Page 1

OPERATOR’S MANUAL

MANUEL D’UTILISATION

MANUAL DEL OPERADOR

18 GA BRAD NAILER

CLOUEUSE À PARQUET

DE CALIBRE 18

CLAVADORA DE PUNTILLAS

CALIBRE 18

P320

TABLE OF CONTENTS

****************

General Power Tool Safety Warnings

........................................................2-3

Nailer Safety Warnings ....................3-5

Symbols ..............................................6

Glossary .............................................7

Features .............................................. 7

Assembly ............................................ 7

Operation .......................................8-10

Maintenance ..................................... 10

Troubleshooting ................................ 11

Illustrations ..................................12-13

Parts Ordering

and Service ........................Back page

TABLE DES MATIÈRES

****************

Règles de sécurité générales relatives

aux outils électriques ......................2-3

Avertissements de sécurité relatifs

cloueuse à parquet .........................3-5

Symboles ............................................6

Glossaire .............................................7

Caractéristiques .................................7

Assemblage ........................................ 7

Utilisation ......................................8-10

Entretien ...........................................10

Dépannage ....................................... 11

Illustrations ..................................12-13

Commande de pièces

et dépannage ...................Page arrière

6

inch

5

4

3

2

1

ÍNDICE DE CONTENIDO

****************

Advertencias de seguridad para

herramientas eléctrica ................... 2-3

Advertencias de clavadora

de puntillas .................................... 3-5

Símbolos ............................................6

Glosario de términos .........................7

Características ...................................7

Armado ..............................................7

Funcionamiento ........................... 8-10

Mantenimiento .................................10

Corrección de problemas ................11

Illustraciones .............................. 12-13

Pedidos de piezas

y servicio ....................... Pág. posterior

WARNING: To reduce the

risk of injury, the user must read and

understand the operator’s manual

before using this product.

SAVE THIS MANUAL FOR

FUTURE REFERENCE

AVERTISSEMENT :

réduire les risques de blessures,

l’utilisateur doit lire et veiller à bien

comprendre le manuel d’utilisation avant

d’employer ce produit.

Pour

CONSERVER CE MANUEL

POUR FUTURE RÉFÉRENCE

ADVERTENCIA: Para reducir

el riesgo de lesiones, el usuario debe leer

y comprender el manual del operador

antes de usar este producto.

GUARDE ESTE MANUAL

PARA FUTURAS CONSULTAS

Page 2

GENERAL POWER TOOL SAFETY WARNINGS

WARNING

Read all safety warnings and all instructions. Failure to

follow the warnings and instructions may result in electric

shock, fire and/or serious injury.

Save all warnings and instructions for future reference.

The term “power tool” in the warnings refers to your mainsoperated (corded) power tool or battery-operated (cordless)

power tool.

WORK AREA SAFETY

Keep work area clean and well lit. Cluttered or dark

areas invite accidents.

Do not operate power tools in explosive atmospheres,

such as in the presence of flammable liquids, gases

or dust. Power tools create sparks which may ignite the

dust or fumes.

Keep children and bystanders away while operating a

power tool. Distractions can cause you to lose control.

ELECTRICAL SAFETY

Power tool plugs must match the outlet. Never modify

the plug in any way. Do not use any adapter plugs with

earthed (grounded) power tools. Unmodified plugs and

matching outlets will reduce risk of electric shock.

Avoid body contact with earthed or grounded surfaces

such as pipes, radiators, ranges and refrigerators.

There is an increased risk of electric shock if your body

is earthed or grounded.

Do not expose power tools to rain or wet conditions.

Water entering a power tool will increase the risk of electric shock.

Do not abuse the cord. Never use the cord for carrying,

pulling or unplugging the power tool. Keep cord away

from heat, oil, sharp edges or moving parts. Damaged

or entangled cords increase the risk of electric shock.

When operating a power tool outdoors, use an exten-

sion cord suitable for outdoor use. Use of a cord suit-

able for outdoor use reduces the risk of electric shock.

If operating a power tool in a damp location is un-

avoidable, use a ground fault circuit interrupter (GFCI)

protected supply. Use of a GFCI reduces the risk of

electric shock.

Use battery only with charger listed. For use with 18V

nickel-cadmium and 18V lithium-ion battery packs, see

tool/appliance/battery pack/charger correlation supplement 987000-432.

PERSONAL SAFETY

Stay alert, watch what you are doing and use com-

mon sense when operating a power tool. Do not use

a power tool while you are tired or under the influence

of drugs, alcohol or medication. A moment of inatten-

2 — English

tion while operating power tools may result in serious

personal injury.

Use personal protective equipment. Always wear eye

protection. Protective equipment such as dust mask,

non-skid safety shoes, hard hat, or hearing protection

used for appropriate conditions will reduce personal

injuries.

Prevent unintentional starting. Ensure the switch is in

the off-position before connecting to power source

and/or battery pack, picking up or carrying the tool.

Carrying power tools with your finger on the switch or

energising power tools that have the switch on invites

accidents.

Remove any adjusting key or wrench before turning

the power tool on. A wrench or a key left attached to

a rotating part of the power tool may result in personal

injury.

Do not overreach. Keep proper footing and balance

at all times. This enables better control of the power tool

in unexpected situations.

Dress properly. Do not wear loose clothing or jewel-

lery. Keep your hair, clothing and gloves away from

moving parts. Loose clothes, jewellery or long hair can

be caught in moving parts.

If devices are provided for the connection of dust

extraction and collection facilities, ensure these are

connected and properly used. Use of dust collection

can reduce dust-related hazards.

Do not wear loose clothing or jewellery. Contain long

hair. Loose clothes, jewelry, or long hair can be drawn

into air vents.

Do not use on a ladder or unstable support. Stable

footing on a solid surface enables better control of the

power tool in unexpected situations.

POWER TOOL USE AND CARE

Do not force the power tool. Use the correct power

tool for your application. The correct power tool will

do the job better and safer at the rate for which it was

designed.

Do not use the power tool if the switch does not turn

it on and off. Any power tool that cannot be controlled

with the switch is dangerous and must be repaired.

Disconnect the plug from the power source and/or

the battery pack from the power tool before making

any adjustments, changing accessories, or storing

power tools. Such preventive safety measures reduce

the risk of starting the power tool accidentally.

Store idle power tools out of the reach of children and

do not allow persons unfamiliar with the power tool

or these instructions to operate the power tool. Power

tools are dangerous in the hands of untrained users.

Page 3

GENERAL POWER TOOL SAFETY WARNINGS

Maintain power tools. Check for misalignment or bind-

ing of moving parts, breakage of parts and any other

condition that may affect the power tool’s operation.

If damaged, have the power tool repaired before use.

Many accidents are caused by poorly maintained power

tools.

Keep cutting tools sharp and clean. Properly main-

tained cutting tools with sharp cutting edges are less

likely to bind and are easier to control.

Use the power tool, accessories and tool bits etc.

in accordance with these instructions, taking into

account the working conditions and the work to be

performed. Use of the power tool for operations different

from those intended could result in a hazardous situation.

BATTERY TOOL USE AND CARE

Recharge only with the charger specified by the

manufacturer. A charger that is suitable for one type

of battery pack may create a risk of fire when used with

another battery pack.

Use power tools only with specifically designated bat-

tery packs. Use of any other battery packs may create

a risk of injury and fire.

When battery pack is not in use, keep it away from

other metal objects, like paper clips, coins, keys, nails,

screws or other small metal objects, that can make a

connection from one terminal to another. Shorting the

battery terminals together may cause burns or a fire.

Under abusive conditions, liquid may be ejected from

the battery; avoid contact. If contact accidentally

occurs, flush with water. If liquid contacts eyes, additionally seek medical help. Liquid ejected from the

battery may cause irritation or burns.

SERVICE

Have your power tool serviced by a qualified repair

person using only identical replacement parts. This will

ensure that the safety of the power tool is maintained.

When servicing a power tool, use only identical

replacement parts. Follow instructions in the Maintenance section of this manual. Use of unauthorized

parts or failure to follow Maintenance instructions may

create a risk of shock or injury.

NAILER SAFETY WARNINGS

Always assume that the tool contains nails. Careless

handling of the nailer can result in unexpected firing of

nails and personal injury.

Do not point the tool towards yourself or anyone

nearby. Unexpected triggering will discharge the nail

causing an injury.

Do not actuate the tool unless the tool is placed firmly

against the workpiece. If the tool is not in contact with

the workpiece, the nail may be deflected away from your

target.

Disconnect the tool from the power source when the

fastener jams in the tool. While removing a jammed

fastener, the tacker may be accidentally activated if it is

plugged in.

Use caution while removing a jammed nail. The mecha-

nism may be under compression and the nail may be

forcefully discharged while attempting to free a jammed

condition.

Do not use this nailer for fastening electrical cables.

It is not designed for electric cable installation and may

damage the insulation of electric cables thereby causing

electric shock or fire hazards.

Hold power tool by insulated gripping surfaces, when

performing an operation where the nail may contact

hidden wiring. Nails contacting a “live” wire may make

exposed metal parts of the power tool “live” and could

give the operator an electric shock.

