Page 1

RBS904

350W BAND SAW WITH WORK-LIGHT

OPERATOR’S MANUAL

Page 2

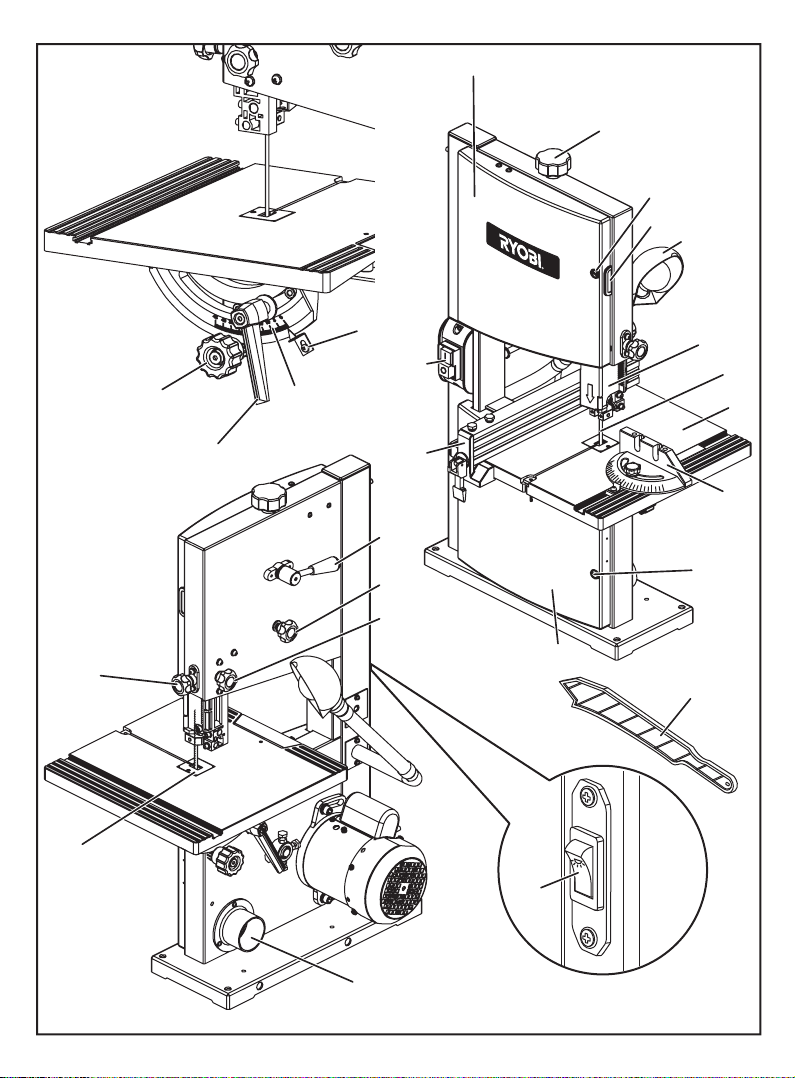

DESCRIPTION

1. Blade tension knob

2. Cover locking screw

3. Tracking view window

4. Work light

5. Blade guard

6. Saw blade

7. Mitre gauge

8. Dust exhaust port

9. Scale indicator

10. Angle adjustment knob

11. Scale

12. Table lock lever

13. Lock knob

14. Blade guide adjustment knob

15. Blade tension lever

16. Throat plate

17. Tracking knob

18. ON/OFF switch

19. Saw table

20. Front-lower panel

21. Front-upper panel

22. Rip fence

23. Work light switch

24. Push stick

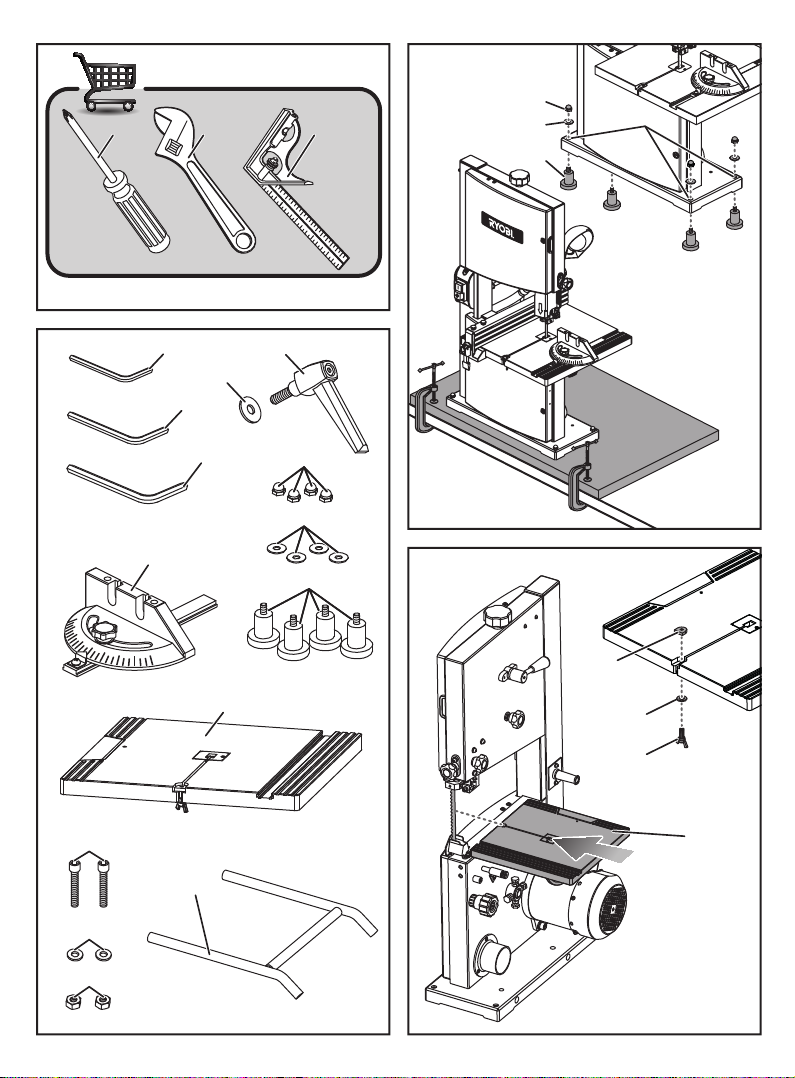

25. Phillips screwdriver (not included)

26. Adjustable wrench (not included)

27. Small combination square (not included)

28. Hex key, 3 mm

29. Hex key, 4 mm

30. Hex key, 5 mm

31. Washer

32. Cap nuts

33. Washers

34. Feet

35. Lock bolts

36. Hex nuts

37. Support extension

38. Holes in saw base

39. D-nut

40. Wing screw

41. Saw table bracket

42. Blade guide assembly

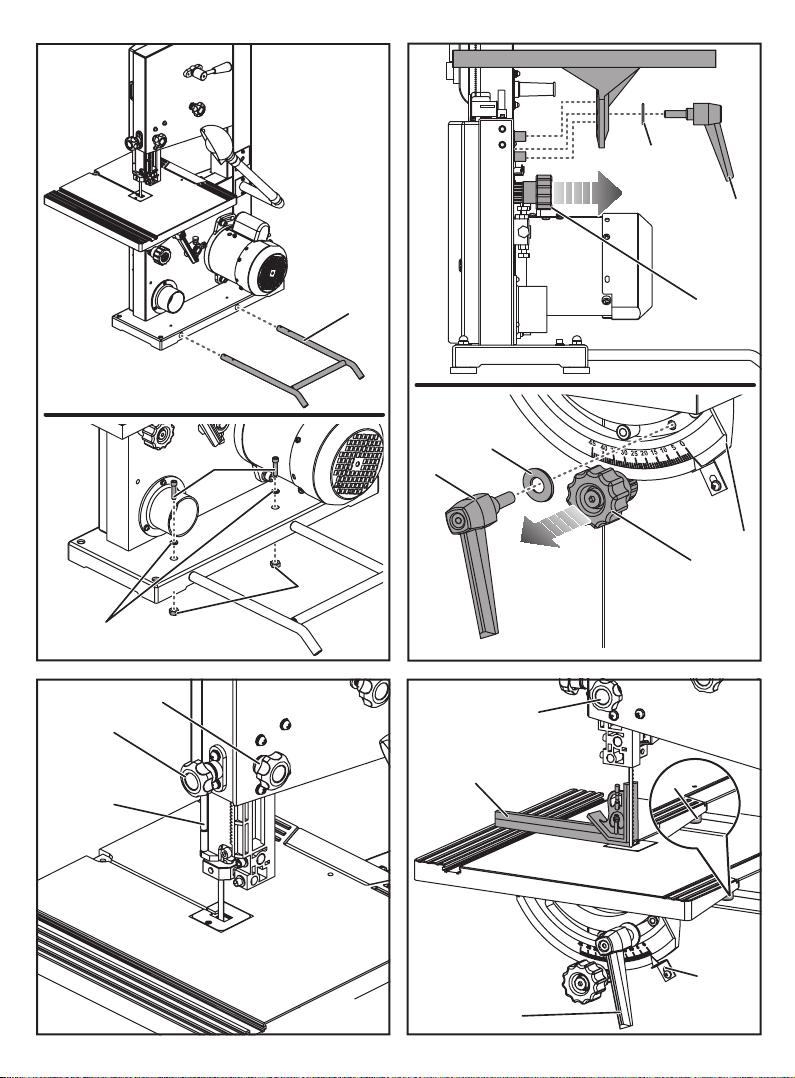

43. Adjusting bolt

44. To decrease tension

45. To increase tension

46. Lock knob

47. Mitre gauge slot

48. Phillips screws

49. Upper wheel

50. Lower blade guides

51. Lower wheel

52. Unlock

53. Lock

54. Thrust bearing

55. Thrust bearing screw

56. Blade guide support screw

57. Upper blade guide support

58. Blade guide

59. Blade guide set screw

60. Blade guide screw

61. Lower blade guide support

62. Brush

63. Washer

64. Screw

65. Tire

2

Page 3

21

1

2

3

4

9

18

10

12

14

16

11

22

15

17

13

20

OFF

23

5

6

19

7

2

24

8

Fig. 1

3

Page 4

25 26 27

Fig. 2

32

33

34

38

28

29

30

7

35

37

12

31

32

33

34

39

19

31

40

Fig. 4

19

33

36

Fig. 3 Fig. 5

4

Page 5

31

12

37

35

36

33

13

14

42

Fig. 6

31

12

13

27

10

41

10

Fig. 7

43

9

Fig. 8 Fig. 9

5

12

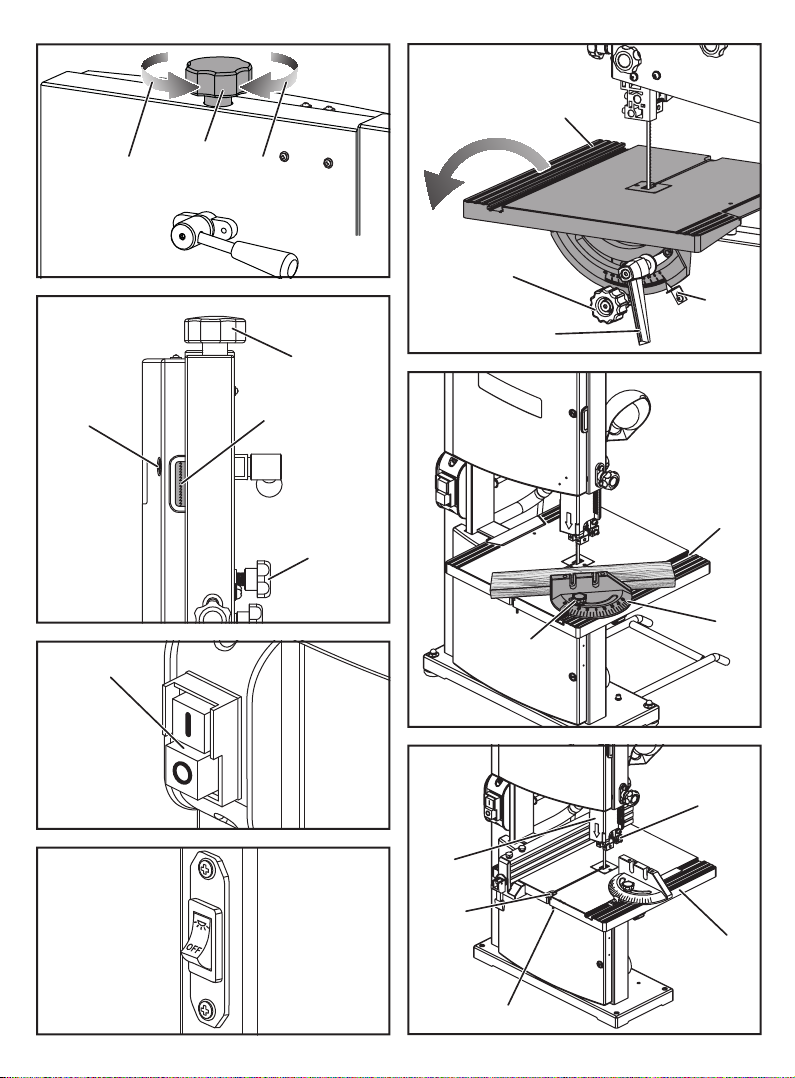

Page 6

19

44 45

2

18

1

Fig. 10

1

3

17

Fig. 11

10

9

12

46

Fig. 14

47

7

Fig. 15

Fig. 12

Fig. 13

48

5

39

19

40

6

Fig. 16

Page 7

15

13

17

1

49

14

42

Fig. 18

42

6

50

51

Fig. 17

