Page 1

Heavy Duty

®

Unit Cooler

Publication No. 101.8

February, 2009

Air Defrost - 16,400 to 273,000 BTUH

Electric Defrost - 11,800 to 248,000 BTUH

Hot Gas Defrost - 11,800 to 248,000 BTUH

3050 Enterprise St., P.O. Box 1030, Brea, CA 92822-1030 • Tel: (714) 529-1935 • Fax: (714) 529-7203

Large Walk-Ins

and Warehouses

Cooler & Freezer

Applications

Visit us on the Web at: www.rus sellc oil.com

Page 2

Features

APPLICATION - Ultra-Temp unit coolers are ideally

suited for a wide range of large coolers, freezers

and blast freezers. The U*U and U*L models are

designed for use below +25°F room temperature.

The U*M and UAH models are designed for coolers

in the medium and high temperature ranges.

SIZES - There are 61 sizes available, ranging in

capacity from 11,800 to 273,000 BTUH @ 10°TD,

and ranging in air flow from 2,720 to 29,900 CFM.

HOUSING - Rust-free, heavy gauge textured

Aluminum; lightweight and durable. Air and electric

defrost models have hinged drain pans to allow for

convenient servicing and maintenance (Hot Gas

drain pans are not hinged).

LIFTING LEGS - 2 fan models and larger are

shipped upright with removable lifting legs, allowing

the unit to be installed quickly, and easily with a

forklift. Slotted hangers are provided for fast

installation.

COIL - Seamless copper tubes are mechanically

expanded into heavy gauge corrugated Aluminum

fins to assure maximum heat transfer. Die formed

fin collars are provided for accurate fin spacing.

Hangers are fastened directly to the tube sheets of

the coil to provide high structural strength. All units

are dehydrated, sealed and shipped with a nitrogen

holding charge.

REFRIGERANTS - For use with direct expansion,

R-22, R-404A, R-502 and R-507. Specify refrigerant

when ordering. A separate compartment is provided

for all refrigeration connections, allowing ample

room for internal mounting of expansion valve(s).

Ultra-Temps can also be used for chilled water or

glycol solutions, contact factory for selection.

ELECTRICAL - Available in 115/1, 208/230/1,

208/230/3, 460/1 and 460/3 (see page 10). UltraTemps can also be operated on 220/1/50, 220/3/50,

380/1/50, and 380/3/50 power (contact factory for

details). All components are factory wired to

convenient screw-type terminal blocks. A large

compartment is supplied for all electrical components

and is easily accessible by removing the end panel.

AIR DEFROST - Available on UAM and UAH series

only for use in coolers at +35°F and above.

Complete Air Defrost systems are available from

Russell.

ELECTRIC DEFROST - Available on all but the UAH

models. Placement of the heaters within the

refrigeration coil allow for a more efficient and rapid

defrost cycle. This arrangement enables heat to be

conducted from the center of the core out, for a more

even defrost pattern. All heaters are factory wired to

screw-type terminal blocks, allowing for a quick field

change over from 1 to 3 phase or 230V to 460V and

vice versa with the use of jumpers. An adjustable,

remote bulb defrost termination and fan delay

(DTFD) is mounted and wired. Drain pans are

heated for fast, reliable drainage. Timer and

contactors are available as options, see page 11.

Complete Electric Defrost systems are available from

Russell.

HOT GAS RE-EVAP DEFROST - Available on all but

the UAH models. Includes an adjustable defrost

termination and fan delay (DTFD), factory installed.

A hot gas drain circuit is supplied, thus eliminating

the need for electric heat and additional wiring. A

Heat Exchanger/Re-Evaporator is supplied with

every unit. Refer to the current Technical Bulletin HG

for piping. Complete Hot Gas Re-Evap systems are

available from Russell, contact factory.

FANS - Powerful, heavy-duty Aluminum fans are

individually balanced to provide vibration-free

operation. Wire fan guards are epoxy coated for

corrosion resistance. Optional air straighteners are

available for increased air throw.

MOTORS - All standard motors are high efficiency

PSC, ball bearing type, life lubricated and thermally

protected. U*U and U*L models use 3/4 HP, 1075

RPM or 3/4 HP, 1625 RPM motors. U*M and UAH

models use 1/3 HP or 3/4 HP, 1075 RPM motors.

Optional EC motors are now available for all UltraTemp models.

HOT GAS REVERSE CYCLE DEFROST - Available

on all but the UAH models. Includes an adjustable

defrost termination and fan delay. (DTFD) factory

installed. A hot gas drain pan circuit is supplied, thus

eliminating the need for electric heat and additional

wiring. Refer th the current Technical Bulletin HG

For piping. This unit is also used for Alternating

Evaporator Systems.

