Page 1

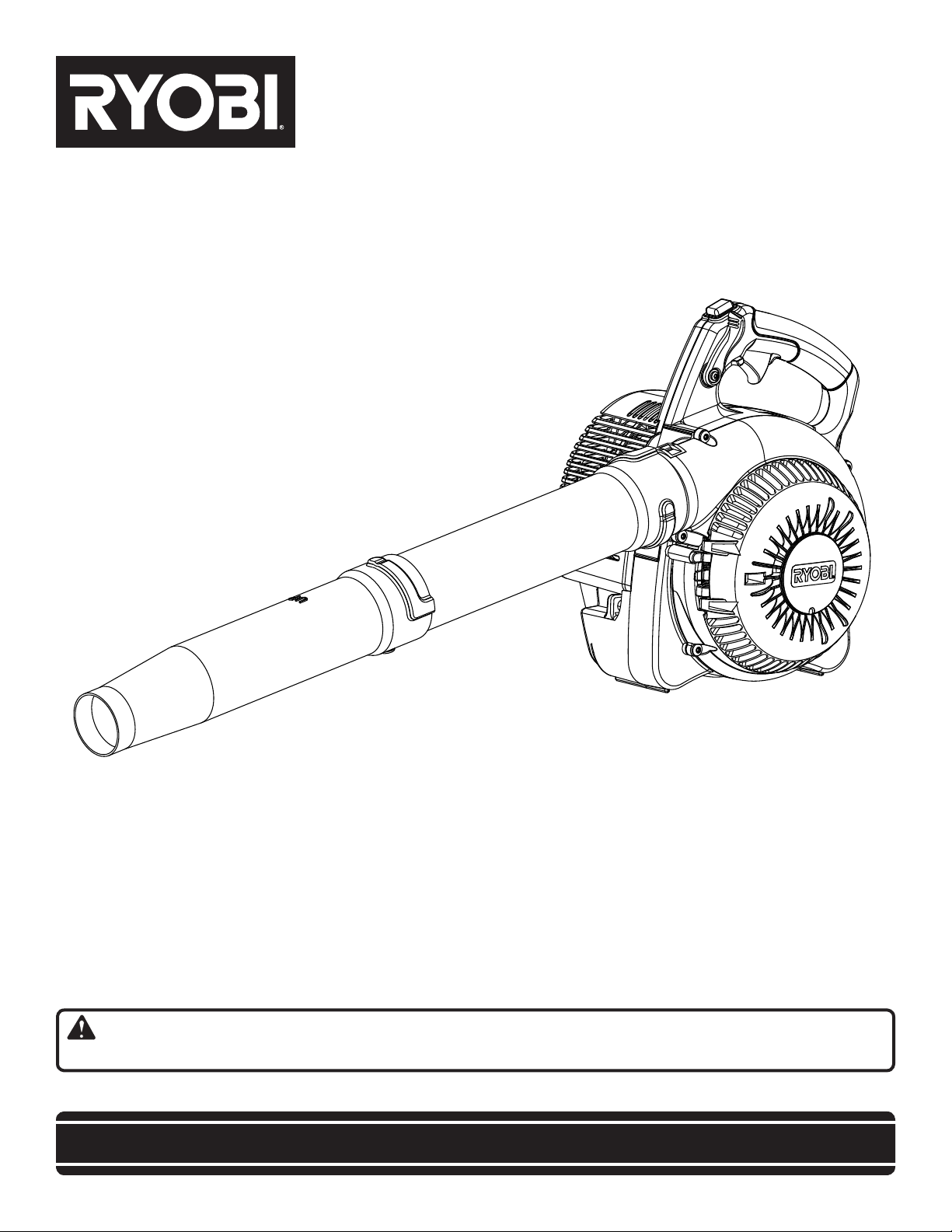

OPERATOR’S MANUAL

BLOWER/VACUUM

RY08554/RY09907

(ALL VERSIONS)

Your blower/vacuum has been engineered and manufactured to our high standard for dependability, ease of operation, and

operator safety. When properly cared for, it will give you years of rugged, trouble-free performance.

WARNING: To reduce the risk of injury, the user must read and understand the operator’s manual before using

this product.

Thank you for your purchase.

SAVE THIS MANUAL FOR FUTURE REFERENCE

Page 2

TABLE OF CONTENTS

Introduction ......................................................................................................................................................................2

General Safety Rules ........................................................................................................................................................ 3

Specific Safety Rules ........................................................................................................................................................4

Symbols .........................................................................................................................................................................5-6

Features .........................................................................................................................................................................7-8

Assembly .....................................................................................................................................................................9-11

Operation ...................................................................................................................................................................12-15

Maintenance ..............................................................................................................................................................15-16

Troubleshooting ..............................................................................................................................................................17

Warranty ...................................................................................................................................................................18-20

Parts Ordering / Service ...................................................................................................................................Back Page

INTRODUCTION

This product has many features for making its use more pleasant and enjoyable. Safety, performance, and dependability

have been given top priority in the design of this product making it easy to maintain and operate.

2

Page 3

GENERAL SAFETY RULES

WARNING:

Read and understand all instructions. Failure to follow

all instructions listed below may result in electric shock,

fire and/or carbon monoxide poisoning which will cause

death or serious personal injury.

Do not allow children or untrained individuals to use this

unit.

Never start or run the engine inside a closed area; breath-

ing exhaust fumes can kill.

Wear eye protection which is marked to comply with ANSI

Z87.1 as well as hearing protection when operating this

equipment.

Keep all bystanders, children, and pets at least 50 feet

away.

Wear heavy long pants, boots, and gloves. Do not wear

loose-fitting clothing, short pants, jewelry of any kind, or

go barefoot.

To reduce the risk of injury associated with objects being

drawn into rotating parts, do not wear loose clothing,

scarves, neck chains, and the like. Secure long hair so it

is above shoulder level to prevent entanglement in any

rotating parts.

Do not operate this unit when you are tired, ill, or under

the influence of alcohol, drugs, or medication.

Do not operate in poor lighting.

Keep all parts of your body away from any moving parts

and all hot surfaces of the unit.

Wear a face filter mask in dusty conditions to reduce the

risk of injury associated with the inhalation of dust.

Check the work area before each use. Remove all objects

such as rocks, broken glass, nails, wire, or string which

can be thrown or become entangled in the machine.

Keep firm footing and balance. Do not overreach. Over-

reaching can result in loss of balance or exposure to hot

surfaces.

Never operate the unit without a spark arrestor screen;

this screen is located inside the muffler.

Product users on United States Forest Service land, and

in some states, must comply with fire prevention regulations. This product is equipped with a spark arrestor;

however, other user requirements may apply. Check with

the federal, state, or local authorities in your area.

Before storing, allow the engine to cool.

Use only

ure to do so may cause poor performance or possible

injury.

Maintain the unit per maintenance instructions in this

operator’s manual.

Inspect the unit before each use for loose fasteners, fuel

leaks, etc. Replace damaged parts.

Ryobi replacement parts and accessories. Fail-

SERVICE

Before cleaning, repairing, or inspecting, shut off the

engine and make certain all moving parts have stopped.

Disconnect the spark plug wire, and keep the wire away

from the plug to prevent starting.

Service on the blower/vacuum must be performed by

qualified repair personnel only. Service or maintenance

performed by unqualified personnel could result in injury

to the user or damage to the product.

Use only identical replacement parts when servicing the

blower/vacuum. Use of unauthorized parts may create

a risk of serious injury to the user, or damage to the

product.

