Russell DHD10H22 Installation Manual

221 S. BERRY ST., BREA, CA. 92821 TEL (714) 529-1935 FAX (714) 529-7203

INSTALLATION,

www.russellcoil.com

OPERATION AND

MAINTENANCE

MANUAL

Publication No. IOM 108.2

February, 2007

TABLE OF CONTENTS

PAGE

INSPECTION 2

INSTALLATION

LOCATING CONDENSING UNITS 2

LOCATING UNIT COOLERS 3

UNIT COOLER MINIMUM DISTANCES 4

FIELD WIRING 5

REFRIGERANT PIPING 5

LEAK TESTING 6

EVACUATION 6

CHARGING & START-UP 7

GENERAL MAINTENANCE 7

TYPICAL FIELD WIRING DIAGRAMS 8

HIGH SIERRA SEQUENCE OF OPERATIONS 9

TROUBLE SHOOTING GUIDE 11-12

REPLACEMENT PARTS 13-16

INSPECTION

When the equipment is received, check the quantity of cartons and crates against the bill of

lading.

· Inspect all containers for visible damage.

· Report any damage or shortages to the freight company immediately.

· It is the customer's responsibility to file a freight claim.

· Check the unit name plates to verify that the voltage and phase is correct before installation.

Installation and maintenance should be performed by qualified personnel who are familiar

with local codes and regulations. Installers should have previous experience with this type of

equipment.

CAUTION: Avoid contact with sharp edges and coil surfaces.

