Page 1

OWNER’S OPERATING MANUAL

1200 WATT ELECTRONIC ROUTER

MODEL ERT241200

SPECIFICATIONS :

Power Input....................1200 watt

No Load Speed..............15000 - 33000 r.p.m.

Collet Capacity...............1/2”, 1/4”

Weight............................3.8 kg

DOUBLEDOUBLE

DOUBLE

DOUBLEDOUBLE

INSULATEDINSULATED

INSULATED

INSULATEDINSULATED

THANK YOU FOR BUYING A RYOBI ELECTRONIC ROUTER

Your new router has been engineered and manufactured to Ryobi's high standard for

dependability, ease of operation, and operator safety. Properly cared for, it will give you years of

rugged, trouble free performance.

CAUTION: Carefully read through this entire owner's manual before using your

router.

Pay close attention to the Rules for Safe Operation, Warnings, and Cautions.

If you use your router properly and only for what it is intended, you will enjoy years of safe,

reliable service.

Thank You again for buying Ryobi tools.

SAVE THIS MANUAL FOR FUTURE REFERENCE.

Page 2

RULES FOR SAFE OPERATION

The purpose of safety rules is to attract your attention to possible

dangers. The safety symbols and the explanations with them,

require your careful attention and understanding. The safety

warnings do not by themselves eliminate any danger. The

instruction or warnings they give are not substitutes for proper

accident prevention measures.

SAFETY ALERT SYMBOL. Indicates caution or

warning. May be used in conjunction with other

symbols or pictures.

WARNING: Failure to obey a safety warning can

result in serious injury to yourself or to others.

Always follow the safety precautions to reduce the

risk of fire, electric shock and personal injury.

WARNING: Do not attempt to operate this tool until

you have read thoroughly and understood

completely, safety rules, etc. contained in this

manual. Failure to comply can result in accidents

involving fire, electric shock or serious personal

injury. Save owners manual and review frequently

for continuing safe operation and instructing others

who may use this tool.

The operation of any tool can result in

foreign objects being thrown into your

eyes, which can result in severe eye

damage. Before beginning power tool

operation, always wear safety goggles

a full face shield when needed. We recommend Wide Vision

Safety Mask for use over eyeglasses or standard safety

glasses with side shields.

1. KNOW YOUR POWER TOOL. Read owners manual carefully.

Learn its applications and limitations as well as the specific

potential hazards related to this tool.

2. GUARD AGAINST ELECTRICAL SHOCK BY PREVENTING

BODY CONTACT WITH GROUNDED SURFACES. For

example, pipes, radiators, ranges, refrigerator enclosures.

3. KEEP WORK AREA CLEAN. Cluttered areas and benches

invite accidents.

4. AVOID DANGEROUS ENVIRONMENT . Don't use power tools

in damp or wet locations or expose to rain. Keep work area

well lit.

5. KEEP CHILDREN AND VISITORS AWAY. Visitors should

wear safety glasses and be kept a safe distance from work

area. Do not let visitors contact tool or extension cord.

6. STORE IDLE TOOLS. When not in use, tools should be stored

in a dry and high or locked-up place, out of reach of children.

7. DON'T FORCE TOOL. It will do the job better and safer at the

rate at which it was designed.

8. USE RIGHT TOOL. Don't force small tool or attachment to do

the job of a heavy duty tool. Don't use tool for purpose not

intended.

9. DRESS PROPERLY. Do not wear loose clothing or jewellery.

They can be caught in moving parts. Rubber gloves and nonskid footwear are recommended when working outdoors. Also

wear protective hair covering to contain long hair.

or safety glasses with side shields and

10.ALWAYS WEAR SAFETY GLASSES. Everyday eyeglasses

have only impact resistant lenses, they are not safety glasses.

11.PROTECT YOUR LUNGS. Wear a dust mask if operation is

dusty.

12. PROTECT YOUR HEARING. Wear hearing protection during

extended periods of operation.

13.DON'T OVERREACH. Keep proper footing and balance at

all times. Do not use tool on a ladder or unstable support.

Secure tools when working at elevated levels.

14. MAINTAIN TOOLS WITH CARE. Keep tools sharp and clean

for better and safer performance. Follow instructions for

lubricating and changing accessories.

