Page 1

OPERATOR'S MANUAL

RANDOM ORBIT SANDER

RS280VS

VARIABLE SPEED – DOUBLE INSULATED

Your new sander has been engineered and manufactured to Ryobi's high standard for dependability, ease of

operation, and operator safety. Properly cared for, it will give you years of rugged, trouble-free performance.

WARNING: To reduce the risk of injury, the user must read and understand the operator’s manual.

Thank you for buying a Ryobi random orbit sander.

SAVE THIS MANUAL FOR FUTURE REFERENCE

Page 2

TABLE OF CONTENTS

■ Introduction ........................................................................................................................................................ 2

■ General Safety Rules .....................................................................................................................................3-4

■ Specific Safety Rules ......................................................................................................................................... 4

■ Symbols ............................................................................................................................................................. 5

■ Specifications .................................................................................................................................................... 6

■ Unpacking .......................................................................................................................................................... 6

■ Applications ....................................................................................................................................................... 6

■ Features .........................................................................................................................................................7-8

■ Operation ......................................................................................................................................................9-13

■ Maintenance ....................................................................................................................................................13

■ Parts, Ordering, and Service ........................................................................................................................... 14

INTRODUCTION

Your sander has many features for making the use of this

tool more pleasant and enjoyable. Safety, performance,

and dependability have been given top priority in the

design of this sander making it easy to maintain and

operate.

WARNING:

Do not attempt to use this tool until you have read

thoroughly and understand completely the operator’s

manual. Pay close attention to the safety rules, including Dangers, Warnings, and Cautions. If you

use your tool properly and only for what it is intended, you will enjoy years of safe, reliable service.

WEAR

YOUR

SAFETY

FORESIGHT IS BETTER

GLASSES

THAN NO SIGHT

Look for this symbol to point out important safety

precautions. It means attention!!! Your safety is involved.

The operation of any power tool can result in foreign objects being thrown into your eyes,

which can result in severe eye damage. Before beginning tool operation, always wear safety

goggles or safety glasses with side shields and a full face shield when needed. We

recommend Wide Vision Safety Mask for use over eyeglasses or standard safety glasses

with side shields. Always wear eye protection which is marked to comply with ANSI Z87.1.

2

Page 3

GENERAL SAFETY RULES

SAVE THESE INSTRUCTIONS

WARNING:

Read and understand all instructions. Failure to follow all instructions listed below, may result in electric

shock, fire and/or serious personal injury.

WORK AREA

■ Keep your work area clean and well lit. Cluttered

benches and dark areas invite accidents.

■ Do not operate power tools in explosive atmospheres, such as in the presence of flammable

liquids, gases, or dust. Power tools may create

sparks which may ignite the dust or fumes.

■ Keep bystanders, children, and visitors away

while operating a power tool. Distractions can

cause you to lose control.

ELECTRICAL SAFETY

■ Double insulated tools are equipped with a polarized plug (one blade is wider than the other).

This plug will fit in a polarized outlet only one

way. If the plug does not fit fully in the outlet,

reverse the plug. If it still does not fit, contact a

qualified electrician to install a polarized outlet.

Do not change the plug in any way. Double insu-

lation eliminates the need for the three-wire

grounded power cord and grounded power supply

system.

■ Avoid body contact with grounded surfaces,

such as pipes, radiators, ranges, and refrigerators. There is an increased risk of electric shock if

your body is grounded.

■ Don’t expose power tools to rain or wet conditions. Water entering a power tool will increase the

risk of electric shock.

■ Do not abuse the cord. Never use the cord to

carry the tools or pull the plug from an outlet.

Keep cord away from heat, oil, sharp edges, or

moving parts. Replace damaged cords immediately. Damaged cords increase the risk of electric

shock.

■ When operating a power tool outside, use an

outdoor extension cord marked “W-A” or “W”.

These cords are rated for outdoor use and reduce

the risk of electric shock.

PERSONAL SAFETY

■ Stay alert, watch what you are doing and use

common sense when operating a power tool. Do

not use tool while tired or under the influence of

drugs, alcohol, or medication. A moment of inat-

tention while operating power tools may result in

serious personal injury.

