Russell ETHN-2 Installation Manual

C

oldZone

OWNERS

INSTRUCTION MANUAL

221 South Berry Street P.O. Box 1030

Brea, CA 92621-4888 Brea, CA 92622-1030

Phone: 714/529-4461 * Fax: 714/529-8503

Cold

ENVIRO-THERM

Zone

ENVIRO-COOL

CUSTOM PACKAGED CLOSED-LOOP SYSTEMS

FOR ALL AMBIENT CONDITIONS

+

OWNER’S

MANUAL

INSTALLATION

OPERATION

MAINTENANCE

A DIVISION OF THE HEAT TRANSFER PRODUCTS GROUP OF ARDCO. INC.

Cold

© AROCO, INC 1990

Zone

221 S. Berry St., Brea, CA 92821-4888

(714) 529-4461 FAX (714) 529-8503

Outside California (800) 772-2653

PRINTED IN U.S.A.

TABLE OF CONTENTS

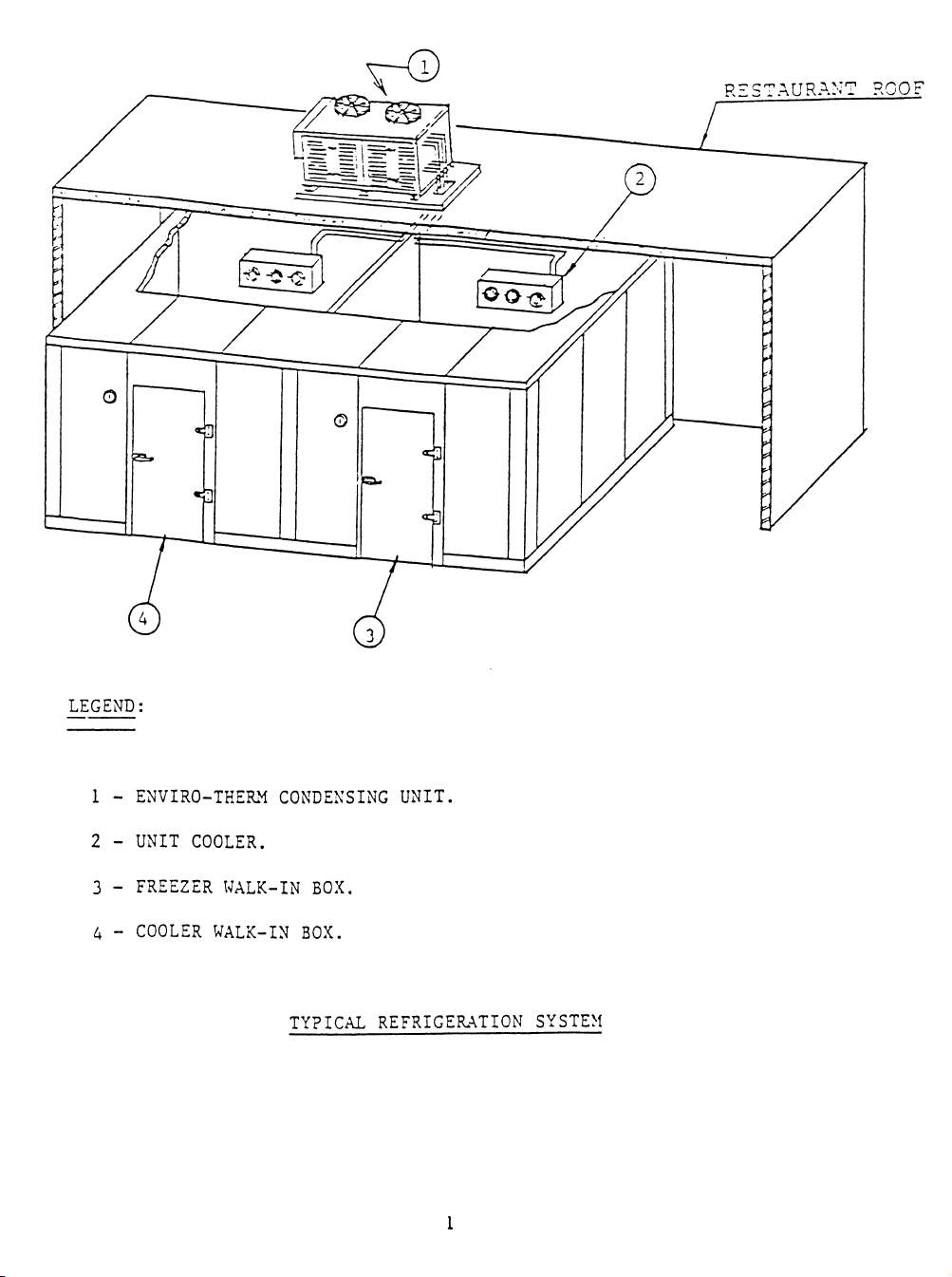

TYPICAL REFRIGERATION SYSTEM.................................. 1

INTRODUCTION ................................................ 2

General Description ..................................... 2

Condensing Unit ......................................... 2

Refrigerant ............................................. 2

Control Panels .......................................... 2

Electrical Defrost ...................................... 3

Electrical Characteristics ............................... 3