INSTALLATION

LOCATING CONDENSING UNITS

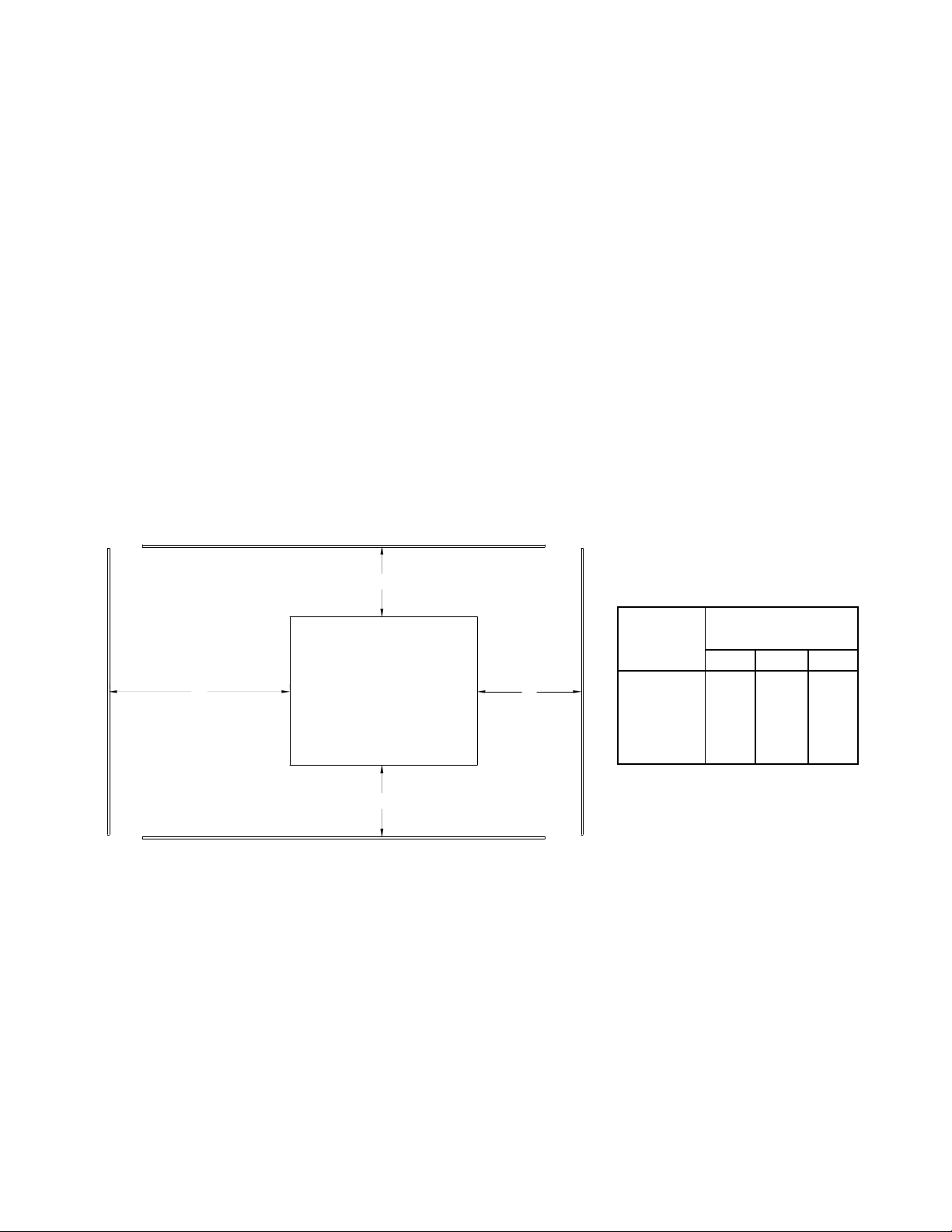

Condensing unit - Minimum clearances

Do not locate condensing units so that they are bordered on three or more sides by tall

obstructions. Condensing units should be positioned so that the airflow through the condenser is the same as the prevailing winds. If strong variable winds are common, a wind

deflector should be used on the discharge side of the unit. Be certain that there is adequate

room around the unit for regular inspection and service. For multiple unit sites, do not locate

units where the air discharge from one condensing unit will enter into the air intake of other

units.

Roof mounted condensing units should be located above supporting walls, over storage

areas or spaces not sensitive to noise or vibration. They must be adequately supported.

Pad mounted condensing units should be installed a minimum of 4 inches above ground

level, away from windows, doors and other areas where noise may be a problem. All units

must be level when mounted.

Minimum

HP Dimensions (in)

ABC

1/2 - 2 60 24 36

3 - 6 72 24 36

8 - 15 72 30 48

20 - 40 48 48 48

C

B

B

A

CONDENSING UNIT

PLAN VIEW

Discharge air Intake air

2

Table 1

Drawing 1

3

CONDENSING UNIT INSTALLATION (continued.)

Condensing units with spring mounted compressors are shipped with retainers under the

compressor feet to prevent damage during shipment. For Copeland H and K body

compressors, remove the retainers and loosen the mounting nut to allow 1/16” clearance

between the nut and rubber spacer. For 3HP and larger units, the mounting nuts must be

removed to insert the rubber spacer. Insert the rubber spacer over the mounting studs,

replace the nut and tighten to within 1/16” of the spacer. DO NOT

TIGHTEN THE NUTS

AGAINST THE SPACER OR FOOT.

Units with iso-pad mounted compressors are shipped with the mounting nuts tight. These

should be checked to make certain that they have not loosened during shipment.

