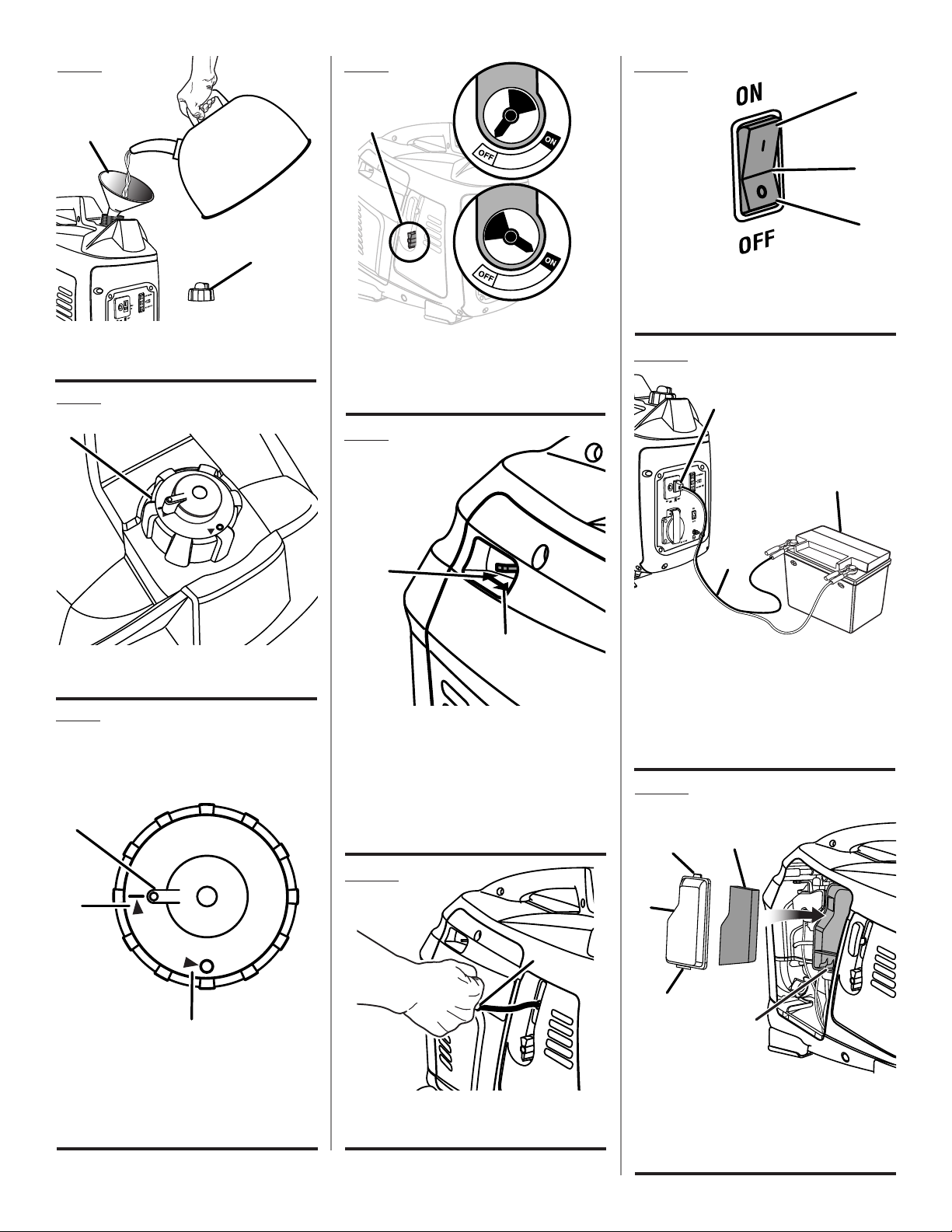

T

H

R

OT

T

LE

S

M

A

R

T

O

F

F

O

N

1

2

0

V

.

C

O

V

E

R

L

OA

D

I

N

D

I

C

A

T

O

R

O

U

T

P

U

T

A

R

M

Fig. 5

Fig. 8

Fig. 11

C

A

B

A - Funnel (entonnoir, embudo)

B - Vented fuel cap (bouchon de carburant

exhalé, tapa del tanque ventilación)

Fig. 6

A

A

B

C

A - On/off switch (commutateur marche/arrêt,

interruptor de encendido y apagado)

B - Off (arret, apagado)

C - On (marche, encendido)

Fig. 9

B

A

B

A - Auto idle (mode de marche au ralenti

automatique, ralentí automático)

B - Off (arret, apagado)

C - On (marche, encendido)

Fig. 12

A

C

B

A - Vented fuel cap (bouchon de carburant

exhalé, tapa del tanque ventilación)

Fig. 7

Top View

Vue de haut / Vista superior

A

B

C

A - Fuel cap lever (levier du bouchon de

carburant, palanca de la tapa de combustible)

B - Open position (I) [position ouverte (I),

posición abierto (I)]

C - Closed/Storage position (O) [position fermé

(O), posición cerrado (O)]

A

A - Move choke lever right to start (tirer droite

le levier d’étranglement pour démarrer,

desplace derecha de la palanca del anegador

para arrancar)

B - Move choke lever left to run (pousser gauche

le levier d’étranglement pour la marche,

desplace izquierda la palanca del anegador

para poner en marcha)

Fig. 10

A

A - Starter grip and rope (poignée du lanceur et

corde, mango del arrancador y cuerda)

iv

A - 12 Volt DC receptacle (prise de 12 V c.c,

receptáculo de 12 V cc)

B - Battery charging cable (câble du charge pile,

cable para cargar la batería)

C - Battery (pile, batería)

Fig. 13

B

A

B

A - Air filter cover (couvercle du filtre à air, tapa

del filtro de aire)

B - Tab (ergot, orejeta)

C - Air filter (filtre à air, filtro de aire)

D - Slot (fente, ranura)

C

D

Page 5

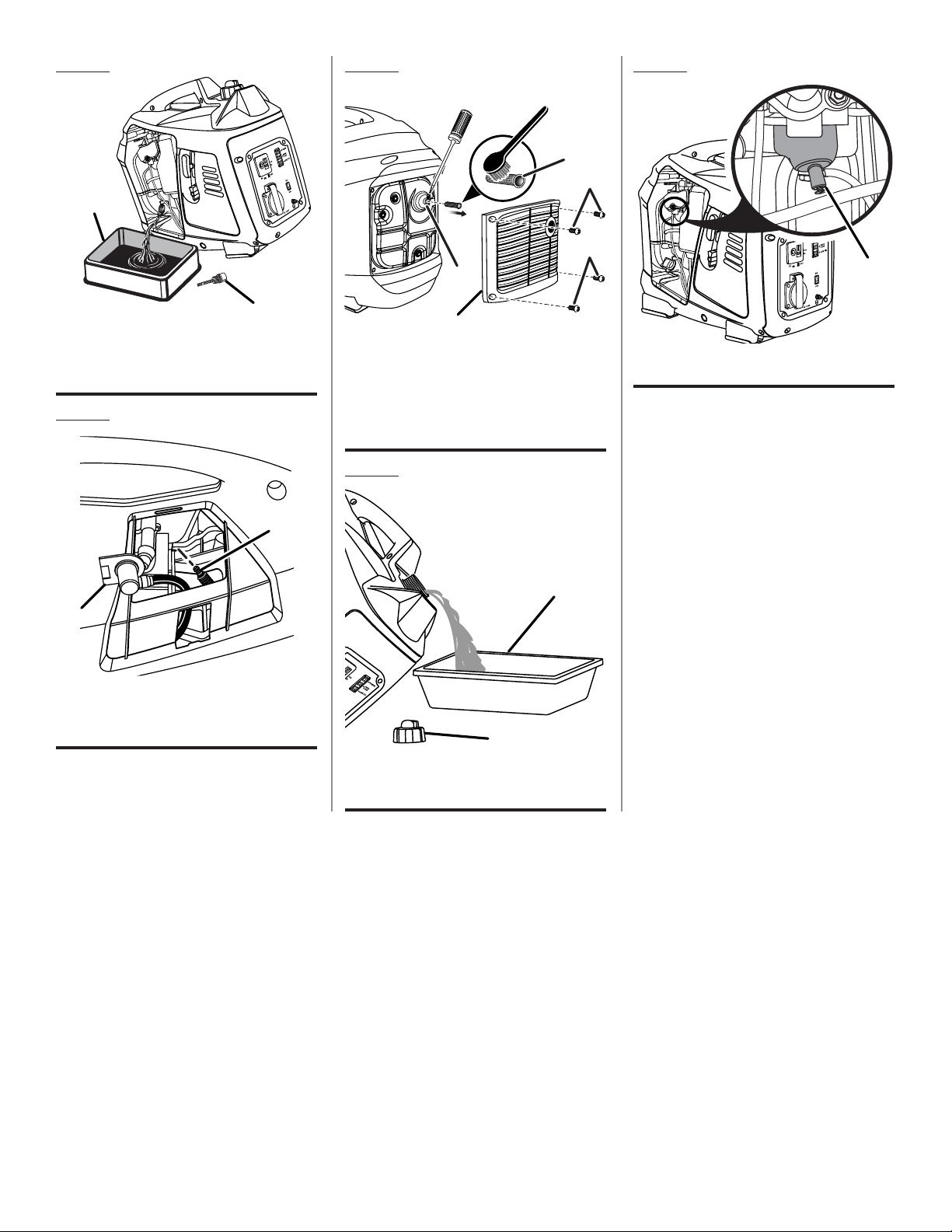

Fig. 14

B

A

A - Oil cap/dipstick (bouchon/ jauge d’huile,

tapa de relleno de aceite/varilla medidora de

aceite)

B - Container (conteneur, recipiente)

Fig. 15

D

C

A

A

B

E

A - Screws (vis, tornillos)

B - Muffler outlet (muffler outlet, recubrimiento

del silenciador)

C - Spark arrestor (pare-étincelles, parachispas)

D - Wire brush (balai de roue, cepillo de alambre)

E - Rear panel (panneau arrière, panel posterior)

Fig. 17

Fig. 18Fig. 16

A

A - Carburetor drain screw (vis de vidange du

carburateur, tornillo de drenaje del caburador)

B

A

A - Spark plug cap (capuchon de bougie, tapa de

la bujía)

B - Spark plug (bougie, bujía)

B

A

A - Vented fuel cap (bouchon de carburant

exhalé, tapa del tanque ventilación)