53

52

Fig. 19

7

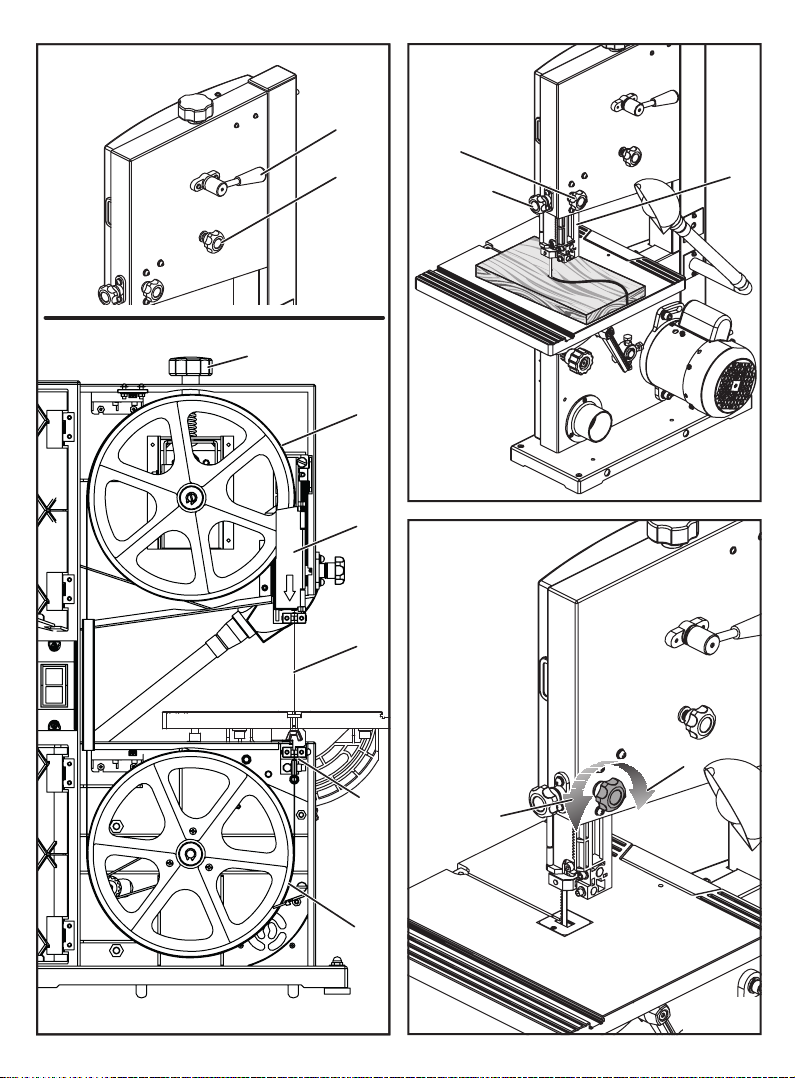

Page 8

56

61

60

13

54

55

56

55

54

Fig. 21

57

59

58

6

Fig. 20

51

62

63

64

65

Fig. 22

8

Page 9

Important!

It is essential that you read the instructions in this manual before

operating this machine.

Subject to technical modications.

9

Page 10

GENERAL POWER TOOL SAFETY WARNINGS

WARNING

When using electric tools, basic safety precautions

should always be followed to reduce the risk of re,

electric shock and personal injury.

Read all these instructions before attempting to

operate this product and save these instructions.

■ Know your power tool. Read the operator’s manual

carefully. Learn the applications and limitations as well

as the specific potential hazards related to this tool.

■ Guard against electrical shock by preventing body

contact with grounded surfaces. For example: pipes,

radiators, ranges, refrigerator enclosures.

■ Keep guards in place and in good working order.

■ Remove adjusting keys and wrenches. Form habit

of checking to see that keys and adjusting wrenches

are removed from tool before turning it on.

■ Keep work area clean. Do not leave tools or pieces

of wood on the saw while it is in operation.

■ Do not use in dangerous environments. Do not use

power tools near gasoline or other flammable liquids,

in damp or wet locations or expose them to rain. Keep

the work area well lit.

■ Keep children and visitors away. All visitors should

wear safety glasses and be kept a safe distance from

work area.

■ Make workshop childproof with padlocks, master

switches, or by removing starter keys.

■ Don’t force the tool. It will do the job better and safer

at the feed rate for which it was designed.

■ Use the right tool. Do not force the tool or attachment

to do a job for which it was not designed.

■ Dress properly. Do not wear loose clothing, gloves,

neckties, or jewellery. They can get caught and draw

you into moving parts. Rubber gloves and nonskid

footwear are recommended when working outdoors.

Also wear protective hair covering to contain long hair.

■ Always wear safety glasses with side shields.