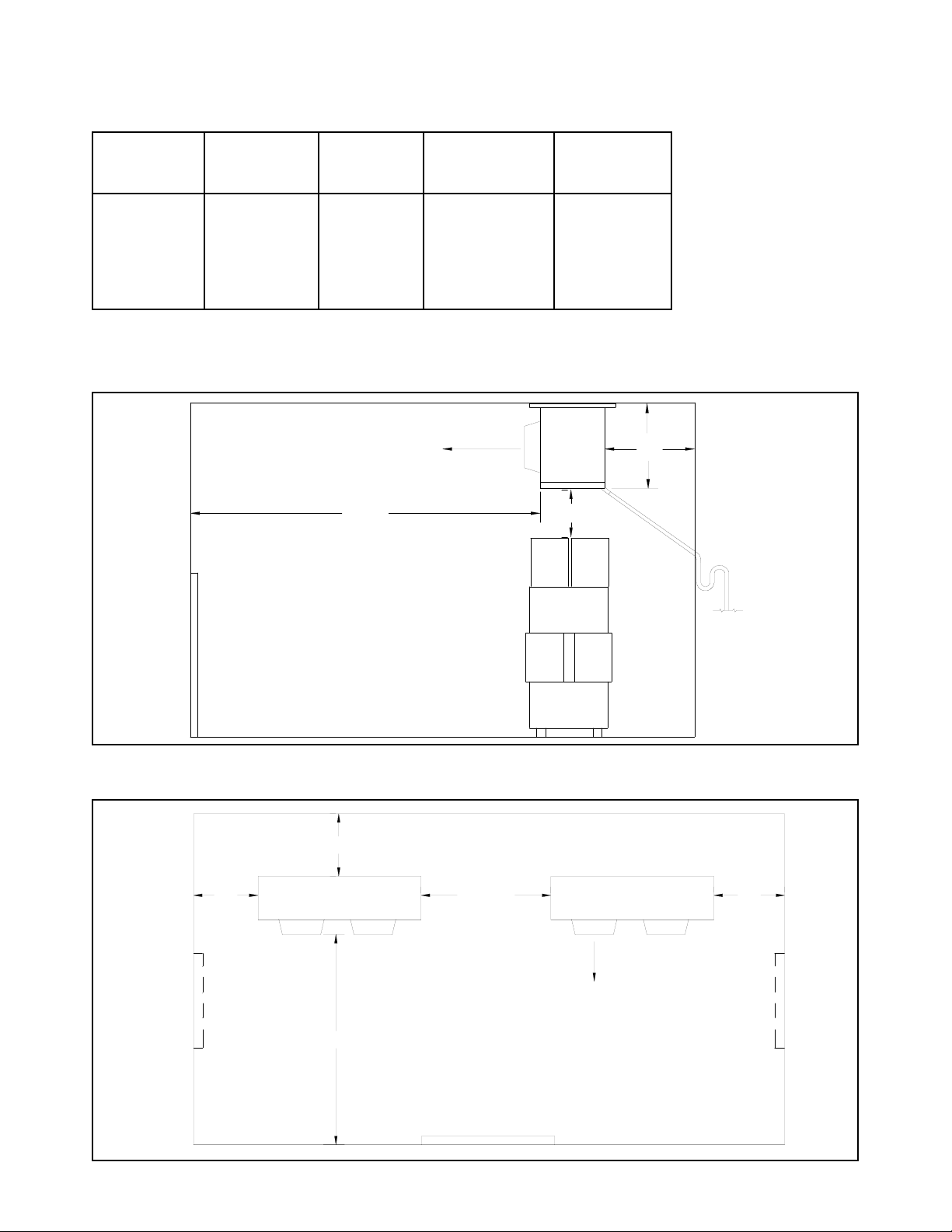

LOCATING AND MOUNTING UNIT COOLERS

Determine the best location for the unit in the walk-in cooler or freezer. Consider the air pattern required to cover the entire space. For High Sierra Systems with two unit coolers, locate

the unit coolers so that the piping runs from the suction and liquid line tees are equal in size

and length.

Do not restrict the inlet or outlet air stream. Place the unit cooler as far as possible from

any door openings. Direct the discharge air stream towards the door whenever possible.

This will help to prevent warm, moist air from being drawn into the coil (Drawings 2, 3 and

Table 2). Adequate clearances should be maintained around the unit cooler to allow for

proper airflow through the unit and for regular maintenance and service to be preformed.

For all Hot Gas defrost unit coolers, ensure that the drain pan is in contact with the Hot Gas

drain pan loop after installation. If the drain pan is removed for any reason, verify

that it has

physical contact with the defrost loop when replaced.

The drain line should be pitched a minimum of 4" per foot to allow proper drainage and

should exit the room as quickly as possible. Do not reduce the drain line size. Do not locate

line bends, elbows or drain traps within the refrigerated space. All drain lines must be

trapped outside of the enclosure where the temperature is never below 35 degrees. Drain

lines should run to an open drain and should never be attached directly to a sewage or waste

line. Drain lines must be protected from possible freezing. Freezer units must have copper

drain lines that are heated and insulated.

Remove all packaging materials before lifting the unit into position. Be certain that the unit is

not sitting on the drain fitting or refrigerant connections. All-Temp units should be hung using

5/16" minimum diameter, stainless steel support rods or fasteners at all hanging slots. Use

minimum 3/8" hanger rods for Inter-Temp and Ultra-Temp models.

