Page 1

CAUTION: Carefully read through this entire owner's manual before using your

plunge router.

SAVE THIS MANUAL FOR FUTURE REFERENCE.

Your new plunge router has been engineered and manufactured to Ryobi's high standard for dependability,

ease of operation and operator safety. Properly cared for, it will give you years of rugged, trouble free

performance.

THANK YOU FOR BUYING A RYOBI PLUNGE ROUTER

OWNER’S OPERATING MANUAL

PLUNGE ROUTER

MODEL ERT2100VK

Pay close attention to the Rules for Safe Operation, Warnings, and Cautions.

If you use your plunge router properly and only for what it is intended, you will enjoy years of safe, reliable

service.

Thank You again for buying Ryobi tools.

SPECIFICATIONS :

Input ......................................... 2100 W

No Load Speed ........................ 8000-23000 min

-1

Collet Capacity.......................... 6.35 mm (1/4")

12.7 mm (1/2”)

Plunge Capacity ....................... 60 mm

Net Weight ................................

7.5 kg

N197

DOUBLE

INSULATED

Page 2

The purpose of safety rules is to attract your attention to possible

dangers. The safety symbols and the explanations with them,

require your careful attention and understanding. The safety

warnings do not by themselves elimin ate any danger. The

instruction or warnings they give are not substitutes for proper

accident prevention measures.

1. K

NOW YOUR POWER TOOL. Read owners manual carefully.

Learn its applications and limitations as well as the specic

potential hazards related to this tool.

2. G

UARD AGAINST ELECTRICAL SHOCK BY PREVENTING

BODY CONTACT WITH GROUND ED SURFACES. For

example, pipes, radiators, ranges, refrigerator enclosures.

3. KEEP

WORK AREA CLEAN. Cluttered areas and benches

invite accidents.

4. A

VOID DANGEROUS ENVIRONMENT. Don't use power tools

in damp or wet locations or expose to rain. Keep work area

well lit.

5. K

EEP CHILDREN AND VISITORS AWAY. Visitors should

wear safety glasses and be kept a safe distance from work

area. Do not let visitors contact tool or extension cord.

6. S

TORE IDLE TOOLS. When not in use, tools should be

stored in a dry and high or locked-up place, out of reach of

children.

7. DON'T

FORCE TOOL. It will do the job better and safer at

the rate at which it was designed.

8. USE

RIGHT TOOL. Don't force small tool or attachment to

do the job of a heavy duty tool. Don't use tool for purpose not

intended.

9. DRESS PROPERLY. Do not wear loose cloth ing or

jewellery. They can be caught in moving parts. Rubber

gloves and non-skid footwear are recommended when

working outdoors. Also wear protective hair covering to

contain long hair.

10. A

LWAYS WE AR S AF ETY GL ASS ES . Ev er yday

eyeglasses have only impact resistant lenses, they are

not safety glasses.

11. PR

OTECT YOUR LUNGS. Wear a dust mask if operation

is dusty.

12. P

ROTECT YOUR HEARING. Wear hearing protection

during extended periods of operation.

13. DO

N'T OVERREACH. Keep proper footing and balance at

all times. Do not use tool on a ladder or unstable support.

Secure tools when working at elevated levels.

14. M

AINTAIN TOOLS WITH CARE. Keep tools sharp and

clean for better and safer performance. Follow instructions

for lubricating and changing accessories.

15. REMO

VE ADJUSTING KEYS AND WRENCHES. Form a

habit of checking to see that keys and adjusting wrenches

are removed from tool before turning it on.

16. N

EVER USE IN AN EXPLOSIVE ATMOSPHERE. Normal

sparking of the motor could ignite fumes.

17. KEEP

HANDLES DRY, CLEAN AND FREE FROM OIL

AND GREASE. Always use a clean cloth when cleaning.

Never use brake uids, gasoline, petroleum based products,

or any strong solvents to clean your tool.

18. ST

AY ALERT AND EXERCISE CONTROL. Watch what

you are doing and use common sense. Do not operate tool

when you are tired. Do not rush operation of tool.

19. C

HECK DAMAGED PARTS. Before further use of the

tool, a guard or any other part that is damaged should be

carefully checked to determine that it will operate properly

and perform its intended function. Check for alignment

of moving parts, binding of moving parts, breakage of

parts, mounting and any other conditions that may affect

its operation. A guard or any other part that is damaged

should be properly repaired or replaced by an authorised

service centre.

