Page 1

RyoB

SPECIFICATIONS

g[],F"il.".fl

l.

r"t

F

$l

A N

i]19,,

Ir

uA

L

THANK

Your new

ity, ease

performance.

YOU

FOR

cut-off

of

operation, and operator safety. Properly

Caution:

machine.

your

use

safe,

Wheel

I nput

Wheel

Wheel

Vise

Max.

Net weight

BUYING

machine has

cut-off

reliable

diameter

speed

angle

cutting

Pipe

Angle

Metal

Carefully

Pay

close

service.

dimensions

steel

siding

A RYOBI

been engineered

read

attention

machine

CUT-OFF MACHINE

through

to

the

properly

120

Volts

3300

5"

6-1

B-1l1

manufactured

and

cared for, it

this entire owner's

for

only

Safe

for

Rules

and

will

Operation,

what

AC,

15

Amps,

(nominal)

RPM

Reinforced

14"

0 -

(outside

12" W

W

6"

to Ryobi's high

give

manual

it

is

intended,

wheels

x 1/8"

45

degrees

diameter)

x

3-5/1

x

2-511

45.3 rb

you years

before using

Warnings,

14"

HP

3

x 1"

H

6"

H

6"

standard for

of rugged,

your

and Cautions. lf

you

will

enjoy

dependabil-

trouble-free

new

cut-off

you

years

of

Please

Thank

fill out

you

'Save

and

again

return

for

buying

the

Warranty

RyobiTools.

Service Registration

Card

so

we

can be

of future

service

you.

to

4980356

Page 2

purpose

The

explanations

themselves

accident

of

with

eliminate

prevention

safety

symbols is to

them,

any

measures.

your

attention to

deserve

your

attract

careful attention

danger. The instructions

possible

and

understanding.

dangers.

or warnings they

The

safety symbols,

The safety warnings do not

give

are

not

substitutes for

and the

by

proper

SYMBOL

NOTE:

IMPORTANT

Servicing requires

For service

we

Organization

extreme

suggest

for repair.

MEANING

SAFETY

Indicates

pictographs.

or

DANGER:

ALERT

caution,

Failure to obey

ortoothers. Alwaysfollowthesafetyprecautionstoreducetheriskof

shock, and

WARNING: Failure

to

or

others. Always follow the

shock, and

CAUTION:

pei'sona!

electric

Advises

injury. Always folfow

shock,

you

of the equipment.

care and knowledge

you

return

When

servicing,

SYMBOL

warning,

personal

injury.

to obey a safety warning

personal

Failure to

and

injury.

obey a

personal

of information

and should be

the tool to

your

only identical

use

or danger.

a safety

warning

safety

safety

the safety

injury.

instructions

or

nearest

Ryobi Factory

May

be used

will

can

precautions

warning

precautions

vitalto

performed

conjunction with

in

result

in

serious injury

result in

to reduce

may

result

to

the

operation

only

by a

serious

Service Center

Ryobi replacement

parts.

other

yourself

to

fire,electric

injury to

yourself

the risk of f ire, electric

property

in

reduee

the

damage

risk

or maintenance

qualified

seruice technician.

Authorized

or

symbols

or

fii"e,

of

Seruice

WARNING:

WARNING:

understand

to

comply can result in

Save

this

others

Observe all normal

Do not

completely

owner's manualand reviewfrequentlyforcontinuing

who

may

use

attempt

instructions,

all

accidents

this tool.

safety

to

precautions

operate this

involving

related

tool

safety rules,

fire,

electric

to

avoiding

you

until

etc., contained

shock,

have

in this

or serious

safe

operation

electrlcal shock.

read thoroughly and

manual. Failure

personal

injury.

and instructing

Page

2

Page 3

RULES

FOR

SAFE

OPERATION

READ

ALL

KNOW

operation

Safe

affixed

machine.

to the

SAFETY

KEEP

1.

REMOVE

2.

adjusting

g.

KEEP

DO NOT

4.

flammable

KEEP

S.

work area.

MAKE

6.

DO NOT

7.

8.

USE

WEAR

9.

could

ALWAYS

10.

NOT safety

PROTECT

11.

PROTECT YOUR

12.

SECURE

13.

frees both

and

NOT OVERREACH.

DO

14.

MAINTATNTHETOOLWITHCARE.

15.