15. REMOVE ADJUSTING KEYS AND WRENCHES. Form a

habit of checking to see that keys and adjusting wrenches

are removed from tool before turning it on.

16. NEVER USE IN AN EXPLOSIVE ATMOSPHERE. Normal

sparking of the motor could ignite fumes.

17. KEEP HANDLES DRY, CLEAN AND FREE FROM OIL AND

GREASE. Always use a clean cloth when cleaning. Never

use brake fluids, gasoline, petroleum based products, or any

strong solvents to clean your tool.

18.STAY ALERT AND EXERCISE CONTROL. Watch what you

are doing and use common sense. Do not operate tool when

you are tired. Do not rush operation of tool.

19.CHECK DAMAGED PARTS. Before further use of the tool,

a guard or any other part that is damaged should be carefully

checked to determine that it will operate properly and perform

its intended function. Check for alignment of moving parts,

binding of moving parts, breakage of parts, mounting and

any other conditions that may affect its operation. A guard or

any other part that is damaged should be properly repaired

or replaced by an authorised service centre.

20.DO NOT USE TOOL IF SWITCH DOES NOT TURN IT ON

AND OFF. Have defective switches replaced by authorised

service centre.

21.DO NOT OPERATE THIS TOOL WHILE UNDER THE

INFLUENCE OF DRUGS, ALCOHOL OR ANY

MEDICATION.

22. THE APPLIANCE IS NOT INTENDED FOR USE BY YOUNG

OR INFIRM PERSONS WITHOUT SUPERVISION. YOUNG

CHILDREN SHOULD BE SUPERVISED TO ENSURE THAT

THEY DO NOT PLAY WITH THE APPLIANCE.

SAVE THESE INSTRUCTIONS

FOR FUTURE REFERENCE

Due to continued product

refinement policy, product features

and specifications can and will

change without notice. Check

current features and specifications

with your retailer.