B - Container (conteneur, recipiente)

v

Page 6

To register your Ryobi product,

please visit: www.ryobitools.com/

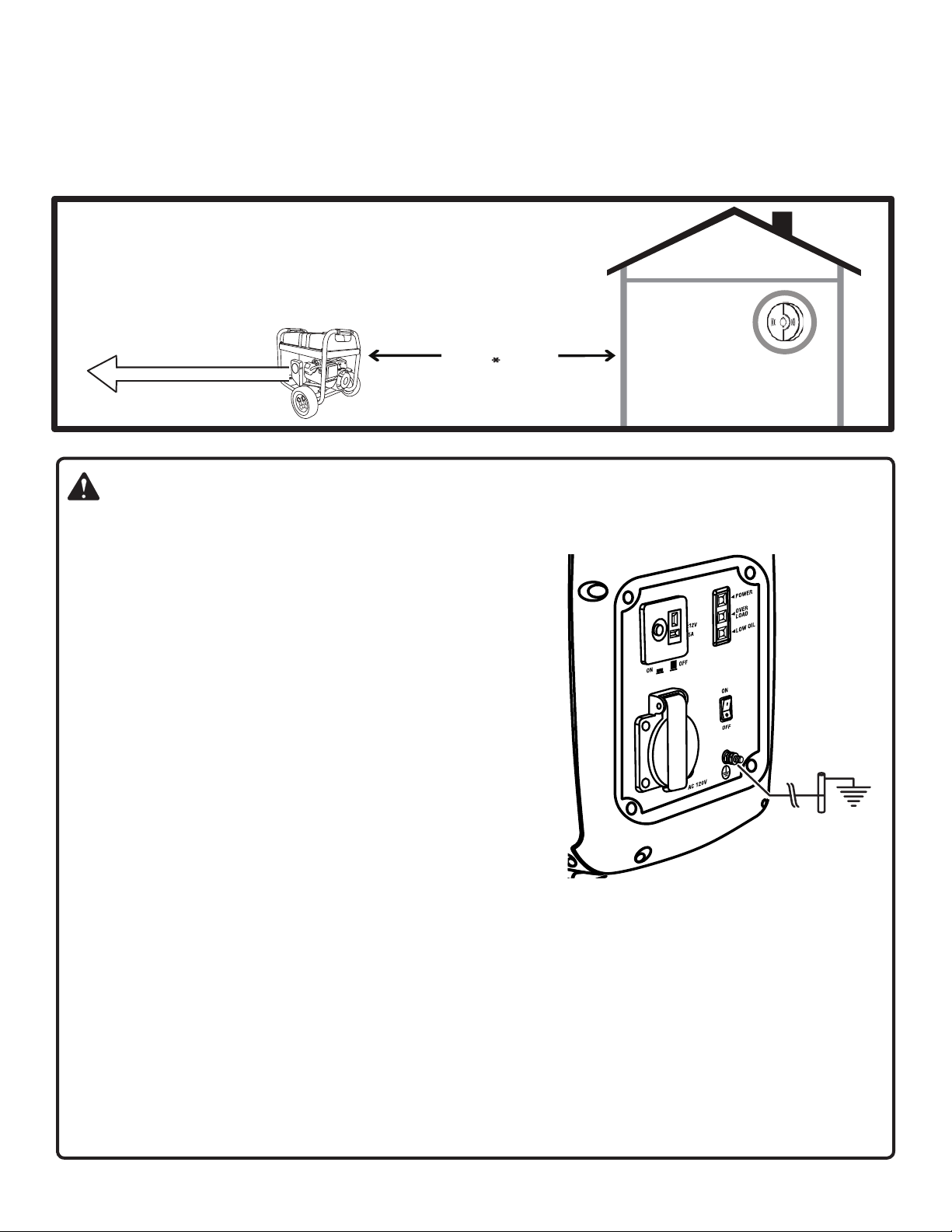

LOCATE GENERATOR AT LEAST 20 FT.* AWAY TO REDUCE THE

RISK OF CARBON MONOXIDE GETTING INSIDE THE HOME

* Minimum distance as recommended by U.S. Department of Health and Human

Services Centers for Disease Control and Prevention (www.cdc.gov/co). Your specific

home and/or wind conditions may require additional distance.

CO Detector

in Living Areas

Exhaust (CO)

Direct exhaust AWAY

from all windows, doors,

and vents.

KEEP AT LEAST

20 FT. AWAY

Only use OUTSIDE and

FAR AWAY from windows,

doors, and vents.

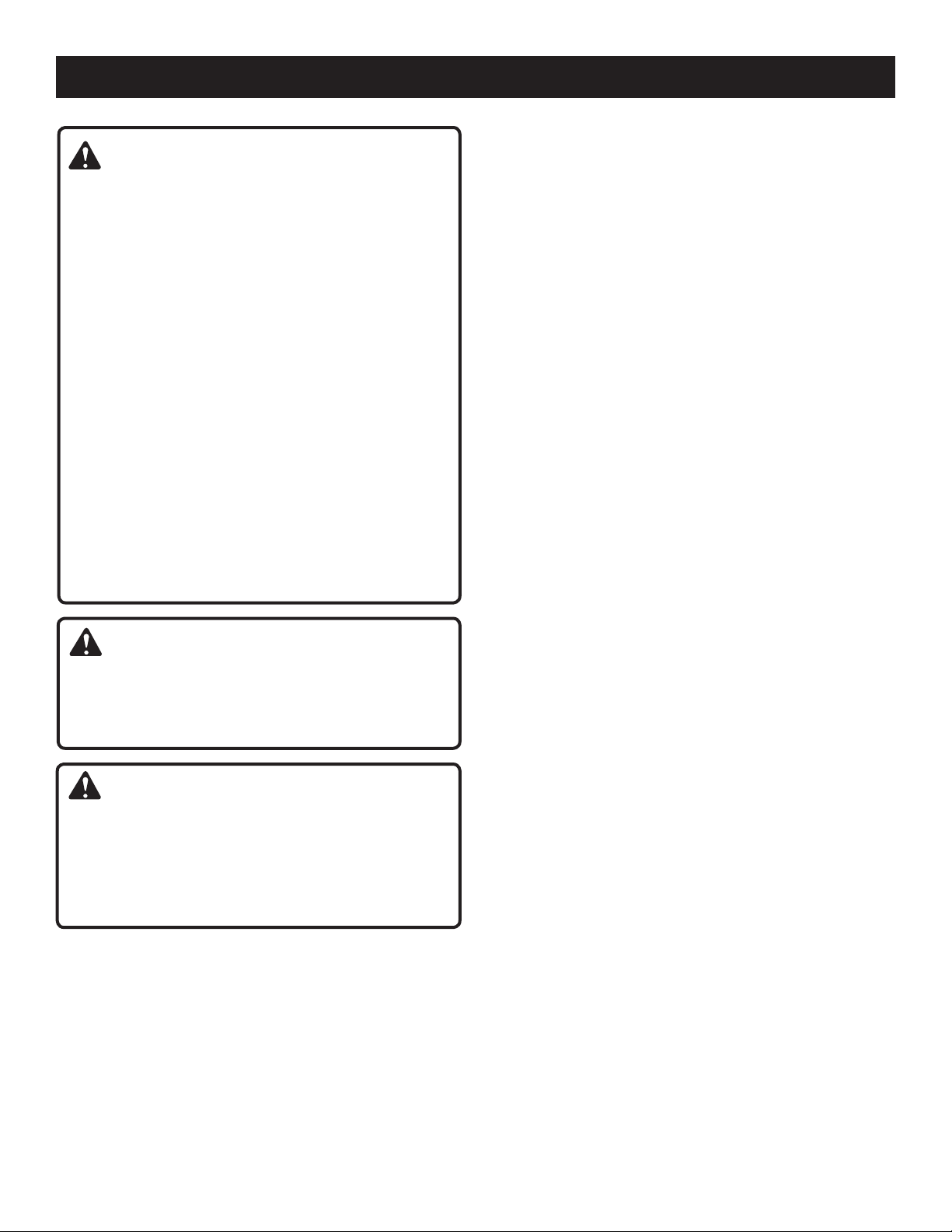

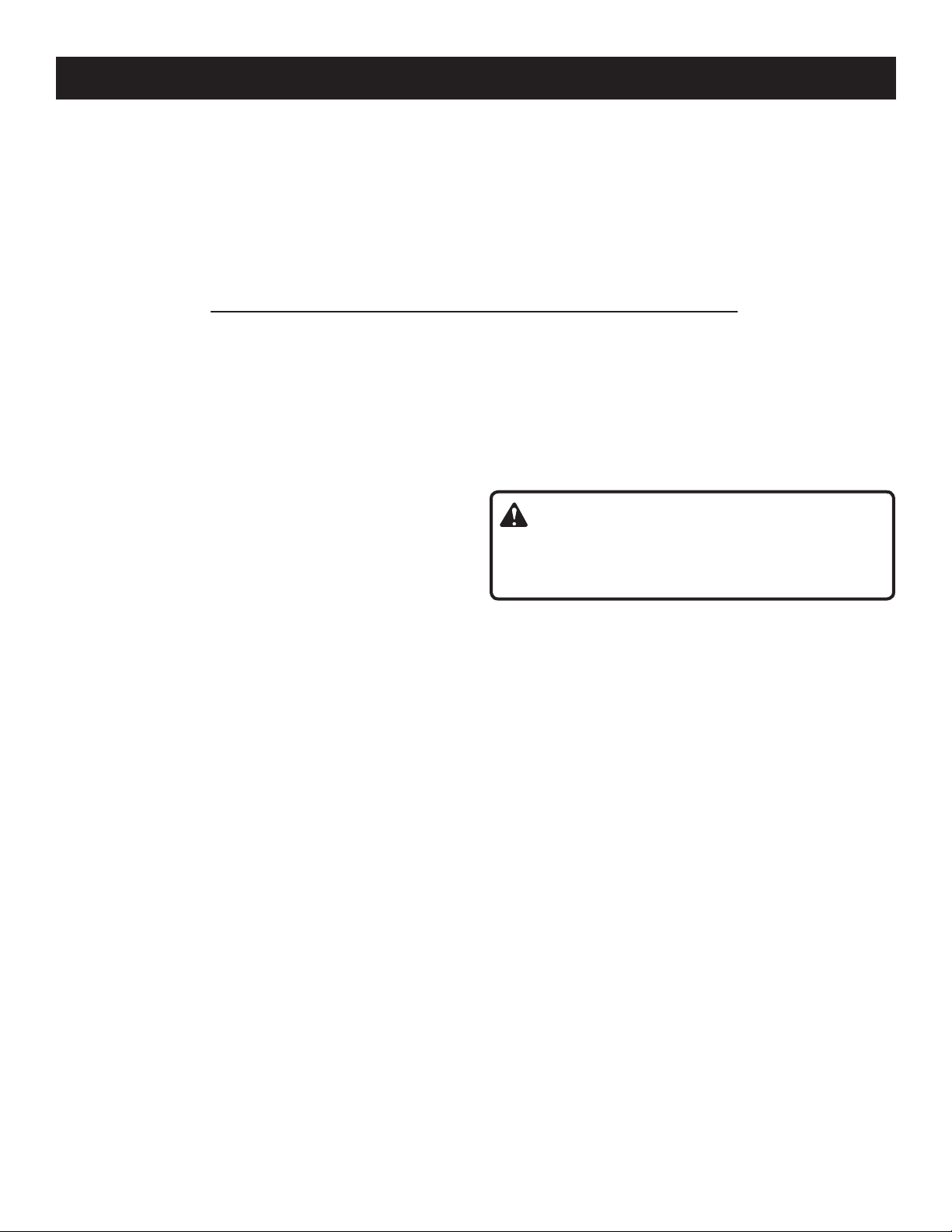

WARNING:

GROUNDING THE GENERATOR

If this generator will be used only with cord and plug-connected

equipment, National Electric Code does not require that the unit be

grounded. However, other methods of using the generator may require

grounding to reduce the risk of shock or electrocution. Consult a qualified electrician, electrical inspector, or local agency having jurisdiction

for local codes or ordinances to find out if grounding is needed in your

situation before using the generator.

When grounding is required, the nut and ground terminal on the frame

are used to connect the generator to a suitable ground source. The

ground path should be made with #8 size wire. Connect the terminal of

the ground wire between the lock washer and the nut, and tighten the

nut fully. Connect the other end of the wire securely to a suitable ground

source that is in contact with the soil for a minimum distance of 8 ft.

The National Electric Code contains several practical ways in which to

establish a good ground source. If a steel or iron rod is used, it should

be at least 5/8 in. diameter, and if a nonferrous rod is used, it should

be at least 1/2 in. diameter and be listed as material for grounding. If

a rock bottom is encountered before reaching a depth of 8 ft., drive

the ground rod in at an angle of up to 45°. If the rock bottom is again encountered, the rod can be buried in a trench

that is at least 30 in. deep. In all cases, the upper end of the grounding rod should either be flush with (or below) the

ground or must be otherwise protected from physical damage.