■ Dress properly. Do not wear loose clothing or

jewelry. Contain long hair. Keep your hair, clothing, and gloves away from moving parts. Loose

clothes, jewelry, or long hair can be caught in moving parts or drawn into air vents.

■ Avoid accidental starting. Be sure switch is off

before plugging in. Carrying tools with your finger

on the switch or plugging in tools that have the switch

on, invites accidents.

■ Remove adjusting keys or wrenches before turning the tool on. A wrench or a key that is left at-

tached to a rotating part of the tool may result in

personal injury.

■ Do not overreach. Keep proper footing and balance at all times. Proper footing and balance en-

ables better control of the tool in unexpected situations. Do not use on a ladder or unstable support.

■ Use safety equipment. Always wear eye protection. Dust mask, nonskid safety shoes, hard hat, or

hearing protection must be used for appropriate conditions.

TOOL USE AND CARE

■ Use clamps or other practical way to secure and

support the workpiece to a stable platform. Hold-

ing the work by hand or against your body is unstable and may lead to loss of control.

■ Do not force tool. Use the correct tool for your

application. The correct tool will do the job better

and safer at the rate for which it is designed.

■ Do not use tool if switch does not turn it on or

off. Any tool that cannot be controlled with the switch

is dangerous and must be repaired.

■ Disconnect the plug from power source before

making any adjustments, changing accessories,

or storing the tool. Such preventive safety mea-

sures reduce the risk of starting the tool accidentally.

■ Store idle tools out of the reach of children and

other untrained persons. Tools are dangerous in

the hands of untrained users.

■ Maintain tools with care. Keep cutting tools sharp

and clean. Properly maintained tools with sharp

cutting edges are less likely to bind and are easier

to control.

■ Check for misalignment or binding of moving

parts, breakage of parts, and any other condition that may affect the tool’s operation. If damaged, have the tool serviced before using. Many

accidents are caused by poorly maintained tools.

■ Use only accessories that are recommended by

the manufacturer for your model. Accessories that

may be suitable for one tool, may become hazardous when used on another tool.

3

Page 4

GENERAL SAFETY RULES

SERVICE

■ Tool service must be performed only by qualified repair personnel. Service or maintenance per-

formed by unqualified personnel could result in a risk

of injury.

■ When servicing a tool, use only identical replacement parts. Follow instructions in the Maintenance section of this manual. Use of unauthorized

parts or failure to follow Maintenance Instructions

may create a risk of electric shock or injury.

SPECIFIC SAFETY RULES

Hold tool by insulated gripping surfaces when performing an operation where the tool may contact

wiring or its cord. Contact with a “live” wire will make exposed metal parts of the tool “live” and shock the operator.

ADDITIONAL SAFETY RULES

■ Know your power tool. Read operator’s manual

carefully. Learn its applications and limitations,

as well as the specific potential hazards related

to this tool. Following this rule will reduce the risk

of electric shock, fire, or serious injury.

■ Always wear safety glasses. Everyday eyeglasses have only impact-resistant lenses; they

are NOT safety glasses. Following this rule will re-

duce the risk of serious personal injury.

■ Protect your lungs. Wear a face or dust mask if

the operation is dusty. Following this rule will re-

duce the risk of serious personal injury.

■ Protect your hearing. Wear hearing protection

during extended periods of operation. Following

this rule will reduce the risk of serious personal injury.

■ Inspect tool cords periodically and, if damaged,

have repaired at your nearest Factory Service

Center or other Authorized Service Organization.

Constantly stay aware of cord location. Follow-

ing this rule will reduce the risk of electric shock or

fire.

■ Check damaged parts. Before further use of the

tool, a guard or other part that is damaged should

be carefully checked to determine that it will

operate properly and perform its intended function. Check for alignment of moving parts, binding of moving parts, breakage of parts, mounting, and any other conditions that may affect its

operation. A guard or other part that is damaged

should be properly repaired or replaced by an

authorized service center. Following this rule will

reduce the risk of shock, fire, or serious injury.

■ Do not abuse cord. Never carry the tool by the

cord or yank it to disconnect it from the receptacle. Keep cord away from heat, oil, and sharp

edges. Following this rule will reduce the risk of elec-

tric shock or fire.