Know your power tool. Read operator’s manual care-

fully. Learn its applications and limitations, as well as

the specific potential hazards related to this power

tool. Following this rule will reduce the risk of electric

shock, fire, or serious injury.

Always wear eye protection with side shields marked

to comply with ANSI Z87.1. Everyday glasses have only

impact resistant lenses. They are not safety glasses. Following this rule will reduce the risk of serious personal

injury.

Eye protection which conforms to ANSI specifications

and provides protection against flying particles both

from the FRONT and SIDE should ALWAYS be worn

by the operator and others in the work area when

loading, operating or servicing this tool. Eye protection

is required to guard against flying fasteners and debris,

which could cause severe eye injury.

3 — English

Page 4

NAILER SAFETY WARNINGS

The employer and/or user must ensure that proper

eye protection is worn. We recommend Wide Vision

Safety Mask for use over eyeglasses or standard safety

glasses that provide protection against flying particles

both from the front and side. Always use eye protection

which is marked to comply with ANSI Z87.1.

Additional safety protection will be required in some

environments. For example, the working area may in-

clude exposure to noise level which can lead to hearing

damage. The employer and user must ensure that any

necessary hearing protection is provided and used by the

operator and others in the work area. Some environments

will require the use of head protection equipment. When

required, the employer and user must ensure that head

protection conforming to ANSI Z89.1-1997 is used.

Keep fingers away from trigger when not driving fasteners to avoid accidental firing

Use safety equipment. Always wear eye protection.

Dust mask, nonskid safety shoes, hard hat, or hearing

protection must be used for appropriate conditions.

Protect your lungs. Wear a face or dust mask if the

operation is dusty. Following this rule will reduce the

risk of serious personal injury.

Protect your hearing. Wear hearing protection during

extended periods of operation. Following this rule will

reduce the risk of serious personal injury.

Battery tools do not have to be plugged into an elec-

trical outlet; therefore, they are always in operating

condition. Be aware of possible hazards when not

using your battery tool or when changing accessories.

Following this rule will reduce the risk of electric shock,

fire, or serious personal injury.

Do not place battery tools or their batteries near fire

or heat. This will reduce the risk of explosion and pos-

sibly injury.

Use the tool only for its intended use. Do not discharge

fasteners into open air.

Use the tool only for the purpose for which it was

designed.

Use only the nails recommended for this tool. Use of

the wrong nails could result in poor nail feeding, jammed

nails, and nails leaving the tool at erratic angles. If nails

are not feeding smoothly and properly, discontinue their

use immediately. Jammed and improperly feeding nails

could result in serious personal injury.

Never use this tool in a manner that could cause a

nail to be directed toward anything other than the

workpiece.

Do not use the tool as a hammer.

Always carry the tool by the handle.

Do not alter or modify this tool from the original design

or function without approval from the manufacturer.

.

Always be aware that misuse and improper handling

of this tool can cause injury to yourself and others.

Never clamp or tape the trigger or workpiece contact

in an actuated position.

Never leave tool unattended if the battery is installed.

Do not operate this tool if it does not contain a legible

warning label.

Keep the tool and its handle dry, clean and free from

oil and grease. Always use a clean cloth when clean-

ing. Never use brake fluids, gasoline, petroleum-based

products, or any strong solvents to clean your tool. Following this rule will reduce the risk of loss of control and

deterioration of the enclosure plastic.

OPERATION

Do not use tool if trigger does not actuate properly.

Any tool that cannot be controlled with the trigger is

dangerous and must be repaired.

Check operation of the workpiece contact mechanism

frequently. Do not use the tool if the workpiece contact

mechanism is not working correctly as accidental driving of a nail may result. Do not interfere with the proper

operation of the workpiece contact mechanism.

Do not use a tool that does not work correctly.

Always assume that the tool contains nails.

Do not carry the tool from place to place holding the

trigger. Accidental discharge could result.

Always handle the tool with care:

• Respect the tool as a working implement.

• Never engage in horseplay.

• Never pull the trigger unless nose is directed toward the

work.

• Keep others a safe distance from the tool while tool is in

operation as accidental actuation may occur, possibly

causing injury.

Choice of triggering method is important. Check

manual for triggering options.

The brad nailer is designed for single-hand use. Do

not hold the tool by the front of the magazine. Do not put

hands, head, or other parts of your body near the bottom

of the magazine where the nail exits the tool, as serious

personal injury could result.

Do not point the tool toward yourself or anyone

whether it contains nails or not.

Do not actuate the tool unless you intend to drive a

nail into the workpiece.

Always ensure that the workpiece contact is fully posi-

tioned above the workpiece. Positioning the workpiece

contact only partially above the workpiece could cause

the nail to miss the workpiece completely and result in

serious personal injury.

4 — English

Page 5

NAILER SAFETY WARNINGS

Do not drive nails near edge of material. The workpiece

may split causing the nail to ricochet, injuring you or a

co-worker. Be aware that the nail may follow the grain

of the wood, causing it to protrude unexpectedly from

the side of the work material or deflect, possibly causing

injury.

Keep hands and body parts clear of immediate work

area. Hold workpiece with clamps when necessary to

keep hands and body out of potential harm. Be sure the

workpiece is properly secured before pressing the fastener against the material. The workpiece contact may

cause the work material to shift unexpectedly.

Keep face and body parts away from back of the tool

cap when working in restricted areas. Sudden recoil

can result in impact to the body, especially when nailing

into hard or dense material.

During normal use the tool will recoil immediately

after driving a fastener. This is a normal function of

the tool. Do not attempt to prevent the recoil by holding

the nailer against the work. Restriction to the recoil can

result in a second fastener being driven from the nailer.

Grip the handle firmly, let the tool do the work and do not

place second hand on top of tool or near exhaust at any

time. Failure to heed this warning can result in serious

personal injury.

Do not drive fasteners on top of other fasteners or with

the tool at an overly steep angle as this may cause

deflection of fasteners which could cause injury.

LOADING TOOL

Do not load the tool with fasteners when any one of

the operating controls is activated.

When loading tool:

Never place a hand or any part of body in fastener

discharge area of tool.

Never point tool at anyone.

Do not pull the trigger or depress the workpiece

contact as accidental actuation may occur, possibly

causing injury.

SAVE THESE INSTRUCTIONS

Refer to them frequently and use them to instruct others

who may use this tool. If you loan someone this tool, loan

them these instructions also.

5 — English

Page 6

SYMBOLS

The following signal words and meanings are intended to explain the levels of risk associated with this product.

SYMBOL SIGNAL MEANING

DANGER:

WARNING:

CAUTION:

NOTICE:

Some of the following symbols may be used on this product. Please study them and learn their meaning. Proper

interpretation of these symbols will allow you to operate the product better and safer.

SYMBOL

Safety Alert Indicates a potential personal injury hazard.

Read Operator’s Manual

Eye Protection

NAME

Indicates an imminently hazardous situation, which, if not avoided, will result

in death or serious injury.

Indicates a potentially hazardous situation, which, if not avoided, could result

in death or serious injury.

Indicates a potentially hazardous situation, which, if not avoided, may result in

minor or moderate injury.

(Without Safety Alert Symbol) Indicates important information not related to an

injury hazard, such as a situation that may result in property damage.

DESIGNATION/EXPLANATION

To reduce the risk of injury, user must read and understand

operator’s manual before using this product.

Always wear eye protection with side shields marked to comply

with ANSI Z87.1.

Keep Hands Away Keep hands and body away from the discharge area of the tool.

Wet Conditions Alert Do not expose to rain or use in damp locations.

This product uses lithium-ion or nickel-cadmium batteries. Local,

Recycle Symbols

V Volts Voltage

A Amperes Current

Hz Hertz Frequency (cycles per second)

min Minutes Time

Direct Current Type or a characteristic of current

n

o

.../min Per Minute Revolutions, strokes, surface speed, orbits etc., per minute

No Load Speed Rotational speed, at no load

state or federal laws may prohibit disposal of batteries in ordinary

trash. Consult your local waste authority for information regarding

available recycling and/or disposal options.

6 — English

Page 7

GLOSSARY

Activate (operating controls)

To move an operating control so that it is in a position that

allows the tool to be actuated or that satisifes one requirement

for the tool to be actuated.

Actuate (tool)

To cause movement of the tool component(s) intended to

drive a fastener.

Actuation system

The use of a trigger, workpiece contact, and/or other operating

control, separately or in some combination or sequence, to

actuate the tool.

• Single sequential actuation

An actuation system in which there is more than one

operating control and the operating controls must be

activated in a specific sequence to actuate the tool.

Additional actuation can occur when a specific operating

control, other than a workpiece contact, is released and

re-activated.

• Contact actuation

An actuation system in which there is more than one

operating control and the operating controls can be

activated in any sequence to actuate the tool. Additional

actuation can occur when any operating control is

released and re-activated.

Fastener

A staple, pin, brad, nail, or other fastening device which is

designed and manufactured for use in the tools within the

scope of this standard.

