Page 1

ETS-1526AL

TABLE SAW

OWNER’S OPERATION MANUAL

N197

THANK YOU FOR BUYING A RYOBI TABLE SAW

Your new table saw has been engineered and manufactured to Ryobi's high standard for

dependability, ease of operation, and operator safety. Properly cared for, it will give you years of rugged,

trouble free performance.

CAUTION: Carefully read through this entire owner's manual before using your

TABLE SAW.

Pay close attention to the Rules for Safe Operation, Warnings, and Cautions.

If you use your saw properly and only for what it is intended, you will enjoy years of safe, reliable

service.

Thank You again for buying Ryobi tools.

SAVE THIS MANUAL FOR FUTURE REFERENCE.

Page 2

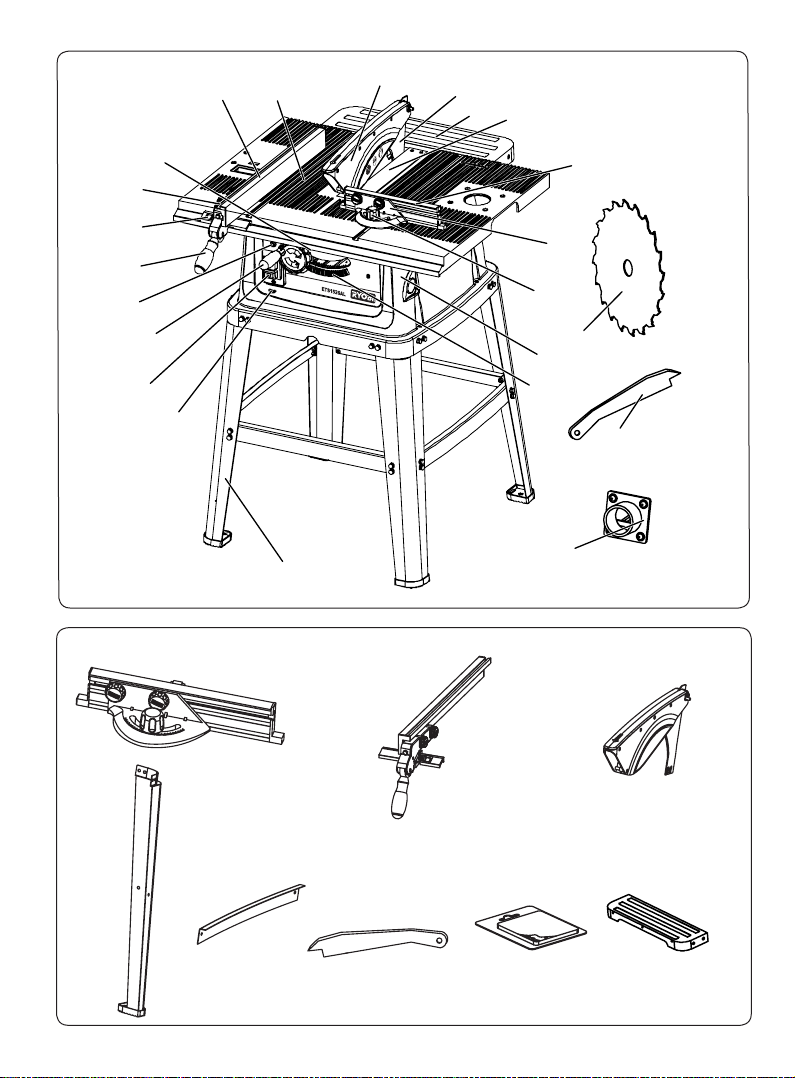

Fig. 0

C

A

D

E

F

G

21

22

15

12

1

10

9

18

17

20

7

86

11

5

19

3

14

13

2

4

B

16

24

H

Page 3

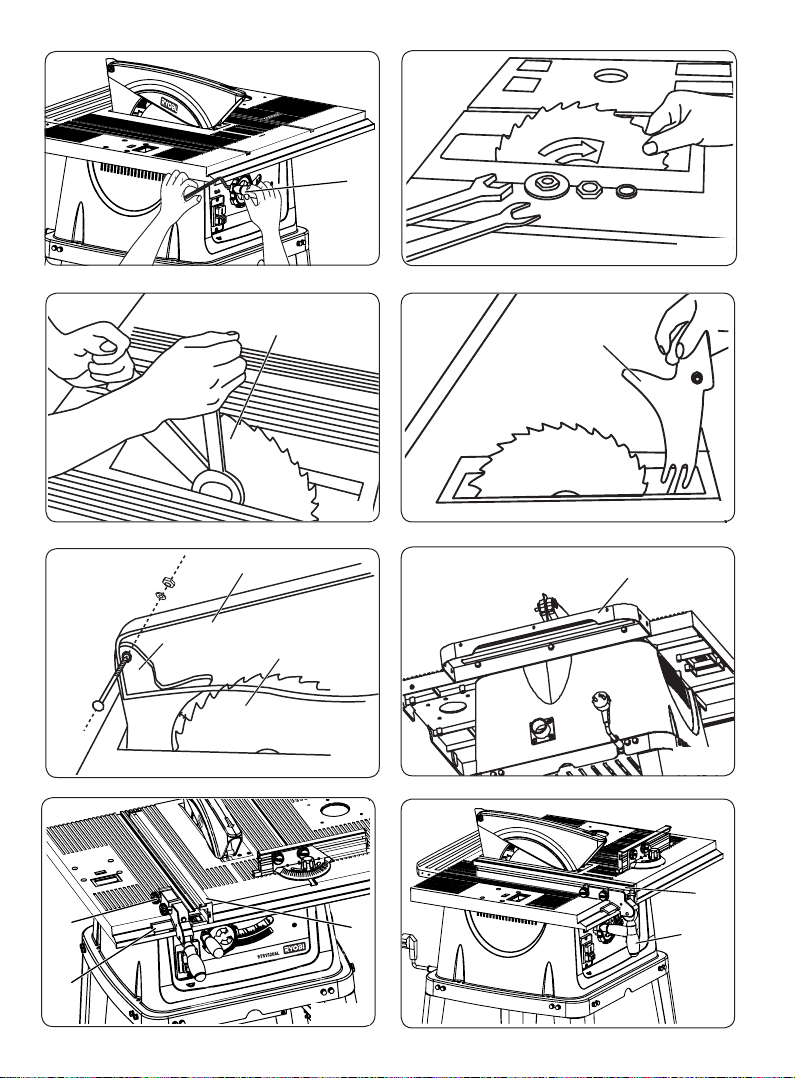

2-5mm

Fig. 1

Fig. 3 Fig. 4

Fig. 6

Fig. 2

