Reliance Worldwide Corporation (UK) Ltd

Worcester Road,

Evesham,

Worcester,

WR11 4RA

Tel: +44(0)1386 712 400

Fax: +44(0)1386 712 401

www.rwc.co.uk

Installation and Maintenance Instructions

Anti Legionella Valve

Reliance Worldwide Corporation (UK) Ltd. reserves the right to make changes to the product which may affect the accuracy of information contained in this

leaflet.

ZINS100005_001_08-15

Contents

Reliance Worldwide Corporation (UK) Ltd........2

Specification and Dimensions...........................3

Installation Guidance.........................................4

5. Ensure that the isolating valve is

in the open position then turn on the

water supply and commission the

system.

Maintenance

Maintenance......................................................6

If for some reason it is necessary

to remove the expansion vessel

for service or replacement the anti

legionella valve helps to make this

quick and easy.

1. Isolate the expansion vessel from

the system using the integral

isolating valve

2. Making sure that you have a

suitable collection vessel to hand remove the plastic test

plug from the port directly opposite the isolating valve to

drain the residual water from the vessel

3. After draining replace the test plug,

service or replace the vessel and open

up the isolating valve to return the

vessel to service.

1

6

Reliance Worldwide Corporation (UK) Ltd

3. Mount the vessel vertically with the

connections at the bottom using

suitable fixings and a strap type

bracket:

5 litre vessel BRKT240021

8 litre vessel BRKT240022

12, 18, 24 litre BRKT240050

Note : Expansion vessels should

always be mounted in vertically

with the connections at the bottom

to avoid the possibility of sediment

and debris being deposited inside the membrane and

providing a possible breeding ground for bacteria such as

Legionella.

For more information refer to the WRAS website and follow

this link https://www.wras.co.uk/consumers/resources/

interpretations_and_advice/installation/i20/

4. Connect the water supply so that

water from the supply enters one end

of the tee and the water that feeds the

system exits from the other side of the

tee.

Reliance Worldwide Corporation (UK) Ltd are part of the

Australian based group of companies collectively known as

Reliance Worldwide Corporation, with the UK brand known as

Reliance Water Controls.

Reliance Worldwide Corporation (UK) Ltd is a specialist in the

design, distribution and technical support for temperature and

flow controls.

With group offices and manufacturing plants throughout the

world RWC offers a wealth of knowledge and expertise which

is reflected throughout our products. Being part of many

specialised trade associations and having our own UKAS

accredited laboratory, makes us at the forefront of any new

regulations or changes which impact the industry, and allows

for continuous product development and innovation, within our

specialised product area.

Our core product range is related to thermostatic control, with

the manufacturing undertaken at our head office in Brisbane

Australia, we have an extensive range of thermostatic mixing

valves, shower control valves, and taps all which use the

same high quality technology to control the temperature of

water, within this range we have different valves to suit various

applications and working parameters, including both TMV2 and

TMV3 approved controls.

RWC, are market leaders of OEM controls with a complete

range of safety valves for use in G3 unvented systems and

a wide range of Underfloor heating controls (UFH) to allow

for safe distribution of hot water, throughout a property. This

range includes; thermostatic control valves for safe hot water

temperatures, manifolds to enable even distribution, complete

UFH kits to allow ease of installation & commissioning, and

a range of modern and stylish programmers to complement

these controls.

25

Description

Installation

The Reliance anti legionella valve is designed to be connected

to a Reliance (Aquasystems) potable water expansion vessel

with a ¾” connection. It is designed to divert a proportion of the

water that is owing through a system into the vessel to cause

turbulence and encourage an exchange of water within it.

Specication

Nominal size DN20

Max. inlet temp. 30°C

Medium Potable Water

Dimensions (Vessel Supplied Separately)

Before installing the anti legionella valve ensure that the water

system has been flushed and is free from debris and that the

system pressures and temperatures are within the working

parameters of the valve.

To install the anti legionella valve onto a vessel follow these

steps.