2 11

Page 3

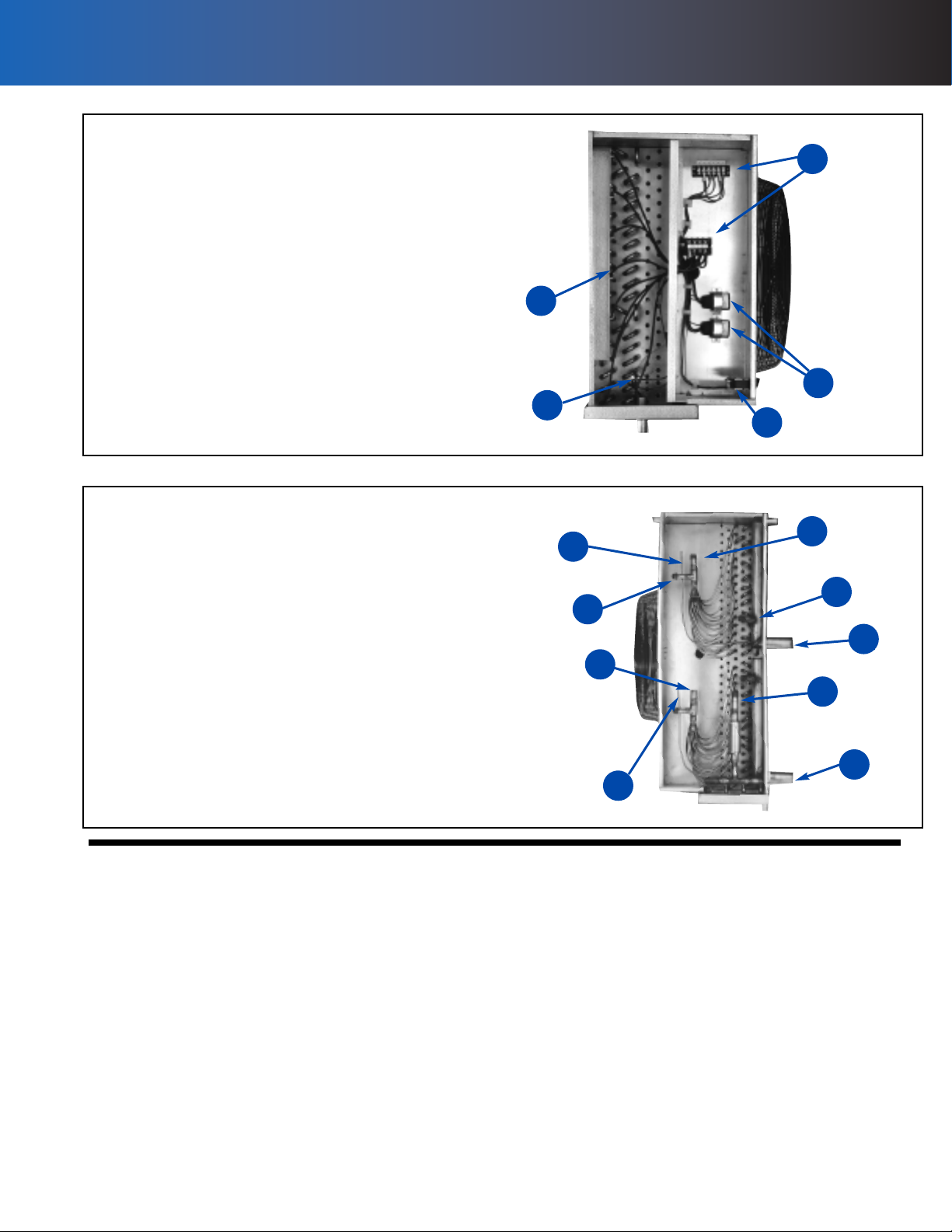

Electric Defrost

Electrical Compartment

A. Defrost control (DTFD)

B. DTFD sensing bulb

C. Fin heater (typical)

D. Field wiring terminal strips

E. Fan motor capacitors

D

C

E

B

A

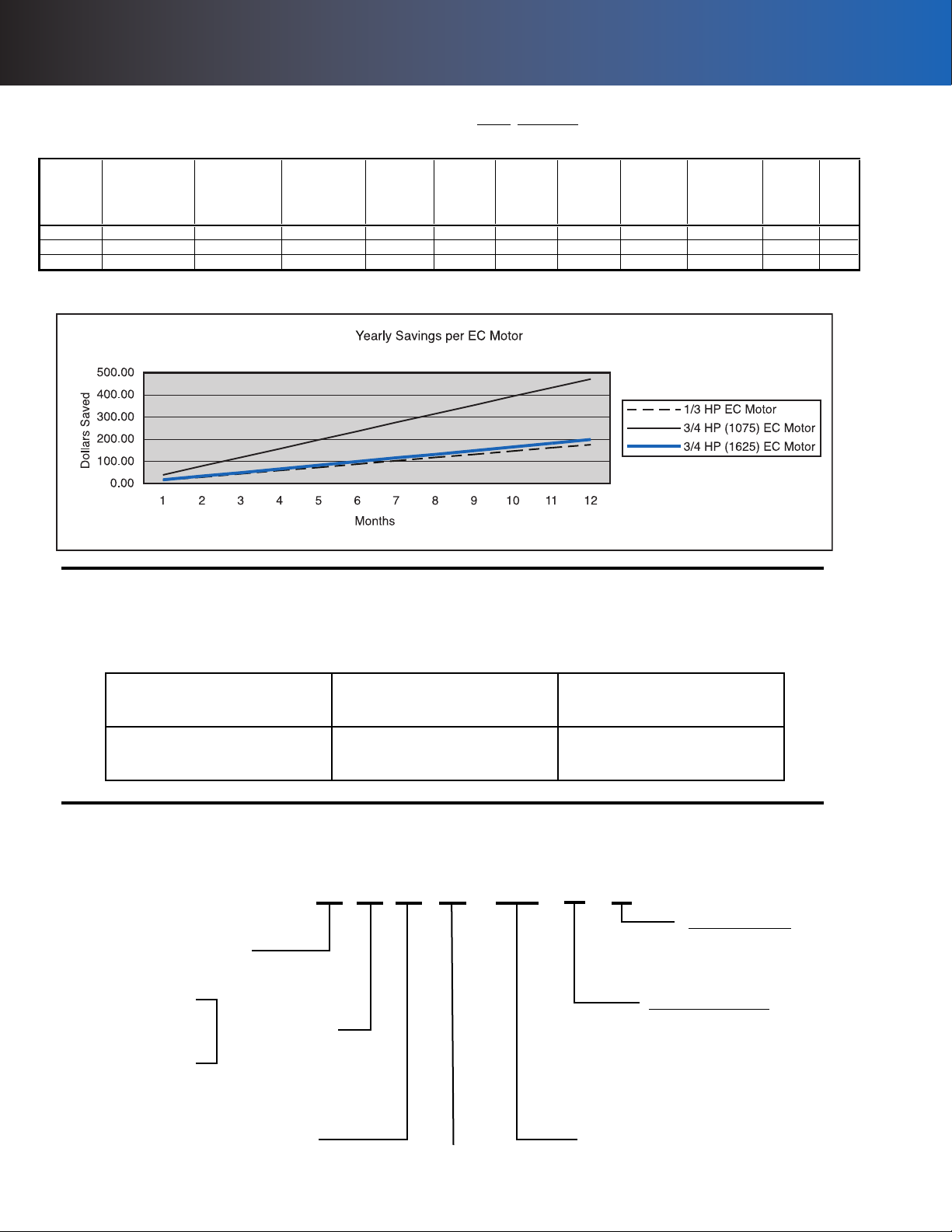

Refrigerant Connection

Compartment

Refrigerant End Compartment

(Larger two-circuit Hot Gas coil shown)

A. Hot gas supply (from drain pan)

B. Hot gas inlet to coil (two-pipe)

C. Hot gas inlet to coil (three-pipe)

Hot gas outlet from coil (two-pipe)

D. Liquid inlet from TX valve

E. Suction connection

F. External equalizer line

Options

• Copper fins.

• Coated fins (air and hot gas models only).

• Galvanized steel casing.

F

D

B

C

E

D

A

E

F

• High pressure propeller fans (up to 0.5” external pressure).

• Inherent 3 phase motors.

• Ultra low temperature motor grease for applications down to -60°F suction

temperature.

• Insulated drain pans.

• Custom circuiting for chilled water or glycol applications.

• High air throw fan guards.

Page 4

B

A

LIQUID

SUCTION

B

A

SUCTION

LIQUID

Motor

HP and

R

PM

Standard PSC

M

otor Input

Power

Watts/Mtr

Optional EC

M

otor Input

Power

Watts/Mtr

Reduced

P

ower

Consumption

Watts/Mtr

Run Time

Hrs/Day

Motor

E

nergy

Savings

kWh/Yr

Motor

E

nergy

Savings

$/Yr

R

educed

Box Load

MBTU/Yr

Cond. Unit

E

nergy

Savings

kWh/Yr

Cond. Unit

E

nergy

Savings

$/Yr

Y

early

Savings

$/Motor

P

ay-

back

Yrs

1

/3 1075 357 225 132 22 1060 106 3,617 695 70 176 0.9

3/4 1075 850 495 355 22 2851 285 9,726 1,870 187 472 0.4

3/4 1625 717 580 137 22 1100 110 3,754 722 72 182 1.0

Energy Saving per Motor

by Changing to more Efficient Unit Cooler Motors (based on Energy Cost of $0.10 per kWh)

Air Throw

Air throw is affected by installation variables. Optimum air throw is obtained by high ceiling with no

interference from beams, product or return air restrictions.