20. DO

NOT USE TOOL IF SWITCH DOES NOT TURN IT ON

AND OFF. Have defective switches replaced by authorised

service centre.

21. D

O N OT O PE RATE TH IS TOO L WHILE UN DER

THE INFLUENCE OF DRUGS , ALCO HOL OR ANY

MEDICATION.

22. T

HE APP LIANC E IS NOT IN TENDE D FO R US E

BY YO UN G OR I NFI RM PERS ON S WI TH OUT

SU PERVIS IO N. YOUNG CH ILDRE N SHOUL D BE

SUPERVISED TO ENSURE THAT THEY DO NOT PLAY

WITH THE APPLIANCE.

RULES FOR SAFE OPERATION

SAVE THESE INSTRUCTIONS

FOR FUTURE REFERENCE

Due to continued product

renement policy, product features

and specications can and will

change without notice. Check

current features and specications

with your retailer.

SAFETY ALERT SYMBOL. Indicates caution or

warning. May be used in conjunction with other

symbols or pictures.

WARNING: Failure to obey a safety warning can

result in serious injury to yourself or to others.

Always follow the safety precautions to reduce the

risk of re, electric shock and personal injury.

WARNING: Do not attempt to operate this tool

until you have read thoroughly and understood

completely, safety rules, etc. contained in this

manual. Failure to comply can result in accidents

involving re, electric shock or serious personal

injury. Save owners manual and review frequently

for continuing safe operation and instructing

others who may use this tool.

The operation of any tool can result in

foreign objects being thrown into your

eyes, which can result in severe eye

damage. Before beginning power tool

operation, always wear safety goggles

or safety glasses with side shields and

a full face shield when needed. We recommend Wide Vision

Safety Mask for use over eyeglasses or standard safety

glasses with side shields.