13

15

20

7

15

20

19

5

6

Fig. 7

3

6

3

Fig. 5

Fig. 5a

24

Page 4

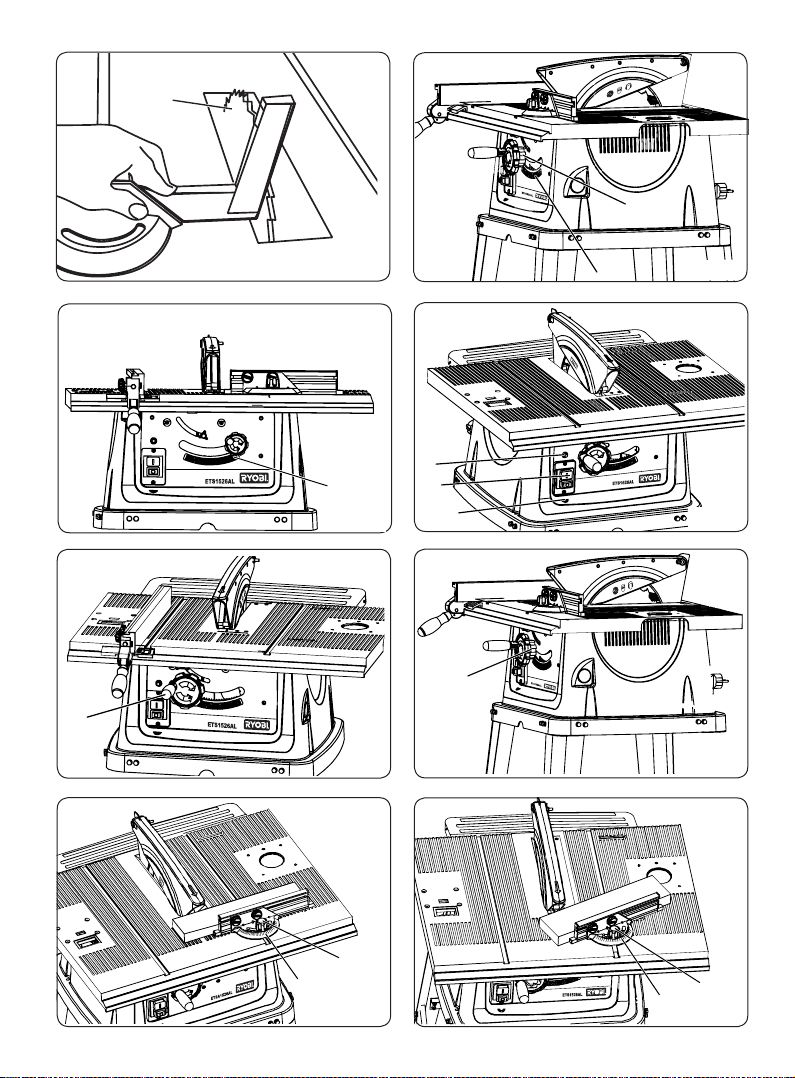

Fig. 10

Fig. 12

Fig. 13

Fig. 14

Fig. 15

12

45

o

2

13

23

9

10

10

23

Fig. 9

4

9

Fig. 11

14

Fig. 8

15

Page 5

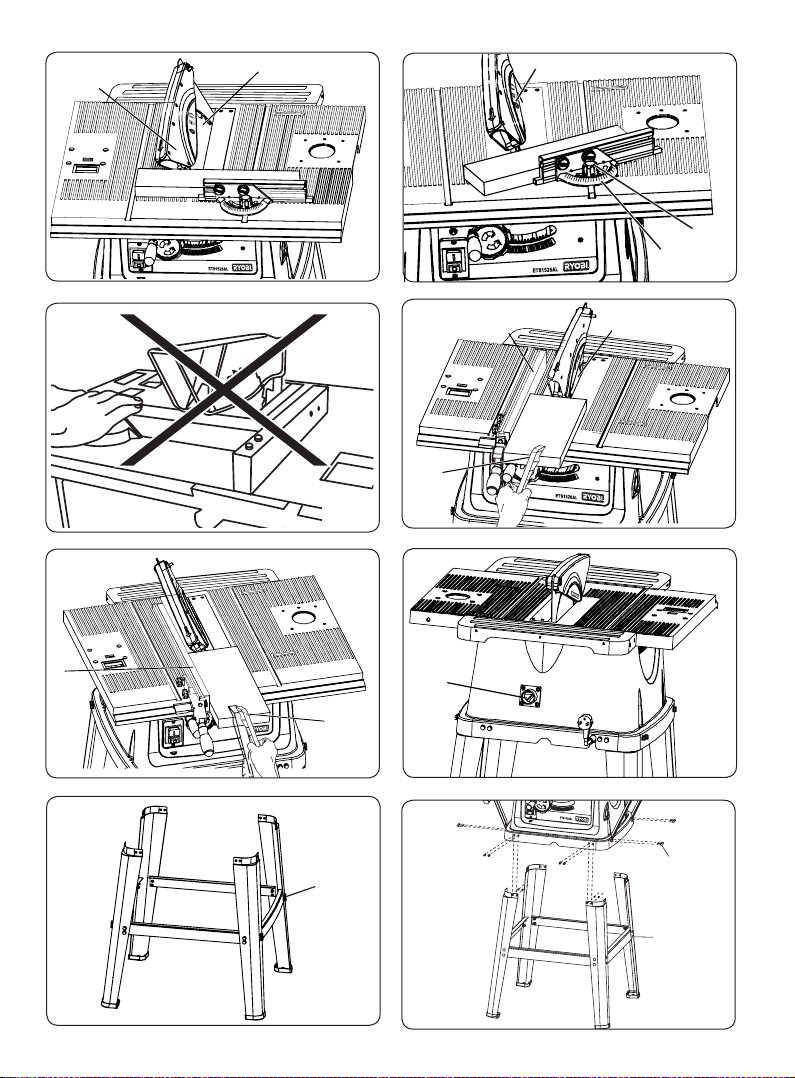

Fig. 17

Fig. 18

Fig. 19

Fig. 20

Fig. 21

Fig. 22

Fig. 16

15

15

10

9

156

16

16

6

M6

7

15

22

Fig. 23

M6

M5

Page 6

Fig. 25

Fig. 24

Page 7

Page 1

WARNING!

