Russell FL26-67, WF-050 Installation Manual

Installation, Operation, and

Part # 08499173

Maintenance Information

Low Velocity Unit Coolers

Bulletin No. IOM 110.3

Table of Contents

Inspection ................................................................................................................................................................................ 2

Installation ....................................................................................................................................................................... 2 – 4

General .................................................................................................................................................................................... 2

Location ............................................................................................................................................................................... 2

Drain Line ............................................................................................................................................................................ 3

Refrigerant Piping ................................................................................................................................................................ 3

Expansion Valve .................................................................................................................................................................. 3

Evacuation ........................................................................................................................................................................... 3

Wiring ............................................................................................................................................................................. 3 - 4

Typical Wiring Diagrams ................................................................................................................................................. 4

Start-up Procedure .......................................................................................................................................................... 5 – 6

System Check ......................................................................................................................................................................... 5

Initial Start-up ...................................................................................................................................................................... 5

Superheat Adjustment ................................................................................................................................................... 5 – 6

Maintenance..................................................................................................................................................................... 6 – 7

General ................................................................................................................................................................................ 6

Cleaning ............................................................................................................................................................................... 6

Check-up .............................................................................................................................................................................. 6

Fan Blade and Motor Replacement ..................................................................................................................................... 6

Defrost Heater Replacement ............................................................................................................................................... 7

Troubleshooting Chart ......................................................................................................................................................... 7

Replacement Parts ................................................................................................................................................................ 8

Service Record ...................................................................................................................................................................... 8

