Page 1

OPERATOR’S MANUAL

MANUEL D’UTILISATION

MANUAL DEL OPERADOR

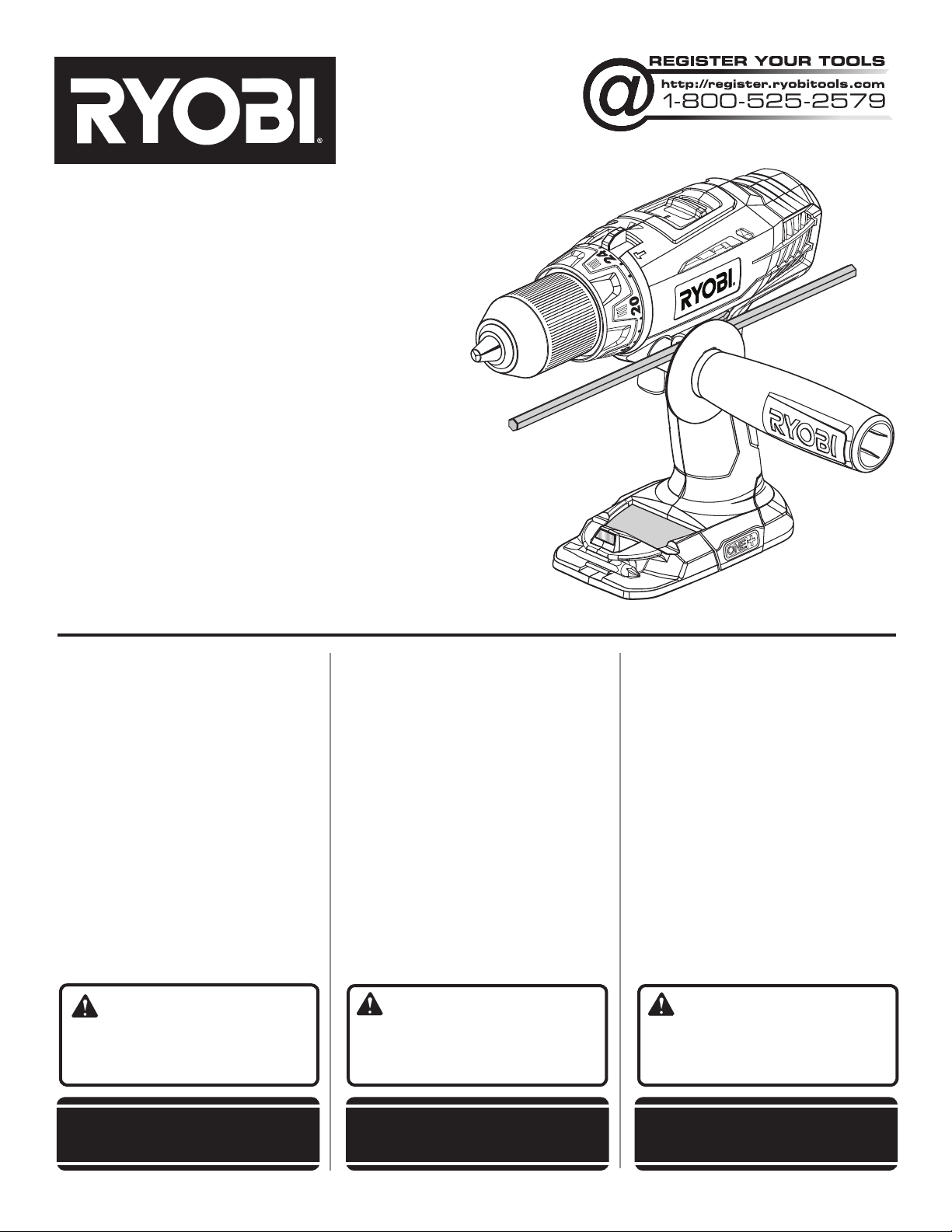

18 VOLT HAMMER DRILL

PERCEUSE À PERCUSSION

DE 18 V

TALADRO DE PERCUSIÓN

DE 18 V

P214

INCLUDES: Hammer Drill, Auxiliary Handle

Assembly, Depth Stop Rod, Operator’s

Manual

TABLE OF CONTENTS

****************

General Power Tool Safety Warnings

........................................................2-3

Drill-Driver Safety Warnings ...............3

Symbols ..............................................4

Features ..............................................5

Assembly ............................................ 5

Operation .........................................6-9

Maintenance ....................................... 9

Illustrations ..................................10-11

Parts Ordering and Service

............................................Back page

WARNING: To reduce the

risk of injury, the user must read and

understand the operator’s manual

before using this product.

INCLUT : Perceuses à percussion, poignée

auxiliaire, tige de butée de profondeur,

manual del utilisation

TABLE DES MATIÈRES

****************

Avertissements de sécurité générales

relatives aux outils électriques ........2-3

Avertissements de sécurité relatifs

perceuses à percussion ..................... 3

Symboles ............................................4

Caractéristiques .................................5

Assemblage ........................................ 5

Utilisation ........................................6-9

Entretien .............................................9

Illustrations ..................................10-11

Commande de pièces et dépannage

......................................... Page arrière

AVERTISSEMENT :

réduire les risques de blessures,

l’utilisateur doit lire et veiller à bien

comprendre le manuel d’utilisation avant

d’employer ce produit.

Pour

INCLUYE: Taladros de impacto, mango

auxiliar, barra limitadora de profundidad,

manual del operador

ÍNDICE DE CONTENIDO

****************

Advertencias de seguridad para

herramientas eléctrica ................... 2-3

Advertencias de seguridad de

taladros de impacto ...........................3

Símbolos ............................................4

Características ...................................5

Armado ..............................................5

Funcionamiento ............................. 6-9

Mantenimiento ...................................9

Illustraciones .............................. 10-11

Pedidos de piezas y servicio

...................................... Pág. posterior

ADVERTENCIA: Para reducir

el riesgo de lesiones, el usuario debe leer

y comprender el manual del operador

antes de usar este producto.

SAVE THIS MANUAL FOR

FUTURE REFERENCE

CONSERVER CE MANUEL

POUR FUTURE RÉFÉRENCE

GUARDE ESTE MANUAL

PARA FUTURAS CONSULTAS

Page 2

GENERAL POWER TOOL SAFETY WARNINGS

WARNING

Read all safety warnings and all instructions. Failure to

follow the warnings and instructions may result in electric

shock, fire and/or serious injury.

Save all warnings and instructions for future reference.

The term “power tool” in the warnings refers to your mainsoperated (corded) power tool or battery-operated (cordless)

power tool.

WORK AREA SAFETY

Keep work area clean and well lit. Cluttered or dark

areas invite accidents.

Do not operate power tools in explosive atmospheres,

such as in the presence of flammable liquids, gases

or dust. Power tools create sparks which may ignite the

dust or fumes.

Keep children and bystanders away while operating a

power tool. Distractions can cause you to lose control.

ELECTRICAL SAFETY

Power tool plugs must match the outlet. Never modify

the plug in any way. Do not use any adapter plugs with

earthed (grounded) power tools. Unmodified plugs and

matching outlets will reduce risk of electric shock.

Avoid body contact with earthed or grounded surfaces

such as pipes, radiators, ranges and refrigerators.

There is an increased risk of electric shock if your body

is earthed or grounded.

Do not expose power tools to rain or wet conditions.

Water entering a power tool will increase the risk of

electric shock.

Do not abuse the cord. Never use the cord for carrying,

pulling or unplugging the power tool. Keep cord away

from heat, oil, sharp edges or moving parts. Damaged

or entangled cords increase the risk of electric shock.

When operating a power tool outdoors, use an

extension cord suitable for outdoor use. Use of a cord

suitable for outdoor use reduces the risk of electric shock.

If operating a power tool in a damp location is

unavoidable, use a ground fault circuit interrupter

(GFCI) protected supply. Use of a GFCI reduces the

risk of electric shock.

Use battery only with charger listed. For use with

18V nickel-cadmium and 18V lithium-ion battery packs,

see tool/appliance/battery pack/charger correlation

supplement 987000-432.

PERSONAL SAFETY

Stay alert, watch what you are doing and use common

sense when operating a power tool. Do not use a power

tool while you are tired or under the influence of drugs,

alcohol or medication. A moment of inattention while

operating power tools may result in serious personal injury.

Use personal protective equipment. Always wear eye

protection. Protective equipment such as dust mask,

non-skid safety shoes, hard hat, or hearing protection

used for appropriate conditions will reduce personal

injuries.

Prevent unintentional starting. Ensure the switch is in

the off-position before connecting to power source

and/or battery pack, picking up or carrying the tool.

Carrying power tools with your finger on the switch or

energising power tools that have the switch on invites

accidents.

Remove any adjusting key or wrench before turning

the power tool on. A wrench or a key left attached to a

rotating part of the power tool may result in personal injury.

Do not overreach. Keep proper footing and balance

at all times. This enables better control of the power tool

in unexpected situations.

Dress properly. Do not wear loose clothing or

jewellery. Keep your hair, clothing and gloves away

from moving parts. Loose clothes, jewellery or long hair

can be caught in moving parts.

If devices are provided for the connection of dust

extraction and collection facilities, ensure these are

connected and properly used. Use of dust collection

can reduce dust-related hazards.

Do not wear loose clothing or jewelry. Contain long

hair. Loose clothes, jewelry, or long hair can be drawn

into air vents.

Do not use on a ladder or unstable support. Stable

footing on a solid surface enables better control of the

power tool in unexpected situations.

POWER TOOL USE AND CARE

Do not force the power tool. Use the correct power

tool for your application. The correct power tool will

do the job better and safer at the rate for which it was

designed.

Do not use the power tool if the switch does not turn

it on and off. Any power tool that cannot be controlled

with the switch is dangerous and must be repaired.

Disconnect the plug from the power source and/or

the battery pack from the power tool before making

any adjustments, changing accessories, or storing

power tools. Such preventive safety measures reduce

the risk of starting the power tool accidentally.

Store idle power tools out of the reach of children and

do not allow persons unfamiliar with the power tool

or these instructions to operate the power tool. Power

tools are dangerous in the hands of untrained users.

Maintain power tools. Check for misalignment or

binding of moving parts, breakage of parts and any

other condition that may affect the power tool’s

operation. If damaged, have the power tool repaired

before use. Many accidents are caused by poorly

maintained power tools.

2 — English

Page 3

GENERAL POWER TOOL SAFETY WARNINGS

Keep cutting tools sharp and clean. Properly maintained

cutting tools with sharp cutting edges are less likely to

bind and are easier to control.