Tighten all fasteners securely. All units must be positioned level, flush with the ceiling and all

gaps must be properly caulked. Allow minimum clearances on all sides of the unit cooler(s) as

indicated in Table 2 (next page).

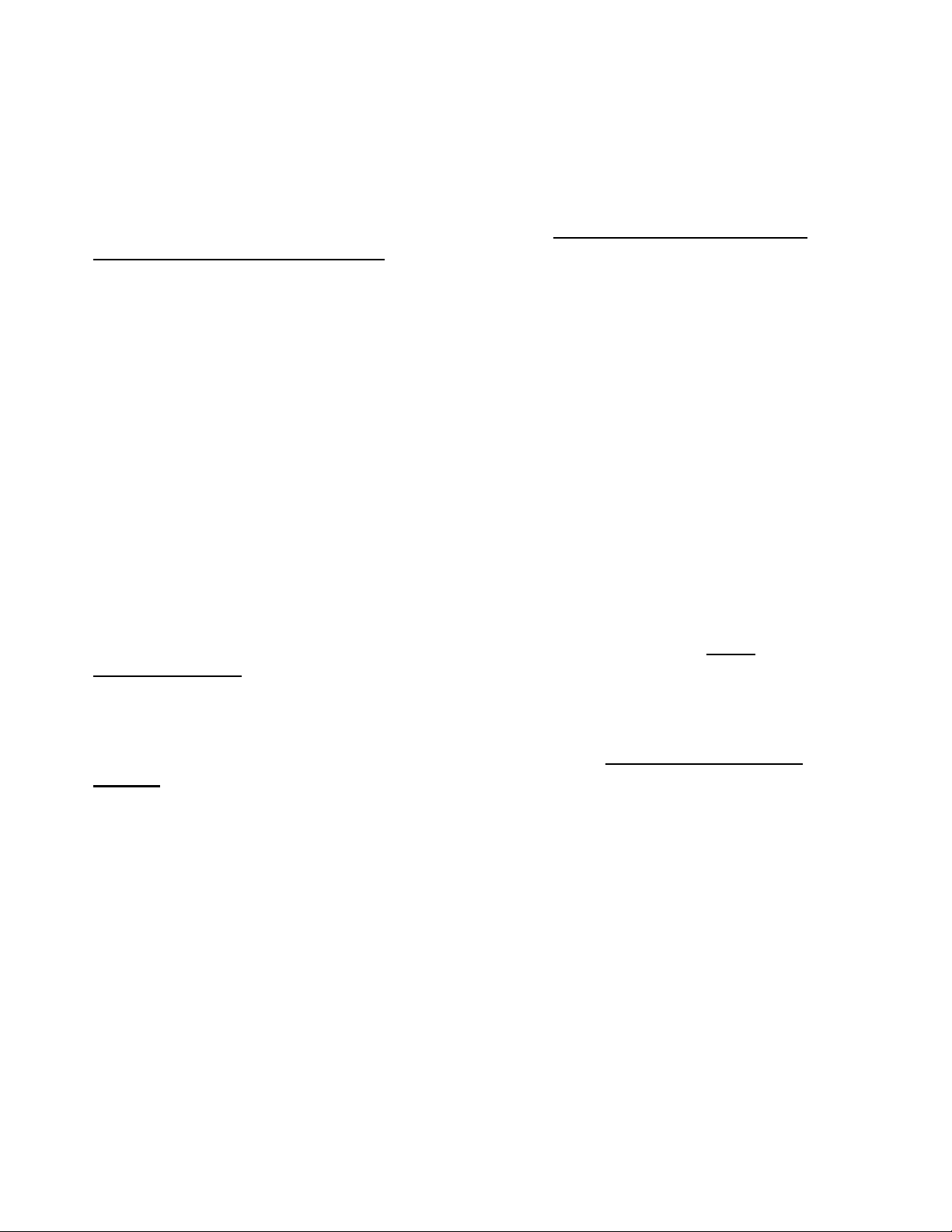

Recommended Minimum Dimensions

Table 2 Dimensions are in inches.

