Page 1

(57291

N197

3/81*(5287(5

2:1(5·6OPERATING0$18$/

DOUBLE

INSULATED

THANK YOU FOR BUYING A RYOBI PLUNGE ROUTER

Your new plunge router has been engineered and manufactured to Ryobi’s high standard for dependability,

ease of operation and operator safety. Properly cared for, it will give you years of rugged, trouble free

performance.

CAUTION: Carefully read through this entire owner’s manual before using your

plunge router.

Pay close attention to the Rules for Safe Operation, Warnings and Cautions.

If you use your plunge router properly and only for what it is intended, you will enjoy years of safe, reliable

service.

Thank you again for buying Ryobi tools.

SAVE THIS MANUAL FOR FUTURE REFERENCE.

Page 2

33

Page 3

)LJǘ )LJ

)LJ )LJ

)LJ

)LJ

Page 4

26

37

Page 5

Page 6

GENERAL SAFETY RULES

SAVE THESE INSTRUCTIONS

WARNING:

Read and understand all instructions. Failure

to follow all instructions listed below may result

in electric shock, fire and/or serious personal

injury.

WORK AREA

Keep your work area clean and well lit. Cluttered

■

benches and dark areas invite accidents.

Do not op era te po wer too ls in e xp lo siv e

■

■

ELECTRICAL SAFETY

■

■

■

■

PERSONAL SAFETY

■

■

pheres, such as in the presence of flammable

atmos

ases or dust. Power tools may create sparks

liquids, g

which may ignite the dust or fumes.

Keep bystanders, children and visitors away while

operating a power tool. Distractions can cause you

to lose control.

Avoid body contact with grounded surfaces, such

ipes, radiators, ranges and refrigerators. There

as p

is an increased risk of electric shock if your body is

grounded.

Do not expose power tools to rain or wet conditions.

Water entering a power tool will increase the risk of

electric shock.

Do not abuse the cord. Never use the cord to carry

the tool or pull the plug from an outlet. Keep cord

away from heat, oil, sharp edges or moving parts.

eplace da

R

cords increase the risk of electric shock.

Use outdoor extension leads. When tool is used

outdoors, u

use.

Stay alert, watch what you are doing and use

common sense when operating a power tool. Do

ot u

n

of d

inattention while operating power tools may result in

serious personal injury.

Dre ss p roperly. Do not wea r lo ose clothing or

jewelry. C

and gloves away from moving parts. Loose clothes,

jewelry or long hair can be caught in moving parts or

drawn into air vents.

maged cords immediately. Damaged

se only extension cords intended for outdoor

se tool while tired or under the influence

rugs, alcohol or medication. A moment of

ontain long hair. Keep your hair, clothing

Avoid accidental starting. Be sure switch is off

■

■

■

■

■

lugging in. Carrying tools with your finger

before p

on the switch or plugging in tools that have the switch

on invites accidents.

Remove adjusting keys or wrenches before turning

the tool on. A wrench or a key that is left attached to a

rotating part of the tool may result in personal injury.

Do not overreach. Keep proper footing and balance

imes. Proper footing and balance enables better

at all t

control of the tool in unexpected situations. Do not use

on a ladder or unstable support.

Use safety equipment. Always wear eye protection.

Dust mask, non skid safety shoes, hard hat or hearing

protection must be used for appropriate conditions.

Connect dust extraction equipment. If devices are

provided for the connected extraction and collection

acilities e

f

used.

nsure these are connected and properly

TOOL USE AND CARE

Use clamps or other practical way to secure and

■

support the workpiece to a stable platform. Holding

the work by hand or against your body is unstable and

may lead to loss of control.

Use the ri ght to ol. Do not force sma ll to ols or

■

attachments to do the job of a heavy duty tool. Do not

use tool for purposes not intended.

Do not use tool if switch does not turn it on or off.

■

Any tool that cannot be controlled with the switch is

dangerous and must be repaired.

Disconnect the plug from power source before

■

making any adjus

or storing the tool. Such preventive safety measures

reduce the risk of starting the tool accidentally.

Store idle tools out of the reach of children and

■

other untrained persons. Tools are dangerous in the

hands of untrained users.

Maintain tools with care. Keep cutting tools sharp

■

and clean. P

cutting edges are less likely to bind and are easier to

control.

Check for misalignment or binding of moving parts,

■

eakage of parts and any other condition that may

br

affect the tools operation. If damaged, have the tool

serviced before using. Many accidents are caused

by poorly maintained tools.

tments, changing accessories

rope rly maintained tools with sharp

1

Page 7

2

■ Only use cutters of the correct shank diameter and

which are suitable for the speed of the tool.

■

Use only accessories that are recommended by

the manufacturer for your model. Accessories that

may be suitable for one tool, may become hazardous

when used on another tool.

SERVICE

■

Tool service must be performed only by qualified repair

personnel. Service or maintenance performed by

unqualified personnel could result in a risk of injury.

■

When servicing a tool, use only identical replacement

part s. Follow instructions in the Maintenance

section of this manual. Use of unauthorized parts or

failure to follow Maintenance Instructions may create

a risk of electric shock or injury.

SPECIFIC SAFETY RULES

Hold tool by insulated gripping surfaces when performing

an operation where the cutting tool may contact hidden

wiring or its cord. Contact with a “live” wire will make

exposed metal parts of the tool “live” and shock the

operator.

ADDITIONAL SAFETY RULES

■

Know your power tool. Read operators manual

carefully. Learn its applications and limitations, as

well as the specific potential hazards related to this

tool. Following this rule will reduce the risk of electric

shock, fire or serious injury.

■

Always wear safety glasses. Everyday eyeglasses

have only impact-resistant lenses; they are NOT

safety glasses. Following this rule will reduce the risk

of serious personal injury.