When using electric tools basic safety

precautions should always be followed to reduce

the risk of fire, electric shock and personal injury.

Read all these instructions before attempting to

operate your product. Save these instructions

for future reference.

Keep your work area clean and well lit.

Cluttered benches and dark areas invite

accidents.

Do not operate power tools in explosive

atmospheres, such as in the presence of

flammable liquids, gases or dust. Power

tools create sparks which may ignite dust or

fumes.

Children, visitors and pets should be kept a

safe distance from the work area.

Avoid wearing loose clothing, jewellery or

anything that could get caught in moving

parts. Long hair should be tied back. Use

of safety goggles is recommended (normal

glasses are not sufficient for eye protection).

Face or dust masks should be used if dust

is produced or working overhead. Ear

protection is advised during periods of

extended operation.

Do not overreach. Keep proper footing and

balance at all times; wear oil-resistant rubber

footwear. Keep floor clear of oil, scrap and

other debris.

Do not force the tool. Do not attempt to

use the tool for a purpose for which it was

not designed. The tool will give much better

service if you do not use excessive force.

Disconnect the plug when not in use, or when

changing accessories, making adjustments,

cleaning or working on tool. Always unplug

when leaving the tool unattended. All tools

should be kept out of the reach of children

when not in use. Do not expose the tool to

rain and moisture.

Only use accessories that are recommended

by the manufacturer of your model.

Accessories that may be suitable for one

tool may create a risk of injury when used on

another tool.

Guard

against electric shocks – avoid body

contact with earthed surface (e.g. radiators,

pipes, dishwashers, refrigerators). Hold the

tool by insulated gripping surfaces when

performing an operation where the cutting

tool may contact hidden wiring.

GENERAL SAFETY PRECAUTIONS

Make sure the cord is located so that it will

not be stepped on, tripped over or otherwise

subjected to damage or stress.

Avoid accidental start-ups, make sure that

the power switch is in “OFF” position before

plugging in the power.

Maintain tools properly. Always keep tools

clean and in good working order. Follow

instructions for lubricating and changing

accessories.

Check damaged parts. Check for alignment

of moving parts, binding of moving parts,

breakage of parts, improper mounting, or

any other condition that may affect the tools

operation. Any part that is damaged should

be properly repaired or replaced.

Never use solvents to clean plastic parts.

Solvents could possibly dissolve or otherwise

damage the material. Only a soft damp cloth

should be used to clean plastic parts.

Always use in a well ventilated area. Remove

sawdust frequently. Clean out sawdust from

the interior of the saw to prevent a potential

fire hazard.

Despite the machine being operated in

conformity with the intended conditions of

use and under observance of all relevant

safety regulations, due to the design required

by the nature of work to be carried out with it,

some residual risks remain possible. These

risks including contact with the revolving

blade in the cutting area, kickback of the

workpiece or parts thereof, breaking of

the saw blade with the broken parts being

ejected from the machine, contact with live

parts when checking electrical components

opened for inspection, emission of harmful

wooden dusts when operated without a dust

collector.

Page 8

Always hold the work firmly against the mitre

gauge or fence.

Never perform any operation “free hand”.

Always use either the fence or the mitre gauge

to position and guide.

Rebating or grooving should not be carried

out.

Saws shall not be used for slotting (stopped

groove).

Use only saw blades for which the maximum

possible speed is not less than the maximum

spindle speed of the tool and the material to

be cut.

Never stand or have any parts of your body in

line with the path of the saw blade. Keep your

hands out of the line of the saw blade.

Move the rip fence out of the way when cross

cutting.

Feed the work into the blade or cutter

AGAINST the direction of rotation only.

Never use the fence as a cut-off gauge when

crosscutting.

Never attempt to free a stalled blade without

first turning the saw OFF. Turn off the power

switch immediately to prevent motor damage.

When transporting the machine use only

transportation devices and never use guards

for handling or transportation.

During transportation the upper part of the

saw blade should be covered; for example by

the guard.

Use an extension table for supporting long

workpieces during cutting operation.