Standard Components ..................................... 3

Factory Installed Accessories ........................... 3

U. L. Approval .......................................... 3

W.I. Unit Coolers .................................. 4

INSTALLATION ................................................. 8

Receipt and Inspection of Equipment ............... 8

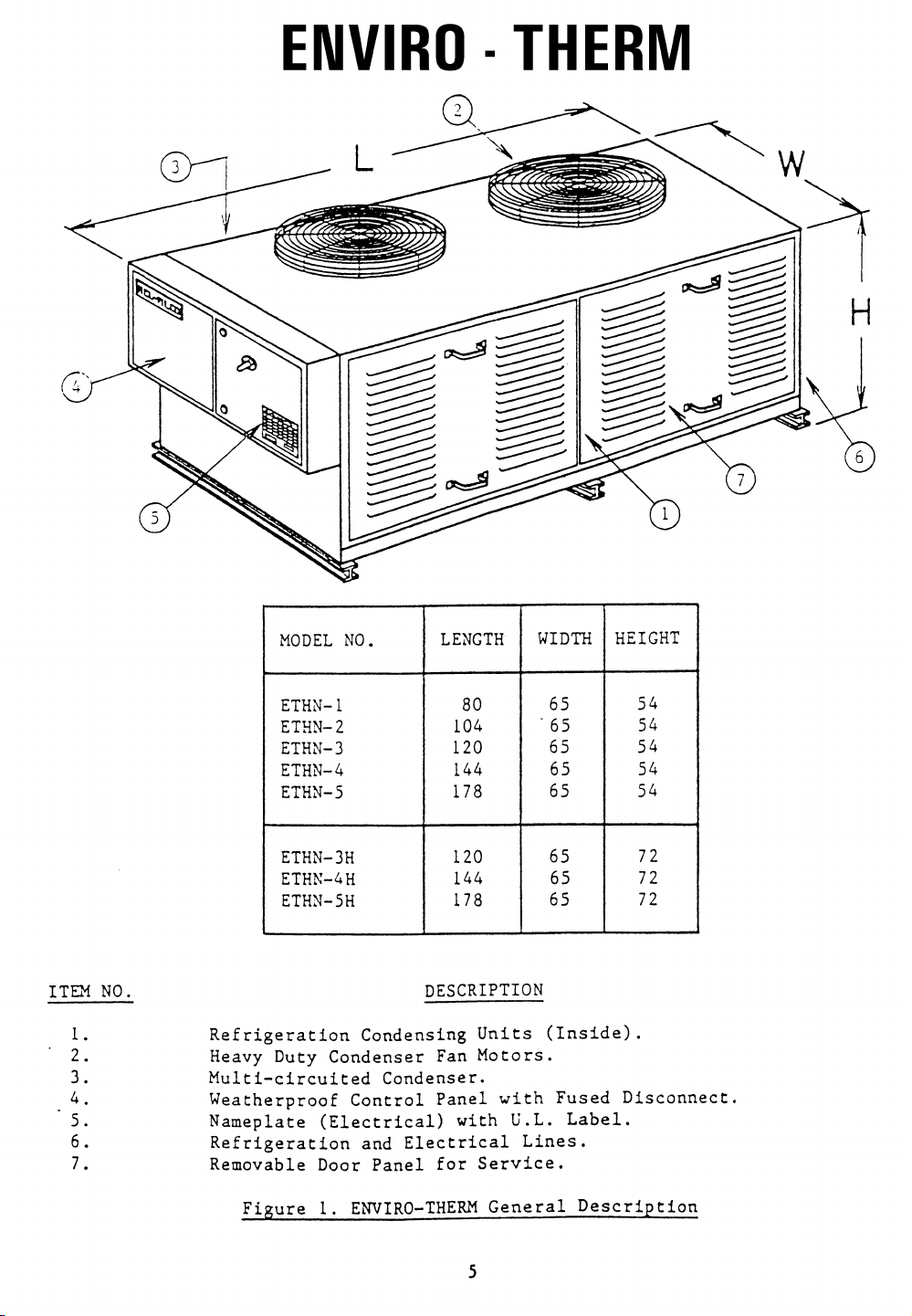

Lifting Instructions ................................. 8

Location and Ventilation .............................. 8

Installation Area ..................................... 8

Roof Rail Requirements .............................. 8

Pitch Pocket .......................................... 8

Electrical ............................................ 11

Refrigeration ......................................... 11

START-UP PROCEDURE ........................................ 13

Condensing Units ........................................ 13

Unit Cooler .............................................. 13

OPERATIONAL CHECK-OUT ........................................ 15

MAINTENANCE .................................................. 18