■ Make sure your extension cord is in good condition. When using an extension cord, be sure to

use one heavy enough to carry the current your

product will draw. A wire gage size (A.W.G.) of at

least 16 is recommended for an extension cord

100 feet or less in length. A cord exceeding 100

feet is not recommended. If in doubt, use the next

heavier gage. The smaller the gage number, the

heavier the cord. An undersized cord will cause a

drop in line voltage resulting in loss of power and

overheating.

■ Inspect for and remove all nails from lumber before sanding. Following this rule will reduce the risk

of serious personal injury.

■ Drugs, alcohol, medication. Do not operate tool

while under the influence of drugs, alcohol, or

any medication. Following this rule will reduce the

risk of electric shock, fire, or serious personal injury.

■ Save these instructions. Refer to them frequently

and use them to instruct others who may use

this tool. If you loan someone this tool, loan them

these instructions also.

WARNING:

Some dust created by power sanding, sawing,

grinding, drilling, and other construction activities

contains chemicals known to cause cancer, birth

defects or other reproductive harm. Some examples

of these chemicals are:

• lead from lead-based paints,

• crystalline silica from bricks and cement

and other masonry products, and

• arsenic and chromium from chemically treated lumber.

Your risk from these exposures varies, depending

on how often you do this type of work. To reduce

your exposure to these chemicals: work in a well

ventilated area, and work with approved safety

equipment, such as those dust masks that are

specially designed to filter out microscopic particles.