Everyday eyeglasses have only impact-resistant

lenses; they are not safety glasses.

■ Secure work. Use clamps or a vice to hold work when

practical. It is safer than using your hand and frees

both hands to operate the tool.

■ Don’t overreach. Keep proper footing and balance at

all times.

■ Maintain tools with care. Keep tools sharp and clean

for better and safer performance. Follow instructions

for lubricating and changing accessories.

■ Disconnect tools. When not in use, before servicing,

or when changing attachments, blades, bits, cutters,

etc., all tools should be disconnected from power

source.

■ Avoid accidental starting. Be sure switch is off when

plugging in any tool.

■ Use recommended accessories. Consult the

operator’s manual for recommended accessories. The

use of improper accessories may result in injury.

■ Never stand on tool. Serious injury could occur

if the tool is tipped or if the blade is unintentionally

contacted.

■ Check for damaged parts. Check for alignment of

moving parts, binding of moving parts, breakage of

parts, mounting and any other conditions that may

affect its operation. A guard or other part that is

damaged must be properly repaired or replaced by

an authorised service centre to avoid risk of personal

injury.

■ Use the right direction of feed. Feed work into a

blade or cutter against the direction or rotation of the

blade or cutter only.

■ Never leave tool running unattended. Turn the

power off. Don't leave tool until it comes to a complete

stop.

■ Do not abuse cord. Never carry tool by the cord or

yank it to disconnect from receptacle. Keep cord away

from heat, oil, and sharp edges.

■ Use outdoor extension cords. When tool is used

outdoors, use only extension cords with approved

ground connection that are intended for use outdoors

and so marked.

■ Protect your lungs. Wear a face or dust mask if the

cutting operation is dusty.

■ Protect your hearing. Wear hearing protection during

extended periods of operation.

■ Blade coasts after being turned off.

■ Never use in an explosive atmosphere. Normal

sparking of the motor could ignite fumes.