Ensure that polyfoam packaging is removed

before use.

Ensure that the yellow warning label is

removed from the table before use.

ADDITIONAL SAFETY PRECAUTIONS FOR TABLE SAW

Do not use saw blades which are damaged or

deformed.

Replace table insert when worn.

Use only saw blades recommended by the

manufacturer.

When changing the saw blade be aware that

the width of the cut will be wider than the body

of the blade,which in turn should be not be

wider than the thickness of the riving knife.

Take care that the selection of the saw blade is

suitable for the material to be cut.

Wear suitable personal protective equipment

when necessary, this could include

- hearing protection to reduce the risk of

induced

hearing loss,

- respiratory protection to reduce the risk of

inhalation of harmful dust,

- wear gloves when handling saw blades and

rough material. Saw blades shall be carried in

a holder whenever practicable.

Dust developing during operation can be

harmful to your health, inflammable or

explosive. Never cut metals or materials which

may make hazardous dust.

Do not use High speed steel blades.

Use the push stick when required. Always use

a push stick for ripping narrow timber. Refer to

ripping applications in this Instruction Manual

where use of the push stick is covered in detail.

The push stick should always be stored with

the machine when not in use.

Always use the saw blade guard and riving

knife for every operation, including through

sawing. Through sawing operations are those

in which the blade cuts completely through

the work piece when ripping or crosscutting.

Page 2

DESCRIPTION(FIG. 0)

1. Body

2. ON/OFF Switch

3.

Rip Fence Lock Handle

4.

Live Tool Indicator

5. Rip Fence Lock Knob

6. Rip Fence

7. Blade Guard

8.

Table Top

9. Mitre Gauge

10.

Mitre Gauge Lock

11. Bevel Lock Knob

12. Bevel Angle Indicator

13. Elevating Handle

14. Reset Button

15.

Saw Blade

16. Push Stick

17. Table Insert/Throat Plate

18. Mitre Fence

19. Sliding Block

20. Riving Knife

21. Stand (Optional)

22.

Dust Port

23. Tilting Handle(Fig. 9&13)

24. Rear extension table

Page 9

A: Mitre gauge assembly

B: Rip fence assembly

C:

Blade guard assembly

D: Leg stand (4pcs)

Page 3

SPECIFICATION

Input voltage 240V ~ 50Hz

Watts 1500W

Blade diameter

254mm

Bore siz

e 15.9mm

No load speed

4500min-1

Depth of cut at 90°

80mm

Depth of cut at 45°

55mm

Main tab

le size 720mm(W) x 520mm(L)

Rear extension table size 440mm(W) x 125mm(L)

Sound pressure le

vel 99 dB(A)

Net w

eight 23.5 kg

WARNING!

Noise can be a health hazard. When the noise level exceeds 85 db (A) be sure to wear ear

protection.

PROPER USE OF MACHINE

This machine is designed to rip and cross cut

wood exclusively up to maximum thickness of

RESTRICTIONS OF USE

DO NOT cut timber greater than 80mm

DO NOT cut metal, stone, rubber, plastic

bones, etc.

DO NOT cut logs or round timber.

DO NOT use to rebate, mould or trench.

DO NOT fit any other tool or combination of

blades.

DO NOT use as a bench or work rest.

DO NOT weld machine.

DO NOT modify the machine or its guards/

controls

DO

NOT run the machine before removing

all packaging.

DO NOT use with any covers/guards

removed.

DO NOT use High Speed Steel (HSS)

blades.

DO NOT use the saw for slotting (stopped

groove).

LOOSE PART LIST

80mm. For correct operation it must be fixed

and operated as explained in this manual.

E: Cross Brace (4pcs)

F: Push stick

G: Blister pack with screws

H:

Extension table

Page 10

MOUNT THE ELEVATING AND LOWERING HANDLE

AND THE TILTING HANDLE (FIG. 1)

Mount the elevating handle(13) on the shaft

on the left hand side of the saw and fix it by

Page 4

MOUNT THE RIVING KNIFE (FIG. 4&5)

If in place, remove the table insert(17)by

removing the four phillips flat head screws.