hidden

4

Page 5

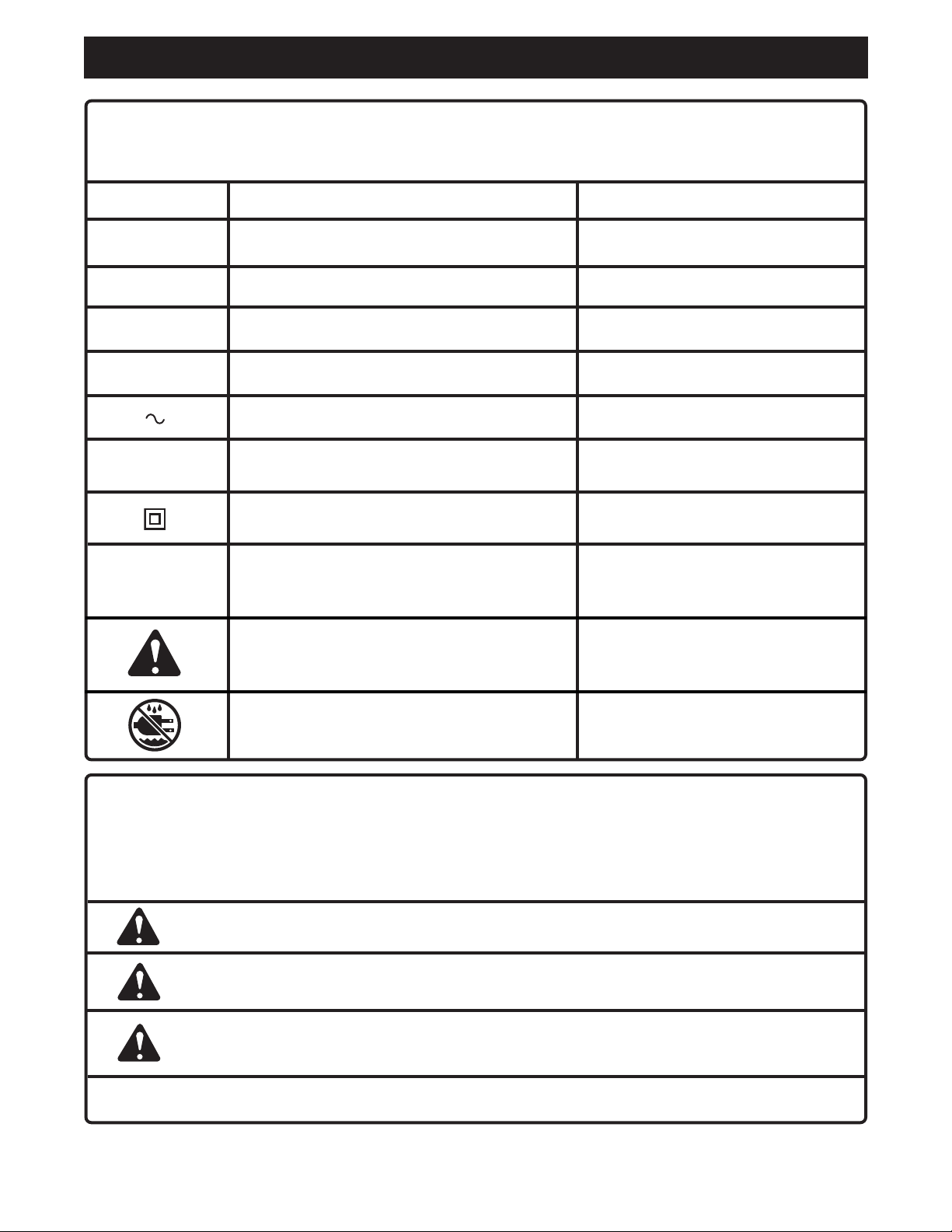

SYMBOLS

Important: Some of the following symbols may be used on your tool. Please study them and learn their meaning.

Proper interpretation of these symbols will allow you to operate the tool better and safer.

SYMBOL NAME DESIGNATION/EXPLANATION

V Volts Voltage

A Amperes Current

Hz Hertz Frequency (cycles per second)

W Watt Power

min Minutes Time

Alternating Current Type or a characteristic of current

n

0

.../min Revolutions or Reciprocation Per Minute Revolutions, strokes, surface speed,

The purpose of safety symbols is to attract your attention to possible dangers. The safety symbols, and the

explanations with them, deserve your careful attention and understanding. The safety warnings do not by

themselves eliminate any danger. The instructions or warnings they give are not substitutes for proper accident

prevention measures.

No Load Speed Rotational speed, at no load

Class II Construction Designates double-insulated

construction tools

orbits etc. per minute

Safety Alert Indicates danger, warning or caution.

It means attention!!! Your safety is

involved.

Wet Conditions Alert Do not expose to rain or use in damp

locations.

SYMBOL MEANING

DANGER: Failure to obey a safety warning will result in serious injury to yourself or to others. Always

follow the safety precautions to reduce the risk of fire, electric shock and personal injury.

WARNING: Failure to obey a safety warning can result in serious injury to yourself or to others.

Always follow the safety precautions to reduce the risk of fire, electric shock and personal injury.

CAUTION: Failure to obey a safety warning may result in property damage or personal injury to

yourself or to others. Always follow the safety precautions to reduce the risk of fire, electric shock and

personal injury.

NOTE: Advises you of information or instructions vital to the operation or maintenance of the equipment.

SAVE THESE INSTRUCTIONS

5

Page 6

SPECIFICATIONS

Sanding Disc Diameter 5 in. (12.7 cm)

Motion Random Orbit

Orbit Diameter 3/32 in. (2.4 mm)

No Load Speed 7,000 - 12,000 Orbits/Min.

Input 120 Volts, 60 Hz, AC only, 2.8 amps

Net Weight 3-1/2 lbs. (1.6 kg.)

UNPACKING

INSTRUCTIONS

Your sander has been shipped completely assembled.

■ Carefully remove the tool and accessories from the

box. Make sure that all items listed in the packing

list are included.

■ Inspect the tool carefully to make sure no breakage

or damage occurred during shipping.

■ Do not discard the packing material until you have

carefully inspected and satisfactorily operated the

tool.

■ If any parts are damaged or missing, please call

1-800-525-2579 for assistance.

APPLICATIONS

You may use your sander for the purposes listed below:

■ Sanding wood surfaces.

■ Sanding steel surfaces.

■ Removing rust from steel surfaces.

PACKING LIST

Random Orbit Sander

Sandpaper (3 sheets)

Conversion Pad

Operator’s Manual

WARNING:

If any parts are missing do not operate your tool until

the missing parts are replaced. Failure to do so

could result in possible serious personal injury.

6

Page 7

FEATURES

DOUBLE INSULATION

Double insulation is a concept in safety in electric power

tools, which eliminates the need for the usual three-wire

grounded power cord. All exposed metal parts are

isolated from the internal metal motor components with

protecting insulation. Double insulated tools do not need

to be grounded.