■ Inspect tool cords periodically. If damaged,

have repaired by a qualified service technician at

an authorised service facility. The conductor with

insulation having an outer surface that is green with

or without yellow stripes is the equipment-grounding

conductor. If repair or replacement of the electric cord

or plug is necessary, do not connect the equipmentgrounding conductor to a live terminal. Repair or

replace a damaged or worn cord immediately. Stay

constantly aware of cord location and keep it well

away from the rotating blade.

■ Inspect extension cords periodically and replace if

damaged.

■ Ground all tools. If tool is equipped with three-prong

plug, it should be plugged into a three-hole electrical

receptacle.

■ Check with a qualified electrician or service

10

Page 11

personnel if the grounding instructions are not

completely understood or if in doubt as to whether the

tool is properly grounded.

■ Use only correct electrical devices: 3-wire extension

cords that have 3-prong grounding plugs and 3-pole

receptacles that accept the tool’s plug.

■ Do not modify the plug provided. If it will not fit the

outlet, have the proper outlet installed by a qualified

electrician.

■ Keep tool dry, clean, and free from oil and grease.

Always use a clean cloth when cleaning. Never use

brake fluids, gasoline, petroleum-based products, or

any solvents to clean tool.

■ Stay alert and exercise control. Watch what you are

doing and use common sense. Do not operate tool

when you are tired. Do not rush.

■ Do not use tool if switch does not turn it on and off.

Have defective switches replaced by an authorised

service centre.

■ Before making a cut, be sure all adjustments are

secure.

■ Be sure blade path is free of nails. Inspect for and

remove all nails from lumber before cutting.

■ Never touch blade or other moving parts during use.

■ Never start a tool when any rotating component is

in contact with the workpiece.

■ Do not operate a tool while under the influence of

drugs, alcohol, or any medication.

■ When servicing use only identical replacement parts.

Use of any other parts may create a hazard or cause

product damage.

■ Use only recommended accessories listed in

this manual or addenda. Use of accessories that

are not listed may cause the risk of personal injury.

Instructions for safe use of accessories are included

with the accessory.

■ Double check all setups. Make sure blade is tight

and not making contact with saw or workpiece before

connecting to power supply.

SPECIAL SAFETY RULES

■ Firmly clamp or bolt the saw to a work bench or leg

stand at approximately hip height.

■ Never operate the saw on the floor.

■ Avoid awkward operations and hand positions

where a sudden slip could cause your hand to move

into the blade. Always make sure you have good

balance.

■ Allow the motor to come up to full speed before

starting a cut to avoid binding or stalling.

■ Do not use tool if switch does not turn it on and off.

Have defective switches replaced by an authorised

service centre.

■ Replacement parts. All repairs, whether electrical or

mechanical, should be made by a qualified service

technician at an authorised service centre.

■ When servicing use only identical replacement parts.

Use of any other parts may create a hazard or cause

product damage.

■ Keep hands away from cutting area. Do not hand

hold pieces so small that your fingers go under the

blade guard. Do not reach underneath work or in

blade cutting path with your hands and fingers for any

reason.

■ Never cut more than one piece at a time or stack

more than one workpiece on the saw table at a time.

■ Do not feed the material too quickly. Do not force

the workpiece against the blade.

■ Use only correct blades. Use the right blade size and

style for the material and the type of cut. Blade teeth

should point down toward the table.

■ Always support large workpieces while cutting to

minimize risk of blade pinching and kickback. Saw

may slip, walk or slide while cutting large or heavy

boards.

■ Do not remove jammed cutoff pieces until blade has

stopped.

■ Never touch blade or other moving parts during use.

■ Before changing the setup and removing covers,

guards or blades, unplug the saw from the power

source.

■ Hold the workpiece firmly against the saw table.

■ To avoid accidental blade contact, minimize blade

breakage, and provide maximum blade support,

always adjust the blade guide assembly to just clear

the workpiece.

■ Keep blades clean, sharp, and with sufficient set.

Sharp blades minimize stalling and kickbacks.

■ Always turn off saw before disconnecting it to avoid

accidental starting when reconnecting to a power

source.

■ Make sure work area has ample lighting to see the

work and that no obstructions will interfere with safe

operation before performing any work using your saw.

■ The blade guides have been preset at the factory.

These settings are functional for some applications.

We recommend that you check and adjust blade

guide settings before first use of your saw. Refer to

Adjusting thrust bearings and blade guide support

procedures explained in the Adjustments section of

this operator’s manual.

■ Do not use tool to cut metal.

■ This tool should have the following markings:

a) wear eye protection.

b) keep fingers away from the blade.

c) do not remove jammed or cutoff pieces until the

11

Page 12

blade has stopped.

d) be sure blade is installed with teeth pointing down.

e) maintain proper adjustment of the blade tension,

blade guides, and thrust bearings.

f) adjust the upper guide to just clear the workpiece.

g) hold the workpiece firmly against the table when

cutting.

■ If the power supply cord is damaged, it must be

replaced only by the manufacturer or by an authorised

service centre to avoid risk.

■ Save these instructions. Refer to them frequently

and use them to instruct other users. If you loan

someone this tool, loan them these instructions also.

ELECTRICAL

EXTENSION CORDS

Use only 3-wire extension cords that have 3-prong

grounding plugs and 3-pole receptacles that accept the

product’s plug. When using a power tool at a considerable

distance from the power source, use an extension cord

heavy enough to carry the current that the product will

draw. An undersized extension cord will cause a drop in

line voltage, resulting in a loss of power and causing the

motor to overheat.

Before using an extension cord, inspect it for loose or

exposed wires and cut or worn insulation.

WARNING

Keep the extension cord clear of the working area.

Position the cord so that it will not get caught on lumber,

tools, or other obstructions while you are working with

a power tool. Failure to do so can result in serious

personal injury.

WARNING

Check extension cords before each use. If damaged

replace immediately. Never use the product with a

damaged cord since touching the damaged area could

cause electrical shock resulting in serious injury.

ELECTRICAL CONNECTION

This product is powered by a precision-built electric motor.

It should be connected to a power supply that is 220-240

V, AC only (normal household current), 50 Hz. Do not

operate this product on direct current (DC). A substantial

voltage drop will cause a loss of power and the motor will

overheat. If the product does not operate when plugged

into an outlet, double check the power supply.

SPEED AND WIRING

The no-load speed of this product is approximately 40m/s.

This speed is not constant and decreases under a load

or with lower voltage. For voltage, the wiring in a shop

is as important as the motor’s horsepower rating. A line

intended only for lights cannot properly carry a power tool

motor. Wire that is heavy enough for a short distance will

be too light for a greater distance. A line that can support

one power tool may not be able to support two or three

products.

GROUNDING INSTRUCTIONS

This product must be grounded. In the event of a

malfunction or breakdown, grounding provides a path

of least resistance for electric current to reduce the

risk of electric shock. This product is equipped with an

electric cord having an equipment-grounding conductor

and a grounding plug. The plug must be plugged into a

matching outlet that is properly installed and grounded in

accordance with all local codes and ordinances.