Use the power tool, accessories and tool bits etc.

in accordance with these instructions, taking into

account the working conditions and the work to be

performed. Use of the power tool for operations different

from those intended could result in a hazardous situation.

BATTERY TOOL USE AND CARE

Recharge only with the charger specified by the

manufacturer. A charger that is suitable for one type

of battery pack may create a risk of fire when used with

another battery pack.

Use power tools only with specifically designated

battery packs. Use of any other battery packs may create

a risk of injury and fire.

When battery pack is not in use, keep it away from

other metal objects, like paper clips, coins, keys, nails,

HAMMER DRILL SAFETY WARNINGS

Wear ear protectors with impact drilling. Exposure to

noise can cause hearing loss.

Use auxiliary handle(s), if supplied with the tool. Loss

of control can cause personal injury.

Hold power tool by insulated gripping surfaces, when

performing an operation where the cutting accessory

may contact hidden wiring. Cutting accessory

contacting a “live” wire may make exposed metal parts

of the power tool “live” and could give the operator an

electric shock.

Know your power tool. Read operator’s manual

carefully. Learn its applications and limitations, as

well as the specific potential hazards related to this

power tool. Following this rule will reduce the risk of

electric shock, fire, or serious injury.

Always wear eye protection with side shields marked

to comply with ANSI Z87.1 when assembling parts,

operating the tool, or performing maintenance.

Following this rule will reduce the risk of serious personal

injury.

Protect your lungs. Wear a face or dust mask if the

operation is dusty. Following this rule will reduce the

risk of serious personal injury.

Protect your hearing. Wear hearing protectors during

extended periods of operation. Following this rule will

reduce the risk of serious personal injury.

Battery tools do not have to be plugged into an

electrical outlet; therefore, they are always in

operating condition. Be aware of possible hazards

when not using your battery tool or when changing

accessories. Following this rule will reduce the risk of

electric shock, fire, or serious personal injury.

3 — English

screws, or other small metal objects, that can make

a connection from one terminal to another. Shorting

the battery terminals together may cause burns or a fire.

Under abusive conditions, liquid may be ejected from

the battery; avoid contact. If contact accidentally

occurs, flush with water. If liquid contacts eyes,

additionally seek medical help. Liquid ejected from the

battery may cause irritation or burns.

SERVICE

Have your power tool serviced by a qualified repair

person using only identical replacement parts. This will

ensure that the safety of the power tool is maintained.

When servicing a power tool, use only identical

replacement parts. Follow instructions in the

Maintenance section of this manual. Use of unauthorized

parts or failure to follow Maintenance instructions may

create a risk of shock or injury.

Do not place battery tools or their batteries near fire

or heat. This will reduce the risk of explosion and possibly

injury.

Do not crush, drop or damage battery pack. Do not

use a battery pack or charger that has been dropped

or received a sharp blow. A damaged battery is subject

to explosion. Properly dispose of a dropped or damaged

battery immediately.

Batteries can explode in the presence of a source

of ignition, such as a pilot light. To reduce the risk of

serious personal injury, never use any cordless product

in the presence of open flame. An exploded battery can

propel debris and chemicals. If exposed, flush with water

immediately.

Do not charge battery tool in a damp or wet location.

Following this rule will reduce the risk of electric shock.

For best results, your battery tool should be charged

in a location where the temperature is more than

50°F but less than 100°F. To reduce the risk of serious

personal injury, do not store outside or in vehicles.

Under extreme usage or temperature conditions,

battery leakage may occur. If liquid comes in contact

with your skin, wash immediately with soap and water.

If liquid gets into your eyes, flush them with clean

water for at least 10 minutes, then seek immediate

medical attention. Following this rule will reduce the risk

of serious personal injury.

Save these instructions. Refer to them frequently and

use them to instruct others who may use this tool. If you

loan someone this tool, loan them these instructions

also.

Page 4

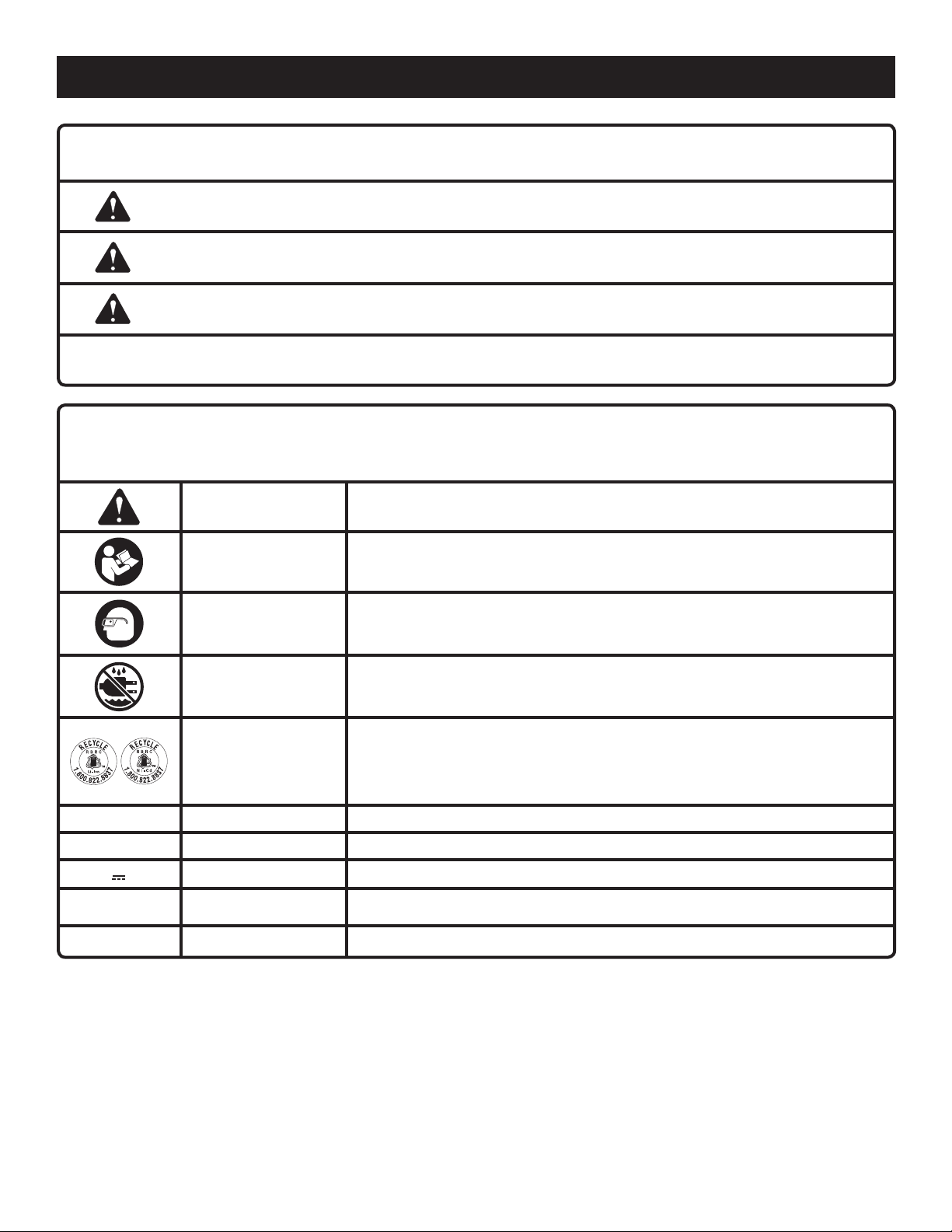

SYMBOLS

The following signal words and meanings are intended to explain the levels of risk associated with this product.

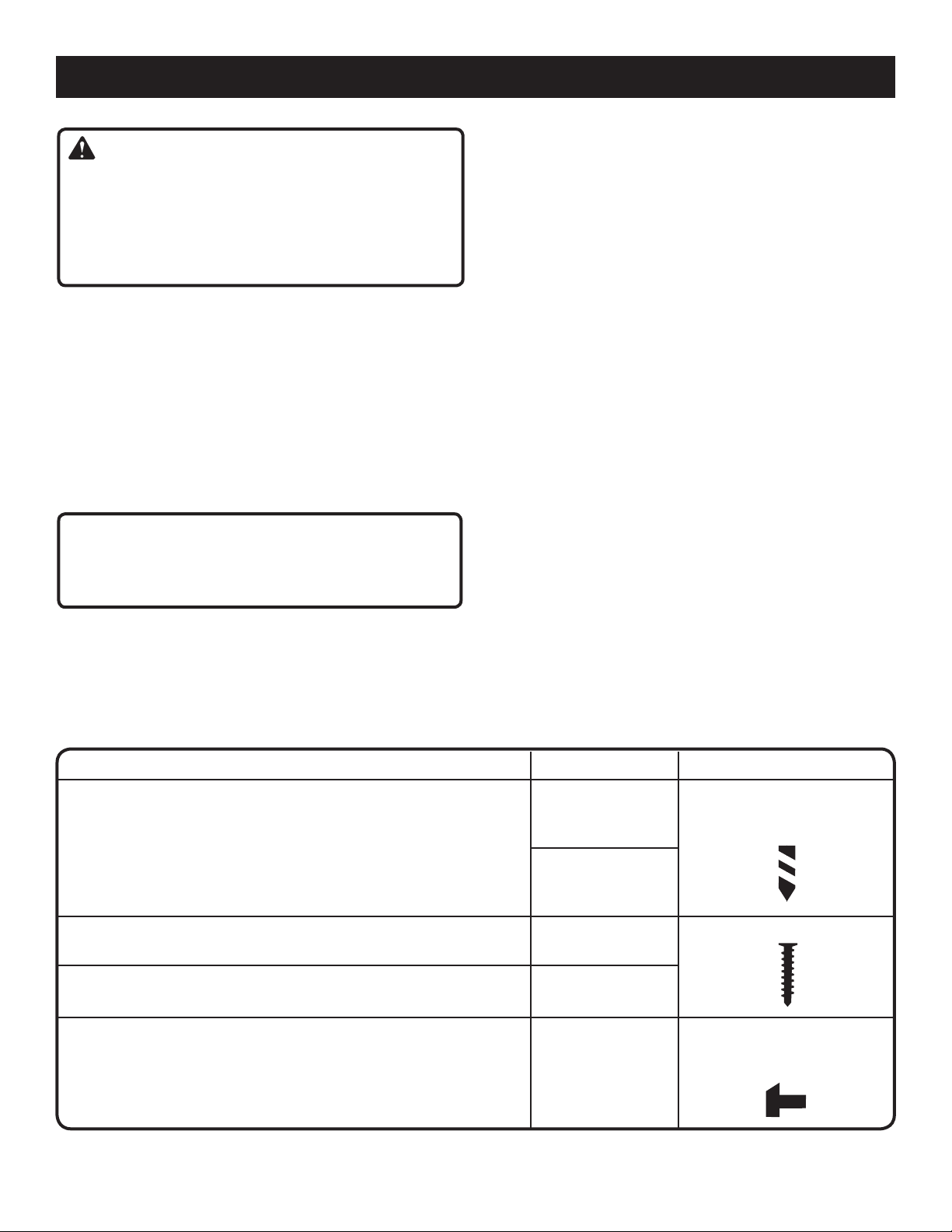

SYMBOL SIGNAL MEANING

DANGER:

WARNING:

CAUTION:

NOTICE:

Some of the following symbols may be used on this product. Please study them and learn their meaning. Proper

interpretation of these symbols will allow you to operate the product better and safer.

