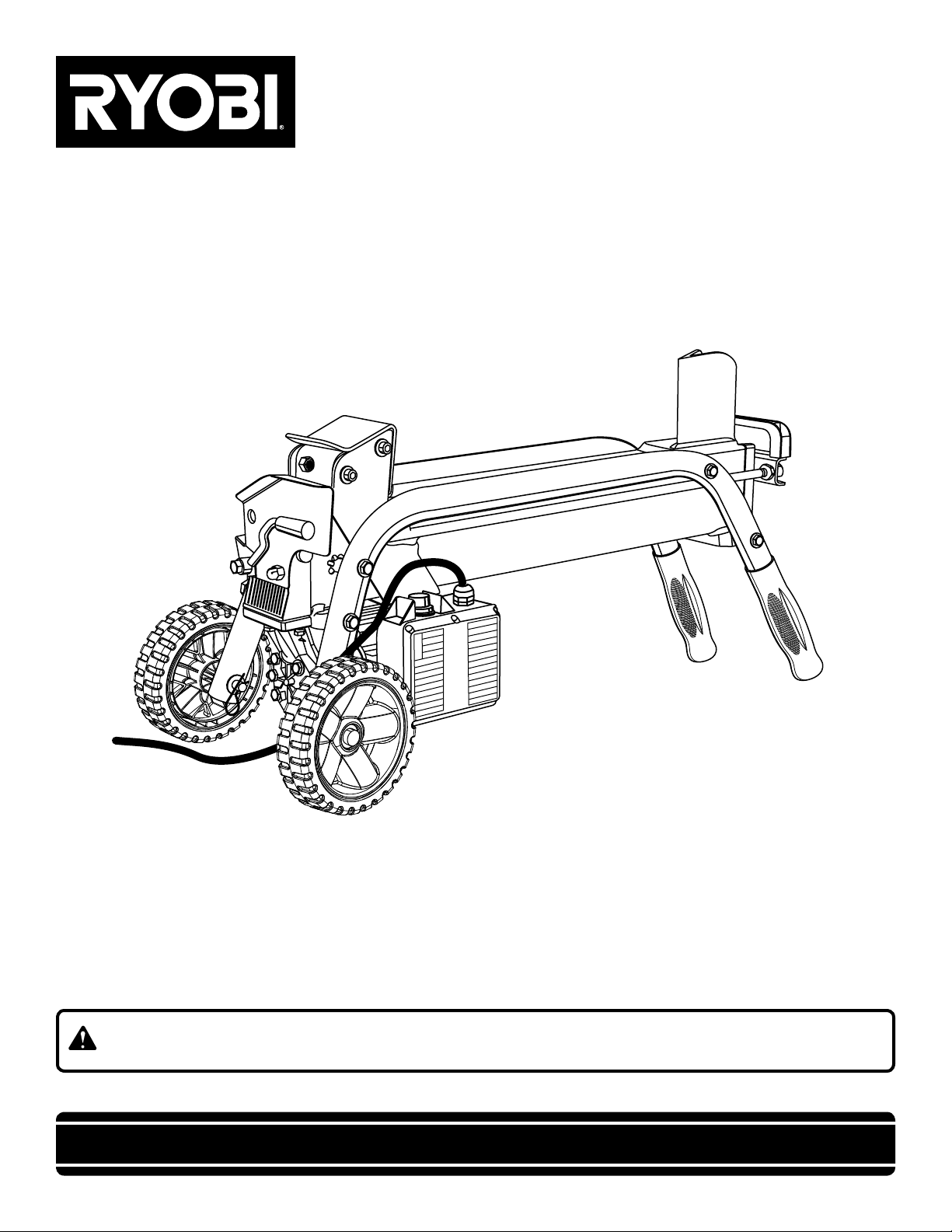

Page 1

OPERATOR’S MANUAL

ELECTRIC LOG SPLITTER

RY49701

Your Log Splitter has been engineered and manufactured to Ryobi’s high standard for dependability, ease of operation, and

operator safety. When properly cared for, it will give you years of rugged, trouble-free performance.

WARNING: To reduce the risk of injury, the user must read and understand the operator's manual before using

this product.

Thank you for buying a Ryobi product.

SAVE THIS MANUAL FOR FUTURE REFERENCE

Page 2

TABLE OF CONTENTS

n Introduction ...................................................................................................................................................................... 2

�n General Safety Rules.....................................................................................................................................................3-4

�n Specific Safety Rules........................................................................................................................................................4

��n Symbols.........................................................................................................................................................................5-6

��n Electrical........................................................................................................................................................................... 7

��n Features............................................................................................................................................................................ 8

��n Assembly.......................................................................................................................................................................... 9

�n Operation...................................................................................................................................................................10-12

�n Maintenance................................................................................................................................................................... 13

n Troubleshooting .............................................................................................................................................................. 14

�n Parts Ordering / Service................................................................................................................................................. 16

INTRODUCTION

This tool has many features for making its use more pleasant and enjoyable. Safety, performance, and dependability have

been given top priority in the design of this product making it easy to maintain and operate.