Page 1

Page 3

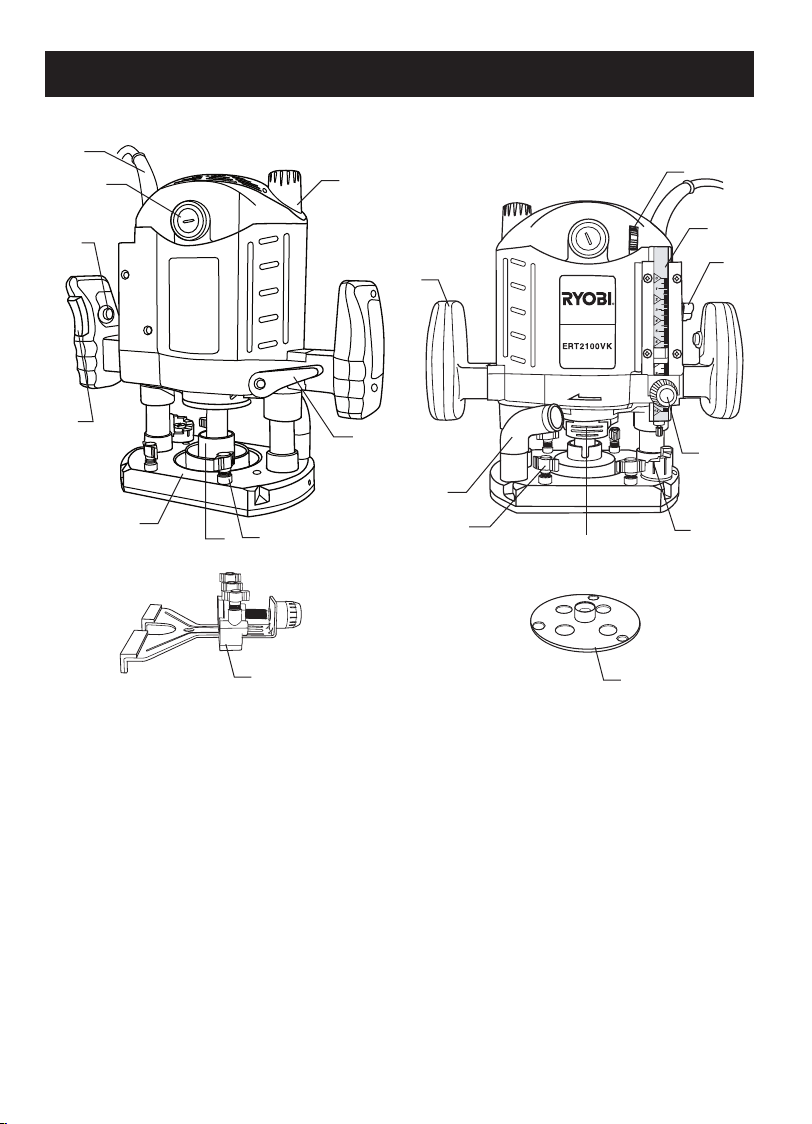

FEATURES

16

15

2

1

4

5

3

19

14

18

13

6

5

7

17

12

11

10

9

8

1. On/Off Switch

2. Lock-on Button

3. Collet

4. Router Base

5. Locking Bolts For Parallel Fence

6. Dust Port

7. Spindle Lock

8. Adjustable Depth Stop

9. Locking Bolt For Depth Stop

10. Depth Stop Adjustment Knob

11. Depth Stop

12. Speed Selector

13. Plunge Lock Lever

14. Fine Adjustment Knob

15. Carbon Brush Holder

16. Cord Sleeve

17. Template Guide

18. Handle

19. Parallel Guide

Page 2

Page 4

APPLICATIONS

T

L

Use your router only for the purposes listed below:

Routing grooves, shaping edges, freehand designs, etc.

in wood.

Chamfering, rebating, dadoing and dovetailing in wood.

Routing edges on laminates.

FEATURES

Your plunge router is a versatile woodworking tool that will

give you years of trouble-free performance. It is engineered

with the professional in mind, but its ease of operation allows

the amateur to produce work that is beautiful and precise.

As the name implies your plunge router can be used for

making plunge cuts in work pieces, routing grooves, edge

routing, routing circles and freehand routing. When used

with recommended accessories, such as router table, depth

adjustment knob and parallel guide, it becomes even more

versatile. Various types of cutters, both with and without roller

bearings as guides also add to the versatility of this tool.

HEAVY DUTY MOTOR

Your router has a powerful motor with sufcient power to

handle tough routing jobs. It delivers high power for heavy

duty performance.

DEPTH STOP SYSTEM

The adjustable depth stop located on the base of your router

provides precise stops for repetitive depth of cut changes. A

depth adjustment scale makes quick adjustments to depth of

cut changes possible.

SPINDLE LOCK

A spindle lock secures the spindle so that only one wrench

is needed to loosen the collet nut and to change the cutters.

NOTE: Do not run router with spindle lock engaged.

ON/OFF SWITCH

Your router starts and stops by depressing the on/off switch

located on the handle. Push the switch down to start the router.

Always ensure you are holding the router properly before

depressing the switch to turn the tool on. To turn the router

off, simply depress the switch again.

VARIABLE SPEED CONTROL

Your router has advanced electronic features, designed to

assist you in getting the maximum use from your router. By

making proper speed selections, your router can be adjusted

to specic routing needs. This eliminates much of the guess

work previously needed to perform operations on router tables

when used with the optional depth control knob.

The electronic feature of your router introduces the exibility

of adjusting the motor speed to required job conditions. An

electronic speed control module senses the load applied

to the motor and increases or decreases motor voltage to

compensate for and maintain desired RPM.

Speed can be set according to the approximate cutter diameter

you will be using and to the hardness of the material being

cut. The best cuts are made when the cutter is fed through

material at the proper rate of feed.

PLUNGE LOCK LEVER

After extended use, the plunge lock may wear. If this happens,

you can easily adjust the lever.

TO ADJUST PLUNGE LOCK LEVER

PLUNGE LOCK LEVER SHOWN AFTER EXTENDED

WEAR (

UNPLUG YOUR ROUTER.

Fig

. 1)

FEATURES

PLUNGE LOCK LEVER SHOWN IN ORIGINAL LOCKED

POSITION (

WARNING:

Failure to unplug your router could result in

accidental starting causing serious injury.

