Page 1

Publication No. RU-HRX-1012A

HR

HEAT RECLAIM

Space Heaters for: Storage rooms, Receiving areas, Loading Docks, Miscellaneous

Supplemental Heating.

In an air conditioning or refrigeration system the heat taken from the conditioned space or product

is usually wasted to the atmosphere by a water or air cooled condenser. The Russell Reclaim Heater

may be used to recapture this wasted heat, (100% recovery on parallel piping arrangement to about

70% for series connection.)

Page 2

2

HEAT RECLAIM

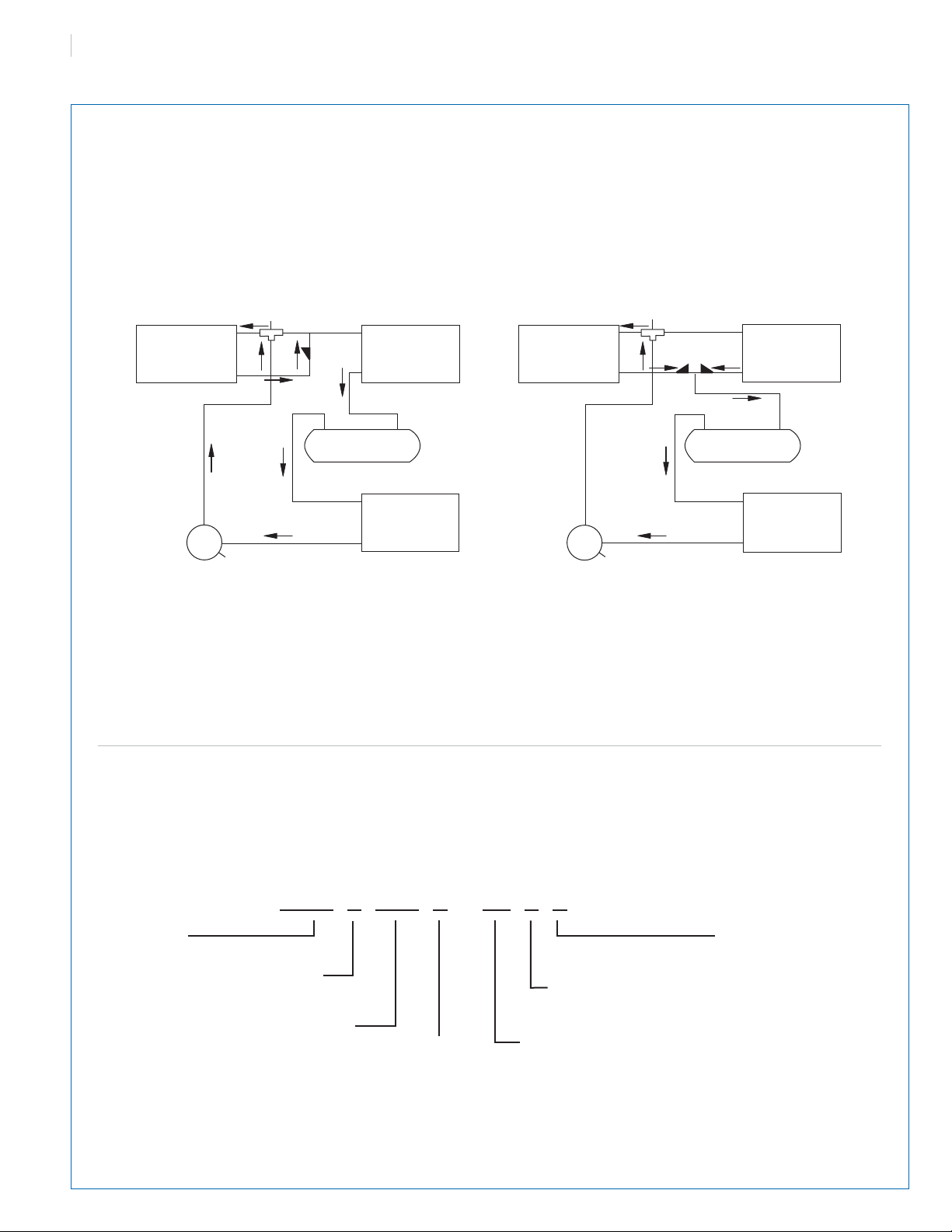

PIPING DIAGRAM

SERIES ARRANGEMENT PARALLEL ARRANGEMENT

3 Way Valve

Heat

Reclaim

*

Air

Cooled

Condenser

Receiver Receiver

Evaporator

Compressor

* Check Valve

NOTE: Arrows show refrigerant path in reclaim mode.

