Russell DC10L44 User Manual

Publication No. RU-DLD-0712A

D Series

AIR COOLED

CONDENSING UNITS

3 TO 22 HP

2

AIR COOLED CONDENSING UNITS 3 TO 22 HP

The outdoor housing of our condensing units have completely re-engineered. Access to all

components is now more convenient than ever. Quick removal of top and side panels allows

quick access to everything. The hinged control panel door swings wide open for maximum

clearance while the unit is being serviced.

STAINLESS STEEL

BRAIDED HOSES*

HIGH-EFFICIENCY

PSC FAN MOTORS

LIQUID LINE

SIGHT GLASS*

SOLID STATE OIL CONTROL*

OSHA APPROVED

FAN GUARDS

SUCTION AND DISCHARGE

VIBRATION ELIMINATORS

HINGED

CONTROL

PANEL DOOR

INTERLOCKING*

NON-FUSED

DISCONNECT

SWITCH

SUCTION

ACCUMULATOR*

The large control panel has abundant space for the controls you choose. They are intelligently

arranged and laid out in a logical fashion which is easy to understand and work with. Each

control and wire is clearly marked with a name or number as shown on the wiring diagram

which is conveniently affixed to the control panel door.

CONTROL CIRCUIT FUSES

RUSSAVER PRESSURE CONTROL*

COMPRESSOR CONTACTOR

POWER TERMINAL BLOCK

EVAP FAN MOTOR CONTACTOR*

NON-FUSED DISCONNECT SWITCH*

EVAPORATOR

FAN AND HEATER SUB-CIRCUIT FUSING*

CONTROL VOLTAGE TRANSFORMER

DEFROST CLOCK*

HINGED DOOR

BLOCK OUT RELAY*

EVAPORATOR DEFROST CONTACTORS*

EVAPORATOR SEQUENCING

RELAYS*

DOOR INTERLOCK*

CONDENSER FAN

MOTOR CAPACITORS

AIR COOLED CONDENSING UNITS 3 TO 22 HP

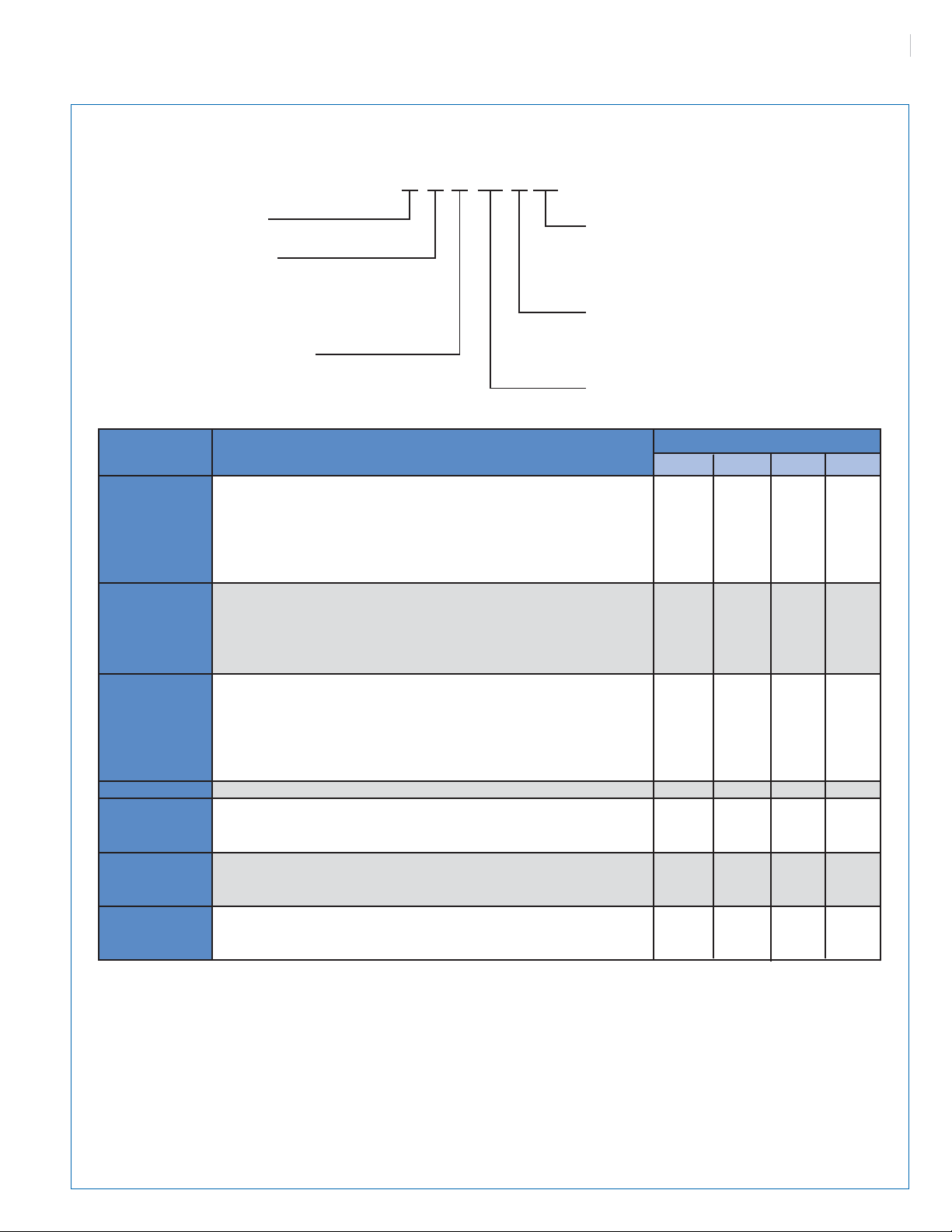

MODEL NUMBER NOMENCLATURE

D L D 22 L 44

3

D STYLE UNIT

STYLE OF UNIT

E = Indoor Unit

L = Outdoor unit w/Flooded controls

S = Outdoor unit w/Russ-Saver controls

C = Outdoor unit w/no head pressure

COMPRESSOR STYLE

D = Copeland Discus

C = Carlyle*

B= Bitzer*

S = Special*

ELECTRICAL

COMPONENTS

CONDENSER

PIPING

COMPONENTS

RECEIVER

HOUSING

LOW AMBIENT

CONTR

OLS

TESTING

REFRIGERANT TYPE

22 = R-22

44 = R-404A / R-507

34 = R-R-134a

OPERATING RANGE

controls

H = High Temp (+10°F to +45°F Suction Temp)

M = High/Medium Temp (-10°F to +45°F Suction Temp)

L = Low Temp (-40°F to 0°F Suction Temp)

NOMINAL HORSEPOWER

FEATURES AT A GLANCE

Crankcase heater

Oil failure control - as required

High-Low pressure control - manual(high)/automatic(low)rest

Compressor contactor

Control circuit fuses - standard 230/1

Power terminal block

Copper tubes with Aluminum fins

Subcooling circuit

Fan motor - PSC over load protection

Fan blade - individually balanced

Fan guard - split for easy motor access: UL listed

Suction line filter

Suction line vibration eliminator

Liquid line filter/drier

Sight glass/moisture indicator

Discharge line vibration eliminator

Inlet and outlet isolation valves

Fusible plug

All weather housing

Control panel - with hinged door

Raised galvanized steel base

Russ-Saver - all ambient energy saver

Pressure fan cycling control- not available on 3HP - 6HPlow temps.

Flooded condenser

UL/cUL listed all models

Leak detection, Dielectric & Run test

Dry nitrogen holding charge

