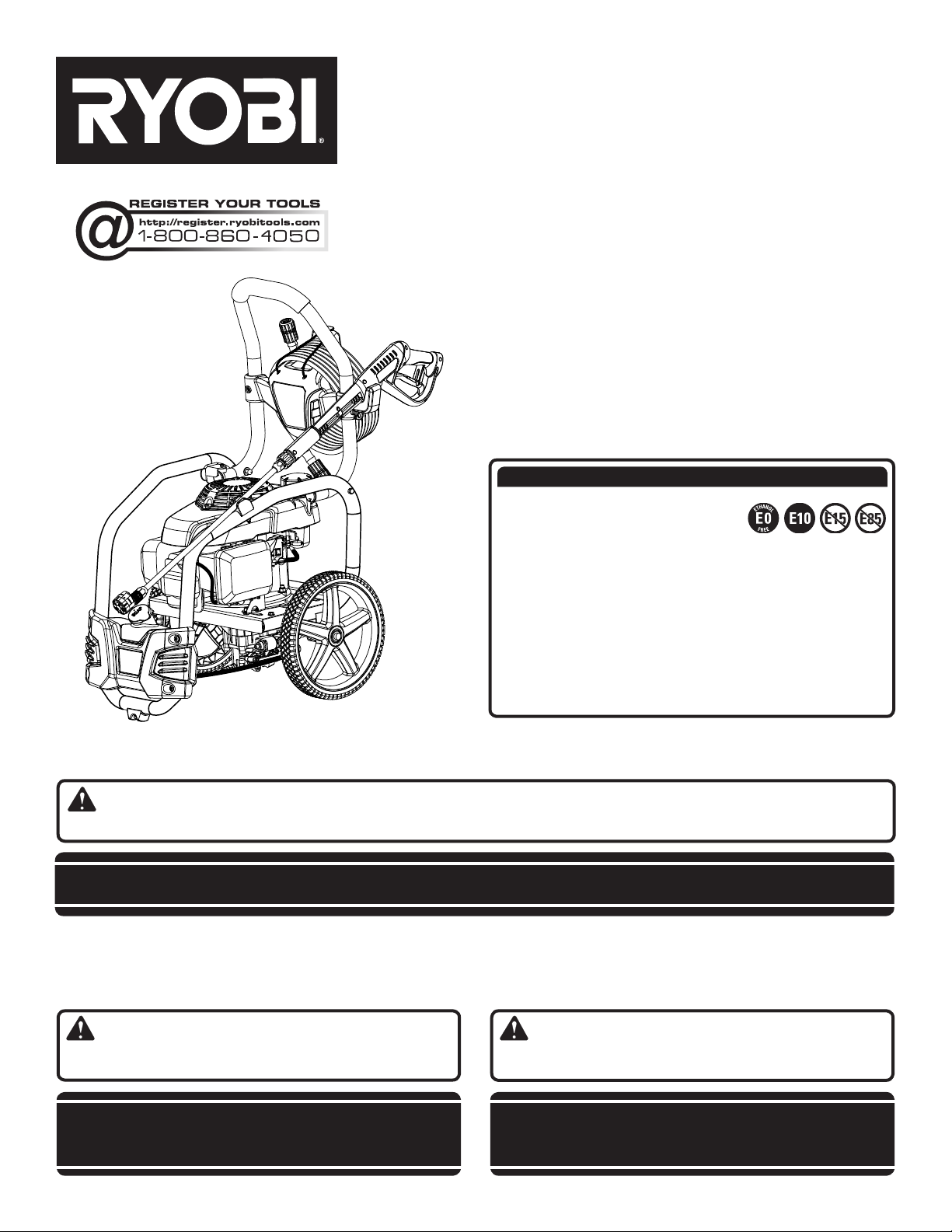

Ryobi RY80940 SERIES, RY80940B Owner's Manual

OPERATOR’S MANUAL

MANUEL D’UTILISATION

MANUAL DEL OPERADOR

3100 PSI PRESSURE WASHER

NETTOYEUR HAUTE PRESSION DE 3 100 PSI

LAVADORA A PRESIÓN DE 3 100 PSI

RY80940

SERIES/SÉRIE/SERIE

NOTICE AVIS AVISO

Do not use E15 or E85 fuel (or fuel

containing greater than 10% ethanol)

in this product. It is a violation of

federal law and will damage the unit and void your warranty.

Ne pas utiliser d’essence E15 ou E85 (ou un carburant

contenant plus de 10 % d’éthanol) dans ce produit. Une

telle utilisation représente une violation de la loi fédérale et

endommagera l’appareil et annulera la garantie.

No utilice combustibles E15 o E85 (ni combustibles que

contengan más de 10 % de etanol) con este producto. Esto

constituye una violación a la ley federal, dañará la unidad

y anulará la garantía.

Your pressure washer has been engineered and manufactured to our high standard for dependability, ease of operation, and

operator safety. When properly cared for, it will give you years of rugged, trouble-free performance.

WARNING: To reduce the risk of injury, the user must read and understand the operator’s manual before using

this product.

SAVE THIS MANUAL FOR FUTURE REFERENCE

Ce nettoyeur haute pression a été conçu et fabriqué conformément

aux strictes normes de fiabilité, simplicité d’emploi et sécurité

d’utilisation. Correctement entretenu, il vous donnera des années

de fonctionnement robuste et sans problème.

AVERTISSEMENT : Pour réduire les risques de

blessures, l’utilisateur doit lire et veiller à bien comprendre le

manuel d’utilisation avant d’utiliser ce produit.

CONSERVER CE MANUEL

POUR FUTURE RÉFÉRENCE

Su lavadora a presión ha sido diseñada y fabricada de conformidad

con las estrictas normas para brindar fiabilidad, facilidad de uso

y seguridad para el operador. Con el debido cuidado, le brindará

muchos años de sólido y eficiente funcionamiento.

ADVERTENCIA: Para reducir el riesgo de lesiones,

el usuario debe leer y comprender el manual del operador antes

de usar este producto.

GUARDE ESTE MANUAL

PARA FUTURAS CONSULTAS

See this fold-out section for all the figures referenced in the operator’s manual.

Consulter l’encart à volets afin d’examiner toutes les figures mentionnées dans le manuel d’utilisation.

Vea esta sección de la página desplegable para todas las figuras mencionó en el manual del operador.

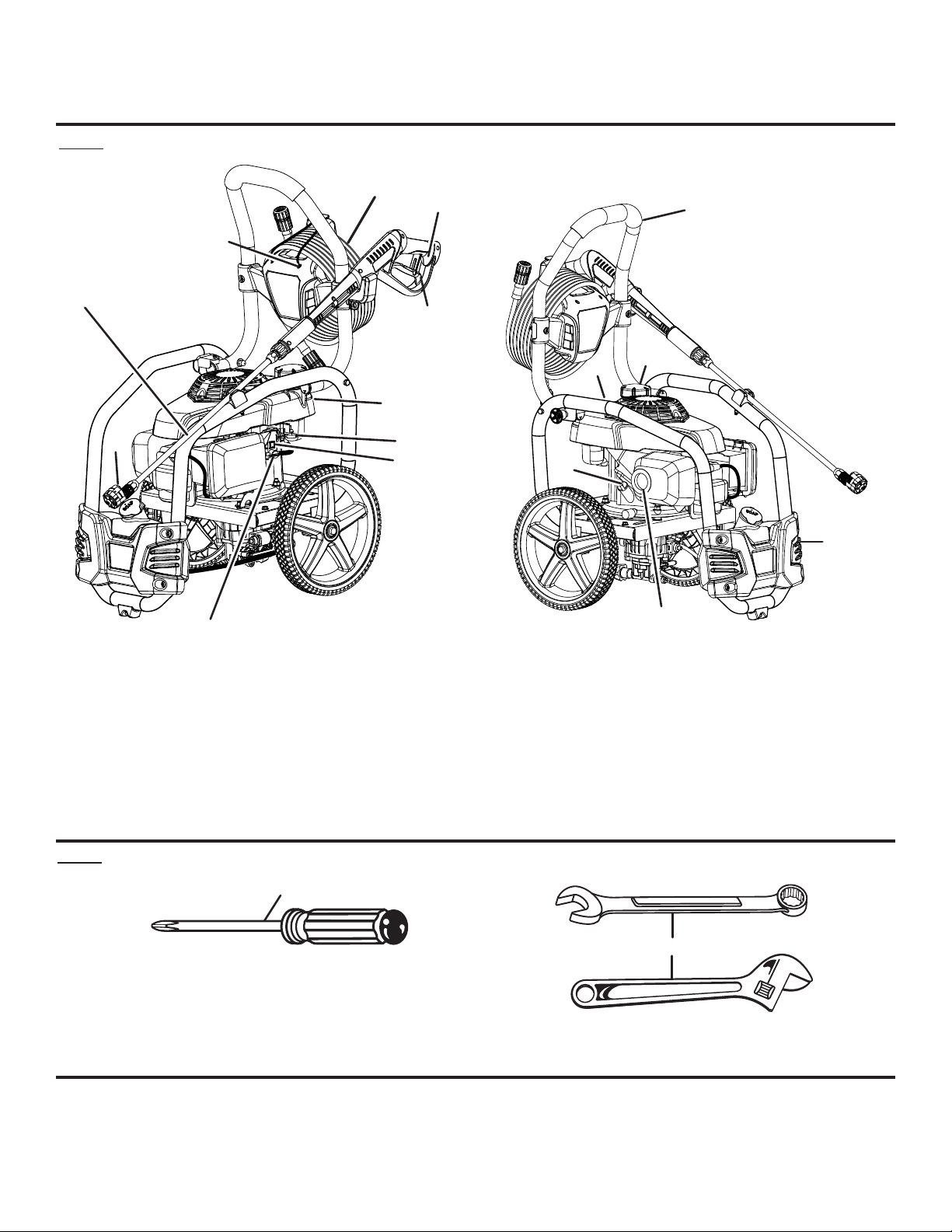

Fig. 1

F

I

G

E

D

H

O

N

L

A

M

J

B

C

P

K

A - 5-in-1 change over nozzle (buse à permutation 5 en 1, boquilla

intercambiable 5 en 1)

