Page 1

BIW180

18 VOLT IMPACT WRENCH

OWNER’S OPERATING MANUAL

Page 2

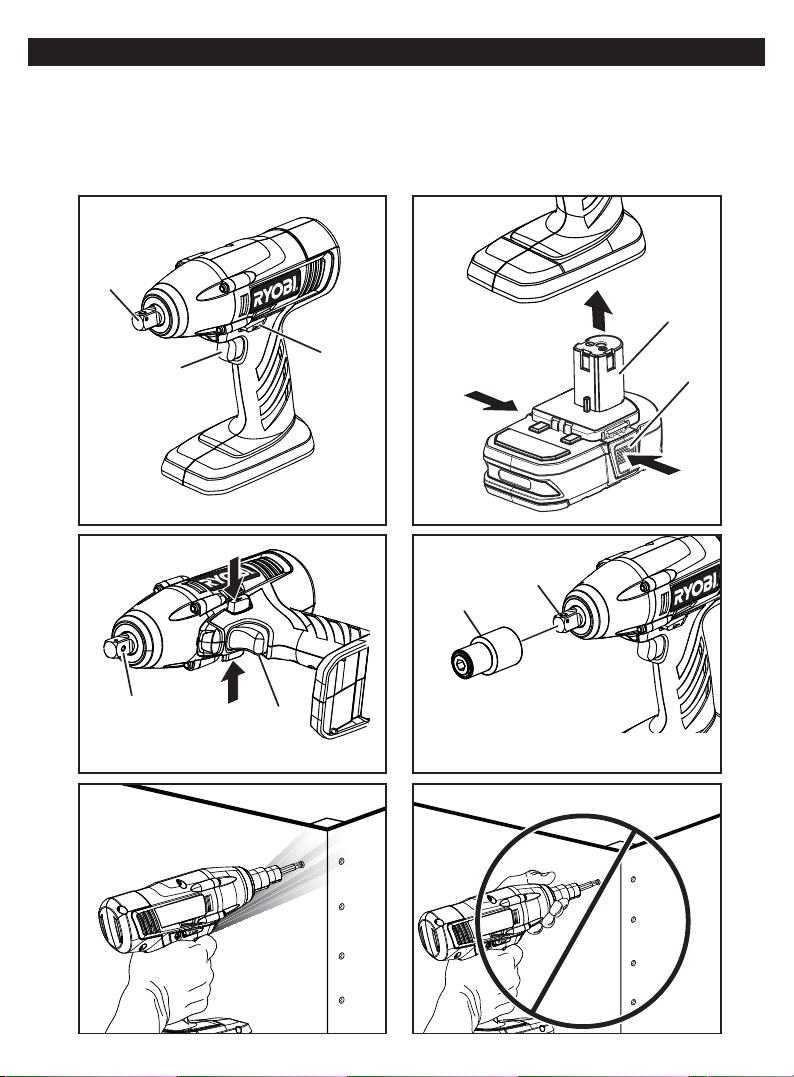

DESCRIPTION

1. 1/2" adaptor

2. Switch trigger

3. Rotation selector (Forward/Reverse)

4. Battery pack (not included)

5. Latches

1

2

7

6. Depress latches to release battery pack

7. Reverse

8. Forward

9. Socket

4

3

6

5

6

Fig. 1

Fig. 2

1

9

1

8

2

Fig. 3

Fig. 5 Fig. 6

Fig. 4

Page 3

Important!

It is essential that you read the instructions in this manual before

operating this machine.

Subject to technical modifications.

Page 4

English

GENERAL POWER TOOL SAFETY WARNINGS

WARNING

Read all safety warnings and all instructions.

Failure to follow the warnings and instructions may result

in electric shock, fi re and/or serious injury.

Save all warnings and instructions for future

reference.

The term “power tool” in the warnings refers to your

mains-operated (corded) power tool or battery-operated

(cordless) power tool.

CLASS 1 LED PRODUCT

1. WORK AREA SAFETY

a. Keep work area clean and well lit. Cluttered or

dark areas invite accidents.

b. Do not operate power tools in explosive

atmospheres, such as in the presence of

flammable liquids, gases, or dust. Power tools

create sparks which may ignite the dust or fumes.

c. Keep children and bystanders away while

operating a power tool. Distractions can cause

you to lose control.