Insert the riving knife(20), so that the long

slots in the riving knife fit around the hexagon

socket head end screws (Fig.4). Adjust the

riving knife(20) so that the clearance between

riving knife(20) and blade(15) is between 2

to 5mm (Fig.5); then tighten the hexagon

socket headed screws. Check to ensure the

riving knife(20) and saw blade(15) is in line.

Then check again that the blade is securely

tightened and remount the table insert.

Then mount the blade guard(7). (Fig. 5)

MOUNT THE RIP FENCE (FIG. 6&7)

Loosen the rip fence lock knobs(5) on the

sliding block(19), then slide the fence(6)

onto the bolt heads and tighten the rip

fence lock knobs(5) (Fig. 6)

To lock the rip fence(6), slide the rip fence

assembly until the indicator is pointing to

the desired setting. Then press rip fence

lock handle (3) downwards (Fig.7), to

lock the fence into position.

Ensure the fence is locked before

operating the saw.

Remove the table insert(17) by removing the

four Philips flat head screws.

Turn the elevating handle(13) (Fig.1) in the

counterclockwise direction to raise the

blade shaft to its highest position (fig.3).

Remove the blade fixing nut by turning in

a counterclockwise direction, then pull the

outer flange from the shaft and the outer

arbor. Mount the blade(15) (be sure that the

teeth are facing downwards at the front side

of the saw). Replace the outer flange and re-

fit the blade fixing bolt. Check that the blade

is correctly seated before tightening the bolt.

Check again that the blade(15) is securely

tightened and re-fit or adjust riving knife as

necessary, before re-mounting the table

insert(17).

WARNING!

Replace table insert when worn.

MOUNT THE BLADE (FIG. 1, 2&3)

tightening the set screw in the handle (fig.1).

ASSEMBLE EXTENSION TABLE (FIG. 5a)

Align the 3 holes of rear extension table

(24) with 3 M6 x12, flat washer, spring

washer and secure the rear extension

table(24) to the main table.

Page 11

ADJUSTMENT OF SAW BLADE (FIG. 8, 9&10)

WARNING:

• Do not use saw blades which are

damaged or deformed.

• Use only saw blades recommended by

the manufacturer.

• Take care that the selection of the saw

blade depends on the material to be cut.

The Blade(15) has been adjusted at the

f

actory, use a square to check that the blade

is at a 90o angle to the table (Fig.8)

Page 5

If adjustment is needed turn the tilting lock

nut (while holding the adjustment in position)

to fix the adjustment.

Then loosen the indicator fixing screw, set the

indicator of the scale(12) on the " 0

o

" marked

then tighten the fixing screw(Fig.9)

After the 90

o

setting of the blade has been

adjusted turn the tilting handle to the 45o

(Fig.10) side and adjust the 45

o

angle.

Turn the adjustment nut so that the blade is

on the 45

o

position and then tighten the lock

nut.

OPERATION ON/OFF MAGNETIC SWITCH (FIG. 11)

The magnetic switch (2) is a safety feature of

the machine. Should the supply be interrupted

the switch will automatically default to the

“OFF” position preventing a dangerous

unexpected startup of the machine when the

supply is restored.

Press the ‘ON’ button to start the machine.

Press the ‘OFF’ button to stop the machine.

WARNING: Before turning the machine

ON, make sure the blade guard is correctly

installed and operating properly.

OVERLOAD RESET BUTTON (FIG. 11)

Your table saw features an overload reset

button(14). In the event that your saw turns off

during operation, turn the saw off and allow

the motor to cool down for approximately

3 minutes. Push the reset button(14) and

attempt to turn the saw on again. If the saw

does not turn on, turn the switch off and

check all cords for proper connection and

retry. If it turns on and then cuts off while you

are working, you may be trying to feed the

workpiece too quickly or may be operating

with a dull blade or may be trying to operate

on an insufficient voltage.

I

O

Live Indicator (FIG. 11)

When the machine is connected with the

power supply, the live indicator (4) will glow.

If not, please check if the power plug is well

connected.

ELEVATING HANDLE (FIG. 12)

Elevating handle (13) is used to raise and

lower the blade. Turn it clockwise to lower and

counterclockwise to raise it.

Please note - this handle will move sideways

as the tilt or bevel is adjusted.