Jam

An obstruction in the feed or drive areas of the tool.

Operating control

A control that separately, or as part of an actuation system,

can cause the actuation of a tool.

Trigger

A tool operating control activated by a tool operator’s fingers.

Workpiece

The intended object into which a fastener is to be driven

by a tool.

Workpiece contact

An operating control element or assembly on the tool intended

to be activated by the material to be fastened.

FEATURES

PRODUCT SPECIFICATIONS

Magazine Capacity ............................................... 105 Nails

Nailer Speed .........................................up to 60 shots/min.

Nail Type ...............................................................18 gauge

Brad Nail Length.................................................. 5/8 - 2 in.

ASSEMBLY

WARNING:

Do not use this product if it is not completely assembled

or if any parts appear to be missing or damaged. Use of

a product that is not properly and completely assembled

or with damaged or missing parts could result in serious

personal injury.

If any parts are damaged or missing, please call 1-800-525-2579 for assistance.

WARNING:

Do not attempt to modify this product or create

accessories or attachments not recommended for use

with this product. Any such alteration or modification is

misuse and could result in a hazardous condition leading

to possible serious personal injury.

7 — English

Page 8

OPERATION

WARNING:

Do not allow familiarity with products to make you careless. Remember that a careless fraction of a second is

sufficient to inflict severe injury.

WARNING:

Always remove battery pack from the tool when you are

assembling parts, making adjustments, cleaning, or when

not in use. Removing battery pack will prevent accidental

starting that could cause serious personal injury.

WARNING:

Always wear eye protection with side shields marked to

comply with ANSI Z87.1. Failure to do so could result in

objects being thrown into your eyes, resulting in possible

serious injury.

APPLICATIONS

You may use this tool for the purposes listed below:

Finish and Trim (Interior and exterior)

Door & Window Casing

Door Jambs

Baseboard

Crown Molding

Cabinetry

Cap and Shoe Molding

Molding

Staircases

Door and Window Trim

Chair Rail

Brickmold

Hardwood Flooring

Paneling

Furniture

ATTACH BELT CLIP

See Figure 1, page 12.

The belt clip can be installed on the left or right side of the

nailer, depending on operator preference.

Alignbeltclipandscrewwithrightorleftsidescrewhole.

Usingaphillipsheadscrewdriver(notincluded)tighten

securely.

TO INSTALL / REMOVE BATTERY PACK

See Figure 2, page 12.

To install battery pack:

Place battery pack in the tool. Align raised rib inside tool

with groove on battery pack.

Make sure the latches on each side of the battery pack

snap into place and battery pack is secured in tool before

beginning operation.

NOTE: Squeeze LED light grip switch to reactivate nailer.

To remove battery pack:

Locate latches on battery pack and depress to release

battery pack from the tool.

NO-MAR PAD

See Figure 3, page 12.

The no-mar pad attached to the nose of the tool helps prevent marring and denting when working with softer woods.

Remove the battery. Remove the pad by pulling it down and

away from the nose. To replace the pad, fit it into place over

the nose and push up to reseat.

On-board storage for the pad is located on the magazine of

the tool. An extra no-mar pad is provided in the on-board

storage area.

LOADING THE TOOL WITH BRAD NAILS

See Figures 4 - 5, page 12.

WARNING:

Keep the tool pointed away from yourself and others

when loading nails. Failure to do so could result in possible serious personal injury.

Remove battery pack from the tool, if installed.

With the nose of the tool pointed away from you, squeeze

magazine release button located at the rear of the magazine and slide the magazine cover open.

Place brad nails in the channel with nail tips pointing down

and resting on bottom of the channel.

Push the magazine cover closed until it securely snaps

into place.

Make sure that the magazine is securely locked in place.

Reinstall battery, and reactivate nailer by pressing the

worklight grip switch.

8 — English

Page 9

OPERATION

SETTING THE AIR PRESSURE

See Figure 6, page 13.

The amount of air pressure required will depend on the size

of the nail and the workpiece material.

Begin testing the depth of drive by driving a test nail into

the same type of workpiece material used for the actual job.

Remove battery pack from the tool, if installed.

Turn air pressure dial clockwise to increase air pressure

or counterclockwise for decreased pressure.

It may be possible to achieve the desired depth with air

pressure adjustments alone. If finer adjustments are needed,

use the depth of drive adjustment on the tool.

NOTE: Under some conditions, the unit may not deliver a

nail when the air pressure dial is turned to the MAXIMUM

pressure setting. The user may need to decrease the pressure setting for desired operation

DEPTH OF DRIVE ADJUSTMENT

See Figure 7, page 13.

The driving depth of the nail may be adjusted beyond air pressure. It is advisable to test the depth on a scrap workpiece

to determine the required depth for the application.

To determine depth of drive, first adjust the air pressure and

drive a test nail. To achieve the desired depth, use the depth

of drive adjustment on the tool. Harder materials and longer

nails will require more force to drive the nail.

Remove battery pack from the tool, if installed.

Turn the depth of drive adjustment left or right to change

the driving depth.

Reinstall battery and reactivate the tool by pressing the

worklight grip switch.

Drive a test nail after each adjustment until the desired

depth is set.

NOTE: Set depth of drive at the shallowest depth that

will meet your needs.

WARNING:

The nailer will not function properly if the selector is not securely seated in either position ( ) or

( ). Always assure the selector is seated properly to

avoid an unexpected nail discharge and possible serious

personal injury.

Reinstall the battery, reactivate tool.

Grip the tool firmly to maintain control. Position the nose

of the tool onto the work surface.

Push the tool against the work surface to depress the

workpiece contact.

Squeeze the trigger to drive a nail. Push the tool against

the work surface to depress the workpiece contact and

drive a nail.

NOTE: Hold trigger until drive cycle is complete.

Always remove your finger from the trigger when the

desired number of nails has been driven.

Contact actuation mode:

Contact actuation allows very fast repetitive nail placement.

Remove battery pack from the tool.

Slide the selector to position ( ).

Reinstall the battery, reactivate tool.

Grip the tool firmly to maintain control.

Squeeze and hold the trigger. Push the tool against the

work surface to depress the workpiece contact and drive

a nail.

NOTE: Hold trigger until drive cycle is complete.

Always remove your finger from the trigger when the

desired number of nails has been driven.

NOTE: In Contact Actuation Mode, the tool may also be

operated by depressing the workpiece contact against the

surface and squeezing the trigger.

DRIVING BRAD NAILS

See Figures 8 - 9, page 13.

WARNING:

Never wedge or hold back the workpiece contact mechanism during operation of the tool. Doing so could result

in possible serious injury.

Single sequential actuation mode:

Single sequential actuation provides the most accurate nail

placement.

Remove battery pack from the tool.

Slide the selector to position ( ).

9 — English

DRY-FIRE LOCKOUT

When the magazine has 0-5 nails remaining, the dry-fire

lockout feature will not allow continued operation.

To resume operation, reload the tool with nails.

LED WORKLIGHTS

See Figure 10, page 13.

Press LED worklight grip switch while firmly holding tool

during operation.

Page 10

OPERATION

DIAGNOSTIC FEEDBACK

The LED Worklights provide feedback to indicate whether

the battery pack is charged sufficiently and/or if the tool is

functioning properly.

If worklights are flashing, install fully charged battery. If light

continue to flash, see Troubleshooting section for more

information.

REMOVING NAILS FROM THE TOOL

See Figure 11, page 13.

WARNING:

Remove the battery pack before removing nails or clearing a jammed nail. Failure to do so could result in serious

personal injury.

Remove battery pack from the tool.

To remove a strip of nails from the tool, depress the maga-

zine release button located at the rear of the magazine

and slide the magazine open.

Remove nails.

Close the magazine.

REMOVING A JAMMED BRAD NAIL

See Figure 12, page 13.

Remove battery pack from the tool.

Open magazine and remove nails from the tool.

Pull up on the latch and open the jam release.

Insert a flat blade screwdriver into the tip of the driving

mechanism and push the driver mechanism back, freeing

the nail jam.

Remove the bent nail.

Close the jam release and latch.

Reinstall nails and close the magazine.

Reinstall the battery, reactivate tool.

NOTE: Driving too deeply into the material, excess debris,

or jammed nails may lead to a driver blade being stuck at

its bottom position.

The driver blade can usually be returned to its operating

position by depressing the work contact element against a

scrap piece of wood and squeezing the trigger.

MAINTENANCE

WARNING:

When servicing, use only identical replacement parts.

Use of any other parts could create a hazard or cause

product damage.

GENERAL MAINTENANCE

Avoid using solvents when cleaning plastic parts. Most

plastics are susceptible to damage from various types of

commercial solvents and may be damaged by their use. Use

clean cloths to remove dirt, dust, oil, grease, etc.