All electrical tools and appliances operated from this generator must be properly grounded by use of a third wire or

be “Double Insulated.”

It is recommended to:

1. Use electrical devices with 3-prong grounded plugs.

2. Use an extension cord intended for outdoor use with a 3-pole receptacle and a 3-prong plug at opposite ends to

ensure continuity of the ground protection from the generator to the appliance.

Check and adhere to all applicable federal, state, and local regulations relating to grounding specifications. Consult a

qualified electrician or service personnel if the grounding instructions are not completely understood or if in doubt as

to whether the generator is properly grounded.

2 — English

Page 7

IMPORTANT SAFETY INSTRUCTIONS

DANGER:

Carbon Monoxide. Using a generator indoors CAN KILL

YOU IN MINUTES.

Generator exhaust contains high levels of carbon

monoxide (CO), a poisonous gas you cannot see or smell.

If you can smell the generator exhaust, you are breathing

CO. But even if you cannot smell the exhaust, you could

be breathing CO.

Never use a generator inside homes, garages,

crawlspaces, or other partly enclosed areas. Deadly

levels of carbon monoxide can build up in these areas.

Using a fan or opening windows and doors does NOT

supply enough fresh air.

ONLY use a generator outdoors and far away from

open windows, doors, and vents. These openings

can pull in generator exhaust.

Even when you use a generator correctly, CO may

leak into the home. ALWAYS use a battery-powered or

battery-backup CO alarm in the home.

If you start to feel sick, dizzy, or weak after the generator

has been running, move to fresh air RIGHT AWAY. See

a doctor. You could have carbon monoxide poisoning.

WARNING:

Read and understand all instructions. Failure to follow

all instructions listed below could result in electrocution,

fire, and/or carbon monoxide poisoning, which can cause

death or serious injury.

WARNING:

In some applications, National Electric Code requires

generator to be grounded to an approved earth ground.

Before using the ground terminal, consult a qualified

electrician, electrical inspector, or local agency having

jurisdiction for local codes or ordinances that apply to

the intended use of the generator.

SAVE THESE INSTRUCTIONS

This manual contains important instructions for this product

that should be followed during installation and maintenance

of the generator.

Do not connect to a building’s electrical system unless

the generator and transfer switch have been properly

installed and the electrical output has been verified by

a qualified electrician. The connection must isolate the

generator power from utility power and must comply with

all applicable laws and electrical codes.

Do not allow children or untrained individuals to use this

unit.

Do not start or operate the engine in a confined space,

building, near open windows, or in other unventilated space

where dangerous carbon monoxide fumes can collect.

Carbon monoxide, a colorless, odorless, and extremely

dangerous gas, can cause unconsciousness or death.

Keep all bystanders, children, and pets at least 10 feet

away.

Wear sturdy and dry shoes or boots. Do not operate while

barefoot.

Do not operate generator when you are tired or under the

influence of drugs, alcohol, or medication.

Keep all parts of your body away from any moving parts

and all hot surfaces of the unit.

Do not touch bare wire or receptacles.

Do not use generator with electrical cords which are worn,

frayed, bare, or otherwise damaged.

Before storing, allow the engine to cool for 30 minutes

and drain fuel from the unit.

Do not operate or store the generator in rain, snow, or

wet weather.

Store the generator in a well-ventilated area with the fuel

tank empty. Fuel should not be stored near the generator.

Empty fuel tank, turn the On/Off switch to OFF and restrain

the unit from moving before transporting in a vehicle.

To reduce the risk of fire and burn injury, handle fuel with

care. It is highly flammable.

Do not smoke while handling fuel.

Store fuel in a container approved for gasoline.

Position the unit on level ground, stop engine, and allow

to cool for five minutes before refueling.

Loosen fuel cap slowly to release pressure and to keep

fuel from escaping around the cap.

Tighten the fuel cap securely after refueling.

Wipe spilled fuel from the unit.

Never attempt to burn off spilled fuel under any

circumstances.

Generators vibrate in normal use. During and after the

use of the generator, inspect the generator as well as

extension cords and power supply cords connected to

it for damage resulting from vibration. Have damaged

items repaired or replaced as necessary. Do not use plugs

or cords that show signs of damage such as broken or

cracked insulation or damaged blades.

For power outages, permanently installed stationary

generators are better suited for providing back-up power

to the home. Even a properly connected portable generator

can become overloaded. This may result in overheating

or stressing the generator components, possibly leading

to generator failure.

3 — English

Page 8

IMPORTANT SAFETY INSTRUCTIONS

Use only authorized replacement parts and accessories

and follow instructions in the Maintenance section of this

manual. Use of unauthorized parts or failure to follow

maintenance instructions may create a risk of shock or

injury.

SPECIFIC SAFETY RULES

WARNING:

When this generator is used to supply a building

wiring system: generator must be installed by a

qualified electrician and connected to a transfer switch

as a separately derived system in accordance with

NFPA 70, National Electrical Code. The generator shall

be connected through a transfer switch that switches

all conductors other than the equipment grounding

conductor. The frame of the generator shall be connected

to an approved grounding electrode. Failure to isolate the

generator from power utility can result in death or injury

to electric utility workers.

Do not use this generator to provide power for emergency

medical equipment or life support devices.

Exhaust contains poisonous carbon monoxide, a

colorless, odorless gas. Breathing exhaust can cause

loss of consciousness and can lead to death. If running

in a confined or partially-enclosed area, the air may

contain a dangerous amount of carbon monoxide. To

keep exhaust fumes from building up, always provide

adequate ventilation.

Always use a battery-powered carbon monoxide detector

when running the generator. If you begin to feel sick,

dizzy, or weak while using the generator, shut it off and

get to fresh air immediately. See a doctor. You may have

carbon monoxide poisoning.

Place the generator on a flat, stable surface with a slope

of no more than 4°.

Operate outdoors in a well-ventilated, well-lit area isolated

from working areas to avoid noise interference.

Operating the generator in wet conditions could result in

electrocution. Keep the unit dry.

Keep the generator a minimum of 3 feet away from all

types of combustible material.

Maintain the unit per maintenance instructions in this

Operator’s Manual.

Inspect the unit before each use for loose fasteners, fuel

leaks, etc. Replace damaged parts.

Do not operate generator near hazardous material.

Do not operate generator at a gas or natural gas filling

station.

Do not touch the muffler or cylinder during or immediately

after use; they are HOT and will cause burn injury.

This generator has a neutral floating condition. This means

the neutral conductor is not electrically connected to the

frame of the machine.

Do not allow the generator’s gas tank to overflow when

filling. Fill to 1 in. below the top neck of the gasoline tank

to allow for fuel expansion. Do not cover the fuel tank cap

when the engine is running. Covering the fuel tank cap

during use may cause engine failure and/or damage to

the tool.

Do not smoke when filling the generator with gasoline.

Shut down the engine and allow to cool for five minutes

before adding gasoline or lubricant to the generator.

Do not remove the oil dipstick or the fuel tank cap when

the engine is running.

Pay close attention to all safety labels located on the

generator.

Keep children a minimum of 10 feet away from the

generator at all times.

The unit operates best in temperatures between 23°F and

104°F with a relative humidity of 90% or less.

Operating voltage and frequency requirement of all

electronic equipment should be checked prior to plugging

them into this generator. Damage may result if the

equipment is not designed to operate within a +/- 10%

voltage variation, and +/- 3 hz frequency variation from

the generator name plate ratings.

For outdoor use only.

Save these instructions. Refer to them frequently and use

them to instruct others who may use this product. If you

loan someone this product, loan them these instructions

also.

4 — English

Page 9

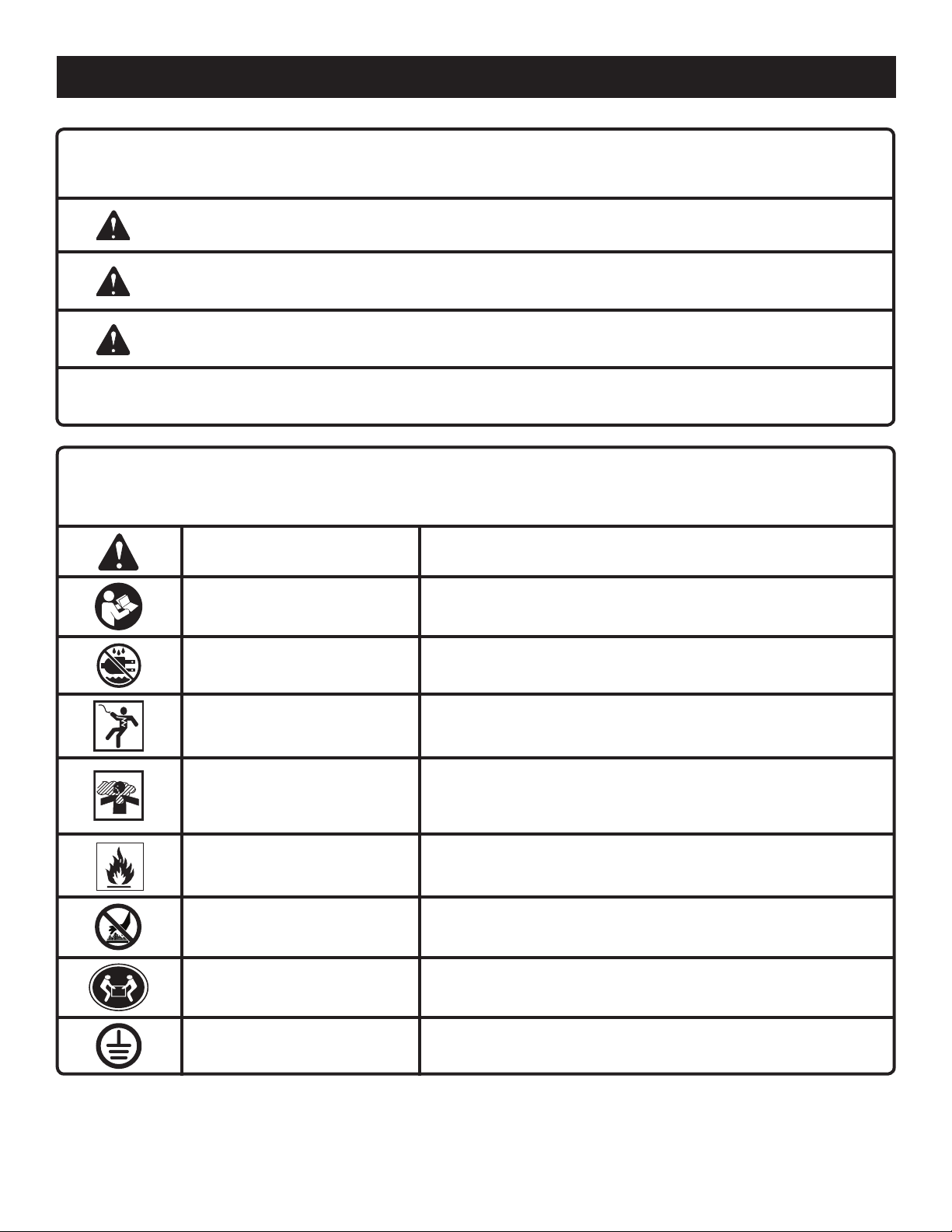

SYMBOLS

The following signal words and meanings are intended to explain the levels of risk associated with this product.