B - Oil cap/dipstick (bouchon / jauge d’huile, tapa del aceite con varilla de

nivel)

C - Detergent tank (réservoir de détergent, tanque de detergente)

D - Spray wand (lance de pulvérisation, tubo rociador)

E - Hose storage (rangement de tuyau, almacenamiento de la manguera)

F - High pressure hose (tuyau haute pression, manguera de alta presión)

G - Handle (poignée, mango)

H - Trigger handle (poignée à gâchette, mango del gatillo)

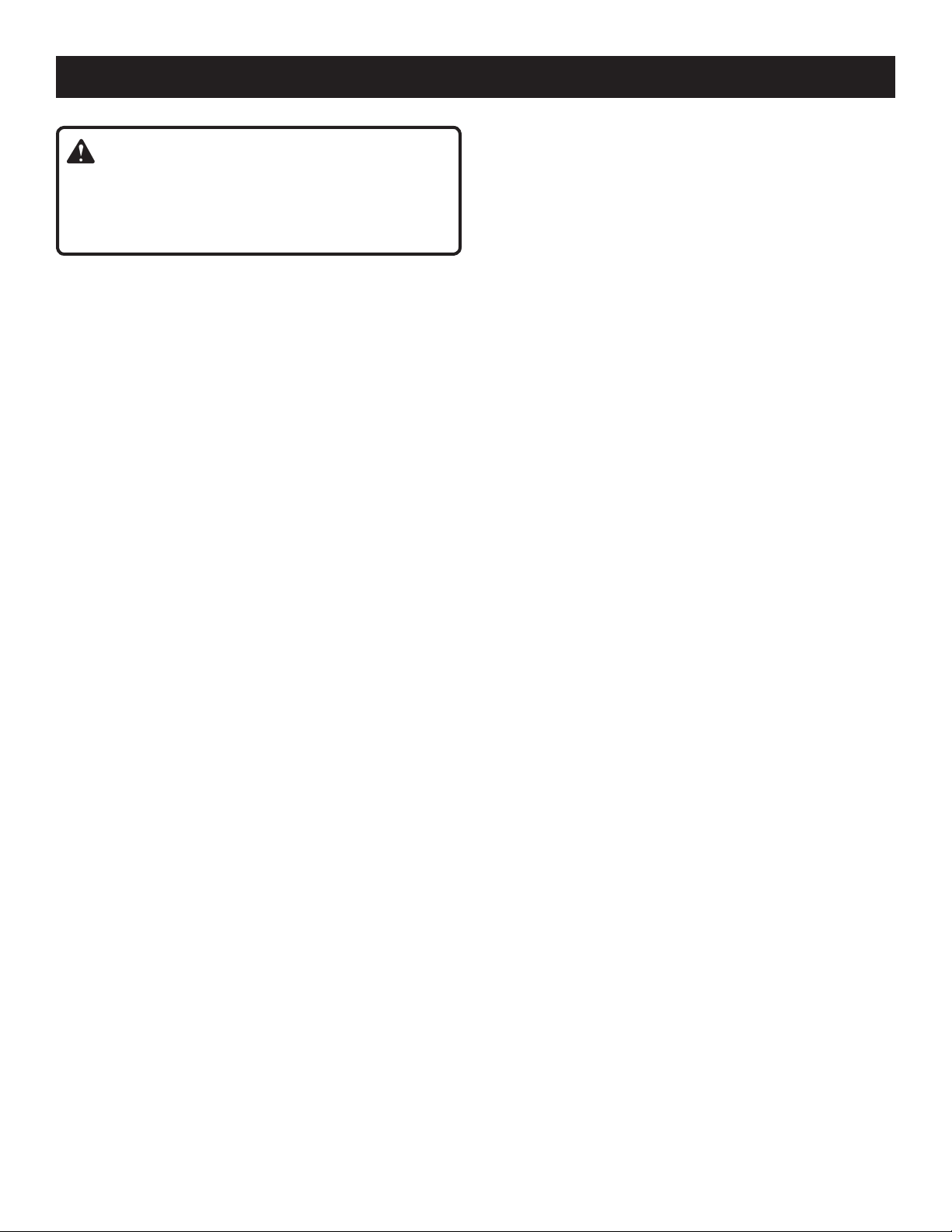

Fig. 2

A

A - Phillips screwdriver (tournevis phillips, destornillador phillips)

I - Trigger with lock out (gâchette avec verrou, gatillo con seguro)

J - On/off switch (commutateur marche/arrêt, interruptor de encendido/

apagado)

K - Fuel valve (robinet de carburant, válvula de combustible)

L - Fuel tank (réservoir de carburant, tanque del combustible)

M - Choke lever (levier de volet de départ, palanca del anegador)

N - Fuel cap (bouchon du réservoir, tapa del tanque de combustible)

O - Starter grip and rope (poignée du lanceur avec corde, mango del

arrancador con cuerda)

P - Muffler (silencieux, silenciador)

B

B - Combination wrench or adjustable wrench (clé mixte ou clé a molette,

llave de combinación o llave ajustable)