MODEL WIRE FAN GUARD

U*U / U*L

U*M / UAH

60 - 80 feet

50 - 70 feet

FAN GUARD / AIR

STRAIGHTENER

80 - 100 feet

70 - 90 feet

Nomenclature

U•U1–118 – D P

MOTOR TYPE

Ultra-Temp

A = Air Defrost (M & H) only

E = Electric Defrost

H = Hot Gas Re-Evap

(U, L & M only)

G = Hot Gas Rev. Cycle

U= 4 Fins/Inch (Freezer)

L=6 Fins/Inch (Freezer)

M = 6 Fins/Inch (Cooler)

H= 8 Fins/Inch (Cooler)

BTUH in Hundreds

Number of Fans

4 9

VOLTAGE CODE

P = PERM. SPLIT

CAPACITOR

E = EC MOTOR

A = 115/1/60

D = 208-230/1/60

E = 208-230/3/60

F = 460/1/60

G = 460/3/60

J = 575/3/60

Page 5

Performance Data

F

R4

E

EF

ZP

EI

R

F

R6

E

EF

ZP

EI

R

MODEL

UMBER

N

U*U1-118

U*U2-236

U*U2-355

U*U3-474

U*U4-711

U*U4-851

U*U4-1080

U*U5-1350

U*U6-1620

U*L1-125

U*L1-152

U*L1-193

U*L2-240

U*L2-304

U*L2-361

U*L2-408

U*L3-445

U*L3-540

U*L3-613

U*L3-660

U*L4-722

U*L4-817

U*L4-950

U*L4-1100

U*L4-1260

U*L4-1380

U*L5-1575

U*L5-1725

U*L6-1890

U*L6-2070

CFM

3750

7500

8200

12450

16400

21600

21600

26200

32400

3750

3650

3550

7600

7300

8300

8100

12800

12450

12150

11800

16600

16200

21500

21200

20800

20400

26000

25500

31200

32100

CAPACITY BTUH @ 10°TD (404A, R-22)

UCTION TEMPERATURE

S

-30°F -20°F -10°F +10°F

2900

1800

1

23600

35500

47400

71100

85100

108000

135000

162000

10900

13200

16800

20900

26400

31400

35500

38700

47000

53300

57400

62700

71100

82500

95700

109600

120000

137000

150000

164400

180000

12400

24700

37100

49500

72800

89000

112900

141000

176600

11700

14200

18100

22400

28400

33800

38200

41600

50500

57300

61700

67500

76400

88900

102900

117800

129000

147300

161300

176700

193500

1

25700

38700

51600

74500

92800

117700

147000

176600

12500

15200

19300

24000

30400

36100

40800

44500

54000

61300

66000

72200

81700

95000

110000

126000

138000

157500

172500

189000

207000

14000

27900

42100

56100

81000

100900

128000

160000

192000

13500

16400

20800

25900

32800

39000

44100

48000

58300

66200

71200

78000

88200

102600

118800

136000

149000

170000

186300

204000

223500

C6

O

OF

LP

EI

R

MODEL

NUMBER

U*M1-164

U*M1-209

U*M2-270

U*M2-329

U*M2-390

U*M2-441

U*M3-583

U*M3-662

U*M4-780

U*M4-882

U*M4-1100

U*M4-1320

U*M4-1656

U*M5-2065

U*M6-2480

CFM

2920

2840

7000

6840

6640

6480

9960

9720

13280

12960

21700

21200

20400

25500

30600

CAPACITY

BTUH@10°TD

+20°F

16400

20900

27000

32900

39000

44100

58300

66200

78000

88200

110000

132000

165600

206500

248000

C8

O

OF

LP

EI

R

MODEL

NUMBER

UAH1-182

UAH1-232

UAH2-300

UAH2-365

UAH2-433

UAH2-490

UAH3-530

UAH3-648

UAH3-736

UAH4-866

UAH4-980

UAH4-1100

UAH4-1452

UAH4-1821

UAH5-2275

UAH6-2730

CFM

2800

2720

6880

6600

6400

6250

9800

9600

9400

12800

12500

12200

20700

19900

24900

29900

CAPACITY

BTUH@10°TD

+25°F

18200

23200

30000

36500

43300

49000

53000

64800

73600

86600

98000

110000

145200

182100

227500

273000

Page 6

8-3/8

8-3/8

3

Defrost

Control

Electrical

Knockouts

Knockout

For Liquid

Connection

(Rear)

Suction

Connection

(Rear)

4

5

2-1/16

E

5

Drain

Air

1(Typ)

A

22-1/2

F

B

C

30 30 30

29-3/8

D

3

18-3/8

8-3/8

8-3/8

3

Defrost

Control

Electrical

Knockouts

4

5

2-1/16

E

5

Drain

Air

1(Typ)

A

22-1/2

F

B

C

30 30 30

29-3/8

D

30 30

Suction Conn. (Rear)

Liquid Conn. (Rear)

3-5/8

18-3/8

17

24

Physical Data

SHIP

W

LBS)

(

T.

FAN

IA.

D

In.)