Follow

INSTRUCTIONS

YOUR

Keep

WARNING:

and

precautions

WenntXC:

reduce

to

these

POWER

this

of

Learn

tool.

manual

this

adjusted

the

basic

power

Donotconnectyourcut-off

tool

its applications

readily

the machine

operating

and

When

Safety

using

risk of fire,

PRECAUTIONS

PLACE

GUARDS

ADJUSTTNG

wrenches

THE

USE

CHTLDREN

THE

FORCE

RIGHT

THE

PROPER

get

in moving

WEAR

THE

instructions

lN

KEYS

are removed

WORK

liquids,

WORKSHOP

glasses.

YOUR

AREA CLEAN.

DANGEROUS

lN

in

damp

AWAY

TOOL.

THE

TOOL.

APPAREL.

par1s.

SAFETY

LUNGS.

HEARING.

WORK.

hands

Use clamps

to operate

for

changing

TOOL

requires

available

electric tools,

electric

Precautions

in

and

AND

wet locations,

or

FROM

CHILD-PROOF

lt

Do not

Do

Non-slip

GLASSES.

Wear

Wear

the

proper

Keep

accessories.

labels

owner's

you

that

and limitations

for future reference.

as described

instructions

shock,

include

good

working

WRENCHES.

from the

ENVIRONMENTS.

POWER

will

force

not

footwear

a face or dust

or

tool before

Cluttered

or

TOOLS.

with

job

the

do

the tool

wear loose

is recommended.

Everyday

earmuffs

vise

a

to hold

tool'

footing and

Keepsawtoolssharpandcleanforthebestandsafestperformance.

and understand

read

well

as

machinetoapowersourceuntilyouhaveassembled

in this

in the

basic

and

the

work

expose

padlocks

better

or attachment

clothing,

or

manual

safety

personal

following:

order.

in the

Get

turning

areas

Do not

them

visitors should

All

and

eyeglasses

if

mask

plugs

during

work when

balance

the

as

manual and

precautions

habit of checking

it

and

to

master switches

and

safer at

to do a

neckties,

have only

the cutting

periods

practical.

at all times.

this

potential hazards

have read

printed

and

should

injury.

on.

work benches

use

rain. Keep the

Wear

Use common

power

the rate

rinQs,

operation

tools

kept at a safe

be

job

for which

bracelets.

protective

impact-resistant

extended

of

lt is safer than

manual and

peculiar

and understood

tool.

the

on

always

sense.

to see

invite accidents.

work

or by

for which

is dusty.

that

gasoline

near

area

distance

removing

it was

was

it

other

or

covering

lenses;they

use.

using

all

cut-off

a

to

all

be followed

Some

hex keys and

weil

starter

designed.

not

designed.

jewelry

over

your

of

or other

lighted.

from the

keys.

that

hair.

long

are

hands

Page 3

Page 4

16. DISCONNECT

abrasive

17.

REDUCE

before

1

I'

USE ONLY

for

19.

NEVER

is

unintentionally

20'

PERIODICALLY

binding

affect

the tool

its

intended function.

21.

NEVER

it

comes

22.

DO NOT

heat,

23.

KEEP

reach

when

24.

KEEP Tootcleaning.

25.

STAY ALERT.

wheel.

THE

RISK

plugging

THE

recommended

STAND

of moving parts,

operation.

is

used

again,

LEAVE

to

a complete stop

ABUSE THE

oil.

and sharp edges.

HANDS

AWAY FROM

underneath

wheel is

moving.

uHY,

Never

Never

medication.

26. DO

27. ALWAYS

28.

29'

NOT

USE TOOL lF THE

replaced

at a Ryobi Authorized

TURN

ALL

REPAIRS, WHETHER

Service

SAVE THESE

instruct

Center.

INSTRUCTIONS

others who may

POWER

in

the

MANUFACTURER'S

accessories.

ON

TOOLS

UNINTENTIONAL STARTING.

OF

BEFORE

tool.

RECOMMENDED ACCESSORIES.

THE

Using

TOOL.

improper accessories

Serious

contacted.

other

or

WORN

OR DAMAGED

parts,

of

part

that is

that the repaired

UNATTENDED.

CHECK FOR

breakage

guard

A

make sure

THE TOOL RUNNING

and is disconnected

CORD.

work

around

cLtsAN,

use

brake fluids,

operate

Never

THE

AND FREE

yank

CUTTING

or

over

gasoline,

power

a

the

tool

SWITCH DOES NOT

Service Center.