3

Page 4

SPECIFIC SAFETY RULES

Always hold the blower in your right hand. Refer to the

OPERATION

information.

To reduce the risk of hearing loss associated with sound

level(s), hearing protection is required.

To reduce the risk of injury associated with contacting

rotating parts, stop the engine before installing or

removing attachments. Do not operate without guard(s)

in place. Always disconnect the spark plug before

performing maintenance or accessing any movable

parts.

Do not point the blower nozzle in the direction of people

or pets.

Never run the unit without the blower tubes installed.

Never place objects inside the blower tubes.

Use only as directed in this operator’s manual.

Do not operate vacuum without vacuum bag installed;

flying debris could cause serious injury. Always close

vacuum bag completely before operating.

Rotating impeller blades can cause severe injury. Stop

the engine before opening the vacuum door or installing/

changing tubes. Do not put hands or any other object into

the vacuum tubes while they are installed on the unit.

Never run the unit without the proper equipment attached.

When used as a blower, always install the blower tubes.

When used as a vacuum, always install the vacuum tubes

and vacuum bag. Make sure the vacuum bag is completely

zipped when the unit is running to avoid flying debris.

Avoid situations that could catch the vacuum bag on

fire. Do not operate near an open flame. Do not vacuum

warm ash from fireplaces, barbecue pits, brush piles, etc.

Do not vacuum discarded cigars or cigarettes unless the

cinders are completely cool.

instructions later in this manual for additional

REFUELING

Fuel is highly flammable. Take precautions when using

to reduce the chance of serious personal injury.

Store fuel in a cool, well-ventilated area, safely away from

spark and/or flame-producing equipment.

Store fuel in containers specifically designed for this

purpose.

Only refuel outdoors and do not smoke while refueling.

Add fuel before starting the engine. Never remove the cap

of the fuel tank or add fuel while the engine is running or

when the engine is hot.

Do not smoke while handling fuel.

Mix and store fuel in a container approved for gasoline.

Mix fuel outdoors where there are no sparks or flames.

Loosen fuel cap slowly to release pressure and to keep

fuel from escaping around the cap.

Tighten the fuel cap securely after refueling.

Wipe spilled fuel from the unit. Move 30 feet away from

refueling site before starting engine.

Never attempt to burn off spilled fuel under any circum

stances.

To reduce the risk of fire and burn injury, handle fuel with

care. It is highly flammable.

If fuel is spilled, do not attempt to start the engine but

move the machine away from the area of spillage and

avoid creating any source of ignition until fuel vapors

have dissipated.

Replace all fuel tank and container caps securely.

Empty fuel tank and restrain the unit from moving before

transporting in a vehicle.

When draining the fuel tank, use an approved fuel storage

container in a well-ventilated area.

Select bare ground, stop engine, and allow to cool before

refueling.

Save these instructions. Refer to them frequently and use

them to instruct others who may use this tool. If you loan

someone this tool, loan them these instructions also.

-

4

Page 5

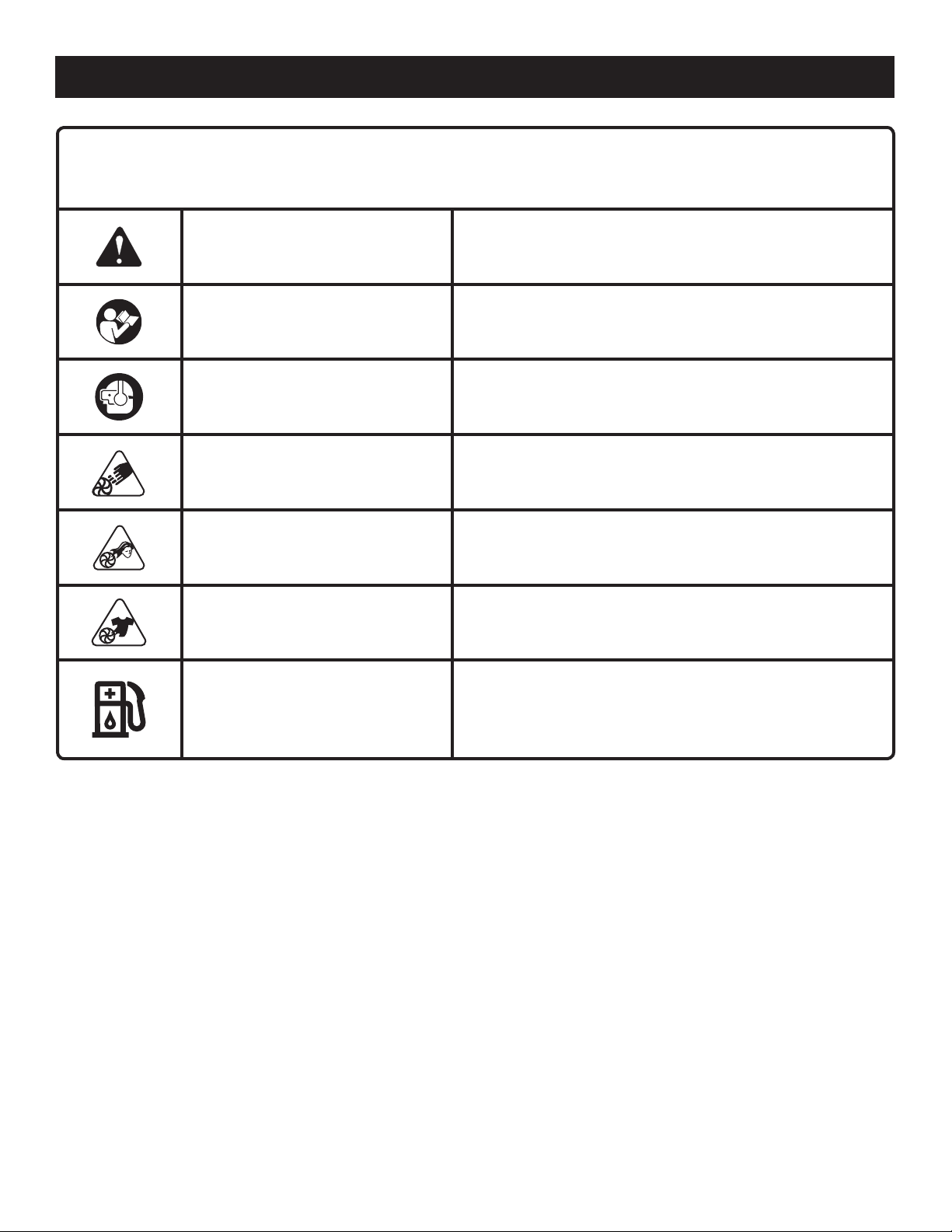

SYMBOLS

Some of the following symbols may be used on this product. Please study them and learn their meaning. Proper

interpretation of these symbols will allow you to operate the product better and safer.

SYMBOL NAME EXPLANATION

Safety Alert Symbol Precautions that involve your safety.

Read the Operator’s Manual

Wear Eye and Hearing Protection

Vacuum Door Do not run unit while vacuum door is unsecured.

Long Hair Risk of long hair being drawn into air inlet.

Loose Clothing Risk of loose clothing being drawn into air intake.

Gasoline and Lubricant

To reduce the risk of injury, user must read and understand

operator’s manual before using this product.

Wear eye protection which is marked to comply with ANSI

Z87.1 as well as hearing protection when operating this

equipment.

Use unleaded gasoline intended for motor vehicle use with

an octane rating of 87 [(R + M) / 2] or higher. This product is

powered by a 2-cycle engine and requires pre-mixing gasoline

and 2-cycle lubricant.