Page 3

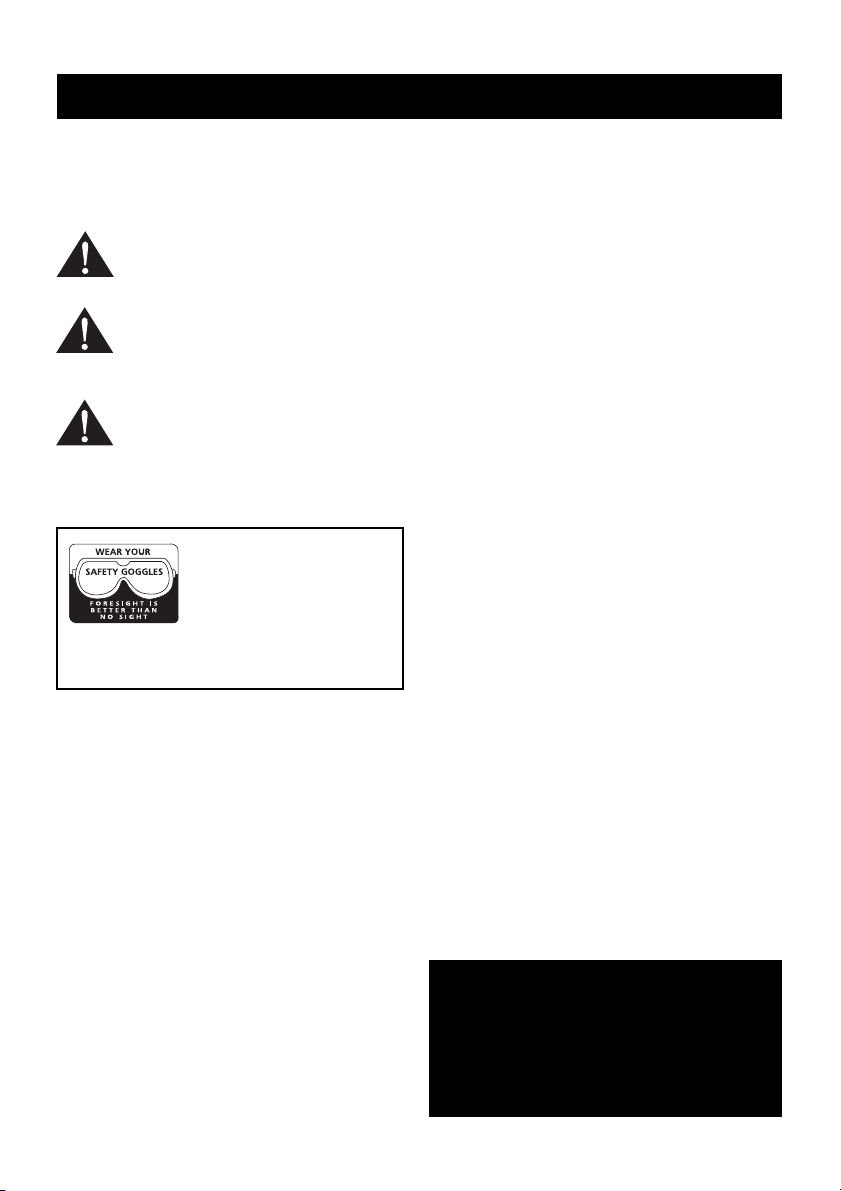

On/Off

Switch

Variable Speed

Control

Depth Set Pole

Straight Guide

Fence Locking

Knobs

Parallel

Fence

Spanner

Template

Guide

Screws

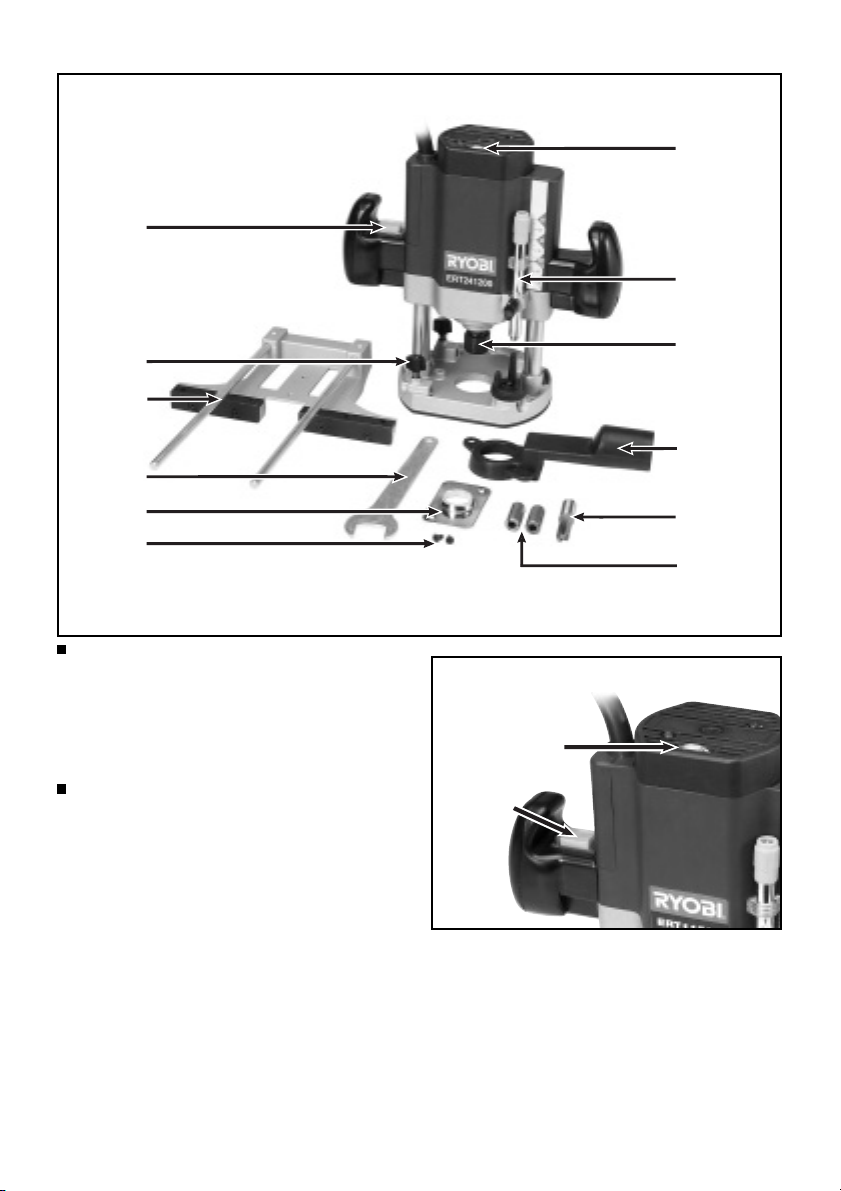

ON/OFF SWITCH (Fig 1)