■

Protect your lungs. Wear a face or dust mask if the

operation is dusty. Following this rule will reduce the

risk of serious personal injury.

■

Protect your hearing. Wear hearing protection

during extended periods of operation. Following this

rule will reduce the risk of serious personal injury.

■

If the supply cord is damaged, it shall be replaced

by the manufacturer or its service agent of similar

qualified person in order to avoid a hazard.

■

Check damaged parts. Before further use of the

tool, a guard or other part that is damaged should

be carefully checked to determine that it will

operate properly and perform its intended function.

Check for alignment of moving parts, binding of

moving parts, breakage of parts, mounting and

any other conditions that may affect its operation.

A guard or other part that is damaged should be

properly repaired or replaced by an authorized

service centre. Following this rule will reduce the risk

of shock, fire or serious injury.

■

Do not abuse cord. Never carry the tool by the cord

or yank it to disconnect it from the power supply.

Keep cord away from heat, oil and sharp edges.

Following this rule will reduce the risk of electric shock

or fire.

■

Inspect for and remove all nails from lumber before

routing. Following this rule will reduce the risk of

serious personal injury.

■

Drugs, alcohol, medication. Do not operate tool

while under the influence of drugs, alcohol or any

medication. Following this rule will reduce the risk of

electric shock, fire or serious personal injury.

■

Save these instructions. Refer to them frequently

and use them to instruct others who may use this

tool. If you loan someone this tool, loan them these

instructions also.

WARNING:

Some dust created by power sanding, sawing,

grinding, drilling and other construction activities

contains chemicals known to cause cancer,

birth defects or other reproductive harm. Some

examples of these chemicals are:

• lead from lead-based paints,

• crystalline silica from bricks and cement and

other masonry products,

• arsenic and chromium from chemically

treated lumber.

Your risk from these exposures varies depending

on how often you do this type of work. To reduce

GENERAL SAFETY RULES

Page 8

3

your exposure to these chemicals: work in a

well

ventilated area, and work with approved

safety equipment, such as dust masks that

are specially designed to filter out microscopic

particles.

SPECIFICATIONS

Voltage : 240V ~ 50Hz

No load speed : 14000-31500min

-1

Input power : 1250W

Plunge depth : 55mm

Collet size : 6.35mm or 12.7mm

DESCRIPTION

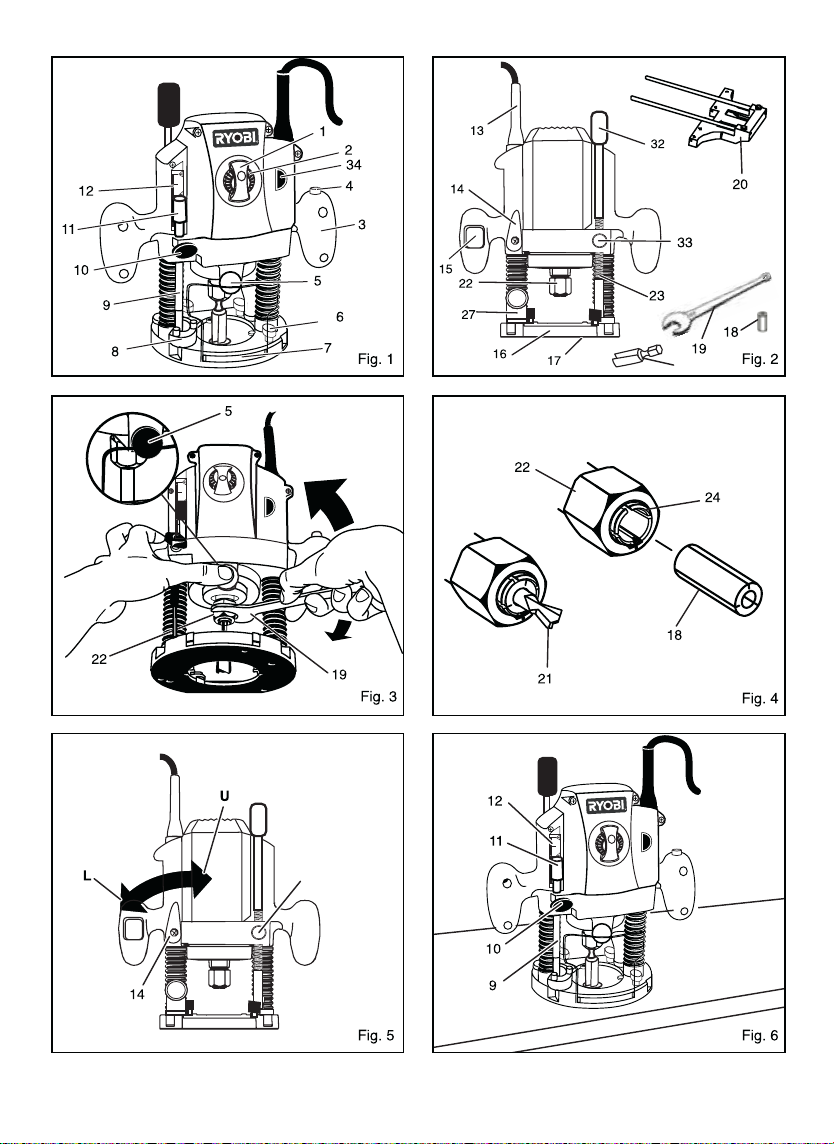

1. Speed selection

sight window

2. Variable speed control

3. Handle

4. Lock-off button

5. Spindle lock button

6. Parallel guide lock knob

7. Chip shield

8. Depth stop

20. Parallel guide

21. Cutter

22. Collet nut

23. Threaded post

24. Collet

25. Router bits

26. Work-piece

27. Dust port

28. Depth of cut

9. Depth stop bar

29. Width of cut

10. Depth stop bar lock knob

30. 1st pass

11. Depth zero reset indicator

31. 2nd pass

12. Scale

32.