SWITCH

OFF before

disconnecting it

ELECTRICAL

Use only Ryobi

replacement

FOR FUTURE

use this

tool. lf

you

SERVICING

or

Make

injury

could

occur

PARTS.

loose

mounting

brackets, and any

damaged should

replaced

or

Turn

power

from

the

cord to disconnect

AREA.

wheel while it

FRoM

Keep

hands

is rotating.

otl AND

GREASE.

petroleum-based

when

tired

or while

TURN

lT

to avoid

MECHANICAL,

OR

parts.

REFERENCE.

loan

someone

this tool, loan

before

changing

sure the

accessories

switch

Consult

may

increase the

if

the tool

Check

is tipped

risk

for

alignment of

other conditions

properly

be

part

is operating

the

off

repaired

power.

properly

Do not leave

source.

from the

away from

products,

under the

AND

ON

receptacle.

the

abrasive wheels.

Do not

attempt to remove

Atways

use

or any solvents

influence

OFF. Have

accidentalstarting.

should

Refer

be made

to them

frequently

them these

such

in

is

the

OFF

this

Owner's

of injury.

or if the

abrasive wheel

moving

that

replaced.

or

performing

and

the

tool

Keep

the

cord from

material

a ctean cloth when

to clean tool.

of drugs,

defective

at a Ryobi

alcohol,

switches

Authorized

and use them to

instructions,

the

as

position

Manual

parts,

might

Before

until

Do not

or

also.

Page

4

Page 5

CUT-OFF

MAKE

1.

MACHINE

SURE

instructions

cause

CHECK

Z.

g.

USE

with

ALWAYS

4.

impact

BEFORE

5.

IMPORTANT

6.

obtained

cracks.

WHEEL

ONLY

ANSI

can break

by

SAFETY

THE

CUT-OFF

before

CUT-OFF

7.1. Always

B

EASE

CUTTING,

writing to:

connecting

FOR FISSURES

WHEEL

ABRASTVE

THE

wheel.

the

press

INFORMATION

WHEEL

the

toolto a

AND

RATED FOR

wheels in

store

WHEEL

trigger switch

the

THE

ON

GRINDING

30200

Cleveland.

WHEEL INSTITUTE

Detroit Road

OH

lS

SECURELY

power

supply,

CRACKS, and

RPM

3300

a dry

place

with little

AGAINST THE

allow the cut-off

and

CUT.OFF

OF

USE

44145-1967

MOUNTED as

not tighten wheel

Do

for normal

test

GREATER

OR

temperature

WORK

PIECE

wheel

WHEELS

described in

excessively, since

prior

operation

manufactured in

and

to use.

variation.

when starling to cut.

reach f ull

to

AND ANSI

speed before

B 7.1 CAN

the operating

this can

compliance

A harsh

cutting.