2

Page 3

GENERAL SAFETY RULES

WARNING:

Read and understand all instructions. Failure to follow

all instructions listed below, may result in electric shock,

fire and/or serious personal injury.

READ ALL INSTRUCTIONS

n KNOW YOUR POWER TOOL. Read the operator’s

manual carefully. Learn the applications and limitations as

well as the specific potential hazards related to this tool.

n G UARD AGA INST EL E CTRI C AL SHOC K BY

PREVENTING BODY CONTACT WITH GROUNDED

SURFACES. For example: pipes, radiators, ranges,

refrigerator enclosures.

n KEEP GUARDS IN PLACE and in good working order.

n REMOVE ADJUSTING KEYS AND WRENCHES. Form

habit of checking to see that keys and adjusting wrenches

are removed from tool before turning it on.

n KEEP WORK AREA CLEAN. Cluttered areas and benches

invite accidents. DO NOT leave tools or pieces of wood

on the tool while it is in operation.

n DO NOT USE IN DANGEROUS ENVIRONMENTS. Do

not use power tools in damp or wet locations or expose

to rain. Keep the work area well lit.

n KEEP CHILDREN AND VISITORS AWAY. All visi-

tors should wear safety glasses and be kept a safe

distance from work area. Do not let visitors contact

tool or extension cord while operating.

n MAKE WORKSHOP CHILDPROOF with padlocks,

master switches, or by removing starter keys.

n DON’T FORCE THE TOOL. It will do the job better and

safer at the feed rate for which it was designed.

n USE THE RIGHT TOOL. Do not force the tool or attach-

ment to do a job for which it was not designed.

n USE THE PROPER EXTENSION CORD. Make sure your

extension cord is in good condition. Use only a cord heavy

enough to carry the current your product will draw. An

undersized cord will cause a drop in line voltage resulting in

loss of power and overheating. A wire gauge size (A.W.G.)

of at least 14 is recommended for an extension cord 25

feet or less in length. If in doubt, use the next heavier

gauge. The smaller the gauge number, the heavier the cord.

n DRESS PROPERLY. Do not wear loose clothing, neckties,

or jewelry that can get caught and draw you into moving

parts. Rubber gloves and nonskid footwear are recommended when working outdoors. Also wear protective

hair covering to contain long hair.

n ALWAYS WE AR SAF ETY GLASSES WITH SIDE

SHIELDS. Everyday eyeglasses have only impact-

resistant lenses, they are NOT safety glasses.

n SECURE WORK. Use clamps or a vise to hold work

when practical, it is safer than using your hand and

frees both hands to operate the tool.

n DO NOT OVERREACH. Keep proper footing and

balance at all times.

n MAINTAIN TOOLS WITH CARE. Keep tools sharp

and clean for better and safer performance. Follow instructions for lubricating and changing accessories.

n DISCONNECT TOOLS. When not in use, before servic-

ing, or when changing attachments, blades, bits, cutters,

etc., all tools should be disconnected from power source.

n AVOID ACCIDENTAL STARTING. Be sure switch is off

when plugging in any tool.

n USE RECOMMENDED ACCESSORIES. Consult the

operator’s manual for recommended accessories. The

use of improper accessories may result in injury.

n NEVER STAND ON TOOL. Serious injury could occur if

the tool is tipped.

n CHECK DAMAGED PARTS. Before further use of the

tool, a guard or other part that is damaged should be

carefully checked to determine that it will operate properly

and perform its intended function. Check for alignment

of moving parts, binding of moving parts, breakage of

parts, mounting and any other conditions that may affect

its operation. A guard or other part that is damaged must

be properly repaired or replaced by an authorized service

center to avoid risk of personal injury.

n USE THE RIGHT DIRECTION OF FEED. Feed work into

a blade, cutter, or sanding spindle against the direction

or rotation of the blade, cutter, or sanding spindle only.

n NEVER LEAVE TOOL RUNNING UNATTENDED. TURN

THE POWER OFF. Don't leave tool until it comes to a

complete stop.

n PROTECT YOUR LUNGS. Wear a face or dust mask if

the cutting operation is dusty.

n PROTECT YOUR HEARING. Wear hearing protection

during extended periods of operation.

n DO NOT ABUSE CORD. Never carry tool by the cord or

yank it to disconnect from receptacle. Keep cord from

heat, oil, and sharp edges.

n USE OUTDOOR EXTENSION CORDS. When tool

is used outdoors, use only extension cords with

approved ground connection that are intended for use

outdoors and so marked.

n NEVER USE IN AN EXPLOSIVE ATMOSPHERE.