Your router has a plunge lock lever that allows for free

plunging. This feature is very useful for table mounted

operations on router tables when used with the optional

depth control knob. Unlocking the plunge lock lever allows

for a smooth, precise plunging action. Once you reach the

desired depth of cut, simply lock the plunge lock lever. The

cutter will then be secured at the desired depth of cut.

Fig

. 2)

Make sure lever is in locked position. (

Remove (L) the screw supporting the plunge lock lever.

Remove the lever.

Place the lever back in the original locked position.

Replace (T) the screw.

Check for free plunge with lever rotated to unlocked

position. If router does not plunge freely, reposition

lever.

Fig

. 3)

WARNING:

Your router should never be connected to power supply

when you are assembling par ts, making adjustments,

installing or removing cutters or when not in use.

Disconnecting your router will prevent accidental starting

that could cause serious injury.

Page 3

Fig. 1

Fig. 2

Fig. 3

Page 5

QUICK SELECT OF DEPTH OF CUT ( Fig. 6&7)

Use the adjustable depth stop for quick select pre-set cutting

depth positions. The position right below the depth stop

denes the cutting depth.

Lift the adjustable depth stop from its current xing point and

turn the desired cutting depth position to the position below

the depth stop.

Make sure the adjustable depth stop is secured in the xing

point.

Follow the instruction below for setting depth of cut.

WARNING:

Fa ilu re to unp lug you r rou ter cou ld re sul t in

accidental starting causing serious injury.

0

1

2

3

4

7

1

1

12

CUTTER INSTALLATION (

Fig

. 4&5)

UNPLUG YOUR ROUTER.

WARNING:

Failure to unplug your rout er cou ld result in

accidental starting causing serious injury.

CAUTION:

To prevent damage to the spindle or spindle lock,

always allow motor to come to a complete stop

before engaging spindle lock.

Depress spindle lock.

Lay router down on work bench in order to gain easy

access to collet nut .

Place the wrench provided through front of router base

onto collet nut and turn counterclockwise to loosen.

WARNING:

If you are changing a cutter immediately after use,

be careful not to touch the cutter or collet with your

hands or ngers. They will get burned because of the

heat build up from cutting. Always use the wrench

provided.

Install router bit once collet nut is loose. If changing bits,

the bit already installed will easily slip from collet after

loosening the collet nut. NOTE: The collet is machined to

precision tolerances to t bits with 12.7 mm (1/2”) diameter

shanks. To use bits with 6.35 mm ( 1/4”) diameter shanks,

insert the 6.35 mm ( 1/4”) collet adaptor into the 12.7 mm

(1/2”)collet.

Tighten the collet nut securely by turning clockwise with

the wrench provided.

Release spindle lock.

WARNING:

If the collet nut is not securely tightened, the cutter may

detach during use causing serious personal injury.

WARNING:

Do not use cutters with undersized shanks. Undersized shanks will not tighten properly and could be

thrown from the tool causing injury.

WARNING:

Do not use cutters that are larger in diameter than the

opening in router base. Use of such cutters will come in

contact with the router base and damage both the cutter

and router base. This situation could also cause possible

loss of control or create other hazardous conditions that

could cause possible serious personal injury.

Page 4

ADJUSTMENTS

Fig. 4

Fig. 5

Fig. 6

Page 6

ADJUSTING DEPTH STOP

Unplug your router.

Loosen the locking bolt for depth stop and release the

plunge lock lever.

Push the machine so far down that the router touches the

work piece and fasten the plunge lock lever.

Rotate depth stop adjustment knob to turn the depth

downwards as far as possible.

Move the pointer if necessary. It indicates zero value on

the scale.

MOUNTING AND ADJUSTING PARALLEL GUIDE

(Fig.10~12)

The parallel guide is used for straight cuts along a work piece

with a straight edge that can be followed.

0

1

2

3

4

7

1

1

12

SETTING DEPTH OF CUT

Unplug your router.

Loosen the locking bolt for depth stop and release the

plunge lock lever.

S

et the depth stop to required cutting depth with scale

indication and tighten the locking bolt.

Push the machine do

wn to the depth stop.

T

urn t he fine adjustment knob for fine adjustment of

cutting depth.

Tur n the nut to set the variable cutting depth.

Fasten the plunge lock lever.