WARNING:

The double insulated system is intended to protect

the user from shock resulting from a break in the

tool's internal wiring. Observe all normal safety precautions to avoid electrical shock.

Important: Servicing of a tool with double insulation

requires extreme care and knowledge of the system and

should be performed only by a qualified service

technician. For service, we suggest you return the tool to

your nearest authorized service center for repair. Always

use original factory replacement parts when servicing.

ELECTRIC MOTOR

Your sander has a precision built electric motor. It

should be connected to a power supply that is 120

volts, 60 Hz, AC only (normal household current). Do

not operate this tool on direct current (DC). A substantial

voltage drop will cause a loss of power and the motor will

overheat. If your tool does not operate when plugged

into an outlet, double-check the power supply.

SWITCH

Your sander has a conveniently located slide switch.

VARIABLE SPEED

The variable speed feature allows you to operate the

sander at different speeds.

BACKING PAD

The backing pad on the sander provides the capability to

use sanding discs with pressure sensitive adhesive

backing material.

CONVERSION PAD

The conversion pad supplied with the sander converts

the backing pad and allows you to use Velcro® type

sanding discs.

RANDOM ORBIT

The random orbit motion provides overlapping sanding

movements by combining orbital and turning motion.

These overlapping sanding movements provide fast

cutting action with excellent sanding results.

ERGONOMIC DESIGN

The design of the sander provides for easy handling. It

is designed for comfort and ease of grasp when operating

in different positions and at different angles.