bE

EXTENSION

When using

from a

enough

undersized

voltage, resulting

A minimum

than 50

round

Laboratories

power

to carry

feet

jacketed

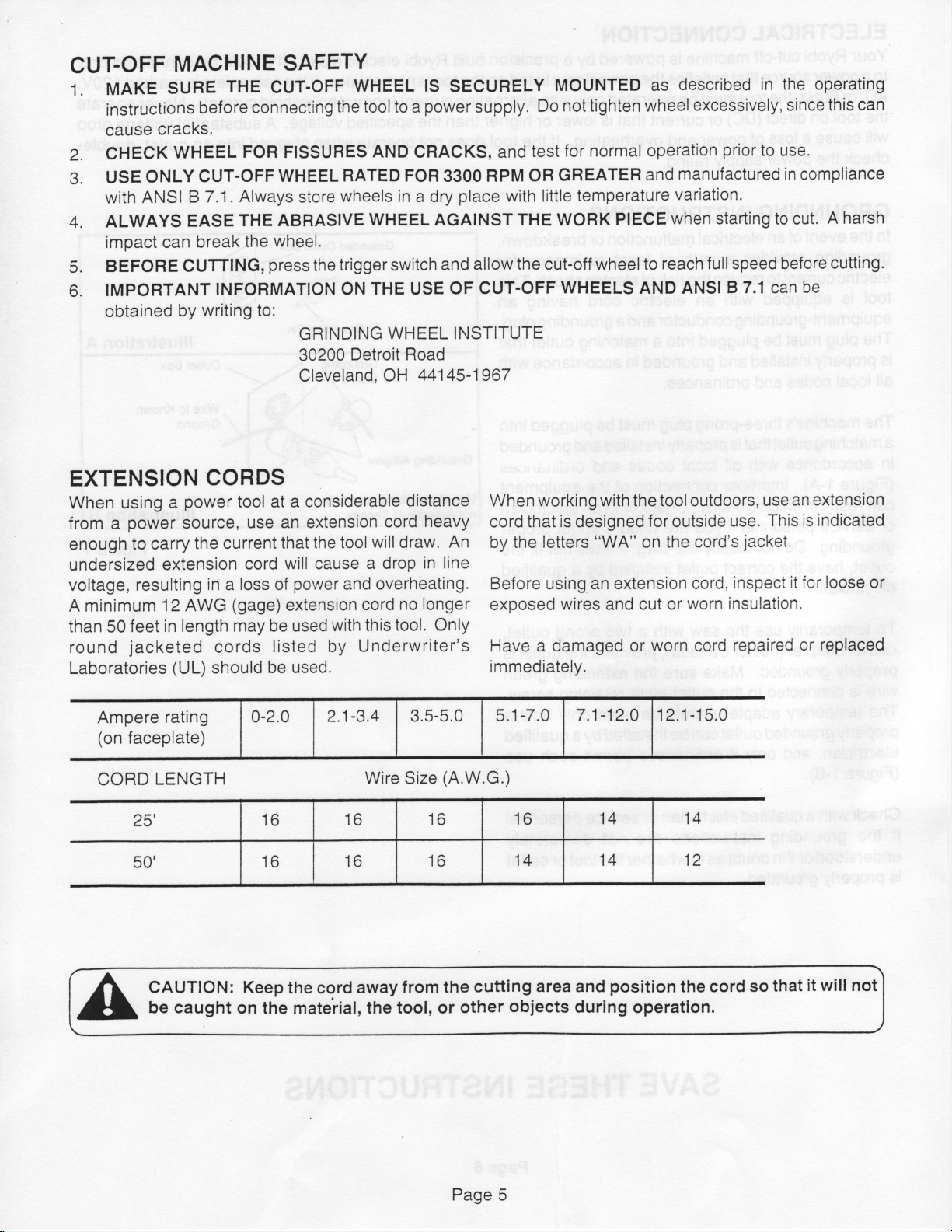

Ampere

(on

faceplate)

CORD

LENGTH

CORDS

power

a

source,

the current

extension

in a loss

12 AWG

in length may be used

cords

(UL)

should

rating

2'',

50'

tool at a considerable

use an extension

that the

tool

cord will cause

of

(gage)

extension

power

and overheating.

with

listed by

Underwriter's

distance

cord heavy

will

draw.

a drop

cord no

tool.

this

be used.

-3,4

0-2.0

16

16

2,1

Wire Size

16

16

An

in line

longer

Only

3.5-5.0

(A.W.G.)

16

16

an extension

When

working with the tool outdoors,

cordthatisdesignedforoutsideuse.

by the

Before

exposed wires and cut

Have a damaged or

letters "VVA" on the cord's

an extension cord,

using

worn insulation,

or

worn

cord

use

Thisisindicated

jacket.

inspect

repaired

it for loose or

or

immediately.

5.1

16

14

-7

.0

.1

7

-12.0

14 14

14 12

-15.0

12.1

replaced

CAUTION: Keep

caught

be

on

the mateiial,

the cord

from the

away

the tool, or

cutt

other

Page

ing

area and

obiects

5

position

during

the cord

operation.

so

that

it will not

Page 6

ELECTRICAL

Your

Ryobi

cut-off

toapowersourcethatsatisfiesthepowerinputlistedonthetool'snameplates.

AC,

or 60H2,

the tool

will

check

on direct (DC)

cause

the

a loss

power

the

tool

CONNECTION

machine

must

or

power

of

supply

powered

is

operated only

be

current

that is

and overheating.

rating.

precision

by a

with

lower

lf

built

alternating

higher

or

than

the tool does

Ryobi electric

currerit

(normal

the specified

not

operate

when

lt

motor.

should

be

lfthenameplateismarked

household

voltage.

plugged

current).