5

Page 6

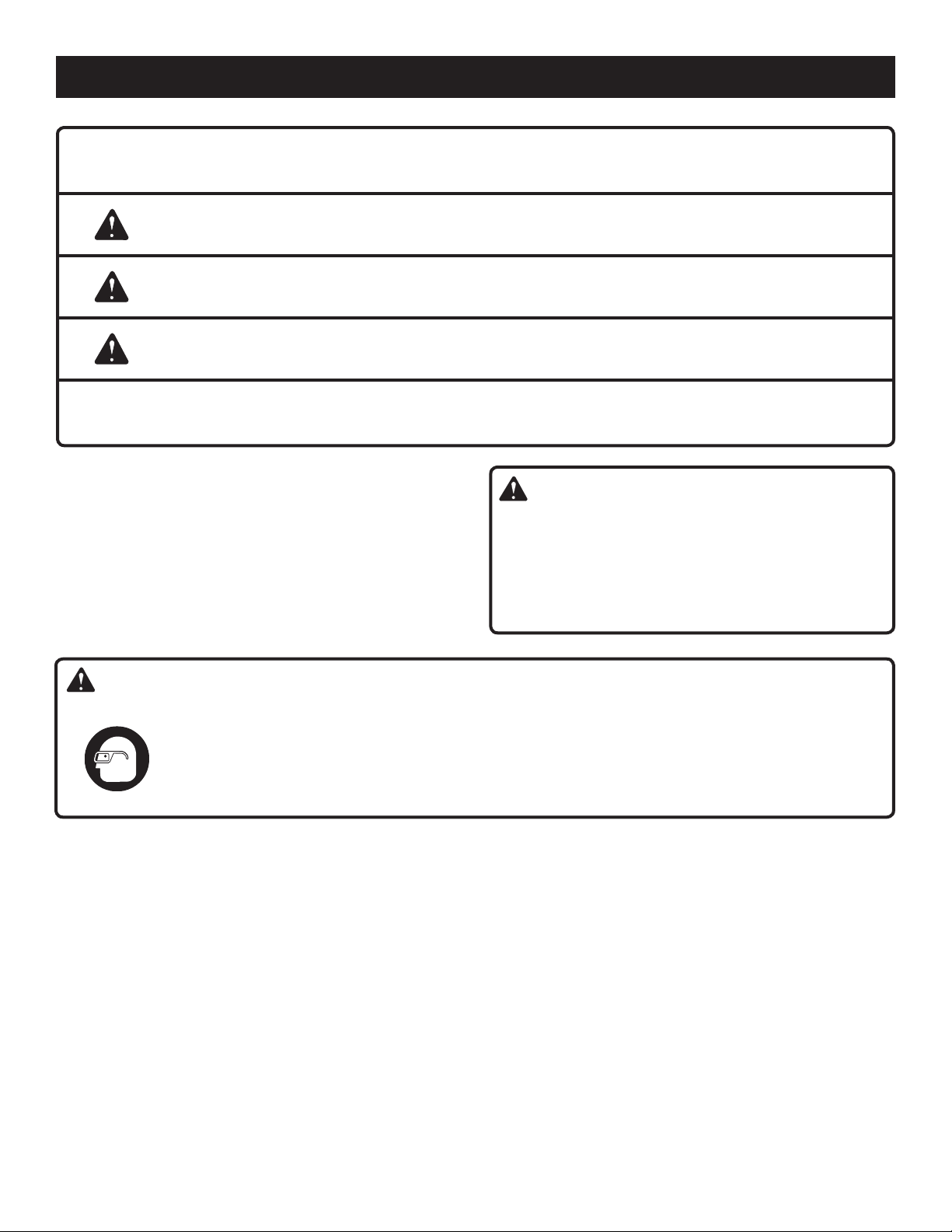

SYMBOLS

The following signal words and meanings are intended to explain the levels of risk associated with this product.

SYMBOL SIGNAL MEANING

DANGER:

WARNING:

CAUTION:

CAUTION:

Indicates an imminently hazardous situation, which, if not avoided, will result

in death or serious injury.

Indicates a potentially hazardous situation, which, if not avoided, could result

in death or serious injury.

Indicates a potentially hazardous situation, which, if not avoided, may result in

minor or moderate injury.

(Without Safety Alert Symbol) Indicates a situation that may result in property

damage.

SERVICE

Servicing requires extreme care and knowledge and should

be performed only by a qualified service technician. For

service we suggest you return the product to your nearest

AUTHORIZED SERVICE CENTER for repair. When

servicing, use only identical replacement parts.

WARNING:

To avoid serious personal injury, do not attempt

to use this product until you read thoroughly and

understand completely the operator’s manual. If you

do not understand the warnings and instructions in the

operator’s manual, do not use this product. Call Ryobi

customer service for assistance.

WARNING:

The operation of any power tool can result in foreign objects being thrown into your eyes, which can

result in severe eye damage. Before beginning power tool operation, always wear safety goggles or

safety glasses with side shields and, when needed, a full face shield. We recommend Wide Vision Safety

Mask for use over eyeglasses or standard safety glasses with side shields. Always use eye protection

which is marked to comply with ANSI Z87.1.