7

Page 8

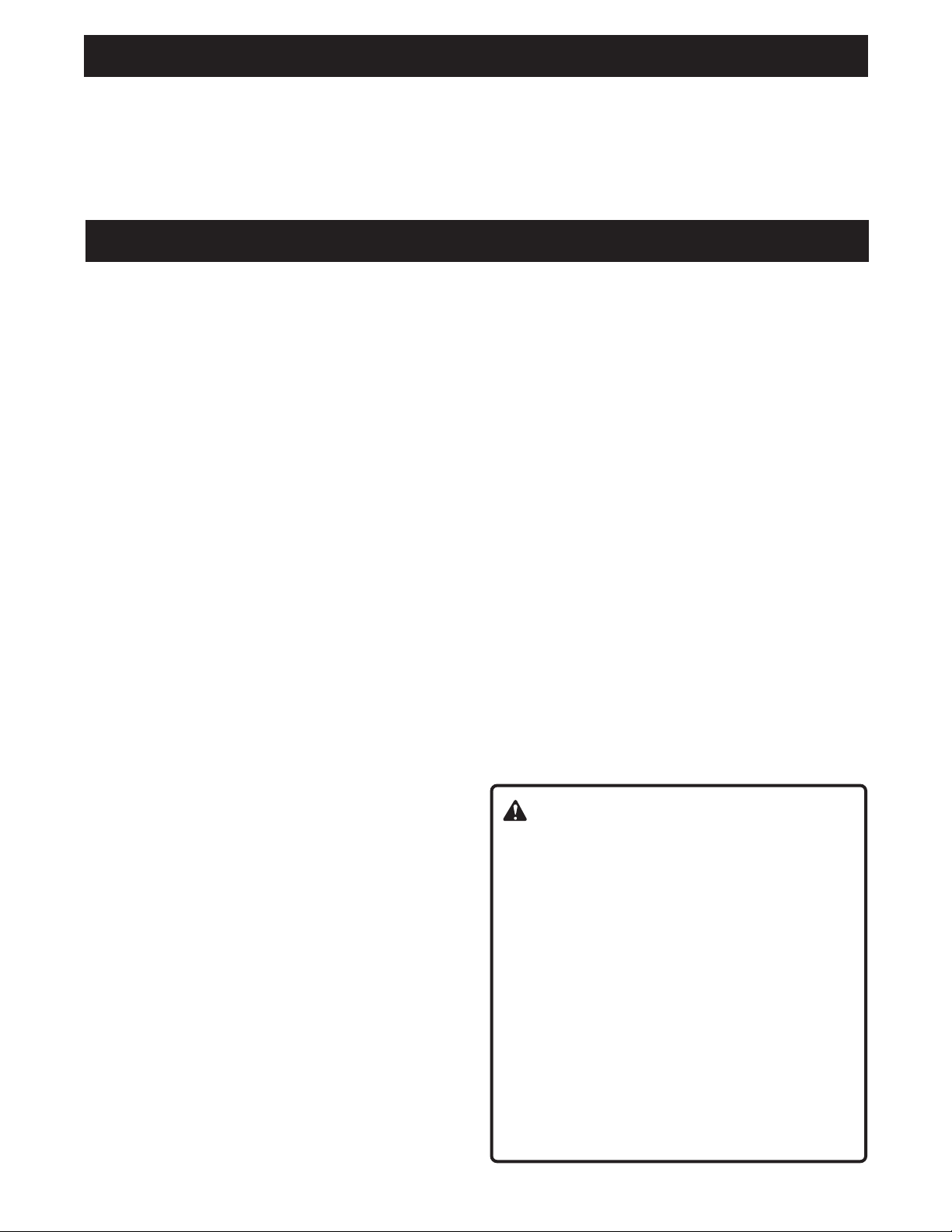

FEATURES

SWITCH

DUST BAG

ASSEMBLY

BACKING PAD

Fig. 1

WARNING:

Do not attempt to modify this tool or create accessories not recommended for use with this tool. Any such

alteration or modification is misuse and could result in a hazardous condition leading to possible serious

personal injury.

8

Page 9

OPERATION

WARNING:

Always wear safety goggles or safety glasses with

side shields when operating this tool. Failure to do

so could result in dust, shavings, or loose particles

being thrown into your eyes, resulting in possible

serious injury.

TURNING THE SANDER ON/OFF

See Figure 2.

Follow these directions to turn the sander on and off.

■

To turn the sander on

■

To turn the sander off

(O).

ADJUSTING THE SPEED

See Figure 3.

The variable speed feature allows the sander to operate

at speeds that can be adjusted by rotating the dial from

A to F. The dial is conveniently located on the motor

housing, allowing operator control of disc speed.

Follow these directions to adjust the speed.

■

To increase the speed

setting (towards F).

■

To decrease the speed

setting (towards A).

: Slide the switch to the left (|).

: Slide the switch to the right

: Turn the dial to a higher

: Turn the dial to a lower

TO

DECREASE

TO

TURN OFF

TO

TURN ON

Fig. 2

TO

INCREASE

SELECTING SANDING DISCS

Selecting the correct size grit and type of sanding disc is

an extremely important step in achieving a high quality

sanded finish. Aluminum oxide, silicon carbide, and

other synthetic abrasives are best for power sanding.

Natural abrasives, such as flint and garnet are too soft

for power sanding.

In general, when sanding, coarse grit removes the most

material and fine grit produces the best finish. The

condition of the surface to be sanded determines which

grit will do the best job. If the surface is rough, start with

a coarse grit and sand until the surface is uniform. Then

use medium grit to remove scratches left by the coarser

grit. Finally, use finer grit for finishing the surface. Always

continue sanding with each grit until the surface is

uniform.

Fig. 3

9

Page 10

OPERATION

ATTACHING ADHESIVE SANDING DISCS

See Figure 4.

Follow these directions to attach adhesive sanding discs.

■ Unplug the sander.

ADHESIVE

SANDING DISC

WARNING:

Failure to unplug the tool could result in accidental

starting causing possible serious injury.

■ Peel the paper backing from the sanding disc.

■ Align the holes in the sanding disc with the holes in

the backing pad.

NOTE: You must line up the holes in the sanding

disc with the holes in the backing pad in order for the

dustless feature to function properly.

■ Press the sticky side of the sanding disc against the

backing pad as firmly as possible.

NOTE: We recommend that you clean the backing

pad occasionally by brushing it lightly with a small

brush. Dust buildup on the backing pad could cause

the sanding disc to not stick properly.

ATTACHING VELCRO® SANDING DISCS

See Figure 5.

Follow these directions to attach Velcro sanding discs.

■ Unplug the sander.

BACKING PAD

Fig. 4

VELCRO

SANDING DISC

CONVERSION

PAD

WARNING:

Failure to unplug the tool could result in accidental

starting causing possible serious injury.

■ Peel the paper backing from the conversion pad.

■ Align the holes in the conversion pad with the holes

in the backing pad.