Your ERT241200 Router starts and stops by depressing the

On/Off Switch located on the body of the tool. Push the switch

down to start the Router. It will lock into place, allowing you to

remove your finger while the Router remains in operation.

Always ensure you are holding the Router properly before

depressing the switch to turn the tool on. To turn the Router

off, simply push the switch up.

VARIABLE SPEED CONTROL (Fig 1)

Your Router features variable speed control to greatly increase

the versatility of the tool. This can be used to adjust the

rotational speed of the bit to its size and the material being

worked on.

NOTE: Select high speed for larger router bits and heavy

grained timber. Use lower speed only for very small router

bits and composition board. Do not overload the router

as this may cause motor damage at lower speed.

Speed Setting

The actual speed will depend on the material and other

conditions and is best determined by use on a scrap piece of

material before routing the actual workpiece.

NOTE: Do not run the tool at low speeds for extended

periods without occasionally running at high speed with

no load applied. At lower speeds the fan does not cool the

motor as effectively as it does at high speed and the motor

may overheat.

Fig 1

On/Off

Switch

Variable Speed

Control

Collet Nut

Dust Port

1/4” Straight

Cutted Bit

Collets

Page 4

DUST EXTRACTION (Fig 2 )

Mount the dust port on the base with hexagon screws supplied.

It is advisable to have the outlet on the opposite side from the

On/Off switch on the body of the Router to allow free access to

the On/Off switch. The dust port can be connected to the dust

extraction channel.

NOTE: Outlet is on the opposite side of the body to the On/Off

switch.

Fig 2

INSTALLING & REMOVING ROUTER BITS (Fig 3 & 4)

Ensure that the bit you wish to use is suited for your Router. It

must be capable of at least 28000 r.p.m

Also, ensure that the tool is switched off and unplugged before

installing or removing the bit.

Before use, check that the bit to be installed for any cracks or

chips. If the bit shows any sign of damage do not use it.

Insert the bit into the collet to a depth of at least twice its

diameter. Finger tighten the collet nut until the bit is held in

place. Depress spindle lock button (situated above the collet)

with finger, locking spindle into place. With the spanner

provided, firmly tighten the collet nut until the bit is securely

held.

Never tighten the collet nut without a cutter bit in the collet.

Be sure to remove the spanner then plug the unit to the power

supply. Turn the Router on to check for any undue vibration or

wobbling which may indicate the bit is damaged or not properly

WARNING Router bits are extremely sharp

Take care when inserting and removing bits

as they can cause serious injury.

Removal is a reverse of the above procedure.

WARNING Do not tighten the collet nut

without first inserting a bit or damage to the

collet cone will result.

Fig 3

Spindle Lock Button

Fig 4

installed.

LOCK LEVER (Fig 5 & 6)

The lock lever on your Router is adjustable. To place the lever

in a position with which you are comfortable, remove the phillips

head screw, pull the lever off its retaining shaft then place it to

your preferred position and re-tighten the screw.

SETTING THE DEPTH OF CUT (Fig 7)

1. Insert the bit into the Router as outlined previously.

2. Loosen the wing screw retaining the depth set pole.

3. With the Router on a flat surface, loosen the lock lever and

lower the Router body until the bit just touches the surface.

Tighten the lock lever.

4. Lift up the depth set pole and lift and rotate the triple depth

set block to a suitable position.

5. Allow the depth set pole to rest on the threaded bolt in the

triple depth set block and note the scale reading where it

enters the upper housing.

6. Add the require depth of cut to the scale reading (in mm),

move the depth set ploe up to the reading and tighten the

wing screw.The Router is now set for the required depth.