Normal sparking of the motor could ignite fumes.

n INSPECT TOOL CORDS PERIODICALLY. If dam-

aged, have repaired by a qualified service technician at

an authorized service facility. The conductor with insulation

having an outer surface that is green with or without yellow

stripes is the equipment-grounding conductor. If repair

or replacement of the electric cord or plug is necessary,

do not connect the equipment-grounding conductor to a

live terminal. Repair or replace a damaged or worn cord

immediately. Stay constantly aware of cord location and

keep it well away from the rotating blade.

n INSPECT EXTENSION CORDS PERIODICALLY and

replace if damaged.

n KEEP TOOL DRY, CLEAN, AND FREE FROM OIL AND

GREASE. Always use a clean cloth when cleaning. Never

use brake fluids, gasoline, petroleum-based products, or

any solvents to clean tool.

n STAY ALERT AND EXERCISE CONTROL. Watch what

you are doing and use common sense. Do not operate

tool when you are tired. Do not rush.

3

Page 4

GENERAL SAFETY RULES

n DO NOT USE TOOL IF SWITCH DOES NOT TURN IT

ON AND OFF. Have defective switches replaced by an

authorized service center.

n DO NOT OPERATE A TOOL WHILE UNDER THE

INF LUENC E O F DR UGS, ALCO HOL, OR ANY

MEDICATION.

n ALWAYS carry the tool only by the carrying handle.

n USE ONLY RECOMMENDED ACCESSORIES listed

in this manual or addendums. Use of accessories that

are not listed may cause the risk of personal injury.

Instructions for safe use of accessories are included

with the accessory.

n TOOL SERVICE MUST BE PERFORMED ONLY BY

QUALIFIED REPAIR PERSONNEL. Service or mainte-

nance performed by unqualified personal could result in

a risk of injury.

SPECIFIC SAFETY RULES

n DO NOT ALLOW anyone to operate the log splitter who

has not read the operator’s manual or has not been

instructed on the safe use of the splitter.

n NEVER ALLOW CHILDREN OR UNTRAINED ADULTS

TO OPERATE THIS MACHINE.

n IF SOMEONE is helping load logs to be split, DO NOT

start the machine until that person is clear of the area.

n NEV ER ALL OW ANY ONE TO RIDE O N THE

MACHINE

n �NEVER TRANSPORT ANYTHING OR ANYONE ON THE

LOG SPLITTER.

n �HIGH FLUID PRESSURES ARE DEVELOPED IN HY-

DRAULIC LOG SPLITTERS. Pressurized hydraulic fluid

escaping through a pin hole opening can puncture skin

and cause severe blood poisoning. Heed the following

instructions at all times:

a) Do not operate the machine with frayed, kinked,

cracked, or damaged hoses, fittings, or tubing.

b) Stop the engine and relieve hydraulic system pressure

before changing or adjusting fittings, hoses, tubing,

or other system components.

c) Do not adjust the pressure settings of the pump or value.

d) Never use your hand. Leaks can be located by

passing cardboard or wood over the suspected area.

Look for discoloration. If injured by escaping fluid,

see a doctor at once. Serious infection or reaction can

develop if proper medical treatment is not adminis-

tered immediately.

n KEEP THE OPERATOR ZONE and adjacent area clear

for safe, secure footing.

n

LOG SPLITTERS SHOULD BE USED ONLY for splitting

wood. DO NOT use for other purposes unless the manu-

facturer provides attachments and instructions.

n MAKE SURE THE LOG SPLITTER is on a level surface.

Block the splitter as required to prevent unintended move-

ment.

n ALWAYS OPERATE the splitter from the manufacturer’s

indicated operator zone.

.

n WHEN SERVICING use only identical replacement parts.

Use of any other parts may create a hazard or cause

product damage.

n ALWAYS STAY ALERT! Do not allow familiarity (gained

from frequent use of your tool) to cause a careless mistake. ALWAYS REMEMBER that a careless fraction of

a second is sufficient to inflict severe injury.

n MAKE SURE THE WORK AREA HAS AMPLE LIGHTING

to see the work and that no obstructions will interfere with

safe operation BEFORE performing any work using your

tool.

n ALWAYS TURN OFF THE TOOL before disconnecting it

to avoid accidental starting when reconnecting to power

supply. NEVER leave the tool unattended while connected

to a power source.

n LOGS TO BE SPLIT ON RAM-TYPE UNITS should be

cut as squarely as possible.

n THE MACHINE OWNER should instruct anyone assisting

him or her in safe log splitting operation.

n ALWAYS operate the log splitter with all safety equip-

ment in place and all controls properly adjusted for safe

operation.

n ALWAYS operate the log splitter at manufacturer’s rec-

ommended speed.