SAVE THESE INSTRUCTIONS

6

Page 7

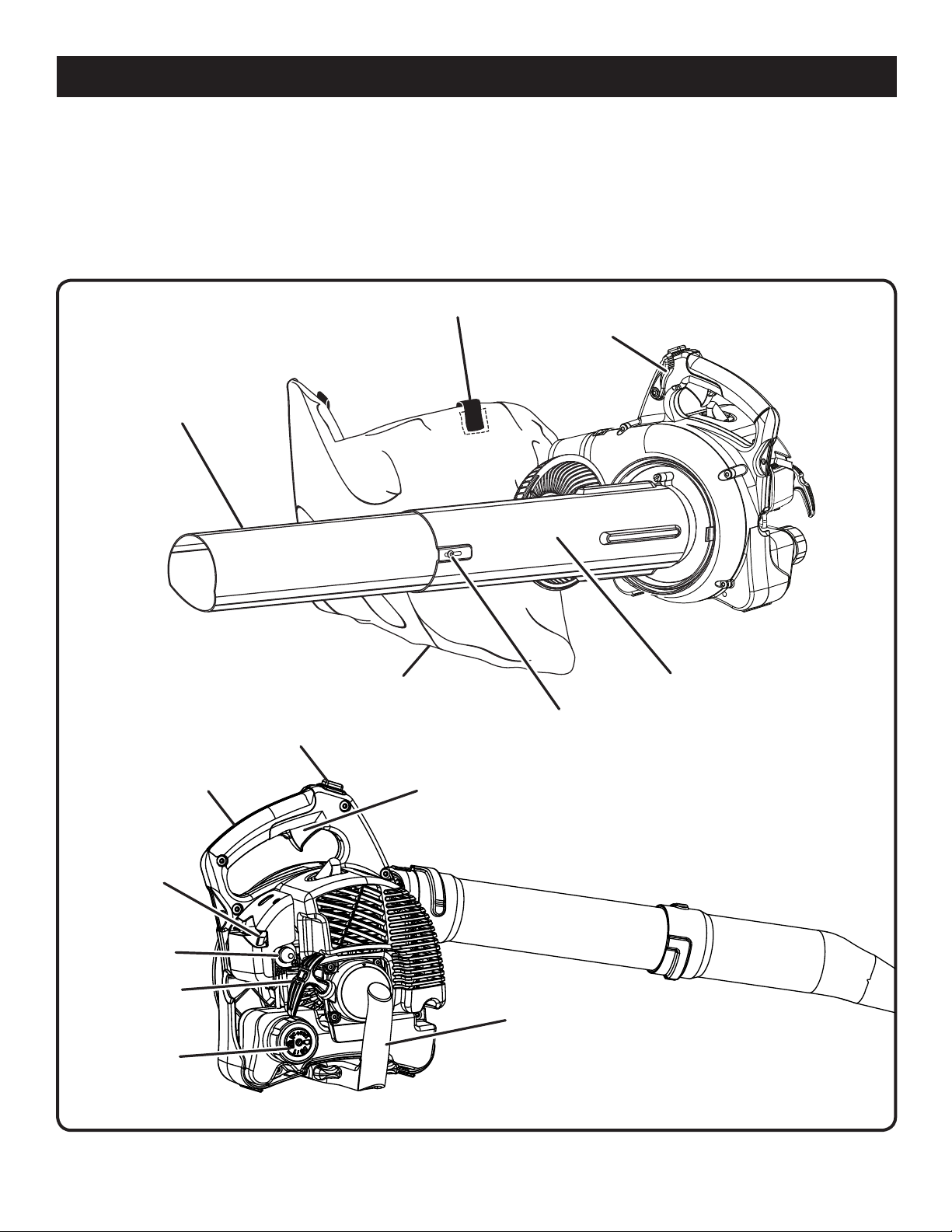

FEATURES

PRODUCT SPECIFICATIONS

Engine Displacement....................................................................................................................................................25.4cc

Air Velocity:

MPH ..................................................................................................................................205 (with high velocity nozzle)

CFM ........................................................................................................................................................

Weight .......................................................................................................................................................................10.4 lbs.

375 (at housing)

loWer

VAcuum Tube

on/oFF SWiTch

ShoulDer STrAp

VAcuum bAG

cruiSe

conTrol

VAcuum

Tube ScreW

upper

VAcuum Tube

upper hAnDle

choke

leVer

primer bulb

STArTer Grip

Fuel cAp

ThroTTle TriGGer

VAcuum hAnDle

Fig. 1a

7

Page 8

hiGh VelociTY noZZle WiTh

WeT leAF ScrAper

SWeeper noZZle

FEATURES

on/oFF SWiTch

ThroTTle TriGGer

cruiSe

conTrol

upper

hAnDle

Door

TAb

KNOW YOUR BLOWER/VACUUM

See Figures 1a - 1b.

The safe use of this product requires an understanding of

the information on the tool and in this operator’s manual as

well as a knowledge of the project you are attempting. Before

use of this product, familiarize yourself with all operating

features and safety rules.

BLOWER TUBE AND NOZZLES

The blower tube can be assembled and installed on the

blower without using any tools.

CRUISE CONTROL

The cruise control feature allows the user to operate the

blower without holding the throttle trigger. To slow the engine,

simply push the cruise control lever forward.

HIGH VELOCITY NOZZLE WITH WET LEAF

SCRAPER

The high velocity nozzle is great for wet sticky leaves. It

allows you to scrape wet leaves or debris while operating

the blower.

MOTOR

The blower has a powerful 25.4cc engine with sufficient

power to handle tough blowing and vacuuming jobs.

upper bloWer

Tube

inleT coVer

Door

Fig. 1b

MULCHER

The blower is equipped with a steel mulching blade that

efficiently reduces leaves at a 12:1 ratio.

SIMPLE START™

The Simple Start allows for easier and quicker starting.

SWEEPER NOZZLE

The sweeper nozzle allows for more area to be covered

during blower operation.

THROTTLE TRIGGER

The blower can be operated at any speed between idle and

full throttle.

VACUUM/MULCHER

Converting the blower to a vacuum/mulcher can be done

without using any tools.

VACUUM BAG

The vacuum bag attaches to the blower easily by using the

vacuum bag adaptor.

VACUUM HANDLE

This feature allows user to perform vacuuming duties

comfortably.

VACUUM TUBES

The vacuum tubes can be installed on the blower without

using any tools.

8

Page 9

ASSEMBLY

UNPACKING

This product requires assembly.

Carefully remove the product and any accessories from

the box. Make sure that all items listed in the packing list

are included.

Inspect the product carefully to make sure no breakage

or damage occurred during shipping.

Do not discard the packing material until you have care-

fully inspected and satisfactorily operated the product.

If any parts are damaged or missing, please call

1-800-860-4050 for assistance.

PACKING LIST

Blower

Upper Blower Tube

Sweeper Nozzle

High Velocity Nozzle

Vacuum Handle

Vacuum Handle Knobs (2)

Grounding Wire

Upper and Lower Vacuum Tubes

Vacuum Tube Screws (2)

Vacuum Bag Assembly

Vacuum Bag Adaptor

2-Cycle Engine Lubricant

Operator’s Manual

NOTE: Read and remove all hang tags and store with your

operator’s manual.

ASSEMBLING THE BLOWER TUBES

See Figure 2.

Align raised tabs on main housing to the slots on upper

tube; slide together and tighten securely by twisting.

Check tightness after initial run and retighten if needed.

To remove the tubes, rotate the tubes to unlock them and

remove from the blower housing outlet.

GROUNDING INSTRUCTIONS

See Figure 3.

Before installing the vacuum handle, connect the grounding

wire as shown. This will help prevent static shock when using

the vacuum in low humidity conditions.

SWeeper noZZle

upper bloWer

Tube

Fig. 2

WARNING:

If any parts are damaged or missing do not operate this

product until the parts are replaced. Failure to heed this

warning could result in serious personal injury.

WARNING:

Do not attempt to modify this product or create accessories not recommended for use with this product. Any

such alteration or modification is misuse and could result

in a hazardous condition leading to possible serious

personal injury.

WARNING:

To prevent accidental starting that could cause serious

personal injury, always disconnect the engine spark plug

wire from the spark plug when assembling parts.

Fig. 3

9

Page 10

ASSEMBLY

INSTALLING THE VACUUM HANDLE

See Figure 4.

Lay unit on side as shown.

Insert vacuum handle into the base of unit.

Secure vacuum handle in place using two knobs as

shown.

VAcuum

hAnDle

VAcuum

hAnDle

knobS

INSTALLING THE VACUUM BAG

See Figures 5 - 6.

Remove the nozzle and upper blower tube from the

blower.

Unzip the vacuum bag and place the adaptor inside as

shown.

Align the raised slots on the bag adaptor with the raised

locking tabs on the blower housing outlet; push the bag

adaptor onto the housing. Twist to lock into place.

Rotate the vacuum bag until the shoulder strap is upright.

Make sure the vacuum bag is zipped and closed before

starting the unit.

ADApTor

Fig. 4

VAcuum bAG

ADApTor inSTAlleD

in VAcuum bAG

rAiSeD

SloT

Fig. 5

rAiSeD

lockinG TAb

Fig. 6

10

Page 11

INSTALLING THE VACUUM TUBES

See Figures 7 - 8.

ASSEMBLY

WARNING:

Rotating impeller blades can cause severe injury. Always

stop the engine before opening the vacuum door or

installing/changing tubes. Do not put hands or any other

object into the vacuum tubes while they are installed on

the unit.

NOTE: This vacuum/blower is equipped with a vacuum door

interlock. If vacuum door is open and vacuum tubes are not

installed, engine will not start.

To install the vacuum tubes:

Secure the upper and lower vacuum tubes together by

aligning the raised locking tabs with the raised slots.