Indicates an imminently hazardous situation, which, if not avoided, will result

in death or serious injury.

Indicates a potentially hazardous situation, which, if not avoided, could result

in death or serious injury.

Indicates a potentially hazardous situation, which, if not avoided, may result in

minor or moderate injury.

(Without Safety Alert Symbol) Indicates important information not related to an

injury hazard, such as a situation that may result in property damage.

SYMBOL NAME DESIGNATION/EXPLANATION

Safety Alert Indicates a potential personal injury hazard.

Read Operator’s

Manual

Eye Protection

To reduce the risk of injury, user must read and understand operator’s manual

before using this product.

Always wear eye protection with side shields marked to comply with ANSI

Z87.1.

Wet Conditions

Alert

Recycle Symbols

V Volts Voltage

min Minutes Time

Direct Current Type or a characteristic of current

n

o

.../min Per Minute Revolutions, strokes, surface speed, orbits etc., per minute

No Load Speed Rotational speed, at no load

Do not expose to rain or use in damp locations.

This product uses nickel- cadmium (Ni-Cd) and lithium-ion (Li-ion) batteries.

Local, state or federal laws may prohibit disposal of batteries in ordinary

trash. Consult your local waste authority for information regarding available

recycling and/or disposal options.

4 — English

Page 5

FEATURES

PRODUCT SPECIFICATIONS

No Load Speed .......................0-375/0-1,600 r/min. (RPM)

Clutch.................................................................24 position

ASSEMBLY

Hammer Speed (Blows per minute)

................................................... 0-5,600/0-24,000 BPM

UNPACKING

This product requires assembly.

Carefully remove the tool and any accessories from the

box. All items listed in the Includes section must be

included at the time of purchase.

WARNING:

Items in this Assembly section are not assembled to

the product by the manufacturer and require customer

installation. Use of a product that may have been

improperly assembled could result in serious personal

injury.

If any parts are damaged or missing, please call

1-800-525-2579 for assistance.

WARNING:

If any parts are damaged or missing do not operate this

product until the parts are replaced. Use of this product

with damaged or missing parts could result in serious

personal injury.

WARNING:

Do not attempt to modify this product or create

accessories or attachments not recommended for use

with this product. Any such alteration or modification is

misuse and could result in a hazardous condition leading

to possible serious personal injury.

INSTALLING/ADJUSTING THE AUXILIARY

HANDLE ASSEMBLY

See Figure 1, page 10.

An auxiliary handle is packed with the drill for ease of operation and to help prevent loss of control. The handle can be

mounted for left or right hand use.

Insert the handle screw into the hole located above the

trigger switch and seat the hex head into the hole.

Slide the handle collar onto the screw. Seat the hex end

of the collar into the hex hole.

NOTE: Be sure the hex hole for the depth stop rod sits

on top of the collar.

Slide the depth stop rod into the hex-shaped hole on top

of the collar.

Slide the depth stop rod clamp into the notch in the collar.

The clamp holds the depth rod firmly in place.

NOTE: When properly installed, the teeth on the depth stop

rod should be facing the direction of the handle.

Thread the auxiliary handle onto the screw and secure

tightly.

NOTE: Be sure the the auxiliary handle is securely tightened

against the depth stop rod clamp. This secures the depth

stop rod at the desired depth of cut. It also secures the

auxiliary handle.

5 — English

Page 6

OPERATION

WARNING:

Do not allow familiarity with this product to make you

careless. Remember that a careless fraction of a second

is sufficient to inflict serious injury.

WARNING:

Always remove battery pack from the tool when you are

assembling parts, making adjustments, cleaning, or when

not in use. Removing battery pack will prevent accidental

starting that could cause serious personal injury.

WARNING:

Always wear eye protection with side shields marked to

comply with ANSI Z87.1, along with hearing protection.

Failure to do so could result in objects being thrown into

your eyes and other possible serious injuries.

WARNING:

Do not use any attachments or accessories not

recommended by the manufacturer of this product. The

use of attachments or accessories not recommended

can result in serious personal injury.

APPLICATIONS

You may use this product for the purposes listed below:

Hammer drilling in concrete, brick, or other masonry

Drilling in all types of wood products (lumber, plywood,

paneling, composition board, and hard board), ceramics,

plastics, fiberglass, laminates, and metals; driving screws

into wood and drywall with screwdriver bits

DIRECTION OF ROTATION SELECTOR

(FORWARD/REVERSE/CENTER LOCK)

See Figure 2, page 10.

Set the direction of rotation selector in the OFF (center lock)

position to lock the switch trigger and help prevent accidental

starting when not in use.

Position the direction of rotation selector to the left of the

switch trigger for forward drilling. Position the selector to the

right of the switch trigger to reverse the direction.

NOTE: The drill will not run unless the direction of rotation

selector is pushed fully to the left or right.

NOTICE:

To prevent gear damage, always allow the chuck to

come to a complete stop before changing the direction

of rotation.

WARNING:

Battery tools are always in operating condition. Lock

the switch when not in use or carrying at your side,

when installing or removing the battery pack, and when

installing or removing bits.

INSTALLING/REMOVING BATTERY PACK

See Figure 3, page 10.

Lock the switch trigger.

Insert the battery pack into the product as shown.

Make sure the latches on each side of the battery pack

snap in place and that battery pack is secured in the

product before beginning operation.

Depress the latches to remove the battery pack.

For complete charging instructions, see the operator’s

manuals for your battery pack and charger.

VARIABLE SPEED SWITCH TRIGGER

See Figure 2, page 10.

The variable speed switch trigger delivers higher speed with

increased trigger pressure and lower speed with decreased

trigger pressure.

To turn the tool ON, depress the switch trigger. To turn it

OFF, release the switch trigger and allow the chuck to come

to a complete stop.

NOTE: A whistling or ringing noise coming from the switch

during use is a normal part of the switch function.

NOTE: Running at low speeds under constant usage may

cause the drill to become overheated. If this occurs, cool the

drill by running it without a load and at full speed.

6 — English

INSTALLING/REMOVING BITS

See Figures 4 - 5, page 10.

The arrows on the keyless chuck indicate which direction

to rotate the chuck sleeve to tighten or release the drill bit.

Do not use a wrench to tighten or loosen the chuck jaws.

To install bits, lock the switch trigger.

Open or close the chuck jaws until the opening is slightly

larger than the bit size you intend to use.

Raise the front of the drill slightly and insert the drill bit.

WARNING:

Make sure to insert the drill bit straight into the chuck

jaws. Do not insert the drill bit into the chuck jaws at

an angle, then tighten. This could cause the drill bit to

be thrown from the drill, resulting in possible serious

personal injury or damage to the chuck.

Page 7

OPERATION

WARNING:

Do not hold the chuck sleeve with one hand and use

the power of the drill to tighten the chuck jaws on the

drill bit. The chuck body could slip in your hand, or your

hand could slip and come in contact with the rotating

drill bit. This could cause an accident resulting in serious

personal injury.

To remove bits, lock the switch trigger and open the

chuck jaws.

The bit provided with the drill can be placed in the storage

area, located on the base of the drill.

TWO-SPEED GEAR TRAIN (HI-LO SWITCH)

See Figure 6, page 11.

Select LOW (1) speed for applications requiring higher

power and torque.

Select HIGH (2) speed for fast drilling, hammer drilling or

driving applications.

NOTICE:

Never change speeds while the tool is running. Failure

to obey this caution could result in serious damage to

the drill.

NOTE: If you have difficulty changing from one gear

range to the other, turn the chuck by hand until the gears

engage.

QUICK MODE SELECTOR

See Figure 7, page 11.

The Quick Mode Selector allows you to quickly switch from

drill mode to drive mode.

Drill mode should be used for drilling and other heavy duty

applications. Drive mode should be used for driving screws.

Hammer mode should be used for hammer drilling.

Using the chart, select the option that best matches the type

of bit, fastener, and material you will be using.

Choose your APPLICATION.

Choose the correct SPEED: (1/LOW OR 2/HIGH)

Choose the correct MODE: (DRIVE, DRILL, OR

HAMMER)

ADJUSTING TORQUE

See Figure 8, page 11.

When using the drill-driver for various driving applications,

increasing or decreasing the torque helps prevent the

possibility of damaging screw heads, threads, workpiece,

etc. In general, torque intensity should correspond to the

screw diameter. If the torque is too high or the screws too

small, the screws may be damaged or broken.

The torque is adjusted by rotating the torque adjustment ring.

The torque is greater when the torque adjustment ring is

set on a higher setting. The torque is less when the torque

adjustment ring is set on a lower setting.

The proper setting depends on the type of material and the

size of screw you are using.