10 — English

Page 11

TROUBLESHOOTING

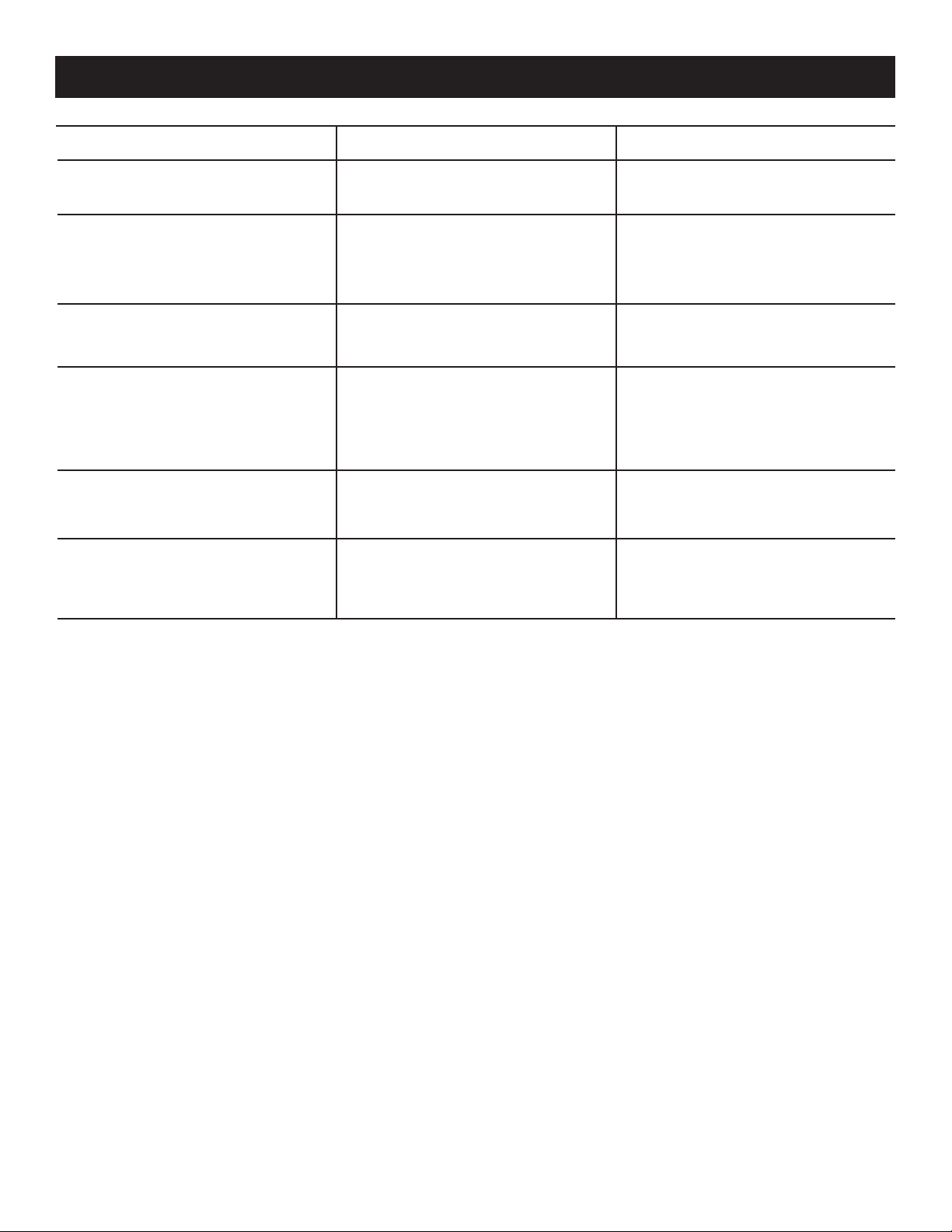

PROBLEM POSSIBLE CAUSE SOLUTION

Work-contacting element does not

depress fully - tool does not operate.

Tool operates properly, but fasteners do

not drive fully

Tool operates properly, but fasteners are

driven too deep

Tool jams frequently Incorrect nails

Tool stops and LED’s flash rapidly Battery is low or has no charge.

Tool has charged battery and LED’s

are slowly flashing or LED’s do not turn

off after approximately ten seconds of

non-use.

Low nails

Work-contacting element is jammed

Air pressure is too low

Depth of drive isn’t deep enought

Nail is too long for wood hardness

Air pressure is too high

Depth of drive is too deep

Damaged nails

Loose magazine

Dirty magazine

Tool is hot

Tool has malfunctioned Take tool to nearest authorized repair

Replenish nails

Remove battery and clear debris

Increase air pressure

Adjust depth of drive

Use nail length that is appropriate for

wood

Decrease air pressure

Adjust depth of drive

Verify that nails are the correct size

Replace nails

Tighten screws

Clean magazine

Recharge battery

Allow tool to cool

center

NOTE: ILLUSTRATIONS START ON PAGE 12

AFTER FRENCH AND SPANISH LANGUAGE SECTIONS.

This product has a Three-year Limited Warranty.

For Warranty details go to www.ryobitools.com

11 — English

Page 12

RÈGLES DE SÉCURITÉ RELATIVES AUX OUTILS ÉLECTRIQUES

Ne recharger les piles qu’avec l’appareil indiqué.

AVERTISSEMENT

Lire tous les avertissements et toutes les instructions.

Ne pas suivre l’ensemble des avertissements et des

instructions peut entraîner une électrocution, un incendie

ou des blessures graves.

Conserver les avertissements et les instructions à des

fins de référence ultérieure.

utilisé dans tous les avertissements ci-dessous désigne tout

outil fonctionnant sur secteur (câblé) ou sur piles (sans fil).

Le terme « outil motorisé »,

SÉCURITÉ DU LIEU DE TRAVAIL

Garder le lieu de travail propre et bien éclairé. Les

endroits encombrés ou sombre s sont propices aux

accidents.

Ne pas utiliser d’outils électriques dans des

atmosphères explosives, par exemple en présence

de liquides, gaz ou poussières inflammables. Les

outils électriques produisent des étincelles risquant

d’enflammer les poussières ou vapeurs.

Garder les enfants et badauds à l’écart pendant

l’utilisation d’un outil électrique. Les distractions

peuvent causer une perte de contrôle.

SÉCURITÉ ÉLECTRIQUE

Les fiches des outils électriques doivent correspondre

à la prise secteur utilisée. Ne jamais modifier la fiche,

de quelque façon que ce soit. Ne jamais utiliser

d’adaptateurs de fiche avec des outils mis à la terre.

Les fiches et prises non modifiées réduisent le risque de

choc électrique.

Éviter tout contact du corps avec des surfaces mises

à la terre, telles que tuyaux, radiateurs, cuisinières et

réfrigérateurs. Le risque de choc électrique est accru

lorsque le corps est mis à la terre.

Ne pas exposer les outils électriques à l’eau ou

l’humidité. La pénétration d’eau dans ces outils accroît

le risque de choc électrique.

Ne pas maltraiter le cordon d’alimentation. Ne jamais

utiliser le cordon d’alimentation pour transporter

l’outil et ne jamais débrancher ce dernier en tirant

sur le cordon. Garder le cordon à l’écart de la chaleur,

de l’huile, des objets tranchants et des pièces en

mouvement. Un cordon endommagé ou emmêlé accroît

le risque de choc électrique.

Pour les travaux à l’extérieur, utiliser un cordon

spécialement conçu à cet effet. Utiliser un cordon

conçu pour l’usage extrérieur pour réduire les risques de

choc électrique.

S’il est nécessaire d’utiliser l’outil électrique dans un

endroit humide, employer un dispositif interrupteur de

défaut à la terre (GFCI). L’utilisation d’un GFCI réduit le

risque de décharge électrique.

Pour utiliser l’appareil avec des piles au nickel-cadmium

et au lithium-ion de 18 V, consulter le supplément de

raccordement pour chargeur/outils/piles/appareil n˚

987000-432.

SÉCURITÉ PERSONNELLE

Rester attentif, prêter attention au travail et faire

preuve de bon sens lors de l’utilisation de tout outil

électrique. Ne pas utiliser cet outil en état de fatigue

ou sous l’influence de l’alcool, de drogues ou de

médicaments. Un moment d’inattention pendant

l’utilisation d’un outil électrique peut entraîner des

blessures graves.

Utiliser l’équipement de sécurité. Toujours porter une

protection oculaire. L’équipement de sécurité, tel qu’un

masque filtrant, de chaussures de sécurité, d’un casque

ou d’une protection auditive, utilisé dans des conditions

appropriées réduira le risque de blessures.

Éviter les démarrages accidentels. S’assurer que

le commutateur est en position d’arrêt avant de

brancher l’outil. Porter un outil avec le doigt sur son

commutateur ou brancher un outil dont le commutateur

est en position de marche peut causer un accident.

Retirer les clés de réglage avant de mettre l’outil en

marche. Une clé laissée sur une pièce rotative de l’outil

peut causer des blessures.

Ne pas travailler hors de portée. Toujours se tenir

bien campé et en équilibre. Ceci permettra de mieux

contrôler l’outil en cas de situation imprévue.