HTPG ● www.htpgusa.com

INSPECTION

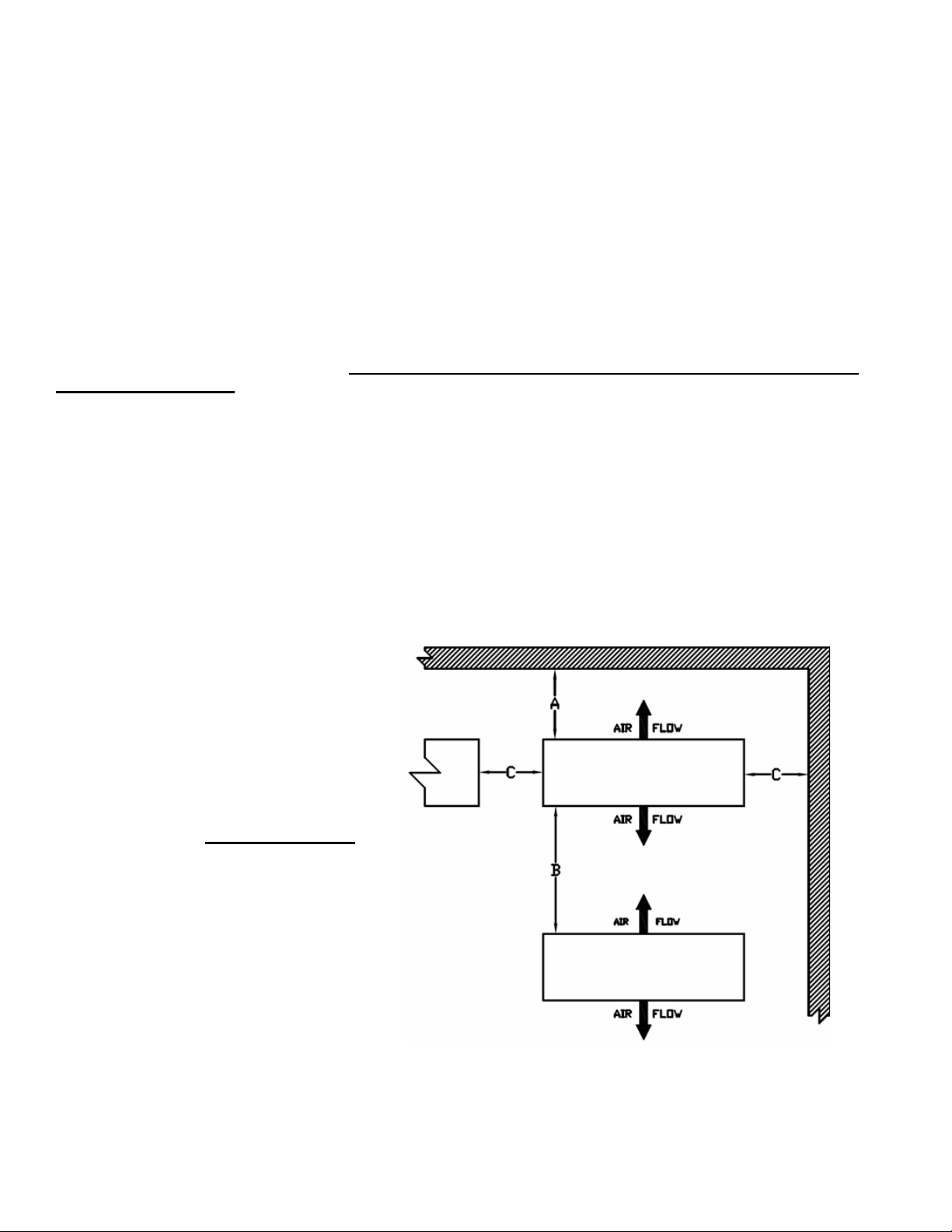

A B C

Min. 5 10 2

Max. 15 30 10

Dimension (Ft.)

Part # 08499173

When the equipment is received, the number of crates and cartons should be checked against the bill of lading. Any

damage or shortages should be noted immediately and a report given to the freight carrier and the manufacturer. It is the

customer’s responsibility to file all freight claims with the carrier. Verify that the voltage listed on the unit nameplate

matches the power supply available.

INSTALLATION

General

Installation and maintenance must be performed by qualified personnel who are familiar with the local codes and

regulations and who are experienced with this type of equipment. When mounting the units, lift and handle them by the

cabinet or hanger flanges only. Lifting by the tubing or fan guards may result in damage to the unit. The unit should be

mounted level to ensure proper drainage. Caution: Avoid contact with sharp edges and coil surface as they are

potential injury hazards.

Location

Determine the best location for the unit cooler in the room to be refrigerated. Placement of the unit should be centered in

the room and away from doors to keep warm, outside air from being drawn into the unit. This dual discharge unit draws air

up through the fan blades and discharges it through the coil surface. Figure 1 shows the proper clearances that should be

maintained for proper air flow and service access to the unit. Allow at least 36 inches space below the drain pan for air

flow and service access. Before unit is raised into position all packaging should be removed while taking care not to

damage the drain fitting or refrigerant connections. The unit should be supported on 5/16” minimum rod hangers, or 5/16”

minimum lag bolts, at all mounting slots. To meet NSF requirements, the unit must be positioned flush with the ceiling and

all gaps properly caulked. If hung below the ceiling, adequate space for cleaning must be provided per NSF requirements.

Drain Line

Figure 1: Unit Location (Top View)

2

The drain line should be pitched at a minimum of 1/2” per foot to allow proper drainage and should exit the refrigerated

Part # 08499173

space as soon as possible. The drain line should be insulated and sealed to protect from freezing where it passes

through the wall and a trap provided outside the refrigerated area. In rooms with temperatures below 34° F, the drain line

should be heated and insulated.

Refrigerant Piping

Refrigerant piping should be installed in accordance with all applicable codes and using good refrigeration practices. For

liquid and suction line sizing, refer to the ASHRAE Refrigeration Handbook. A trap must be installed prior to any risers in

the suction line. Horizontal suction lines should be sloped at a minimum of 1/8” per foot to provide proper oil return to the

compressor. Suction lines should be properly insulated to prevent sweating and higher return gas temperatures.

Expansion Valve

Expansion valves are to be sized and installed in accordance with the valve manufacturer’s recommendations. Valves

should include an external equalizer line, which must be connected. Proper location of the sensing bulb is extremely

important to the performance of the coil. Good thermal contact to the suction line is essential. On solder type valves, a

wet cloth wrapped around the valve during installation will help protect it from overheating and damage during the

installation process.

Evacuation

Proper evacuation is essential prior to charging the system. This avoids many problems that may arise due to lack of

detail in this step. After charging, the system should be checked through all cycles to ensure proper operation. See Startup Procedure section in this bulletin.

Wiring

Wiring should be done in accordance with all national and local codes. Electric defrost units are supplied with a

temperature sensing defrost termination switch which will terminate the defrost at a preset temperature. A fan delay

switch is also provided to allow the coil to cool down prior to the fans restarting after the defrost cycle. The time clock

should be adjusted to have a maximum 30 minute override to prevent overheating and steaming of the coils. Typically

one to two defrosts per day are recommended however the number of defrosts are ultimately dictated by the usage of the

box and the actual amount of frost buildup on the coils.

3

Loading...

Loading...