n WHEN LOADING a ram-type log splitter, place your

hands on the sides of the log not at the ends. NEVER

place your hands or any part of your body between a log

and any part of the log splitter.

n ON RAM-TYPE log splitters, NEVER attempt to split

more than one (1) log at a time unless the ram has been

fully extended and a second log is needed to complete

the separation of the first log.

n �ON RAM-TYPE log splitters on which the logs are not

square, the longest portion of the log should be rotated

down and the most square end placed against the ram.

n CLEAR DEBRIS from moving parts but only when the

power source is shut off.

n USE ONLY YOUR HAND TO OPERATE THE LOG

SPLITTER CONTROLS.

n ALWAYS UNPLUG FROM THE POWER SOURCE while

repairing or adjusting the splitter except as recommended

by the manufacturer.

n CIRCUIT CAPACITY AND FUSES:

a) Use only an electrical circuit having adequate capacity

as recommended by the log splitter manufacturer.

b) “Blowing” a fuse or tripping a circuit breaker is usually

a warning that you are overloading the machine or

have too many devices taking power from the circuit,

or both. Do not install a higher capacity fuse!

n LEARN AND UNDERSTAND all controls and the proper

use of the equipment.

n SAVE T HESE I NSTRU CTION S. Ref e r to t hem

frequently and use to instruct other users. If you loan

someone this tool, loan them these instructions also.

4

Page 5

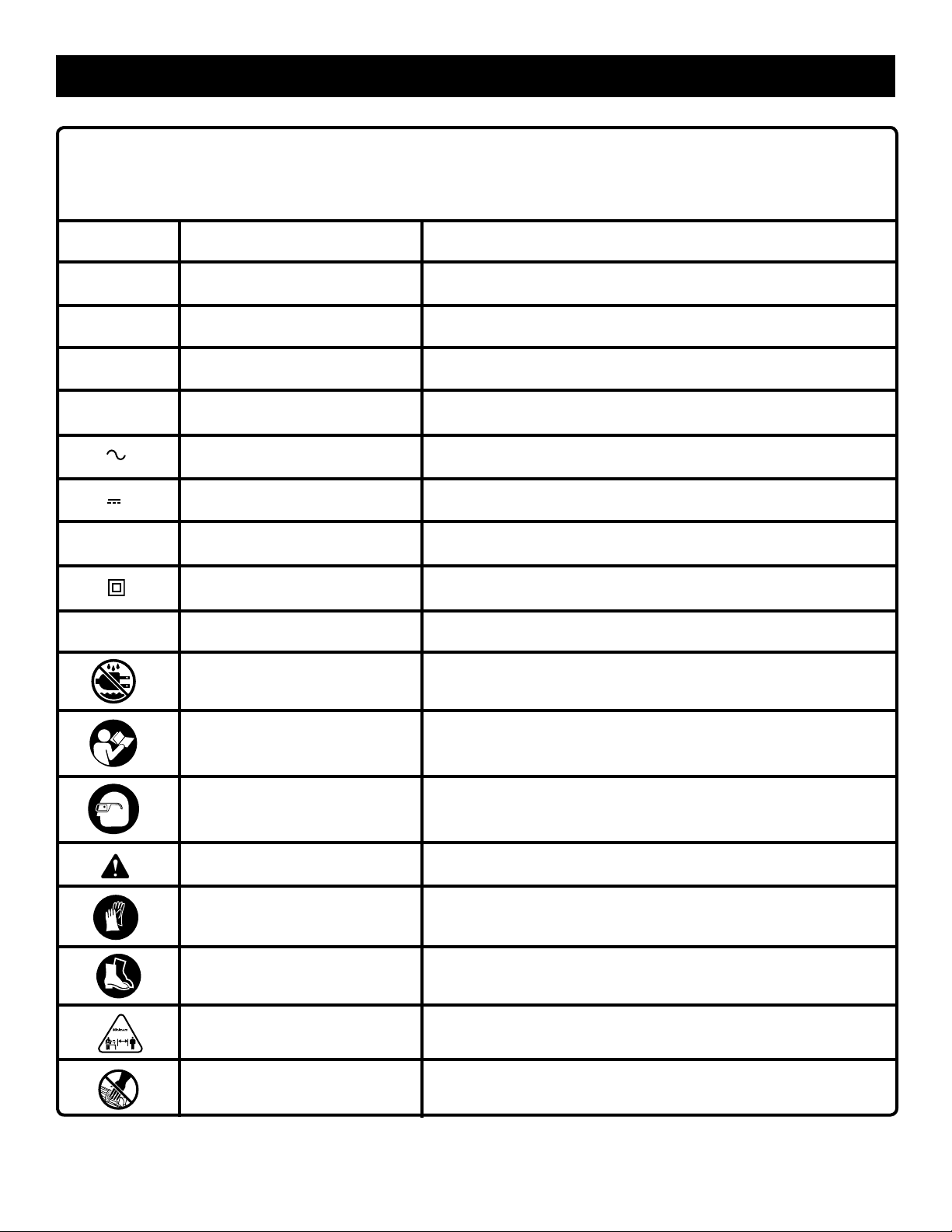

SYMBOLS

10' 3m

Some of the following symbols may be used on this tool. Please study them and learn their meaning. Proper interpretation of these symbols will allow you to operate the tool better and safer.