2. ELECTRICAL SAFETY

a. Power tool plugs must match the outlet. Never

modify the plug in any way. Do not use any

adaptor plugs with earthed (grounded) power

tools. Unmodifi ed plugs and matching outlets will

reduce risk of electric shock.

b. Avoid body contact with earthed or grounded

surfaces such as pipes, radiators, ranges and

refrigerators. There is an increased risk of elec-

tric shock if your body is earthed or grounded.

c. Do not expose power tools to rain or wet con-

ditions. Water entering a power tool will increase

the risk of electric shock.

d. Do not abuse the cord. Never use the cord for

carrying, pulling or unplugging the power tool.

Keep cord away from heat, oil, sharp edges

or moving parts. Damaged or entangled cords

increase the risk of electric shock.

e. When operating a power tool outdoors, use an

extension cord suitable for outdoor use. Use

of a cord suitable for outdoor use reduces the risk

of electric shock.

f. If operating power tools in a damp location

is unavoidable, use a residual current device

(RCD) protected supply. Use of an RCD reduces

the risk of electric shock.

3. PERSONAL SAFETY

a. Stay alert, watch what you are doing and use

common sense when operating a power tool.

Do not use a power tool while you are tired or

under the influence of drugs, alcohol or medication. A moment of inattention while operating

power tools may result in serious personal injury.

b. Use personal protective equipment. Always

wear eye protection. Protective equipment such

as dust mask, non-skid safety shoes, hard hat, or

hearing protection used for appropriate conditions

will reduce personal injuries.

c. Prevent unintentional starting. Ensure the

switch is in the off-position before connecting

to power source and/or battery pack, picking

up or carrying the tool. Carrying power tools

with your fi nger on the switch or energising power

tools that have the switch on invites accidents.

d. Remove any adjusting key or wrench before

turning the power tool on. A wrench or a key left

attached to a rotating part of the power tool may

result in personal injury.

e. Do not overreach. Keep proper footing and

balance at all times. This enables better control

of the power tool in unexpected situations.

f. Dress properly. Do not wear loose clothing or

jewellery. Keep your hair, clothing and gloves

away from moving parts. Loose clothes, jewel-

lery or long hair can be caught in moving parts.

g. If devices are provided for the connection of

dust extraction and collection facilities, ensure these are connected and properly used.

Use of dust collection can reduce dust-related

hazards.

4. POWER TOOL USE AND CARE

a. Do not force the power tool. Use the correct

power tool for your application. The correct

power tool will do the job better and safer at the

rate for which it was designed.

b. Do not use the power tool if the switch does

not turn it on and off. Any power tool that can

not be controlled with the switch is dangerous and

must be repaired.

c. Disconnect the plug from the power source

and/or the battery pack from the power tool

before making any adjustments, changing accessories, or storing power tools. Such preven-

1

Page 5

English

tive safety measures reduce the risk of starting

the power tool accidentally.

d. Store idle power tools out of the reach of chil-

dren and do not allow persons unfamiliar with

the power tool or these instructions to operate

the power tool. Power tools are dangerous in the

hands of untrained users.

e. Maintain power tools. Check for misalignment

or binding of moving parts, breakage of parts

and any other condition that may affect the

power tools operation. If damaged, have the

power tool repaired before use. Many accidents

are caused by poorly maintained power tools.

f. Keep cutting tools sharp and clean. Properly

maintained cutting tools with sharp cutting edges

are less likely to bind and are easier to control.

g. Use the power tool, accessories and tool bits

etc., in accordance with these instructions and

in the manner intended for the particular type

of power tool, taking into account the working

conditions and the work to be performed. Use

of the power tool for operations different from

intended could result in a hazardous situation.

5. BATTERY TOOL USE AND CARE

a. Recharge only with the charger specified by

the manufacturer. A charger that is suitable for

one type of battery pack may create a risk of fi re

when used with another battery pack.

b. Use power tools only with specifically desig-

nated battery packs. Use of any other battery

packs may create a risk of injury and fi re.

c. When battery pack is not in use, keep it away

from other metal objects, like paper clips,

coins, keys, nails, screws or other small metal

objects, that can make a connection from one

terminal to another. Shorting the battery termi-

nals together may cause burns or a fi re.

d. Under abusive conditions, liquid may be

ejected from the battery; avoid contact. If contact accidentally occurs, flush with water. If

liquid contacts eyes, additionally seek medical

help. Liquid ejected from the battery may cause

irritation or burns.

