Page 1

PROCEDURE FOR REPLACEMENT OF

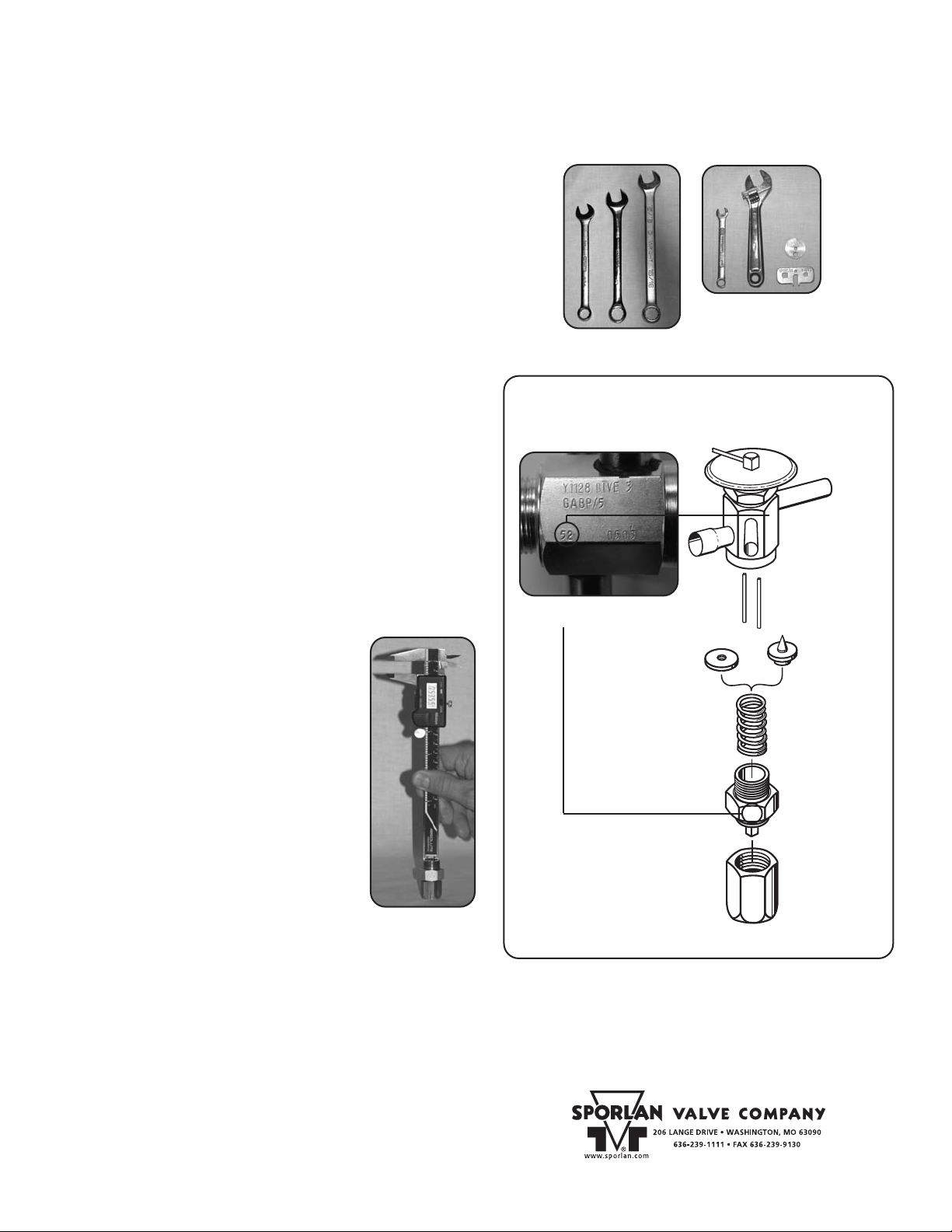

52 Date Code

Y1128 BIVE 3

GABP/5

52

KA-4 ADJUSTABLE BOTTOM CAP ASSEMBLIES

On Valves With Special Or Standard Superheat Settings

ools Required:

T

(1) – 15/16” Open End Wrench (fits valve body)

(1) – 7/8” Open End Wrench (fits bottom adjustment assembly)

(1) – 3/4” Open End W

(1) – Dial caliper, depth micrometer, steel rule, or other tool for measuring the depth.