NOTE: Always do a trial run of a new set depth on a scrap

piece of material to ensure the depth of cut is exactly as

required.

NOTE: When you have plunged the router into the timber

Page 5

Lock Lever

Lock

Lever

Fig 5

Lock Lever

Fig 6

to the required depth it is essential that the depth setting

lock lever be locked TIGHTLY into the locked position.

If making a deep cut, it is advisable to make more than one

pass to achieve the desired depth. The depth of cut achievable

with each pass depends greatly on the size of the bit and the

material being worked. Excessive depth of cut will unduly labour

the motor, place excessive strain on the bit, make the Router

more difficult to control and significantly reduce the quality of

the cut being made.

The triple depth set block can be used to assist in making

multiple passes, particularly when working on more than one

piece of material. If the final depth of cut is set using the shortest

of the three threaded bolts, the two longer bolts can be set to

two appropriately shallower depths. Using the block in this

manner removes the necessity for resetting the depth set pole

for each pass.

ROUTING

1. Be sure the work piece is clamped or otherwise firmly

secured.

2. Switch on the Router and allow the motor to come up to the

full selected speed.

3. Plunge the bit down into the work piece to the set depth and

firmly lock it in place with the lock lever.

4. Holding the tool firmly with both hands, progress smoothly

through the cut until complete.

Wing

Screw

Fig 7

5. Release the lock lever and allow the bit to come free of the

Fig 8

Scale

Reading

Depth

Set Pole

Trip Depth

Set Block

CUTTING

BLADE

LAMINATE

BENCH TOP

BEARING

BEARING

SCREW

EDGE

work piece before removing the Router.

TRIMMING (Fig 8)

1. You must select a bit that has a bearing attached.

2. When trimming follow Router directions.

3. To sight work easier, dust extractor might need to be

removed.

4. NOTE: If the edge where your bearing is running along is

laminated or veneered, run some masking tape along it to

protect the surface.

5. The bearing changes the distance trimmed. Different bearing

size are available from your retailer.

6. Always check that the trimming bit blade does not damage

other surfaces.

DIRECTION OF FEED

The Router motor, and therefore the bit, revolves in a clockwise

direction. This gives the tool a tendency to twist counter

clockwise in your hands, particularly when starting the tool. The

router bits are designed to use this clockwise rotation to assist

in the cutting and clearing of the material. Therefore when using

Page 6

the Router it should always be moved from left to right as you

are facing the workpiece. When cutting edges, move the Router

anti-clockwise for outside edges and clockwise when cutting

inside edges.

RATE OF FEED

The rate at which the Router is moved through the material

has a significant effect on the quality of the cut and the length

of service you will get from your Router and bits.

Moving the Router through the cut too fast, as well as possibly

overloading the tool and damaging the bit, will cause the bit to

take larger pieces of material with each rotation, thereby causing

a rough, uneven cut.

Moving the Router through the cut too slowly tends to cause

burning of the timber and if excessive, will cause overheating

of the bit.

The proper feed rate to use depends on the bit size, the mateial

being cut, the depth of cut and the speed selected. With all

these variables the best way to ensure that you get the best

quality and efficiency of cut is to practice on a scrap piece of

the same material to get a feel for what feed rate to use. This

will also show you exactly how the cut will look and allow you

to check your cutting depth.

STRAIGHT CUTS (Fig 9 & 10)

The straight guide is used for straight cuts along a work piece

with a straight edge that can be followed. To use the guide

attach the two fence poles to the fence bracket with the allen

screws provided. Attach the fence to the Router base by passing

the poles through the holes provided in the base and fix it in

the required position.NOTE: It is essential that the 2 straight

fence locking knobs be locked TIGHTLY into the locked

positions. Make sure that each of the poles passes through

both holes in the base otherwise there may be some movement

that will cause the cut to not be exactly parallel with the

reference edge.

If the edge is too far away from the fence to reach whilst still

keeping the poles retained in the base, or there is not a straight

Fig 10

edge ot follow, a piece of wood or other straight material can

be clamped alongside where the cut is to be made. The straight

edge of the base can then be used to guide the Router instead

of the fence.