Fine height adjuster knob

13. Power cord

33. Fine height adjuster

14. Plunge lock lever

quick release button

15. Switch

34. Livetool Indicator

TM

16. Router base

35. Template guide

17. Sub-base

36. Screw

18. Collet adaptor

19. Spanner 23.8mm

APPLICATIONS

Use your router only for the purposes listed below:

■

Routing grooves, shaping edges, freehand designs,

etc. in wood.

■

Chamfering, rabbeting, dadoing, and dovetailing in

wood.

■

Routing edges on laminates.

FEATURES

Your plunge router is a versatile woodworking tool that

will give you years of trouble-free performance. It is

engineered with the professional in mind, but its ease

of operation allows the amateur to produce work that is

beautiful and precise. As the name implies your plunge

router can be used for making plunge cuts in workpieces,

routing grooves, edge routing, routing circles and freehand

routing. When used with recommended accessories, such

as a router table, depth adjustment knob and straight guide;

it becomes even more versatile. Various types of cutters,

both with and without roller bearings as guides, also add

to the versatility of this tool.

HEAVY DUTY MOTOR

Your router has a powerful motor with sufficient power to

handle tough routing jobs. It delivers 1.5 horsepower for

heavy duty performance.

CHIP SHIELD

A plastic chip shield has been provided on the base of

your router for protection against flying dust and chips.

It is designed to fit the front opening of the router base.

SPINDLE LOCK

The spindle lock secures the spindle so that only one

wrench is needed to loosen collet nut and change

cutters. To operate push the button whilst loosening the

collet nut. NOTE: Do not run router with spindle lock engaged.

SPECIFIC SAFETY RULES

Peak horsepower : 1.5 HP

Net weight : 4.5 kg.

37. Locking anchor

Page 9

4

FEATURES

VARIABLE SPEED

Your router has advanced electronic features, designed to

assist you in getting the maximum use from your router.

By making proper speed selections, your router can be

adjusted to specific routing needs.

The variable speed control allows the router to develop a

no load speed that can be adjusted from 14,000 to 31,500

min-1. The variable speed control selector is conveniently

located on the front of the router.

The electronic feature of your router introduces the flexibility

of adjusting the motor speed to required

job conditions. An

electronic speed control module senses the load applied

to the motor and increases or decreases motor voltage to

compensate for and maintain desired RPM.

Speed can be

set according to the approximate cutter diameter you will

be using and to the hardness of the material being cut. The

best cuts are made when the cutter is fed through material

at the proper rate of feed.

PLUNGE LOCK LEVER

Your router has a plunge lock lever that allows for free

plunging. This feature is very useful for table mounted

operations on router tables when used with the fine height

adjuster quick release mechanism. Unlocking the plunge

lock lever and releasing the fine height adjuster allows for

a smooth, precise plunging action. Once you reach the

desired depth of

cut, simply lock the plunge lock lever. The

cutter will then be secured at the desired depth of cut.

After extended use, the plunge lock may wear. If this

happens, you can easily adjust the lever.