(1) – Adjustment stem tool, 3/16” open end wrench, or small crescent wrench to

adjust bottom adjustment assembly. Must be a tool that allows the exact turns

of adjustment made on the bottom adjustment assembly to be counted.

Service Ratchet Not Recommended.

Installation Instructions:

Determine if the valve has a special OEM setting. Valves with special

OEM settings are indicated by a number stamped on the bottom

adjustment assembly or on the valve body, e.g. 52. See Figure 2.

If the valve does not have a special OEM setting (no number/setting

marked on valve) follow Steps 1 and 2, then skip to Step 3.

A special setting can be approximated using one of two possible

methods, as described below in

1. Before disassembling the TEV, be sure the refrigerant pressure in

the system has been reduced to a safe level (0 PSIG).

2. Disassemble the bottom adjustment assembly and seal cap from the

valve body.

ment assembly at this time. See Figure 2.

Method A

Use a dial caliper or other method for measuring the distance from the top of the bottom

adjustment assembly (see Figure 1) to the

spring guide surface inside the

adjustment assembly. Record this measurement

or mark this dimension on the tool used for

measuring the depth.

Remove seal cap from

bly. Adjust spring guide position to same position as measured above on

to Step 3.

rench (fits seal cap)

Method A and Method B.

DO NOT remove the seal cap from the bottom adjust-

OLD bottom

NEW bottom cap assem

-

OLD assembly. Skip

KA-4 for Valve Types BBI*, (E)BF, (E)BQ,

(E)F, (E)Q, FB, SBF, SBQ, SQ

Valve setting indicated on valve body

or bottom adjustment assembly.

SPRING GUIDE

(BBI, BQ, CBBI, (E)BF,

EBQ, RC, SBF, SBQ)

October 2004

Tool options for adjusting the stem

on bottom adjustment assembly.

VALVE BODY

PUSHRODS

PIN & CARRIER

(CBI, (E)F, EQ,

FB, Q, SQ)

SPRING

BOTTOM

ADJUSTMENT

ASSEMBLY

Method B

Remove the seal cap from the OLD bottom

adjustment assembly

stem out counterclockwise, counting the number of turns until you come in contact with the

stop on the adjustment stem. The adjustment

stem will turn freely until you come in contact

. Back the adjustment

Figure 1

Figure 2

SEAL CAP

* For straight through connections ONL

.

Y

with the stop.

Remove the seal cap from the

Make certain that the adjustment stem on the

NEW bottom adjustment assembly

NEW bottom adjustment

assembly is backed out counterclockwise all the way. Turn the adjustment stem on the

NEW bottom adjustment assembly clockwise the

same number of turns that you backed the adjustment stem out on the

OLD bottom adjustment assembly

.

.

4. Install seal cap on NEW bottom adjustment assembly and tighten

with wrenches 1/8 to 1/6 of a turn beyond hand tight. This cap is the

primary seal.

5. After system is started, check and verify proper superheat setting

as recommended by the Equipment Manufacturer

.

3. Install NEW replacement bottom adjustment assembly. It is impor-

tant

that the PIN remains seated in the valve port, otherwise flood

ing will occur. Tighten with wrenches approximately 1/4 of a turn

beyond hand tight.

PRINTED IN THE U.S. OF A. SD-24B-1004

-

© COPYRIGHT 20 04 BY SPORLAN VALVE COMPANY, WASHINGTON, MO

Loading...

Loading...