(

F

R4

E

EF

ZP

EI

R

F

R6

E

EF

ZP

EI

R

C

O6

O

LF

EP

RI

C

O8

O

LF

EP

RI

MODEL

NUMBER

*U1-118 20 1 3/4 1625 HX-150 HEA2A 1/2FL 1-1/8 7/8 3/4 190

U

*U2-236 20 2 3/4 1625 HX-250 HEA3A 7/8 ODS 1-3/8 7/8 3/4 370

U

*U2-355 24 2 3/4 1075 HX-350 HEA4A 7/8 ODS 1-5/8 7/8 3/4 440

U

*U3-474 24 3 3/4 1075 HX-350 HEA5A 7/8 ODS 1-5/8 7/8 3/4 570

U

U*U4-711 24 4 3/4 1075 HX-500 HEA6A 7/8 ODS 2-1/8 1-1/8 1-1/4 665

U*U4-851 24 4 3/4 1075 (2) HX-500 (2) HEA5A (2) 7/8 ODS (2) 2-1/8 1-1/8 1-1/4 875

U*U4-1080 24 4 3/4 1075 (2) HX-500 (2) HEA5A (2) 7/8 ODS (2) 2-1/8 1-1/8 1-1/4 900

*U5-1350 24 5 3/4 1075 (2) HX-500 N/ A (2) 7/8 ODS (2) 2-1/8 1-1/8 1-1/4 1125

U

*U6-1620 24 6 3/4 1075 (2) HX-500 N/ A (2) 1-1/8 ODS (2) 2-5/8 1-1/8 1-1/4 1350

U

U*L1-125 20 1 3/4 1625 HX-150 HEA3A 1/2FL 1-1/8 7/8 3/4 180

U*L1-152 20 1 3/4 1625 HX-150 HEA3A 1/2FL 1-1/8 7/8 3/4 200

U*L1-193 20 1 3/4 1625 HX-150 HEA3A 5/8 ODS 1-1/8 7/8 3/4 220

U*L2-240 20 2 3/4 1625 HX-250 HEA4A 7/8 ODS 1-3/8 7/8 3/4 370

*L2-304 20 2 3/4 1625 HX-250 HEA4A 7/8 ODS 1-3/8 7/8 3/4 400

U

*L2-361 24 2 3/4 1075 HX-350 HEA4A 7/8 ODS 1-5/8 7/8 3/4 425

U

*L2-408 24 2 3/4 1075 HX-350 HEA5A 7/8 ODS 1-5/8 7/8 3/4 446

U

U*L3-445 24 3 3/4 1075 HX-500 HEA5A 7/8 ODS 2-1/8 7/8 3/4 525

U*L3-540 24 3 3/4 1075 HX-500 HEA5A 7/8 ODS 2-1/8 7/8 3/4 585

U*L3-613 24 3 3/4 1075 HX-500 HEA6A 7/8 ODS 2-1/8 7/8 3/4 620

U*L3-660 24 3 3/4 1075 HX-500 HEA6A 7/8 ODS 2-1/8 7/8 3/4 645

*L4-722 24 4 3/4 1075 HX-500 HEA6A 1-3/8 ODS 2-1/8 1-1/8 1-1/4 675

U

*L4-817 24 4 3/4 1075 HX-500 (2) HEA5A 7/8 ODS 2-1/8 1-1/8 1-1/4 726

U

*L4-950 24 4 3/4 1075 HX-500 (2) HEA5A (2) 7/8 ODS (2) 2-1/8 1-1/8 1-1/4 850

U

U*L4-1100 24 4 3/4 1075 (2) HX-500 (2) HEA5A (2) 7/8 ODS (2) 2-1/8 1-1/8 1-1/4 885

U*L4-1260 24 4 3/4 1075 (2) HX-500 (2) HEA6A (2) 7/8 ODS (2) 2-1/8 1-1/8 1-1/4 895

U*L4-1380 24 4 3/4 1075 (2) HX-500 (2) HEA6A (2) 7/8 ODS (2) 2-1/8 1-1/8 1-1/4 910

U*L5-1575 24 5 3/4 1075 (2) HX-500 N/A (2) 1-1/8 ODS (2) 2-1/8 1-1/8 1-1/4 1120

U*L5-1725 24 5 3/4 1075 (2) HX-500 N/A (2) 1-1/8 ODS (2) 2-1/8 1-1/8 1-1/4 1140

U*L6-1890 24 6 3/4 1075 (2) HX-500 N/A (2) 1-3/8 ODS (2) 2-5/8 1-1/8 1-1/4 1345

U*L6-2070 24 6 3/4 1075 (2) HX-500 N/A (2) 1-3/8 ODS (2) 2-5/8 1-1/8 1-1/4 1365

U*M1-164 20 1 1/3 1075 HX-150 HEA3A 1/2FL 7/8 7/8 3/4 200

U*M1-209 20 1 1/3 1075 HX-150 HEA3A 5/8 ODS 7/8 7/8 3/4 220

U*M2-270 20 2 1/3 1075 HX-250 HEA4A 5/8 ODS 1-1/8 7/8 3/4 360

U*M2-329 20 2 1/3 1075 HX-250 HEA4A 5/8 ODS 1-1/8 7/8 3/4 400

U*M2-390 24 2 1/3 1075 HX-250 HEA4A 5/8 ODS 1-1/8 7/8 3/4 425

U*M2-441 24 2 1/3 1075 HX-250 HEA5A 5/8 ODS 1-1/8 7/8 3/4 446

U*M3-583 24 3 1/3 1075 HX-350 HEA5A 5/8 ODS 1-3/8 7/8 3/4 585

U*M3-662 24 3 1/3 1075 HX-350 HEA6A 7/8 ODS 1-3/8 7/8 3/4 620

U*M4-780 24 4 1/3 1075 HX-350 HEA6A 7/8 ODS 1-3/8 1-1/8 1-1/4 675

U*M4-882 24 4 1/3 1075 HX-500 (2) HEA5A 7/8 ODS 1-3/8 1-1/8 1-1/4 726

U*M4-1100 24 4 3/4 1075 (2) HX-350 (2) HEA5A 7/8 ODS 1-5/8 1-1/8 1-1/4 830

U*M4-1320 24 4 3/4 1075 (2) HX-350 (2) HEA5A 1-1/8 ODS 1-5/8 1-1/8 1-1/4 885

U*M4-1656 24 4 3/4 1075 (2) HX-500 (2) HEA6A 1-1/8 ODS 2-1/8 1-1/8 1-1/4 910

U*M5-2065 24 5 3/4 1075 (2) HX-500 N/A 1-5/8 ODS 2-5/8 1-1/8 1-1/4 1140

U*M6-2480 24 6 3/4 1075 (2) HX-500 N/A 1-5/8 ODS 2-5/8 1-1/8 1-1/4 1365

UAH1-182 20 1 1/3 1075 HX-150 N/A 5/8 ODS 7/8 N/A 3/4 210

UAH1-232 20 1 1/3 1075 HX-150 N/A 5/8 ODS 7/8 N/A 3/4 230

UAH2-300 20 2 1/3 1075 HX-250 N/A 5/8 ODS 1-1/8 N/A 3/4 370

UAH2-365 20 2 1/3 1075 HX-250 N/A 5/8 ODS 1-1/8 N/A 3/4 410

UAH2-433 24 2 1/3 1075 HX-250 N/A 5/8 ODS 1-1/8 N/A 3/4 435

UAH2-490 24 2 1/3 1075 HX-250 N/A 5/8 ODS 1-1/8 N/A 3/4 458

UAH3-530 24 3 1/3 1075 HX-250 N/A 7/8 ODS 1-3/8 N/A 3/4 550

UAH3-648 24 3 1/3 1075 HX-350 N/A 7/8 ODS 1-3/8 N/A 3/4 600

UAH3-736 24 3 1/3 1075 HX-350 N/A 7/8 ODS 1-3/8 N/A 3/4 635

UAH4-866 24 4 1/3 1075 HX-350 N/A 7/8 ODS 1-3/8 N/A 1-1/4 690

UAH4-980 24 4 1/3 1075 HX-500 N/A 7/8 ODS 1-3/8 N/A 1-1/4 746

UAH4-1100 24 4 1/3 1075 (2) HX-350 N/A 7/8 ODS 1-3/8 N/A 1-1/4 785

UAH4-1452 24 4 3/4 1075 (2) HX-350 N/A 7/8 ODS 1-5/8 N/A 1-1/4 905

UAH4-1821 24 4 3/4 1075 (2) HX-500 N/A 7/8 ODS 2-1/8 N/A 1-1/4 930

UAH5-2275 24 5 3/4 1075 (2) HX-500 N/A 1-5/8 ODS 2-5/8 N/A 1-1/4 1165

UAH6-2730 24 6 3/4 1075 (2) HX-500 N/A 1-5/8 ODS 2-5/8 N/A 1-1/4 1395

(1) All motors are single phase. All three fan models and larger are delta wired

for three phase power. Inherent three phase motors are available, contact

factory.

(2) All Ultra-Temps are custom circuited for optimum peformance and operating

efficiency. Should conditions vary from those listed to the right, *connection

sizes and quantity may be subject to change, contact factory to confirm.

OTOR DATA (1)

M

TY RPM

Q

HP

PTIONAL

O

HEAT EXCH.

(UNMTD.)

E-EVAP

R

HEAT EXCH.

(UNMTD.)

IQUID

L

* Connection sizes are based on the following criteria:

U*U: - 30° ST, 10°TD R-404A

U*L: - 20° ST, 10°TD R-404A

U*M: +20° ST, 10°TD R-22

UAH: +25° ST, 10°TD R-22

6 7

ONNECTIONS (In.) (2)

C

SUCTION

ODS

H.G.