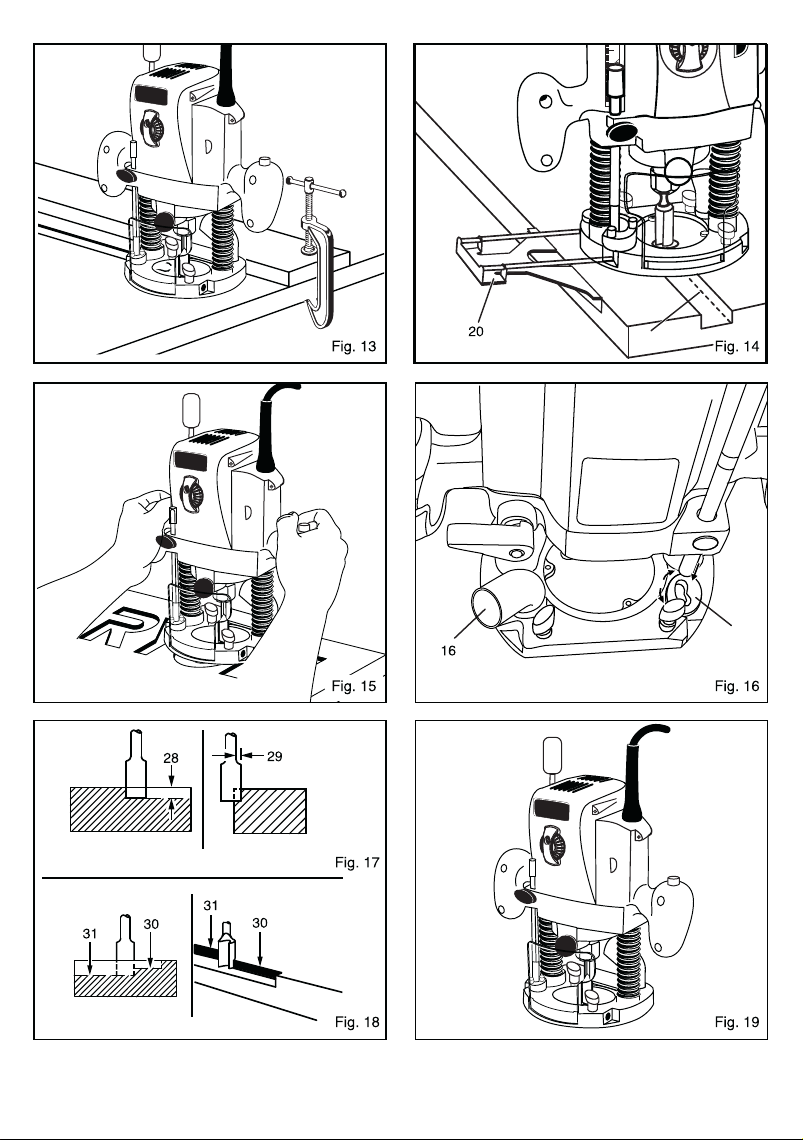

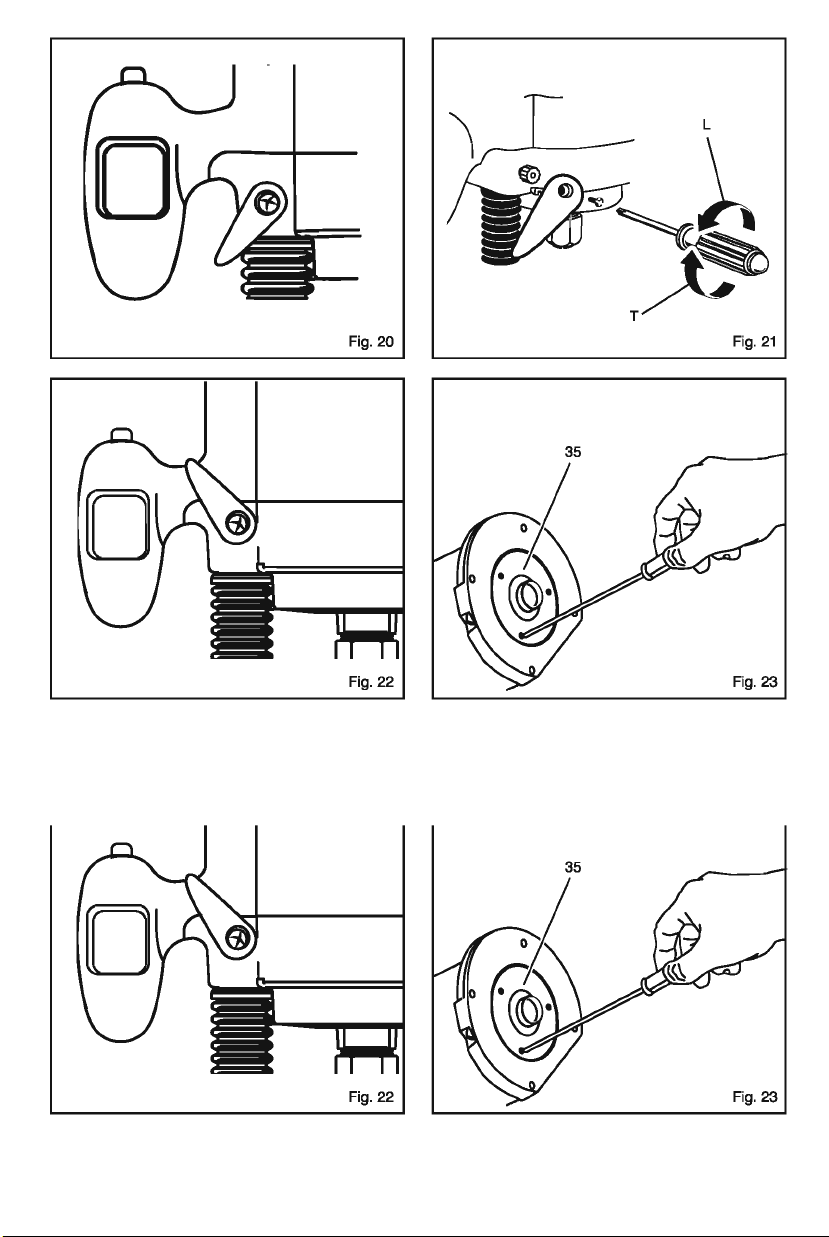

TO ADJUST PLUNGE LOCK LEVER (FIG. 21)

■

UNPLUG YOUR ROUTER.

WARNING:

Failure to unplug your router could result in

accidental starting causing serious injury.

■

Make sure lever is in locked position.

■

Remove (L) the screw supporting the plunge lock

lever.

■

Remove the lever.

■

Place the lever back in the original locked position.

■

Replace (T) the screw.

■

Check for free plunge with lever rotated to unlocked

position. If router does not plunge freely, reposition

lever.

PLUNGE LOCK LEVER SHOWN AFTER

EXTENDED WEAR (FIG. 20)

PLUNGE LOCK LEVER SHOWN IN ORIGINAL

LOCKED POSITION (FIG. 22)

TEMPLATE GUIDE (FIG. 23)

The template guide (35) can be fitted to the base of the

router to accurately duplicate curves and other complex

shape. These shapes can be easily made by using a jigsaw

to cut out a template. Fix the guide to the base of the router

by placing the guide in the recess provided in the base

and inserting the 3 screws provided. The guide protrudes

below the bottom of the base allowing the router to follow the

template, which must be securely fixed to the workpiece and

a firm pressure applied to the router at all times to ensure

that the edge of the guide accurately follows the template.

The template must be at least 5mm thick to allow for the

protrusion of the guide. Allowance must also be made in

the template for the distance between the cutting edge of

the bit and the outside edge of the template guide.

ERGONOMIC DESIGN

The design of this tool provides for easy handling. It is

designed for comfort and ease of grasp when operating

in different positions and at different angles.

ELECTRICAL CONNECTION

Your router has a precision built electric motor. It should

only be connected to a power supply of the type specified

on the rating plate of the machine, AC only. Do not operate

this tool on direct current (DC). A voltage drop of more than

10 percent will cause a loss of power and overheating.

If your tool does not operate when plugged into an outlet,

double-check the power supply.

DOUBLE INSULATION

Double insulation is a concept in safety in electric power

tools, which eliminates the need for the usual threewire grounded power cord. All exposed metal parts are

isolated from the internal metal motor components with

protecting insulation. Double insulated tools do not need

to be grounded.