* Absolute minimum Distance

** 15’ is adequate clearance for these models

12"

min.

Slope Drain

line 4" per foot

and trap.

Air

5 x H*

obstruction

free area

door

H*

Drawing 2

Unit cooler Air intake* Side Air discharge Unit to

Height clearance clearance clearance floor

H 1 x H 1 x H 2 x H 5 x H

15 15 15 30 75

19 19 19 38 95

25 25 25 50 125

32 32 32 64 160

50 50 50 100 180**

Door

H* H*

H*

5 x H*

Back Wall

Front Wall

Alternate

Door

Location

Alternate

Door

Location

Air

Keep air discharge

area free from

obstruction

2 x H*

Discharge

Drawing 3

4

5

FIELD WIRING

All field wiring must be done in compliance with local and national electrical codes. Use only

properly sized Copper conductors. A system wiring diagram is located inside the condensing

unit control box. Wire components as indicated on the diagram. The equipment nameplates are

marked with electrical characteristics. All field wiring should enter the equipment through

electrical conduit bushings. Note: All units must be grounded.

Before applying power to the units, check all connections to ensure they have not come loose

during shipment. Be

certain that the power is disconnected before tightening any electrical

connections. Disconnect switches and evaporator branch circuit protection are supplied by the

equipment installer and must conform to governing electrical codes. Air defrost systems are

wired so that the evaporator fans run continuously. For electric defrost and High Sierra systems,

the evaporator fans are cycled off during the defrost and re-cooling period.

Electric defrost unit coolers are supplied with a temperature sensing defrost termination switch

that will end the defrost at a preset coil temperature. (Recommended time clock settings for

electric defrost are 2 defrosts per day, with a twenty minute fail safe setting. Adjust according to

job site conditions. Fewest possible defrost

s for the shortest possible duration are desirable.)

A high limit control is provided to prevent overheating if there is a component failure. A fan delay

control is installed to allow the water condensate on the fins to freeze before the evaporator fan

motors start. A pumpdown cycle is mandatory for all systems.

For both Sierra and High Sierra systems, a liquid line solenoid is factory installed and wired to

each unit cooler terminal board (multiple evap systems receive multiple solenoid valves). Follow

the system wiring diagram (provided in the condensing unit). Connection to

TB1-44 must be

made to assure proper pumpdown function. The room thermostat is mounted on the unit cooler

for single evaporator systems and supplied loose for multiple evaporator systems. Follow the

system wiring diagram supplied in the condensing unit.

REFRIGERANT PIPING

Condensing units and unit coolers are thoroughly cleaned and dehydrated at the factory. Use

only ACR (refrigeration grade) tubing that is dehydrated and sealed. Only use WROT Copper

fittings, cast fittings are a source of refrigerant leaks. All liquid and suction elbows must be long

radius types for minimum pressure drop. Refrigerant lines must be properly supported to

prevent vibration and breakage. Tube clamps should have a gasketed liner to prevent abrasion of

the tubing. Sierra and High Sierra must not exceed more then a 100’ refrigerant line run.

Install all piping and components in accordance with local and national codes. Make refrigerant

connections by using only hard or Silver bearing solder such as Silfos, Stay-Silv or higher Silver

content brazing material. Slowly purge dry nitrogen through the tubing while brazing to prevent

the formation of Copper oxide scale.

LIQUID LINE

Refer to the current ASHRAE Refrigeration Systems and Applications Handbook for assistance

in determining appropriate liquid line sizes.

Horizontal and vertical liquid lines are normally the same diameter. However, pressure loss due

to vertical lift may lead to flash gas that can inhibit proper TXV (and system) performance if not

properly accounted for. Under sizing the liquid line can result in flash gas while over sizing the

liquid line will unnecessarily increase the system charge requirement.

Sierra and High Sierra condensing units include Russell’s patented finned receiver

®

, which is

integrated into the air-cooled condenser. This finned receiver®also acts as an efficient liquid

sub-cooler. An additional liquid to suction heat exchanger is not normally required. The liquid

line must be insulated to obtain the maximum benefits of the subcooled liquid.

Loading...

Loading...