Do not modify the plug provided. If it will not t the outlet,

have the proper outlet installed by a qualied electrician.

Repair or replace a damaged or worn cord immediately.

SPECIFICATIONS

Product Specifications

Net weight 19.6 kg

Blade Width 3.2 mm to 9.5 mm

Blade Length 1572 mm (62")

Frame to Blade Capacity 230 mm (9")

Cutting Thickness Capacity 80 mm (3-1/8")

Table Size 305 mm x 305 mm

Input 220-240 V, 1.46 Amps,

No Load Speed 40m/s

Dust Port 53 mm (2-1/8")

Work light power 15 W, 230 V

KNOW YOUR BAND SAW

See Figure 1.

The safe use of this product requires an understanding of

the information on the tool and in this operator’s manual

as well as a knowledge of the project you are attempting.

Before use of this product, familiarize yourself with all

operating features and safety rules.

ANGLE ADJUSTMENT KNOB

Tilts the saw table for bevel cutting.

(1/8" to 3/8")

(12" x 12")

50 Hz.

12

Page 13

BLADE GUARD

Protects the operator from coming in contact with the

blade.

BLADE GUIDE ADJUSTMENT KNOB

Use the blade guide adjustment knob to adjust the blade

guide assembly up and down, and to keep the blade

from twisting or breaking. Always lock the blade guide

assembly in place before turning on the band saw.

BLADE GUIDES

Upper and lower blade guides helps keep the blade from

twisting during operation.

DUST EXHAUST PORT

A 53 mm (2-1/8") dust exhaust port makes dustless cutting

possible. Attach a dust bag (not included) or a shop vac to

the dust exhaust port.

COVER LOCKING SCREW

Allows front cover to be opened for making adjustments.

MITRE GAUGE

This gauge aligns the wood for a crosscut. The easy-toread indicator shows the exact angle for a mitre cut at 90°

and 45°.

RAPIDSET™ BLADE TENSION LEVER

Controls blade tension when changing blades and making

adjustments for various sawing applications.

SAW BLADE

Saw comes with a standard 6.35 mm (1/4”) blade.

SAW TABLE WITH THROAT PLATE

Your band saw has a saw table with tilt control. The throat

plate, installed in the saw table at the factory, allows for

blade clearance.

SCALE AND SCALE INDICATOR

The scale and scale indicator show the angle or degree

the saw table is tilted for bevel cutting.

TABLE LOCK LEVER

Loosening the table lock lever allows the saw table to be

tilted at different angles. Tightening the table lock lever

locks the saw table in place.

TRACKING KNOB

Adjusts tracking to keep blade centred on the wheels.

TRACKING VIEW WINDOW

The tracking view window makes tracking adjustments

easier to see.

PUSH STICK

Always use the push stick to feed the workpiece until it is

clear of the table.

LOOSE PART LIST

Item Description

1 Washers

2 Table lock lever

3 Hex key, 3 mm

4 Hex key, 4 mm

5 Hex key, 5 mm

6 Mitre gauge

7 Acorn nuts

8 Feets

9 Saw table

10 Locking bolts

11 Hex nuts

12 Extension support

ASSEMBLY

UNPACKING

This product requires assembly.

■ Carefully lift the saw from the carton and place on a

level work surface.

WARNING

Do not use this product if any parts on the Loose Part

List are already assembled to your product when you

unpack it. Parts on this list are not assembled to the

product by the manufacturer and require customer

installation. Use of a product that may have been

improperly assembled could result in serious personal

injury.

■ Inspect the tool carefully to make sure no

breakage or damage occurred during shipping.

NOTE: This saw has been shipped with no blade

tension. Do not turn this saw on until blade tension has

been properly set.

■ Do not discard the packing material until you have

carefully inspected and satisfactorily operated the tool.

■ If any parts are damaged or missing, please call your

service centre for assistance.

13

Page 14

WARNING

If any parts are damaged or missing do not operate this

product until the parts are replaced. Use of this product

with damaged or missing parts could result in serious

personal injury.

WARNING

Do not attempt to modify this tool or create accessories

not recommended for use with this tool. Any such

alteration or modication is misuse and could result

in a hazardous condition leading to possible serious

personal injury.

WARNING

Do not connect to power supply until assembly is

complete. Failure to comply could result in accidental

starting and possible serious personal injury.

MOUNTING BAND SAW TO WORKBENCH

If the band saw is to be used in a permanent location, the

band saw must be mounted to a rm supporting surface

such as a workbench. Four bolt holes have been provided

in the saw’s base for this purpose. Bolts (not included)

should be of sufcient length to accommodate the saw

base, lock washers (not included), hex nuts (not included),

and the thickness of the workbench. Tighten all four bolts

securely.

Carefully check the workbench after mounting to make

sure that no movement can occur during use. If any

tipping, sliding, or walking is noted, secure the workbench

to the oor before operating.

■ Place band saw on the workbench. Using the saw

base as a pattern, locate and mark the holes where

the band saw is to be mounted.

■ Drill holes through the workbench.

■ Place band saw on the workbench aligning holes in

the saw base with the holes drilled in the workbench.

■ Insert bolts (not included) and tighten securely

with lock washers and hex nuts (not included).

NOTE: all bolts should be inserted from the top. Install

the lock washers and hex nuts from the underside of

the bench.

CLAMPING BAND SAW TO WORKBENCH

See Figure 4.

If the band saw is to be used as a portable tool, it is

recommended that you fasten it permanently to a mounting

board that can easily be clamped to a workbench or other

supporting surface. The mounting board should be of

sufcient size to avoid tipping of saw while in use. Any

good grade plywood or chipboard with a 19 mm (3/4”)

Thickness is recommended.

If lag bolts are used, make sure they are long enough to

go through holes in the saw base and material the saw is

being mounted to. If machine bolts are being used, make

sure bolts are long enough to go through holes in the saw

base, the material being mounted to, and the lock washers

and hex nuts.

NOTE: it may be necessary to countersink hex nuts and

washers on bottom side of mounting board.

■ Mount saw to board using holes in saw base as a

template for hole pattern. Locate and mark the holes

where the band saw is to be mounted.

■ Follow the last three steps in the section Mounting

Band Saw to Workbench, shown above.

MOUNTING THE SAW TABLE

See Figures 5, 7.

■ Remove the d-nut, washers, and wing screw on the

saw table.

■ Standing at the front of the band saw, slide the saw

table past the blade and through the slot moving from

the right side of the saw table to the left.

■ Holding the saw table with your left hand while pulling

the angle adjustment knob away from the saw frame,

align the teeth on the saw table bracket into the teeth

on the angle adjustment knob. Release the knob.

■ Fit the pins on the frame into the slots of the saw table

bracket.