ii

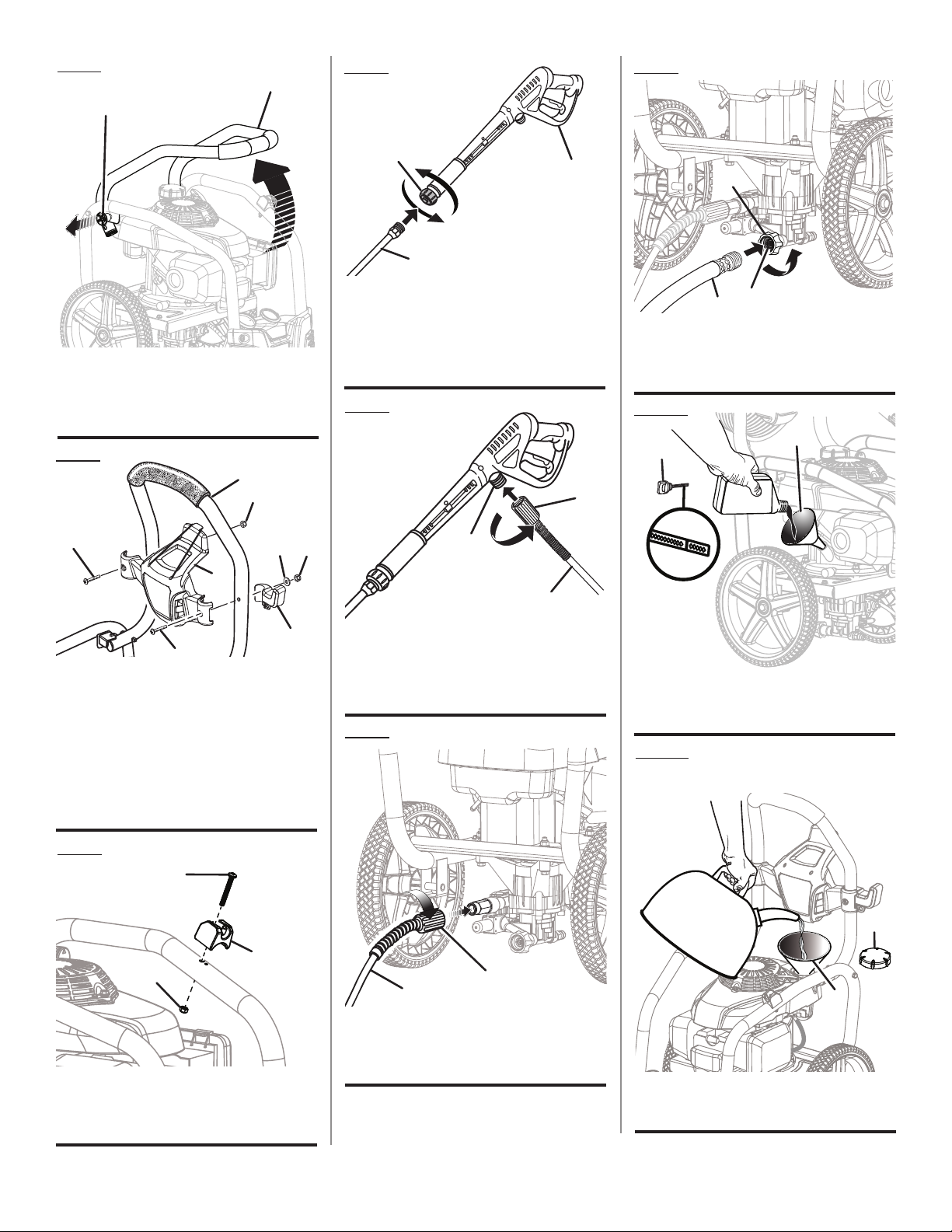

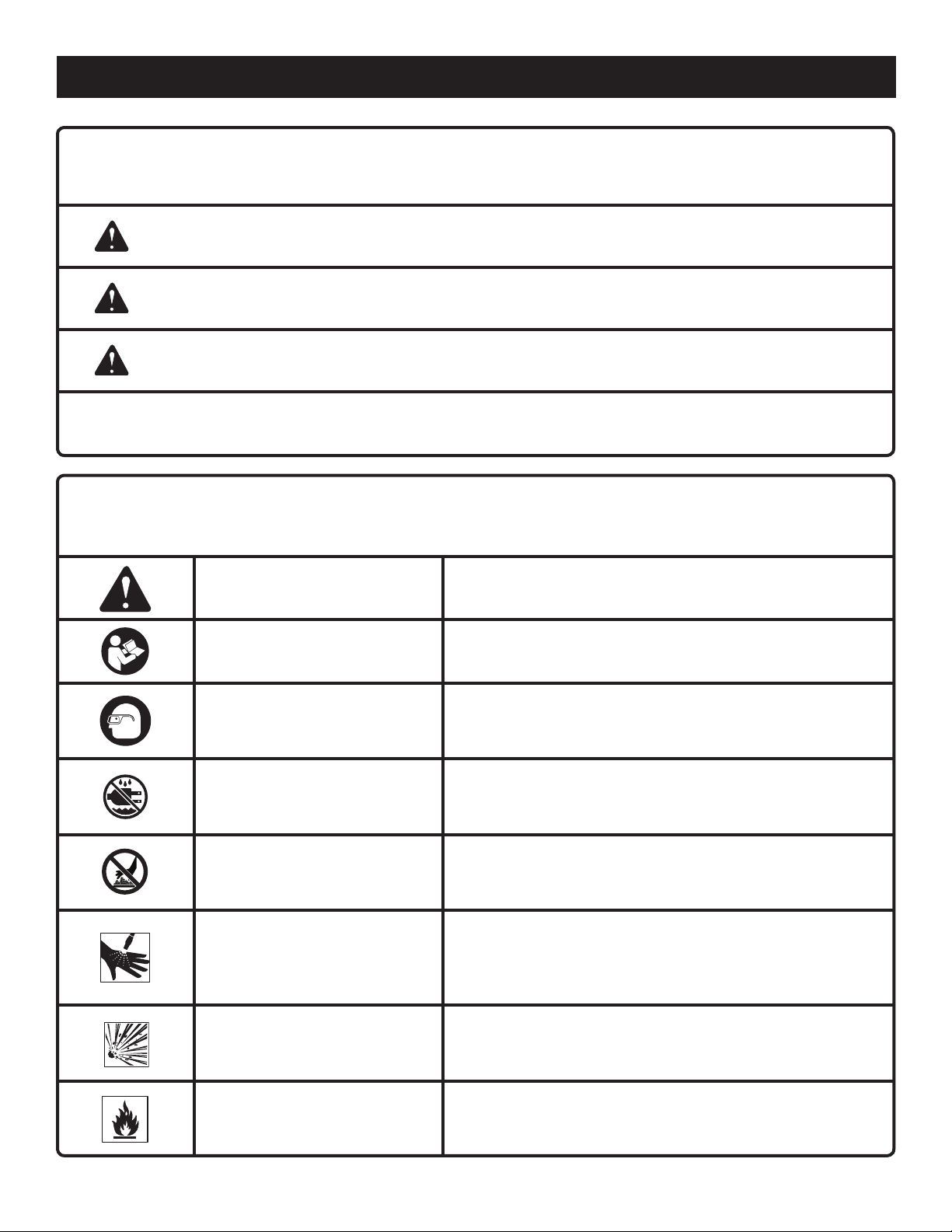

Fig. 3

B

A

A - Handle release knob (bouton de dégagement

de la poignée, perilla de liberación del

mango)

B - Handle (poignée, mango)

Fig. 4

C

D

Fig. 6

B

A

C

A - Trigger handle (poignée à gâchette, mango

del gatillo)

B - Connector (connecteur, conector)

C - Spray wand (lance de pulvérisation, tubo

rociador)

Fig. 7

A

Fig. 9

A

B

C

A - Water intake (prise d’eau, entrada de agua)

B - Screen (tamis, cedazo)

C - Garden hose (tuyau d’arrosage, manguera de

jardín)

Fig. 10

A

B

A

F

D

B

E

A

A - Screw (vis, tornillo)

B - Hose storage (rangement de tuyau,

almacenamiento de la manguera)

C - Handle (poignée, mango)

D - Hex nut (écrou hexagonal, tuerca hexagonal)

E - Trigger handle holder (support de la poignée

à gâchette, almacenamiento de mango del

gatillo)

F - Washer (rondelle, arandela)

Fig. 5

C

B

A

B

C

A - Collar (collier, casquillo)

B - Inlet coupler (raccord d’entrée, acoplador de

entrada)

C - High pressure hose (tuyau haute pression,

manguera de alta presión)

Fig. 8

B

A

A - Oil cap/dipstick (bouchon / jauge d’huile,

tapa del aceite con varilla de nivel)

B - Funnel (entonnoir, embudo)

Fig. 11

B

A

A - Hex nut (écrou hexagonal, tuerca hexagonal)

B - Spray wand holder (support de la lance

d’arrosage, soporte del tubo rociador)

C - Screw (vis, tornillo)

A - High pressure hose (tuyau haute pression,

manguera de alta presión)

B - Collar (collier, casquillo)

A - Funnel (entonnoir, embudo)

B - Fuel cap (bouchon de carburant, tapa del

tanque de combustible)

iii

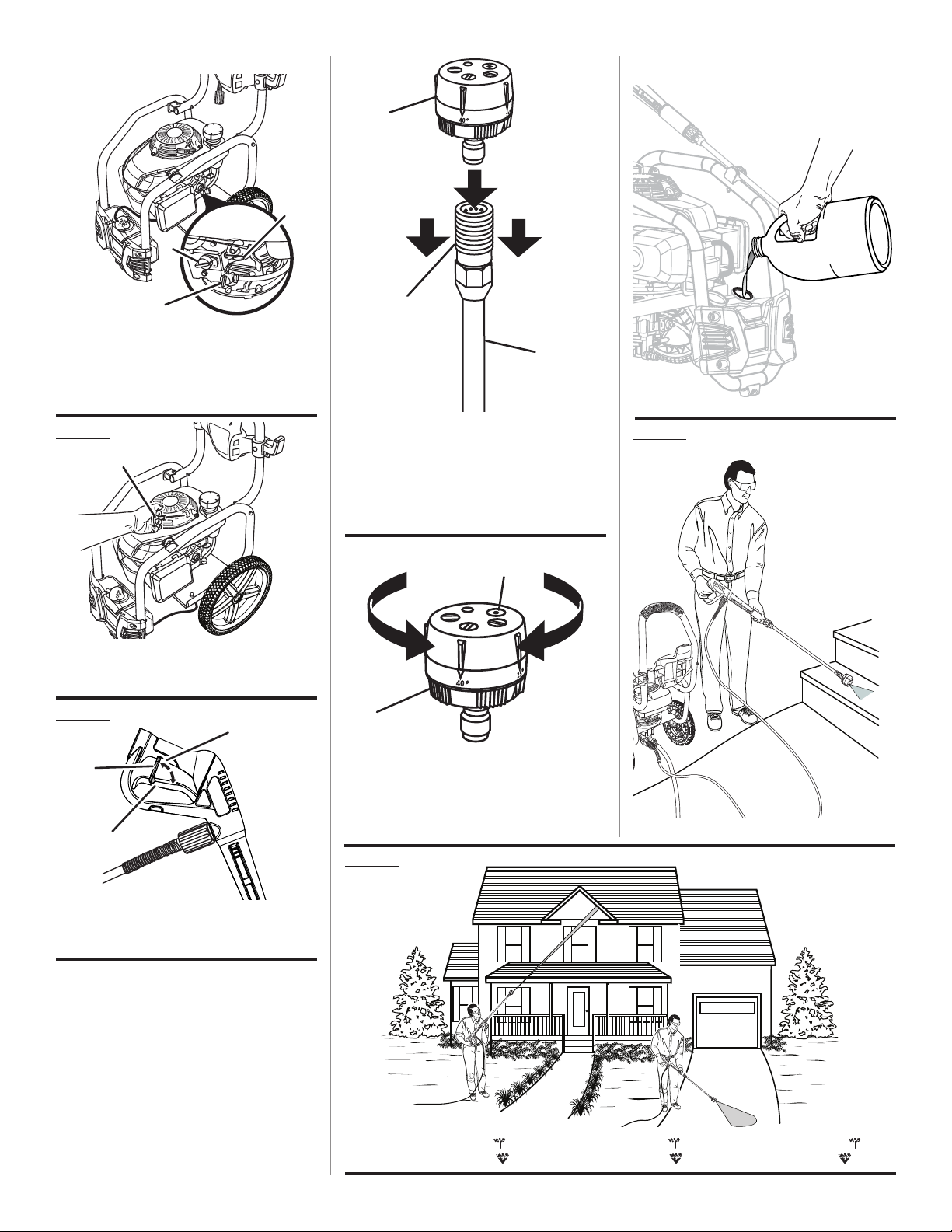

Fig. 12

Fig. 15

Fig. 18

A

“CLICK”

DÉCLIC

B

CLIC

A

C

A - On/off switch (commutateur marche / arrêt,

interruptor de encendido/apagado)

B - Choke lever (levier de volet de départ,

palanca del anegador)

C - Fuel valve (robinet de carburant, válvula de

combustible)

Fig. 13

A

SOAP

A - Starter grip and rope (poignée du lanceur

avec corde, mango del arrancador con

cuerda)

Fig. 14

A

B

C

A - 5-in-1 change over nozzle (buse à

permutation 5 en 1, boquilla intercambiable

5 en 1)

B - Quick-connect collar (collier à ressort,

casquillo de conexión rápida)

C - Spray wand (lance de pulvérisation, tubo

rociador)

Fig. 16

B

A

Fig. 19

B

C

A - Slot (encoche, ranura)