Heat

Reclaim

3Way Valve

**

Compressor

Air

Cooled

Condenser

Evaporator

MODEL

SERIES

MODEL NUMBER NOMENCLATURE

HAC S 001 B -08V E

FAN MOTOR SPEED:

S = 1140 RPM

NOMINALCAPACITY

Tons @ 30° TD, R-22

COIL TUBE SIZE

B = 3/8” Tubing

AIR DISCHARGE

H - Horizontal Discharge

V - Vertical Discharge

COIL FIN SPACING

08, 10, FPI

ELECTRICAL CODE

D - 208-230/1/60

E - 208-230/3/60

F - 460/1/60

G - 460/3/60

H = 575/1

Page 3

HEAT RECLAIM

SPECIFICATIONS — RUSSELL HEAT RECLAIM UNIT HEATERS

R-404A

Capacity

HACS001B-08 32,000 29,000 3100 1 18" 1/2 1140 2.5 2.0 1.0

HACS002B-08 57,000 53,000 2750 1 18" 1/2 1140 2.5 2.0 1.0

HACS003B-08 83,000 83,000 3850 1 22" 1/2 1140 2.5 2.0 1.0

HACS005B-10 127,000 115,000 3700 1 22" 1/2 1140 2.5 2.0 1.0

HACS008B-10 178,000 176,000 7700 2 22" 1/2 1140 5.0 4.0 2.0

HACS010B-10

HACS012B-10 310,000 270,000 7000 2 22" 1/2 1140 5.0 4.0 2.0

NOTE: Capacities shown in Gray have Opposite End Connections. Special conditions on certain models may make it necessary to use OEC’s.

Capacities shown are for 50°F TD(condensing temperature minus entering air temperature).

† - Heating Capacity

254,000

R-22

Capacity

230,000 7400 2 22" 1/2 1140 5.0 4.0 2.0

Correction factors below are for capacities at other TD’s.

TD 30 35 40 45 50 55 60

Factor 0.6 0.7 0.8 0.9 1.0 1.1 1.2

MotorsFans

3

spmA rotoM latoTLATOTledoM

stloV 064stloV 3/032stloV 1/032MPR.P.H.aiD.muNMFCrebmuN

EXAMPLE: 65° Entering Air, Compressor Total Heat Rejection at 110° Condensing Temperature 44,000 BTU/HR

110 - 65 = 45 use correction factor 0.9, = 48,889 use HACS002

44,000

0.9

DIMENSIONS

Model W

HACS Drawing A B C D E F Net Shipping

001 1 12 9/16 28 25 5/8 26 1/2 15 40 78 97

002

1 12 9/16 28 25 5/8 26 1/2 16 1/2 40 86 105

003 1 14 1/2 33 30 5/8 31 1/2 16 1/2 45 107 128

005 1 14 1/2 33 30 5/8 31 1/2 17 1/2 45 116 137

008 2 14 1/2 — — — — — 164 190

010214 1/2—————179 205

012215 3/4—————195 221

eight (lbs.)

Page 4

HEAT RECLAIM

Drawing - 1

Horizontal Discharge Vertical Discharge

3 3/4

9/16 DIA.

LIFTING

HOLES (4)

Drawing - 2

9/16 DIA.

HOLES (4)

3 3/4

LIFTING

ELECTRICAL BOX

A

D

B

9/16 DIA. (4)

MT'G HOLES

E

C

A

15

15

C

F

9/16 DIA.

LIFTING

HOLES (4)

Horizontal Discharge Vertical Discharge

A

D

B

9/16 DIA. (4)

MT'G HOLES

E

ELECTRICAL BOX

C

15

9/16 DIA.

LIFTING

HOLES (4)

C

A

15

F

ELECTRICAL

B

9/16 DIA. (4)

MT'G HOLES

E

BOX

B

9/16 DIA. (4)

MT'G HOLES

E

ELECTRICAL

BOX

Due to continuing product development, specifi cations are subject to change without notice.

201 Thomas French Drive, Scottsboro, AL 35769 PHONE (256) 259-7400 FAX (256) 259-7478 russell.htpgusa.com

Loading...

Loading...