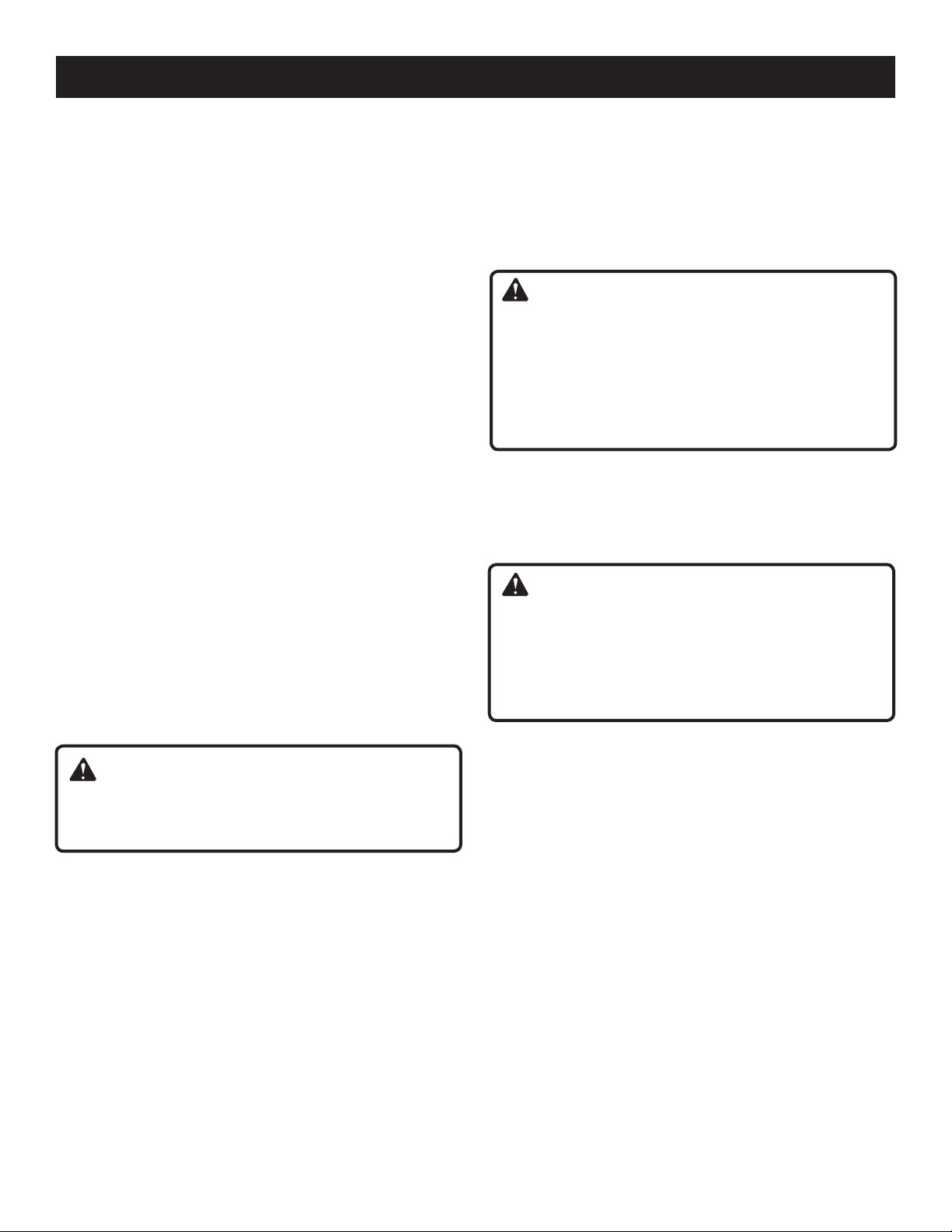

APPLICATION SPEED MODE

• Lag screws up to 3/8 in. dia. by 1-1/2 in. long

• Hole saw up to 2 in.

• Spade bits up to 1-1/2 in.

• Drill bits up to 1/2 in.

• Drilling into metal

• Concrete screws

• Deck or wood screws up to 3 in.

• Self tapping screws

• Deck or wood screws up to 2 in.

• Small screws or delicate work that requires more control

• Drilling into masonry and concrete.

7 — English

1/LOW

2/HIGH

1/LOW

2/HIGH

2/HIGH

DRILL MODE

(TORQUE ADJUSTMENT

NOT ACTIVE)

DRIVE MODE

HAMMER MODE

(TORQUE ADJUSTMENT

NOT ACTIVE)

Page 8

OPERATION

ADJUSTING THE AUXILIARY HANDLE

ASSEMBLY

See Figure 9, page 11.

To adjust the auxiliary handle assembly:

Loosen the handle assembly by turning the handle

counterclockwise.

Insert the auxiliary handle assembly in the desired

operating position.

Securely tighten by turning the auxiliary handle clockwise.

NOTE: Be sure the auxiliary handle is securely tightened

against the depth stop rod clamp. This secures the depth

stop rod at the desired depth of cut. It also secures the

auxiliary handle.

ADJUSTING THE DEPTH STOP ROD

See Figure 9, page 11.

The depth stop rod helps control the depth of drilled holes.

To adjust the depth stop rod:

Lock the switch trigger by placing the direction of rotation

selector in the center position.

Loosen the auxiliary handle assembly by turning the knob

counterclockwise.

Adjust the depth stop rod so that the drill bit extends

beyond the end of the rod to the required drilling depth.

Tighten the auxiliary handle assembly by turning the knob

clockwise.

NOTE: When properly installed, the teeth on the depth stop

rod should be facing the direction of the handle.

DRILLING/DRIVING SCREWS

See Figure 10, page 11.

WARNING:

Always use the auxiliary handle when using this tool to

help resist torque reactions. Binding or stalling of this

product could lead to serious personal injury.

Installtheauxiliaryhandle.

Check the direction of rotation selector for the correct

setting(forwardorreverse).

Use LOW (1) speed for high torque applications and

HIGH (2) speed for fast drilling or driving applications.

Refer to Two-Speed Gear Train and Adjusting Torque.

Secure the workpiece in a vise or with clamps to keep it

fromturningasthebitrotates.

Hold the drill firmly and place the bit at the point to be

drilled,orwherethescrewistobedriven.

WARNING:

Do not drive a screw where there is likely to be hidden

wiring behind the surface. Contact with a “live” wire will

make exposed metal parts of the tool “live” and possibly

shock the operator. If you must drive a screw where

hidden wire may be present, always hold tool by insulated

gripping surfaces (handle) when performing the operation

to prevent a shock to the operator.

Depress the switch trigger to start the drill.

Move the bit into the workpiece, applying only enough

pressure to keep the bit cutting or driving the screw. Do

not force the drill or apply side pressure to elongate a

hole. Let the tool do the work.

WARNING:

When drilling, be prepared for binding at bit breakthrough.

When these situations occur, drill has a tendency to grab

and kick opposite to the direction of rotation and could

cause loss of control when breaking through material. If

not prepared, this loss of control can result in possible

serious injury.

When drilling hard, smooth surfaces, use a center punch

to mark the desired hole location. This will prevent the bit

from slipping off-center as the hole is started.

If the bit jams in the workpiece or if the drill stalls, stop

the tool immediately. Remove the bit from the workpiece

and determine the reason for jamming.

NOTE: This drill has an electric brake. When the switch trigger is released, the chuck stops turning. When the brake is

functioning properly, sparks will be visible through the vent

slots on the housing. This is normal and is the action of the

brake.

8 — English

Page 9

OPERATION

WOOD AND METAL DRILLING

For maximum performance, use high speed steel bits for

woodormetaldrilling.Selectdrillingmode.Begindrilling

at a very low speed to prevent the bit from slipping off the

starting point.

Wood Drilling

Increasethespeedasthedrillbitbitesintothematerial.

When drilling through holes, place a block of wood behind

the workpiece to prevent ragged or splintered edges on

thebacksideofthehole.

Metal and Steel Drilling

Use a light oil on the drill bit to keep it from overheating.

The oil will prolong the life of the bit and increase the

drilling action.

Maintain a speed and pressure which allows cutting

without overheating the bit. Applying too much pressure

will:

• Overheat the drill;

• Wear the bearings;

MAINTENANCE

• Bend or burn bits; and

•Produceoff-centerorirregular-shapedholes.

When drilling large holes in metal, start with a small bit,

then finish with a larger bit.

MASONRY DRILLING

For maximum performance, use carbide-tipped masonry

impact bits or designated hammer drill bits when drilling

holes in brick, tile, concrete, etc. Select hammer mode.

Apply light pressure at medium speed for best results in

brick.

Apply additional pressure for hard materials such as

concrete.

When drilling holes in tile, practice on a scrap piece to

determine the best speed and pressure. Begin drilling at

a very low speed to prevent the bit from slipping off the

startingpoint.

GENERAL MAINTENANCE

WARNING:

When servicing, use only identical replacement parts.

Use of any other parts could create a hazard or cause

product damage.

Avoid using solvents when cleaning plastic parts. Most

plastics are susceptible to damage from various types of

commercial solvents and may be damaged by their use. Use

clean cloths to remove dirt, dust, oil, grease, etc.

CALIFORNIA PROPOSITION 65

WARNING:

This product and some dust created by power sanding, sawing, grinding, drilling, and other construction activities may

contain chemicals, including lead, known to the State of California to cause cancer, birth defects, or other reproductive

harm. Wash hands after handling.

Some examples of these chemicals are:

• lead from lead-based paints,

• crystalline silica from bricks and cement and other masonry products and,

• arsenic and chromium from chemically treated lumber.

Your risk from exposure to these chemicals varies, depending on how often you do this type of work. To reduce your

exposure, work in a well-ventilated area and with approved safety equipment, such as dust masks that are specially

designed to filter out microscopic particles.

NOTE: ILLUSTRATIONS START ON PAGE 10 AFTER FRENCH

AND SPANISH LANGUAGE SECTIONS.

9 — English

Page 10

AVERTISSEMENTS DE SÉCURITÉ GÉNÉRALES RELATIVES

AUX OUTILS ÉLECTRIQUES

Utiliser l’équipement de sécurité. Toujours porter une

AVERTISSEMENT

Lire tous les avertissements et toutes les instructions. Ne pas

suivre l’ensemble des avertissements et des instructions peut

entraîner une électrocution, un incendie ou des blessures graves.

Conserver les avertissements et les instructions à des fins de

référence ultérieure. Le terme « outil motorisé », utilisé dans tous

les avertissements ci-dessous désigne tout outil fonctionnant sur

secteur (câblé) ou sur piles (sans fil).

SÉCURITÉ DU LIEU DE TRAVAIL

Garder le lieu de travail propre et bien éclairé. Les endroits

encombrés ou sombre s sont propices aux accidents.

Ne pas utiliser d’outils électriques dans des atmosphères

explosives, par exemple en présence de liquides, gaz ou

poussières inflammables. Les outils électriques produisent des

étincelles risquant d’enflammer les poussières ou vapeurs.

Garder les enfants et badauds à l’écart pendant l’utilisation

d’un outil électrique. Les distractions peuvent causer une perte

de contrôle.

SÉCURITÉ ÉLECTRIQUE

Les fiches des outils électriques doivent correspondre à la

prise secteur utilisée. Ne jamais modifier la fiche, de quelque

façon que ce soit. Ne jamais utiliser d’adaptateurs de fiche

avec des outils mis à la terre. Les fiches et prises non modifiées

réduisent le risque de choc électrique.

Éviter tout contact du corps avec des surfaces mises

à la terre, telles que tuyaux, radiateurs, cuisinières et

réfrigérateurs. Le risque de choc électrique est accru lorsque

le corps est mis à la terre.

Ne pas exposer les outils électriques à l’eau ou l’humidité.