A

substantial

into

an

connected

only

1ZOV,

Never

ou1et,

operate

voltage

drop

double-

GROUNDING

In

the

event

of

grounding

electric

tool

is

equipment-grounding

plug

The

properly

is

all

local

The

machine's

a matching

in

acccrdance

(Figure

can

result

or service

grounding.

outlet,

electrician.

To

temporarily

use

an

properfy

wire

is

The

temporary

properly

electrician,

(Figure

provides

current

equipped

must

installed

codes

outletthat

1-A).

in

electric

personnel

Do

have

the

adapter (not

grounded.

connected

grounded

and

1-B).

INSTRUCTIONS

an

electrical

a

to

reduce

with

conductor

plugged

be

and

and

ordinances.

three-prong

properly

is

'with

ali local

lmproper

shock.

you

if

not

modify

correct

use the

adapter

onfy

saw

for

Canada),

Make

to the

outlet

if

ordinances

malf

unction

path

the risk

an

grounded

connection

the

outlet

sure

ouilet-plate

should

can

reast

of

of

electric

electric cord

and

into

matching

a

in

plug

must

installed

codes

of the

Check

are

with

be installed

with

unsure

plug;

installed

a two-prong

provided

the

extending green

be

used

permit

or

breakdown.

resistance

shock.

having

grounding

a

ouilet

accordance

plugged

be

grounded

and

aiid

oi'"iirtar

equipment

an

electrician

about

if

it

will

by

retaining

by

proper

not

qualified

a

ouilet.

the

outlet

screw.

only

until

qualified

a

such

fit

for

This

an

plug.

that

with

intc

rudc

the

is

a

use

Grounding

grounding

Use of

not

available

Grounding

Means

Adapter

adapter

in

Canada.

Groundins

Pin

t4

,/ 'Y-

is

lllustration

Outlet Box

Wire

to

Known

round

G

lllustration

A

B

Figure

1

Check

if

understood

is

with

grounding

the

properly

grounded.

a

or

qualified

if in

electrician

instructions

doubt

or

service

are Frct

as

to

whether

SAVE

completely

the tool

TH

ESE

personnel

or

outlet

I NSTRUCTIONS

Page

6

Page 7

UNPACKING

Caref

1 .

Do

2.

have

List.

lf all

3.

assembly.

4.

lf

obtain

Push

5.

the

Examine

6.

occurred

must

tool.

lly remove all

u

discard

not

identified

parts

you

are

it before

the

handle.

be

the

the

all

have

missing

attempting

handle

all

during

replaced

down and remove

parts

to

shipping.

Trigger

parts

packing

parls

been

part,

a

make sure

before attempting

Lock-On

the shipping

f rom

materials

the

using

included,

contact

to

your

operate

the chain

no breakage has

Any damaged

Machine

Button

Loose Parts

proceed

the

to use

carton.

you

until

dealer

tool.

from

part

the

Handle

to

to

Loose Parts

Cut-off

Wrench

NOTE: Cut-off

WARNING:

locked-down

the

used

chain

storing

warning

InJU

machine

is

the

can

ry.

List

Wheel is

On/Off

feature; see

Trigger

Never

tool. Failure

result in

Owner's

Warranty

operate

position.

only

for

Operating

Registration

factory

Switch

Figure

5

transporting

serious

installed.

(with

for detail)

the

transport

The

heed

to

personal

Manual

Lock-Out

tool

this

Card

in

or

Carrying

External

Power

Transport Chain

Adjustable Depth Stop

Adjustable

Vise

Front

Handle

Brush

Clamp

Caps

Stationary

Vise

Wrench

Shaft

14'

Metal

$r

Quick

Machine

Base

Lever

Lcck

Abrasive

Cutting

Lock-Release

Vise Screw

Wheel,

Shaft

Vise

Crank

Handle

Vise

Page

Fig

7

ure

2

Page 8

ASSEMBLY

Your

Ryobi

cut-off

machine

comes

fulfy

assembled.

WARNING:

power

cornplete.

in

accidentaf

serious

REMOVAL

AND

CUT.OFF

WHEEL

1.

Be

source.

2.

Raise

the

head

wneet

Push

3.

the

locking

while

4.

supplied

bolt

hex

abrasive

REMOVAL

sure the

the

tool to its fulf

lower

wheel

bolt

which

arDor

in

the

wheel

by rotating

head

until

the

wheel in

holding

17

bolt, wosher,

wheel.