Tap tube assembly on ground until the screw holes in

lower tube are in the raised slot of the upper tube. Secure

with supplied screws.

Depress door tab and open vacuum inlet door.

Align tabs on housing with tube assembly. Insert tube

assembly into vacuum opening. Twist clockwise and lock

the upper vacuum tube into the blower housing.

Tighten screw on upper vacuum tube to secure to blower

housing.

To remove the vacuum tubes:

Twist to loosen the upper vacuum tube by turning

counterclockwise.

Remove the vacuum tube assembly from the blower

housing.

Close the vacuum inlet cover door securely.

VAcuum bAG

ASSemblY

VAcuum

Door hinGe

VAcuum Tube

ASSemblY

VAcuum

inleT Door

VAcuum

inleT Door

Door

TAb

Fig. 7

VAcuum

openinG

ScreW

11

upper

VAcuum Tube

lockinG TAb

lockinG TAb

Fig. 8

Page 12

OPERATION

WARNING:

Do not allow familiarity with this product to make you

careless. Remember that a careless fraction of a second is

sufficient to inflict serious injury.

WARNING:

Always wear safety goggles or safety glasses with side

shields when operating this product. Failure to do so

could result in objects being thrown into your eyes

resulting in possible serious injury.

APPLICATIONS

You may use this product for the purposes listed below:

Clearing leaves and other debris from your lawn

Keeping decks and driveways free from leaves and pine

needles

Vacuuming leaves from your lawn

MIXING THE FUEL

This product is powered by a 2-cycle engine and requires

premixing gasoline and 2-cycle oil. The mixture should be at

a 50:1 ratio, using Premium Exact Mix™ 2-cycle engine oil. If

Premium Exact Mix™ 2-cycle engine oil is not available, use

a high quality 2-cycle engine oil, mixed at a 50:1 ratio. See

chart later in this section.

TO MIX THE FUEL:

Use a clean container that is approved for use with gaso-

line.

Mix the Premium Exact Mix™ 2-cycle engine oil with

unleaded gasoline in the container, according to the

instructions on the oil package.

This engine is certified to operate on unleaded gasoline

intended for automotive use with an octane rating of 87

[(R + M) / 2] or higher. Do not use automotive oil or 2-cycle

outboard oil.

NOTE: Premium Exact Mix™ fuel mixture will stay fresh up

to 30 days. DO NOT mix quantities larger than usable in a

30 day period.

FILLING THE TANK

WARNING:

Gasoline is extremely flammable and explosive. A fire or

explosion from gasoline will burn you and others. Always

stop the engine before filling the fuel tank. Never add fuel

to a machine with a running or hot engine. Move at least

30 ft. from the refueling area before starting engine. Do

not smoke while filling the tank.

Clean the surface around the fuel cap to prevent con-

tamination.

Loosen the fuel cap slowly by turning counterclock-

wise.

Pour the fuel mixture carefully into the tank.

Clean and inspect the fuel cap gasket before replacing

the fuel cap.

Replace the fuel cap and tighten it by turning it clock-

wise.

Wipe spilled fuel from the product.

Move at least 30 ft. away from refueling area before start-

ing the product.

NOTE:

engine during first use.

It is normal for smoke to be emitted from a new

WARNING:

Check for fuel leaks. A leaking fuel cap is a fire hazard

and must be replaced immediately. If you find any leaks,

correct the problem before using the product. Failure

to do so could result in a fire that could cause serious

personal injury.

PREMIUM EXACT MIX™ (50:1)

GASOLINE OIL

1 gallon (US) 2.6 oz.

1 liter 20 cc (20 ml)

12

Page 13

OPERATION

OXYGENATED FUELS

Some conventional gasolines are blended with alcohol or an

ether compound. These gasolines are collectively referred

to as oxygenated fuels. To meet clean air standards, some

areas of the United States and Canada use oxygenated fuels

to help reduce emissions.

If using an oxygenated fuel, make sure it is unleaded and

meets the minimum octane rating requirements. Before using

an oxygenated fuel, try to confirm the fuel’s contents. Some

states/provinces require this information to be posted on the

pump. The following are the EPA approved percentages of

oxygenates:

Ethanol (ethyl or grain alcohol) 10% by volume. You

may use gasoline containing up to 10% ethanol by volume.

Gasoline containing ethanol may be marketed under the

name “Gasohol.” Do not use E85 fuel.

MTBE (methyl tertiary butyl ether) 15% by volume. You

may use gasoline containing up to 15% MTBE by volume.

Methanol (methyl or wood alcohol) 5% by volume. You

may use gasoline containing up to 5% methanol by volume

as long as it also contains cosolvents and corrosion inhibitors

to protect the fuel system. Gasoline containing more than 5%

methanol by volume may cause starting and/or performance

problems. It may also damage metal, rubber, and plastic

parts of the product or your fuel system.

If you notice any undesirable operating symptoms, try another

service station or switch to another brand of gasoline.

NOTE: Fuel system damage or performance problems

resulting from the use of an oxygenated fuel containing more

than the percentages of oxygenates stated previously are

not covered under warranty.

STARTING AND STOPPING

See Figures 9 - 10.

To start a cold engine:

DO NOT squeeze the throttle trigger until the engine starts

and runs.

Lay the blower/vacuum on a flat, bare surface.

PRIME - Press the primer bulb 7 times.

SET the start lever to the START position.

PULL the starter grip until the engine starts.

Wait 6-10 seconds, then squeeze the trigger to run.

NOTE: Squeezing and releasing the throttle trigger releases

the start lever to the RUN position.

ThroTTle

TriGGer

choke

leVer

primer

bulb

STArTer

Grip

on/oFF SWiTch

Fig. 9

Fig. 10

proper operATinG poSiTion

To start a warm engine:

PULL the starter grip until the engine starts.

To stop the engine:

Press and hold the switch in the stop “ ” position until

the engine stops.

Fig. 11

13

Page 14

OPERATING THE BLOWER

See Figures 11 - 12.

OPERATION

WARNING:

Never run the unit without the blower tubes installed or

the vacuum door securely closed. Failure to heed this

warning could result in serious personal injury.

Start the blower. Refer to Starting and Stopping earlier

in this manual. Hold the blower with the upper handle in

your right hand.

WARNING:

Keep away from all hot surfaces of the blower. Failure to

do so could result in possible serious personal injury.

To keep from scattering debris, blow around the outer

edges of a debris pile. Never blow directly into the center

of a pile.

Operate power equipment at reasonable hours only - not

early in the morning or late at night when people might

be disturbed. Comply with the times listed in local ordinances.

To reduce sound levels, limit the number of pieces of

equipment used at any one time.

Conserve water by using power blowers instead of hoses

for many lawn and garden applications, including areas

such as gutters, screens, patios, grills, porches, and

gardens.

Operate blower at the lowest possible throttle speed to

do the job.

Check your equipment before operation, especially the

muffler, air intakes, and air filters.

Use rakes and brooms to loosen debris before blowing.

In dusty conditions, slightly dampen surfaces when water

is available.

Watch out for children, pets, open windows, or freshly

washed cars, and blow debris safely away.

Use the full blower nozzle extension so the air stream can

work close to the ground.

After using blowers or other equipment, CLEAN UP!

Dispose of debris properly.

Use the sweeper nozzle for the everyday blowing opera-

tion. This nozzle allows for more area to be covered during

the blowing operation.

The high velocity nozzle is specifically designed for wet

sticky leaves. It allows you to scrape wet leaves or debris

while operating the blower.

