Russell FC11A Installation Manual

C

oldZone

OWNERS

INSTRUCTION MANUAL

221 South Berry Street P.O. Box 1030

Brea, CA 92621-4888 Brea, CA 92622-1030

Phone: 714/529-4461 * Fax: 714/529-8503

TABLE OF CONTENTS

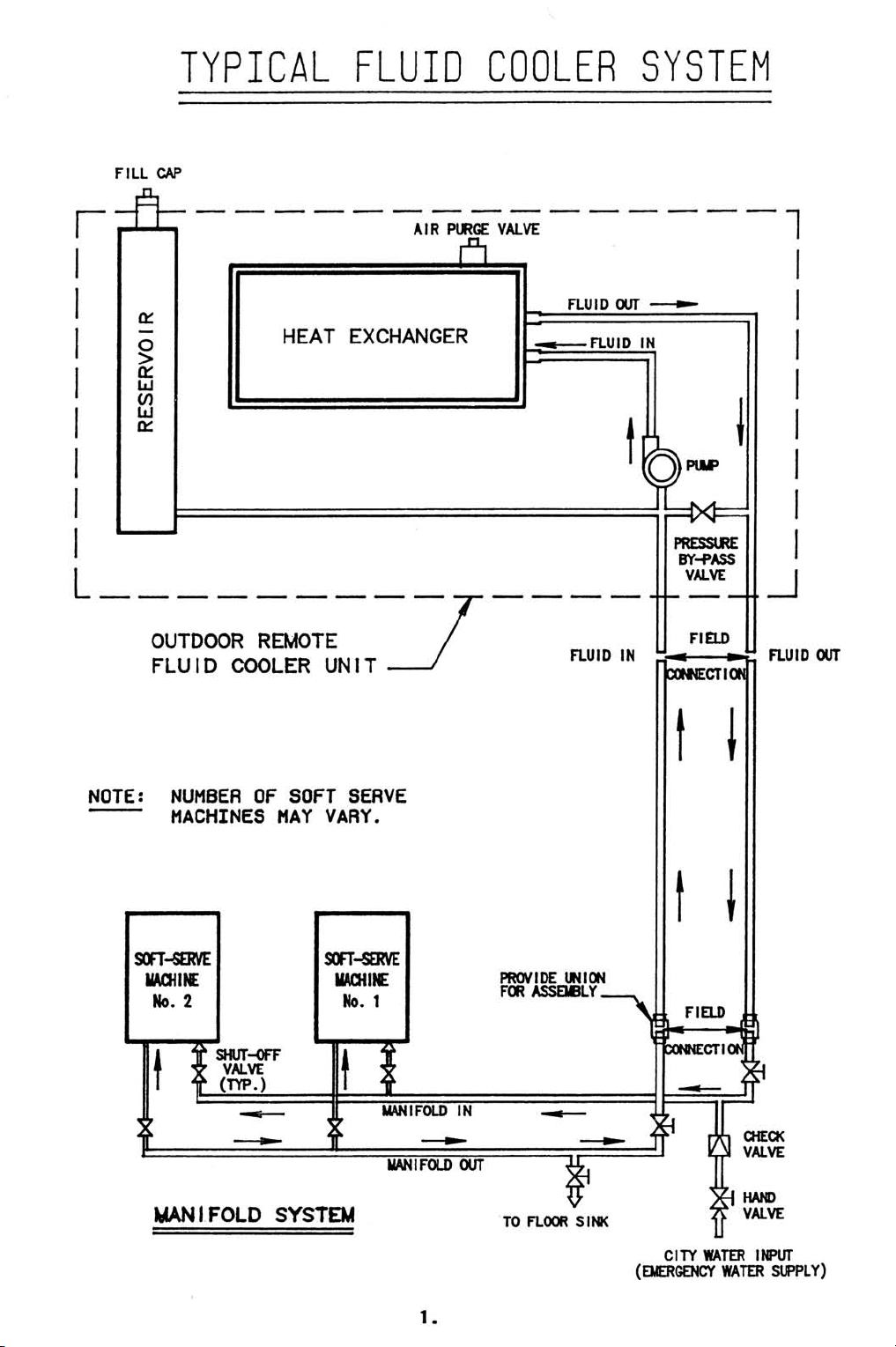

TYPICAL FLUID COOLER SYSTEM………………………………...1

INTRODUCTION………………………………………………………..2

General Description …...........................................................................2