6. SERVICE

a. Have your power tool serviced by a qualified

repair person using only identical replacement

parts. This will ensure that the safety of the power

tool is maintained.

IMPACT WRENCH SAFETY WARNINGS

■ Wear ear protectors with impact wrench. Exposure

to noise can cause hearing loss.

INSTRUCTIONS FOR SAFE HANDLING

■ Make sure that the tool is only connected to the

voltage marked on the name plate.

■ Never use the tool if its cover or any bolts are

missing. If the cover or bolts have been removed,

replace them prior to use. Maintain all parts in good

working order.

■ Always secure tools when working in elevated

positions.

■ Never touch the blade, drill bit, grinding wheel or

other moving parts during use.

■ Never start a tool when its rotating component is in

contact with the work piece.

■ Never lay a tool down before its moving parts have

come to a complete stop.

■ ACCESSORIES: The use of accessories or

attachments other than those recommended in this

manual might present a hazard.

■ REPLACEMENT PARTS: When servicing use only

identical replacement parts.

SPECIFICATIONS

Voltage 18 V

Coupler 12.7 mm

Switch Variable speed

No load speed 0 - 3000 minMax. Torque 265 Nm

Blows Per Minute 0 - 3000 BPM

Weight (not included battery pack) 1.6 Kg

MODEL

PACK

(not included)

BPL-1820

BPL-1815

BATTERY

BIW180

ABP1801

ABP1802

ABP-1813

ABP-1815

OPERATION

WARNING

Do not allow familiarity with products to make you

2

COMPATIBLE

CHARGER

(not included)

BCL-1800

BCL1418

BCS618

BCL-1800

BCL1418

BCS618

ACR1800

260022029

1

Page 6

English

careless. Remember that a careless fraction of a

second is sufficient to inflict serious injury.

WARNING

Always wear safety goggles or safety glasses with

side shields when operating products. Failure to

do so could result in objects being thrown into your

eyes, resulting in possible serious injury.

WARNING

Do not use any attachments or accessories not

recommended by the manufacturer of this product.

The use of attachments or accessories not

recommended can result in serious personal injury.

APPLICATIONS

You may use this product for the purposes listed below:

■ Fastening/removing screws and bolts.

This product will accept Ryobi One+ 18 V lithium-ion

battery packs and Ryobi One+ 18 V nickel-cadmium

battery packs.

WARNING

Always remove battery pack from your impact

wrench when you are assembling parts, making

adjustments, assembling or removing bits,

cleaning, or when not in use. Removing battery

pack will prevent accidental starting that could

cause serious personal injury.

BATTERY PROTECTION FEATURES

Ryobi 18 V lithium-ion batteries are designed with

features that protect the lithium-ion cells and maximize

battery life. Under some operating conditions, these

built-in features may cause the battery and the tool it is

powering to act differently from nickel-cadmium batteries.

During some applications, the battery electronics may

signal the battery to shut down, and cause the tool to

stop running. To reset the battery and tool, release the

trigger and resume normal operation.

NOTE: To prevent further shut down of the battery, avoid

forcing the tool.

If releasing the trigger does not reset the battery and

tool, the battery pack is depleted. If depleted, the battery

pack will begin charging when placed on the lithium-ion

charger.

TO INSTALL BATTERY PACK

See Figure 2.

■ Place the rotation selector in the center position.

■ Insert the battery pack into the product as shown.

■ Make sure the latches on each side of the battery

pack snap in place and that battery pack is secured in

the product before beginning operation.

TO REMOVE BATTERY PACK

■ Depress the latches on each side of the battery pack.

■ Remove the battery pack from the impact wrench.

WARNING

Battery products are always in operating

condition. Therefore, the switch should always

be locked when not in use or carrying at your

side.

CAUTION

The metal surface may become hot during use.

Avoid contact with it to avoid possible burn injury.

SWITCH TRIGGER

See Figure 3.

To turn the impact wrench ON, depress the switch trigger.

To turn it OFF, release the switch trigger.

The switch trigger can be locked in the OFF (center)

position. This feature can be used to prevent the

possibility of accidental starting when not in use. To lock

switch trigger, place the direction of rotation selector in

center position.