Page 10

FEATIRES

5

ADJUSTMENTS

WARNING:

Your router should never be connected to power

supply when you are assembling parts, making

adjustments, installing or removing cutters or

when not in use. Disconnecting your router will

prevent accidental starting that could cause

serious injury.

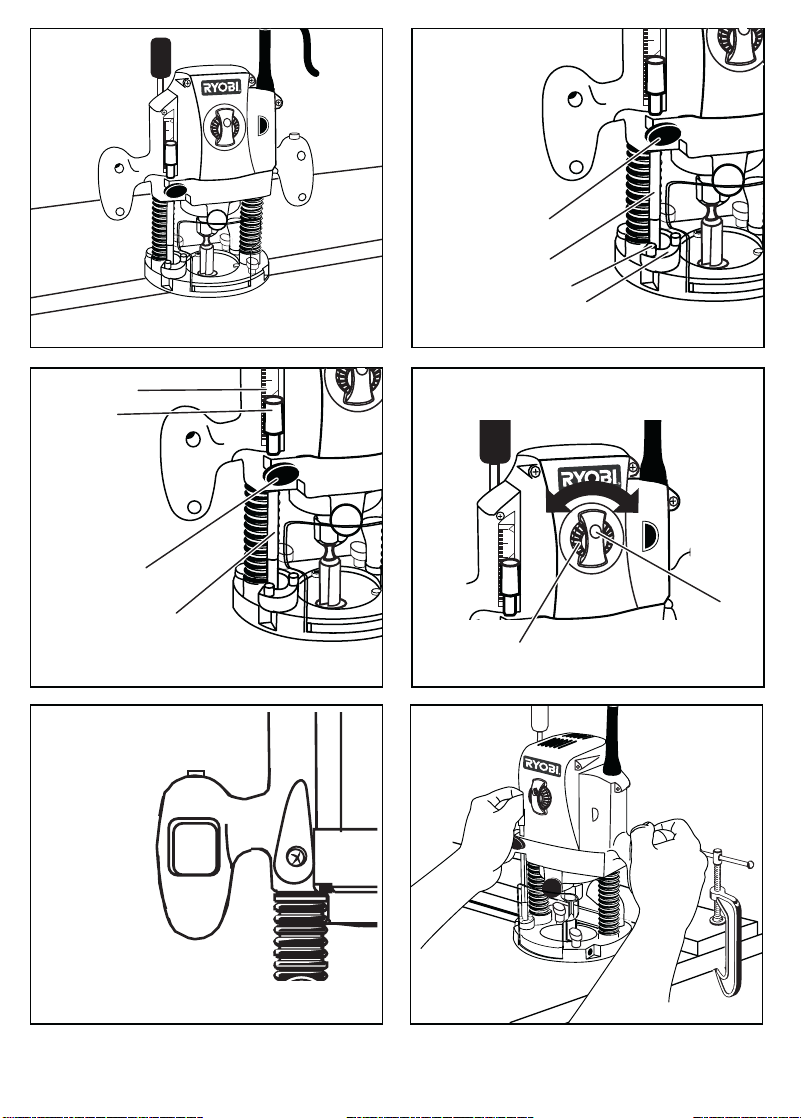

CUTTER INSTALLATION (FIG. 3 & 4)

■

UNPLUG YOUR ROUTER.

WARNING:

Failure to unplug your router could result in

accidental starting causing serious injury.

CAUTION:

To prevent damage to the spindle or spindle

lock, always allow motor to come to a complete

stop before engaging spindle lock.

■

Remove chip shield (7) from router base (16).

■

Depress spindle lock (5).

■

Lay router down on workbench in order to gain easy

access to collet nut (22). Place the spanner (19)

provided through front of router

and turn counterclockwise to loosen.

base onto collet nut

WARNING:

The double insulated system is intended to

protect the user from shock resulting from a

break in the tools internal wiring. Observe all

normal safety precautions to avoid electrical

shock.

Important: Servicing of a tool with double insulation

requires extreme care and knowledge of the system and

should be performed only by a qualified service

technician. For service, we suggest you return the tool to

your nearest authorized service center for repair.

WARNING:

Do not attempt to modify this tool or create

accessories not recommended for use with

this tool. Any such alteration or modification

is misuse and could result in a hazardous

condition leading to possible serious personal

injury.

ADJUSTMENTS

FEATURES

WARNING:

Your router should never be connected to power

supply when you are assembling parts, making

adjustments, installing or removing cutters or

when not in use. Disconnecting your router will

prevent accidental starting that could cause

serious injury.

CUTTER INSTALLATION (FIG. 3 & 4)

■

UNPLUG YOUR ROUTER.

WARNING:

Failure to unplug your router could result in

accidental starting causing serious injury.

CAUTION:

To prevent damage to the spindle or spindle

lock, always allow motor to come to a complete

stop before engaging spindle lock.

■

Remove chip shield (7) from router base (16).

■

Depress spindle lock (5).

■

Lay router down on workbench in order to gain easy

access to collet nut (22). Place the spanner (19)

provided through front of router

and turn counterclockwise to loosen.

base onto collet nut

WARNING:

If you are changing a cutter immediately after

use, be careful not to touch the cutter or collet

with your hands or fingers. They will get burnt

because of the heat buildup from cutting. Always

use the wrench provided.

■

Install cutter (21) once collet nut is loose. If changing

cutters, cutter will easily slip from collet (24) after

loosenin g c oll et nut. For ex amp le: The collet is

machined to precision tolerances to fit cutters with

12.7 mm diameter shanks. To use cutters with 6.35 mm

diameter shanks, insert the 6.35 mm collet adaptor (18)

into the 12.7 mm collet.