La pénétration d’eau dans ces outils accroît le risque de choc

électrique.

Ne pas maltraiter le cordon d’alimentation. Ne jamais

utiliser le cordon d’alimentation pour transporter l’outil et

ne jamais débrancher ce dernier en tirant sur le cordon.

Garder le cordon à l’écart de la chaleur, de l’huile, des

objets tranchants et des pièces en mouvement. Un cordon

endommagé ou emmêlé accroît le risque de choc électrique.

Pour les travaux à l’extérieur, utiliser un cordon spécialement

conçu à cet effet. Utiliser un cordon conçu pour l’usage

extrérieur pour réduire les risques de choc électrique.

S’il est nécessaire d’utiliser l’outil électrique dans un endroit

humide, employer un dispositif interrupteur de défaut à la

terre (GFCI). L’utilisation d’un GFCI réduit le risque de décharge

électrique.

Ne recharger les piles qu’avec l’appareil indiqué. Pour utiliser

l’appareil avec des piles au nickel-cadmium et au lithium-ion de

18 V, consulter le supplément de raccordement pour chargeur/

outils/piles/appareil n˚ 987000-432.

SÉCURITÉ PERSONNELLE

Rester attentif, prêter attention au travail et faire preuve

de bon sens lors de l’utilisation de tout outil électrique. Ne

pas utiliser cet outil en état de fatigue ou sous l’influence

de l’alcool, de drogues ou de médicaments. Un moment

d’inattention pendant l’utilisation d’un outil électrique peut

entraîner des blessures graves.

2 — Français

protection oculaire. L’équipement de sécurité, tel qu’un

masque filtrant, de chaussures de sécurité, d’un casque ou

d’une protection auditive, utilisé dans des conditions appropriées

réduira le risque de blessures.

Éviter les démarrages accidentels. S’assurer que le

commutateur est en position d’arrêt avant de brancher l’outil.

Porter un outil avec le doigt sur son commutateur ou brancher un

outil dont le commutateur est en position de marche peut causer

un accident.

Retirer les clés de réglage avant de mettre l’outil en marche.

Une clé laissée sur une pièce rotative de l’outil peut causer des

blessures.

Ne pas travailler hors de portée. Toujours se tenir bien campé

et en équilibre. Ceci permettra de mieux contrôler l’outil en cas

de situation imprévue.

Porter une tenue appropriée. Ne porter ni vêtements amples,

ni bijoux. Garder les cheveux, les vêtements et les gants à

l’écart des pièces en mouvement. Les vêtements amples,

bijoux et cheveux longs peuvent se prendre dans les pièces en

mouvement.

Si les outils sont équipés de dispositifs de dépoussiérage,

s’assurer qu’ils sont connectés et correctement utilisés.

L’usage de ces dispositifs de dépoussiérage peut réduire les

dangers présentés par la poussière.

Ne porter ni vêtements amples, ni bijoux. Attacher ou couvrir

les cheveux longs. Les vêtements amples, bijoux et cheveux

longs peuvent se prendre dans les ouïes d’aération.

Ne pas utiliser l’outil sur une échelle ou un support instable.

Une bonne tenue et un bon équilibre permettent de mieux

contrôler l’outil en cas de situation imprévue.

UTILISATION ET ENTRETIEN DES OUTILS

ÉLECTRIQUES

Ne pas forcer l’outil. Utiliser l’outil approprié pour l’application.

Un outil approprié exécutera le travail mieux et de façon moins

dangereuse s’il est utilisé dans les limites prévues.

Ne pas utiliser l’outil si le commutateur ne permet pas de le

mettre en marche ou de l’arrêter. Tout outil qui ne peut pas

être contrôlé par son commutateur est dangereux et doit être

réparé.

Débrancher l’outil et/ou retirer le bloc-piles avant d’effectuer

des réglages, de changer d’accessoire ou de remiser l’outil.

Ces mesures de sécurité préventives réduisent les risques de

démarrage accidentel de l’outil.

Ranger les outils motorisés hors de la portée des enfants et

ne laisser personne n’étant pas familiarisé avec l’outil ou ces

instructions utiliser l’outil. Dans les mains de personnes n’ayant

pas reçu des instructions adéquates, les outils sont dangereux.

Entretenir les outils motorisés. Vérifier qu’aucune pièce

mobile n’est mal alignée ou bloquée, qu’aucune pièce n’est

brisée et s’assurer qu’aucun autre problème ne risque

d’affecter le bon fonctionnement de l’outil. En cas de

dommages faire réparer l’outil avant de l’utiliser de nouveau.

Beaucoup d’accidents sont causés par des outils mal entretenus.

Garder les outils bien affûtés et propres. Des outils

correctement entretenus et dont les tranchants sont bien affûtés

risquent moins de se bloquer et sont plus faciles à contrôler.

Page 11

AVERTISSEMENTS DE SÉCURITÉ GÉNÉRALES RELATIVES

AUX OUTILS ÉLECTRIQUES

Utiliser l’outil, les accessoires et embouts, etc. conformément

à ces instrutions pour les applications pour lesquelles ils sont

conçus, en tenant compte des conditions et du type de travail

à exécuter. L’usage d’un outil motorisé pour des applications

pour lesquelles il n’est pas conçu peut être dangereux.

UTILISATION ET ENTRETIEN DE LA PILE

Ne recharger qu’avec l’appareil spécifié par le fabricant. Un

chargeur approprié pour un type de pile peut créer un risque

d’incendie s’il est utilisé avec un autre type de pile.

Utiliser exclusivement le bloc-pile spécifiquement indiqué

pour l’outil. L’usage de tout autre bloc peut créer un risque de

blessures et d’incendie.

Lorsque le bloc-piles n’est pas en usage, le garder à l’écart

d’articles tels qu’attaches trombones, pièces de monnaie,

clous, vis ou autres petits objets métalliques risquant d’établir

le contact entre les deux bornes. La mise en court-circuit des

bornes de piles peut causer des étincelles, des brûlures ou un

incendie.

AVERTISSEMENTS DE SÉCURITÉ RELATIFS AU

PERCEUSE À PERCUSSION

Porter des protecteurs d’oreilles avec les perceuses à

percussion. L’exposition au bruit peut entraîner une perte

auditive.

Utiliser les poignées auxiliaires, si elles sont fournies avec

l’outil. La perte de contrôle peut causer des blessures.

Lorsque l’outil est utilisé pour un travail risquant de le mettre

en contact avec des fils électriques cachés, le tenir par les

surfaces de prise isolées. Le contact d’un accessoire de coupe

avec un fil sous tension « électrifie » les pièces métalliques

exposées de l’outil et peut électrocuter l’utilisateur.

Apprendre à connaître l’outil. Lire attentivement le manuel

d’utilisation. Apprendre les applications et les limites

de l’outil, ainsi que les risques spécifiques relatifs à son

utilisation. Le respect de cette consigne réduira les risques

d’incendie, de choc électrique et de blessures graves.

Toujours porter une protection oculaire munie d’écrans

latéraux certifiée conforme à la norme ANSI Z87.1 lors du

montage des pièces, du fonctionnement de l’outil ou au

moment de l’entretien. Le respect de cette règle réduira les

risques de blessures graves.

Protection respiratoire. Porter un masque facial ou un

masque antipoussière si le travail produit de la poussière.

Le respect de cette consigne réduira les risques de blessures

graves.

Protection auditive. Porter une protection auditive lors de

l’utilisation prolongée. Le respect de cette règle réduira les

risques de blessures graves.

Les outils fonctionnant sur piles n’ayant pas besoin d’être

branchés sur une prise secteur, ils sont toujours en état

de fonctionnement. Tenir compte des dangers possibles

lorsque l’outil n’est pas en usage et lors du remplacement

des piles. Le respect de cette consigne réduira les risques

d’incendie, de choc électrique et de blessures graves.

3 — Français

En cas d’usage abusif, du liquide peut s’échapper des

piles. Éviter tout contact avec ce liquide. En cas de contact

accidentel, rincer immédiatement les parties atteintes avec

de l’eau. En cas d’éclaboussure dans les yeux consulter

un médecin. Le liquide s’échappant des piles peut causer des

irritations ou des brûlures.

DÉPANNAGE

Les réparations doivent être confiées à un technicien qualifié,

utilisant exclusivement des pièces identiques à celles

d’origine. Ceci assurera le maintien de la sécurité de l’outil.

Utiliser exclusivement des pièces identiques à celles d’origine

pour les réparations. Se conformer aux instructions de

la section Entretien de ce manuel. L’usage de pièces non

autorisées ou le non-respect des instructions peut présenter des

risques de choc électrique ou de blessures.

Ne pas placer les outils électriques sans fil ou leurs piles

à proximité de flammes ou d’une source de chaleur. Ceci

réduira les risques d’explosion et de blessures.

Ne pas écraser, faire tomber ou endommager le bloc-piles.

Ne jamais utiliser un bloc-piles ou un chargeur qui est tombé,

a été écrasé, a reçu un choc violent ou a été endommagé

de quelque façon que ce soit. Une pile endommagée risque

d’exploser. Éliminer immédiatement toute pile endommagée,

selon une méthode appropriée.

Les piles peuvent exploser en présence d’une source

d’allumage, telle qu’une veilleuse. Pour réduire les risques

de blessures graves, ne jamais utiliser un appareil sans fil, quel

qu’il soit, en présence d’une flamme vive. En explosant, une

pile peut projeter des débris et des produits chimiques. En cas

d’exposition, rincer immédiatement les parties atteintes avec

de l’eau.

Ne pas recharger un outil fonctionnant sur piles dans un

endroit humide ou mouillé. Le respect de cette règle réduira

les risques de choc électrique.

Pour un résultat optimal, le piles de l’outil doivent être

rechargées dans un local où la température est de 10 à

38 °C (50 à 100 °F). Ne pas ranger l’outil à l’extérieur ou dans

un véhicule.

Si l’outil est utilisé de façon intensive ou sous des

températures extrêmes, des fuites de pile peuvent se

produire. En cas de contact du liquide avec la peau,

rincer immédiatement la partie atteinte avec de l’eau.

En cas d’éclaboussure dans les yeux, les rincer à l’eau

fraîche pendant au moins 10 minutes, puis contacter

immédiatement un médecin. Le respect de cette règle réduira

les risques de blessures graves.

Conserver ces instructions. Les consulter fréquemment et

les utiliser pour instruire les autres utilisateurs éventuels. Si cet

outil est prêté, il doit être accompagné de ces instructions.

Page 12

SYMBOLES

Les termes de mise en garde suivants et leur signification ont pour but d’expliquer le degré de risques associé à l’utilisation

de ce produit.