Do

source

Failureto

injury.

connect

not

until

comply

starting

INSTALLATION

WHEEL

tool is

(Ftgure

shaft lock

mm wrench

disconnected

position

open

guard

secures

the

it

upward,

the

abrasive wheel

3).

(Figure

lever

the

shaft

place.

shaft lock lever

counterclockwise.

lock

loosen

and

outside flange,

machine

assembly

could

possible

and

OF

from the

and

exposing

lever

place,

in

the

4)

and

engages,

use

the

hex

Remove

to

is

resuft

power

rotate

hex

to

the

rotate

the

head

the

and

Abrasive

Outer

Flange

Washer

Hex

Head

Bolt

Wheel

o

h

Lower

Guard

Wheel

(raised)

Figure

3

NOTE:

The

inside flange

spring

wheel

components;

for

clip

arbor.

wheel

and

changes.

is

held

inner

Do

not

removal

place

in

washer

remove

is

not required

onto

these

by

the

a

Fig

ure

4

Page

B

Page 9

WHEEL

Be sure

1.

Inspect

2.

are

Remove any

3.

INSTALLATION

the tool

the

found or the speed

is

replacement

debris from

inner washer and against

Clean and align the outside

4.

the

abrasive

lnsert the hex head bolt

5.

wheel.

snug. Then depress the

to securely

tighten

disconnected

wheel

rating

the

from

for

defects such

is not

inside

the inside

flange to

the threaded

into

lock lever

shaft

the hex head

bolt to

power

the

greater

flange

than

and inner washer. Position the

flange.

the wheel

end of the

prevent

to

hold

the abrasive wheel

source.

as cracks.

rpm, discard

3300

arbor,

then slide

wheel

the

shaft

chipping,

and

the

correct

wheel

new

it

onto the

arbor

and

f rom

rotating, use the supplied

firmly

arbor

place.

in

it in

rotate

speed

and

abrasive

until

a clockwise

rating. lf

select

another.

wheel

it rests

1

flush against

direction

7 mm wrench

defects

over the

until

WARNING: Do

to crack, resulting

Return the wheel

6.

WARNING

the new wheel does

lowered. Failure to heed this WARNING

TRIGGER

prevent

To

padlock

a

Figure

When

inoperable.

5. Use

the

LOCK

unauthorized use of the

through

a

lock is

Store

guard

: Be

SWITCH

hole in

the

padlock

with a 1

installed

padlock

the

not

overtighten

premature

in

to its lowest

to check the

sure

not cut into

the

switch as

3/64"

locked,

and

in

key

the hex head

position.

position

the work surface

miter

saw, install

shown

shank

another

diameter.

the

switch

location.

failure

in

is

bolt. Overtightening

possibie

and

of the

mach i ne

serious

arm

beneath

can result

in

serious

can cause the

personal

adjustable

the

base when

personal

new wheel

injury.

depth stop

the saw

arm is fully

injury.

to ensure

Page

Figure

9

5

Page 10

ADJUSTIVI

ADJ

USTAB

The

adjustable

your

cut-off

cutting

allow

machine.

angles

greater

cutting

ENTS

LE

STATIONARY

stationary

This

from

0

to

widths.

vise

vise

45

and

located

is

be

can

moved

VISE

at the rear of

rotated

to

rearward

attain

to

WARNING:

from

adjustments

maintenance.

can

CUTTING

To

adjust

1

.

Locate

fence

2.

Using the

bolts

Rotate

3.

is

aligned with the indicator

base.

NOTE:

4.

Check

wheel

device.

5.

Using

two hex

base.

ANGLE

the angle

the

(Figure

the

Angle

vise

the

using

the

head

power

result

Always

Failure

in

serious

unplug

source

performing

or

to heed

personal

ADJUSTM

of cut:

two hex

6).

supplied 17

vise

indicators

base in

angle

protractor,

a

supplied wrench,

bolts

head

bolts behind

mm

wrench,

fence

until

the

groove

are

5 degree increments.

the vise

of

holding

fence

bevel

securely

the vise

the machine

before

this

injury.