B - Lock out (verrouillage, seguro)

C - Trigger (gâchette, gatillo)

A - 5-in-1 change over nozzle (buse à

permutation 5 en 1, boquilla intercambiable

5 en 1)

B - Spray selector (sélecteur de jets , selector de

rociado )

Fig. 17

A - Long range detergent [ ] (détergent à longue portée [ ], detergente de gran alcance [ ])

B - Short range detergent [ ] (détergent à courte portée [ ], detergente corto alcance [ ])

iv

Fig. 20

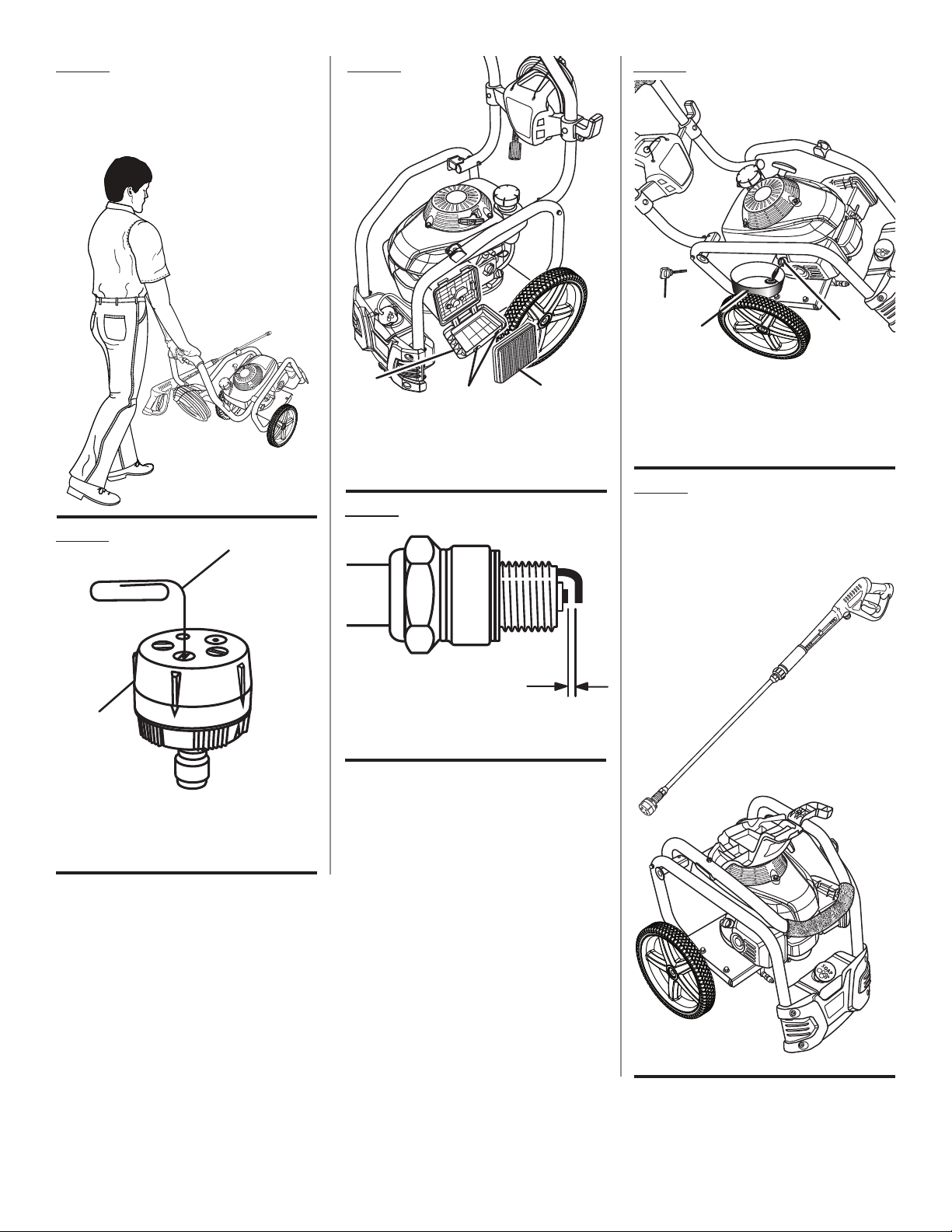

TO MOVE THE PRESSURE WASHER

POUR DÉPLACER L’ÉQUIPEMENT

PARA MOVER LA MÁQUINA

Fig. 22

Fig. 24

SOAP

Fig. 21

B

SOAP

A

C

A - Air filter cover (couvercle du filtre à air,

tapa del filtro de aire)

B - Air filter (filtre à air, filtro de aire)

C - Tabs (ergots, orejetas)

B

Fig. 23

A

A

C

A - Oil cap / dipstick (bouchon/jauge d’huile,

tapa del aceite con varilla de nivel)

B - Oil fill hole (orifice de remplissage d’huile,

agujero de llenado de aceite)

C - Container (récipient, recipiente)

B

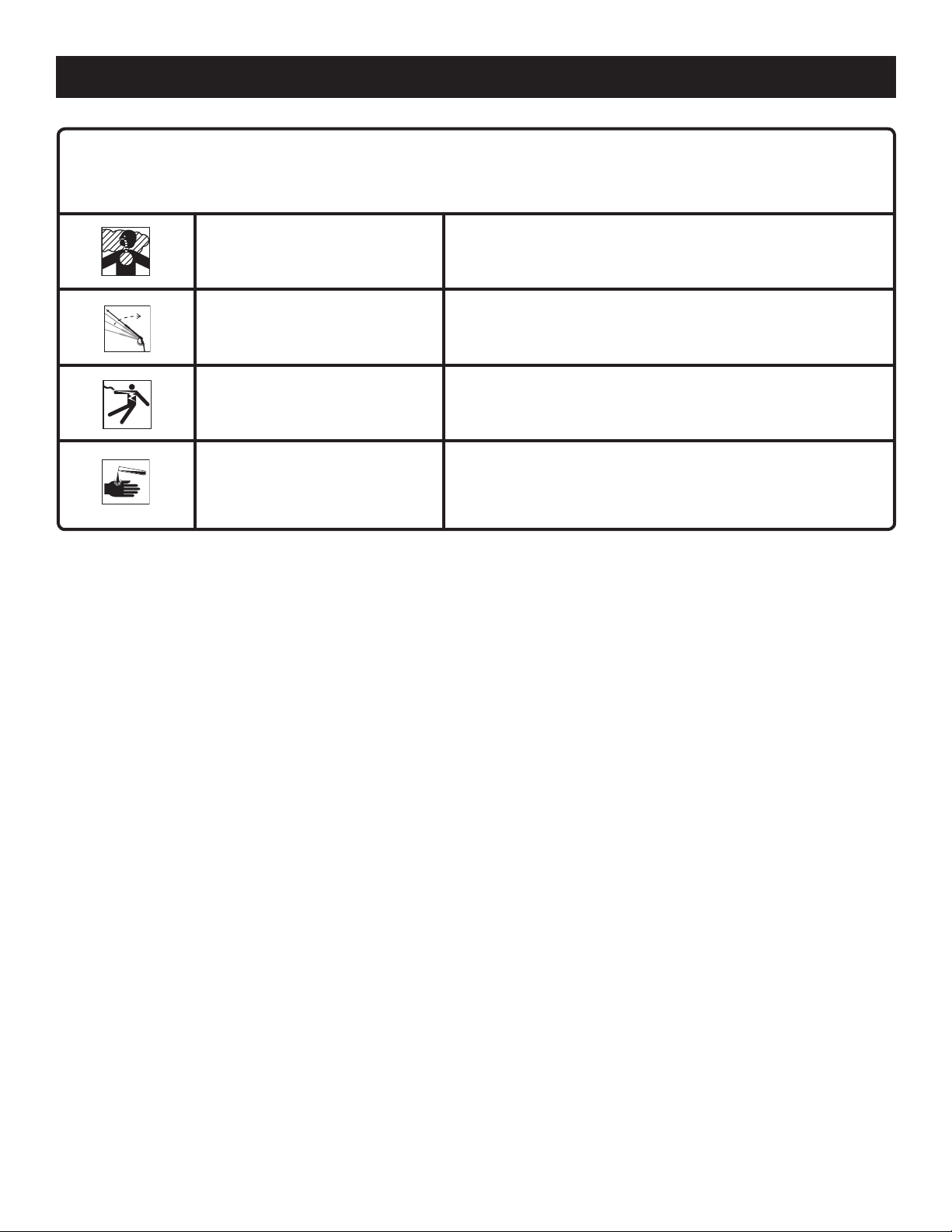

Fig. 25

TO STORE THE MACHINE

POUR REMISER L’ÉQUIPEMENT

PARA GUARDAR LA MÁQUINA

A

A - .028 in. - .032 in. (0.7 mm - 0.8 mm)

[0,028 po - 0,032 po (0,7 mm - 0,8 mm)

0,028 pulg. - 0,032 pulg. (0,7 mm - 0,8 mm)]

A - Paper clip (pièces de papier, clips de papel)

B - 5-in-1 change over nozzle (buse à

permutation 5 en 1, boquilla intercambiable

5 en 1)

v

TABLE OF CONTENTS

TABLE DES MATIÈRES / ÍNDICE DE CONTENIDO

Introduction ......................................................................................................................................................................2

Introduction / Introducción

Important Safety Instructions ........................................................................................................................................... 3

Instructions importantes concernant la sécurité / Instrucciones de seguridad importantes

Specific Safety Rules ........................................................................................................................................................ 4

Règles de sécurité particulières / Reglas de seguridad específicas

Symbols .........................................................................................................................................................................5-6

Symboles / Símbolos

Features ............................................................................................................................................................................7

Caractéristiques / Características

Assembly .......................................................................................................................................................................8-9

Assemblage / Armado

Operation ...................................................................................................................................................................10-13

Utilisation / Funcionamiento

Maintenance ..............................................................................................................................................................14-16

Entretien / Mantenimiento

Troubleshooting .............................................................................................................................................................. 17

Dépannage / Solución de problemas

Warranty .........................................................................................................................................................................18

Garantie / Garantía

Parts Ordering and Service ...............................................................................................................................Back Page

Commande de pièces et réparation / Pedidos de piezas y servicio ..................................... Page arrière / Pág. posterior

INTRODUCTION

INTRODUCTION / INTRODUCCIÓN

This product has many features for making its use more pleasant and enjoyable. Safety, performance, and dependability

have been given top priority in the design of this product making it easy to maintain and operate.