ODS

DRAIN

M

PT

Page 7

8-3/8

8-3/8

3

Defrost

Control

Electrical

Knockouts

Knockout

For Liquid

Connection

(Rear)

Suction

Connection

(Rear)

4

5

2-1/16

E

5

Drain

Air

1(Typ)

A

22-1/2

F

B

C

30 30 30

29-3/8

D

3

18-3/8

8-3/8

8-3/8

3

Defrost

Control

Electrical

Knockouts

4

5

2-1/16

E

5

Drain

Air

1(Typ)

A

22-1/2

F

B

C

30 30 30

29-3/8

D

30 30

Suction Conn. (Rear)

Liquid Conn. (Rear)

3-5/8

18-3/8

17

24

Dimensions - Air & Electric Defrost Models

AIR & ELECTRIC DEFROST

MODELS

*L1-125 U*U1-118 U*M1-164 UAH1-182

U

*L1-152 U*M1-209 UAH1-232

U

U*L1-193

U*L2-240 U*U2-236 U*M2-270 UAH2-300

*L2-304 U*M2-329 UAH2-365

U

*L2-361 U*U2-355 U*M2-390 UAH2-433

U

U*L2-408 U*M2-441 UAH2-490

U*L3-445 U*U3-474 U*M3-583 UAH3-530

*L3-540 U*M3-662 UAH3-648

U

U*L3-613 UAH3-736

U*L3-660

*L4-722 U*U4-711 U*M4-780 UAH4-866

U

*L4-817 U*M4-882 UAH4-980

U

U*L4-950 U*U4-851 U*M4-1100 UAH4-1452

*L4-1100 U*U4-1080 U*M4-1320 UAH4-1821

U

U*L4-1260 U*M4-1656

U*L4-1380

*L5-1575 U*U5-1350 U*M5-2065 UAH5-2275

U

*L5-1725

U

U*L6-1890 U*U6-1620 U*M6-2480 UAH6-2730

U*L6-2070

UAH4-1100

QTY

OF

HANGERS

2127-3/8 25-3/4 46-1/8 46-1/2 4

3

3

4129-1/8 32 106-1/8 106-1/2 5-3/4

5

5229-1/8 50-1/4 136-1/8 136-1/2 5-3/4

6229-1/8 50-1/2 166-1/8 166-1/2 5-3/4

7229-1/8 50-3/4 196-1/8 196-1/2 5-3/4

DIMENSIONS

FIG.

(In.)

ABC DE

1 27-3/8 26 76-1/8 76-1/2 4

1 29-1/8 31-3/4 76-1/8 76-1/2 5-3/4

1 29-1/8 32-1/4 136-1/8 136-1/2 5-3/4

1) 29-3/8 MOUNTING DIMENSION IS CONSISTENT ON ALL 1 THRU 4 FANS MODELS.

2) REFRIGERATION CONNECTIONS ARE ON THE AIR INLET SIDE (REAR) OF THE UNIT.

Figure 1

Figure 2

3) HANGER SLOTS ARE

4) ALL DIMENSIONS ARE IN INCHES.

1) 29-3/8 MOUNTING DIMENSION IS CONSISTENT ON ALL 4 THRU 6 FANS MODELS.

2) REFRIGERATION CONNECTIONS ARE ON THE AIR INLET SIDE (REAR) OF THE UNIT.

3) HANGER SLOTS ARE

4) ALL DIMENSIONS ARE IN INCHES.

1

⁄2 x 11⁄4.

1

⁄2 x 11⁄4.

Page 8

8 3/8

8 3/8

3

Defrost

Control

Electrical

Knockouts

Knockout

For Liquid

Connection

(Rear)

Suction

Connection

(Rear)

4

5

22 1/2

2 1/16

E

5

Drain

Hot Gas

Connection

(Rear)

Air

B

F

1(Typ)

C

D

30 30 30

29 3/8

18 3/8

3

A

8-3/8

8-3/8

3

Defrost

Control

Electrical

Knockouts

4

5

2-1/16

E

5

Drain

Air

1(Typ)

A

22-1/2

F

B

C

30 30 30

29-3/8

D

30 30

Suction Conn. (Rear)

Liquid Conn. (Rear)

3-5/8

18-3/8

17

24

Dimensions - Hot Gas Defrost Models

HOT GAS DEFROST MODELS

(Re-Evap & Reverse cycle)

U*L1-125 U*U1-118 U*M1-164

*L1-152 U*M1-209

U

*L1-193

U

U*L2-240 U*U2-236 U*M2-270

*L2-304 U*M2-329

U

*L2-361 U*U2-355 U*M2-390

U

U*L2-408 U*M2-441

U*L3-445 U*U3-474 U*M3-583

*L3-540 U*M3-662

U

*L3-613

U

U*L3-660

U*L4-722 U*U4-711 U*M4-780

*L4-817 U*M4-882

U

U*L4-950 U*U4-851 U*M4-1100

U*L4-1100 U*U4-1080 U*M4-1320

*L4-1260 U*M4-1656

U

*L4-1380

U

U*L5-1575 U*U5-1350 U*M5-2065

U*L5-1725

*L6-1890 U*U6-1620 U*M6-2480

U

U*L6-2070

QTY

OF

FIG.

HANGERS

2327-3/8 26-7/8 46-1/8 46-1/2 4 26-1/8

3

3

4329-1/8 33-7/8 106-1/8 106-1/2 5-3/4 32-1/8

5329-1/8 34-1/4 136-1/8 136-1/2 5-3/4 32-1/8

5429-1/8 52-1/4 136-1/8 136-1/2 5-3/4 50-1/8

6

7429-1/8 53-1/4 196-1/8 196-1/2 5-3/4 50-1/8

3 27-3/8 27-3/8 76-1/8 76-1/2 4 26-1/8

3 29-1/8 33-3/8 76-1/8 76-1/2 5-3/4 32-1/8

4 29-1/8 52-3/4 166-1/8 166-1/2 5-3/4 50-1/8

DIMENSIONS

(In.)

ABC DEF

1) 29-3/8 MOUNTING DIMENSION IS CONSISTENT ON ALL 1 THRU 4 FANS MODELS.

2) REFRIGERATION CONNECTIONS ARE ON THE AIR INLET SIDE (REAR) OF THE UNIT.

Figure 3

Figure 4

3) HANGER SLOTS ARE

4) ALL DIMENSIONS ARE IN INCHES.

1) 29-3/8 MOUNTING DIMENSION IS CONSISTENT ON ALL 4 THRU 6 FANS MODELS.

2) REFRIGERATION CONNECTIONS ARE ON THE AIR INLET SIDE (REAR) OF THE UNIT.

3) HANGER SLOTS ARE

4) ALL DIMENSIONS ARE IN INCHES.

8 5

1

⁄2 x 11⁄4.

1

⁄2 x 11⁄4.

Page 9

B

A

LIQUID

SUCTION

B

A

SUCTION

LIQUID

Suction Line Heat Exchangers

MODEL

NUMBER

HX - 25

HX - 50

HX - 75

HX - 100

HX - 150

HX - 250

HX - 350

HX - 500

LHX - 15

LHX - 20

LHX - 25

LHX - 30

CAPACITY - BTUH (R-22, R-404A)

SUCTION TEMPERATURE (°F)

-40°F -20°F +10°F +25°F

2.6

4.5

7.0

9.6

14.0

23.0

34.4

47.2

70.1

92.4

108.4

140.3

3.4

6.0

9.4

12.8

18.7

30.6

45.9

62.9

93.5

123.3

144.5

187.0

6.0

11.9

17.8

24.7

36.6

59.5

90.1

120.7

182.3

238.0

289.0

348.5

6.8

13.6

21.3

28.1

42.5

69.7

102.0

141.1

204.0

272.0

348.5

399.5

DIMENSIONS

(In)

AB

11-1/2

12-3/4

13-5/8

14-1/8

14-1/8

14-1/4

16-1/4

17-1/4

29-1/2

29-1/2

38

38

1-3/4

2-3/8

2-5/8

2-7/8

3

3-5/8

3-5/8

4-5/8

6-7/8

6-7/8

7-1/2

8

CONNECTIONS

(ODS) (In)

LIQUID SUCTION

1/4

3/8

3/8

3/8

1/2

5/8

5/8

7/8

7/8

1-1/8

1-1/8

1-3/8

1/2

5/8

7/8

1-1/8

1-1/8

1-3/8

1-5/8

2-1/8

2-1/8

2-1/8

2-5/8

2-5/8

WT.