ENT

loosen

desired

stamped

square, or

angle

in the machine

the

to

tighten the

to

the machine

making

routine

warning

the vise

both

of cut

into

the

abrasive

similar

Fonruard

Distance

Position,

to Front

Rear

Distance

Vise

Position,

to Front

-1

: 7

Vise:

Adjustable

Stationary

Figure

14"

B-1 12"

6

MOVING

To

increase

1

.

Locate

fence

2.

Locate

directly

3. Using

hex

machine

THE

the

the

(Figure

the

behind

the

head

STATIONARY

width

of

cut

of

two hex head

6).

threaded

supplied

bolts

base.

hole

vise

the

securing

base.

rnm wrench,

17

the

VISE

your

cut-off

bolts behind

the

in

vise

machine:

machine

r€move

to

the

the

vise

base

both

cut-off

Page

Reposition

4.

the

base

NOT

Align

5.

threaded

hex head

Check

6.

tighten

wrench.

1

0

the

most

rearward

and install

TIGHTEN.

the

remaining

hole

bolt.

or

adjust

both

hex head

curved

a hex

in

slot

threaded

head

vise

bolt hole

the machine

the

cutting

bolts

of the vise

hole in

bolt in

angle

the machine

this hole.

with

base

and

and

the

with

Figure

with

base

the

middle

install

securely

supplied

7

Do

a

Page 11

QUICK

cut-off

Your

release

featu

without

vise

you

re

repetitive

close the

and

vise

the

VISE

with

LOCK-RELEASE

is

machine

system

able

are

turning

equipped

as standard equipment.

to

open

of

quick

a

vise

crank

lock-

With

this

quickly

handle.

USING

THE

QUICK

VISE

loosen:

To

1 .

Slightly

crank

Lift up

2.

pull

To tighten:

Push the

1 .

against

Push

2.

(Figure

Rotate

3.

vise

release

handle

the

back

the

down

B)

the crank

against

ADJUSTABLE

As

shown

threaded

raising

wrench

travels

in Figure

into the

lowering

and

you

when

can

the

tension on

counterclockwise

quick

lock-release

on crank

crank

handle

work

on

to engage

work

the

POSITIVE

9,

base of

the depth

control

machine

LOCK.RELEASE

vise by

the

112 to

(Figure

lever

handle

fonrvard

piece.

quick

the

its threads

handle

Piece.

to slide

clockwise

open

to

slide

lock-release

with vise

to

DEPTH STOP

the adjustable

machine

the

stop

how far the

handle

depth

the

at

with

bolt

abrasive

is depressed.

and

8)

vise.

the

vise

the

lever

screw.

stop

rear.

mm

a12

wheel

the

the

By

rotating

1 turn.

tighten

is

Closed

Figure

B

particularly

feature

This

.

TRANSPORT

transport chain

The

machine

and

for carrying

attached

transport

loop

and

machine

the

is

increase

to

wheel

to

tire

or

to

useful after

wheel.

wears,

"cinch-up"

i.rarrspori

during

limittravel

CHAIN

behind

arm,

the

cut-off

to the machine

or store

one

the

of

the

using

useful:

wheel travel

machine's

the

moving

when

chain

storage,

the abrasive

of

installation

is attached to

the

machine

arm

cut-off machine,

chain's

the

links

carrying handle

of a

motor,

is

a

over

the abrasive

as

handle

the

wheel,

the

(Figure

metal

especially

new abrasive

machine base

is

and

lower the

hook.

hook.

the

(Figure

only

9).

against

machine

used

Also

To

handle

Move

2).

Figure

9

Page

1

1

Page 12

OPERATING

POWER

Before

power

listed

cause a

Common

overheating

multiple tools operating

SUPPLY

operating

supply and

on the

nameplate.

loss

of

causes

are insufficient

your,cut-off

make

sure

A

substantial

power

and machine

power

of

from

SWITCH

To

start the

located

To

stop

For continuous operation,

trigger switch and,

depress

tne trigger switch on

To

discontinue continuous

trigger lock-on

trigger switch and

disengage

tool.

completely

in the rnachine

the

the trigger

release

tool,

feature, completely depress

the trigger

handle

while holding it in

lock-on

the

then

lock-on feature.

depress

trigger switch

the

button located

tool

operation

release it.

machine,

meets

it

loss

extension

the

same

(Figure

completely depress

place

handle

check

requirements

the

voltage

overheating.

and

cord size and

power

the

trigger

10).

completely.