SYMBOL SIGNAL MEANING

DANGER:

WARNING:

CAUTION:

NOTICE:

Some of the following symbols may be used on this product. Please study them and learn their meaning. Proper

interpretation of these symbols will allow you to operate the product better and safer.

Indicates an imminently hazardous situation, which, if not avoided, will result

in death or serious injury.

Indicates a potentially hazardous situation, which, if not avoided, could result

in death or serious injury.

Indicates a potentially hazardous situation, which, if not avoided, may result in

minor or moderate injury.

(Without Safety Alert Symbol) Indicates important information not related to an

injury hazard, such as a situation that may result in property damage.

SYMBOL NAME DESIGNATION/EXPLANATION

Safety Alert Indicates a potential personal injury hazard.

Read Operator’s Manual

Wet Conditions Alert Do not expose to rain or use in damp locations.

To reduce the risk of injury, user must read and understand

operator’s manual before using this product.

Electric Shock

Toxic Fumes

Fire/Explosion

Hot Surface

Lifting Hazard

Ground

Failure to use in dry conditions and to observe safe practices can

result in electric shock.

Running generator gives off carbon monoxide, an odorless, colorless, poison gas. Breathing carbon monoxide can cause nausea,

fainting, or death.

Fuel and its vapors are extremely flammable and explosive. Fire

or explosion can cause severe burns or death.

To reduce the risk of injury or damage, avoid contact with any hot

surface.

To reduce the risk of serious injury, avoid attempting to lift the

generator alone.

Consult with local electrician to determine grounding requirements

before operation.

5 — English

Page 10

SYMBOLS

Some of the following symbols may be used on this product. Please study them and learn their meaning. Proper

interpretation of these symbols will allow you to operate the product better and safer.

SYMBOL NAME DESIGNATION/EXPLANATION

V Volts Voltage

A Amperes Current

Hz Hertz Frequency (cycles per second)

W Watt Power

hrs Hours Time

gal Gallon Volume

qt Quart Volume

SAFETY LABELS

The information below can be found on the generator. For your

safety, please study and understand all of the labels before starting

the generator.

If any of the labels come off the unit or become hard to read, contact

an authorized service center for replacement.

You WILL be KILLED or SERIOUSLY HURT if you do not follow

the Operator’s Manual instructions.

Risk of Fire. Do not add fuel while the product is operating.

Generator is a potential source of electric shock. Do not expose

to moisture, rain, or snow. Do not operate with wet hands or feet.

Exhaust contains poisonous carbon monoxide gas that can cause

unconsciousness or DEATH. Operate in well-ventilated, outdoor

areas away from open windows or doors.

Do not expose to rain or use in damp locations.

Using a generator indoors CAN KILL YOU IN MINUTES. Generator exhaust

contains carbon monoxide. This is a poison you cannot see or smell.

NEVER use inside a home or garage, EVEN IF doors and windows are

open.

Only use OUTSIDE and far away from windows, doors, and vents.

FUEL WARNING

No smoking when filling with gasoline. Do not overfill. Full level is 1 in. below

the top of the fuel neck. Stop the engine for five minutes before refueling to

avoid the heat from the muffler igniting fuel vapors.

6 — English

Page 11

SYMBOLS

ENGINE LUBRICANT WARNING

You must add lubricant before first operating the generator.

Always check the lubricant level before each operation. The

lubricant level should always register between the hatched

areas on the dipstick. The unit is equipped with a sensor

which will automatically shut off the engine if the lubricant

level falls below a safe limit.

GROUNDING WARNING

This generator does not include a ground rod or copper wire. Call a qualified electrician for local grounding requirements.

HOT SURFACE WARNING

Do not touch the muffler or aluminum cylinder of the engine. They are very HOT and will cause severe burns. Don’t put any

flammable or combustible materials in the direct path of the exhaust.

CLEARANCE WARNING

While operating and storing, keep at least 3 feet of clearance on all

sides of this product, including overhead. Allow a minimum of 30

minutes of “cool down” time before storage. Heat created by muffler

and exhaust gases could be hot enough to cause serious burns and/

or ignite combustible objects.

SPARK ARRESTOR

Operation of this equipment may create sparks that can start fires

around dry vegetation. A spark arrestor may be required. The operator

should contact local fire agencies for laws or regulations relating to

fire prevention requirements.

7 — English

Page 12

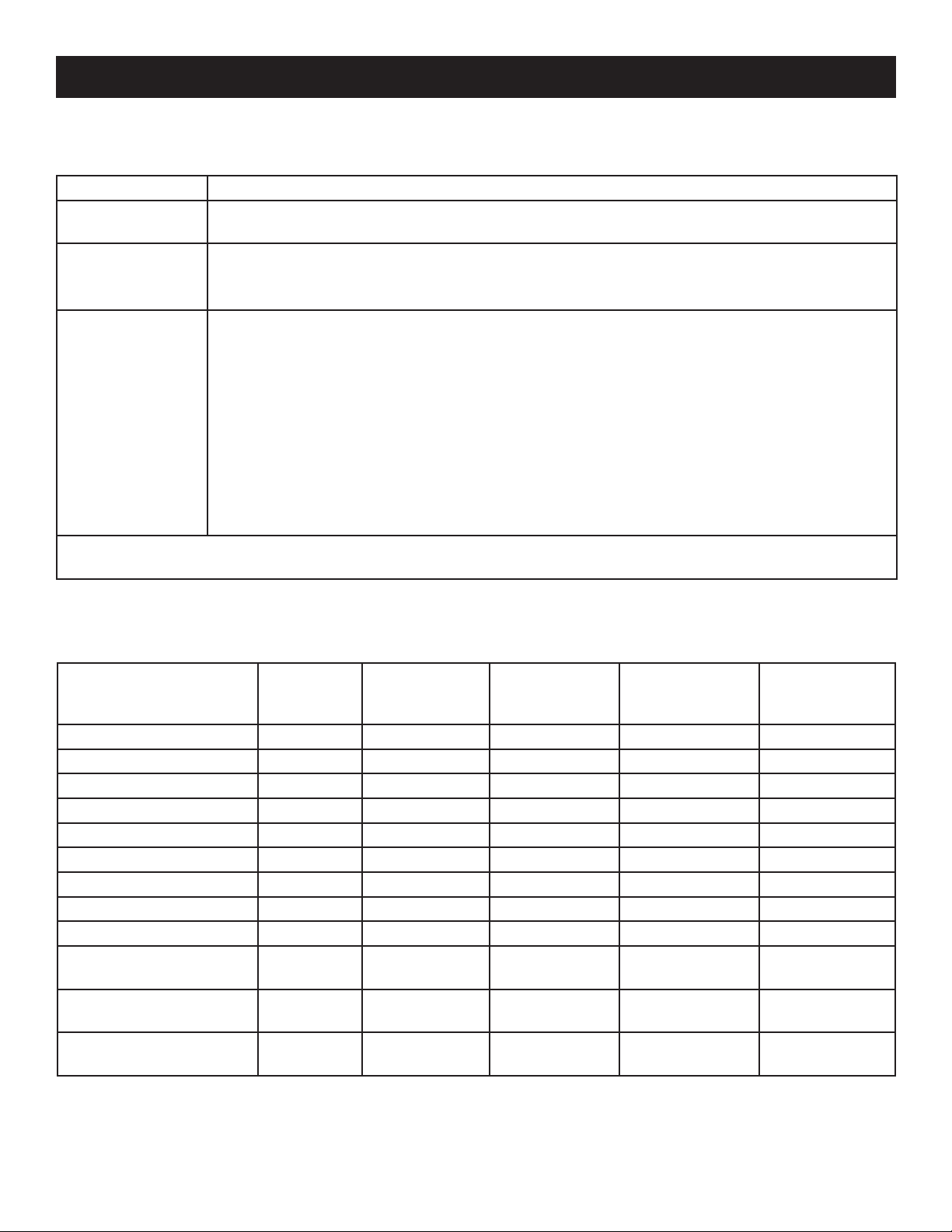

ELECTRICAL

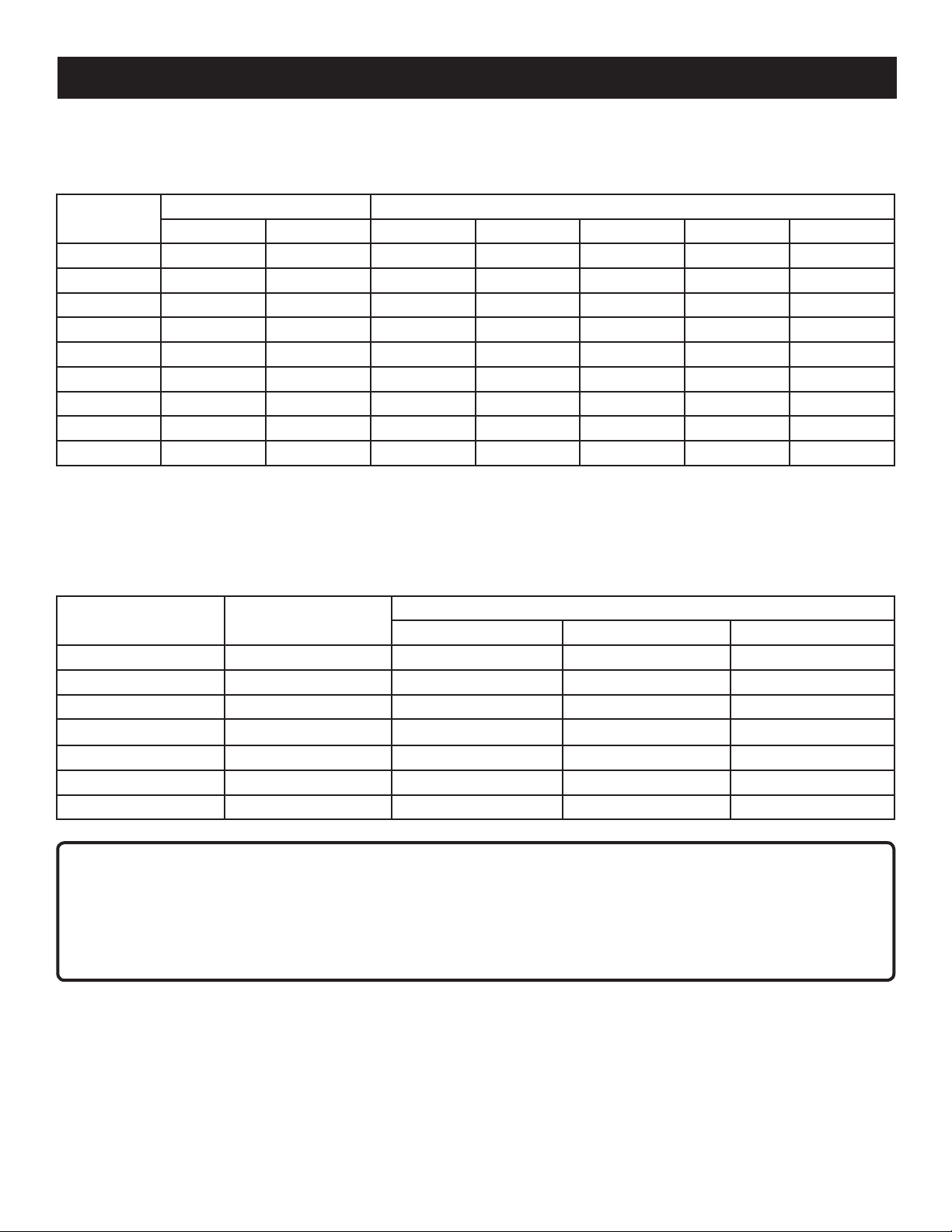

EXTENSION CORD CABLE SIZE

Refer to the table below to ensure the cable size of the extension cords you use are capable of carrying the required load.