SWeeper noZZle

hiGh VelociTY

noZZle

Fig. 12

cruiSe

conTrol

ThroTTle TriGGer

Fig. 13

CRUISE CONTROL

See Figure 13.

The cruise control can be used to operate the blower without

holding the throttle trigger.

To engage the cruise control:

Pull cruise control lever back towards user, and stop at

the desired throttle setting.

To release the cruise control, push cruise control lever all

the way towards the front of unit.

14

Page 15

OPERATION

VACUUM OPERATION

See Figure 14.

WARNING:

Never run the unit without the vacuum tubes, vacuum

bag, and vacuum handle installed. Failure to heed this

warning could result in serious personal injury.

Install the vacuum tubes, vacuum handle, and bag. Refer

to the ASSEMBLY section earlier in this manual.

Start the blower. Refer to Starting and Stopping earlier

in this manual.

Place the vacuum bag strap over your right shoulder.

Hold the upper handle in your left hand and the vacuum

handle in your right hand.

Move the blower/vacuum from side to side along outer

edge of the debris. To avoid clogging, do not place the

vacuum tube directly into the debris pile.

Hold the engine higher than the inlet end of the vacuum

tube.

Always point vacuum tube downhill when working on a

hillside.

To avoid injury to the operator or unit, do not pick up

rocks, broken glass, bottles, or other similar objects.

If the vacuum tubes should clog, stop the engine and

disconnect the spark plug wire before cleaning out the

obstruction.

Remove the vacuum tubes and clear the debris from the

blower fan housing. Remove the bag and clear the tube.

A small rod or stick may be required to clear the entire

tube length. Ensure that all debris has been cleared before

reassembling the vacuum tubes.

proper operATinG poSiTion

Fig. 14

MAINTENANCE

WARNING:

When servicing, use only identical replacement parts.

Use of any other parts may create a hazard or cause

product damage.

WARNING:

Always wear safety goggles or safety glasses with side

shields during power tool operation or when blowing

dust. If operation is dusty, also wear a dust mask.

WARNING:

Before inspecting, cleaning, or servicing the machine,

shut off engine, wait for all moving parts to stop, and

disconnect spark plug wire and move it away from spark

plug. Failure to follow these instructions can result in

serious personal injury or property damage.

GENERAL MAINTENANCE

Avoid using solvents when cleaning plastic parts. Most

plastics are susceptible to damage from various types of

commercial solvents and may be damaged by their use. Use

clean cloths to remove dirt, dust, lubricant, grease, etc.

WARNING:

Do not at any time let brake fluids, gasoline, petroleumbased products, penetrating lubricants, etc., come in contact with plastic parts. Chemicals can damage, weaken or

destroy plastic which may result in serious personal

injury.

You can often make adjustments and repairs described here.

For other repairs, have the blower/vacuum serviced by an

authorized service dealer.

15

Page 16

MAINTENANCE

CLEANING THE AIR FILTER SCREEN

See Figure 15 - 16.

For proper performance and long life, keep air filter screen

clean.

Remove the air filter cover by pushing down on the latch

with your thumb while gently pulling on the cover.

Brush the air filter screen lightly to clean.

Replace the air filter cover by inserting the tabs on the

bottom of the cover into the slots on the air filter base;

push the cover up until it latches securely in place.

CLEANING THE EXHAUST PORT, MUFFLER

AND SPARK ARRESTOR

NOTE: Depending on the type of fuel used, the type and

amount of lubricant used, and/or your operating conditions, the

exhaust port, muffler, and/or spark arrestor screen may

become blocked with carbon deposits. If you notice a

power loss with your gas powered tool, you may need to

remove these deposits to restore performance. We highly

recommend that only qualified service technicians perform

this service.

The spark arrestor must be cleaned or replaced every

50 hours or yearly to ensure proper performance of your

product. Spark arrestors may be in different locations

depending on the model purchased. Please contact your

nearest service dealer for the location of the spark arrestor

for your model.

pull coVer

To open

lATch

Air

FilTer

coVer

Fig. 15

bruSh

WARNING:

To avoid a fire hazard, never run the blower without the

spark arrestor in place.

VACUUM BAG

A dirty bag will reduce performance. To clean the bag, turn it

inside out and shake. Wash the bag in soapy water at least

once a year. To obtain a replacement bag, see How to Order

Replacement Parts on the back page of this manual.

FUEL CAP

WARNING:

A leaking fuel cap is a fire hazard and must be replaced

immediately.

The fuel cap contains a non-serviceable filter and a

check valve. A clogged fuel filter will cause poor engine

performance. If performance improves when the fuel cap

is loosened, check valve may be faulty or filter clogged.

Replace fuel cap if required.

Air FilTer

Screen

Fig. 16

SPARK PLUG REPLACEMENT

This engine uses a Champion RCJ-6Y or NGK BPMR7A

spark plug with .025 in. electrode gap. Use an exact

replacement and replace annually.

STORING THE PRODUCT

Clean all foreign material from the product. Store idle unit

indoors in a dry, well-ventilated area that is inaccessible

to children. Keep away from corrosive agents such as

garden chemicals and de-icing salts.

Abide by all ISO and local regulations for the safe storage

and handling of gasoline.

When storing 1 month or longer:

Drain all fuel from tank into a container approved for

gasoline. Run engine until it stops.

16

Page 17

TROUBLESHOOTING

IF THESE SOLUTIONS DO NOT SOLVE THE PROBLEM, CONTACT YOUR AUTHORIZED SERVICING DEALER.

PROBLEM CAUSE REMEDY

Engine fails to start. No fuel in tank.

Spark plug shorted or fouled.

Spark plug is broken. (cracked

porcelain or electrodes broken)

Ignition lead wire shorted, broken, or

disconnected from spark plug.

Ignition inoperative.

Engine hard to start. Water in gasoline or stale fuel mixture.

Too much lubricant in fuel mixture.

Engine is under or over choked.

Weak spark at spark plug.

Engine lacks power. Air filter clogged. Clean air filter. Refer to Cleaning the

Engine overheats. Insufficient lubricant in fuel mixture. Mix fuel as described in starting

Fill tank.

Replace spark plug.

Replace spark plug.

Replace lead wire or attach to spark

plug.

Contact authorized service center.

Drain entire system and refill with fresh

fuel.

Drain and refill with correct mixture.

Adjust choke as necessary.

Contact authorized service center.

Air Filter Screen earlier in this manual.

instructions.

17

Page 18

WARRANTY

LIMITED WARRANTY STATEMENT

Techtronic Industries North America, Inc., warrants to the

original retail purchaser that this RYOBI® brand outdoor

product is free from defect in material and workmanship

and agrees to repair or replace, at Techtronic Industries

North America, Inc.’s, discretion, any defective product

free of charge within these time periods from the date of

purchase.

Two years if the product is used for personal, family or

household use;

90 days, if used for any other purpose, such as

commercial or rental.

This warranty extends to the original retail purchaser

only and commences on the date of the original retail

purchase.

Any part of this product found in the reasonable judgment

of Techtronic Industries North America, Inc. to be defective

in material or workmanship will be repaired or replaced

without charge for parts and labor by an authorized service

center for RYOBI® brand outdoor products (Authorized

Ryobi Service Center).

The product, including any defective part, must be returned

to an authorized Ryobi service center within the warranty

period. The expense of delivering the product to the service

center for warranty work and the expense of returning it

back to the owner after repair or replacement will be paid

by the owner. Techtronic Industries North America, Inc.’s,

responsibility in respect to claims is limited to making the

required repairs or replacements and no claim of breach of

warranty shall be cause for cancellation or rescission of the

contract of sale of any RYOBI® brand outdoor product. Proof

of purchase will be required by the dealer to substantiate

any warranty claim. All warranty work must be performed

by an authorized service dealer.