* * *

Ce produit offre de nombreuses fonctions destinées à rendre son utilisation plus plaisante et satisfaisante. Lors de la

conception de ce produit, l’accent a été mis sur la sécurité, les performances et la fiabilité, afin d’en faire un outil facile à

utiliser et à entretenir.

* * *

Este producto ofrece numerosas características para hacer más agradable y placentero su uso. En el diseño de este producto

se ha conferido prioridad a la seguridad, el desempeño y la fiabilidad, por lo cual se facilita su manejo y mantenimiento.

2 — English

IMPORTANT SAFETY INSTRUCTIONS

WARNING:

Read and understand all instructions. Failure to follow all

instructions listed below may result in electric shock, fire

and/or carbon monoxide poisoning which will cause death

or serious personal injury.

READ ALL INSTRUCTIONS

Know your tool. Read the operator’s manual carefully.

Learn the machine’s applications and limitations as well

as the specific potential hazards related to this tool.

Keep guards in place and in working order. Never operate

the tool with any guard or cover removed. Make sure all

guards are operating properly before each use.

Remove adjusting keys and wrenches. Form habit of

checking to see that keys and adjusting wrenches are

removed from tool before turning it on.

To reduce the risk of injury, keep children and visitors

away. All visitors should wear safety glasses and be kept

a safe distance from work area.

Keep the area of operation clear of all persons,

particularly small children, and pets.

Do not start or operate the engine in a confined space,

building, near open windows, or in other unventilated

space where dangerous carbon monoxide fumes can

collect. Carbon monoxide, a colorless, odorless, and

extremely dangerous gas, can cause unconsciousness

or death.

Use right tool. Don’t force tool or attachment to do a

job it was not designed for. Don’t use it for a purpose not

intended.

Dress properly. Do not wear loose clothing, gloves,

neckties, or jewelry. They can get caught and draw you

into moving parts. Rubber gloves and nonskid footwear

are recommended when working outdoors. Also wear

protective hair covering to contain long hair.

Do not operate the equipment while barefoot or when

wearing sandals or similar lightweight footwear. Wear

protective footwear that will protect your feet and improve

your footing on slippery surfaces.

Exercise caution to avoid slipping or falling.

Always wear eye protection with side shields marked

to comply with ANSI Z87.1. Following this rule will reduce

the risk of serious personal injury.

Don’t overreach or stand on unstable support. Keep

proper footing and balance at all times.

Use only recommended accessories. The use of

improper accessories may cause risk of injury.

Follow the maintenance instructions specified in this

manual.

Check damaged parts. Before further use of the

or other part that is damaged should be carefully checked

to determine that it will operate properly and perform its

intended function. Check for alignment of moving parts,

binding of moving parts, breakage of parts, mounting,

and any other conditions that may affect its operation.

A guard or other part that is damaged must be properly

repaired or replaced by an authorized service center to

avoid risk of personal injury.

Never leave tool running unattended. Turn power off.

Don’t leave tool until it comes to a complete stop.

Keep the engine free of grass, leaves, or grease to

reduce the chance of a fire hazard.

Keep the exhaust pipe free of foreign objects.

Follow manufacturer’s recommendations for safe

loading, unloading, transport, and storage of

machine.

Be thoroughly familiar with controls. Know how to stop

the product and bleed pressure quickly.

Keep tool dry, clean, and free from lubricant and

grease. Always use a clean cloth when cleaning. Never use

brake fluids, gasoline, petroleum-based products, or any

solvents to clean tool.

Stay alert and exercise control. Watch what you are

doing and use common sense. Do not operate tool when

you are tired. Do not rush.

Do not operate the product while under the influence

of drugs, alcohol, or any medication.

Check the work area before each use. Remove all

objects such as rocks, broken glass, nails, wire, or string

which can be thrown or become entangled in the

machine.

Do not use tool if switch does not turn it off. Have

defective switches replaced by an authorized service

center.

Before cleaning, repairing, or inspecting, shut off the

engine and make certain all moving parts have stopped.

Disconnect the spark plug wire, and keep the wire away

from the plug to prevent accidental starting.

Avoid dangerous environment. Don’t use in damp or

wet locations or expose to rain. Keep work area well

lit.

Never use in an explosive atmosphere. Normal

sparking of the motor could ignite fumes.

Do not operate while smoking or near an open flame.

Do not operate around dry brush, twigs, cloth rags, or

other flammable materials.

WARNING: Risk of injection or injury – Do not direct

discharge stream at persons.

tool, a guard

3 — English

SPECIFIC SAFETY RULES

Use caution when positioning the pressure washer for

use. Warm air from the engine could cause discolored

spots on grass.

Never direct a water stream toward people or pets,

or any electrical device.

Before starting any cleaning operation, close doors

and windows. Clear the area to be cleaned of debris,

toys, outdoor furniture, or other objects that could create

a hazard.

Never pick up or carry a machine while the engine is

running.

Never start the machine if ice has formed in any part

of the equipment.

Do not use acids, alkalines, solvents, flammable

material, bleaches, or industrial grade solutions

in this product. These products can cause physical

injuries to the operator and irreversible damage to the

machine.

Always operate the machine on a level surface. If the

engine is on an incline, it could seize due to improper

lubrication (even at the maximum lubricant level).

WARNING: High pressure jets can be dangerous if

subject to misuse. The jet must not be directed at

persons, animals, electrical devices, or the machine

itself.

Hold the handle and wand securely with both hands.

Expect the trigger handle to move when the trigger is

pulled due to reaction forces. Failure to do so could cause

loss of control and injury to yourself and others.

Never attempt to make any adjustments while the

engine (motor) is running (except where specifically

recommended by the manufacturer).

Protective covers must always cover rotating parts

when the engine is running.

Keep cooling air intake (recoil starter area) and muffler

side of the engine at least 3 feet away from buildings,

obstructions, and other combustible objects.

Keep the engine away from flammables and other

hazardous materials.

Keep away from hot parts. The muffler and other engine

parts become very hot; use caution.

Do not touch the spark plug and ignition cable when

starting and operating the engine.

Check fuel hoses and joints for looseness and fuel

leakage before each use.

Check bolts and nuts for looseness before each use.

A loose bolt or nut may cause serious engine problems.

Always refuel outdoors. Never refuel indoors or in a

poorly ventilated area.

Never store the machine with fuel in the fuel tank

inside a building where ignition sources are present,

such as hot water and space heaters, clothes dryers,

and the like.

If the fuel tank has to be drained, do this outdoors.

To reduce the risk of fire and burn injury, handle fuel

with care. It is highly flammable.

Do not smoke while handling fuel.

Add fuel before starting the engine. Never remove the

cap of the fuel tank or add fuel while the engine is running

or when the engine is hot.

Loosen fuel cap slowly to release pressure and to keep

fuel from escaping around the cap.

Replace all fuel tank and container caps securely.

Wipe spilled fuel from the unit. Move 30 feet away from

refueling site before starting engine.

If fuel is spilled, do not attempt to start the engine but

move the machine away from the area of spillage and

avoid creating any source of ignition until fuel vapors

have dissipated.

Never attempt to burn off spilled fuel under any

circumstances.

Before storing, allow the engine to cool and drain fuel

from the unit.

Store fuel in a cool, well-ventilated area, safely away

from spark and/or flame-producing equipment.

Store fuel in containers specifically designed for this

purpose.

Empty fuel tank and restrain the unit from moving

before transporting in a vehicle.

When servicing use only identical replacement parts.

Use of any other parts may create a hazard or cause

product damage.

ONLY use cold water.

Make sure minimum clearance of 3 feet is maintained

from combustible materials.

Never spray close to the surface to be cleaned as you

can damage the surface.

After stopping the engine, always pull the trigger on

the trigger handle to relieve stored pressure in the high

pressure hose. Failure to do so could result in serious

personal injury.

For outdoor use only.

Ensure the high pressure hose is properly connected

before using the product.

Save these instructions. Refer to them frequently and

use them to instruct other users. If you loan someone this

tool, loan them these instructions also.

4 — English

SYMBOLS

The following signal words and meanings are intended to explain the levels of risk associated with this product.

SYMBOL SIGNAL MEANING

DANGER:

WARNING:

CAUTION:

NOTICE:

Some of the following symbols may be used on this product. Please study them and learn their meaning for safe

operation of this product.

Indicates an imminently hazardous situation, which, if not avoided, will result

in death or serious injury.

Indicates a potentially hazardous situation, which, if not avoided, could result

in death or serious injury.

Indicates a potentially hazardous situation, which, if not avoided, may result in

minor or moderate injury.

(Without Safety Alert Symbol) Indicates important information not related to an

injury hazard, such as a situation that may result in property damage.

SYMBOL NAME EXPLANATION

Safety Alert Indicates a potential personal injury hazard.

Read Operator’s Manual

To reduce the risk of injury, user must read and understand

operator’s manual before using this product.