■ Insert the washer on the threaded end of the table

lock lever. Tighten the saw table to the saw frame by

turning the table lock lever clockwise.

■ Attach the d-nut, washers, and wing screw to the saw

table.

NOTE: the wing screw goes below the saw table.

INSTALLING EXTENSION SUPPORT

See Figure 6.

■ Insert the tubes of the extension support into the holes

in the saw base from the rear.

■ Align the holes on the tubes and those on the saw

base.

■ Insert locking bolts and tighten with washers and hex

nuts.

SQUARING THE SAW TABLE TO THE BLADE

See Figures 8 - 9.

■ Turn the lock knob counterclockwise to unlock the

blade guide assembly. Turning the blade guide

adjustment knob clockwise, raise the blade guide

assembly as far as it will go. Turn the lock knob

clockwise to retighten.

■ Place a small combination square on the saw table

beside the blade.

■ Loosen the table lock lever and rotate the angle

adjustment knob to tilt the saw table up or down to

align table 90° to blade (0° position). Retighten the

14

Page 15

table lock lever.

■ Using an adjustable wrench, loosen the jam nut.

■ Turn the adjusting bolt until the bolt just touches the

saw housing.

■ Check squareness of the saw table to the blade. Make

readjustments if necessary.

■ Once squareness is confirmed, retighten the jam nut.

■ Set scale indicator to zero and tighten screw with a

phillips screwdriver.

NOTE: always make a test cut to insure the squareness of

the blade prior to beginning any new project. If not square,

it may be necessary to loosen the screws under the saw

table to make the adjustment (mitre slot must be parallel to

the saw blade). Once square, retighten screws.

ADJUSTING BLADE TENSION

See Figures 10-11.

■ Switch off the saw.

■ Before using the band saw, turn the blade tension knob

on the top of the saw clockwise to engage tension.

■ Note: adjustments of blade tension can be made at

anytime.

■ Pluck the back straight edge of the saw blade like a

guitar string while turning the tension knob.

Sound becomes higher pitched as tension increases.

Never increase blade tension so tight as to completely

compress the spring. When completely compressed, the

spring can no longer act as a shock absorber.

Too much tension may cause the blade to break. Thicker

workpieces require higher tension; maximum tension is

not needed for all cuts. Too little tension may cause the

blade to slip on the wheels.

TRACKING THE BLADE

See Figure 11.

Adjust blade tension properly before making tracking

adjustments. Check that blade guides do not interfere

with the blade. Blade gullet (the deepest part of the blade

tooth) should be in the centre of the tire.

To adjust:

Disconnect from power. Open front covers by unscrewing

the cover locking screw. Watch the blade’s position on the

upper tire as, by hand, you slowly turn the upper wheel

clockwise. If the blade moves away from the centre of the

tire, the tracking must be adjusted.

If the blade has moved left or right of centre:

■ Turn the blade tracking knob (clockwise if blade has

moved left; counterclockwise if blade has moved right)

while turning the wheel by hand until the blade moves

back and rides in the centre of the tire.

■ Check the position of the blade on the lower tire. The

blade should be completely on the tire (gullet of the

blade teeth in the centre). If not, adjust the tracking

until the blade is on both tires.

■ Rotate the upper wheel by hand in a clockwise

direction for a few more turns. Make sure the blade

stays in the same location on the tires. Readjust, if

necessary, until blade is tracking properly.

■ Close front covers and tighten cover locking screw.

■ Switch on the saw.

■ Verify saw blade is centred on the tire (through the

tracking view window). If not centred, repeat above

steps.

WARNING

The blade guides have been preset at the factory.

These settings are functional for some applications.

We recommend that you check and adjust blade guide

settings before rst use of your saw. Refer to Adjusting

Blade Guide Support and Thrust Bearings

procedures explained in the "Adjustment" section of this

operator’s manual.

INSTALLING THE RIP FENCE

■ Place the rip fence on the left side of the saw table,

with the lock handle at the front.

■ Push down the lock handle to lock the position of the

rip fence.

■ Turn the lock handle to adjust tightness of the clamps.

OPERATION

WARNING

Do not allow familiarity with the product to make you

careless. Remember that a careless fraction of a

second is sufcient to inict serious injury.

WARNING

Always wear eye protection. Failure to do so could

result in objects being thrown into your eyes, resulting

in possible serious injury.

WARNING

Do not use any attachments or accessories not

recommended by the manufacturer of this product. The

use of attachments or accessories not recommended

can result in serious personal injury.

15

Page 16

WARNING

To avoid blade contact, adjust the blade guide assembly

to just clear the workpiece. Failure to do so could result

in serious personal injury.

WARNING

Never operate saw without the blade guard secured

and the front covers locked. To do so could result in

serious personal injury.

APPLICATIONS

You may use this product for the purposes listed below:

■ Scroll cutting and circle cutting of wood and wood

composition products

■ Various straight line cutting operations in wood and

wood composition products

BASIC OPERATION OF THE BAND SAW

A band saw is basically a “curve cutting” machine that

can also be used for straight-line cutting operations like

cross cutting, mitring, beveling, compound cutting, and

resawing. When using the band saw for straight line

cutting, the user can install a fence using an appropriately

sized piece of wood clamped to the table with “C” clamps.

It is not capable of making inside or non-through cuts.

Before starting a cut, watch the saw run. If you experience

excessive vibration or unusual noise, stop immediately.

Turn the saw off and unplug the saw. Do not restart until

locating and correcting the problem.

CUTTING PROCEDURES

■ Hold the workpiece firmly against the saw table.

■ Use gentle pressure and both hands when feeding the

work into the blade. Do not force the work; allow the

blade to cut.

■ The smallest diameter circle that can be cut is

determined by blade width. A 6.35 mm (1/4”) wide

blade will cut a minimum diameter of 38 mm (1-1/2”); a

3.2 mm (1/8”) wide blade will cut a minimum diameter

of 13 mm (1/2”).

■ Keep your hands away from the blade. Do not hand

hold pieces so small your fingers will go under the

blade guard.

■ Avoid awkward operations and hand positions where

a sudden slip could cause serious injury from contact

with the blade. Never place hands in blade path.

■ Use extra supports (tables, saw horses, blocks, etc.)

when cutting large, small, or awkward workpieces.

■ Never use a person as a substitute for a table

extension or as additional support for a workpiece that

is longer or wider than the basic saw table.

■ When cutting irregularly shaped workpieces, plan your

work so it will not pinch the blade. For example, a piece

of molding must lay flat on the saw table. Workpieces

must not twist, rock, or slip while being cut.

When backing up the workpiece, the blade may bind in

the kerf (cut). This is usually caused by sawdust clogging

the kerf or when the blade comes out of the guides. If this

happens:

■ Switch off the saw. Wait until the saw has come to a

full and complete stop. Unplug the saw from the power

source.