This warranty is limited to ninety (90) days from the date

of original retail purchase for any RYOBI® brand outdoor

product that is used for rental or commercial purposes, or

any other income-producing purpose.

This warranty does not cover any product that has been

subject to misuse, neglect, negligence, or accident, or that

has been operated in any way contrary to the operating

instructions as specified in this operator’s manual. This

warranty does not apply to any damage to the product that

is the result of improper maintenance or to any product

that has been altered or modified. The warranty does not

extend to repairs made necessary by normal wear or by the

use of parts or accessories which are either incompatible

with the RYOBI® brand outdoor product or adversely affect

its operation, performance, or durability. In addition, this

warranty does not cover:

A. Tune-ups – Spark Plugs, Carburetor, Carburetor

Adjustments, Ignition, Filters

B. Wear items – Bump Knobs, Outer Spools, Cutting

Lines, Inner Reels, Starter Pulleys, Starter Ropes, Drive

Belts, Tines, Felt Washers, Hitch Pins, Mulching Blades,

Blower Fans, Blower and Vacuum Tubes, Vacuum Bag

and Straps, Guide Bars, Saw Chains

Techtronic Industries North America, Inc., reserves the

right to change or improve the design of any RYOBI® brand

outdoor product without assuming any obligation to modify

any product previously manufactured.

ALL IMPLIED WARRANTIES ARE LIMITED IN DURATION

TO THE STATED WARRANTY PERIOD. ACCORDINGLY,

ANY SUCH IMPLIED WARRANTIES INCLUDING

MERCHANTABILITY, FITNESS FOR A PARTICULAR

PURPOSE, OR OTHERWISE, ARE DISCLAIMED IN

THEIR ENTIRETY AFTER THE EXPIRATION OF THE

APPROPRIATE TWO-YEAR, ONE-YEAR, OR NINETYDAY WARRANTY PERIOD. TECHTRONIC INDUSTRIES

NORTH AMERICA, INC.’S, OBLIGATION UNDER THIS

WARRANTY IS STRICTLY AND EXCLUSIVELY LIMITED TO

THE REPAIR OR REPLACEMENT OF DEFECTIVE PARTS

AND TECHTRONIC INDUSTRIES NORTH AMERICA,

INC., DOES NOT ASSUME OR AUTHORIZE ANYONE

TO ASSUME FOR THEM ANY OTHER OBLIGATION.

SOME STATES DO NOT ALLOW LIMITATIONS ON HOW

LONG AN IMPLIED WARRANTY LASTS, SO THE ABOVE

LIMITATION MAY NOT APPLY TO YOU. TECHTRONIC

INDUSTRIES NORTH AMERICA, INC., ASSUMES NO

RESPONSIBILITY FOR INCIDENTAL, CONSEQUENTIAL,

OR OTHER DAMAGES INCLUDING, BUT NOT LIMITED

TO, EXPENSE OF RETURNING THE PRODUCT TO AN

AUTHORIZED RYOBI SERVICE CENTER AND EXPENSE

OF DELIVERING IT BACK TO THE OWNER, MECHANIC’S

TRAVEL TIME, TELEPHONE OR TELEGRAM CHARGES,

RENTAL OF A LIKE PRODUCT DURING THE TIME

WARRANTY SERVICE IS BEING PERFORMED, TRAVEL,

LOSS OR DAMAGE TO PERSONAL PROPERTY, LOSS

OF REVENUE, LOSS OF USE OF THE PRODUCT,

LOSS OF TIME, OR INCONVENIENCE. SOME STATES

DO NOT ALLOW THE EXCLUSION OR LIMITATION OF

INCIDENTAL OR CONSEQUENTIAL DAMAGES, SO THE

ABOVE LIMITATION OR EXCLUSION MAY NOT APPLY

TO YOU.

This warranty gives you specific legal rights, and you may

also have other rights which vary from state to state.

This warranty applies to all RYOBI® brand outdoor products

manufactured by or for Techtronic Industries North America,

Inc., and sold in the United States and Canada.

To locate your nearest Authorized Ryobi Service Center,

dial 1-800-860-4050.

18

Page 19

WARRANTY

THE FOLLOWING CALIFORNIA AIR RESOURCES BOARD (CARB) STATEMENT ONLY APPLIES TO MODEL NUMBERS REqUIRED TO MEET THE CARB REqUIREMENTS.

TECHTRONIC INDUSTRIES NORTH AMERICA, INC., LIMITED WARRANTY STATEMENT FOR FEDERAL

AND CALIFORNIA EMISSION CONTROL SYSTEMS NON-ROAD AND SMALL OFF-ROAD ENGINES

YOUR WARRANTY RIGHTS AND OBLIGATIONS

The U.S. Environmental Protection Agency (EPA), the California Air Resources Board

(CARB), and Techtronic Industries North America, Inc., are pleased to explain the

Emissions Control System Warranty on your 2008 model year non-road or small offroad engine. In California, new equipment that uses small off-road engines must be

designed, built, and equipped to meet the state’s stringent anti-smog standards. In

other states, new 2000 and later model year non-road engines must be designed,

built, and equipped at the time of sale to meet the U.S. EPA regulations for small

non-road engines. The non-road engine must be free from defects in materials and

workmanship which cause it to fail to conform with U.S. EPA standards for the first

two years of engine use from the date of sale to the ultimate purchaser. Techtronic

Industries North America, Inc., must warrant the emission control system on your

non-road or small off-road engine for the period of time listed above provided there

has been no abuse, neglect, or improper maintenance of your non-road or small

off-road engine.

Your emission control system may include parts such as the carburetor or fuel injection

system, the ignition system, catalytic converters, fuel tanks, valves, filters, clamps,

connectors, and other associated components. Also included may be hoses, belts

and connectors, and other emission-related assemblies.

Where a warrantable condition exists, Techtronic Industries North America, Inc., will

repair your non-road or small off-road engine at no cost to you, including diagnosis, parts, and labor performed at an authorized service center for RYOBI® brand

outdoor products.

MANUFACTURER’S WARRANTY COVERAGE:

This product’s emissions control system is warranted for two years. If any emission-related part on your engine is defective, the part will be repaired or replaced by

Techtronic Industries North America, Inc., free of charge.

OWNER’S WARRANTY RESPONSIBILITIES

(a) As the non-road or small off-road engine owner, you are responsible for

the performance of the required maintenance listed in your operator’s manual.

Techtronic Industries North America, Inc., recommends that you retain all receipts covering maintenance on your non-road or small off-road engine, but

Techtronic Industries North America, Inc., cannot deny warranty solely for the

lack of receipts or for your failure to ensure the performance of all scheduled

maintenance. Any replacement part or service that is equivalent in performance

and durability may be used in non-warranty maintenance or repairs, and shall

not reduce the warranty obligations of Techtronic Industries North America, Inc.

(b) As the non-road or small off-road engine owner, you should be aware, however,

that Techtronic Industries North America, Inc., may deny you warranty coverage if

your non-road or small off-road engine or a part has failed due to abuse, neglect,

improper maintenance, or unapproved modifications.

(c) You are responsible for presenting your non-road or small off-road engine to an

authorized service dealer as soon as a problem exists. The warranty repairs should

be completed in a reasonable amount of time, not to exceed 30 days.

If you have any questions regarding your warranty rights and responsibilities, you

should contact a Techtronic Industries North America, Inc., Customer Representative at 1-800-860-4050.