Eye Protection

Wet Conditions Alert Do not expose to rain or use in damp locations.

Hot Surface

Risk of Injections

Risk of Explosion

Risk of Fire

Always wear eye protection with side shields marked to comply

with ANSI Z87.1.

To reduce the risk of injury or damage, avoid contact with any

hot surface.

To reduce the risk of injection or injury, never direct a water

stream towards people or pets or place any body part in the

stream. Leaking hoses and fittings are also capable of causing

injection injury. Do not hold hoses or fittings.

Fuel and its vapors are explosive and can cause severe burns

or death.

Fuel and its vapors are extremely flammable and explosive. Fire

can cause severe burns or death.

5 — English

SYMBOLS

Some of the following symbols may be used on this product. Please study them and learn their meaning for safe

operation of this product.

SYMBOL NAME EXPLANATION

Gas products emit carbon monoxide, an odorless, colorless,

Toxic Fumes

poison gas. Breathing carbon monoxide can cause nausea,

fainting, or death.

Kickback

Electric Shock

Chemical Burns

To reduce the risk of injury from kickback, hold the spray wand

securely with both hands when the machine is on.

Failure to use in dry conditions and to observe safe practices

can result in electric shock.

To reduce the risk of injury or damage, DO NOT USE ACIDS,

ALKALINES, BLEACHES, SOLVENTS, FLAMMABLE MATERIAL,

OR INDUSTRIAL GRADE SOLUTIONS in this product.

6 — English

FEATURES

PRODUCT SPECIFICATIONS

Fuel Tank Capacity ..................................................................................................................................................... 0.96 gal

Honda GCV190 engine..................................................................................................................................................187cc

Maximum Pounds Per Square Inch Pressure* .........................................................................................................3,100 psi

Maximum Gallons Per Minute* ...................................................................................................................................2.5 gpm

Maximum Inlet Water Temperature ................................................................................................................................104˚F

*Max. rating determined by PWMA Standard 101

KNOW YOUR PRESSURE WASHER

See Figure 1.

The safe use of this product requires an understanding of

the information on the tool and in this operator’s manual as

well as a knowledge of the project you are attempting. Before

use of this product, familiarize yourself with all operating

features and safety rules.

5-IN-1 CHANGE OVER NOZZLE

The 5-in-1 Change Over Nozzle makes it easy to change

spray patterns.

AUTOMATIC DETERGENT INJECTION SYSTEM

Pour pressure washer detergent into the detergent tank to

apply detergent quickly and easily to your cleaning project.

Use of the soap nozzle will activate the detergent injector

at a 20:1 dilution ratio.

FUEL TANK

This fuel tank has a maximum capacity of 0.96 gal. Use

unleaded automotive gasoline in the engine.

HONDA GCV190 ENGINE

This Honda engine enables the pressure washer to achieve

3,100 psi (pounds per square inch) at a rate of 2.5 gpm

(gallons per minute). Please read the engine manual included

with this product.

HOSE STORAGE

Once the high pressure hose is rolled, hang it on the back

of the machine using the stretch strap to secure in place.

IDLE DOWN

The engine idle speed is automatically reduced when the

trigger is released. This feature increases fuel efficiency,

reduces the noise level, and decreases wear and tear over

the life of the pressure washer.

ON/OFF SWITCH

The on/off switch is used in combination with the starter

grip and rope to start the engine. It is also used to turn the

engine off.

STARTER GRIP AND ROPE

The starter grip and rope is pulled to start the machine.

THERMAL RELIEF VALVE

This pump feature will prevent water temperatures from

reaching harmful levels by releasing a small amount of

water. Once the water has drained, the thermal relief valve

will reset itself.

TRIGGER HANDLE

The trigger handle has a gripping surface that provides

added control of the spray wand and helps reduce fatigue.

TRIGGER WITH LOCK OUT

Pulling the trigger releases a stream of water for high

pressure cleaning. The lock out provides protection against

unauthorized use.

7 — English

ASSEMBLY

UNPACKING

This product requires assembly.

Carefully remove the product and any accessories from

the box. Make sure that all items listed in the packing list

are included.

NOTE: This tool is heavy. To avoid back injury, lift with

your legs, not your back, and get help when needed.

WARNING:

Do not use this product if any parts on the Packing List

are already assembled to your product when you unpack

it. Parts on this list are not assembled to the product by

the manufacturer and require customer installation. Use

of a product that may have been improperly assembled

could result in serious personal injury.

Inspect the tool carefully to make sure no breakage or

damage occurred during shipping.

Do not discard the packing material until you have carefully

inspected and satisfactorily operated the tool.

If any parts are damaged or missing, please call

1-800-860-4050 for assistance.

PACKING LIST

Pressure Washer

25 ft. High Pressure Hose

Trigger Handle Holder

Spray Wand Holder

Screw (3)

Nut (3)

Trigger Handle

Spray Wand

5-in-1 Change-Over Nozzle

Washer

4-Cycle Engine Lubricant (SAE 30 or SAE 10W30)

Disposable Funnel

High Pressure Hose Storage

Operator’s Manual

WARNING:

If any parts are damaged or missing do not operate this

product until the parts are replaced. Use of this product

with damaged or missing parts could result in serious

personal injury.

WARNING:

To prevent accidental starting that could cause serious

personal injury, always disconnect the engine spark plug

wire from the spark plug when assembling parts.

TOOLS NEEDED

See Figure 2.

The following tools (not included or drawn to scale) are

needed for assembly:

Combination Wrench or Adjustable Wrench

Phillips Screwdriver

RAISING AND LOWERING THE HANDLE

See Figure 3.

To raise the handle: pull the handle up until the handle

release knob snaps through the locking hole to secure

the handle in place.

To lower the handle: pull the handle release knob out then

lower the handle to the position shown in figure 3.

INSTALLING TRIGGER HANDLE HOLDER,

SPRAY WAND HOLDER, AND HOSE STORAGE

See Figure 4 - 5.

Raise handle as described in the Raising and Lowering

Handle section.

Place hose storage onto the handle as shown.

Align the holes in the hose storage with the holes in the

handle.

Insert screw through the holes in the left side of the handle

and hose storage.

Place hex nut onto screw and tighten securely.

Place the trigger handle holder onto the handle as shown.

Align the holes in the trigger handle holder with the holes

in the hose storage and the handle.

Insert screw through the holes in handle, hose storage,

and trigger handle holder.

Slide washer onto screw. Then, place nut onto screw and

tighten securely.

Place spray wand holder onto pressure washer frame.

Align the holes in the spray wand holder with the holes

in the pressure washer frame.

Insert screw through the holes in the spray wand holder

and the pressure washer frame.

Place nut onto screw and tighten securely.

WARNING:

Do not attempt to modify this product or create

accessories not recommended for use with this product.

Any such alteration or modification is misuse and could

result in a hazardous condition leading to possible serious

personal injury.

8 — English

ASSEMBLING THE TRIGGER HANDLE

See Figure 6.

Place the threaded end of the spray wand in the connector

on the end of the trigger handle.

Turn the connector clockwise until it stops. This secures

the spray wand in place.

ASSEMBLY

CONNECTING HIGH PRESSURE HOSE TO

TRIGGER HANDLE

See Figure 7.

Screw the collar on the high pressure hose into the trigger

handle inlet coupler by turning the hose collar clockwise.

Tighten securely.

NOTE: Be careful to avoid cross-threading, which can

cause the trigger handle to leak during use.

Pull on the hose to be certain it is properly secured.

CONNECTING THE HIGH PRESSURE HOSE TO

THE PUMP

See Figure 8.

Completely uncoil and straighten the high pressure hose

to prevent kinks.

NOTE: See Using the High Pressure Hose in Operation

for more information about using the high pressure hose.

Align the collar on the threaded nipple on the pump.

Insert the nozzle on the end of the high pressure hose

collar into the threaded nipple.

Turn the collar clockwise to tighten the hose securely to

the pump.

NOTE: Be careful to avoid cross-threading, which can

cause the hose to leak during use.

Pull on the hose to be certain it is properly secured.

CONNECTING THE GARDEN HOSE TO THE

PRESSURE WASHER

See Figure 9.

The water supply must come from a water main. NEVER use

hot water or water from pools, lakes, etc. Before connecting

the garden hose to the pressure washer:

Run water through the hose for 30 seconds to clean any

debris from the hose.

Inspect the screen in the water intake.

If the screen is damaged, do not use the machine until

the screen has been replaced.

If the screen is dirty, clean it before connecting the garden

hose to the machine.

To connect the garden hose to the machine:

Completely uncoil the garden hose or remove completely

from reel to prevent kinks.

NOTE: There must be a minimum of 10 feet of unrestricted

hose between the pressure washer intake and the hose

faucet or shut off valve (such as a “Y” shut off connector).

With the hose faucet turned completely off, attach the

end of the garden hose to the water intake. Tighten by

hand.

NOTICE:

Do not run the pressure washer pump without water

supply connected and turned on, as this may damage the

high pressure seals and decrease pump life. Completely

unwind the hose from its reel or coil and make sure the

hose is not being restricted by tires, rocks, or any other

objects that may lessen or prevent water flow to the

pressure washer.

NOTICE:

Always observe all local regulations when connnecting

hoses to the water main. Some areas have restrictions

against connecting directly to public drinking water

supply to prevent the feedback of chemicals into the

drinking water supply. Direct connection through a

receiver tank or backflow preventer is usually permitted.

DO NOT OVERTILT THE UNIT!

9 — English

OPERATION

WARNING:

Do not allow familiarity with this product to make you

careless. Remember that a careless fraction of a second is

sufficient to inflict serious injury.