(lbs)

2.0

2.0

2.0

3.0

3.0

4.0

6.0

7.0

12.0

15.0

18.0

20.0

“HX” STYLE

“LHX” STYLE

Figure 5

Suction Line Heat Exchangers - Accumulator

MODEL

NUMBER

HEA-1A

HEA-2A

HEA-3A

HEA-4A

HEA-5A

HEA-6A

CAPACITY

BTUH

6, 0 0 0

12 , 0 0 0

24 , 0 0 0

36 , 0 0 0

55 , 0 0 0

80 , 0 0 0

9-3/4

15-3/4

27-3/4

37-3/4

45-3/8

64-3/8

DIMENSIONS

(In)

AB

5

5

5

5

6

6

LIQUID (ODS) SUCTION (ODS)

INLET OUTLET INLET OUTLET

3/8

1/2

1/2

5/8

5/8

7/8

CONNECTIONS (In.)

3/8

1/2

1/2

5/8

5/8

7/8

7/8

1-1/8

1-3/8

1-5/8

2-1/8

2-5/8

7/8

1-1/8

1-3/8

1-5/8

2-1/8

2-5/8

WT.

(lbs)

10

15

20

25

40

50

Figure 6

Page 10

F

R4

E

EF

ZP

EI

R

F

R6

E

EF

ZP

EI

R

Electrical Data

ERMANENTLY SPLIT CAPACITOR MOTORS (PSC)

P

ODEL

M

NUMBER

U*U1-118 ----- 4.4 ----- 2.0 ----- 717 ----- 4.6 ----- ----- ----- 580

U*U2-236 ----- 8.8 ----- 4.0 ----- 1434 ----- 9.2 ----- ----- ----- 1160

U*U2-355 ----- 8.8 ----- 4.2 ----- 1700 ----- 10.4 ----- ----- ----- 990

*U3-474 ----- 13.2 7.6 ----- 3.6 2550 ----- 15.6 9.0 ----- ----- 1485

U

*U4-711 ----- 17.6 11.6 ----- 5.6 3400 ----- 20.8 13.8 ----- ----- 1980

U

*U4-851 ----- 17.6 11.6 ----- 5.6 3400 ----- 20.8 13.8 ----- ----- 1980

U

U*U4-1080 ----- 17.6 11.6 ----- 5.6 3400 ----- 20.8 13.8 ----- ----- 1980

U*U5-1350 ----- 22.0 15.2 ----- 7.3 4250 ----- 26.0 15.0 ----- ----- 2475

U*U6-1620 ----- 26.4 15.2 ----- 7.3 5100 ----- 31.2 18.0 ----- ----- 2970

*L1-125 ----- 4.4 ----- 2.0 ----- 717 ----- 4.6 ----- ----- ----- 580

U

*L1-152 ----- 4.4 ----- 2.0 ----- 717 ----- 4.6 ----- ----- ----- 580

U

U*L1-193 ----- 4.4 ----- 2.0 ----- 717 ----- 4.6 ----- ----- ----- 580

U*L2-240 ----- 8.8 ----- 4.0 ----- 1434 ----- 9.2 ----- ----- ----- 1160

U*L2-304 ----- 8.8 ----- 4.0 ----- 1434 ----- 9.2 ----- ----- ----- 1160

U*L2-361 ----- 8.8 ----- 4.2 ----- 1700 ----- 10.4 ----- ----- ----- 990

*L2-408 ----- 8.8 ----- 4.2 ----- 1700 ----- 10.4 ----- ----- ----- 990

U

*L3-445 ----- 13.2 7.6 ----- 3.6 2550 ----- 15.6 9.0 ----- ----- 1485

U

*L3-540 ----- 13.2 7.6 ----- 3.6 2550 ----- 15.6 9.0 ----- ----- 1485

U

U*L3-613 ----- 13.2 7.6 ----- 3.6 2550 ----- 15.6 9.0 ----- ----- 1485

U*L3-660 ----- 13.2 7.6 ----- 3.6 2550 ----- 15.6 9.0 ----- ----- 1485

U*L4-722 ----- 17.6 11.6 ----- 5.6 3400 ----- 20.8 13.8 ----- ----- 1980

U*L4-817 ----- 17.6 11.6 ----- 5.6 3400 ----- 20.8 13.8 ----- ----- 1980

U*L4-950 ----- 17.6 11.6 ----- 5.6 3400 ----- 20.8 13.8 ----- ----- 1980

U*L4-1100 ----- 17.6 11.6 ----- 5.6 3400 ----- 20.8 13.8 ----- ----- 1980

U*L4-1260 ----- 17.6 11.6 ----- 5.6 3400 ----- 20.8 13.8 ----- ----- 1980

U*L4-1380 ----- 17.6 11.6 ----- 5.6 3400 ----- 20.8 13.8 ----- ----- 1980

U*L5-1575 ----- 22.0 15.2 ----- 7.3 4250 ----- 26.0 15.0 ----- ----- 2475

U*L5-1725 ----- 22.0 15.2 ----- 7.3 4250 ----- 26.0 15.0 ----- ----- 2475

U*L6-1890 ----- 25.2 15.2 ----- 7.3 5100 ----- 31.2 18.0 ----- ----- 2970

U*L6-2070 ----- 26.4 15.2 ----- 7.3 5100 ----- 31.2 18.0 ----- ----- 2970

TOTAL MOTOR AMPS (3) - 60 Hz TOTAL

15 V. 208-230 V. 460 V. MOTOR

1

1 PH 1 PH 3 PH 1 PH 3 PH WATTS

LECTRICALLY COMMUTATED MOTORS (ECM)