DEFECT WARRANTY COVERAGE REqUIREMENTS:

(a) The warranty period begins on the date the engine or equipment is delivered to

an ultimate purchaser.

(b) General Emissions Warranty Coverage. Techtronic Industries North America,

Inc., warrants to the ultimate purchaser and each subsequent purchaser that your

non-road or small off-road engine is designed, built, and equipped at the time of sale

to conform with all applicable regulations adopted by the California Air Resources

Board or the United States Environmental Protection Agency; and that it is free from

defects in materials and workmanship which cause the engine to fail to conform with

applicable regulations for a period of two years from the date the non-road or small

off-road engine is purchased by the initial purchaser.

(c) The warranty on emissions-related parts will be interpreted as follows: Any

warranted part that is not scheduled for replacement as required in the Emissions

Maintenance Schedule and Warranty Parts List set forth below is warranted for two

years. If any such part (including any part that is scheduled only for regular inspection)

fails during the period of warranty coverage, it will be repaired or replaced at any

RYOBI® Authorized Service Center at no charge. Any such part repaired or replaced

under warranty will be warranted for the remaining warranty period. A statement to

the effect of “repair or replace as necessary” would not reduce the period of warranty coverage. Any warranted part that is scheduled for replacement as required

maintenance in the Emissions Maintenance Schedule and Warranty Parts List is

warranted for the period of time prior to the first scheduled replacement point for

that part. Any such part repaired or replaced under warranty is warranted for the

remainder of the period prior to the first scheduled replacement point, and will be

repaired or replaced at any RYOBI® Authorized Service Center for no charge until

that replacement point is reached.

Techtronic Industries North America, Inc., shall remedy warranty defects at any

authorized RYOBI® Authorized Service Center, including any distribution center

that may be franchised to service the subject engines. Any diagnostic work done

at a RYOBI® Authorized Service Center shall be free of charge to the owner if such

work determines that a warranted part is defective. Any manufacturer-approved or

equivalent replacement part may be used for any warranty maintenance or repairs

on emission-related parts, and must be provided free of charge to the owner if the

part is still under warranty. Techtronic Industries North America, Inc., is liable for

damages to other engine components caused by the failure of a warranted part

still under warranty.

Add-on or modified parts that are not exempted by the California Air Resource Board

may not be used. The use of any non-exempted add-on or modified parts will be

grounds for disallowing a warranty claim. Techtronic Industries North America, Inc.,

will not be liable to warrant failures of warranted parts caused by the use of a nonexempted add-on or modified part.

The California Air Resources Board’s Emission Warranty Parts List specifically defines

the emission-related warranted parts. (EPA’s regulations do not include a parts list,

but the EPA considers emission-related warranted parts to include all the parts listed

below.) Techtronic Industries North America, Inc., will provide any documents that

describe its warranty procedures or policies within five days upon request by the

California Air Resources Board.

EMISSIONS PARTS LIST

Emissions parts vary from product to product. Your emissions control system warranty

applies to any of the following components that may be included on your product:

(1) Fuel Metering System

(i) Carburetor and internal parts (and/or pressure regulator or fuel injection

system).

(ii) Air/fuel ratio feedback and control system.

(iii) Cold start enrichment system.

(iv) Fuel Tank.

(2) Air Induction System

(i) Controlled hot air intake system.

(ii) Intake manifold.

(iii) Air filter.

(3) Ignition System

(i) Spark Plugs.

(ii) Magneto or electronic ignition system.

(iii) Spark advance/retard system.

(4) Exhaust Gas Recirculation (EGR) System

(i) EGR valve body and carburetor spacer, if applicable.

(ii) EGR rate feedback and control system.

(5) Air Injection System

(i) Air pump or pulse valve.

(ii) Valves affecting distribution of flow.

(iii) Distribution manifold.

(6) Catalyst or Thermal Reactor System

(i) Catalytic converter.

(ii) Thermal reactor.

(iii) Exhaust manifold.

(7) Particulate Controls

(i) Traps, filters, precipitators, and any other device used to capture particulate

emissions.

(8) Miscellaneous Items Used in Above Systems

(i) Electronic controls.

(ii) Vacuum, temperature, and time sensitive valves and switches.

(iii) Hoses, belts, connectors, and assemblies.

Techtronic Industries North America, Inc., will furnish with each new engine written

instructions for its maintenance and use by the owner.

The Emissions Compliance Period referred to on the Emissions Compliance label

indicates the number of operating hours for which the engine has been shown to

meet Federal emission requirements. Category C=50 hours, B=125 hours, and

A=300 hours.

19

Page 20

CAL

L

1-800-860-4050

www

.ryobitools.com

WARRANTY

THIS PRODUCT WAS MANUFACTURED WITH A CATALYST MUFFLER

Congratulations! You have made an investment toward protecting the environment. In order to maintain this product’s

original emission level, please refer to the maintenance section below.

EMISSIONS MAINTENANCE SCHEDULE AND WARRANTED PARTS LIST

Emissions Parts Inspect Before Clean Every Replace Clean Every Replace Every

Each Use 5 Hours Every 25 Hours 25 Hours 50 Hours

or Yearly or Yearly

CATALYTIC MUFFLER ASSEMBLY ................................................................................................................... X

AIR FILTER ASSY

includes:

Filter Screen ..................................................... X

SPARK SCREEN ................................................................................................................................................X

CARBURETOR ASSY

includes:

Heat Dam ........................ X

Gaskets ........................... X

FUEL TANK ASSY

includes:

Fuel Lines ........................ X

Fuel Cap .......................... X

Fuel Filter

IGNITION ASSY

includes:

Spark Plug ........................................................................................ X

ALL EMISSIONS-RELATED PARTS ARE WARRANTED FOR TWO YEARS OR FOR THE PERIOD OF TIME PRIOR TO

THE PARTS FIRST SCHEDULED REPLACEMENT WHICHEVER COMES FIRST.

cAll uS FirST

For any questions about operating or maintaining your product,

call the Ryobi® Help Line!

Your product has been fully tested prior to shipment to ensure

your complete satisfaction.

20

Page 21

NOTES

21

Page 22

OPERATOR’S MANUAL

BLOWER/VACUUM

RY08554/RY09907

(ALL VERSIONS)

WARNING:

The engine exhaust from this product contains chemicals known to the State of California to cause

cancer, birth defects, or other reproductive harm.

CALIFORNIA PROPOSITION 65

• PARTS AND SERVICE

Prior to requesting service or purchasing replacement parts, please obtain your model

and serial number from the product data plate.

• MODEL NUMBER

• SERIAL NUMBER

RY08554/RY09907

• HOW TO OBTAIN REPLACEMENT PARTS:

Replacement parts can be purchased online at www.ryobitools.com or by calling

1-800-860-4050. Replacement parts can also be obtained at one of our Authorized

Service Centers.

• HOW TO LOCATE AN AUTHORIZED SERVICE CENTER:

Authorized Service Centers can be located online at www.ryobitools.com or by calling

1-800-860-4050.

• HOW TO OBTAIN CUSTOMER OR TECHNICAL SUPPORT:

To obtain Customer or Technical Support please contact us at 1-800-860-4050.

® is a registered trademark of Ryobi Limited used under license.

Ryobi

987000-308

1-12-09 (REV:02)

TECHTRONIC INDUSTRIES NORTH AMERICA, INC.

1428 Pearman Dairy Road

Anderson, SC 29625

Phone 1-800-860-4050

www.ryobitools.com

Loading...

Loading...