TEMPLATE GUIDE (Fig 11)

The template guide can be fitted to the base of the Router to

accurately duplicate curves and other complex shapes. These

shapes can be easily made by using a jigsaw to cut out the

Fig 11

Template Guide

Fig 9

required designs. Fix the guide to the base of the Router by

removing the two screws retaining the dust extraction duct,

placing the guide in the recess provided in the base and

replacing the screws. The dust extraction duct must be in place

when fitting the guide to hold the screws.

The guide protrudes below the bottom of the base allowing the

Router to follow the template.

A template must be securely fixed to the workpiece and a firm

pressure applied to the Router at all times to ensure that the

edge of the guide accurately follows the template. The template

must be at least 5mm thick to allow for the protrusion of the

guide. Allowance must also be made in the template for the

distance between the cutting edge of the bit and the outside

edge of thd guide.

Page 7

RYOBI TECHNOLOGIES AUSTRALIA PTY . LTD.

GUARANTEE

Subject to the guarantee condition below, this Ryobi tool

(hereinafter called “the product”) is guaranteed by Ryobi

(hereinafter called “the Company”) to be free from

defects in material or workmanship for a period of 24

months from the date of original purchase covering

both parts and labour. Under the terms of this

guarantee, the repair or replacement of any part shall

be the opinion of the Company or its authorised agent.

Should service become necessary during the warranty

period, the owner should contact the Authorised Ryobi

Retailer from whom the Product was purchased, or the

nearest Company Branch Office. In order to obtain

guarantee service, the owner must present the sales

docket and Guarantee Certificate to confirm date of

purchase. This product is sold by the dealer or agent as

principal and the dealer has no authority from the

Company to give any additional guarantee on the

Company’s behalf except as herein contained or herein

referred to.

Guarantee Conditions

This guarantee only applies provided that the Product

has been used in accordance with the manufacturer’s

recommendations under normal use and reasonable

care (in the opinion of the Company) and such

RYOBI TECHNOLOGIES AUSTRALIA PTY. LTD.

A.B.N. 98 002 277 509

SYDNEY: 359-361 Horsley Road, Milperra, N.S.W. 2214.

Contact during normal business hours.

Tel: (02) 9792 9888 - Fax: 1800 807 993 - Email: info@ryobi.aust.com

BRISBANE: All enquiries Tel : 1300 361 505

TOWNSVILLE: All enquiries Tel : 1300 361 505

MELBOURNE: 960 Stud Road, Rowville,Vic. 3178

Tel : (03) 9764 8655

guarantee does not cover damage, malfunction or

failure resulting from misuse, neglect, abuse, or used

for a purpose for which it was not designed or is not

suited and no repairs, alterations or modifications

have been attempted by other than an Authorised

ServiceAgent. This guarantee will not apply if the tool is

damaged by accident or if repairs arise from normal

wear and tear.

The Company accepts no additional liability pursuant to

this guarantee for the costs of travelling or

transportation of the Product or parts to and from the

service dealer or agent - such costs are not included in

this guarantee.

Certain legislation, including the Trade Practices Act,

1974 (as amended) and other state and territorial laws

give rights to the buyer and impose liability on the seller in

certain circumstances. Nothing herein shall have the effect

of excluding, restricting or modifying any condition,

guarantee, right or liability imposed, to the extent only

that such exclusion, restriction or modification

would render any term herein void.

HOBART: All enquiries Tel : 1300 360 216

ADELAIDE: All enquiries Tel : 1300 360 216

PERTH:

33-35 Sorbonne Cres., Canning Vale,W.A. 6155.

Tel : (08) 9455 7775

Tel: (09) 573 0230 - Free Call: 0800 279 624 - Fax: (09) 573 0231 - Email: info@ryobi.co.nz

AUCKLAND: 503 Mt Wellington Highway, Mt Wellington, N.Z.

RYOBI NEW ZEALAND PTY. LTD.

Contact during normal business hours.

This Guarantee Form Should Be Retained By The Customer At All Times

For your record and to assist in establishing date of purchase (necessary for in-guarantee service)

please keep your purchase docket and this form completed with the following particulars.

Purchased From

Address Of Dealer

Date Model No Serial No

Present This Form With Your Purchase Docket When Guarantee Service Is Required.

Loading...

Loading...