SYMBOL NAME DESIGNATION/EXPLANATION

V Volts

A Amperes

Hz Hertz

W Watt

min Minutes

Alternating Current

Direct Current

n

o

.../min

No Load Speed

Class II Construction

Per Minute

Wet Conditions Alert

Voltage

Current

Frequency (cycles per second)

Power

Time

Type of current

Type or a characteristic of current

Rotational speed, at no load

Double-insulated construction

Revolutions, strokes, surface speed, orbits etc., per minute

Do not expose to rain or use in damp locations.

Read The Operator’s Manual

Eye Protection

Safety Alert

Wear Gloves

Wear Safety Footwear

Keep Hands Away Always keep hands away from the wedge and the ram.

To reduce the risk of injury, user must read and understand

operator’s manual before using this product.

Always wear safety goggles or safety glasses with side shields

and a full face shield when operating this product.

Precautions that involve your safety.

Always wear nonslip, heavy-duty protective gloves when

operating this product.

Always wear nonslip safety footwear when operating this product.

Always keep bystanders at least 10 ft. (3 m) away.Keep Bystanders Away

5

Page 6

SYMBOLS

The following signal words and meanings are intended to explain the levels of risk associated with this product.

SYMBOL SIGNAL MEANING

DANGER: Indicates an imminently hazardous situation, which, if not avoided, will

result in death or serious injury.

WARNING: Indicates a potentially hazardous situation, which, if not avoided, could

result in death or serious injury.

CAUTION: Indicates a potentially hazardous situation, which, if not avoided, may

result in minor or moderate injury.

CAUTION: (Without Safety Alert Symbol) Indicates a situation that may result in

property damage.

SERVICE

Servicing requires extreme care and knowledge and should

be performed only by a qualified service technician. For

service we suggest you return the product to your nearest

AUTHORIZED SERVICE CENTER for repair. When servicing, use only identical replacement parts.

WARNING:

To avoid serious personal injury, do not attempt to use

this product until you read thoroughly and understand

completely the operator’s manual. Save this operator’s

manual and review frequently for continuing safe operation and instructing others who may use this product.

WARNING:

The operation of any power tool can result in foreign objects being thrown into your eyes, which can

result in severe eye damage. Before beginning power tool operation, always wear safety goggles or

safety glasses with side shields and a full face shield when needed. We recommend Wide Vision Safety

Mask for use over eyeglasses or standard safety glasses with side shields. Always use eye protection

which is marked to comply with ANSI Z87.1.

SAVE THESE INSTRUCTIONS

6

Page 7

ELECTRICAL

EXTENSION CORDS

Use only 3-wire extension cords that have 3-prong grounding plugs and 3-pole receptacles that accept the tool's plug.

When using a power tool at a considerable distance from the

power source, use an extension cord heavy enough to carry

the current that the tool will draw. An undersized extension

cord will cause a drop in line voltage, resulting in a loss of

power and causing the motor to overheat. Use the chart

provided below to determine the minimum wire size required

in an extension cord. Only round jacketed cords listed by

Underwriter's Laboratories (UL) should be used.

**Ampere rating (on tool faceplate)

0-2.0 2.1-3.4 3.5-5.0 5.1-7.0 7.1-12.0 12.1-16.0

Cord Length Wire Size (A.W.G.)

25' 16 16 16 16 14 14

50' 16 16 16 14 14 12

100' 16 16 14 12 10 —

**Used on 12 gauge - 20 amp circuit.

NOTE: AWG = American Wire Gauge

When working with the tool outdoors, use an extension cord

that is designed for outside use. This is indicated by the

letters "WA" on the cord's jacket.

Before using an extension cord, inspect it for loose or

exposed wires and cut or worn insulation.

WARNING:

Keep the extension cord clear of the working area.

Position the cord so that it will not get caught on lumber,

tools or other obstructions while you are working with a

power tool. Failure to do so can result in serious personal

injury.

SPEED AND WIRING

The speed is not constant and decreases under a load

or with lower voltage. For voltage, the wiring in a shop

is as important as the motor’s horsepower rating. A line

intended only for lights cannot properly carry a power

tool motor. Wire that is heavy enough for a short distance

will be too light for a greater distance. A line that can

support one power tool may not be able to support two

or three tools.