Porter une tenue appropriée. Ne porter ni vêtements

amples, ni bijoux. Garder les cheveux, les vêtements

et les gants à l’écart des pièces en mouvement. Les

vêtements amples, bijoux et cheveux longs peuvent se

prendre dans les pièces en mouvement.

Si les outils sont équipés de dispositifs de

dépoussiérage, s’assurer qu’ils sont connectés et

correctement utilisés. L’usage de ces dispositifs de

dépoussiérage peut réduire les dangers présentés par

la poussière.

Ne porter ni vêtements amples, ni bijoux. Attacher

ou couvrir les cheveux longs. Les vêtements amples,

bijoux et cheveux longs peuvent se prendre dans les

ouïes d’aération.

Ne pas utiliser l’outil sur une échelle ou un support

instable. Une bonne tenue et un bon équilibre permettent

de mieux contrôler l’outil en cas de situation imprévue.

UTILISATION ET ENTRETIEN DES OUTILS

ÉLECTRIQUES

Ne pas forcer l’outil. Utiliser l’outil approprié pour

l’application. Un outil approprié exécutera le travail

mieux et de façon moins dangereuse s’il est utilisé dans

les limites prévues.

2 — Français

Page 13

RÈGLES DE SÉCURITÉ RELATIVES AUX OUTILS ÉLECTRIQUES

Ne pas utiliser l’outil si le commutateur ne permet

pas de le mettre en marche ou de l’arrêter. Tout outil

qui ne peut pas être contrôlé par son commutateur est

dangereux et doit être réparé.

Débrancher l’outil et/ou retirer le bloc-piles avant

d’effectuer des réglages, de changer d’accessoire ou

de remiser l’outil. Ces mesures de sécurité préventives

réduisent les risques de démarrage accidentel de l’outil.

Ranger les outils motorisés hors de la portée des

enfants et ne laisser personne n’étant pas familiarisé

avec l’outil ou ces instructions utiliser l’outil. Dans les

mains de personnes n’ayant pas reçu des instructions

adéquates, les outils sont dangereux.

Entretenir les outils motorisés. Vérifier qu’aucune

pièce mobile n’est mal alignée ou bloquée, qu’aucune

pièce n’est brisée et s’assurer qu’aucun autre

problème ne risque d’affecter le bon fonctionnement

de l’outil. En cas de dommages faire réparer l’outil

avant de l’utiliser de nouveau. Beaucoup d’accidents

sont causés par des outils mal entretenus.

Garder les outils bien affûtés et propres. Des outils

correctement entretenus et dont les tranchants sont bien

affûtés risquent moins de se bloquer et sont plus faciles

à contrôler.

Utiliser l’outil, les accessoires et embouts, etc.

conformément à ces instrutions pour les applications

pour lesquelles ils sont conçus, en tenant compte des

conditions et du type de travail à exécuter. L’usage

d’un outil motorisé pour des applications pour lesquelles

il n’est pas conçu peut être dangereux.

UTILISATION ET ENTRETIEN DE LA PILE

Ne recharger qu’avec l’appareil spécifié par le

fabricant. Un chargeur approprié pour un type de pile

peut créer un risque d’incendie s’il est utilisé avec un

autre type de pile.

Utiliser exclusivement le bloc-pile spécifiquement

indiqué pour l’outil. L’usage de tout autre bloc peut créer

un risque de blessures et d’incendie.

Lorsque le bloc-piles n’est pas en usage, le garder

à l’écart d’articles tels qu’attaches trombones,

pièces de monnaie, clous, vis ou autres petits objets

métalliques risquant d’établir le contact entre les deux

bornes. La mise en court-circuit des bornes de piles peut

causer des irritations ou des brûlures.

En cas d’usage abusif, du liquide peut s’échapper des

piles. Éviter tout contact avec ce liquide. En cas de

contact accidentel, rincer immédiatement les parties

atteintes avec de l’eau. En cas d’éclaboussure dans

les yeux consulter un médecin. Le liquide s’échappant

des piles peut causer des irritations ou des brûlures.

DÉPANNAGE

Les réparations doivent être confiées à un technicien

qualifié, utilisant exclusivement des pièces identiques

à celles d’origine. Ceci assurera le maintien de la sécurité

de l’outil.

Utiliser exclusivement des pièces identiques à celles

d’origine pour les réparations. Se conformer aux

instructions de la section Entretien de ce manuel.

L’usage de pièces non autorisées ou le non-respect des

instructions peut présenter des risques de choc électrique

ou de blessures.

RÈGLES DE SÉCURITÉ RELATIVES AUX CLOUEUSE

Toujours présumer que l’outil contient des attaches. La

manipulation inadéquate de la cloueuse peut provoquer

un tir accidentel d’attaches et causer des blessures.

Ne pas pointer l’outil vers soi ou d’autres personnes.

L’actionnement accidentel entraînera le tir d’une attache

et causera des blessures.

Ne pas actionner l’outil s’il n’est pas fermement

appuyé sur la pièce à clouer. Lorsque l’outil n’est pas en

contact avec la pièce à clouer, l’attache peut être déviée

de sa cible.

Débrancher l’outil de la source d’alimentation

lorsque les confitures de fixation de l’outil. Tout en

retirant une agrafe coincée, l’agrafeuse peut être activé

accidentellement s’il est branché po.

Être prudent lors du retrait d’une attache bloquée.

Le mécanisme peut être comprimé et l’attache peut être

projetée avec force pendant la tentative de délogement.

3 — Français

Ne pas utiliser cette cloueuse pour fixer du câblage

électrique. Cet outil n’est pas conçu pour fixer du

câblage électrique et peut endommager l’isolant des

câbles et des risques d’électrocution et d’incendie.

Lorsque l’outil est utilisé pour un travail risquant de

le mettre en contact avec des fils électriques cachés,

le tenir par les surfaces de prise isolées. Le contact

d’un dispositif de fixation avec un fil sous tension expose

les pièces métalliques de l’outil et peut électrocuter

l’utilisateur.

Apprendre à connaître l’outil. Lire attentivement le

manuel d’utilisation. Apprendre les applications et

les limites de l’outil, ainsi que les risques spécifiques

relatifs à son utilisation. Le respect de cette consigne

réduira les risques d’incendie, de choc électrique et de

blessures graves.

Page 14

RÈGLES DE SÉCURITÉ RELATIVES AUX CLOUEUSE

Toujours porter une protection oculaire aven écran de

protection latéra certifiée conforme à la norme ANSI

Z87.1. Les lunettes de vue ordinaires ne sont munies que

de verres résistants aux chocs. Ces dernières ne sont

PAS des lunettes de sécurité. Le respect de cette règle

réduira les risques de blessures graves.

Lors du chargement, de l’utilisation ou de l’entretien

de cet outil, l’opérateur et les personnes se trouvant

sur le lieu de travail doivent TOUJOURS porter

un dispositif oculaire à protection FRONTALE et

LATÉRALE, conforme aux normes ANSI. Une telle

protection est requise, car les clous / agrafes et débris

projetés peuvent causer des lésions oculaires graves.

Il incombe à l’employeur et / ou l’utilisateur de veiller

à ce qu’une protection oculaire adéquate soit utilisée.

Nous recommandons d’utiliser un masque facial à champ

de vision se portant par-dessus des lunettes de vue ou de

sécurité et potégeant des débris projetés sur le devant et

les côtés. Toujours porter une protection oculaire certifiée

conforme à la norme ANSI Z87.1.

Des équipements de protection supplémentaires sont

requis dans certains environnements. Par exemple,

le lieu de travail peut présenter un niveau de bruit

susceptible d’entraîner des lésions auditives. Il incombe à

l’opérateur et à l’utilisateur qu’une protection audidive soit

fournie et utilisée par l’opérateur et les autres personnes

se trouvant sur le lieu de travail. Certains environnements

requièrent le port d’un casque. Il incombe à l’employeur

et / ou l’utilisateur de veiller à ce qu’un casque conforme

à la norme ANSI Z89.1-1997 soit utilisé.

Excepté pour planter des clous, garder les doigts à

l’écart de la gâchette, pour éviter un déclenchement

accidentel.

Utiliser l’équipement de sécurité. Toujours porter une

protection oculaire. Suivant les conditions, le port d’un

masque antipoussière, de chaussures de sécurité, d’un

casque ou d’une protection auditive est recommandé.

Protection respiratoire. Porter un masque facial ou

un masque antipoussière si le travail produit de la

poussière. Le respect de cette consigne réduira les

risques de blessures graves.

Protection auditive. Porter une protection auditive

lors de l’utilisation prolongée. Le respect de cette règle

réduira les risques de blessures graves.

Les outils fonctionnant sur piles n’ayant pas besoin

d’être branchés sur une prise secteur, ils sont toujours

en état de fonctionnement. Tenir compte des dangers

possibles lorsque l’outil n’est pas en usage et lors du

remplacement des piles. Le respect de cette consigne

réduira les risques d’incendie, de choc électrique et de

blessures graves.

Ne pas placer les outils électriques sans fil ou leurs

piles à proximité de flammes ou d’une source de

chaleur. Ceci réduira les risques d’explosion et de

blessures.