NOTE: You must line up the holes in the conversion

pad with the holes in the backing pad in order for the

dustless feature to function properly.

■ Press the sticky side of the conversion pad against

the backing pad as firmly as possible.

■ Align the holes in the Velcro sanding disc with the

holes in the conversion pad.

NOTE: You must line up the holes in the sanding

disc with the holes in the conversion pad in order for

the dustless feature to function properly.

■ Press the fuzzy side of the sanding disc against the

conversion pad as firmly as possible.

NOTE: You can reuse Velcro type sanding discs for

the life of the sanding abrasive. We recommend that

you clean the sanding disc backing and the

conversion pad occasionally by brushing them lightly

with a small brush to provide for their best adhesion.

BACKING PAD

Fig. 5

10

Page 11

OPERATION

USING THE DUST BAG ASSEMBLY

The dust bag assembly provides a dust collection system

for the sander. Sanding dust is drawn up through the

holes of the sanding disc and collected in the dust bag

during sanding.

TO ATTACH THE DUST BAG ASSEMBLY

See Figure 6.

Follow these directions to attach the dust bag assembly.

■ Unplug the sander.

DUST BAG

ASSEMBLY

WARNING:

Failure to unplug the tool could result in accidental

starting causing possible serious injury.

■ Slide the dust bag assembly onto the blower exhaust on the sander using a slight twisting motion.

TO EMPTY THE DUST BAG ASSEMBLY

See Figure 6 and 7.

For more efficient operation, empty the dust bag when it

is no more than half full. This will permit the air to flow

through the bag better. Always empty and clean the dust

bag thoroughly upon completion of a sanding operation

and before placing the sander in storage.

WARNING:

Collected sanding dust from sanding surface coatings such as polyurethanes, linseed oil, etc. can selfignite in your sander dust bag or elsewhere and

cause fire. To reduce the risk of fire always empty

your dust bag frequently (10-15 minutes) while sanding and never store or leave a sander without totally

emptying its dust bag. Also follow the recommendations of the coatings manufacturers.

BLOWER

EXHAUST

BLOWER

EXHAUST

DUST BAG

ASSEMBLY

FRAME

Fig. 6

Fig. 7

Follow these directions to empty the dust bag assembly.

■ Unplug the sander.

WARNING:

Failure to unplug the tool could result in accidental

starting causing possible serious injury.

■ Remove the dust bag assembly from the sander.

■ Remove the dust bag from the frame.

■ Shake out the dust.

■ Replace the dust bag on the frame.

■ Replace the dust bag assembly on the sander.

11

Page 12

OPERATION

ATTACHING THE SANDER TO A VACUUM

See Figure 8.

When sanding for an extended period of time, you can

easily attach the dust collection system of the sander to

a vacuum.

Follow these steps to attach the sander to a vacuum.

■ Unplug the sander.

WARNING:

Failure to unplug the tool could result in accidental

starting causing possible serious injury.

■ Remove the dust bag assembly from the sander.

■ Attach the vacuum hose to the blower exhaust on

the sander.

NOTE: The vacuum hose fits inside the blower

exhaust. The figure illustrates a standard 1-1/4 in.

(3.2 cm) vacuum connection.

■ Connect the sander and vacuum to a power supply.

OPERATING THE SANDER

See Figures 9 and 10.

Follow these steps to operate the sander.

■ Secure the work to prevent it from moving under the

sander.

VACUUM

BLOWER

EXHAUST

HOSE

Fig. 8

WARNING:

Unsecured work could be thrown towards the operator causing injury.

WARNING:

Keep your head away from the sander and the sanding area. Your hair could be drawn into the sander

causing serious injury.

■ Place the sander on the workpiece so that all of the

sanding disc surface is in contact with the workpiece.

CAUTION:

Be careful not to let your hand cover the air vents.

■ Start the sander and move it slowly over the

workpiece.

■ Make successive passes in parallel lines, circles, or

crosswise movements.

NOTE: The front edge of the sander allows for flush

sanding. See Figure 10.

■ Turn the sander off and wait until the sanding disc

comes to a complete stop before removing it from

the workpiece.