■ Wedge the kerf open with a flat screwdriver or wooden

wedge.

■ Open front cover and turn the upper wheel by hand

while backing up the workpiece.

RELIEF CUTS

Relief cuts are made when an intricate curve (too small

a radius for the blade) is to be cut. Cut through a scrap

section of the workpiece to curve in pattern line then

carefully back the blade out. Several relief cuts should be

made for intricate curves before following the pattern line

as sections are cut off of curve “relieving” blade pressure.

SCROLL CUTTING

For general type scroll cutting, follow the pattern lines by

pushing and turning the workpiece at the same time. Do

not try to turn the workpiece while engaged in the blade

without pushing it – the workpiece could bind or twist the

blade.

REMOVING JAMMED MATERIAL

Never remove jammed cutoff pieces until the blade has

come to a full and complete stop.

■ Switch off the saw. Wait until the saw has come to a

full and complete stop.

■ Unplug the saw from the power source before

removing jammed material.

AVOIDING INJURY

■ Make sure saw is level and does not rock. Saw should

always be on a firm, level surface with plenty of room

for handling and properly supporting the workpiece.

■ Bolt saw to the support surface to prevent slipping,

walking, or sliding during operations like cutting long,

heavy boards.

■ Switch off the saw and unplug cord from the power

source before moving the saw.

■ Do not remove jammed cutoff pieces until blade has

come to a full and complete stop.

■ Choose the right size and style blade for the material

and type of cut you plan to do.

■ Make sure that the blade teeth point down toward the

saw table, that the blade guides, thrust bearings, and

blade tension are properly adjusted, that the blade

guide knob is tight, and that no parts have excessive

16

Page 17

play.

■ To avoid accidental blade contact, minimize blade

breakage, and provide maximum blade support,

always adjust the blade guide assembly to just clear

the workpiece.

■ Use only recommended accessories.

■ With the exception of the workpiece and related

support devices, clear everything off the saw table

before turning the saw on.

■ Properly support round materials such as dowel rods

or tubing because they have a tendency to roll during

a cut causing the blade to “bite”. To avoid this, always

use a “V” block or clamp workpiece to a mitre gauge.

■ Before removing loose pieces from the saw table,

switch off the saw and wait for all moving parts to stop.

SWITCHING ON/OFF THE PRODUCT

See Figure 12.

■ Press I to switch on the product.

■ Press O to switch off the product.

BEFORE LEAVING THE SAW

See Figure 12.

■ Switch off the saw. Wait until the saw has come to a

full and complete stop.

■ Unplug the saw from the power source.

■ Make workshop childproof.

■ Release the tension from the saw blade using the

Rapidset™ blade tension lever to prolong the life of

the blade.

■ Lock the shop.

SWITCHING ON/OFF THE WORK LIGHT

See gure 13.

■ Press to switch on work light.

■ Press OFF to switch off work light.

TILTING THE TABLE

See Figure 14.

■ Loosen the table lock knob slightly.

■ Turn the angle adjustment knob, tilting the saw table

until it reaches the desired angle.

■ Using the scale indicator, check angle markings.

■ Retighten the table lock knob to hold saw table

securely in place.

OPERATION

USING THE MITRE GAUGE

See Figures 15 - 16.

The mitre gauge can be turned 30° to the right or left.

■ Loosen the lock knob on the mitre gauge.

■ With the mitre gauge in the mitre gauge slot, rotate

the gauge until the desired angle is reached on the

index scale.

■ Retighten the lock knob.

USING THE RIP FENCE

The rip fence is used for all ripping operations. Never rip

freehand without the fence in place and securely locked.

■ Position the fence to the desired width of the rip and

lock it in place.

■ Before starting to rip, be sure the rip fence is parallel

to the saw blade. When ripping long boards or large

panels, always use a work support.

■ Hold the piece against the fence and feed it through

the saw blade with a smooth, steady pressure.

ADJUSTMENTS

WARNING

Before performing any adjustment, make sure the tool

is unplugged from the power supply and the switch is in

the off position. Failure to heed this warning could result

in serious personal injury.

WARNING

To avoid personal injury, maintain proper adjustment of

blade tension, blade tracking, blade guides, and thrust

bearings.

INSTALLING AND ADJUSTING THE BLADE

See Figure 17.

■ Loosen and remove the wing screw, washers, and

D-nut from the saw table.

■ Open the front covers by unscrewing the cover locking

screw.

■ Turn the lock knob counterclockwise to unlock the

blade guide assembly. Turning the blade guide

knob (clockwise raises the blade guide assembly;

counterclockwise lowers it), position the blade guide

assembly about halfway between the saw table and

saw housing. Retighten the lock knob.

■ Open the blade guard by pulling the left side of the

guard out and away from the wheel.

■ Release all blade tension from the blade.

■ Carefully remove the old blade.

■ Wearing gloves, carefully uncoil the new blade at arms

length. If the new blade was oiled to prevent rusting,

it may need to be wiped to keep the oil from your

workpiece. Carefully wipe in the same direction the

teeth are pointing so the rag does not catch on the

teeth of the saw blade.

17

Page 18

NOTE: The blade may need to be turned inside out if the

teeth are pointing in the wrong direction. Hold the blade

with both hands and rotate it inward.

■ With the teeth of the blade toward the left of the saw

and facing downward, place the blade through the

lower blade guides and around both wheels.

■ Slowly turn the upper wheel to the right or clockwise by

hand to centre the blade on the rubber tires.

■ Re-engage the RapidSet™ blade tension lever then

adjust the blade tension; check or adjust the blade

tracking.

■ Adjust both upper and lower blade guides and thrust

bearings as explained later in this Operator’s Manual.

■ Reattach the wing screw, washers, and D-nut. Tighten

securely.

■ Close the blade guard and front cover. Tighten the

cover locking screw.

ADJUSTING BLADE GUIDE ASSEMBLY

See Figures 18 - 19.

To prevent the blade from twisting or breaking, the blade

guide assembly should always be set approximately 3.2

mm (1/8”) above the workpiece.

■ Turn the lock knob counterclockwise to unlock the

blade guide assembly.

■ As a guide, use a scrap piece of the same wood you

are about to cut to set the height of the blade guide

assembly. Adjust the blade guide assembly by turning

the blade guide knob.

■ Lock blade guide assembly in place by turning the lock

knob clockwise.

■ Always lock the blade guide assembly in place before

turning on the band saw.

ADJUSTING BLADE GUIDE SUPPORT AND THRUST

BEARINGS

See Figures 20 - 21.

NOTE: Tighten the lock knob and refer to Adjusting

Blade Tension and Tracking the Blade procedures

explained in the ASSEMBLY section of this operator’s

manual prior to making adjustments.

The upper and lower blade thrust bearings support and

bearing guides the saw blade during cutting operations.

The adjustment of the bearings and guides should be

checked whenever a different blade is installed.