4 — Français

L’outil ne doit être utilisé que pour les applications

pour lesquelles il est conçu. Ne pas décharger des

clous / agrafes dans le vide.

Cet outil ne doit être utilisé que pour les applicactions

pour lesquelles il est conçu.

Utiliser seulement les agrafes recommandées pour

cet outil. L’utilisation du mauvais type d’agrafes pourrait

nuire au débit des agrafes et entraîner des bourrages

d’agrafes ainsi que l’éjection des clous de l’outil à des

angles irréguliers. Si le débit des agrafes n’est pas

constant et fluide, cesser de les utiliser sur le champ.

Les bourrages et un débit d’agrafes irrégulier peuvent

occasionner des blessures graves.

Ne jamais utiliser cet outil de façon à ce qu’un clou puisse

être dirigé vers quoi que ce soit d’autre que la pièce

à clouer.

Ne pas utiliser cet outil comme un marteau.

Toujours transporter l’outil par la poignée.

Ne pas altérer ou modifier cet outil, ni l’utiliser

pour des fonctions autres que celles prévues, sans

autorisation préalable de son fabricant.

Ne jamais oublier qu’un usage incorrect ou abusif

de cet outil peut mettre l’opérateur et les autres

personnes présentes en danger.

Ne jamais bloquer la gâchette ou le contact de la

cloususe en position de déclenchement avec du ruban

adhésif ou un quelconque autre système.

Ne jamais laisser un outil sans surveillance si la pile

est installée.

Ne pas utiliser cet outil s’il ne comporte pas

d’autocollant d’avertissement.

Garder l’outil et sa poignée secs, propres et exempts

d’huile ou de graisse. Toujours utiliser un chiffon propre

pour le nettoyage. Ne jamais utiliser de liquide de freins,

d’essence, de produits à base de pétrole ou de solvants

forts pour nettoyer l’outil. Le respect de cette règle réduira

les risques de perte du contrôle et d’endommagement

du boîtier en plastique.

UTILISATION

Ne pas utiliser l’outil si la gâchette ne fonctionne pas

correctement. Tout outil qui ne peut pas être contrôlé

par la gâchette est dangereux et doit être réparé.

Vérifier le mécanisme de contact de la tête de l’outil

fréquemment. Ne pas utiliser l’outil si le mécanisme

de déclenchement par contact ne fonctionne pas

correctement, car l’éjection accidentelle d’une agrafe

pourrait se produire. Ne pas empêcher le fonctionnement

correct du mécanisme de contact de la tête de la

cloueuse.

Ne pas utiliser un outil qui ne fonctionne pas

correctement.

Page 15

RÈGLES DE SÉCURITÉ RELATIVES AUX CLOUEUSE

Toujours présumer que l’outil contient des clous /

agrafes.

Ne pas transporter l’outil avec le doigt sur la gâchette.

Un clou pourrait être éjecté accidentellement.

Toujours manipuler l’outil avec précaution :

• Respecter cet outil comme tout équipement de travail.

• Ne pas l’utiliser comme un jouet.

• Ne jamais appuyer sur la gâchette si la tête de l’outil

n’est pas dirigée vers la pièce à clouer.

• Garder toutes les personnes présentes à distance sûre

de l’outil, car un éventuel déclenchement accidentel

pourraît entraîner des blessures.

Le choix de la méthode de déclenchement est

important. Voir les options de déclenchement dans

le manuel.

Les outils sont conçus pour une utilisation à une main.

Ne pas tenir l’outil par la face avant du chargeur. Tenir les

mains, la tête et toute autre partie du corps à distance du

point d’éjection des clous, près du chargeur, afin d’éviter

des blessures graves.

Ne pointer l’outil ni vers soi, ni vers quiconque, qu’il

contienne des clous / agrafes ou non.

N’actionner l’outil que pour planter un clou dans la

pièce à assujettir.

Toujours s’assurer que la surface de contact est

exactement positionnée sur la pièce à clouer. Un

positionnement seulement partiel de la surface de contact

sur la pièce à clouer peut occasionner des blessures

graves car l’agrafe risque d’être éjectée complètement

à côté de la pièce.

Ne pas planter de clous près du bord du matériau.

La pièce à clouer peut se fendre, causant un ricochet

du clou, qui risque alors de blesser l’opérateur ou une

autre personne présente. Ne pas oublier que le clou peut

suivre le grain du bois et que sa pointe peut ressortir

inopinément par le bord de la planche.

Garder les mains et toutes les parties du corps à

l’écart du point à clouer. Au besoin, assujettir la pièce à

clouer avec des serre-joint pour garder les mains à l’écart

de la zone dangereuse. S’assurer que la pièce à clouer

est correctement assujettie avant d’appuyer la cloueuse

à sa surface. Le contact de la cloueuse peut causer un

déplacement inopiné de la pièce.

Lors du travail dans des endroits confinés, garder le

visage et le corps à l’écart de l’arrière de l’outil. Un

recul brusque peut projeter la cloueuse contre le corps,

en particulier lors du clouage de matériaux denses.

Durant l’utilisation normale de l’outil, un recul se

produit lorsqu’un clou est planté. Ce recul est normal.

Ne pas essayer de l’empêcher en maintenant l’outil contre

la pièce à clouer. Empêcher le recul pourrait causer

l’éjection d’un second clou. Tenir la poignée fermement,

laisser l’outil exécuter le travail et ne jamais placer l’autre

main sur le dessus de l’outil ou près de l’échappement.

Le non respect de cette mise en garde peut entraîner des

blessures graves.

Ne pas planter un clou sur un autre ou avec l’outil à

un angle trop prononcé, car le clou pourrait dévier et

blesser quelqu’un.

CHARGEMENT DE L’OUTIL

Ne pas charger l’outil lorsque l’une des commandes de

déclenchement est activée.

Lors du chargement de l’outil :

Ne jamais placer une main ou une partie quelconque du

corps devant la tête de l’outil.

Ne jamais pointer l’outil sur qui que ce soit.

Ne pas appuyer sur la gâchette ou sur le mécanisme de

contact, car l’outil pourrait éjecter une agrafe, risquant

blesser quelqu’un.

CONSERVER CES INSTRUCTIONS

Les consulter fréquemment et les utiliser pour instruire

les autres utilisateurs éventuels. Si cet outil est prêté, il

doit être accompagné de ces instructions.

5 — Français

Page 16

SYMBOLES

Les termes de mise en garde suivants et leur signification ont pour but d’expliquer le degré de risques associé à

l’utilisation de ce produit.

SYMBOLE SIGNAL SIGNIFICATION

DANGER :

AVERTISSEMENT :

ATTENTION :

AVIS :

Certains des symboles ci-dessous peuvent être utilisés sur produit. Veiller à les étudier et à apprendre leur signification.

Une interprétation correcte de ces symboles permettra d’utiliser produit plus efficacement et de réduire les risques.

Indique une situation extrêmement dangereuse qui, si elle n’est pas évitée,

aura pour conséquences des blessures graves ou mortelles.

Indique une situation potentiellement dangereuse qui, si elle n’est pas

évitée, pourrait entraîner des blessures graves ou mortelles.

Indique une situation potentiellement dangereuse qui, si elle n’est pas

évitée, pourraît entraîner des blessures légères ou de gravité modérée.

(Sans symbole d’alerte de sécurité) Indique une information importante

ne concernant pas un risque de blessure comme une situation pouvant

occasionner des dommages matériels.

SYMBOLE NOM DÉSIGNATION / EXPLICATION

Symbole d’alerte de sécurité Indique un risque de blessure potentiel.

Lire le manuel d’utilisation

Protection oculaire

Pour réduire les risques de blessures, l’utilisateur doit lire et veiller à

bien comprendre le manuel d’utilisation avant d’utiliser ce produit.

Toujours porter une protection oculaire avec écrans latéraux

certifiée conforme à la norme ANSI Z87.1.

Garder les mains à l’écart Garder les mains et le corps à l’écart de de la décharge de l’outil.

Avertissement concernant

l’humidité

Surface brûlante

Symboles de recyclage

V Volts Tension

min Minutes Temps

Courant continu Type ou caractéristique du courant

n

o

.../min Par minute Tours, coups, vitesse périphérique, orbites, etc., par minute

Vitesse à vide Vitesse de rotation à vide

Ne pas exposer à la pluie ou l’humidité.

Pour éviter les risques de blessures ou de dommages, éviter tout

contact avec les surfaces bûlantes.

Ce produit utilise les piles de nickel-cadmium (Ni-Cd) ou lithium-ion

(Li-ion). Les réglementations locales ou gouvernementales peuvent

interdire de jeter les piles dans les ordures ménagères. Consulter

les autorités locales compétentes pour les options de recyclage

et/ou l’élimination.

6 — Français

Page 17

GLOSSAIRE

Activer (commandes de l’outil)

Mettre une commande sur une position déclenchant ou

permettant de déclencher l’outil.

Actionner (outil)

Causer le mouvement des pièces conçues pour chasser

une agrafe.