Closed-Loop Glycol Fluid Cooler..……………………………………2

Closed-Coupled Centrifugal Pump …………………………………..2

Heat Exchanger ………………….…………………………………….2

Fan Motor .,……………………….……………………………………3

Glycol Fluid ……………………………………………………………3

Fluid Manifolds ………………………………………………………..3

Control Panel ………………………………………………………….3

Electrical Characteristics ……………………………………………..3

Standard Components ………………………………………………...3

Diagram Size and Weight………………..…………………………....4

Diagram Rigging Detail ……………………………………………….5

INSTALLATION………………………………………………………...6

Receipt and Inspection of Equipment…………….………………….6

Lifting Instructions …………………………………...………………6

Location and Ventilation ……………………………..………………6

Installation Area ………………………………………...…………….6

Roof Rail Requirements …………………………………..…………..6

Pitch Pocket ……………………………………………………………6

Electrical ……………………………………………………..………...7

Glycol Piping …………………………………………………………..7

Diagram Rail, and Cubb Detail ………………………………………8

Diagram Wiring Diagram …………………………………….………9

START-UP PROCEDURE …….………………………………………10

Mechanical Seal……………………………………………………….10

MAINTENANCE …………………………………….…………………11

Heat Transfer Surface ………………………………………………..11

Electric Motor ………………………………………………………...11

Repairs or Replacement of Parts ………………………………….....11

Removal of Old Seal …………………………………………………. 11

Installation of Replacement Seal ……………………………………..12

SERVICE DIAGNOSIS………………………………………………… 13

Trouble Shooting Chart ………………………………………………13

STANDARD WARRANTY ……………………………………………..14

PROPYLENE GLYCOL (MSDS)…………………………………...15-17

INTRODUCTION

GENERAL DESCRIPTION

The COLDZONE "Fluid Cooler" system is (U.L. File #SA2285, Vol. 1 Section 3) designed

primarily for fast food requirements and installations where only a small quantity of water

cooled refrigerated fixtures are to be remote, ie; soft-serve freezers for ice cream and frozen

yogurt and water cooled condensing units. This will allow heat dissipation on the roof for the

high heat producing condensing units, thus eliminating water consumption and reducing indoor

air conditioning requirements at a very nominal cost. Totally pre-piped, pre-wired, and

weatherized for fast, low cost rigging and installation on rooftop, it is only necessary to provide

main power lines to control panel. In addition, the unit has been carefully designed for easy

installation, providing ready access for service and maintenance of all major components.

CLOSED-LOOP GLYCOL FLUID COOLER

A closed-loop glycol fluid cooling system is installed with the anticipation that it will provide

many years of trouble-free operation with minimum maintenance. Usually the length of service

life realized from a particular fluid cooler is directly proportional to the care with which the

original installation was performed. Cleanliness is absolutely mandatory when installing the

system. All tubing, valves and fittings must be carefully inspected to insure cleanliness.

The correct electrical supply must be provided to the fluid cooler control panel. The voltage at

the pump and fan motor terminals should be checked during start-up and unit operation under

full load to insure a tolerance of plus or minus 10% of the nameplate rating.