Air-Cooled Condenser .................................... 18

Electrical and Piping Connections ....................... 18

Crankcase Lubrication ................................... 18

Unit Cooler ............................................. 19

Heater Replacement in Low Temp Unit Cooler .............. 19

SERVICE DIAGNOSIS ........................................... 21

Condensing Units ......................................... 21

STANDARD WARRANTY ........................................... 26

DIRECTORY OF AUTHORIZED WHOLESALERS

REPLACEMENT POLICY

INTRODUCTION

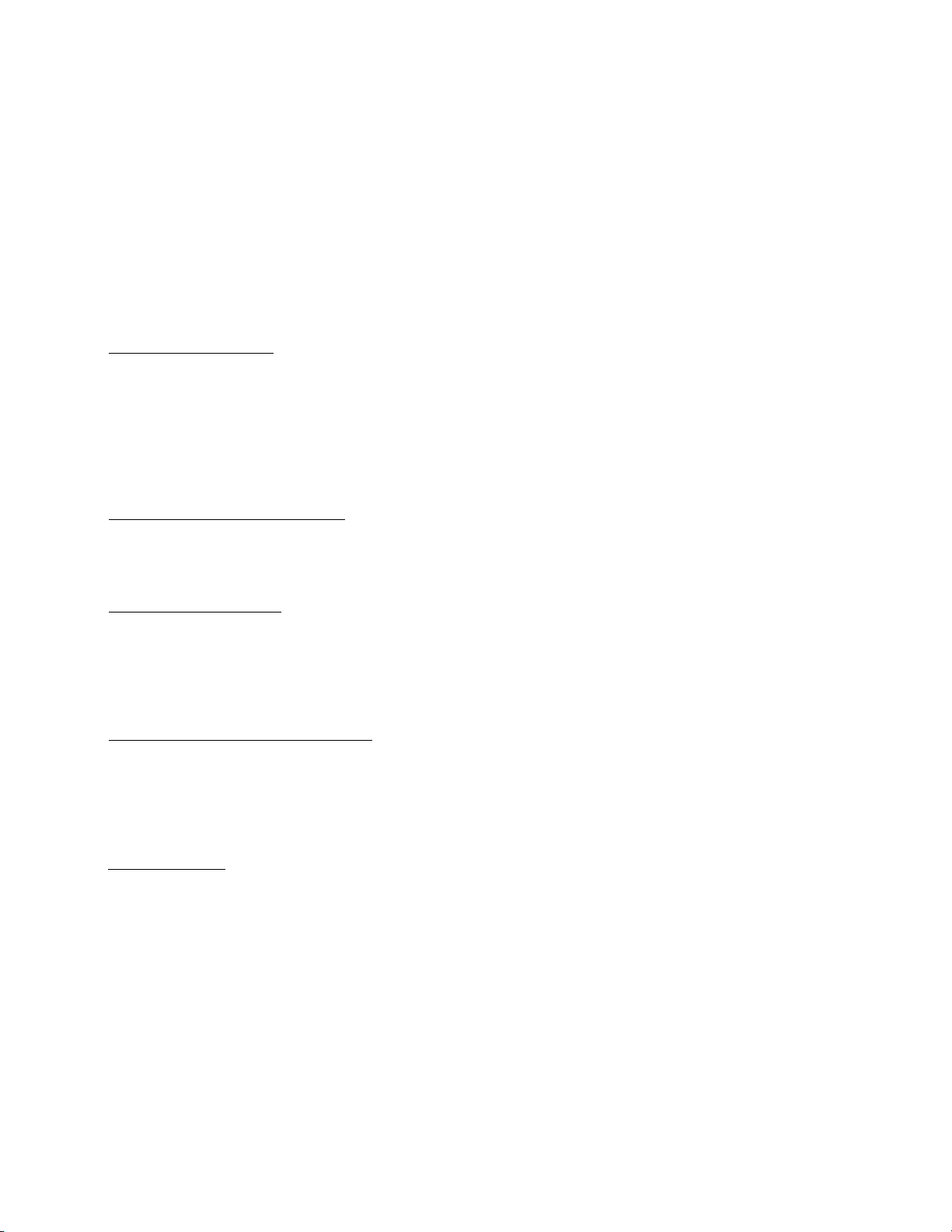

GENERAL DESCRIPTION (Figure 1)

The CZ + FILCO "Enviro-Therm" Outdoor Refrigeration System is designed

primarily for restaurant and hotel requirements and installations where

all refrigerated fixtures are to be remoted, i.e., walk-in

coolers/freezers, backbars, bottle and draft beer coolers, under counter

refrigerators/freezers and ice machines. This will allow the high heat

producing condensing units to be placed outside the building, thus

reducing indoor air conditioning requirements at a very nominal cost.