Système de déclenchement

Gâchette, déclencheur par contact et / ou autre commande

qui, utilisées séparément ou conjointement déclenchent

l’outil.

• Déclenchement par séquence unique

Système de déclenchement comprenant plus d’une

commande et dont les commandes doivent être

actionnées dans un ordre donné pour déclencher

l’outil. Le déclenchement peut être répété lorsqu’une

commande, autre que le déclencheur par contact, est

relâchée, puis actionnée de nouveau.

• Déclenchement par contact

Système de déclenchement comprenant plus d’une

commande et dont les commandes doivent être

actionnées dans n’importe quel ordre pour déclencher

l’outil. Le déclenchement peut être répété lorsqu’une

commande est relâchée, puis actionnée de nouveau.

Pièce de fixation

Agrafe, cheville, clou ou autre pièce de fixation conçue

et fabriquée pour être utilisée pour les outils répondant à

cette norme.

Blocage

Obstruction dans le système d’alimentation ou de décharge

de l’outil.

Commande

Dispositif qui, séparément ou en conjonction avec un système,

peut causer le déclenchement de l’outil.

Gâchette

Commande de l’outil actionnée par le doigt de l’opérateur.

Pièce

Objet dans lequel un clou, une agrafe ou autre pièce de

fixation est enfoncé par l’outil.

Contact de déclenchement

Pièce ou partie de l’outil conçue pour le déclencher par

contact avec la pièce à assujettir.

CARACTÉRISTIQUES

FICHE TECHNIQUE

Capacité du magasin ............................................ 105 clous

Vitesse d’enfoncement des pièces de fixation ....................

.............................................................. jusqu’à 60 tirs/min.

Type de pièces de fixation .................................. Calibre 18

Longueur du clou à parquet ................................ 5/8 à 2 po

ASSEMBLAGE

AVERTISSEMENT :

Ne pas utiliser le produit s’il n’est pas complètement

assemblé ou si des pièces semblent manquantes ou

endommagées. L’utilisation d’un produit dont l’assemblage

est incorrect ou incomplet ou comportant des pièces

endommagées ou absentes représente un risque de

blessures graves.

Si des pièces manquent ou sont endommagées, veuillez appeler au 1-800-525-2579 pour obtenir de l’aide.

AVERTISSEMENT :

Ne pas essayer de modifier cet outil ou de créer des pièces

et accessoires non recommandés. De telles altérations ou

modifications sont considérées comme un usage abusif

et peuvent créer des conditions dangereuses, risquant

d’entraîner des blessures graves.

7 — Français

Page 18

UTILISATION

AVERTISSEMENT :

Ne pas laisser la familiarité avec l’outil faire oublier la

prudence. Ne pas oublier qu’une fraction de seconde

d’inattention peut entraîner des blessures graves.

AVERTISSEMENT :

S’assurer que ses deux loquets latéraux s’engagent

correctement et vérifier que le bloc-piles est bien fixé avant

d’utiliser l’outil.

NOTE : Presser l’interrupteur d’éclairage DEL sur la prise pour

réactiver la cloueuse.

Retirer le bloc-piles :

Appuyer sur les deux loquets se trouvant sur les côtés du

bloc-piles pour le retirer de l’outil.

Toujours retirer la pile de l’outil au moment d’assembler

des pièces, d’effectuer des réglages et de procéder au

nettoyage, ou lorsque l’outil n’est pas utilisé. Le fait de retirer

la pile permet d’empêcher un démarrage accidentel pouvant

entraîner des blessures graves.

AVERTISSEMENT :

Toujours porter une protection oculaire certifiée conforme

à la norme ANSI Z87.1. Si cette précaution n’est pas prise,

des objets peuvent être projetés dans les yeux et causer

des lésions graves.

APPLICATIONS

Cet outil peut être utilisé pour les applications ci-dessous :

Finition et décoration (intérieur et extérieur)

Encadrement de portes et fenêtres

Montants de porte

Plinthes

Moulure couronnée

Ébénisterie

Moulures de plinthes et cimaises

Moulures

Escaliers

Cadres de portes et fenêtres

Protections murales

Coffrages

Planchers en bois

Panneautage

Fabrication de meubles

AGRAFE POUR COURROIE

Voir la figure 1, page 12.

L’agrafe pour courroie peut être installée du côté gauche ou

droit de la cloueuse, selon les préférences de l’utilisateur.

Aligner l’agrafe pour courroie et la vis avec l’orifice pour vis

droit ou gauche.

Utiliser un tournevis à tête cruciforme (non fourni) pour visser

fermement.

INSTALLATION / RETRAIT DU BLOC-PILES

Voir le figure 2, page 12.

Installation le bloc-piles :

Aligner la nervure du bloc-piles sur la rainure intérieure de

la perceuse.

COUSSINET DE PROTECTION

Voir la figure 3, page 12.

Le coussinet de protection empêche de marquer ou d’érafler

les bois tendres.

Retirer le bloc-piles. Retirer coussinet en le tirant vers le bas et

en l’éloignant du nez. Pour remettre le coussinet en place, le

placer sur le nez et le pousser vers le haut pour le fixer.

Un compartiment de rangement du coussinet est prévu sur le

magasin de l’outil. Ce compartiment contient un coussinet de

rechange.

CHARGEMENT DES CLOUS Á PARQUET

Voir les figures 4 et 5, page 12.

AVERTISSEMENT :

Veiller à ne pointer l’outil ni vers soi, ni vers d’autres

personnes lors du chargement de clous. Ne pas prendre

cette précaution pourrait entraîner des blessures graves.

Retirer le bloc-piles, s’il est installé.

Tout en éloignant le nez de l’outil de votre corps, presser

le bouton de dégagement du magasin situé à l’arrière du

magasin et glisser le couvercle pour ouvrir le magasin.

Insérer les clous à parquet dans la rainure en positionnant

les pointes de clous vers le bas et les faire reposer au

fond de la rainure.

Pousser le couvercle du magasin en vue de le fermer

jusqu’à ce qu’il s’enclenche solidement en place.

S’assurer que le magasin est correctement verrouillé.

Installer la pile et réactiver l’outil en appuyant sur

l’interrupteur du témoin situé sur la prise.

RÉGLAGE DE LA PRESSION D’AIR

Voir la figure 6, page 13.

Le réglage de pression d’air dépend de la dimension des clous

et du type de matériau à clouer.

Begin testing the depth of drive by driving a test nail into the

same type of workpiece material used for the actual job.

Retirer le bloc-piles, s’il est installé.

Tourner le cadran de pression d’air vers la droite pour

augmenter la pression d’air ou vers la gauche pour diminuer

la pression d’air.

Il est possible d’obtenir la profondeur désirée simplement en

réglant la pression d’air. Si des réglages fins sont nécessaires,

utiliser le réglage de profondeur d’enfoncement de l’outil.

8 — Français

Page 19

UTILISATION

NOTE : Sous certaines conditions, il est possible que l’outil ne

tire pas de clou si le cadran de pression d’air est tourné vers le

réglage de pression MAXIMALE. L’utilisateur devra diminuer le

réglage de pression selon le fonctionnement désiré.

RÉGLAGE DE PROFONDEUR

D’ENFONCEMENT

Voir la figure 7, page 13.

La profondeur d’enfoncement du clou peut être réglée au-delà

de la pression d’air.

Pour déterminer la profondeur, régler d’abord la pression d’air,

puis faire un essai d’enfoncement avec un clou. Pour obtenir

la profondeur nécessaire, utiliser le réglage de profondeur

d’enfoncement de l’outil. Les matériaux plus durs et des clous

plus longs nécessiteront une force d’enfoncement plus grande

du clou.

Retirer le bloc-piles, s’il est installé.

Tourner le réglage de profondeur d’enfoncement gauche ou

droit pour modifier la profondeur d’enfoncement.

Installer la pile et réactiver l’outil en appuyant sur l’interrupteur

du témoin situé sur la prise.

Faire un essai d’enfoncement d’un clou après chaque

réglage, jusqu’à ce que la profondeur désirée soit obtenue.

NOTE : Régler la profondeur d’enfoncement selon la

profondeur minimale qui conviendra au travail à effectuer.

AVERTISSEMENT :

Durant l’utilisation normale de l’outil, un recul se produit

lorsqu’un clou est planté. Ce recul est normal. Ne pas

essayer de l’empêcher en maintenant l’outil contre la pièce

à clouer. Cela pourrait causer l’éjection d’un second clou.

Tenir la poignée fermement, laisser l’outil exécuter le travail

et ne jamais placer l’autre main sur le dessus de l’outil.

Le non respect de cette mise en garde peut entraîner des

blessures graves.

ENFONCEMENT DES CLOUS À PARQUET

Voir les figures 8 et 9, page 13.

AVERTISSEMENT :

Ne jamais caler ou bloquer le mécanisme de sûreté de

déclenchement par contact pendant que l’outil est en

fonctionnement. Cela pourrait entraîner des blessures

graves.

Déclenchement par séquence unique :

Le mode de déclenchement par séquence unique permet le

placement le plus précis des agrafes.