SYMBOLE SIGNAL SIGNIFICATION

DANGER:

AVERTISSEMENT :

ATTENTION :

AVIS :

Certains des symboles ci-dessous peuvent être utilisés sur produit. Veiller à les étudier et à apprendre leur signification.

Une interprétation correcte de ces symboles permettra d’utiliser produit plus efficacement et de réduire les risques.

Indique une situation extrêmement dangereuse qui, si elle n’est pas évitée, aura

pour conséquences des blessures graves ou mortelles.

Indique une situation potentiellement dangereuse qui, si elle n’est pas évitée,

pourrait entraîner des blessures graves ou mortelles.

Indique une situation potentiellement dangereuse qui, si elle n’est pas évitée,

pourraît entraîner des blessures légères ou de gravité modérée.

(Sans symbole d’alerte de sécurité)Indique une information importante ne

concernant pas un risque de blessure comme une situation pouvant occasionner

des dommages matériels.

SYMBOLE NOM DÉSIGNATION / EXPLICATION

Symbole d’alerte de

sécurité

Lire manuel d’utilisation

Protection oculaire

Indique un risque de blessure potentiel.

Pour réduire les risques de blessures, l’utilisateur doit lire et veiller à bien

comprendre le manuel d’utilisation avant d’utiliser ce produit.

Toujours porter une protection oculaire avec écrans latéraux certifiée conforme

à la norme ANSI Z87.1.

V

min

n

o

.../min

Avertissement

concernant l’humidité

Symboles de recyclage

Volts Tension

Minutes Temps

Courant continu Type ou caractéristique du courant

Vitesse à vide Vitesse de rotation à vide

Par minute Tours, coups, vitesse périphérique, orbites, etc., par minute

Ne pas exposer à la pluie ou l’humidité.

Ce produit utilise les piles de nickel-cadmium (Ni-Cd) et lithium-ion (Li-ion).

Les réglementations locales ou gouvernementales peuvent interdire de

jeter les piles dans les ordures ménagères. Consulter les autorités locales

compétentes pour les options de recyclage et/ou l’élimination.

4 — Français

Page 13

CARACTÉRISTIQUES

FICHE TECHNIQUE

Vitesse à vide .....................0 - 375 / 0 - 1 600 r/min (RPM)

Embrayage........................................................24 positions

ASSEMBLAGE

Vitesse de percussion (Coups par minute)

............................................. 0 à 5 600 / 0 à 24 000 cpm

DÉBALLAGE

Ce produit nécessite un assemblage.

Avec précaution, sortir l’outil et les accessoires de la

boîte. Tous les articles énumérés sous « Inclut » doivent

se trouver dans l’emballage au moment de l’achat.

AVERTISSEMENT :

Certaines pièces figurant dans cette section Assemblage

n’ont pas été installées sur le produit par le fabricant

et exigent une installation du client. Le fait d’utiliser un

produit qui a été assemblé de façon inadéquate peut

entraîner des blessures.

Si des pièces manquent ou sont endommagées, veuillez

appeler au 1-800-525-2579 pour obtenir de l’aide. Au

Mexique, veuillez composer le numéro 01-800-843-1111.

AVERTISSEMENT :

Si des pièces manquent ou sont endommagées, ne pas

utiliser cet outil avant qu’elles aient été remplacées. Le

non-respect de cet avertissement pourrait entraîner des

blessures graves.

AVERTISSEMENT :

Ne pas essayer de modifier cet outil ou de créer des

accessoires ou de pièces non recommandés pour l’outil.

De telles altérations ou modifications sont considérées

comme un usage abusif et peuvent créer des conditions

dangereuses, risquant d’entraîner des blessures graves.

INSTALLATION/RÉGLAGE ENSEMBLE DE

POIGNÉE AUXILIAIRE

Voir la figure 1, page 10.

Une poignée auxiliaire est ajoutée à la perceuse pour faciliter

l’utilisation et éviter toute perte de contrôle. La poignée peut

être installée de l’un ou l’autre des côtés de la perceuse pour

être utilisée de la main gauche ou de la main droite.

Insérer la vis de la poignée dans le trou situé au-dessus

de la gâchette et asseoir la tête hexagonale dans le trou.

Glisser le collier de la poignée sur la vis, et asseoir

l’extrémité hexagonale du collier dans le trou hexagonal.

NOTE : S’assurer que le trou hexagonal servant pour la

tige de butée de profondeur est positionné sur le dessus

du collier.

Glisser la tige de butée de profondeur dans le trou

hexagonal situé sur le dessus du collier.

Glisser la bride de la tige de butée de profondeur dans

l’encoche du collier. La bride permet de tenir la tige de

butée de profondeur fermement en place.

NOTE : Si l’installation est correcte, les dents de la tige de

butée de profondeur doivent être face à la direction de la

poignée.

Visser la poignée auxiliaire sur la vis et la serrer solidement.

NOTE : S’assurer que la poignée auxiliaire est fixée

solidement contre la bride de la tige de butée de profondeur.

Cela permet de régler la tige de butée de profondeur à la

profondeur de perçage désirée. Cela permet également de

fixer la poignée auxiliaire.

5 — Français

Page 14

UTILISATION

AVERTISSEMENT :

Ne pas laisser la familiarité avec l’outil faire oublier la

prudence. Ne pas oublier qu’une fraction de seconde

d’inattention peut entraîner des blessures graves.

AVERTISSEMENT :

Toujours retirer la bloc-pile de l’outil au moment d’assembler

des pièces, d’effectuer des réglages et de procéder au

nettoyage, ou lorsque l’outil n’est pas utilisé. Si cette

précaution n’est pas prise, des objets peuvent être projetés

dans les yeux et causer des lésions graves.

AVERTISSEMENT :

Toujours porter une protection oculaire avec écrans latéraux

certifiée conforme à la norme ANSI Z87.1. Si une opération

dégage de la poussière, porter également un masque antipoussière.

AVERTISSEMENT :

Ne pas utiliser d’outils ou accessoires non recommandés

par le fabricant pour cet outil. L’utilisation de pièces et

accessoires non recommandés peut entraîner des blessures

graves.

APPLICATIONS

Cet outil ne doit être utilisé que pour les applications listées

ci-dessous.

Perçage en mode de percussion dans le béton, la brique et

autres pièces de maçonnerie

Perçage et du vissage de vis de produits du bois (bois

d’oeuvre, contreplaqué, lambris, aggloméré et bois dur),

céramique, plastique, fibre de verre, matériaux laminés,

métaux mous et durs; Visser différents types de vis dans le

bois et les cloisons sèches à l’aide d’embouts de tournevis

GÂCHETTE À VARIATION DE VITESSE

Voir la figure 2, page 10.

La gâchette avec variation de vitesse procurera des vitesses

plus élevées si une pression accrue est exercée et des vitesses

moins élevées dans le cas d’une pression réduite.

Pour mettre la perceuse EN MARCHE, appuyer sur la gâchette.

Pour ÉTEINDRE la perceuse, relâcher la gâchette et laisser le

mandrin parvenir à l’arrêt complet.

NOTE : Un bruit de sifflement ou de tintement provenant de

la gâchette pendant l’utilisation est une situation normale pour

cet interrupteur.

NOTE : L’utilisation de la perceuse à faible vitesse de façon

continue peut entraîner une surchauffe. Si la perceuse

surchauffe, la refroidir en la laissant tourner à vide et à la vitesse

maximum.

SÉLECTEUR DE SENS DE ROTATION

(AVANT/ARRIÈRE/POSITION CENTRALE VERROUILLÉE)

Voir la figure 2, page 10.

Régler le sélecteur de sens de rotation à la position OFF (position

centrale verrouillée) pour verrouiller la gâchette pour réduire la

possibilité d’un démarrage accidentel lorsque l’appareil n’est

pas utilisé.

Positionner le sélecteur de sens de rotation du côté gauche

de la gâchette pour pouvoir percer vers l’avant. Positionner le

sélecteur de sens de rotation du côté droit de la gâchette pour

inverser le sens de rotation.

NOTE : La perceuse ne peut fonctionner que si le sélecteur de

sens de rotation est poussé à fond vers la droite ou la gauche.

AVIS :

Pour éviter des dommages aux engrenages, toujours laisser

le mandrin parvenir à l’arrêt complet avant de changer de

sens de rotation.

AVERTISSEMENT :

Les outils à piles sont toujours en état de fonctionnement.

Verrouiller la gâchette lorsque l’outil n’est pas utilisé ou

pour le transporter le long du corps, pour insérer ou retirer

le bloc-piles et lors de l’installation ou du retrait des forets.

INSTALLATION/RETRAIT DU BLOC-PILES

Voir la figure 3, page 10.

Verrouiller la gâchette.

Insérer la pile dans l’outil comme illustré.

S’assurer que les loquets de chaque côté de la pile

s’enclenchent en place et que la pile est bien fixée à l’outil

avant de mettre l’outil en marche.

Relâcher les loquets pour retirer le bloc-piles.

Pour prendre connaissance des consignes de chargement,

consulter le manuel d’utilisation des piles et des chargeurs.

INSTALLATION/RETRAIT FORETS

Voir les figures 4 et 5, page 10.

Les flèches sur le mandrin sans clé indiquent le sens de rotation du

corps du mandrin pour serrer ou dégager le foret de la perceuse.

Ne pas utiliser une clé ordinaire ou une pince pour serrer ou

desserrer les mors du mandrin.

Pour insérer les forets, verrouiller la gâchette.

Ouvrir suffisamment les mors du mandrin pour pouvoir y

insérer le foret à utiliser.

Relever légère la partie avant de la perceuse et insérer le

foret.

AVERTISSEMENT :

Veiller à insérer le foret ou l’embout droit dans les mors du

mandrin. Ne pas insérer un foret dans les mors en serrant.

Le foret pourrait être éjecté de la perceuse et causer des

blessures graves ou endommager le mandrin.

6 — Français

Page 15

UTILISATION

AVERTISSEMENT :

Ne pas tenir le corps du mandrin d’une main et utiliser la

force du moteur pour serrer les mors du mandrin sur le foret

ou l’embout. Le mandrin pourrait glisser de la main et celle-ci

risquerait d’être heurtée par le foret en rotation. Ceci pourrait

entraîner des blessures graves.

Pour retirer les forets, verrouiller la gâchette et ouvrir les

mors du mandrin.

Il est possible d’insérer le foret fourni avec la perceuse dans

le rangement situé sur la base de l’outil.

TRAIN D’ENGRENAGES À DEUX VITESSES

(COMMUTATEUR HI-LO)

Voir la figure 6, page 11.