■

Insert shank of cutter until shank bottoms out, then pull

it out 1.6 mm to allow for expansion when the bit get hot.

■

Tighten the collet nut securely by turning clockwise

with the wrench provided.

■

Release spindle lock.

■

Replace chip shield.

WARNING:

If the collet nut is not securely tightened, the cutter

may detach during use causing serious personal

injury.

WARNING:

Do not use cutters with undersized shanks.

Undersized shanks will not tighten properly and

could be thrown from the tool causing injury.

WARNING:

Do not use cutters that are larger in diameter

than the opening in router base. Use of such

cutters will come in contact with the router base

and damage both the cutter and router base.

This situation could also cause possible loss of

control or create other hazardous conditions that

could cause possible serious personal injury.

DEPTH OF CUT

When routing a groove that is too deep to safely cut in

one pass, it is best to make the cut in several passes.

We recommend that cuts be made at a depth not

exceeding 3.2 mm and that several passes be made to

reach deeper cuts.

Proper depth of cut depends on several factors

Page 11

6

horsepower of router motor, type of cutter being used and

type of wood being routed. A lightweight, low horsepower

router is designed for making shallow cuts. A router with

h

igh horsepower rating can safely cut

deeper. For example:

small bits (21), such as veining b

its with 1.6mm cutting

diameters, are

designed to remove only small amounts or

small amounts of wood. Large bits, such as straight-flute

b

its, are made to remove

larger amounts of wood in a single

pass. Cuts can be

made deeper in soft woods, such as

white pine, than in

tough hardwoods, like oak or maple.

Based upon these considerations, choose a depth of cut

that will not place excessive strain on router motor. If you

fi

nd that extra

force is needed or that the motor speed

slows down

considerably, turn off router and reduce the

depth of cut.

Then, make the the cut in two or more passes.

TO ADJUST DEPTH OF CUT (FIG. 5-7)

■

Loosen the stop bar (9)

■

Unlock (U) the plunge lock lever (14).

■

Lower the router body until the cutter is in contact with

the work-piece.

■

Lock the depth stop (8) at the right height.

■

Set the exact depth of cut using the graduation. The

distance between the stop bar (9) and screw of the

depth stop (8) is setting plunge depth.

■

Tighten the stop bar lock knob (10) to set depth of

plunge.

DEPTH STOP (FIG. 8 & 9)

■

The depth stop (8) can be used to set three different

depths. This is particularly useful for deep cuts

performed in steps.

■

If required, set all three screws.

VARIABLE SPEED CONTROL SELECTOR

(FIG. 10)

Your router has a variable speed control selector (2)

designed to allow operator control of speed and torque

l

imits. Yo

u can make speed selections best suited to

the type of cut, the material being cut, and the size of bit

b

eing u

sed. The variable speed control selector allows

ADJUSTMENTS

you to adjust router speed from 14,000 to 31,500 min-1.

There is a six step scale (A to F) on the variable speed

control selector. To increase the speed and torque of your

router, turn the variable speed control selector to a higher

s

etting (F). Tu

rn to a lower setting to decrease speed

and torque.

NOTE: If you do not want to use the variable speed control

selector, turn it to the highest possible setting, and the

feature will not be active.

We s

uggest that you practice with the variable speed

feature of your router before installing a cutter and making

cuts in wood.

ZERO RESET INDICATOR

The zero reset indicator(11) allows you to use the scale

provided o

n the housing to make quick depth of cut

changes to existing depth of cut settings. Simply choose

a reference point on the scale and slide the zero reset

indicator up or down the scale the distance required for

n

ew d

epth of cut. Then change stop bar position by

loosening lock knob and adjusting stop bar until red line

on zero reset indicator moves back to reference point.

Ti

ghten lock knob securely to lock stop bar in new position.

The c

utter position will now increase or decrease the exact

distance the stop bar was adjusted.

NOTE: Each mark on the inch scale indicates 1.6 mm.

OPERATION

SWITCH (FIG.11)

To turn the router ON, press the lock-off button (4) and

squeeze the switch (15). To turn the router OFF, release

both the switch & lock-off button.

CAUTION:

We suggest that you practice with your router

before installing a cutter and making cuts in

wood.

Livetool IndicatorTM (34)

This tool features a Livetool IndicatorTM which illuminates

as soon as the tool is connected to the power supply. This

warns the user that the tool is connected to live power

and will operate when the switch is pressed.

ROUTING (FIG. 12)

For ease of operation and maintaining proper control,

your router has two handles (3), one on each side of the

Page 12

7

router. When using your router hold it firmly with both

hands.

Before starting the router, unplug it and make sure the

cutter is securely tightened in collet nut and that depth of

cut is properly set.

Plug router into power supply, turn it on and let motor

build to its full speed, then gradually plunge or feed cutter

into workpiece. Do not let the cutter contact workpiece

before turning on router and allowing it to develop full

speed.

Remain alert and watch what you are doing. Do not operate

router when fatigued or under the influence of drugs,

alcohol or any medication.

ROUTING GROOVES (FIG. 13)

When routing across the face of boards, set router at

desired depth of cut, place the edge of router base against

workpiece and turn on the router. Slowly feed the cutter

into the workpiece along desired line of cut.

WARNING:

If desired depth of cut is greater than can be

safely cut in one pass, make cuts in two or more

passes.

When routing straight cuts across timber, clamp a straight

edge to the workpiece to use as a guide. Position the

straight edge parallel to the line of cut and offset the

distance between the cutting edge of the cutter and the

edge of the router base. Hold the route base against

the straight edge and route the groove.

When routing a groove wider than the diameter of the

cutter, clamp a straight edge on both sides of the cutlines. Position both guides parallel to the desired line of

cut and spaced equal distances from the desired edges

of the groove. Route along one guide; then, reverse

direction and route along the other guide. Clean out any

remaining waste in the center of the groove freehand.