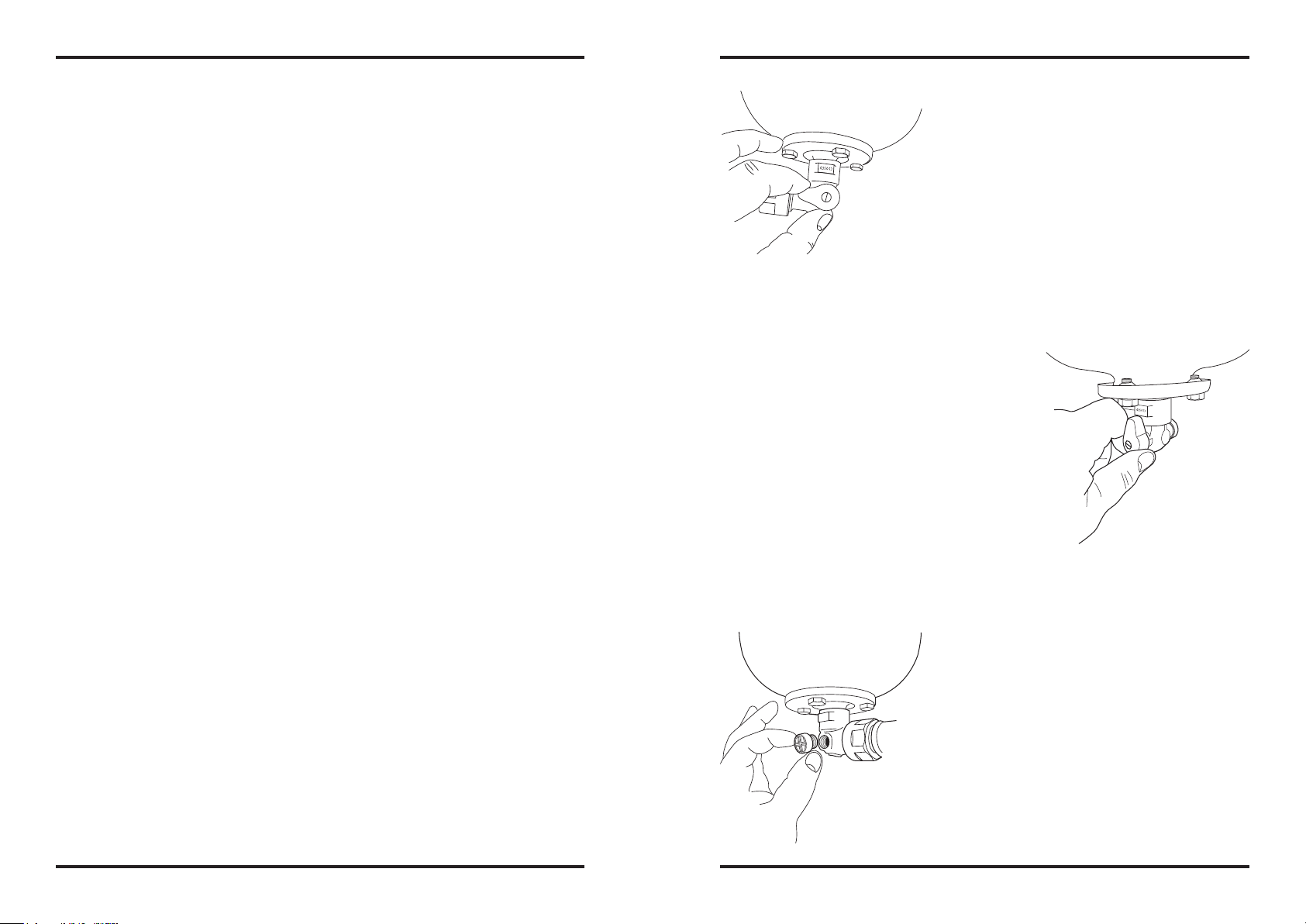

1. First insert the paddle retaining

tube into the vessel connection as

shown. This is the small plastic

tube with a cut down the side.

To insert it you squeeze the tube

together and push it into the vessel

connection and then let it spring

back into place.

2. Taking

care not to damage the paddle or

the paddle retaining clip, screw

the anti legionella valve onto the

expansion vessel and tighten up

with a spanner. Note the valve

includes a rubber seat so extra

washers and PTFE tape are not

needed.

2. Connect the ¾” FBSP tee piece

onto the anti legionella valve

and tighten with a spanner, the

36

connection is sealed by an oring so

extra washers and PTFE tape are

not needed. The tee piece remains

80 100

Dimensions in mm unless otherwise stated.

3

rotatable through 360° when

tightened.

4

Loading...

Loading...