Russell ET-5H User Manual

Model ET-5H

Air Cooled

Refrigeration

Systems

ENVIRO-THERM REFRIGERATION SYSTEM

CONTROL PANEL

INTERNAL REFRIGERATION PIPING

COMPRESSOR AND CONDENSER SYSTEMS

FRAME AND HOUSING

221 S. Berry St., P.O. Box 1030, Brea, CA 92822-1030 • Tel (714) 529-4461 • FAX (714) 529-8503

The packaged refrigeration system is to be U.L. Listed and will be

located on a pad outside of the building. This unit includes the

outdoor weather housing, compressor and condenser systems and

electrical control panel, all housed within a single assembly. The

evaporator coil assemblies will be supplied with all the required

options and accessories. All of the component parts, options and

accessories will be provided, mounted, piped and wired, as required

by the manufacturer. The system shall be manufactured to operate

at: _______ volts, ________ phase, ________hertz.

The outdoor weather shall include a welded, de-burred and cleaned

structural steel base frame made of 3 inch members. The exterior

housing and access doors will be manufactured of a minimum of 16

gauge galvanized steel which has been assembled and cleaned.

The frame and housing shall be painted with a baked polyester

powder coating.

All compressors will be Copelaweld, Tecumseh, Copelametic or

Discus. All compressors will be manufactured to operate with R-22

or R-404A refrigerant. Each Compressor system shall be filled with

refrigerant compatible refrigeration oil by the manufacturer and will

include discharge and suction line vibration protection (vibrasorbers

with Copelametic and Discus compressors), dual pressure control

with stainless steel braided piping, liquid line filter-dryer, moisture

indicating sight glass, flooded head pressure control valve and

crankcase heater. Each of these systems shall also include a

receiver tank capable of accepting all of the system refrigerant

without exceeding 90% of its volumetric capacity. Each receiver will

be provided with a pressure relief vent and, at its inlet and outlet, a

roto-lock isolation valve with a service port. Additionally, all

compressor systems that will operate at suction temperatures below

0°F shall include a suction line accumulator.

The condenser system shall include the Multi-Circuited condenser,

³⁄₄ horse power condenser fan motors with 24 inch fan blades

mounted in a venturi contoured air-scoop protected by plastic coated

fan guards, and flooded headpressure controls. The compressors

and condenser circuits shall be sized to operate at an average

temperature differential between the ambient and condensing

temperatures of 20°F.

The exterior mounted, weather proof, electrical control panel will be

manufactured of 14 gauge galvanized steel which has been

assembled, welded, de-burred and cleaned. The control panel shall

include hinged access doors with a built-in fused disconnect switch

inter-locked to shutoff all system electrical power when the doors are

opened, circuit breakers and contactors for each compressor,

required defrost time clocks, and circuit breakers, start capacitors,

and fan cycle control thermostats for each of the condenser fan

motors. A wiring diagram of the refrigeration system shall be photo

etched onto an anodized aluminum plate and permanently affixed to

the inside of the refrigeration system. All internal wiring shall be held

in place with fasteners and individually numbered. The wire

numbers shall be shown on the wiring diagram

All of the internal refrigeration piping shall be extended to one side

of the refrigeration system in a neat and orderly manner. Each set

of piping shall have a label permanently affixed identifying the

system it will service. All internal refrigeration piping shall be

refrigerant grade A.C.R. or type L copper tubing. All tubing shall be

held in place with Uni-Strut channels and clamps and protected with

neoprene grommets. A minimum of

¹⁄₂ inch thick insulation shall

cover all suction lines.

After circuiting the condenser shall be tested for leaks at a minimum

pressure of 500 pounds per square inch/gauge (psig). After final

assembly the entire system shall be tested for leaks at 300 psig and

evacuated pressure test at 500 microns at the factory. The

refrigeration system shall be shipped with a 25 psig charge of dry

nitrogren.

EVAPORATOR COILS

The evaporator assemblies, and the parts associated with them, will

be mounted inside of the walk-ins. Each evaporator coil shall

include a matching thermostatic expansion valve, liquid line solenoid

valve and thermostat. In cases where two (2) or more evaporator

coils are to be piped to a single compressor the thermostat and liquid

line solenoid valve will be shipped loose to be mounted and wired at

the job site.