DEPTH STOP (

Fig

. 8&9)

The depth stop is located on the base of your router and makes

it possible to make deep or heavy cuts in successive passes

by use of the Adjustable Depth Stop System. Alignment marks

make depth of cut changes quick and easy.

A preset cutting depth is achieved by plunging router until stop

bar comes in contact with depth stop. The micro-adjusting

feature provides alignment marks at each 90˚ rotation of the

depth stop knob. Each 90˚ rotation of the knob changes depth

of cut setting 0.75 mm.

A

complete rotation (360˚) of the depth stop knob changes the

depth of cut setting 3 mm.

The

Adjustable Depth Stop System provides for depth of cut

changes to be made from 0 to 12 cm from the initial setting

of the stop bar.

This initial setting of the stop bar can be “zero” depth of cut or

it can be any depth of cut setting that you choose as a star ting

point for a particular job to be performed.

WARNING:

Always wear safety goggles or safety glasses with

side shields when using your router. Failure to do so

could result in dust, shavings, chips, loose particles

or foreign objects being thrown in your eyes resulting

in possible serious injur y. If the operation is dusty,

also wear a face or dust mask.

WARNING:

Failure to unpl ug you r router cou ld res ult in

accidental starting causing serious injury.

Page 5

0

1

2

3

4

7

1

1

12

ADJUSTMENTS

0

1

2

3

4

7

1

1

12

Fig. 7

Fig. 8

Slide the guide rods in corresponding holes and tighten

the locking bolts.

Slide the parallel guide in the router base and tighten the

locking bolts.

Set the parallel guide to the desired guide distance.

For ne adjustment of guide distance, turn ne

adjustment knob.

Fig. 9

Page 7

ADJUSTMENTS

Fig. 10

Fig. 11

Fig. 12

MOUNTING TEMPLATE GUIDE (Fig. 13&14)

The template guide can be tted to the router base to accurately

duplicate curves and other complex shapes. These shapes

can be easily made by using a jigsaw to cut out the required

designs.

Place the template guide in the recess provided in the

base and tighten screws.

The guide protrudes below the bottom of the base allowing

the router to follow the template.

A template must be securely xed to the work piece and a

rm pressure applied to the router at all times to ensure that

the edge of the guide accurately follows the template.

Fig. 13

Work Peice

Template

Collet Nut

Template

Guide

Router Base

Fig. 14

ROUTING (Fig. 15)

For ease of operation and maintaining proper control, your

router has two handles, one on each side of the router

When using your router, hold it rmly with both hands.

Before starting the router, unplug it and make sure the cutter

base.

is securely tightened in collet nut and that depth of cut is

properly set.

Plug router into power supply, turn it on and let motor build

to its full speed, then gradually plunge or feed cutter into

workpiece. Do not let the cutter contact workpiece before

turning on the router and allowing it to develop full speed.

Remain alert and watch what you are doing. Do not operate

router when fatigued or under the inuence of drugs, alcohol

or any medication.

0

1

2

3

4

7

11

12

Fig. 15

Page 6

Page 8

ADJUSTMENTS

0

1

2

3

4

7

11

12

ROUTING GROOVES (

Fig

. 16)

When routing across the face of boards, set router at

desired depth of cut, place the edge of router base against

workpiece and turn on the router. Slowly feed the cutter into

the workpiece along desired line of cut.

WARNING:

If desired depth of cut is greater than can be safely

cut in one pass, make cuts in two or more passes.

When routing straight cuts across stock, clamp a straight edge to

the workpiece to use as a guide. Position the straight edge parallel

to the line of cut and offset the distance between the cutting edge

of the cutter and the edge of the router base. Hold the router base

against the straight edge and rout the groove.

When routing a groove wider than the diameter of the cutter, clamp

a straight edge on both sides of the cutlines. Position both guides

parallel to the desired line of cut and spaced equal distances

from the desired edges of the groove. Rout along one guide; then,

reverse direction and rout along the other guide.

remaining waste in the center of the groove freehand.

Clean out any

Fig. 16

30

31

Fig. 17

33

32

33

32

Fig. 18

DEPTH OF CUT (

As previously mentioned, the depth of cut is important because it

affects the rate of feed that, in turn, affects the quality of the cut

(and also the possibility of damage to your router motor and bit).

A deep cut requires a slower feed than a shallow one and a too

deep cut will cause you to slow the feed so much that the bit is

no longer cutting, it is scraping, instead.