(tool

to

(Figure 10).

when using

This action

your

drop

machine

source.

switch

running),

left of

the

the

onlott

will

the

the

will

Figure

10

CUTTING

WARNING: Do

or rnasonry

cut magnesium

this tool. Failure

warning

inju

1.

Secure the tool in

2.

Firmly

3.

Start

before

4.

Slowly

a steady and

5.

When the cut is

open

secure the material

WARNING:

of clamping to be secured

hold

the machine

contacting

push

position.

coufd

ry.

material

by fully depressing

down

even

complete,

not

attempt

with this machine.

or magnesium

to

result in

place

prevent

to

to be

to cut

comply

serious

machine

using

cut

Large, circular, or

place

in

securely.

Failure to

the trigger

wheel to

on

pressure

material.

machine arm

the

to obtain

release

the

wood

Never

alloy with

with

this

personal

movement

machine's

the

tipping

or

vise

during

(Figure

1 1).

irregularly shaped material may

for

adequately

comply

handle

a

uniform

trigger

switch

could

switch

the

until

cut.

and

Never

cutting. Use

result

and allow

cut-off

the

wheel

force

allow the

in serious

cut-otf wheel

contacts

wheel into the material.

the

wheel to

Figure

the

cutting

procedure.

require additional means

"C" clamps and blocks

personal

injury.

to come up to full speed

the material

stop before raising

being

it to

cut.

the

1 1

to

Use

full

,

-l

n

DANGER:

this warning

Donottouchthecutmaterialuntil itcoolsoryouwillbeburned! Failuretoheed

will result

in

serious

personal

Page

injury.

12

Page 13

MAINTENANCE

the tool clean.

Keep

metal

Make

check

Apply dry

extend

L u b

particles

sure

screws

machine

i

ri

cat

Tr:"::l'"w

o

front

o

slide

WARNING:

machine from the

off

before

adiustments.

from

Always disconnect the

servicing

Remove

working

WARNING:

ventilation

not use

tool

the

and

lubricant

when

solvents

operates

for

bolts

monthly

service

life

s h art

vise clamp

vise

of

way

unit

the

accumulated

parts.

Provide

using

clean

to

properly.

tightness.

the

to

(Figure

rotation

shaft

power

or

source

making

dust

adequate

solvents.

plastic

points

12).

parts.

Periodically

listed to

cut-

and

Do

Figure

12

Remove

the

"standard

brush,

It is

the

Authorized Service

!ubr!cat!on.

the brush

carbon

recommended

tool to

brushes.

(Figure

Line"

replace them.

Ryobi

a

WARNING:

reliability, all

of

externally

performed

be

Authorized

Ryobi

replacement

Center

regular

at

caps

When the brushes

13),

?s

that at

Factory Service

least

for a thorough

To

repairs

accessible

at a

Service

intervals

indicated

once

Center

ensure

(with

brushes)

Ryobi

Center.

parts.

to check

to

worn

are

the

on

year

a

cleaning

safety and

the exception

Factory

Use

the

carbon

you

take

Ryobi

or

and

should

or

only

Standard

Line

4'

A

I

I

I

i

Figure

13

Page

1

3

Page 14

O

SERVICE

Now

your

pertinent

O

The model number

O

WHEN

you

that

nearest

facts when

MODEL

HOWTO

ORDERING REPAIR PARTS,

.

MODEL NUMBER

C-356 type lll

.

NAME

14"

purchased

have

Ryobi

of

OF ITEM

Cut-Off Machine

your

tool,

Authorized

you

Service Center or Ryobi Factory

call or

visit.

NO.

your

tool will

ORDER

should a need

be found

on a

ever exist for repair

plate

REPAIR

ALWAYS

.

PART DESCRIPTION

GIVE THE FOLLOWING

Service Center.

attached

to the motor

parts

or service,

Be sure to

housing.

PARTS

INFORMATION:

simply

contact

provide

all

pafts

All

5201

P.O. Box 1207

lisied may

RYOBI AMERICA

Pearman

be ordered from

Dairy

Road Anderson

Phone

1-800-525-2579

any

CORPORATION

SC

29025-8950

Anderson

SC

29622-1207

RyobiAuthorized

Service

Centeror

Cambridge,

Ryobi Factory

RYOBI CANADA,

P.O. Box

Phone

Service

INC.

910

Ontario

1-800-265-6778

N1R

GKz

Center.

Loading...

Loading...