ITEM NO:_______

Model ET-5H

Air Cooled

Refrigeration

Systems

U

L

®

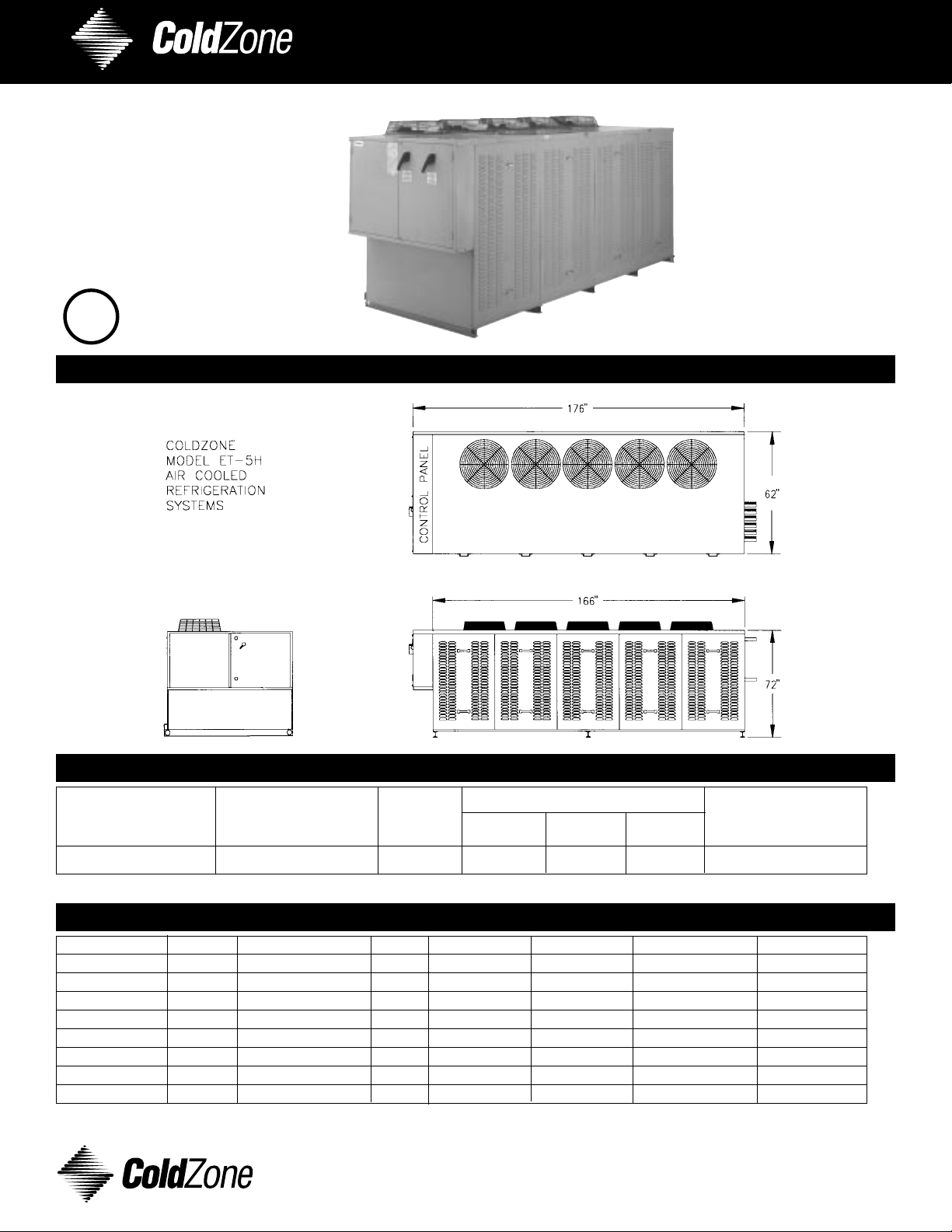

DIMENSIONAL DATA

PHYSICAL DATA

COMPRESSOR DATA

MEA

Approx. Maximum Number Typical Overall Dimensions (In.) Approx.

Total Number of of Weight

HP* Comp. (Spaces)** Fans

Length Width Height

(lbs.)

37.0 16 5 176 61

¹⁄₂ 72 5850

System Item Fixture Description Freon Compressor Voltage Evaporator(s) Voltage

* Total compressor HP will be determined by comp(s). used.

**

¹⁄₂ - 3 HP = 1 comp. space, 5 HP = 2 comp. spaces.

Note: Compressors are designed with matching evaporator coil.

Consult factory for specific electric data.

Specification subject to change without prior notice.

221 S. Berry St., P.O. Box 1030, Brea, CA 92822-1030 • Tel (714) 529-4461 • FAX (714) 529-8503

Loading...

Loading...