Fig. 9

Fig. 10

12

Page 13

OPERATION

HELPFUL TIPS

■ Do not force the sander. The weight of the unit

supplies adequate pressure; therefore, let the sanding disc and sander do the work. Applying additional

pressure only slows the motor, rapidly wears the

sanding disc, and greatly reduces the sander speed.

Excessive pressure will overload the motor causing

possible damage from motor overheating and can

result in inferior work. Any finish or resin on the

wood may soften from the frictional heat.

■ Do not sand on one spot too long. The sander’s

rapid action may remove too much material, making

the surface uneven. Extended periods of sanding

may tend to overheat the motor. If this occurs, turn

off the sander and wait until the sanding disc comes

to a complete stop. Then remove the sander from

the workpiece. Remove your hand from the vent

area, remove the sanding disc, then (with your hand

removed from the vent area) turn on the sander and

run it free, without a load, to cool the motor.

MAINTENANCE

WARNING:

When servicing use only identical Ryobi replacement parts. Use of any other parts may create a hazard or cause

product damage.

GENERAL

Avoid using solvents when cleaning plastic parts. Most

plastics are susceptible to damage from various types of

commercial solvents and may be damaged by their use.

Use clean cloths to remove dirt, carbon dust, etc.

WARNING:

Do not at any time let brake fluids, gasoline, petroleum-based products, penetrating oils, etc. come in

contact with plastic parts. They contain chemicals

that can damage, weaken, or destroy plastic.

When electric tools are used on fiberglass boats, sports

cars, wallboard, spackling compounds, or plaster, it has

been found that they are subject to accelerated wear and

possible premature failure, as the fiberglass chips and

grindings are highly abrasive to bearings, brushes,

commutators, etc. Consequently, it is not recommended

that this tool be used for extended work on any fiberglass

material, wallboard, spackling compounds, or plaster. If,

however, you do work with any of these materials, it is

extremely important that the tool is cleaned frequently by

blowing with an air jet.

WARNING:

Always wear safety goggles or safety glasses with

side shields during power tool operation or when

blowing dust. If operation is dusty, also wear a dust

mask.

13

Page 14

OPERATOR'S MANUAL

RANDOM ORBIT SANDER

RS280VS

VARIABLE SPEED – DOUBLE INSULATED

EXTENSION CORD CAUTION

When using a power tool at a considerable distance from a

power source, be sure to use an extension cord that has the

capacity to handle the current the tool will draw. An undersized cord will cause a drop in line voltage, resulting in overheating and loss of power. Use the chart to determine the minimum wire size required in an extension cord. Only round jacketed cords should be used.

When working with a tool outdoors, use an extension cord

that is designed for outside use. This is indicated by the letters

"WA" on the cord's jacket.

Before using any extension cord, inspect it for loose or exposed wires and cut or worn insulation.

**Ampere rating

(on tool faceplate) 0-2.0 2.1-3.4 3.5-5.0 5.1-7.0 7.1-12.0 12.1-16.0

Cord Length Wire Size (A.W.G.)

25' 16 16 16 16 14 14

50' 16 16 16 14 14 12

100' 16 16 14 12 10 —

CAUTION: Keep the extension cord clear of the working

area. Position the cord so that it will not get caught on

lumber, tools or other obstructions while you are working

with a power tool.

**Used on 12 gauge - 20 amp circuit.

• SERVICE

Now that you have purchased your tool, should a need ever exist for repair parts or

service, simply contact your nearest Ryobi Authorized Service Center. Be sure to

provide all pertinent facts when you call or visit. Please call 1-800-525-2579 for your

nearest Ryobi Authorized Service Center. You can also check our Web site at

www.ryobitools.com for a complete list of Authorized Service Centers.

• MODEL NO. AND SERIAL NO.

The model number of this tool will be found on a plate attached to the motor housing.

Please record the model number and serial number in the space provided below.

• HOW TO ORDER REPAIR PARTS

983000-128

7-02

WHEN ORDERING REPAIR PARTS,

ALWAYS GIVE THE FOLLOWING INFORMATION:

• MODEL NUMBER

RS280VS

• SERIAL NUMBER

RYOBI TECHNOLOGIES INC.

1428 Pearman Dairy Road Anderson, SC 29625

Post Office Box 1207 Anderson, SC 29622

www.ryobitools.com

Phone 1-800-525-2579

Loading...

Loading...