Inadequate size cables can cause a voltage drop, which can damage the appliance and overheat the cord.

Current in

Amperes

2.5 300 600 1000 ft. 600 ft. 375 ft. 250 ft.

5 600 1200 500 ft. 300 ft. 200 ft. 125 ft.

7.5 900 1800 350 ft. 200 ft. 125 ft. 100 ft.

10 1200 2400 250 ft. 150 ft. 100 ft. 50 ft.

15 1800 3600 150 ft. 100 ft. 65 ft.

20 2400 4800 175 ft. 125 ft. 75 ft.

25 3000 6000 150 ft. 100 ft.

30 3600 7200 125 ft. 65 ft.

40 4800 9600 90 ft.

Load in Watts Maximum Allowable Cord Length

At 120V At 240V #8 Wire #10 Wire #12 Wire #14 Wire #16 Wire

ELECTRIC MOTOR LOADS

It is characteristic of common electric motors in normal operation to draw up to six times their running current while starting.

This table may be used to estimate the watts required to start electric motors; however, if an electric motor fails to start or

reach running speed, turn off the appliance or tool immediately to avoid equipment damage. Always check the requirements

of the tool or appliance being used compared to the rated output of the generator.

Motor Size (H.P.) Running Watts

1/8 275 N/A 850 1200

1/6 275 600 850 2050

1/4 400 800 1050 2400

1/3 450 950 1350 2700

1/2 600 1000 1800 3600

3/4 850 1200 2600 —

1 1100

Universal Capacitor Split Phase

N/A

Watts Required to Start Motor

3300 —

NOTICE:

Operating voltage and frequency requirement of all electronic equipment should be checked prior to plugging them

into this generator. Damage may result if the equipment is not designed to operate within a +/- 10% voltage variation,

and +/- 3 hz frequency variation from the generator name plate ratings. To avoid damage, always have an additional

load plugged into the generator if solid state equipment (such as a television set) is used. A power line conditioner is

recommended for some solid state applications.

8 — English

Page 13

ELECTRICAL

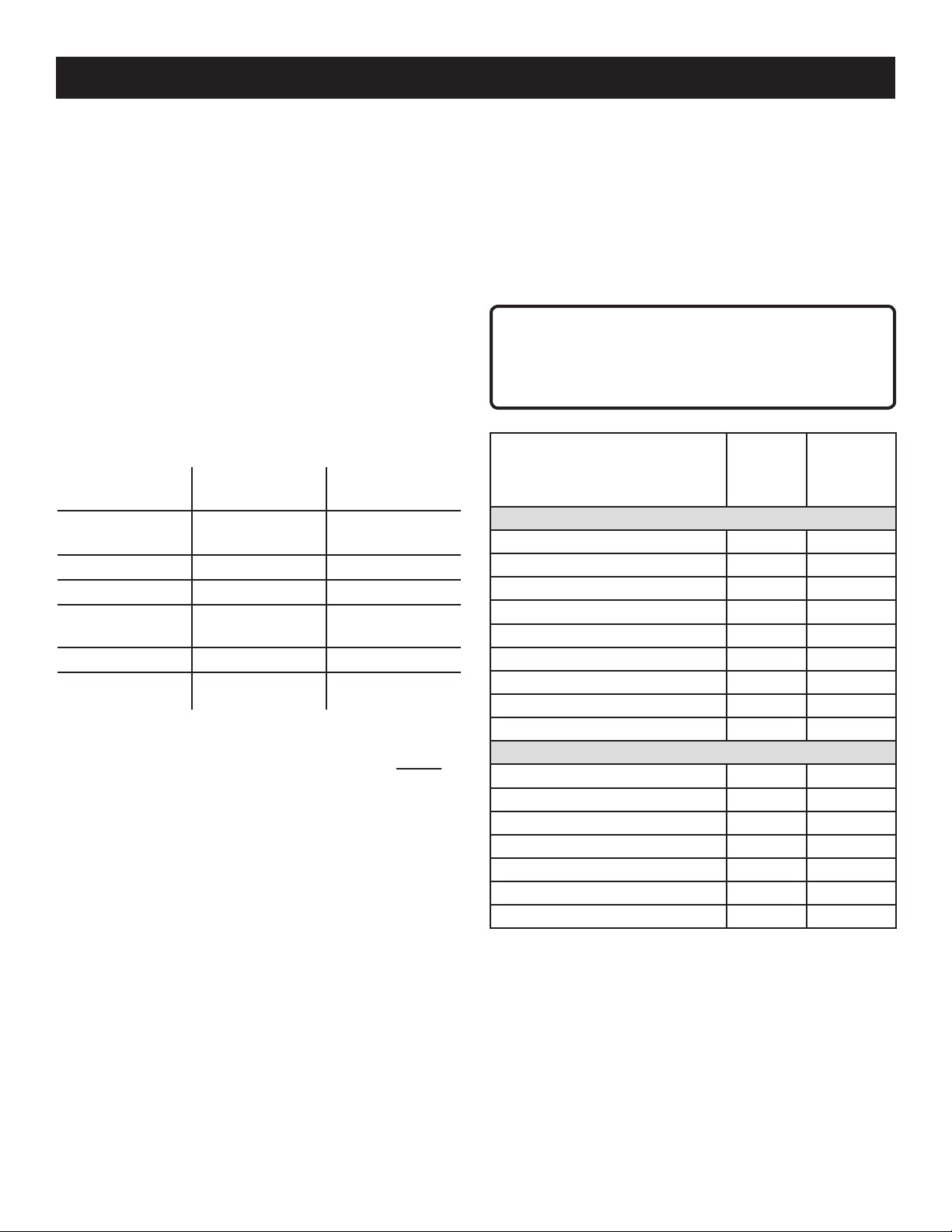

GENERATOR CAPACITY

Make sure the generator can supply enough continuous (running) and surge (starting) watts for the items you will power

at the same time. Follow these simple steps.

1. Select the items you will power at the same time.

2. Total the continuous (running) watts of these items. This

is the amount of power the generator must produce to

keep the items running. See the wattage reference chart

at right.

3. Estimate how many surge (starting) watts you will need.

Surge wattage is the short burst of power needed to

start electric motor-driven tools or appliances such as a

circular saw or refrigerator. Because not all motors start

at the same time, total surge watts can be estimated by

adding only the item(s) with the highest additional surge

watts to the total rated watts from step 2.

Example:

Tool or Appliance

Running

Watts*

Starting

Watts*

Refrigerator 700 1350

Portable Fan 40 120

Laptop 250 250

46 in. Flat Panel

190 190

Television

Light (75 Watts) 75 75

1255 Total

Running Watts

1350 Highest

Starting Watts

Total Running Watts 1255

Highest Starting Watts + 1350

Total Starting Watts Needed 2605

POWER MANAGEMENT

To prolong the life of the generator and attached devices,

it is important to take care when adding electrical loads to

the generator. There should be nothing connected to the

generator outlets before starting its engine. The correct and

safe way to manage generator power is to sequentially add

loads as follows:

1. With nothing connected to the generator, start the engine

as described later in this manual.

2. Plug in and turn on the first load, preferably the largest

load you have.

3. Permit the generator output to stabilize (engine runs

smoothly and attached device operates properly).

4. Plug in and turn on the next load.

5. Again, permit the generator to stabilize.

6. Repeat steps 4 and 5 for each additional load.

Never add more loads than the generator capacity. Take

special care to consider surge loads in generator capacity

as previously described.

NOTICE:

Do not overload the generator’s capacity. Exceeding the

generator’s wattage/amperage capacity may damage

the generator and/or electrical devices connected to it.

Estimated

Application/Equipment

Emergency / Home Standby

Lights (qty. 4 x 75 W) 300 300

Refrigerator 700 1350

46 in. Flat Panel Television 190 190

Satelite Receiver 250 250

Portable Fan 40 120

Heater 1300 1300

Laptop 250 250

Slow Cooker 270 270

Radio 50 50

Job Site

Electric Drill − 3/8 in. 600 1000

Quartz Halogen Work Light 1000 1000

Reciprocating Saw 960 1920

Circular Saw − 7-1/4 in. 1400 2300

Miter Saw − 10 in. 1800 1800

Air Compressor − 1/4 HP 970 1600

Airless Sprayer − 1/3 HP 600 1200

*Wattages listed are approximate. Check tool or appliance for actual wattage.

Running

Watts*

Estimated*

Starting

Watts

9 — English

Page 14

FEATURES

PRODUCT SPECIFICATIONS

ENGINE

Engine Type .................... Single Cylinder (OHV) Four Cycle

Spark Plug ............................................... NHSP LD A7RTC

Engine Lubricant Volume.......................................13.52 oz.

Fuel Volume .............................................................0.6 Gal.

GENERATOR

Rated Voltage .........................................120 V AC/12 V DC

Rated Amps ............................................7.5 A AC/7.5 A DC

Rated Running Watts ................................................900 W

Starting Watts ......................................................... 1,000 W

Rated Frequency ........................................................ 60 Hz

KNOW YOUR GENERATOR

See Figure 1.

The safe use of this product requires an understanding of the

information on the product and in this operator’s manual as

well as a knowledge of the project you are attempting. Before

use of this product, familiarize yourself with all operating

features and safety rules.

120 V AC RECEPTACLE

Your generator has a single phase, 60 Hz outlet that is a 120

Volt AC, 15 Amp receptacle. It can be used for operating

appropriate appliances, electrical lighting, tools, and motor

loads.

AIR FILTER

The air filter helps to limit the amount of dirt and dust drawn

into the unit during operation.

AUTO IDLE SWITCH

The auto idle switch is used to control the speed of the

engine and conserve fuel. When the switch is in the ON (I)

position and no appliances are connected to the unit, the

engine will idle. If an appliance is added, the engine speed

will increase to power the item. If the appliance is removed,

the engine will return to idle.

DC CIRCUIT BREAKER

The circuit breaker is provided to protect the generator

against electrical overload.

DC RECEPTACLE

Your generator has a 12 volt, 7.5 Amp DC receptacle for

charging lead acid batteries.

WARNING:

The 12 V DC receptacle is designed to charge vented wet

lead acid batteries only. Other types of batteries could

burst, causing personal injury and damage.

FUEL TANK

The fuel tank has a capacity of 0.6 gallon.

NOTE: The fuel flows from the fuel tank to the carburetor

only when the on/off switch is in the ON (I) position.

GROUND TERMINAL

The ground terminal is used to assist in properly grounding

the generator to help protect against electrical shock.

Consult with a qualified local electrician for grounding

requirements in your area.

BATTERY CHARGING CABLE

The battery charging cable makes it easy to charge 12 Volt

lead acid batteries with the generator.

NOTE: Only use battery charging cable to charge vented

wet lead acid batteries.

CARRY HANDLE

The generator has a carry handle for easy transport.

CHOKE LEVER

The choke lever is used when starting the engine.

10 — English

LED DISPLAY

LEDs provide feedback to indicate whether the generator is

in use, overloaded, or in need of lubricant.

LOW OIL SHUT DOWN PROTECTOR

The low oil sensor causes the engine to stop if the level of

lubricant in the crankcase is insufficient.

OIL CAP/DIPSTICK

Remove the oil fill cap to check and add lubricant to the

generator when necessary.

Page 15

FEATURES

ON/OFF SWITCH

The on/off switch is used in combination with the starter

grip and rope to start the generator. It is also used to turn

the generator off.

STARTER GRIP AND ROPE

The starter grip and rope is used (along with the on/off switch)

to start the generator’s engine.