GROUNDING INSTRUCTIONS

In the event of a malfunction or breakdown, grounding

provides a path of least resistance for electric current to

reduce the risk of electric shock. This tool is equipped with

an electric cord having an equipment-grounding conductor and a grounding plug. The plug must be plugged into a

matching outlet that is properly installed and grounded in

accordance with all local codes and ordinances.

Do not modify the plug provided. If it will not fit the outlet,

have the proper outlet installed by a qualified electrician.

Improper connection of the equipment-grounding conductor

can result in a risk of electric shock. The conductor with

insulation having an outer surface that is green with or without yellow stripes is the equipment-grounding conductor. If

repair or replacement of the electric cord or plug is necessary, do not connect the equipment-grounding conductor

to a live terminal.

Check with a qualified electrician or service personnel if the

grounding instructions are not completely understood, or if

in doubt as to whether the tool is properly grounded.

Repair or replace a damaged or worn cord immediately.

This tool is intended for use on a circuit that has an outlet

like the one shown in figure 1. It also has a grounding pin

like the one shown.

WARNING:

Check extension cords before each use. If damaged

replace immediately. Never use tool with a damaged cord

since touching the damaged area could cause electrical

shock resulting in serious injury.

ELECTRICAL CONNECTION

This tool is powered by a precision built electric motor. It

should be connected to a power supply that is 120 volts,

60 Hz, AC only (normal household current). Do not operate

this tool on direct current (DC). A substantial voltage drop

will cause a loss of power and the motor will overheat. If

the product does not operate when plugged into an outlet,

double check the power supply.

GROUNDING

PIN

7

COVER OF GROUNDED

OUTLET BOX

Fig. 1

Page 8

FEATURES

PRODUCT SPECIFICATIONS

Hydraulic Cylinder Pressure................................. 2320 psi

Oil Capacity......................................... 118 oz. (3.7 quarts)

Input ................................120 V, 60 Hz, AC only, 15 Amps

Net Weight`......................................................... 101.4 lbs.

Log Capacity Diameter, maximum............................ 10 in.

Log Capacity Diameter, minimum............................... 4 in.

Log Capacity Length .............................................. 20.5 in.

OIL DRAIN BOLT

WITH DIPSTICK

HYDRAULIC CONTROL

LEVER

BLEED SCREW

WEDGE

RAM

WORK TABLE

SIDE

SUPPORTS

KNOW YOUR LOG SPLITTER

See Figure 2.

Before attempting to use this product, familiarize yourself

with all operating features and safety rules.

BLEED SCREW

Loosen the bleed screw to ensure the smooth flow of air in

and out of the oil tank.

HYDRAULIC CONTROL LEVER

Push down on the hydraulic control lever and the ram starts

pushing the log into the wedge.

LIFT HANDLE

The lift handle makes rolling the log splitter from one location

to another simple and easy.

PUSHBUTTON

BOX

ON/OFF

SWITCH

Fig. 2

RESET/OVERLOAD BUTTON

If the motor is overloaded the machine will shut off. Remove

the load and push the reset/overload button to restart the

machine.

OIL DRAIN BOLT WITH DIPSTICK

Oil drain bolt with dipstick makes checking and changing

hydraulic oil easy.

SIDE SUPPORTS

Side supports on each side of the work table keep logs

resting securely on the log splitter.

WORK TABLE

Provides surface to support log prior to splitting operation.

8

Page 9

ASSEMBLY

UNPACKING

This product has been shipped completely assembled.

n Carefully remove the tool and any accessories from the

box. Make sure that all items listed in the packing list are

included.

n Inspect the tool carefully to make sure no breakage or

damage occurred during shipping.

n Do not discard the packing material until you have care-

fully inspected and satisfactorily operated the tool.

n If any parts are damaged or missing, please call

1-800-860-4050 for assistance.

AXLE

PACKING LIST

Log Splitter

Wheel (2)

Hardware Bag

Operator’s Manual

Warranty Registration Card

WARNING:

If any parts are missing do not operate this tool until the

missing parts are replaced. Failure to do so could result

in possible serious personal injury.

WARNING:

Do not attempt to modify this tool or create accessories not recommended for use with this tool. Any such

alteration or modification is misuse and could result in a

hazardous condition leading to possible serious personal

injury.

WASHER

HITCH PIN

Fig. 3

ASSEMBLING THE WHEELS

See Figure 3.

To attach the wheels to the base:

n Locate the axle assembly; remove the hitch pin from the

axle.

n Lift the machine slightly and slip the axle into the wheel

hole.

n Next, slide the washer onto the axle. Still lifting the

machine, slide the axle/wheel/washer combination into

the wheel mounting hole in the machine base as shown

in figure 3.

n �Slide the washer onto the axle. Push the hitch pin into

the hole on the end of the axle to secure the wheel

assembly.