Totally ore-piped, pre-wired, and weatherized for fast, low cost rigging

and installation on rooftop, it is only necessary to provide main power

lines to control panel and wiring for control and defrost heaters between

panel and refrigeration fixtures. The system accommodates up to sixteen

compressor units and three ice machine condenser in one compact cabinet

thus handling all your refrigeration requirements. In addition, the unit

has been carefully designed for easy installation, providing ready access

for service and maintenance of all major components.

CONDENSING UNIT

A refrigeration condensing unit is a highly sophisticated apparatus. It

is installed with the anticipation that it will provide many years of

trouble-free operation with minimal maintenance. Usually the length of

service life realized from a particular condensing unit is directly

proportional to the care with which the original installation was

performed.

Cleanliness is absolutely mandatory when installing a condensing unit.

Utmost care has been taken at the factory to insure that the unit is free

of all contamination. The factory-applied seals must not be removed

until the unit is ready for installation. All tubing, valves and

fittings must be carefully inspected to insure cleanliness.

The correct electrical supply must be provided to the condensing unit

control panel. The voltage at the motor-compressor terminals should be

checked during start-up and unit operation under full load to insure a

tolerance of plus or minus 10 percent of the nameplate rating.

The lubrication recommendations for the motor-compressor and fan motors

(where applicable) must be carefully adhered to.

REFRIGERANT

R-22 is used for the Walk-In Cooler. R-502 is used for Walk-In Freezer.

CONTROL PANEL

Each Enviro-Therm system is provided with a prewired, weatherproof

control panel for single point connection with main fused disconnect.

2

Control panel is designed Co assure efficient unit operation and provide

a pre-selected sequence of operation during the refrigeration and defrost

cycles. Each control panel is equipped with an interlocked main fused

disconnect, motor compressor breakers, contactors, fan motor capacitor,

defrost time clock for freezer, and metal photo wiring diagram plate for

service. An inside pocket is provided for engineering sheet (R-1) and

installation manual.

The control panel only requires 3-wires for power supply and 4-wires for

defrost heaters and unit cooler fan motors in freezer. All system

circuits are labeled for easy identification.

ELECTRICAL DEFROST

An electric defrost heater in the freezer is field-connected to the time

clock in the control panel. Defrost is initiated by a timeclock and

stopped by a termination solenoid in the timeclock connected to defrost

limit thermostat in the freezer coil. The timeclock is set to fail safe

termination period at 45 minutes. The freezer requires four defrosts per

day starting at 12:00 a.m., 6:00 a.m., 12:00 p.m., and 6:00 p.m..

ELECTRICAL CHARACTERISTICS

Each Enviro-Therm is equipped with 208-230 volts, 3 phase, 60 hertz power

supply with a total connected load of 20 amps.

STANDARD COMPONENTS

Each Enviro-Therm consists of six to sixteen semi-hermetic compressors,

multi-circuited condenser with heavy duty fan motors, oversized

receivers, factory installed accessories, unit coolers with T-Stat,

solenoid valve, TX valve and suction line P-Trap for freezer and cooler.

FACTORY INSTALLED ACCESSORIES

Drier, sight glass, suction and discharge vibration eliminators, head

pressure, control, crankcase heater, dual pressure control, prewired

control panel.

U.L. APPROVAL

The "Enviro-Therm" system is approved by Underwriters Laboratories and

displays the U.L. Label on the Control Panel, U.L. File No. SA6629(s)

under condensing and compressor units (SGYU).

3

W.I. UNIT COOLERS

1. Freezer

A low temperature electric defrost Lo-silhouette Unit Cooler for the

freezer is provided with each Enviro-Therm unit. The Unit Cooler

draws air in through the coil and discharges it through the fans.

For best results, the Unit Cooler should be located 18" from the

back wall and blow towards the door. T-Stat, solenoid valve and TX

valve are installed in the Unit Cooler at the factory. A suction

line P-Trap is also installed in the Unit Cooler for better oil

return.

2. Cooler

A medium temperature Lo-silhouette Unit Cooler for the cooler is

provided with each Enviro-Therm unit. Air defrost is used for

defrosting Unit Cooler. The Unit Cooler is provided with T-Stat,

solenoid valve, TX valve and suction line P-Trap and is prepiped and

prewired for final connections.

The C/Z+FILCO "Enviro-Therm" package refrigeration units are tested and

assembled under strict quality assurance procedures. Each unit is tested and

charged with nitrogen prior to shipment.

4

Loading...

Loading...