FITTING AND ADJUSTING THE PARALLEL

GUIDE (FIG. 14)

■

Insert the parallel guide (20) into the hole of the Router

base (16).

■

Draw a cutting line on the work-piece (26).

■

Lower the router body until the cutter is in contact

with the work-piece.

OPERATION

■

Postion the router on the cutting line. The outer cutting

edge of the cutter must coincide with the cutting line.

■

Without moving the router push the guide to the edge

of the workpiece before tightening the lock knob (6).

ROUTING BY FREEHAND (FIG. 15)

When used freehand, your plunge router becomes a

flexible and versatile tool. This flexibility makes it possible to easily route signs, relief sculptures, etc. There are

two basic techniques for freehand routing:

■

Routing letters, grooves and patterns into wood.

■

Routing out the background, leaving the letters or

pattern raised above the surface.

When freehand routing, we suggest the

following:

■

Draw or layout the pattern on workpiece.

■

Choose the appropriate cutter.

NOTE: A core box or V-groove bit is often used for

routing letters and engraving objects. Straight bits

and ball mills are often used to make relief carvings.

Veining bits are used to carve small, intricate details.

■

Route the pattern in two or more passes. Make the

first pass at 25% of the desired depth of cut. This

process will provide better control as well as being a

guide for the next pass.

■

Do not route deeper than 3.2 mm per pass or cut.

Follow these directions when routing by

freehand:

■

Choose the appropriate cutter, set desired depth of

cut, carefully check set-up, and secure workpiece.

■

Make a test cut in a scrap piece of wood from the

same workpiece if possible.

■

Unlock plunge lock lever to raise cutter from any preset

depth of cut. This also permits raising cutter inside

router base.

■

Place router on wor kpi ece ins ide patter n to be

routed.

■

Grasp handles securely and press the switch to start

your router.

Page 13

OPERATION

■

Let motor build to full speed, then gradually plunge

cutter into workpiece until stop bar comes into contact

with depth stop.

■

Lock plunge lock lever to secure depth of cut setting.

■

Begin routing out the pattern, continuing until a

complete pass at this depth of cut has been made.

WARNING:

Do not use large router bits for freehand routing.

Use of large router bits when freehand routing

could cause loss of control or create other

hazardous conditions that could cause possible

serious personal injury.

■

Several cuts that require repositioning of router may

be needed for a particular job. If this situation exists,

unlock plunge lock lever to raise cutter inside router

base after each cut, reposition router for next cut,

gradually plunge cutter into workpiece until stop bar

c

ontacts depth stop, lock plunge lock lever and continue

routing.

■

■

After all cuts have been made, unlock plunge lock

lever, raise cutter inside router base, remove router

from workpiece, turn off the router and allow cutter to

come to a complete stop.

ROUTING EDGES

Place router on workpiece, making sure the router bit

does not contact workpiece. Turn router on and let the

m

otor b

uild to its full speed. Begin your cut, gradually

feeding cutter into workpiece.

WARNING:

Keep a firm grip on router with both hands at all

times. Failure to do so could result in loss of

control leading to possible serious injury.

Upon completion of cut, turn motor off and let it come to

a complete stop before removing router from work

surface.

WARNING:

Never pull router out of work and place upside

down on work surface before the cutter stops.

CONNECTING A DUST EXTRACTOR (FIG. 16)

The dust extractor hose can be connected to the dust

extraction port located on the base with a 25.4mm O.D.

FINE HEIGHT ADJUSTER (32)

It is used to precisely control the depth of the cutter.

■

To use the fine height adjuster, ensure that the

plunge lock is released.

■

Ro tat e the knob clockw ise to rai se the cut ter,

anticlockwise to lower the cutter.

■

When the desired position is reached, re-engage the

plunge lock before use.

FINE HEIGHT ADJUSTER QUICK RELEASE

BUTTON (33)

This disengages the fine height adjuster allowing a large

adjustments of plunge depth to be quickly made.

■

To make large adjustments to cutter height, ensure

that the plunge lock is released.

■

Press the quick release button whilst plunging the

router to the required height.

■

Release the button, check the height, make fine

adjustments if necessary with the fine height adjuster,

then re-engage the plunge lock before use.

8

LOCKING ANCHOR FOR THREADED FINE

HEIGHT ADJUSTMENT ROD (FIG. 16)

The locking anchor (37) is located on the base of the router,

it is designed to hold the threaded fine height adjustment

rod in place to allow the fine height adjustment to

operate. When the fine height adjustment is required,

release the fine height adjuster quick release button and

push down on the fine height adjuster knob so that the

bottom of the threaded rod makes contact with the base

and locking anchor. Make sure the locking anchor is

positioned so that the bottom of the threaded rod goes into

the right hand side of the elongated hole (the larger side

of the opening). Once in place turn the locking anchor to

the right to secure the threaded rod. To release, turn the

locking anchor to the left and push the fine height

adjuster quick release button and pull the fine height

adjuster knob upwards.

Page 14

9

MAINTENANCE

WARNING:

When servicing use only identical Ryobi replace-

ment parts. Use of any other parts may create a

hazard or cause product damage.

GENERAL

Avoid using solvents when cleaning plastic parts. Most

plastics are susceptible to damage from various types of

commercial solvents and may be damaged by their use.

Use clean cloths to remove dirt, carbon dust etc.

WARNING:

Do not at any time let brake fluids, petrol, petroleum

- based products, penetrating oils etc. come in

contact with plastic parts. They contain chemicals

that can damage, weaken or destroy plastic.

Electric tools used on fiberglass material, wallboard,

spackling compounds or plaster are subject to

acelerated wear and possible premature failure, as the

fiberglass chips and grindings are highly abrasive to

bearings, brushes, commutators etc. Consequently, we

do not recommended that this tool be used for extended

work on these types of materials. If, however, you do

work with any of these materials, it is extremely important that you clean the tool frequently by blowing it with

an air jet.