Sélectionner la basse vitesse (BASSE) (1) pour des

applications nécessitant plus de puissance et un couple

plus élevé.

Sélectionner la vitesse élevée (HAUTE) (2) pour un

perçage rapide, perçage avec percussion ou pour d’autres

applications.

AVIS :

Ne jamais changer de gamme de vitesse lorsque l’outil est

en fonctionnement. Le non respect de cette mise en garde

pourrait entraîner de sérieux dommages à la perceuse.

NOTE : S’il est difficile de changer de gamme de vitesse,

tourner le mandrin à la main, jusqu’à ce que les pignons

s’engrènent.

SÉLECTEUR DE MODE RAPIDE

Voir le figure 7, page 11.

Ce sélecteur permet de passer rapidement du mode de perçage

au mode de vissage.

Mode de perçage doit être utilisé pour le perçage et autres travaux

durs. Le mode de vissage doit être utilisé pour visser. Le mode

martelage doit être utilisé pour le martelage.

Consulter le tableau ci-dessous pour sélectionner le réglage

correspondant le mieux au type d’embout / foret, de vis et de

matériau.

Choisir L’APPLICATION

Choisir la VITESSE appropriée: (1 / BASSE ou 2 / HAUTE)

Choisir le MODE approprié:

(PERÇAGE, VISSAGE, MARTELAGE)

RÉGLAGE DU COUPLE

Voir la figure 8, page 11.

Selon l’application pour laquelle la perceuse-tournevis est

utilisée, le couple doit être augmenté ou réduit afin d’éviter

d’endommager les têtes ou le filetage des vis, la pièce de bois,

etc. En général, le couple à utiliser est déterminé par le diamètre

de la vis. Si le couple est trop élevé pour la taille des vis, cellesci risquent d’être endommagées ou brisées.

Le couple s’ajuste au moyen de la bague de réglage.

Le couple est plus élevé lorsque la bague est réglée sur une

valeur plus élevée. Le couple est moins élevé lorsque la bague

est réglée sur une valeur plus basse.

Le réglage dépend du type de matériau et de la taille de la vis

utilisée.

• Vis tire-fond de 9.5 mm (3/8 po) dia sur 38,1 mm (1-1/2 po) de

long

• Scie les trous jusqu’à 50,8 mm (2 po)

• Forets plats jusqu’à 38,1 mm (1-1/2 po) maximum

• Forets jusqu’à 12,7 mm (1/2 po) maximum

• Perçage du métal

• Vis de scellement

• Vis à bois jusqu’à 76,2 mm (3 po) maximum

• Vis autotaraudeuses

• Vis à bois jusqu’à 50,8 mm (2 po) maximum

• Petites vis ou travail délicat exigeant une plus grande maîtrise

• Pour percer des trous dans la maçonnerie et le béton.

APLICACIÓN

VITESSE

1 / BASSE

2 / HAUTE

1 / BASSE

2 / HAUTE

2 / HAUTE

MODE

MODE DE PERÇAGE

(RÉGLAGE DE COUPLE

DÉSACTIVÉ)

MODE DE VISSAGE

MODE DE PERCUSSION

(RÉGLAGE DE COUPLE

DÉSACTIVÉ)

7 — Français

Page 16

UTILISATION

RÉGLAGE DE LA POIGNÉE AUXILIAIRE

Voir la figure 9, page 11.

Pour régler la poigné auxiliaire :

Desserrer la poignée en la tournant dans le sens inverse des

aiguilles d’une montre.

Insérer la poignée auxiliaire sur la position désirée.

Resserrer bien la poignée en la tournant dans le sens horaire.

NOTE : S’assurer que la poignée auxiliaire est bien serrée contre

le collier de la tige de butée de profondeur. Ceci maintient la

tige de butée à la profondeur désirée. Permet également de

sécuriser la poignée auxiliaire.

RÉGLAGE DE LA TIGE DE BUTÉE DE

PROFONDEUR

Voir la figure 9, page 11.

La tige de butée de profondeur permet de contrôler la profondeur

des trous percés.

Pour régler la butée de profondeur :

Verrouiller la gâchette en mettant le sélecteur de sens de

rotation en position centrale.

Desserrer la poignée auxiliaire en tournant le bouton vers la

gauche.

Ajuster la tige de butée de profondeur de façon à ce que le

foret dépasse son extrémité de la longueur correspondant

à la profondeur de perçage désirée.

Assujettir fermement la poignée auxiliaire en tournant le

bouton vers la droite.

NOTE : Si l’installation est correcte, les dents de la tige de

butée de profondeur doivent être face à la direction de la

poignée.

PERÇAGE/VISSER DE VIS

Voir la figure 10, page 11.

AVERTISSEMENT :

Ne pas enfoncer de vis dans des surfaces pouvant

dissimuler des fils électriques. En cas de contact avec un

fil sous tension, les parties métalliques de l’outil seraient

mises sous tension et probablement choc l’opérateur. Si

vous devez enfoncer une vis dans un endroit où des fils

électriques cachés peuvent être présents, tenir l’outil par

les surfaces de prise isolées pour éviter un choc électrique.

Appuyer sur la gâchette pour mettre le foret en rotation.

Percer en appuyant assez de pression sur la perceuse

pour que le foret morde dans le matériau. Ne pas forcer la

perceuse ou appliquer une force latérale pour ovaliser le

trou. Laisser l’outil faire le travail.

AVERTISSEMENT :

Lors du perçage, se tenir prêt pour un blocage lorsque le

foret traverse le matériau. Dans ces situations, la perceuse

à tendance â être propulsée dans le sens contraire à

la rotation, ce qui peut causer la perte de contrôle. Si

l’opérateur n’est pas préparé, cette perte de contrôle peut

entraîner des blessures graves.

Avant de percer un matériau dur et lisse, poinçonner

l’emplacement désiré du trou.Cette précaution empêchera

le foret de glisser au départ du trou.

Si le foret se bloque dans la pièce ou si la perceuse cale,

l’arrêter immédiatement. Sortir le foret de la pièce et

déterminer la raison du blocage.

NOTE : Cette perceuse est équipée d’un frein électrique. Lorsque

la gâchette est relâchée, le mandrin cesse de tourner. Si le frein

fonctionne correctement, des étincelles sont visibles au travers

des trous d’aération du corps de la perceuse. Ces étincelles,

causées par le fonctionnement du frein, sont normales.

AVERTISSEMENT :

Toujours utiliser la poignée auxiliaire pendant l’utilisation de

l’outil pour prévenir les réactions causées par le couple. La

déformation par torsion ou le blocage de ce produit peut

entraîner des blessures graves.

Installer la poignée auxiliaire.

Vérifier la position du sélecteur de rotation (rotation avant

ou arrière).

Utiliser la vitesse BASSE (1) pour les applications exigeant

beaucoup de puissance et de couple, et la vitesse HAUTE (2)

pour visser ou percer rapidement. Se reporter aux sections

Train d’engrenages à deux vitesses et Réglage du couple.

Bloquer la pièce de travail dans un étau au avec des serre-

joint pour l’empêcher de tourner avec le foret.

Tenir solidement la perceuse et positionner le foret à l’endroit

où percer ou visser.

8 — Français

PERÇAGE DU BOIS ET DU MÉTAL

Pour une performance optimale, utiliser des forets en acier haute

vitesse pour percer le métal ou l’acier. Sélectionner le mode

de perçage. Commencer le perçage à très basse vitesse pour

éviter que la pointe du foret ne glisse.

Perçage du bois

Augmenter la vitesse une fois que le foret à mordu dans le

matériau.

Lors du perçage de trous traversants, placer un morceau

de bois derrière la pièce pour éviter l’éclatement du bord

inférieur du trou.

Page 17

UTILISATION

Perçage du métal et de l’acier

Avant de percer un matériau dur et lisse, poinçonner

l’emplacement du trou. Cette précaution empêchera le foret

de glisser au départ du trou.

Appuyer sur la gâchette de façon à maintenir une vitesse ne

causant pas la surchauffe du foret. Une pression excessive

causerait :

• La surchauffe de la perceuse ;

• Une usure excessive des roulements ;

• La déformation ou le brûlage du foret: et

• Des trous décentrés ou de forme irrégulière.

Lors du perçage de gros trous dans le métal, commencer

avec un foret de petite taille avant d’élargir le trou avec un

foret de plus grande taille.

ENTRETIEN

AVERTISSEMENT :

Utiliser exclusivement des pièces d’origine pour les

réparations. L’usage de toute autre pièce pourrait créer

une situation dangereuse ou endommager l’outil.

PERÇAGE DE PIÈCES DE MAÇONNERIE

Pour une performance optimale, utiliser des embouts pour

percussion avec bout enduit au carbure pour la maçonnerie

ou des embouts conçus pour les marteaux perforateurs pour

percer des trous dans la brique, le carrelage, le ciment, etc.

Mettre le sélecteur sur le perçage de percussion.

Pour un résultat optimal dans la brique, appliquer une

pression légère et utiliser une vitesse moyenne.

Exercer une pression plus forte pour percer les matériaux

durs, tels que le béton.

Avant de percer dans la brique, pratiquer sur une chute pour

déterminer la pression et la vitesse optimales. Commencer

le perçage à basse vitesse pour éviter que la pointe du foret

ne glisse.

ENTRETIEN GÉNÉRAL

Éviter d’utiliser des solvants pour le nettoyage des pièces en

plastique. La plupart des matières plastiques peuvent être

endommagées par divers types de solvants du commerce.

Utiliser un chiffon propre pour éliminer la saleté, la poussière,

l’huile, la graisse, etc.

PROPOSITION 65 DE L’ÉTAT DE CALIFORNIE

AVERTISSEMENT :

Ce produit et la poussière dégagée lors du ponçage, sciage, meulage, perçage de certains matériaux et lors d’autres

opérations de construction peuvent contenir des produits chimiques, notamment du plomb qui, selon l’État de la Californie,

peuvent causer le cancer, des anomalies congénitales et d’autres dommages au système reproducteur. Bien se laver

les mains après toute manipulation.

Voici certains exemples de ces produits chimiques :

le plomb contenu dans la peinture au plomb,

la silice cristalline contenue dans les briques, le béton et d'autres produits de maçonnerie, ainsi que

l’arsenic et le chrome contenus dans le bois de construction traité par produits chimiques.

Le risque présenté par l’exposition à ces produits varie en fonction de la fréquence de ce type de travail. Pour réduire

l’exposition, travailler dans un endroit bien aéré et utiliser des équipements de sécurité approuvés tels que masques

antipoussières spécialement conçus pour filtrer les particules microscopiques.