ASSEMBLY

UNPACKING

This product has been shipped completely assembled.

Carefully remove the product and any accessories from

the box. Make sure that all items listed in the packing list

are included.

WARNING:

Do not use this product if it is not completely assembled

or if any parts appear to be missing or damaged. Use of

a product that is not properly and completely assembled

could result in serious personal injury.

Inspect the product carefully to make sure no breakage

or damage occurred during shipping.

Do not discard the packing material until you have

carefully inspected and satisfactorily operated the

product.

If any parts are damaged or missing, please call

1-800-860-4050 for assistance.

PACKING LIST

Generator

Battery Charging Cable

Engine Lubricant (SAE 10W 30)

Funnel

Operator’s Manual

VENTED FUEL CAP

The generator has a fuel cap with a vent that can be opened

and closed. During normal operation the vent should be in

the OPEN (I) position.

WARNING:

If any parts are damaged or missing do not operate this

product until the parts are replaced. Use of this product

with damaged or missing parts could result in serious

personal injury.

WARNING:

Do not attempt to operate the generator until assembly

is complete. Failure to comply could result in possible

serious personal injury.

WARNING:

Do not attempt to modify this product or create accessories not recommended for use with this product. Any

such alteration or modification is misuse and could result

in a hazardous condition leading to possible serious

personal injury.

11 — English

Page 16

OPERATION

DANGER:

Carbon Monoxide. Using a generator indoors CAN KILL

YOU IN MINUTES.

Generator exhaust contains high levels of carbon

monoxide (CO), a poisonous gas you cannot see or smell.

If you can smell the generator exhaust, you are breathing

CO. But even if you cannot smell the exhaust, you could

be breathing CO.

Never use a generator inside homes, garages,

crawlspaces, or other partly enclosed areas. Deadly

levels of carbon monoxide can build up in these

areas. Using a fan or opening windows and doors

does NOT supply enough fresh air.

ONLY use a generator outdoors and far away from

open windows, doors, and vents. These openings

can pull in generator exhaust.

Even when you use a generator correctly, CO may

leak into the home. ALWAYS use a battery-powered or

battery-backup CO alarm in the home.

If you start to feel sick, dizzy, or weak after the generator

has been running, move to fresh air RIGHT AWAY. See

a doctor. You could have carbon monoxide poisoning.

WARNING:

If this generator will be used only with cord and plugconnected equipment, National Electric Code does

not require that the unit be grounded. However, other

methods of using the generator may require grounding

to reduce the risk of shock or electrocution. Consult a

qualified electrician, electrical inspector, or local agency

having jurisdiction for local codes or ordinances to find

out if grounding is needed in your situation before using

the generator.

WARNING:

Do not allow familiarity with this product to make you

careless. Remember that a careless fraction of a second

is sufficient to inflict serious injury.

WARNING:

Do not use any attachments or accessories not

recommended by the manufacturer of this product. The

use of attachments or accessories not recommended

can result in serious personal injury.

NOTICE:

The spark arrestor on this product has not been evaluated

by the USDA Forest Service and cannot be used on U.S.

forest lands. In addition, product users must comply

with Federal, State, and local fire prevention regulations.

Check with appropriate authorities. Contact customer

service to purchase a replacement spark arrestor.

NOTICE:

Before each use, inspect the entire product for damaged,

missing, or loose parts such as screws, nuts, bolts, caps,

etc. Tighten securely all fasteners and caps and do not

operate this product until all missing or damaged parts

are replaced. Please call 1-800-860-4050 or contact an

authorized service center for assistance.

APPLICATIONS

This generator is designed to supply electrical power for

operating compatible electrical lighting, appliances, tools,

and motor loads.

BEFORE OPERATING THE UNIT

Only use OUTSIDE and far away from windows, doors,

and vents.

NEVER use inside a home or garage, EVEN IF doors and

windows are open.

Always position the generator on a flat firm surface.

SPECIAL REQUIREMENTS:

There may be General or State Occupational Safety and

Health Administration (OSHA) regulations, local codes or

ordinances that apply to the intended use of the generator.

Please consult a qualified electrician, electrical inspector, or

the local agency having jurisdiction:

In some areas, generators are required to be registered

with local utility companies.

If the generator is used at a construction site, there may

be additional regulations which must be observed.

LED DISPLAY

See Figure 2.

Power:

The power indicator will light when the generator is on and

the receptacles are operational.

NOTE: If the generator is overloaded, the power indicator

light will go off.

Overload:

The overload indicator will blink when the generator’s

maximum wattage/amperage is reached. If the wattage/

amperage capacity is exceeded, the LED will become solid

and the unit’s output will automatically shut down. To reset

the generator, remove all loads from the generator and turn

12 — English

Page 17

OPERATION

the generator off. Restart the unit and add loads back to

the generator one at a time being careful not to exceed the

generators wattage rating.

Lubricant:

The oil indicator will light and the engine will automatically

shut off whenever the lubricant level in the engine becomes

low. The engine may not be restarted until sufficient engine

lubricant has been added to the generator.

NOTE: It is normal for the indicator lights to illuminate and/

or blink each time the engine is started. Once the engine

warms up, the lights should default to the pattern above.

CHECKING/ADDING LUBRICANT

See Figures 3 - 4.

NOTICE:

Attempting to start the engine before it has been properly

filled with lubricant will result in equipment failure.

Engine lubricant has a major influence on engine performance and service life. For general, all-temperature use,

SAE 10W-30 is recommended. Always use a 4-stroke motor

lubricant that meets or exceeds the requirements for API

service classification SJ.

NOTE: Non-detergent or 2-stroke engine lubricants will

damage the engine and should not be used.

Loosen the screw at the top of the engine maintenance

cover. Remove cover and set aside.

Unscrew the oil cap/dipstick and remove.

Wipe dipstick clean and re-seat in hole; do not re-thread.

Remove dipstick again and check lubricant level.

Lubricant level should fall between the minimum and

maximum marks on the dipstick.

If level is low, add engine lubricant until the fluid level

rises between the minimum and maximum marks on the

dipstick.

Replace and secure the oil cap/dipstick.

Replace the engine maintenance cover and reinstall the

screw to secure.

USING FUEL STABILIZER

Fuel gets old, oxidizes, and breaks down over time. Adding

a fuel stabilizer (not included) extends the usable life of fuel

and helps prevent deposits from forming that can clog the

fuel system. Follow fuel stabilizer manufacturer’s directions

for correct ratio of stabilizer to fuel.

Mix fuel stabilizer and gasoline prior to filling the tank

by using a gas can or other approved fuel container and

shaking gently to combine.

NOTE: To control the amount of fuel stabilizer being added

to the engine, always mix fuel stabilizer with gasoline

before fueling the tank rather than adding fuel stabilizer

directly into the generator’s fuel tank.

Replace and secure the fuel tank cap.

Start and run the engine for at least 5 minutes to allow

stabilizer to treat the entire fuel system.

OXYGENATED FUELS

NOTICE:

Do not use E15 or E85 fuel (or fuel containing greater

than 10% ethanol) in this product. It is a violation of

federal law and will damage the unit and void your

warranty.

Fuel system damage or performance problems resulting

from the use of an oxygenated fuel containing more than

the percentage of oxygenates stated below are not covered

under warranty.

Ethanol. Gasoline containing up to 10% ethanol by volume

(commonly referred to as E10) is acceptable. E15 and E85

are not.

CHECKING/ADDING FUEL

See Figures 5 and 8.

WARNING:

Gasoline and its vapors are highly flammable and

explosive. To prevent serious personal injury and property

damage, handle gasoline with care. Keep away from

ignition sources, handle outdoors only, do not smoke

while adding fuel, and wipe up spills immediately.

When adding gas to the generator, make sure the unit is

sitting on a flat, level surface. If the engine is hot, let the

generator cool for at least five minutes before adding gas.

ALWAYS fill the fuel tank outdoors with the machine turned

off.

Remove the fuel cap slowly.

Put the on/off switch in the ON ( I ) position.

Fill the fuel tank to 1 in. below the top of the fuel neck.

Replace and secure the fuel cap.

NOTE: Always use unleaded gasoline with a pump octane

rating of 86 or higher. Never use old, stale, or contaminated

gasoline, and do not use an oil/gas mixture. Do not allow dirt

or water into the fuel tank. Do not use E85 fuel.

OPENING AND CLOSING VENTED FUEL CAP

See Figures 6 - 7.

The generator has a fuel cap with a vent that can be opened

and closed.

To open the vent, rotate the fuel cap lever to the OPEN

(I) position. The vent should be open during operation.

To close the vent, rotate the fuel cap lever to the CLOSED

(O) position. The vent should be closed when the

generator is not in use.

13 — English

Page 18

OPERATION

STARTING THE ENGINE

See Figures 7 - 11.

NOTICE:

On a level surface with the engine off, check the lubricant

level before each use of the generator.

NOTE: If location of generator is not level, the unit may not

start or may shut down during operation.

Unplug all loads from the generator.

Open the vent on the fuel cap by rotating the fuel cap

lever to the OPEN (I) position.

Put the auto idle switch in the OFF (O) position.

Put the on/off switch in the ON ( I ) position.

NOTE: When the on/off switch is in the ON ( I ) position

fuel will flow from the fuel tank to the engine.

Move the choke lever to the START position.

NOTE: If engine is warm, move the choke lever to the

RUN position.

Pull the starter grip and rope until the engine runs

(a maximum of 6 times).

NOTE: Do not allow the grip to snap back after starting;

return it gently to its original place.

Allow the engine to run for 15 - 30 seconds, then move

the choke lever in to the RUN position.

NOTE: For quieter more efficient operation, place the

auto idle switch in the ON (I) position.

STOPPING THE ENGINE

See Figures 7 and 9.

Remove any load from the generator.

Put the on/off switch in the OFF (O) position.

Close the vent on the fuel cap by rotating the fuel cap

lever to the CLOSED (O) position.

NOTE: If the temperature is above 75˚F, leave the vent

on the fuel cap open to relieve pressure.

To stop the engine in an emergency situation:

Put the on/off switch in the OFF (O) position.

WARNING:

While operating and storing, keep at least 3 feet of

clearance on all sides of this product, including overhead.

Allow a minimum of 30 minutes of “cool down” time

before storage. Heat created by muffler and exhaust

gases could be hot enough to cause serious burns and/

or ignite combustible objects.

USING THE BATTERY CHARGING CABLE

See Figure 12.

WARNING:

The 12 V DC receptacle is designed to charge vented wet

lead acid batteries only. Other types of batteries could

burst, causing personal injury and damage.

NOTICE:

The 12 V DC receptacle provides continuous charge. Do

not overcharge battery or leave battery unattended. Doing

so may cause damage to the battery.

NOTICE:

Do not use the generator to jump start vehicles. Doing

so could result in damage to the vehicle or it’s electrical

components.

Place the auto idle switch in the OFF (O) position.

Using the battery clamps, connect the battery charging

cable assembly to the battery terminal. Connect the

red wire to the positive (+) terminal first, then connect

the black wire to the negative (–) terminal. Make sure all

connections are secure.

NOTE: Be careful not to short across the terminals when

installing. Shorting the terminals together can cause

sparks, damage to the battery or generator, or even burns

or explosions.

NOTE: To prevent short circuit, keep away from a metal

surface during clamp connection.

Connect the battery charging cable assembly to the

12 V DC receptacle.

Start the generator.

NOTE: The AC receptacles can be used while the DC

receptacle is in use.

The battery will become slightly warm to the touch while

charging. This is normal and does not indicate a problem.