E

TOTAL MOTOR AMPS (3) - 60 Hz TOTAL

15 V. 208-230 V. 460 V. MOTOR

1

1 PH 1 PH 3 PH 1 PH 3 PH WATTS

C

O6

O

LF

EP

RI

C

O8

O

LF

EP

RI

U*M1-164 7.1 3.1 ----- 1.3 ----- 357 3.0 2.1 ----- ----- ----- 225

U*M1-209 7.1 3.1 ----- 1.3 ----- 357 3.0 2.1 ----- ----- ----- 225

U*M2-270 14.2 6.2 ----- 2.6 ----- 714 6.0 4.2 ----- ----- ----- 450

U*M2-329 14.2 6.2 ----- 2.6 ----- 714 6.0 4.2 ----- ----- ----- 450

U*M2-390 14.2 6.2 ----- 2.6 ----- 714 6.0 4.2 ----- ----- ----- 450

U*M2-441 14.2 6.2 ----- 2.6 ----- 714 6.0 4.2 ----- ----- ----- 450

U*M3-583 21.3 9.3 5.4 3.9 2.3 1071 9.0 6.3 3.6 ----- ----- 675

U*M3-662 21.3 9.3 5.4 3.9 2.3 1071 9.0 6.3 3.6 ----- ----- 675

U*M4-780 28.4 12.4 8.2 5.2 3.4 1428 12.0 8.4 5.6 ----- ----- 900

U*M4-882 28.4 12.4 8.2 5.2 3.4 1428 12.0 8.4 5.6 ----- ----- 900

U*M4-1100 ----- 17.2 11.4 10.0 6.6 3400 ----- 20.8 13.8 ----- ----- 1980

U*M4-1320 ----- 17.2 11.4 10.0 6.6 3400 ----- 20.8 13.8 ----- ----- 1980

U*M4-1656 ----- 17.2 11.4 10.0 6.6 3400 ----- 20.8 13.8 ----- ----- 1980

U*M5-2065 ----- 21.5 14.9 12.5 8.7 4250 ----- 26.0 15.0 ----- ----- 2475

U*M6-2480 ----- 25.8 14.9 15.0 8.7 5100 ----- 31.2 18.0 ----- ----- 2970

UAH1-182 7.1 3.1 ----- 1.3 ----- 357 3.0 2.1 ----- ----- ----- 225

UAH1-232 7.1 3.1 ----- 1.3 ----- 357 3.0 2.1 ----- ----- ----- 225

UAH2-300 14.2 6.2 ----- 2.6 ----- 714 6.0 4.2 ----- ----- ----- 450

UAH2-365 14.2 6.2 ----- 2.6 ----- 714 6.0 4.2 ----- ----- ----- 450

UAH2-433 14.2 6.2 ----- 2.6 ----- 714 6.0 4.2 ----- ----- ----- 450

UAH2-490 14.2 6.2 ----- 2.6 ----- 714 6.0 4.2 ----- ----- ----- 450

UAH3-530 21.3 9.3 5.4 3.9 2.3 1071 18.0 6.3 3.6 ----- ----- 675

UAH3-648 21.3 9.3 5.4 3.9 2.3 1071 18.0 6.3 3.6 ----- ----- 675

UAH3-736 21.3 9.3 5.4 3.9 2.3 1071 18.0 6.3 3.6 ----- ----- 675

UAH4-866 28.4 12.4 8.2 5.2 3.4 1428 21.0 8.4 5.6 ----- ----- 900

UAH4-980 28.4 12.4 8.2 5.2 3.4 1428 21.0 8.4 5.6 ----- ----- 900

UAH4-1100 28.4 12.4 8.2 5.2 3.4 1428 21.0 8.4 5.6 ----- ----- 900

UAH4-1452 ----- 17.2 11.4 10.0 6.6 3400 ----- 20.8 13.8 ----- ----- 1980

UAH4-1821 ----- 17.2 11.4 10.0 6.6 3400 ----- 20.8 13.8 ----- ----- 1980

UAH5-2275 ----- 21.5 14.9 12.5 8.7 4250 ----- 26.0 15.0 ----- ----- 2475

UAH6-2730 ----- 25.8 14.9 15.0 8.7 5100 ----- 31.2 18.0 ----- ----- 2970

(3) All models have single phase motors. Three fan models and larger are delta wired for three phase supply power.

10 3

Page 11

Electrical Data

F

R4

E

EF

ZP

EI

R

F

R6

E

EF

ZP

EI

R

MODEL

NUMBER

1 PH 3 PH 1 PH 3 PH 1 PH 3 PH

U*U1-118 19.9 13.2 22.0 14.6 11.0 9.5 5,512

U*U2-236 35.5 23.5 39.3 26.0 19.6 17.0 9,832

U*U2-355 35.5 23.5 39.3 26.0 19.6 17.0 9,832

U*U3-474 ----- 33.8 ----- 37.4 28.5 24.5 14,152

U*U4-711 ----- 43.3 ----- 47.8 ----- 26.0 18,440

U*U4-851 ----- 61.0 ----- 67.5 ----- 33.8 27,660

U*U4-1080 ----- 61.0 ----- 67.5 ----- 33.8 27,660

U*U5-1350 ----- 75.2 ----- 83.9 ----- 41.6 34,575

U*U6-1620 ----- 89.3 ----- 98.7 ----- 49.3 41,490

U*L1-125 19.9 13.2 22.0 14.6 11.0 9.5 5,512

U*L1-152 19.9 13.2 22.0 14.6 11.0 9.5 5,512

U*L1-193 19.9 13.2 22.0 14.6 11.0 9.5 5,512

U*L2-240 35.5 23.5 39.3 26.0 19.6 17.0 9,832

U*L2-304 35.5 23.5 39.3 26.0 19.6 17.0 9,832

U*L2-361 35.5 23.5 39.3 26.0 19.6 17.0 9,832

U*L2-408 35.5 23.5 39.3 26.0 19.6 17.0 9,832

U*L3-445 ----- 33.8 ----- 37.4 28.2 24.5 14,152

U*L3-540 ----- 33.8 ----- 37.4 28.2 24.5 14,152

U*L3-613 ----- 33.8 ----- 37.4 28.2 24.5 14,152

U*L3-660 ----- 33.8 ----- 37.4 28.2 24.5 14,152

U*L4-722 ----- 43.2 ----- 47.8 ----- 26.0 18,440

U*L4-817 ----- 43.2 ----- 47.8 ----- 26.0 18,440

U*L4-950 ----- 61.0 ----- 67.5 ----- 33.8 27,660

U*L4-1100 ----- 61.0 ----- 67.5 ----- 33.8 27,660

U*L4-1260 ----- 61.0 ----- 67.5 ----- 33.8 27,660

U*L4-1380 ----- 61.0 ----- 67.5 ----- 33.8 27,660

U*L5-1575 ----- 75.2 ----- 83.9 ----- 41.6 34,575

U*L5-1725 ----- 75.2 ----- 83.9 ----- 41.6 34,575

U*L6-1890 ----- 89.3 ----- 98.1 ----- 49.3 41,490

U*L6-2070 ----- 89.3 ----- 98.1 ----- 49.3 41,490

AMPERAGE RATINGS @ 60 Hz

208 V. 230 V. 460 V.

ELECTRIC DEFROST (4)

WATTS

C

O6

O

LF

EP

RI

U*M1-164 19.9 13.2 22.0 14.6 11.0 9.5 5,512

U*M1-209 19.9 13.2 22.0 14.6 11.0 9.5 5,512

U*M2-270 35.5 23.5 39.3 26.0 19.6 17.0 9,832

U*M2-329 35.5 23.5 39.3 26.0 19.6 17.0 9,832

U*M2-390 35.5 23.5 39.3 26.0 19.6 17.0 9,832

U*M2-441 35.5 23.5 39.3 26.0 19.6 17.0 9,832

U*M3-583 ----- 33.8 ----- 37.4 ----- 24.5 14,152

U*M3-662 ----- 33.8 ----- 37.4 ----- 24.5 14,152

U*M4-780 ----- 43.3 ----- 47.8 ----- 24.3 18,440

U*M4-882 ----- 43.3 ----- 47.8 ----- 24.3 18,440

U*M4-1100 ----- 64.3 ----- 71.3 ----- 33.7 27,660

U*M4-1320 ----- 64.3 ----- 71.3 ----- 33.7 27,660

U*M4-1656 ----- 64.3 ----- 71.3 ----- 33.7 27,660

U*M5-2065 ----- 72.2 ----- 79.8 ----- 39.9 34,575

U*M6-2480 ----- 86.6 ----- 95.7 ----- 47.9 41,490

(4) All electric defrost models are standard three phase heaters unless otherwise specified.