NOTE : ILLUSTRATIONS COMMENÇANT

SUR 10 DE PAGE APRÈS LE SECTION ESPANOL.

9 — Français

Page 18

ADVERTENCIAS DE SEGURIDAD GENERALES PARA LA

HERRAMIENTA ELÉCTRICA

ADVERTENCIA

Lea todas las advertencias de seguridad y las instrucciones.

El incumplimiento de las advertencias e instrucciones puede

ocasionar descarga eléctrica, fuego o lesiones graves.

Guarde todas las advertencias e instrucciones para futuras

consultas.

avisos de advertencia enumerados abajo se refiere a las herramientas

eléctricas de cordón (alámbricas) y de baterías (inalámbricas).

SEGURIDAD EN EL ÁREA DE TRABAJO

Mantenga limpia y bien iluminada el área de trabajo. Un área

de trabajo mal despejada o mal iluminada propicia accidentes.

No utilice herramientas motorizadas en atmósferas

explosivas, como las existentes alrededor de líquidos,

gases y polvos inflamables. Las herramientas eléctricas

generan chispas que pueden encender el polvo y los vapores

inflamables.

Mantenga alejados a los niños y circunstantes al maniobrar

una herramienta eléctrica. Toda distracción puede causar

pérdida del control de la herramienta.

SEGURIDAD ELÉCTRICA

Las clavijas de las herramientas eléctricas deben

corresponder a las tomas de corriente donde se conectan.

Nunca modifique la clavija de ninguna forma. No utilice

ninguna clavija adaptadora con herramientas eléctricas

dotadas de contacto a tierra. Conectando las clavijas

originales en las tomas de corriente donde corresponden se

disminuye el riesgo de una descarga eléctrica.

Evite el contacto del cuerpo con las superficies de objetos

que estén haciendo tierra o estén conectados a ésta, como

tuberías, radiadores, estufas y refrigeradores. Existe un

mayor riesgo de descargas eléctricas si el cuerpo está haciendo

tierra.

No exponga las herramientas eléctricas a la lluvia ni a

condiciones de humedad. La introducción de agua en una

herramienta eléctrica aumenta el riesgo de descargas eléctricas.

No maltrate el cordón eléctrico. Nunca utilice el cordón para

trasladar, desconectar o tirar de la herramienta eléctrica.

Mantenga el cordón alejado del calor, del aceite, de bordes

afilados y de piezas móviles. Los cordones eléctricos dañados

o enredados aumentan el riesgo de descargas eléctricas.

Al utilizar una herramienta eléctrica a la intemperie, use

un cordón de extensión apropiado para el exterior. Usando

un cordón adecuado para el exterior se disminuye el riesgo de

descargas eléctricas.

Si debe operar una herramienta en lugares húmedos, use

un suministro protegido por un interruptor de circuito con

pérdida a tierra (GFCI). El uso de un GFCI reduce el riesgo de

descargas eléctricas.

Cargue las baterías solamente con el cargador indicado.

Para utilizar con paquetes de baterías de níquel-cadmio

de 18 V o de iones de litio de 18 V, consulte el folleto

de la herramienta/aparato/paquete de baterías/cargador

complementario 987000-432.

SEGURIDAD PERSONAL

Permanezca alerta, preste atención a lo que esté haciendo y

aplique el sentido común al utilizar herramientas eléctricas.

No utilice la herramienta eléctrica si está cansado o se

encuentra bajo los efectos de alguna droga, alcohol o

El término “herramienta eléctrica” empleado en todos los

2 — Español

medicamento. Un momento de inatención al utilizar una

herramienta eléctrica puede causar lesiones corporales serias.

Use equipo de seguridad. Siempre póngase protección

ocular. El uso de equipo de seguridad como mascarilla para el

polvo, calzado de seguridad, casco y protección para los oídos

en las circunstancias donde corresponda disminuye el riesgo

de lesiones.

Evite un arranque accidental de la unidad. Asegúrese de

que el interruptor esté en la posición de apagado antes de

conectar la herramienta. Portar las herramientas eléctricas

con el dedo en el interruptor, o conectarlas con el interruptor

puesto, propicia accidentes.

Retire toda llave o herramienta de ajuste antes de encender

la herramienta eléctrica. Toda llave o herramienta de ajuste

dejada en una pieza giratoria de la herramienta eléctrica puede

causar lesiones.

No estire el cuerpo para alcanzar mayor distancia. Mantenga

una postura firme y buen equilibrio en todo momento. De

esta manera se logra un mejor control de la herramienta eléctrica

en situaciones inesperadas.

Vístase adecuadamente. No vista ropas holgadas ni joyas.

Mantenga el cabello, la ropa y los guantes alejados de las

piezas móviles. Las ropas holgadas, las joyas y el cabello largo

pueden engancharse en las piezas móviles.

Si se suministran dispositivos para conectar mangueras

de extracción y captación de polvo, asegúrese de que

éstas estén bien conectadas y se usen correctamente. La

utilización de captador de polvo puede disminuir los peligros

relacionados con el polvo.

No vista ropas holgadas ni joyas. Recójase el cabello si

está largo. Las ropas holgadas y las joyas, así como el cabello

largo, pueden resultar atraídas hacia el interior de las aberturas

de ventilación.

No utilice la unidad al estar en una escalera o en un

soporte inestable. Una postura estable sobre una superficie

sólida permite un mejor control de la herramienta eléctrica en

situaciones inesperadas.

EMPLEO Y CUIDADO DE LA HERRAMIENTA

ELÉCTRICA

No fuerce la herramienta eléctrica. Utilice la herramienta

eléctrica adecuada para cada trabajo. La herramienta

eléctrica adecuada efectúa mejor y de manera más segura el

trabajo, si además se maneja a la velocidad para la que está

diseñada.

No utilice la herramienta si el interruptor no enciende o

no apaga. Cualquier herramienta eléctrica que no pueda

controlarse con el interruptor es peligrosa y debe repararse.

Desconecte la clavija del suministro de corriente o

retire el paquete de baterías de la herramienta eléctrica,

según sea el caso, antes de efectuarle cualquier ajuste,

cambiarle accesorios o guardarla. Tales medidas preventivas

de seguridad reducen el riesgo de poner en marcha

accidentalmente la herramienta.

Guarde las herramientas eléctricas desocupadas fuera del

alcance de los niños y no permita que las utilicen personas

no familiarizadas con las mismas o con estas instrucciones.

Las herramientas eléctricas son peligrosas en manos de

personas no capacitadas en el uso de las mismas.

Preste servicio a las herramientas eléctricas. Revise para

ver si hay desalineación o atoramiento de piezas móviles,

ruptura de piezas o cualquier otra condición que pueda

afectar el funcionamiento de la herramienta. Si está dañada

Page 19

ADVERTENCIAS DE SEGURIDAD GENERALES PARA

LA HERRAMIENTA ELÉCTRICA

la herramienta eléctrica, permita que la reparen antes de

usarla. Numerosos accidentes son causados por herramientas

eléctricas mal cuidadas.

Mantenga las herramientas de corte afiladas y limpias. Las

herramientas de corte bien cuidadas y con bordes bien afilados,

tienen menos probabilidad de atascarse en la pieza de trabajo

y son más fáciles de controlar.

Utilice la herramienta eléctrica, los accesorios y brocas,

hojas y cuchillas de corte, ruedas de esmeril, etc. de

conformidad con estas instrucciones, tomando en cuenta

las condiciones de trabajo y la tarea por realizar. Si se utiliza

la herramienta eléctrica para operaciones diferentes de las

indicadas podría originar una situación peligrosa.

EMPLEO Y CUIDADO DE LA HERRAMIENTA DE

BATERÍAS

Sólo cargue el paquete de baterías con el cargador

especificado por el fabricante. Un cargador adecuado para un

tipo paquete de baterías puede significar un riesgo de incendio

si se emplea con un paquete de baterías diferente.

Utilice las herramientas eléctricas sólo con los paquetes de

baterías específicamente indicados. El empleo de paquetes

de baterías diferentes puede presentar un riesgo de incendio.

Cuando no esté utilizándose el paquete de baterías,

manténgalo lejos de otros objetos metálicos, como clips,

monedas, llaves, clavos, tornillos o otros objetos metálicos,

pequeños que puedan establecer conexión entre ambas

terminales. Establecer una conexión directa entre las dos

terminales de las baterías puede causar quemaduras o

incendios.

Si se maltratan las baterías, puede derramarse líquido de las

mismas; evite todo contacto con éste. En caso de contacto,

lávese con agua. Si el líquido llega a tocar los ojos, además

busque atención médica. El líquido de las baterías puede

causar irritación y quemaduras.

SERVICIO

Permita que un técnico de reparación calificado preste

servicio a la herramienta eléctrica, y sólo con piezas de

repuesto idénticas. De esta manera se mantiene la seguridad

de la herramienta eléctrica.

Al dar servicio a una herramienta eléctrica, sólo utilice piezas

de repuesto idénticas. Siga las instrucciones señaladas en la

sección Mantenimiento de este manual. El empleo de piezas

no autorizadas o el incumplimiento de las instrucciones de

mantenimiento puede significar un riesgo de descarga eléctrica

o de lesiones.

ADVERTENCIAS DE SEGURIDAD PARA TALADRO DE IMPACTO

Al utilizar taladros de impacto póngase protectores para

los oídos. La exposición a ruido puede producir la pérdida de

la audición.

Utilice el o los mangos auxiliares, de venir provistos junto

con la herramienta. Cualquier pérdida de control puede causar

lesiones personales.

Sujete las herramientas eléctricas por las superficies

aisladas de sujeción al efectuar una operación en la cual la

herramienta de corte pueda entrar en contacto con cables

ocultos o con su propio cordón eléctrico. Todo contacto

de una herramienta con un cable cargado carga las piezas

metálicas expuestas de la herramienta y da una descarga

eléctrica al operador.

Familiarícese con su herramienta eléctrica. Lea

cuidadosamente el manual del operador. Aprenda sus usos

y limitaciones, así como los posibles peligros específicos

de esta herramienta eléctrica. Con el cumplimiento de esta

regla se reduce el riesgo de una descarga eléctrica, incendio o

lesión seria.

Siempre use protección ocular con laterales protectores

con la marca de cumplimiento con la norma ANSI Z87.1

al ensamblar piezas, utilizar la herramienta o llevar a cabo

tareas de mantenimiento. Con el cumplimiento de esta regla

se reduce el riesgo de lesiones corporales serias.

Protéjase los pulmones. Use una careta o mascarilla

contra el polvo si la operación genera mucho polvo. Con

el cumplimiento de esta regla se reduce el riesgo de lesiones

serias.