Page 12

CROSSCUTTING (FIG. 14)

Page 6

Crosscutting is cutting wood across the grain

at 90° or square with both the edge and the

flat side of the wood. This is done with the

mitre gauge(9) set at “0”. Before using it,

make sure it is locked(10). The mitre gauge

(9) can be used on either of the grooves in the

table. To change groove,slide the mitre gauge

assembly out of its groove and into the other

groove .Adjust it to the desired setting before

operating.

MITRE CROSSCUTTING (FIG. 15)

Mitre crosscutting is cutting the wood at

an angle other than 0° with the edge of the

wood on the mitre gauge(9). Follow the same

procedures as you would for crosscutting.

Adjust the Mitre gauge (9) to the desired

angle.

BEVEL CUTTING (FIG. 16)

Bevel crosscutting is similar to crosscutting

except that the wood is cut at an angle other

than the 90° with the flat side of the wood or

table. Adjust the blade to the desired angle.

COMPOUND MITRE CUTTING (FIG. 17)

Compound mitre cutting is a combination of

mitre cutting and bevel crosscutting. The cut

is made at an angle other than 90° to both

the edge and the flat side of the wood. Adjust

the mitre gauge(9) and the blade(15) to the

desired angle and ensure the mitre gauge(9)

is locked by using the mitre gauge lock(10).

REPETITIVE CUTTING (FIG. 18&19)

Repetitive cutting is cutting a number of

pieces the same length without having to

mark each piece. Do not feed the workpiece

with your hand (Fig.18). Guide it and make

sure that it does not bind or pinch the saw

blade (Fig.19). Never use the rip fence (6) as

a length stop because the cutoff piece could

bind between the fence (6) and the blade (15)

causing a kickback.

USING RIP FENCE (FIG. 19&20)

The rip fence (6) is used for all ripping

operations. Never rip freehand without the

fence in place and securely locked.

Ripping is cutting a piece of wood with the

grain or length wise(Fig.19). This is done

using the rip fence(6). Position the fence by to

the desired width of the rip and lock it in place.

Before starting to rip, be sure the rip fence is

parallel to the saw blade (15) and the riving

knife is properly aligned with the saw blade.

When ripping long boards or large panels,

always use a work support. Hold the piece

against the fence (6) and feed it through the

blade (15) with a smooth, steady pressure.

Always use the push stick (16) to feed the

workpiece until it is clear of the table. (Fig. 20)

MITRE GAUGE (FIG. 14)

The head is locked in the desired position for

crosscutting or mitre cutting by tightening the

mitre gauge lock(10). Always lock it securely

when in use by turning the mitre gauge

lock(10).

TILTING HANDLE (FIG. 13)

The tilting handle(23) is used to tilt the blade

for bevel cutting. Turn it clockwise to tilt toward

the left and counterclockwise to tilt toward the

right.

Page 13

BEVEL RIPPING (FIG. 20)

When bevel ripping material of 6” (150mm) or

narrower, use only the push stick(16) to feed

Page 7

DUST COLLECTION (FIG. 21)

Fasten your dust collector to the back side of

the table to the dust port(22) (Fig. 21).

The dust efficiency measurement is 45%.

MOUNT THE TABLE SAW TO THE STAND (FIG. 22&23)

Do not make any adjustment while the motor

is in motion. Always make sure the machines

plug has been removed from the mains power

source before changing brushes, lubricating

or when doing any works or maintenance

on the machine. After each use, check your

machine for damage or broken parts and

keep it in top working condition by repairing

or replacing parts immediately. Clean out

accumulated dust. To assure safety and

reliability, all repairs with the exception of

externally accessible brushes should be

performed by an AUTHORISED SERVICE

CENTRE. Faults in the machine, including

guards or saw blades, should be reported as

soon as they are discovered.

MAINTENANCE

Turn stand(21) u pr ight as shown.

Insert the cr os s head screws, spring

washers and flat washer t o assembl e the

fou r legs and cross braces first. (Fig. 23)

leave all bolts f in ger tig ht - do not f ul ly

tighten until as se mbly is co mp le te.

Remove the lower extension table brace

bolts Ca re fully place table saw on t op of

stand. Align holes i n t he tabl e saw ba se

with holes in st an d (F ig. 2 3) .

Fully tighte n al l bolts to the st an d before

operation.

WARNING!