See table above to determine models applicable to single phase heater applications.

Page 12

®

Electrical Defrost Kits

F

R4

E

EF

ZP

EI

R

F

R6

E

EF

ZP

EI

R

C

O6

O

LF

EP

RI

MODEL

NUMBER

*U1-118

U

*U2-236

U

U*U2-355

U*U3-474

*U4-711

U

*U4-851

U

*U4-1080

U

U*U5-1350

*U6-1620

U

U*L1-125

U*L1-152

*L1-193

U

*L2-240

U

U*L2-304

U*L2-361

*L2-408

U

*L3-445

U

U*L3-540

*L3-613

U

*L3-660

U

*L4-722

U

*L4-817

U

*L4-950

U

*L4-1100

U

U*L4-1260

U*L4-1380

*L5-1575

U

*L5-1725

U

U*L6-1890

U*L6-2070

U*M1-164

U*M1-209

U*M2-270

U*M2-329

U*M2-390

U*M2-441

U*M3-583

U*M3-662

U*M4-780

U*M4-882

U*M4-1100

U*M4-1320

U*M4-1656

U*M5-2065

U*M6-2480

1 EVAPORATOR

230/3 460/3

D-11

E

D-11

E

D-11

E

ED-14

D-14

E

D-16

E

D-16

E

ED-16

1)

(

ED-11

ED-11

D-11

E

ED-11

ED-11

ED-11

D-11

E

D-14

E

ED-14

ED-14

D-14

E

D-14

E

D-14

E

ED-16

ED-16

D-16

E

ED-16

ED-16

ED-16

(1)

(1)

ED-11

ED-11

ED-11

ED-11

ED-11

ED-11

ED-14

ED-14

ED-14

ED-14

ED-16

ED-16

ED-16

ED-16

(1)

ED-12

D-12

E

ED-12

ED-12

D-12

E

D-14

E

ED-14

ED-14

D-16

E

ED-12

ED-12

D-12

E

D-12

E

ED-12

ED-12

D-12

E

ED-12

ED-12

ED-12

ED-12

D-12

E

ED-12

D-14

E

D-14

E

ED-14

D-14

E

D-14

E

D-14

E

ED-16

ED-16

ED-12

ED-12

ED-12

ED-12

ED-12

ED-12

ED-12

ED-12

ED-12

ED-12

ED-14

ED-14

ED-14

ED-14

ED-16

Electrical Defrost Kit Components

MODEL

NUMBER

ED-10

ED-11

ED-12

ED-13

ED-14

ED-15

ED-16

ED-20

ED-21

ED-22

ED-23

ED-24

ED-25

ED-26

ED-27

ED-28

ED-30

ED-32

ED-33

ED-34

ED-35

ED-36

ED-37

ED-38

TIMER

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

AUXILIARY

SWITCH

----1

1

1

1

1

1

----1

1

1

1

1

1

1

1

----1

1

1

1

1

1

1

BLOCK-

OUT

RELAY

1-30A

-----

-----

-----

-----

-----

-----

1-30A

-----

-----

-----

-----

-----

-----

-----

-----

1-30A

-----

-----

-----

-----

-----

-----

-----

CONTACTORS

DEFROST

HEATERS

----1-30A

1-30A

1-50A

1-50A

2-50A

2-50A

----2-15A

2-15A

2-25A

2-25A

2-50A

2-50A

2-75A

2-75A

----3-10A

3-15A

3-15A

3-30A

3-30A

3-50A

3-50A

1-25A

1-25A

1-25A

1-25A

1-25A

1-25A

1-25A

1-25A

1-25A

1-25A

1-40A

FAN

-----

-----

-----

-----

-----

-----

-----

-----

-----

-----

-----

-----

-----

2 EVAPORATORS

230/3 460/3

ED-21

D-25

E

D-25

E

ED-26

ED-26

D-28

E

D-28

E

(1)

(1)

D-21

E

D-21

E

ED-21

ED-25

ED-25

D-25

E

ED-25

ED-26

D-26

E

D-26

E

D-26

E

ED-26

D-26

E

ED-28

ED-28

D-28

E

D-28

E

(1)

(1)

(1)

(1)

ED-21

ED-21

ED-25

ED-25

ED-25

ED-25

ED-26

ED-26

ED-28

ED-28

ED-28

ED-28

ED-28

(1)

(1)

SEQUENCY

RELAY

-----

-----

-----

-----

-----

-----

----2

2

2

2

2

2

2

2

2

3

3

3

3

3

3

3

3

TIMER

Initiates the defrost cycle. Also used as over ride protection

for defrost termination.

AUXILIARY SWITCH

Mounted on the compressor contactor, it prevents the defrost

contactor from operating whenever the compressor is

energized.

BLOCK-OUT RELAY

Serves the same function as auxiliary switch, except used

when defrost contactor is not required (single phase only).

FAN CONTACTOR

Used with 460 V. motors or when 230 V. motors are wired for

3 phase power.

DEFROST CONTACTOR

Carries amperage load for heaters. Contactor selection is

based on the maximum resistive load rating of the contactor.

SEQUENCING RELAYS

Provides interconnection of multiple unit coolers on a single

system so that each unit cooler is allowed to individually

terminate defrost on temperature.

Ultra - Temp Ultra - Temp

3 EVAPORATORS

230/3 460/3

D-22

E

ED-24

ED-24

D-24

E

D-26

E

ED-26

ED-26

D-26

E

D-28

E

D-22

E

ED-22

D-22

E

D-24

E

ED-24

ED-24

ED-24

D-24

E

ED-24

ED-24

ED-24

D-24

E

ED-24

D-26

E

ED-26

ED-26

D-26

E

ED-26

ED-26

ED-28

ED-28

ED-22

ED-22

ED-24

ED-24

ED-24

ED-24

ED-24

ED-24

ED-24

ED-24

ED-26

ED-26

ED-26

ED-26

ED-28

D-33

E

ED-35

ED-35

D-38

E

D-38

E

1)

(

(1)

1)

(

1)

(

ED-33

ED-33

ED-33

ED-35

ED-35

ED-35

D-35

E

ED-38

ED-38

D-38

E

D-38

E

D-38

E

D-38

E

1)

(

(1)

(1)

1)

(

(1)

(1)

(1)

(1)

ED-33

ED-33

ED-35

ED-35

ED-35

ED-35

ED-38

ED-38

ED-38

ED-38

(1)

(1)

(1)

(1)

(1)

(1) Consult factory.

D-32

E

D-36

E

D-36

E

ED-36

D-36

E

D-38

E

ED-38

ED-38

D-38

E

D-32

E

D-32

E

ED-32

ED-36

D-36

E

D-36

E

ED-36

D-36

E

D-36

E

D-36

E

ED-36

ED-36

D-36

E

ED-38

ED-38

D-38

E

D-38

E

ED-38

ED-38

ED-38

ED-38

ED-32

ED-32

ED-36

ED-36

ED-36

ED-36

ED-36

ED-36

ED-36

ED-36

ED-38

ED-38

ED-38

ED-38

ED-38

3050 Enterprise St., P.O. Box 1030, Brea, CA 92822-1030 • Tel: (714) 529-1935 • Fax: (714) 529-7203

Loading...

Loading...