NOTE: Only use battery charging cable assembly to

charge vented wet lead acid batteries.

When batteries become fully charged, disconnect

the battery charging cable assembly from the battery.

Disconnect the negative (black) wire first, then the positive

(red) wire, being careful not to short across the terminals.

Always abide by the safety warnings provided with the

battery.

NOTE: Most batteries will be completely charged after

30 to 120 minutes. However, it is highly recommended

that you refer to your battery manufacturer’s instructions

for specific charge times.

Unplug battery charging cable assembly and store for

later use.

14 — English

Page 19

OPERATION

HIGH ALTITUDE OPERATION

Specific modifications are needed for high-altitude operation

for equipment operating in altitudes greater than 5000 feet

above sea level. Please contact your authorized service cen-

MAINTENANCE

WARNING:

When servicing, use only identical replacement parts.

Use of any other parts could create a hazard or cause

product damage.

WARNING:

Before inspecting, cleaning, or servicing the machine,

shut off engine, wait for all moving parts to stop, and

disconnect spark plug wire and move it away from

spark plug. Allow 30 minutes of cool down time before

performing any maintenance. Failure to follow these

instructions can result in serious personal injury or

property damage.

NOTICE:

Periodically inspect the entire product for damaged,

missing, or loose parts such as screws, nuts, bolts, caps,

etc. Tighten securely all fasteners and caps and do not

operate this product until all missing or damaged parts

are replaced. Please call 1-800-860-4050 or contact an

authorized service center for assistance.

GENERAL MAINTENANCE

Keep the generator in a clean and dry environment where it

is not exposed to dust, dirt, moisture, or corrosive vapors.

Do not allow the cooling air slots in the generator to become

clogged with foreign material such as leaves, etc.

Do not use a garden hose to clean the generator. Water

entering the fuel system or other internal parts of the unit can

cause problems that will decrease the life of the generator.

To clean the unit:

Use a soft bristle brush and/or vacuum cleaner to loosen

and remove dirt and debris.

Clean air vents with low pressure air that does not exceed

25 psi.

Wipe the exterior surfaces of the generator with a damp cloth.

CHECKING/CLEANING AIR FILTER

See Figure 13.

For proper performance and long life, keep air filter clean.

Loosen the screw at the top of the engine maintenance

cover. Remove cover and set aside.

Depress tabs on top and bottom of air filter cover. Remove

cover and set aside.

15 — English

ter for important information regarding these modifications.

Operating this engine without the proper altitude modification may increase the engine’s emissions and decrease fuel

economy and performance.

Remove the air filter.

Wash the air filter with warm, soapy water. Rinse and

squeeze to dry.

Reinstall the air filter.

NOTE: Make sure the filter is seated properly inside the

generator. Installing the filter incorrectly will allow dirt to

enter the engine, causing rapid engine wear.

Reinstall the air filter cover by aligniing the tabs on the

cover with the slots in the generator housing.

Replace the engine maintenance cover and reinstall the

screw to secure.

CHANGING ENGINE LUBRICANT

See Figure 14.

Loosen the screw at the top of the engine maintenance

cover. Remove cover and set aside.

Remove the oil fill cap/dipstick.

Tilt the generator to the side and allow lubricant to drain

from the oil fill hole into an approved container.

NOTE: Drain the lubricant while the engine is still warm

but not hot. Warm lubricant will drain quickly and more

completely.

WARNING:

Do not change engine lubricant while it is hot. Accidental

contact with hot engine lubricant could result in serious

burns.

Return the generator to an upright position and refill with

lubricant following the instructions in the Checking/

Adding Lubricant section previously in this manual.

For amount of lubricant needed to refill, see Product

Specifications earlier in this manual or the accompanying

engine manual, if applicable.

Replace and secure the oil cap/dipstick.

Replace the engine maintenance cover and reinstall the

screw to secure.

NOTE: Consult hazardous waste management guidelines in

your area for the proper way to dispose of used lubricant.

SPARK PLUG REPLACEMENT

See Figure 15.

The spark plug must be properly gapped and free of deposits

in order to ensure proper engine operation. To check:

Remove the spark plug cover.

Remove the spark plug cap.

Page 20

MAINTENANCE

Clean any dirt from around base of spark plug.

Remove spark plug using spark plug wrench (not

included).

Inspect spark plug for damage, and clean with a wire

brush before reinstalling. If insulator is cracked or

chipped, spark plug should be replaced. For replacement

spark plug, see Product Specifications earlier in this

manual or the accompanying engine manual, if applicable.

Measure plug gap. The correct gap is 0.024−0.028 in.

(0.60-0.70 mm). To widen gap, if necessary, carefully

bend the ground (top) electrode. To lessen gap, gently

tap ground electrode on a hard surface.

Seat spark plug in position; thread in by hand to prevent

cross-threading.

NOTICE:

Be careful not to cross-thread the spark plug. Crossthreading will seriously damage the product.

Tighten with wrench (not included) to compress washer.

If spark plug is new, use 1/2 turn to compress washer

appropriate amount. If reusing old spark plug, use 1/8 to

1/4 turn for proper washer compression.

NOTE: An improperly tightened spark plug will become

very hot and could damage the engine.

CLEANING THE EXHAUST PORT AND

MUFFLER

Depending on the type of fuel used, the type and amount of

lubricant used, and/or your operating conditions, the exhaust

port and muffler may become blocked with carbon deposits.

If you notice a power loss with your gas-powered products,

you may need to remove these deposits to restore performance. We highly recommend that only qualified service

technicians perform this service.

SPARK ARRESTOR

See Figure 16.

NOTICE:

The spark arrestor on this product has not been evaluated

by the USDA Forest Service and cannot be used on U.S.

forest lands. In addition, product users must comply

with Federal, State, and local fire prevention regulations.

Check with appropriate authorities. Contact customer

service to purchase a replacement spark arrestor.

The spark arrestor must be cleaned or replaced every 50

hours or yearly to ensure proper performance of your product. Spark arrestors may be in different locations depending

on the model purchased. Please contact your nearest service

dealer for the location of the spark arrestor for your model.

To clean the spark arrestor:

Loosen the screws on the rear panel. Remove rear panel

and set aside.

Remove the screw securing the spark arrestor in place.

Remove the spark arrestor and gently clean using a wire

brush.

Replace the spark arrestor and rear panel. Ensure that

all screws are tightened securely.

DRAINING FUEL TANK/CARBURETOR

See Figures 17 - 18.

To help prevent gum deposits in the fuel system, drain the

fuel from the tank and carburetor before storing.

DRAINING THE FUEL TANK:

NOTICE:

Remove all lubricant from the unit before draining the fuel

tank. Failure to do so could cause damage to the unit.

Remove the fuel cap.

Tilt the generator and allow fuel to drain from the fuel tank

into an approved container.

When the fuel has drained from the tank, replace the fuel

cap.

DRAINING THE CARBURETOR:

Loosen the screw at the top of the engine maintenance

cover. Remove cover and set aside.

Put the on/off switch in the OFF (O) position.

Position a suitable container under the carburetor drain

screw to catch fuel; loosen the screw.

Allow fuel to drain completely into container.

Retighten drain screw securely.

Replace the engine maintenance cover and reinstall the

screw to secure.

NOTE: Consult hazardous waste management guidelines in

your area for the proper way to dispose of used fuel.

TRANSPORTING

Put the on/off switch in the OFF (O) position.

Close the vent on the fuel cap by rotating the fuel cap

lever to the OFF (O) position.

Make sure engine and exhaust of unit is cool.

If transporting in a vehicle, drain the fuel tank, and

securely restrain the generator.

Do not drop or strike unit or place under heavy objects.

16 — English

Page 21

MAINTENANCE

STORAGE

When preparing the generator for storage, allow the unit to cool for 30 minutes then follow the guidelines below.

STORAGE TIME PRIOR TO STORING

Less than 2 months Drain gasoline from tank and dispose of in a suitable container according to state and local

ordinances.

2 months to 1 year Drain fuel from carburetor.

Drain gasoline from tank and dispose of in a suitable container according to state and local

ordinances.

1 year or more Drain fuel from the carburetor.

Remove spark plug.

Drain gasoline from tank and dispose of in a suitable container according to state and local

ordinances.

Put a tablespoon of engine lubricant into the spark plug cylinder. Turn the engine slowly with the

pull rope to distribute the lubricant.

Reinstall spark plug.

Change engine lubricant.

After removal from storage:

Fill with fresh gasoline.

NOTE: If storing gasoline in suitable container for later use, make sure gasoline has been treated with fuel stabilizer according to stabilizer manufacturer’s instructions.

MAINTENANCE SCHEDULE

NOTE: If a separate engine manual is provided for this generator, please follow the maintenance schedule provided in the

engine manual instead of the maintenance information listed below.

Before

each use

Check Engine Lubricant

Change Engine Lubricant

Check Air Filter

Clean Air Filter

Change Air Filter

Check/Adjust Spark Plug

Replace Spark Plug

Clean Fuel Tank and Filter

Check Fuel Hose

Check All Hose

Connections

Inspect Fuel Tank Vapor

Vent (If Equipped)

Inspect Carbon Canister

(CARB Models Only)

1. These items should only be carried out by an authorized service center.

NOTE: Maintenance should be performed more frequently when generator is used in dusty areas.

When generator has exceeded the maximum figures specified in the table, maintenance should still be cycled

according to the intervals of time or hours stated herein.

1

After 1st month

or 20 hours of

operation

Every 3 months

or 50 hours of

operation

Every 6 months

or 100 hours

of operation

Every year or

after 300 hours

of operation

17 — English

Page 22

TROUBLESHOOTING

PROBLEM POSSIBLE CAUSE SOLUTION

Engine will not start. On/Off switch is OFF (O).

No fuel.

Stale gasoline or water in gasoline.

Lubricant level is low.

Spark plug faulty, fouled, or improperly

gapped.

Choke lever is in RUN position.

Engine stored without treating or

draining gasoline, or refueled with bad

gasoline.

Dirty fuel filter.

Engine hard to start Water in gasoline.

Weak spark at spark plug.

Engine lacks power. Dirty air filter.

Engine stored without treating or

draining gasoline, or refueled with bad

gasoline.

AC receptacle does not work. Generator is overloaded.

Item plugged in is defective.

DC receptacle does not work. Circuit protector engaged

Item plugged in is defective.

Turn On/Off switch to ON (I).

Fill fuel tank.

Drain entire system and refill with fresh

fuel.

Engine is equipped with Low Oil Shutoff.

If engine lubricant level is low, it must be

filled before unit will start. Check engine

lubricant level and fill, if necessary.

Replace spark plug.

Put the choke lever in the START

position.

Drain fuel and carburetor. Refuel with

fresh gasoline.

Contact authorized service center.

Drain entire system and refill with fresh

fuel.

Contact authorized service center.

Check air filter. Clean or replace as

needed.

Drain fuel and carburetor. Refuel with

fresh gasoline.

Turn the generator off and remove all

loads. Restart the unit.

Try a different item.

Remove any load from the generator.

Turn the auto idle switch to off, then

depress the DC circuit breaker.

Try a different item.

Generator makes a “spark knock” or

“pinging” noise.

If problem persists after trying the above solutions, contact your nearest authorized service center for assistance.

The following symptoms may indicate problems that will affect the emissions level of the unit:

Hard starting or stalling after starting

Rough idle

Misfiring or backfiring under load

Afterburning (backfiring)

Black exhaust smoke or high fuel consumption

If you encounter any of these symptoms, have the unit inspected and repaired by the nearest authorized service center.

An occasional light “knocking” or “pinging” under heavy load is not a cause

for concern. However, if the knocking

or pinging occurs under normal load

at a steady engine speed, the problem

may be with the brand of gasoline being used.