WARNING:

Always wear eye protection with side shields marked to

comply with ANSI Z87.1. Failure to do so could result in

objects being thrown into your eyes resulting in possible

serious injury.

WARNING:

Do not use any attachments or accessories not

recommended by the manufacturer of this product. The use of

attachments or accessories not recommended can result

in serious personal injury.

WARNING:

Never direct a water stream toward people or pets, or

any electrical device. Failure to heed this warning could

result in serious injury.

NOTICE:

This product is not equipped with a spark arrestor and

cannot be used on U.S. forest lands; in addition, product

users must comply with Federal, State, and local fire prevention regulations. Check with appropriate authorities.

Refer to accompanying engine manual for maintenance

and replacement parts.

APPLICATIONS

You may use this tool around the house for cleaning most

small to large horizontal or vertical exterior surfaces, smaller

exterior objects and structures, and outdoor equipment and

tools.* You can:

Clean or remove mold and mildew from weathered decks,

driveways, patios, walkways, sidewalks, etc.

Remove dirt from various exterior vertical surfaces such

as house exteriors, siding, fences, brick, concrete or stone

walls, etc.

Wash boats, outdoor furniture, powered or non-powered

garden equipment, gutters, window screens, grills,

playground equipment, etc.

*Always test in an inconspicuous area first.

ADDING/CHECKING ENGINE LUBRICANT

See Figure 10.

NOTE: This machine has been shipped with approximately

2 oz. of lubricant in the engine from testing. You must add

lubricant to the engine before starting it the first time.

NOTICE:

Any attempt to start the engine without adding lubricant

will result in engine failure.

To add engine lubricant:

Place pressure washer on a flat, level surface. Do not tilt.

Unscrew the oil cap / dipstick by turning counter-

clockwise.

Using 4-stroke engine lubricant (SAE 30 or SAE 10W30),

add engine lubricant until the fluid level rises to the upper

portion of the hatched area on the dipstick (12 oz., 4-cycle

engine lubricant provided). Do not overfill.

Replace the oil cap / dipstick and securely tighten.

To check the engine lubricant level:

Place pressure washer on a flat, level surface. Do not tilt.

Unscrew the oil cap/dipstick by turning counterclockwise.

Wipe dipstick clean and re-seat in hole; do not rethread.

Remove dipstick again and check lubricant level. Lubricant

level should fall within the hatched area on the dipstick.

If level is low, add engine lubricant until the fluid level rises

to the upper portion of the hatched area on the dipstick.

Replace and secure the oil cap/dipstick.

NOTICE:

Any attempt to start the engine without adding lubricant

will result in engine failure.

OXYGENATED FUELS

NOTICE:

Do not use E15 or E85 fuel (or fuel containing greater

than 10% ethanol) in this product. It is a violation of

federal law and will damage the unit and void your

warranty.

Fuel system damage or performance problems resulting

from the use of an oxygenated fuel containing more than

the percentage of oxygenates stated below are not covered

under warranty.

Ethanol. Gasoline containing up to 10% ethanol by volume

(commonly referred to as E10) is acceptable. E15 and E85

are not.

10 — English

OPERATION

ADDING GASOLINE TO THE FUEL TANK

See Figure 11.

WARNING:

Gasoline and its vapors are highly flammable and

explosive. To prevent serious personal injury and property

damage, handle gasoline with care. Keep away from

ignition sources, handle outdoors only, do not smoke

while adding fuel, and wipe up spills immediately.

When adding gas to the pressure washer, make sure the unit

is sitting on a flat, level surface. If the engine is hot, let the

pressure washer cool before adding gas. ALWAYS fill the

fuel tank outdoors with the machine turned off.

NOTE: This is a 4-cycle engine. DO NOT mix fuel and

lubricant together.

Mix fuel stabilizer with gasoline according to fuel stabilizer

manufacturer’s directions.

Before removing the fuel cap, clean the area around it.

Remove the fuel cap.

Insert a clean funnel into the fuel tank then slowly

pour gasoline into the tank. Fill tank to approximately

1-1/2 in. below the top of the tank neck (this allows for

fuel expansion).

Replace fuel cap and tighten until the cap “clicks”.

Clean up any spills before starting the engine.

STARTING AND STOPPING THE PRESSURE

WASHER

See Figures 12 - 13.

To start the engine:

Turn the fuel valve to the ON position.

Pull choke out to the START position.

NOTE: If restarting after a brief stop (i.e., after refueling

or moving), leave the choke lever in the RUN position.

Put the on/off switch in the ON position.

Grasp the starter grip and rope and pull slowly until

resistance is felt. Give the starter grip and rope a short,

brisk pull to start the engine.

NOTE: Do not allow the starter grip and rope to snap

back after starting; return it gently to its original place.

Let engine run for several seconds, then push choke in

to the RUN position.

To stop the engine:

Put the on/off switch in the OFF position.

Turn the fuel valve to the OFF position.

Shut off the water supply and pull trigger to release water

pressure.

WARNING:

While operating and storing, keep at least 3 feet of

clearance on all sides of this product, including overhead.

Allow a minimum of 30 minutes of “cool down” time

before storage. Keep all body parts, clothing, combustible

materials, and hoses away from the muffler. Heat created

by muffler and exhaust gases could be hot enough to

cause serious burns, ignite combustible objects, and/

or damage high pressure hoses that can result in an

injection injury.

NOTICE:

Do not run the pressure washer pump without water

supply connected and turned on, as this may damage the

high pressure seals and decrease pump life. Completely

unwind the hose from its reel or coil and make sure the

hose is not being restricted by tires, rocks, or any other

objects that may lessen or prevent water flow to the

pressure washer.

Before starting the engine:

Connect all hoses.

NOTE: Make sure the pressure washer’s water intake

screen is in place and unclogged before connecting

garden hose.

Check all fluids (lubricant and gas).

Turn on the garden hose then squeeze the trigger to

relieve air pressure; hold the trigger until a steady stream

of water appears.

NOTE: Make sure the faucet is turned on fully and that

there are no kinks or leaks in the hose.

11 — English

USING THE SPRAY WAND TRIGGER

See Figure 14.

For greater control and safety, keep both hands on the trigger

handle at all times.

Pull back and hold the trigger to operate the pressure

washer.

Release the trigger to stop the flow of water through the

nozzle.

To engage the lock out:

Push up on the lock out until it clicks into the slot.

To disengage the lock out:

Push the lock out down and into its original position.

To use the spray wand, start with the nozzle 1-2 ft. away

from the cleaning surface. Carefully approach the surface

just until the desired level of cleaning is achieved. If the spray

is too close it can damage the cleaning surface.

OPERATION

INSTALLING/REMOVING NOZZLE

See Figure 15.

WARNING:

NEVER change nozzles without locking the lock out on

the trigger handle and NEVER point the wand at your

face or at others. The quick-connect feature contains

small springs that could eject the nozzle with some force.

Failure to heed this warning could cause personal injury.

To connect the nozzle to the trigger handle:

Turn off the pressure washer and shut off the water supply.

Pull trigger to release water pressure.

Engage the lock out on the trigger handle by pushing up

on the lock out until it clicks into the slot.

Push the nozzle into the quick-connect collar until it clicks

in place and is secured properly.

To disconnect the nozzle from the trigger handle once

the cleaning job is complete:

Turn off the pressure washer and shut off the water

supply. Pull trigger to release water pressure.

Engage the lock out on the trigger handle by pushing up

on the lock out until it clicks into the slot.

Remove the nozzle by placing hand over nozzle then

pulling back the quick-connect collar.

USING THE 5-IN-1 CHANGE OVER NOZZLE

See Figure 16.

There are five spray pattern settings located on the 5-in-1

Change Over Nozzle. To select a spray pattern, rotate the

spray selector to the desired setting. Refer to the Nozzle

Selection Guide for more information about which setting

to choose.

USING THE HIGH PRESSURE HOSE

The high pressure hose features an outer covering that

provides strength to the hose. If the outer covering becomes

damaged, the hose must be replaced immediately. Do

not use a high pressure hose if the outer covering is

damaged.

To prevent damage to the outer covering:

Inspect the hose before every use.

Fully unwrap and straighten hose before use.