VARIABLE SPEED

The variable speed switch trigger delivers higher speed

with increased trigger pressure and lower speed with

decreased trigger pressure.

NOTE: You might hear a whistling or ringing noise from

the switch during use. Do not be concerned; this is a

normal part of the switch function.

ROTATION SELECTOR

(FORWARD/REVERSE/CENTER LOCK)

See Figure 3.

The direction of bit rotation is reversible and is controlled

by a selector located above the switch trigger. With the

impact wrench held in normal operating position, the

rotation selector should be positioned to the left of the

switch trigger for forward drilling. The drilling direction is

reversed when the selector is to the right of the switch

trigger.

Setting the switch trigger in the OFF (center lock) position

helps reduce the possibility of accidental starting when

not in use.

3

Page 7

English

CAUTION:

To prevent gear damage, always allow the chuck

to come to a complete stop before changing the

direction of rotation.

To stop, release switch trigger and allow the coupler to

come to a complete stop.

WARNING

Make sure the bit is secured in the coupler

before using the impact wrench. Failure to do so

could cause serious personal injury.

WARNING

Do not drive a screw where there is likely to

be hidden wiring behind the surface. Contact

with a “live” wire will make exposed metal parts

of the tool “live” and shock the operator. If you

must drive a screw where hidden wire may be

present, always hold tool by insulated gripping

surfaces (handle) when performing the operation

to prevent a shock to the operator, as seen in

figure 5.

CAUTION:

The impact wrench is not designed to be used as

a drill.

INSTALLING AND REMOVING SOCKETS

See Figures 4.

Use only sockets designed for impact wrenches. Always

select the correct size impact socket for nuts and bolts.

Using the wrong size socket may damage the nut or

bolt and cause the fastening torque to be inaccurate or

inconsistent.

■ Remove the battery pack.

■ Push the socket onto the drive shank until the detent

pin locks it into place.

■ To remove the socket, pull it away from the drive

shank.

OPERATING THE IMPACT WRENCH

See Figures 5.

Proper fastening torque may be determined by the

kind of bolt, the size of the bolt or the material or the

workpiece. It is helpful to perform a test operation to

determine the proper fastening time for the nut or bolt

you are using. While performing the test, make note of

the speed selection.

■ Hold the tool pointed straight at the nut or bolt.

■ Depress the switch and fasten for the proper

fastening time.

■ After fastening, always check the torque with a torque

wrench.

NOTE: Do not use this tool to install lug nuts on

wheels without a torque limiting device. Doing so

could result in galled or broken lugs.

IMPACT TIME

Many variables exist that will cause the available torque

of the fastener to vary considerably. The optimum impact

time is approximately 6 seconds.

NOTE: Using a universal joint or extension bar may

reduce the fastening force of the impact wrench and

require longer fastening time.

DRIVING OR REMOVING SCREWS

See Figures 5 - 6.

■ Place the rotation selector in the correct position for

the operation.

■ Hold the impact driver with one hand.

■ Place the bit on the screw head and slowly depress

the switch trigger. Start the bit slowly for more control.

■ As the screw is driven, impacting will begin.

MAINTENANCE

WARNING:

When servicing, use only identical Ryobi

replacement parts. Use of any other parts may

create a hazard or cause product damage.

WARNING:

Always wear safety goggles or safety glasses

with side shields during power product operation

or when blowing dust. If operation is dusty, also

wear a dust mask.

WARNING:

To avoid serious personal injury, always remove

the battery pack from the product when cleaning

or performing any maintenance.

Avoid using solvents when cleaning plastic parts. Most

plastics are susceptible to damage from various types of

commercial solvents and may be damaged by their use.

Use clean cloths to remove dirt, dust, oil, grease, etc.

WARNING

Do not at any time let brake fluids, gasoline,

petroleum-based products, penetrating oils, etc.,

4

Page 8

English

come in contact with plastic parts. Chemicals can

damage, weaken or destroy plastic which may

result in serious personal injury.

Do not abuse power tools. Abusive practices can damage

the tool as well as workpiece.

5

Page 9

TECHTRONIC INDUSTRIES (AUSTRALIA) PTY. LTD.

Tel: 61 3 9840 3226 Fax No.: 613 9840 6133 www.ryobi.com.au

Level 1. 666 Doncaster Road,

Doncaster, Victoria 3108

Australia.

Loading...

Loading...