The stand consists of 4 holes for mounting

to the ground. Always ensure your table

saw with stand is securely mounted to

the ground. If however, you have decided

not to mount your table saw onto the

stand, please refer to the 4 holes on

the table saw and mount the unit to the

workbench. Always ensure the table saw

is mounted securely either to the stand or

the workbench. Failure to do so, will cause

serious personal injury.

the workpiece past the saw blade.

WARNING!

The dust from some types of wood can

be harmful.

For instance, beech and oak dusts are

especially detrimental to health and therefore

may be worked only with dust collector.

MOUNT THE JIGSAW MOUNTING PLATE TO THE TABLE SAW (FIG. 24)

For details, p le ase re fer t o the Manual of

HBT250/139 Jigsaw Mounting P la te.

MOUNT THE ROUTER MOUNTING PLATE TO THE TABLE SAW (FIG 25)

For details, p le ase re fer t o the Manual of

HBT250/NCF Route r Mo un ting Kit.

Page 14

RYOBI TECHNOLOGIES AUSTRALIA PTY. LTD.

GUARANTEE

RYOBI TECHNOLOGIES AUSTRALIA PTY. LTD.

A.B.N. 98 002 277 509

Contact during normal business hours.

RYOBI NEW ZEALAND PTY. LTD.

AUCKLAND: 27 Clemow Drive, Mt Wellington, N.Z.

Contact during normal business hours.

Subject to the guarantee condition below, this Ryobi tool

(hereinafter called “the product”) is guaranteed by Ryobi

(hereinafter called “the Company”) to be free from

defects in material or workmanship for a period of 24

months from the date of original purchase covering

both parts and labour. Under the terms of this

guarantee, the repair or replacement of any part shall

be the opinion of the Company or its authorised agent.

Should service become necessary during the warranty

period, the owner should contact the RYOBI HELPLINE

1300 361 505 or contact the retailer from whom the

product was purchased.

In order to obtain guarantee service, the owner must

present the sales docket and Guarantee Certificate

to confirm date of purchase. This product is sold by the

dealer or agent as principal and the dealer has no

authority from the Company to give any additional

guarantee on the Company’s behalf except as herein

contained or herein referred to.

Guarantee Conditions

This guarantee only applies provided that the Product

has been used in accordance with the manufacturer’s

recommendations under normal use and reasonable

care (in the opinion of the Company) and such

guarantee does not cover damage, malfunction or

failure resulting from misuse, neglect, abuse, or used

for a purpose for which it was not designed or is not

suited and no repairs, alterations or modifications

have been attempted by other than an Authorised

Service Agent. This guarantee will not apply if the tool is

damaged by accident or if repairs arise from normal

wear and tear.

The Company accepts no additional liability pursuant to

this guarantee for the costs of travelling or

transportation of the Product or parts to and from the

service dealer or agent - such costs are not included in

this guarantee.

Certain legislation, including the Trade Practices Act,

1974 (as amended) and other state and territorial laws

give rights to the buyer and impose liability on the seller in

certain circumstances. Nothing herein shall have the effect

of excluding, restricting or modifying any condition,

guarantee, right or liability imposed, to the extent only

that such exclusion, restriction or modification

would render any term herein void.

BRISBANE : All enquiries Tel : 1300 361 505

TOWNSVILLE: All enquiries Tel : 1300 361 505

MELBOURNE: 960 Stud Road, Rowville,Vic. 3178

Tel : (03) 9764 8656

HOBART: All enquiries Tel : 1300 361 505

ADELAIDE: All enquiries Tel : 1300 361 505

PERTH: 33-35 Sorbonne Cres. Canning Vale, W.A. 6155

Address Of Dealer

Present This Form With Your Purchase Docket When Guarantee Service Is Required.

Tel: 1300 361 505 - Fax: 1800 807 993 - www.ryobi.com.au

Tel: (09) 573 0230 - Free Call: 0800 279 624 - Fax: (09) 573 0231 - www.ryobi.co.nz

SYDNEY: Building B, Rosehill Industrial Estate, 3 - 5 Shirley Street, Rosehill N.S.W. 2142

Tel : (08) 9455 7775

This Guarantee Form Should Be Retained By The Customer At All Times

For your record and to assist in establishing date of purchase (necessary for in-guarantee service)

please keep your purchase docket and this form completed with the following particulars.

Date Model No Serial No

Loading...

Loading...