NOTE: The hitch pin should be pushed into the axle until

the center of the pin rests on top of the axle.

n Repeat with the second wheel assembly.

WARNING:

Do not connect to power supply until assembly is

complete. Failure to comply could result in accidental

starting and possible serious personal injury.

WARNING:

Failure to loosen the bleed screw prior to operation of this

product may cause the seals in the hydraulic system to

blow out. Blown seals could cause permanent damage

to the log splitter.

9

Page 10

OPERATION

WARNING:

Do not allow familiarity with tools to make you careless. Remember that a careless fraction of a second is

sufficient to inflict serious injury.

WARNING:

Always wear safety goggles or safety glasses with

side shields when operating this tool. Failure to do

so could result in objects being thrown into your eyes

resulting in possible serious injury.

WARNING:

Do not use any attachments or accessories not

recommended by the manufacturer of this tool. The use

of attachments or accessories not recommended can

result in serious personal injury.

BEFORE USING THE LOG SPLITTER

See Figures 4 - 5.

Never operate the log splitter until the bleed screw

has been slightly loosened (one to two full turns). Air

flow through the bleed screw should be detectable

once the log splitter is started. If no air flow is detected, loosen the screw until the air flow can be felt.

Air must flow in and out of the oil tank during operation to

prevent the seals in the hydraulic system from rupturing.

This tool is designed for home use only. Never split logs

larger than 10 in. diameter or 20-1/2 in. long. Some types

of wood are harder to split than others. If the log splitter is

having trouble splitting a log, never continue to try for longer

than five seconds.

Always check the oil level before you start the log splitter.

To check the oil level:

n Unplug the log splitter.

n Using the lift handle, stand the log splitter on the end with

the wheels (see figure 12).

n Using an 8 mm hex key, remove the oil drain bolt and

wipe the dipstick clean.

n Wipe the dipstick clean then reinsert it back into the oil

tank.

n Remove the dipstick and check to see if the oil level is

between the first and second groove on the dipstick.

n If there is not enough oil in the oil tank, add oil until the

proper level is reached.

n If there is the proper amount of oil in the oil tank, wipe the

dipstick clean then replace it in the oil tank and tighten

the oil drain bolt securely.

NOTE: See “Replacing Hydraulic Oil” in the Maintenance

section for recommended oil or equivalents.

BLEED SCREW

OIL DRAIN BOLT

WITH DIPSTICK

Fig. 4

DIP

STICK

OIL

LINES

Fig. 5

10

Page 11

OPERATION

STARTING THE LOG SPLITTER

See Figures 6 - 7.

n Operator should be positioned at the rear of the log split-

ter as shown in figure 7.

n Place the left hand on the hydraulic control lever and the

right hand on the on/off switch.

n Push down and hold the on/off switch.

n While continuing to hold down the on/off switch, push

down and hold the hydraulic control lever.

NOTE: Both hands are required to start this product. The

combination of both steps starts the ram which pushes

the log into the wedge.

n To stop the splitter, release both controls to return the

ram to the starting position.

NOTE: If only one hand is removed from either the switch

or the lever, the log splitter will freeze in place. When both

the switch and the lever are released, the ram will return to

the starting position.

SPLITTING LOGS

See Figures 8 - 9.

������Always place logs lengthwise on the work table and resting

firmly on the side supports. Place logs flat and in the direction of the grain. Never angle the log to split it or place the

log crosswise on the splitter. Never split more than one log

at a time.

HYDRAULIC

CONTROL

LEVER

ON/OFF SWITCH

Fig. 6

CAUTION:

Never keep pressure on the wood by trying to force the

log splitter for more than five seconds. After five seconds,

the oil will heat and can damage the tool.

n Place log lengthwise and lying flat on the work table.

NOTE: If the log is small, place it against the wedge before

starting the splitter.

n Using the right hand, push down and hold the on/off

switch.

n Push down and hold the hydraulic control lever with the

left hand. With both the lever and the on/off switch acti-

vated, the ram will push the log into the wedge and split

the wood.

n Once the log is split, release both controls to return the

ram to the starting position.

Fig. 7

11

RIGHT

Fig. 8

Page 12

OPERATION

FREEING A JAMMED LOG

See Figures 10 - 11.

n Release both controls.

n After the ram is back at the starting position, insert a

wood wedge under the jammed log.

n Start the log splitter to push the wood wedge completely

under the jammed log.

n If the log is still jammed, repeat the above steps as

needed using a thicker angled wood wedge until the log

is completely freed.

NOTE: Never try to knock the jammed log off the splitter.

Doing so may damage the tool or may cause the log to fly

up and hit someone causing injury.

WEDGE

RIGHT

WEDGE

Fig. 10

WRONG

Fig. 9

RIGHT

Fig. 11

12

Page 13

MAINTENANCE

WARNING:

When servicing, use only identical Ryobi replacement

parts. Use of any other parts may create a hazard or

cause product damage.