WARNING:

Always wear safety goggles or safety glasses

with side shields during power tool operation or

when blowing dust. If operation is dusty, also

wear a dust mask.

LUBRICATION

All of the bearings in this tool are lubricated with a sufficient

amount of high grade lubricant for the life of the unit under

normal operating conditions. Therefore, no further lubrication

is required.

CUTTERS

Get faster and more accurate cutting results by keeping

cutters clean and sharp. Remove all accumulated pitch

and gum from cutters after each use.

When sharpening cutters, sharpen only the inside of the

cutting edge. Never grind the outside diameter. Be sure

when sharpening the end of a cutter to grind the

clearance angle the same as originally ground.

COLLET

Dust and chips may collect on the collet from time to time,

making it necessary to clean the collet. To do so, remove

the collet assembly and wipe it with a clean dry cloth.

Clean the taper in the shaft in the same manner. Never

immerse the collet or end of the shaft in a solvent or in

water. Before replacing the collet assembly, put a drop

of motor oil on the inside of the nut, on the threads of the

shaft and on the taper in the shaft. Replace the collet

assembly onto the shaft by hand only. Never tighten the

collet nut without a bit in the collet. This action could

permanently damage the collet.

ADJUSTMENTS

DEPTH OF CUT

As previously mentioned, the depth of cut (30) is important

because it affects the rate of feed that, in turn, affects the

quality of the cut (and also, the possibility of damage to

your router motor and bit). A deep cut requires a slower

feed than a shallow one, and a too deep cut will cause

you to slow the feed so much that the bit is no longer

cutting, it is scraping, instead.

Making a deep cut is never advisable. The smaller bits

— are easily broken off when subjected to too much side

thrust. A large enough bit may not be broken, but if the

cut is too deep a rough cut will result — and it may be very

difficult to guide and control the bit as desired. For these

reasons, we recommend that you do not exceed 3.2 mm

depth of cut in a single pass, regardless of the bit size or

the softness or condition of the workpiece. To make deeper

cuts it is therefore necessary to make as many successive

passes as required, lowering the bit 3.2mm for each new

pass. In order to save time, do all the cutting necessary

at one depth setting, before lowering the bit for the next

pass. This will also assure a uniform depth when the final

pass is completed.

Page 15

RYOBI TECHNOLOGIES AUSTRALIA PTY. LTD.

GUARANTEE

RYOBI TECHNOLOGIES AUSTRALIA PTY. LTD.

A.B.N. 98 002 277 509

SYDNEY: 359-361 Horsley Road, Milperra, N.S.W. 2214.

Contact during normal business hours.

RYOBI NEW ZEALAND PTY. LTD.

AUCKLAND: 27 Clemow Drive, Mt Wellington, N.Z.

Contact during normal business hours.

Subject to the guarantee condition below, this Ryobi tool

(hereinafter called “the product”) is guaranteed by Ryobi

(hereinafter called “the Company”) to be free from

defects in material or workmanship for a period of 24

months from the date of original purchase covering

both parts and labour. Under the terms of this

guarantee, the repair or replacement of any part shall

be the opinion of the Company or its authorised agent.

Should service become necessary during the warranty

period, the owner should contact the RYOBI HELPLINE

1300 361 505 or contact the retailer from whom the

product was purchased.

In order to obtain guarantee service, the owner must

present the sales docket and Guarantee Certificate

to confirm date of purchase. This product is sold by the

dealer or agent as principal and the dealer has no

authority from the Company to give any additional

guarantee on the Company’s behalf except as herein

contained or herein referred to.

Guarantee Conditions

This guarantee only applies provided that the Product

has been used in accordance with the manufacturer’s

recommendations under normal use and reasonable

care (in the opinion of the Company) and such

guarantee does not cover damage, malfunction or

failure resulting from misuse, neglect, abuse, or used

for a purpose for which it was not designed or is not

suited and no repairs, alterations or modifications

have been attempted by other than an Authorised

Service Agent. This guarantee will not apply if the tool is

damaged by accident or if repairs arise from normal

wear and tear.

The Company accepts no additional liability pursuant to

this guarantee for the costs of travelling or

transportation of the Product or parts to and from the

service dealer or agent - such costs are not included in

this guarantee.

Certain legislation, including the Trade Practices Act,

1974 (as amended) and other state and territorial laws

give rights to the buyer and impose liability on the seller in

certain circumstances. Nothing herein shall have the effect

of excluding, restricting or modifying any condition,

guarantee, right or liability imposed, to the extent only

that such exclusion, restriction or modification

would render any term herein void.

BRISBANE : All enquiries Tel : 1300 361 505

TOWNSVILLE: All enquiries Tel : 1300 361 505

MELBOURNE: 960 Stud Road, Rowville,Vic. 3178

Tel : (03) 9764 8656

HOBART: All enquiries Tel : 1300 361 505

ADELAIDE: All enquiries Tel : 1300 361 505

PERTH: 33-35 Sorbonne Cres. Canning Vale, W.A. 6155

Address Of Dealer

Present This Form With Your Purchase Docket When Guarantee Service Is Required.

Tel: (02) 9792 9800 - Fax: 1800 807 993 - www.ryobi.com.au

Tel: (09) 573 0230 - Free Call: 0800 279 624 - Fax: (09) 573 0231 - www.ryobi.co.nz

Tel : (08) 9455 7775

This Guarantee Form Should Be Retained By The Customer At All Times

For your record and to assist in establishing date of purchase (necessary for in-guarantee service)

please keep your purchase docket and this form completed with the following particulars.

Date Model No Serial No

Loading...

Loading...