MODEL

DE DC DS DL

OPT.

STD

STD

STD

STD

OPT

STD

STD

STD

STD

STD

OPT

OPT.

OPT.

OPT.

STD

STD

STD

OPT.

STD

STD

N/A

OPT

OPT.

STD

STD

STD

STD

STD

STD

STD

STD

.

STD

STD

STD

STD

STD

STD

STD

.

STD

STD

STD

STD

STD

STD

STD

STD

STD

N/A

.

OPT

OPT.

STD

STD

STD

STD

STD

STD

STD

STD

STD

STD

STD

STD

STD

STD

STD

STD

STD

STD

STD

STD

STD

STD

STD

STD

STD

STD

.

N/A

STD

STD

STD

STD

STD

STD

STD

STD

STD

STD

STD

STD

STD

STD

STD

STD

STD

STD

STD

STD

STD

STD

STD

STD

N/A

N/A

STD

STD

STD

STD

OPTIONS:

* Contact factory for details.

4 year extended compressor warranty

Air defrost time clock

Compressor unloading

Copper or coated condenser fi ns

Crankcase pressure regulator

Electric Defrost with heater contactors, timer, block out relay

Evap sub circuit fusing

Fused disconnect

Heated and insulated receiver

Hot Gas Defrost components

Liquid line solenoid valve

Oil separator

Oversized reciever

Phase loss monitor

Sentronic oil saftey control

Spring loaded relief valve

Stainless steel hoses

Suction line accumulator

Non-Fused Disconnect

4

AIR COOLED CONDENSING UNITS 3 TO 22 HP

RUSS-SAVER

The initial cost of quality refrigeration equipment is a substantial investment. But the costs of

installation and operation are also formidable. Rising to the challenge, Russell engineers have

designed the RUSS-SAVER system to meet the highest standards of performance and

reliability while effectively addressing the problem of these profit draining costs.

REDUCED INSTALLATION COSTS

The installation of a refrigeration system using RUSS-SAVER requires a smaller refrigerant

charge than equipment which utlilze other types of low ambient controls. As the more

expensive zero ozone depleting, refrigerants become the refrigerants of choice, the reduced

charge requirements provided by RUSS-SAVER affords substantial and immediate cost

saving benefits.

REDUCED OPERATING COSTS

The most expensive part of an operating refrigeration system is the cost of energy to operate

the compressor. Day and night, year after year, the cost of electricity to operate your

eqiupment is unrelenting. These dollars are pulled right from your bottom line.

A typical installation provides for equipment which is designed to furnish adequate cooling on

the hottest of days. The RUSS-SAVER system is designed to meet this need but also be

flexible enough to take advantage of reduced ambient conditions during off-peak times. As the

outside air temperature decreases, head pressures are allowed to drop. This action results in

increased efficiency, requiring less energy and saving substantial amounts of your money!

RUSS-SAVER even saves money during hot weather.

The sub cooling loop provided in the condenser of the RUSS-SAVER condensing unit

increases the system efficiency 1/2% for each degree of sub cooling provided, thereby making

the compressor’s job easier. RUSS-SAVER’S efficiency saves you money during summer

operation and even more during the winter months.

Loading...

Loading...