WARNING:

Always wear safety goggles or safety glasses with side

shields during power tool operation or when blowing

dust. If operation is dusty, also wear a dust mask.

GENERAL MAINTENANCE

Avoid using solvents when cleaning plastic parts. Most

plastics are susceptible to damage from various types of

commercial solvents and may be damaged by their use. Use

clean cloths to remove dirt, dust, oil, grease, etc.

WARNING:

NOTE: The oil level should be between the two grooves

around the bottom of the dipstick as shown in figure 5.

n Replace oil drain bolt. Tighten securely.

n Dispose old oil at an oil recycling center.

SHARPENING THE WEDGE

After using the log splitter for some time, it may be necessary

to sharpen the wedge. Using a fine-toothed file, smooth any

burrs or crushed areas along the cutting edge.

Do not at any time let brake fluids, gasoline, petroleumbased products, penetrating oils, etc., come in contact

with plastic parts. Chemicals can damage, weaken or

destroy plastic which may result in serious personal

injury.

LUBRICATION

All of the bearings in this tool are lubricated with a sufficient

amount of high grade lubricant for the life of the unit under

normal operating conditions. Therefore, no further lubrication is required.

REPLACING HYDRAULIC OIL

See Figures 12 - 13.

The hydraulic oil in the log splitter needs to be changed

every 150 hours of use.

n Unplug the log splitter.

n Position the log splitter so that the motor end is slightly

higher than the oil drain plug.

n Using an 8 mm hex key, remove the oil drain bolt.

n Drain the hydraulic oil from the oil tank into a four liter

capacity container.

n Once the oil has drained from the oil tank, turn the log

splitter on the end with the wheels.

n Refill the oil tank with fresh hydraulic oil (3.7 quarts or

118 oz.). The following hydraulic oils are recommended:

- SHELL Tellus 22

- MOBIL DTE 11

- ARAL Vitam GF 22

- BP Energol HLP-HM 22

n Place the cleaned dipstick into the oil tank. Remove and

check the oil level.

POSITION IN WHICH TO CHECK OIL LEVEL

Fig. 12

DRAINING OIL FROM OIL TANK

Fig. 13

13

Page 14

TROUBLESHOOTING

PROBLEM POSSIBLE CAUSE SOLUTION

Motor fails to start

Won’t split logs

Log mover jerks and vibrates

Oil leaks around cylinder ram or

from other points

1. Overload Protection Device is

disengaged to protect the log

splitter from being damaged.

1. Log is improperly positioned.

2. The size or hardness of the log

exceeds the machine’s capacity.

3. Wedge cutting edge is blunt.

4. Oil leaks.

5. Unauthorized adjustment was

made on the Maximum Pressure

Limiting Screw. Lower maximum

pressure rating was set.

1. Lack of hydraulic oil and

excessive air in the hydraulic

system.

1. Air sealed in hydraulic system

while operating.

2. Bleed screw is not tightened

before moving the log splitter.

3. Oil drain bolt is not tight.

4. Hydraulic control valve assembly

and/or seal(s) are worn.

1. Push reset button.

1. Refer to Operation section for log

loading.

2. Reduce the log size before splitting.

3. Refer to “Sharpening Wedge” in the

Maintenance section.

4. Locate leak(s). Contact the dealer.

5. Contact the dealer.

1. Check oil level for possible oil

refilling. Contact the dealer.

1. Loosen bleed screw by 3-4 rotations

before operating the log splitter.

2. Tighten the bleed screw before

moving the log splitter.

3. Tighten the oil drain bolt.

4. Contact the dealer.

14

RESET

BUTTON

Fig. 14

Page 15

NOTES

15

Page 16

OPERATOR’S MANUAL

ELECTRIC LOG SPLITTER

RY49701

• SERVICE

Now that you have purchased your tool, should a need ever exist for repair parts or

service, simply contact your nearest Ryobi Authorized Service Center. Be sure to provide

all pertinent facts when you call or visit. Please call 1-800-860-4050 for your nearest Ryobi

Authorized Service Center. You can also check our web site at www.ryobitools.com for a

complete list of Authorized Service Centers.

• MODEL NO. AND SERIAL NO.

The model number of this tool will be found on a plate attached to the housing.

Please record the model number and serial number in the space provided below.

• HOW TO ORDER REPAIR PARTS

When ordering repair parts, always give the following information:

• MODEL NUMBER

• SERIAL NUMBER

RYOBI TECHNOLOGIES, INC.

1428 Pearman Dairy Road, Anderson, SC 29625

Post Office Box 1207, Anderson, SC 29622-1207

RY49701

Phone 1-800-860-4050

www.ryobitools.com

983000-588

11-04

Loading...

Loading...