18 — English

Switch to a different brand of gasoline,

making sure that the octane rating is 86

or higher. If problem continues, contact

your nearest authorized service center.

Page 23

WARRANTY

LIMITED WARRANTY STATEMENT

Techtronic Industries North America, Inc., warrants to the

original retail purchaser that this RYOBI® brand outdoor

product is free from defect in material and workmanship

and agrees to repair or replace, at Techtronic Industries

North America, Inc.’s, discretion, any defective product

free of charge within these time periods from the date of

purchase.

Three years if the product is used for personal, family

or household use;

90 days, if used for any other purpose, such as

commercial or rental.

This warranty extends to the original retail purchaser only

and commences on the date of the original retail purchase.

Any part of this product found in the reasonable judgment

of Techtronic Industries North America, Inc. to be defective

in material or workmanship will be repaired or replaced

without charge for parts and labor by an authorized service

center for RYOBI® brand outdoor products (Authorized

Ryobi Service Center).

The product, including any defective part, must be returned

to an authorized Ryobi service center within the warranty

period. The expense of delivering the product to the service

center for warranty work and the expense of returning it

back to the owner after repair or replacement will be paid

by the owner. Techtronic Industries North America, Inc.’s,

responsibility in respect to claims is limited to making the

required repairs or replacements and no claim of breach of

warranty shall be cause for cancellation or rescission of the

contract of sale of any RYOBI® brand outdoor product. Proof

of purchase will be required by the dealer to substantiate

any warranty claim. All warranty work must be performed

by an authorized service center.

This warranty is limited to ninety (90) days from the date

of original retail purchase for any RYOBI® brand outdoor

product that is used for rental or commercial purposes, or

any other income-producing purpose.

This warranty does not cover any product that has been

subject to abuse, misuse, neglect, negligence, accident,

the effects of corrosion or erosion, or that has been

operated in any way contrary to the operating instructions

as specified in this operator’s manual. This warranty does

not apply to any damage to the product that is the result

of improper maintenance or to any product that has been

altered or modified. The warranty does not extend to

repairs made necessary by normal wear or by the use of

parts or accessories which are either incompatible with

the RYOBI® brand outdoor product or adversely affect

its operation, performance, or durability.

In addition, this warranty does not cover:

Tune-ups – Spark Plugs, Carburetor, Carburetor

Adjustments, Ignition, Filters, Oil Change

Wear items – Recoil Starter Rope, Motor Brushes, Alternator

Brushes, Cotter Pins, Wheels, a High Pressure Hose,

Spray Wand, Nozzles, Trigger Handle, Supply Hoses,

Quick Couplers, Gaskets, Valves, Pistons, Pump Valve

Assemblies, O-Rings, Water and Oil Seals, Detergent Tanks.

IMPORTANT: Some components not covered under

this warranty may still be covered by a separate

warranty issued by the engine manufacturer. Please

see the Engine Manufacturer Warranty (if any) supplied

with this product for further details.

The Company will not pay for repairs or adjustments to

the Product, or for any costs or labor, performed without

the Company’s prior authorization.

Techtronic Industries North America, Inc., reserves the

right to change or improve the design of any RYOBI®

brand outdoor product without assuming any obligation

to modify any product previously manufactured.

ALL IMPLIED WARRANTIES ARE LIMITED IN DURATION

TO THE STATED WARRANTY PERIOD. ACCORDINGLY,

ANY SUCH IMPLIED WARRANTIES INCLUDING

MERCHANTABILITY, FITNESS FOR A PARTICULAR

PURPOSE, OR OTHERWISE, ARE DISCLAIMED

IN THEIR ENTIRETY AFTER THE EXPIRATION OF

THE APPROPRIATE THREE-YEAR OR NINETY-DAY

WARRANTY PERIOD. TECHTRONIC INDUSTRIES

NORTH AMERICA, INC.’S, OBLIGATION UNDER THIS

WARRANTY IS STRICTLY AND EXCLUSIVELY LIMITED TO

THE REPAIR OR REPLACEMENT OF DEFECTIVE PARTS

AND TECHTRONIC INDUSTRIES NORTH AMERICA,

INC., DOES NOT ASSUME OR AUTHORIZE ANYONE

TO ASSUME FOR THEM ANY OTHER OBLIGATION.

SOME STATES DO NOT ALLOW LIMITATIONS ON HOW

LONG AN IMPLIED WARRANTY LASTS, SO THE ABOVE

LIMITATION MAY NOT APPLY TO YOU. TECHTRONIC

INDUSTRIES NORTH AMERICA, INC., ASSUMES NO

RESPONSIBILITY FOR INCIDENTAL, CONSEQUENTIAL,

OR OTHER DAMAGES INCLUDING, BUT NOT LIMITED

TO, EXPENSE OF RETURNING THE PRODUCT TO AN

AUTHORIZED RYOBI SERVICE CENTER AND EXPENSE

OF DELIVERING IT BACK TO THE OWNER, MECHANIC’S

TRAVEL TIME, TELEPHONE OR TELEGRAM CHARGES,

RENTAL OF A LIKE PRODUCT DURING THE TIME

WARRANTY SERVICE IS BEING PERFORMED, TRAVEL,

LOSS OR DAMAGE TO PERSONAL PROPERTY, LOSS

OF REVENUE, LOSS OF USE OF THE PRODUCT, LOSS

OF TIME, OR INCONVENIENCE. SOME STATES DO NOT

ALLOW THE EXCLUSION OR LIMITATION OF INCIDENTAL

OR CONSEQUENTIAL DAMAGES, SO THE ABOVE

LIMITATION OR EXCLUSION MAY NOT APPLY TO YOU.

This warranty gives you specific legal rights, and you may

also have other rights which vary from state to state.

This warranty applies this Ryobi® brand outdoor product

manufactured by or for Techtronic Industries North America,

Inc., and sold in the United States and Canada.

To locate your nearest Authorized Ryobi Service Center,

dial 1-800-860-4050.

19 — English

Page 24

WARRANTY

LIMITED ENGINE WARRANTY

Techtronic Industries North America, Inc. (herein

“Techtronic Industries”), warrants that each new engine

sold by it will be free, under normal use and service,

from defects in material and workmanship for a period

listed below from the date of sale to the original retail

purchaser. Techtronic Industries obligation under this

Limited Warranty shall be limited to the repair and

replacement, at Techtronic Industries option, of any part or

parts which upon examination is/are found, in Techtronic

Industries judgment, to have been defective in material or

workmanship. It shall be a condition of Techtronic Industries

obligation under this Limited Warranty that Techtronic

Industries, directly or through one of its Distributors or

Service Centers authorized to service the particular engine

involved, receive prompt notice of any warranty claim

and that the engine or the part or parts claimed to be

defective be promptly delivered, transportation prepaid,

to such Distributor or Service Center for inspection and

repair. All repairs qualifying under this Limited Warranty

must be performed by Techtronic Industries or one of its

authorized Distributors or Service Centers.

WARRANTY PERIODS:

158F Gasoline Engine (Private/Residential) Limited 2

year Warranty

158F Gasoline Engines (Commercial) Limited 90 Day

Warranty

The repair or replacement of any part or parts under this

Limited Warranty shall not extend the term of the engine

warranty beyond the original term as set forth above.

LIMITATIONS AND EXCLUSIONS: This Limited Warranty

shall not apply to:

1. Repair required because of prolonged storage including

damage caused by old or contaminated fuel in the fuel

tank, fuel lines, or carburetor, sticky valves or corrosion

and rust of engine parts.

2. Repair required due to overheating. (Most often caused

by overloaded or clogged or damaged or missing flywheel,

fan, inlet air passages, cooling fins, or air shrouds.)

3. Dirt or grit related wear caused by improper air cleaner

maintenance (most often resulting in worn piston, piston

rings, cylinders, valves, valve guides, carburetor, or other

internal components).

4. Broken or scored parts caused by low oil level, dirty,

or improper grade of oil.

5. Engine tune-ups and normal maintenance service

including, but not limited to, valve adjustment, normal

replacement of service items, fuel, and lubricating oil, etc.

6. Any engine which has been subject to negligence,

misuse, accident, misapplication, or overspeeding.

7. Any engine that has been installed, repaired, or altered

by anyone in a manner which in Techtronic Industries sole

judgment adversely affects its performance or reliability.

8. Any engine which has been fitted with or repaired with

parts or components not manufactured or approved by

Techtronic Industries which in Techtronic Industries’ sole

judgment adversely affects its performance or reliability.

9. Instances when normal use has exhausted the life of

a component or an engine.

The customer is responsible for all transportation charges

in connection with any warranty work.

Techtronic Industries reserves the right to modify, alter,

or improve any engines or parts without incurring any

obligation to modify or replace any engine or parts

previously sold without such modification, alternation,

or improvement.

No person is authorized to give any other warranty or to

assume any additional obligation on Techtronic Industries’

behalf unless made in writing and signed by an officer of

Techtronic Industries.

THIS WARRANTY, TECHTRONIC INDUSTRIES

OBLIGATION HERE UNDER, ARE IN LIEU OF ANY

OTHER WARRANTIES OR OBLIGATIONS OF ANY

KIND, EXPRESSED OR IMPLIED, INCLUDING ANY

WARRANTIES OF MERCHANTABILITY OR FITNESS

FOR A PARTICULAR PURPOSE. THERE ARE NO

WARRANTIES WHICH EXTEND BEYOND THE

DESCRIPTION ON THE FACE HERE-OF. TECHTRONIC

INDUSTRIES SHALL IN NO EVENT BE LIABLE FOR

ANY CONSEQUENTIAL OR INCIDENTAL DAMAGES.

IF YOU HAVE ANY QUESTIONS REGARDING YOUR WARRANTY RIGHTS AND RESPONSIBILITIES, CONTACT

YOUR NEAREST AUTHORIZED RYOBI SERVICE CENTER AT 1-800-860-4050.

20 — English

Page 25

WARRANTY

CALIFORNIA EMISSIONS CONTROL WARRANTY STATEMENT

YOUR WARRANTY RIGHTS AND OBLIGATIONS

The California Air Resources Board, United Sates Environmental Protection

Agency (EPA), and Zhejiang ZhongJian Technology Co., Ltd. are pleased

to explain the emissions control system warranty on your 2014/2015 small

off-road engine (SORE). In California, new SOREs must be designed, built

and equipped to meet the State’s stringent anti-smog standards. Zhejiang

ZhongJian Technology Co., Ltd. must warrant the emissions control system

on your SOREs for the periods of time listed below provided there has been

no abuse, neglect or improper maintenance of your SOREs.

Your emission control system may include parts such as the carburetor,

fuel tanks, fuel caps, fuel lines, the ignition system, and catalytic converter.

Also included may be hoses, belts, clamps, connectors and other emissionrelated assemblies.

For engines less than or equal to 80 cc only the fuel tank is subject to the

evaporative emission control warranty requirements of this section. (California

Only).

Where a warrantable condition exists, Zhejiang ZhongJian Technology Co.,

Ltd. will repair your small off-road engine at no cost to you including diagnosis,

parts and labor.

MANUFACTURER’S WARRANTY COVERAGE

The emissions control system is warranted for two years. If any emissionsrelated part on your engine is defective, the part will be repaired or replaced

by Zhejiang ZhongJian Technology Co., Ltd.

OWNER’S WARRANTY RESPONSIBILITIES

As the SORE owner, you are responsible for the performance of the

required maintenance listed in your owner’s manual. Zhejiang ZhongJian

Technology Co., Ltd. recommends that you retain all receipts covering