CLOSED-COUPLED CENTRIFUGAL PUMP

A closed-coupled centrifugal pump is precision built for liquid transfer and recirculation of

glycol fluid from water copied condenser to rooftop heat exchanger. The pump is equipped with

a drip-proof motor with shielded ball bearings, thermal protector, sintered iron and BUNA N

mechanical seal and type 303 stainless steel shaft. Discharge port of the pump can be rotated in

90° increments to accommodate various applications.

HEAT EXCHANGER

A heat exchanger is installed in the fluid cooler system to reject heat on the roof to provide a

10°F differential. Each coil is made with aluminum fins bonded upon copper tubing. A shroud is

incorporated in the construction of the condenser to provide controlled air flow over the cooling

surface.

2.

FAN MOTOR

Each fluid cooler package is equipped with at least one fan motor to reject heat. Fan motors capable

of operating for years with trouble free maintenance are permanently lubricated with inherent

overload protection to prevent locked rotor or overheating.

GLYCOL FLUID

ColdZone provides 100% propylene glycol, field mixing is required. A 50% propylene glycol and

water solution is recommend for cooling media. In geographical area's where the outside

temperature may reach -20°F or below contact the ColdZone Service Department. ColdZone

provides 100% propylene glycol, field mixing is required.

FLUID MANIFOLDS

Two fluid manifolds are provided with shut-off valves and by pass valves. Emergency water supply

should be piped through manifolds. Emergency water discharge should be piped to a floor drain.

CONTROL PANEL

Each system is provided with a pre-wired, weather-proof control panel for single point power

connection with main-fused disconnect.

ELECTRICAL CHARACTERISTICS

Each "Fluid Cooler" is equipped for 208/230 volts, 1 phase, 60 hertz power supply.

STANDARD COMPONENTS

Each "Fluid Cooler" consists of closed coupled centrifugal pump, heat exchanger with heavy duty fan

motor, oversized reservoir, control panel with main-fused disconnect and two fluid manifolds.

The "Fluid Cooler" package system is tested and assembled under strict quality assurance

procedures. Each unit is tested for leaks prior to shipment.

3.

NNOOTTEE:: 3366"" MMIINNIIMMUUMM SSPPAACCEE RREEQQUUIIRREEDD OONN AALLLL FFOOUURR SSIIDDEESS OOFF FFLLUUIIDD CCOOOOLLEERR FFOORR

VVEENNTTIILLAATTIIOONN AANNDD SSEERRVVIICCAABBIILLIITTYY..

CONNECTIONS

(O. D.)

DIMENSIONS

(INCH)

COLOZONE

MODEL

NO.

NUMBER

OF FANS

HEAT OF

REJECTION

(BTU)

TOTAL

FLUID

VOLUME

(SAL)

FLUID

FLOW

(SPM)

HOT

FLUID

(INLET)

COLD

FLUID

(OUTLET)

L V H

TOTAL

SYS. AMPS

(230VOLT/

1PH/60HZ)

SHIPPING

WEIGHT

(LBS. )

DRY

WEIGHT

(LBS.)

FC-3A 1 30.000 4 4 1 1/8 1 1/8 43.5 48 43 9.7 625 400

FC-5A 2 50.000 5 8 1 1/8 1 1/8 73 48 43 13.9 750 470

FC-7A 2 70.000 8 12 1 1/8 1 1/8 73 48 43 16.2 850 570

FC-9A 2 90.000 10 16 1 3/8 1 3/8 73 48 43 16.2 950 670

FC-11A 2 110.000 12 18 1 5/8 1 5/8 73 48 43 17.7 1050 770

FC-15A 3 150.000 14 22 1 5/8 1 5/8 103 48 43 21.9 1350 1000

COLDZONE RESERVES THE RIGHT TO MAKE CHANGES IN DESIGN AND CONTRUCTION AT ANY TIME WITHOUT NOTICE. MAXIMUM

LINE RUN 65' HORIZONTALLY AND 30' VERTICAL. FOR LONGER LINE RUNS. CONSULTS THE FACTORY.

4.

Loading...

Loading...