Making a deep cut is never advisable. The smaller bits are easily

broken off when subjected to too much side thrust. A large enough

bit may not be broken, but if the cut is too deep a rough cut will

result - and it may be very difcult to guide and control the bit as

desired. For these reasons, we recommed that you do not exceed

3.2 mm depth of cut in a single pass regardless of the bit size or

the softness or condition of the workpiece.

To make deeper cuts it is therefore necessary to mark as many

successive passes as required, lowering the bit 3.2 mm for each

new pass. In order to save time, do all the cutting necessary at one

depth setting, before lowering the bit for the next pass. This will also

assure a uniform dept when the nal pass is completed.

Fig

. 17&18)

Page 7

Page 9

RYOBI TECHNOLOGIES AUSTRALIA PTY. LTD.

GUARANTEE

RYOBI TECHNOLOGIES AUSTRALIA PTY. LTD.

A.B.N. 98 002 277 509

SYDNEY: 359-361 Horsley Road, Milperra, N.S.W. 2214.

Contact during normal business hours.

Tel: (02) 9792 9888 - Fax: 1800 807 993 - www.ryobi.com.au

RYOBI NEW ZEALAND PTY. LTD.

AUCKLAND: 27 Clemow Drive, Mt Wellington, N.Z.

Tel: (09) 573 0230 - Free Call: 0800 279 624 - Fax: (09) 573 0231 - www.ryobi.co.nz

Contact during normal business hours.

Subject to the guarantee condition below, this Ryobi tool

(hereinafter called “the product”) is guaranteed by Ryobi

(hereinafter called “the Company”) to be free from

defects in material or workmanship for a period of 24

months from the date of original purchase covering

both parts and labo ur. Under the terms of this

guarantee, the repair or replacement of any part shall

be the opinion of the Company or its authorised agent.

Should service become necessary during the warranty

period, the owner should contact the Authorised Ryobi

Retailer from whom the Product was purchased, or the

nearest Company Branch Ofce. In order to obtain

guarantee service, the owner must present the sales

docket and Guarantee Certicate to conrm date of

purchase. This product is sold by the dealer or agent

as principal and the dealer has no authority from

the Company to give any additional guarantee on

the Company’s behalf except as herein contained or

herein referred to.

Guarantee Conditions

This guarantee only applies provided that the Product

has been used in accordance with the manufacturer’s

recommendations under normal use and reasonable

care (in the opinion of the Compa ny) and such

guarantee does not cover damage, malfunction or

failure resulting from misuse, neglect, abuse, or

used for a purpose for which it was not designed

or is not suited and no repai rs, alteratio ns or

modic ati ons have been attempted by other than

an Authorised Service Agent. This guarantee will not

apply if the tool is damaged by accident or if repairs

arise from normal wear and tear.

The Company accepts no additional liability pursuant to

th is g ua ra ntee for the cost s of t ra ve ll in g or

transportation of the Product or parts to and from the

service dealer or agent - such costs are not included

in this guarantee.

Certain legislation, including the Trade Practices Act,

1974 (as amended) and other state and territorial laws

give rights to the buyer and impose liability on the seller

in certain circumstances. Nothing herein shall have the

effect of excluding, restricting or modifying any

condition, guarantee, right or liability imposed, to the

extent only th at such exclusion, r est riction o r

modication would render any term herein void.

BRISBANE: All enquiries Tel : 1300 361 505

TOWNSVILLE: All enquiries Tel : 1300 361 505

MELBOURNE: 960 Stud Road, Rowville,Vic. 3178

Tel : (03) 9764 8655

HOBART:

All enquiries Tel : 1300 360 216

ADELAIDE:

All enquiries Tel : 1300 360 216

PERTH:

33-35 Sorbonne Cres., Canning Vale,W.A. 6155.

Tel : (08) 9455 7775

Purchased From

Address Of Dealer

Date Model No Serial No

This Guarantee Form Should Be Retained By The Customer At All Times

For your record and to assist in establishing date of purchase (necessary for in-guarantee service)

please ke ep you r p urchase docket and thi s f orm completed with the fo llo win g particulars.

Present This Form With Your Purchase Docket When Guarantee Service Is Required.

Loading...

Loading...