Retirer le bloc-piles, s’il est installé.

Glisser le sélecteur à la position ( ).

AVERTISSEMENT :

La cloueuse ne fonctionnera pas correctement si le

sélecteur n’est pas positionné fermement sur ( ) ou

( ). Toujours s’assurer que le sélecteur est positionné

correctement afin d’éviter un tir accidentel du clou et les

risques de blessures graves.

Réinstallez le bloc-pile, réactiver la cloueuse.

Saisir l’outil fermement pour maintenir le contrôle. Placer la

tête de l’outil contre la pièce à clouer.

Appuyer à fond sur la gâchette pour planter une agrafe.

Appuyer l’outil contre la pièce à clouer pour actionner le

dispositif de déclenchement par contact.

NOTE: Tenez la gâchette jusqu’à ce cycle d’entraînement

est terminée.

Toujours retirer son doigt de la gâchette dès que la quantité

de clous désirée est enfoncée.

Déclenchement par contact :

Le déclenchement par contact permet de planter un grand

nombre de clous très rapidement.

Retirer le bloc-piles, s’il est installé.

Glisser le sélecteur sur la position ( ).

Réinstallez le bloc-pile, réactiver la cloueuse.

Saisir l’outil fermement pour maintenir le contrôle.

Appuyer sur la gâchette et la maintenir enfoncée.

Appuyer l’outil contre la pièce à clouer pour actionner

le dispositif de déclenchement par contact et planter

un clou.

NOTE: Tenez la gâchette jusqu’à ce cycle d’entraînement

est terminée.

Toujours retirer son doigt de la gâchette dès que la quantité

de clous désirée est enfoncée.

NOTE : En mode de déclenchement par contact, les clous

peuvent également être plantés en appuyant la tête de l’outil

sur la pièce et en pressant la gâchette.

VERROUILLAGE DE TIR À VIDE

Lorsque le magazine a 0-5 clous restants, le verrouillage de tir

à vide empêche le fonctionnement de l’outil.

Pour continuer le travail, recharger la cloueuse.

TÉMOINS DEL

Voir la figure 10, page 13.

Appuyer sur l’interrupteur de témoin DEL sur la prise tout en

maintenant fermement l’outil pendant le fonctionnement.

DIAGNOSTIC RÉTROACTIF

Les témoins DEL offrent une rétroaction indiquant la charge

suffisante du bloc-piles et le fonctionnement adéquat de l’outil.

Installer un bloc-piles complètement chargé lorsque les témoins

clignotent. Si le clignotement du témoin n’est pas interrompu,

consulter le chapitre Dépannage pour obtenir plus de détails.

9 — Français

Page 20

UTILISATION

RETRAIT DE CLOUS DE L’OUTIL

Voir la figure 11, page 13.

AVERTISSEMENT :

Retirer le bloc-piles avant de retirer ou de dégager les clous.

Ne pas prendre cette précaution peut causer des blessures

graves.

Retirer le bloc-piles.

Pour retirer une bande de clous de l’outil, presser le bouton

de dégagement du magasin situé à l’arrière du magasin et

ouvrir en faisant glisser le magasin.

Retirer les clous.

Fermer le magasin.

ENTRETIEN

RETRAIT D’UN CLOU À PARQUET COINCÉ

Voir la figure 12, page 13.

Retirer le bloc-piles de l’outil.

Ouvrir le magasin et retirer les clous de l’outil.

Soulever le loquet et ouvrir le mécanisme de déblocage.

Insérer un tournevis à lame plate dans le mécanisme

d’entraînement et pousser ce dernier vers l’arrière, pour

déloger le clou bloqué.

Retirer le clou plié.

Refermer le couvercle du mécanisme de déblocage et le

loquet.

Insérer des clous et fermer le magasin.

Réinstallez le bloc-pile.

NOTE : Un enfoncement trop profond dans le matériau, une

quantité excessive de débris ou des clous coincés peuvent

provoquer le blocage de la lame d’entraînement vers le bas.

La lame d’entraînement peut habituellement être remise en

position de fonctionnement en appuyant sur l’élément de contact

contre un échantillon de bois et en appuyant sur la gâchette.

AVERTISSEMENT :

Utiliser exclusivement des pièces d’origine pour les

réparations. L’usage de toute autre pièce pourrait créer

une situation dangereuse ou endommager l’produit.

ENTRETIEN GÉNÉRAL

Éviter d’utiliser des solvants pour le nettoyage des pièces en

plastique. La plupart des matières plastiques peuvent être

endommagées par divers types de solvants du commerce.

Utiliser un chiffon propre pour éliminer la saleté, la poussière,

l’huile, la graisse, etc.

10 — Français

Page 21

DÉPANNAGE

PROBLÈME CAUSE POSSIBLE SOLUTION

La pièce de déclenchement par contact

n’est pas complètement enfoncée l’outil ne fonctionne pas

L’outil fonctionne correctement, mais

les pièces de fixation ne s’enfoncent

pas complètement

L’outil fonctionne correctement, mais

les pièces de fixation s’enfoncent trop

L’outil se bloque fréquemment Clous de type incorrects

L’outil s’arrête et les témoins DEL

clignotent rapidement

Quantité faible de clous

La pièce de déclenchement par contact

est bloquée

La pression d’air est trop faible

La distance d’enfoncement n’est pas

assez grande

Le clou est trop long et ne convient pas

à la dureté du bois

La pression d’air est trop élevée

La distance d’enfoncement est trop

profonde

Clous endommagés

Magasin desserré

Magasin encrassé

La pile est faible ou épuisée

L’outil est chaud

Recharger des clous

Retirer la pile et déloger les débris

Augmenter la pression d’air

Régler la profondeur d’enfoncement

Utiliser une longueur de clou selon le

bois à clouer

Diminuer la pression d’air.

Régler la profondeur d’enfoncement

S’assurer que les clous sont de taille

correcte.

Remplacer les clous

Serrer les vis

Nettoyer le magasin

Recharger les piles

Laisser refroidir l’outil

Outil a chargé la pile et LED clignote

lentement ou sont les LED ne s’éteint

pas après approxmimately dix secondes

de non-utilisation

L’outil n’a pas fonctionné correctement Apporter l’outil au Centre de réparations

autorisé le plus près

NOTE : ILLUSTRATIONS COMMENÇANT SUR 12 DE PAGE APRÈS LE

SECTION ESPAGNOL.

Ce produit est couvert par une garantie limitée de trois (3) ans. Veuillez visiter notre site

internet au www.ryobitools.com pour obtenir tous les détails de la garantie.

11 — Français

Page 22

ADVERTENCIAS DE SEGURIDAD PARA HERRAMIENTAS

ELÉCTRICAS

Si debe operar una herramienta en lugares húmedos, use

ADVERTENCIA

Lea todas las advertencias de seguridad y las

instrucciones. El incumplimiento de las advertencias e

instrucciones puede ocasionar descarga eléctrica, fuego o

lesiones graves.

Guarde todas las advertencias e instrucciones para futuras

consultas.

todos los avisos de advertencia enumerados abajo se refiere

a las herramientas eléctricas de cordón (alámbricas) y de

El término “herramienta eléctrica” empleado en

baterías (inalámbricas).

SEGURIDAD EN EL ÁREA DE TRABAJO

Mantenga limpia y bien iluminada el área de trabajo.

Un área de trabajo mal despejada o mal iluminada propicia

accidentes.

No utilice herramientas motorizadas en atmósferas

explosivas, como las existentes alrededor de líquidos,

gases y polvos inflamables. Las herramientas eléctricas

generan chispas que pueden encender el polvo y los vapores

inflamables.

Mantenga alejados a los niños y circunstantes al

maniobrar una herramienta eléctrica. Toda distracción

puede causar pérdida del control de la herramienta.

SEGURIDAD ELÉCTRICA

Las clavijas de las herramientas eléctricas deben

corresponder a las tomas de corriente donde se

conectan. Nunca modifique la clavija de ninguna forma.

No utilice ninguna clavija adaptadora con herramientas

eléctricas dotadas de contacto a tierra. Conectando

las clavijas originales en las tomas de corriente donde

corresponden se disminuye el riesgo de una descarga

eléctrica.

Evite el contacto del cuerpo con las superficies de

objetos que estén haciendo tierra o estén conectados a

ésta, como tuberías, radiadores, estufas y refrigeradores.

Existe un mayor riesgo de descargas eléctricas si el cuerpo

está haciendo tierra.

No exponga las herramientas eléctricas a la lluvia ni

a condiciones de humedad. La introducción de agua en

una herramienta eléctrica aumenta el riesgo de descargas

eléctricas.

No maltrate el cordón eléctrico. Nunca utilice el cordón

para trasladar, desconectar o tirar de la herramienta

eléctrica. Mantenga el cordón alejado del calor, del

aceite, de bordes afilados y de piezas móviles. Los

cordones eléctricos dañados o enredados aumentan el

riesgo de descargas eléctricas.

Al utilizar una herramienta eléctrica a la intemperie,