To adjust thrust bearings:

The thrust bearings support the back edge of the blade

during cutting. The blade should not contact the thrust

bearings when you stop cutting. It is important that both

upper and lower thrust bearings be adjusted equally.

■ Open the front covers and blade guard.

■ Using a hex key, loosen the upper and lower thrust

bearing screws and push thrust bearings to the back

of the saw.

■ Verify that saw blade is tracking correctly, then slide

the thrust bearing forward until the bearing is within

0.4 mm (1/64”) of the blade. Tighten the thrust bearing

screw securely.

■ Slide lower bearing forward until it has proper

clearance. Tighten the thrust bearing screw securely.

To adjust blade guide support:

■ Loosen the blade guide support and blade guide set

screws using hex keys.

■ Slide the upper blade guide support on the shaft until

the front edge of the guides contact the saw blade

behind the gullet. Tighten the screw securely.

■ Push the right guide to contact the blade and release.

Slowly rotate wheel one full rotation. Tighten blade

guide set screws.

■ Adjust left side guide to allow 0.4 mm (1/64”) clearance

between the blade and guide (about the thickness of a

playing card) by inserting a playing card between left

guide and blade.

■ Apply pressure to left guide pin to hold the playing card

in place. Tighten set screw and remove the playing

card.

■ Rotate, by hand, a full three rotations to make sure

blade will not bind.

■ Close the blade guard and front cover. Lock with

screw.

Repeat this procedure for the lower blade guide support.

ADJUSTING THE RIP FENCE

■ Loosen the lock handle by turning it counterclockwise.

■ Move the rip fence to the desired position.

■ Push down the lock handle to lock the position of the

rip fence.

■ Turn the lock handle to adjust tightness of the clamps.

MAINTENANCE

WARNING

When servicing, use only identical replacement parts.

Use of any other parts can create a hazard or cause

product damage.

WARNING

Always wear eye protection during product operation. If

operation is dusty, also wear a dust mask.

18

Page 19

WARNING

Before performing any maintenance, make sure the tool

is unplugged from the power supply and the switch is in

the off position. Failure to heed this warning could result

in serious personal injury.

GENERAL MAINTENANCE

Avoid using solvents when cleaning plastic parts. Most

plastics are susceptible to damage from various types of

commercial solvents and may be damaged by their use.

Use clean cloths to remove dirt, dust, oil, grease, etc.

adjusted or replaced.

■ Remove the screw and washer then pull the brush off.

■ Place the new brush in the groove.

■ Reinstall using the washer and screw.

ENVIRONMENTAL PROTECTION

Recycle raw materials instead of disposing

of as waste. The machine, accessories

and packaging should be sorted for

environmental-friendly recycling.

WARNING

Do not at any time let brake uids, gasoline, petroleum-

based products, penetrating oils, etc., come in contact

with plastic parts. Chemicals can damage, weaken or

destroy plastic which may result in serious personal

injury.

■ Keep your band saw clean.

■ Remove sawdust from the inside frequently.

■ Do not allow pitch to accumulate on the saw table,

blade guides, or thrust bearings. Clean them with gum

and pitch remover.

■ Apply a thin coat of automobile type wax to the saw

table’s top so the wood slides easily while cutting.

Lubrication

All of the bearings in this tool are lubricated with a sufcient

amount of high grade lubricant for the life of the unit

under normal operating conditions. Therefore, no further

lubrication is required.

TIRES

Cleaning tires:

■ Pitch and sawdust accumulates on tires and needs to

be removed with a fine wire brush or a piece of wood.

Do not use a sharp knife or any kind of solvent.

Replacing tires:

■ Open front cover and remove saw blade. See section

on Installing and Adjusting the Blade.

■ Pry the worn tire away from the wheel carefully.

■ Stretch the new tire around the wheel.

■ Replace the saw blade and close the front cover.

BRUSH

See Figure 22.

There is a brush located inside the saw housing next to the

wheel. It helps protect the tire and wheel by brushing off

saw dust. As the brush becomes worn, it will need to be

SYMBOL

Safety alert

Regulatory Compliance Mark (RCM). Product

meets applicable regulatory requirements.

Please read the instructions carefully before

starting the product.

Wear eye protection.

Wear ear protection.

Wear ear protection, eye protection and a

mask.

DANGER! Sharp blade.

Lock

Unlock

Waste electrical products should not be

disposed of with household waste. Please

recycle where facilities exist. Check with your

Local Authority or retailer for recycling advice.

19

Page 20

TROUBLE SHOOTING

PROBLEM CAUSE SOLUTION

Motor will not run. 1. Problem with ON/OFF switch

Blade does not run in the

approximate centre of the upper

wheel.

Band Saw slows down when 1. Cutting too small a radius.

Blade breaking. 1. Too much blade tension.

Saw is noisy when running. 1. Too much blade tension.

Blade will not cut straight. 1. Blade guides and bearings not

Blade guides will not stay in

position.

Motor runs but blade does not

turn

or power cord.

2. Motor defective.

3. Blade is binding.

1. Not tracking properly. 1. Adjust tracking, See ADJUSTMENTS

2. Dull blade.

2. Kink in blade caused by cutting

too small radius or turning the

material too fast when cutting.

3. Thrust bearings scarred or not

rotating.

2. Blade guides and bearings are

in contact with the blade.

properly adjusted.

2. Worn or defective blade.

1. Blade guide screws have

loosened.

1. Tension not set properly.

2. Drive belt broken.

1. Have worn parts replaced before

using band saw again.

2. Do not attempt any repair. Have

tool repaired by a qualied service

technician.

3. Remove jammed material.

section, “Tracking the Blade”.

2. Have tool repaired by a qualied

service technician.

1. Stop feeding and back up the cutting

material slightly until the band saw

speeds up.

2. Replace blade.

1. Adjust tension. See ADJUSTMENTS

section, Adjusting Blade Tension.

2. Use correct cutting technique. See

section, Operation.

3. Replace the thrust bearings.

1. Adjust tension. See ADJUSTMENTS

section, Adjusting Blade Tension.

2. Adjust upper and lower blade guides

and bearings. See ADJUSTMENTS

sections, Adjusting Thrust Bearings

and Blade Guide Support.

1. Adjust upper and lower blade guides

and bearings. See ADJUSTMENTS

sections, Adjusting Thrust Bearings

and Blade Guide Support.

2. Replace blade.

1. Tighten blade guide screws securely.

1. Use Rapidset Blade Tension Lever to

set tension.

2. Have tool repaired by a qualied

service technician.

20

Page 21

Techtronic Industries (Australia) Pty. Ltd.

Level 1, 660 Doncaster Road

Doncaster, VIC 3108, Australia

Techtronic Industries New Zealand Ltd.

18-26 Amelia Earhart Avenue

Mangere, Auckland 2022, New Zealand

Loading...

Loading...