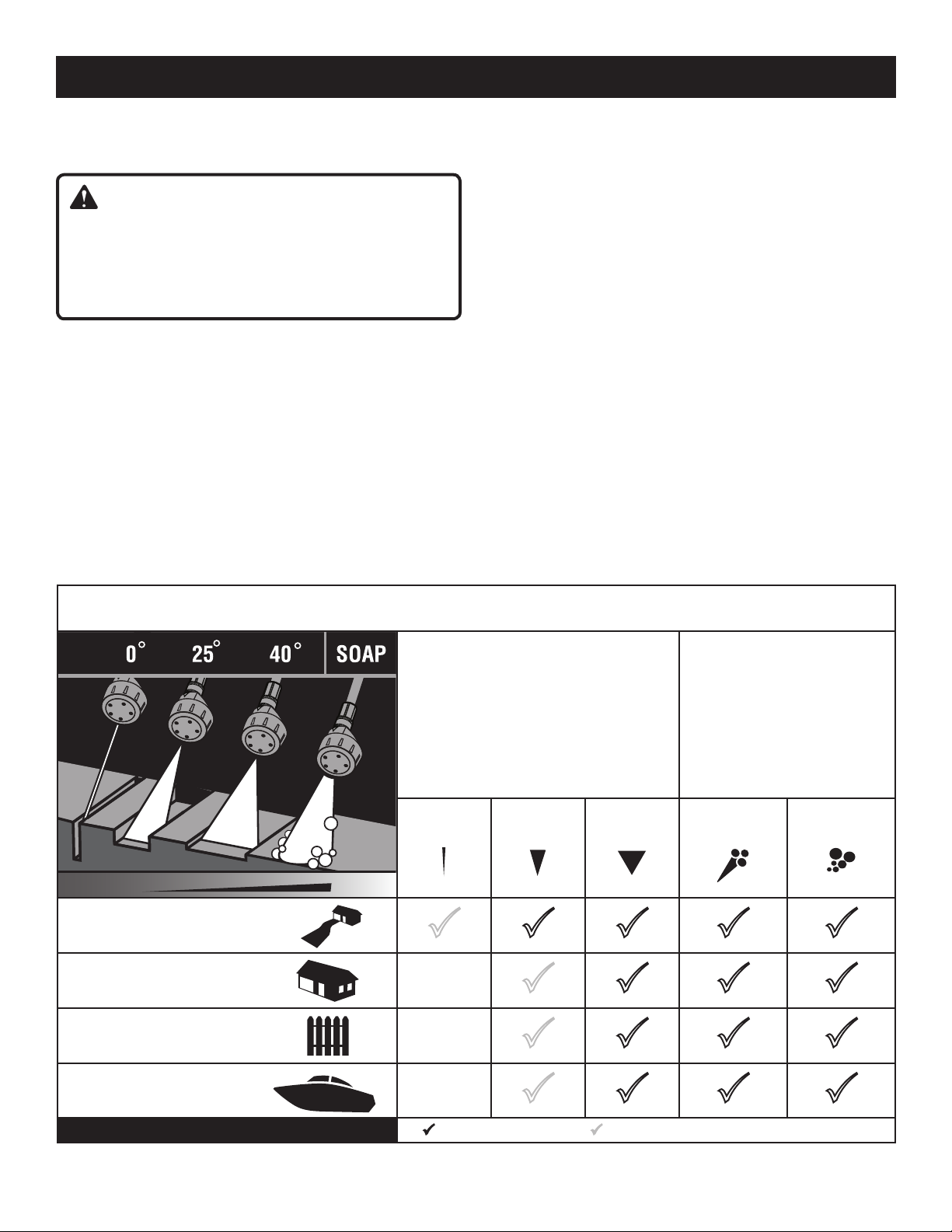

NOZZLE SELECTION GUIDE

ABRASIVE GENTLE

Concrete, Brick, Masonry

Siding, Gutters, House

Fencing, Deck, Patio

HIGH PRESSURE

(NO SOAP WHEN USING THESE NOZZLES)

0º

25º 40º

LOW PRESSURE

(FOR SOAP OR

GENTLE RINSE)

Long Range

Short Range

Lawn Equipment, Boat, RV

Recommended Nozzle Use With Caution for Certain Applications

12 — English

OPERATION

Do not allow the high pressure hose to be kinked.

Keep hose away from hot surfaces and sharp edges.

Do not pull unit by high pressure hose.

Do not allow hose to be crushed or wrapped around

objects.

WASHING WITH DETERGENT

See Figures 17 - 19.

As sold, this unit is designed for use with “downstream”

pressure washer detergents. To convert for use with

“upstream” detergents, contact an authorized customer

service center for more information.

USE ONLY DETERGENTS DESIGNED FOR PRESSURE

WASHERS; Do not use household detergents, acids,

alkalines, bleaches, solvents, flammable material, or

industrial grade solutions, which can damage the pump.

Many detergents may require mixing prior to use. Prepare

cleaning solution as instructed on the solution bottle. Always

test in an inconspicuous area before beginning.

Remove the cap from the detergent tank and pour pressure

washer detergent in the tank. Replace cap on tank.

NOTE: The machine setting of this unit is 20:1, which

usually allows the use of 1 gallon pressure washer

detergent without further dilution. Check your detergent

instructions to be sure additional dilution is not necessary.

Install 5-in-1 Change Over Nozzle (if necessary). Rotate

the spray selector on the nozzle to either the blue short

range detergent ( ) or blue long range detergent ( )

setting.

Squeeze the trigger and wait approximately 5 seconds

for the detergent to appear.

Spray the detergent on a dry surface using long, even,

overlapping strokes. To prevent streaking, do not allow

detergent to dry on the surface.

For long range detergent application:

With the nozzle installed on the spray wand and the engine

shut off, rotate the spray selector to the long range detergent

[ ] setting.

For short range detergent application:

With the nozzle installed on the spray wand and the engine

shut off, rotate the spray selector to the short range detergent

[ ] setting.

Before shutting off the engine:

Fill the detergent tank with clean water.

Spray the clear water through the spray wand until the

tank is empty.

If any soap remains in the spray, repeat with a second

tank of clean water.

Shut off the engine.

NOTE: Shutting OFF ( O ) the engine WILL NOT relieve

pressure in the system. Pull trigger to release water

pressure.

RINSING WITH THE PRESSURE WASHER

Turn off the pressure washer and shut off the water supply.

Pull trigger to release water pressure.

Engage the lock out on the trigger handle by pushing up

on the lock out until it clicks into the slot.

Select the right nozzle setting for the job. See the chart

on the previous page for selecting the appropriate nozzle

setting.

When using these settings, test a small area first to avoid

surface damage.

Start at the top of the area to be rinsed and work down,

overlapping the strokes.

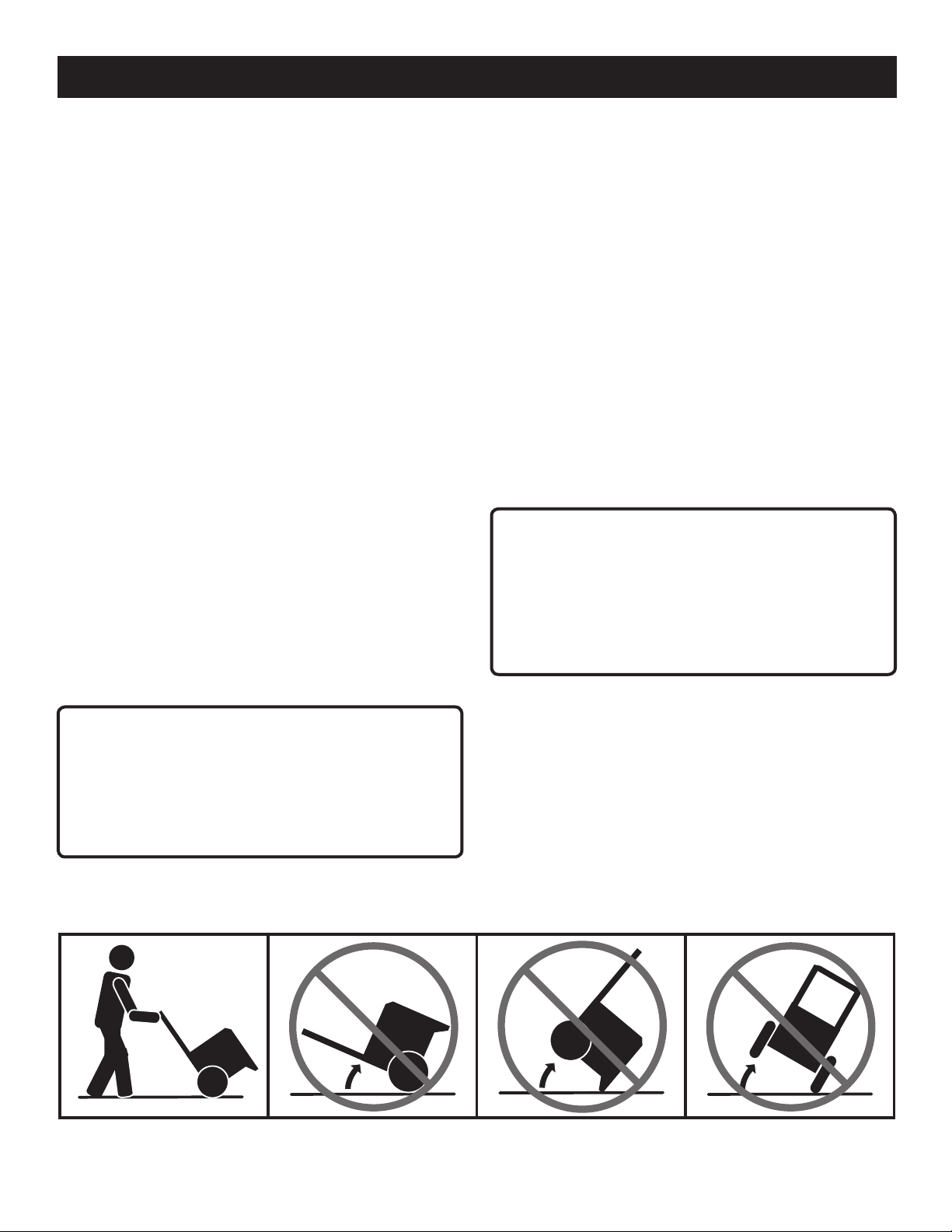

MOVING THE PRESSURE WASHER

See Figure 20.

NOTE: Never lift or carry this product using the handle and

never place the unit in any position other than upright on

its wheels.

Turn the pressure washer off and ensure the fuel valve is

closed.

Pull the handle up until the handle release knob snaps into

the locking position (if not already up and locked). Ensure

the lock is secured in the frame hole before moving.

Tilt the machine toward you slightly until it balances on

the wheels then roll the machine to the desired position.

Do not tilt forward or sideways when moving.

DO NOT attempt to move the unit by pulling on any of

the hoses.

HIGH ALTITUDE OPERATION

Specific modifications are needed for high-altitude operation.

Please contact your authorized service center for important

information regarding these modifications. Operating this

engine without the proper altitude modification may increase

the engine’s emissions and decrease fuel economy and

performance.

13 — English

Loading...

Loading...