Russell CAC 6 Installation Manual

Russell

MULTICON

MAINTENANCE

MANUAL

Bulletin No. IOM 400.0

November 1993

AIR COOLED CONDENSERS

MODELS CAC, RAC, VAC, & VEQ

INSTALLATION AND

Russell

221 S. Berry St., CA 92821 Tel (714) 529-1935 FAX (714) 529-7203

GENERAL SAFETY INFORMATION

• Installation and maintenance are to be

performed only by qualified personnel who

are familiar with type of equipment.

• Make sure that all field wiring conforms to

the requirements of the equipment and all

applicable national and local codes.

• Avoid contact with sharp edges and coil

surfaces. They are a potential injury hazard.

• Make sure all power sources are

disconnected before any service work is

done on the units.

RIGGING AND HANDLING

All Russell CAC and VAC 5 thru 19 model

condensers are shipped on their sides with the

exception of the smaller RAC models and

larger VAC and VEQ models. All units come

shipped on a skid with a wooden skeleton

frame to prevent damage in transit. Leave all

framing attached until the unit is as close as

possible to its final installed location.

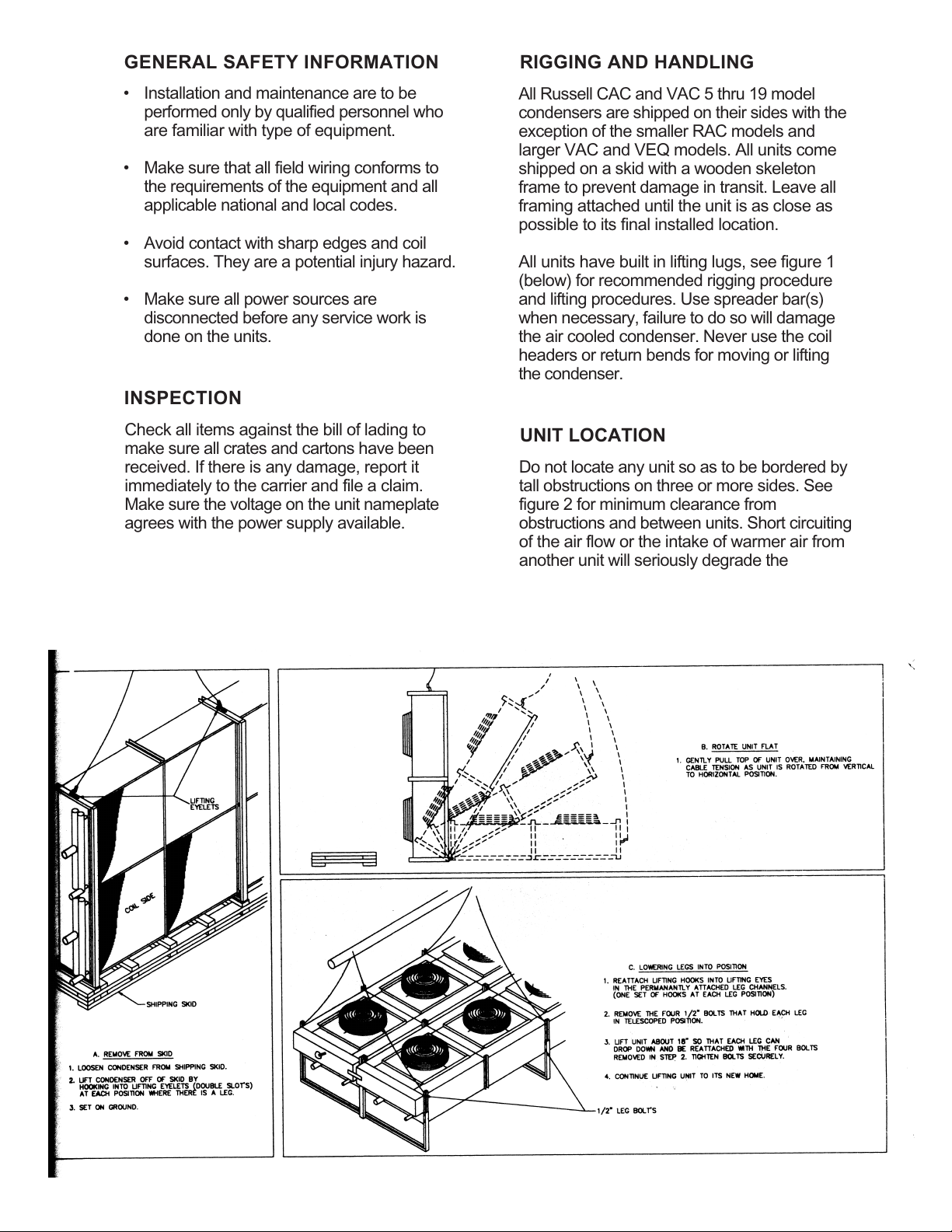

All units have built in lifting lugs, see figure 1

(below) for recommended rigging procedure

and lifting procedures. Use spreader bar(s)

when necessary, failure to do so will damage

the air cooled condenser. Never use the coil

headers or return bends for moving or lifting

the condenser.

INSPECTION

Check all items against the bill of lading to

make sure all crates and cartons have been

received. If there is any damage, report it

immediately to the carrier and file a claim.

Make sure the voltage on the unit nameplate

agrees with the power supply available.

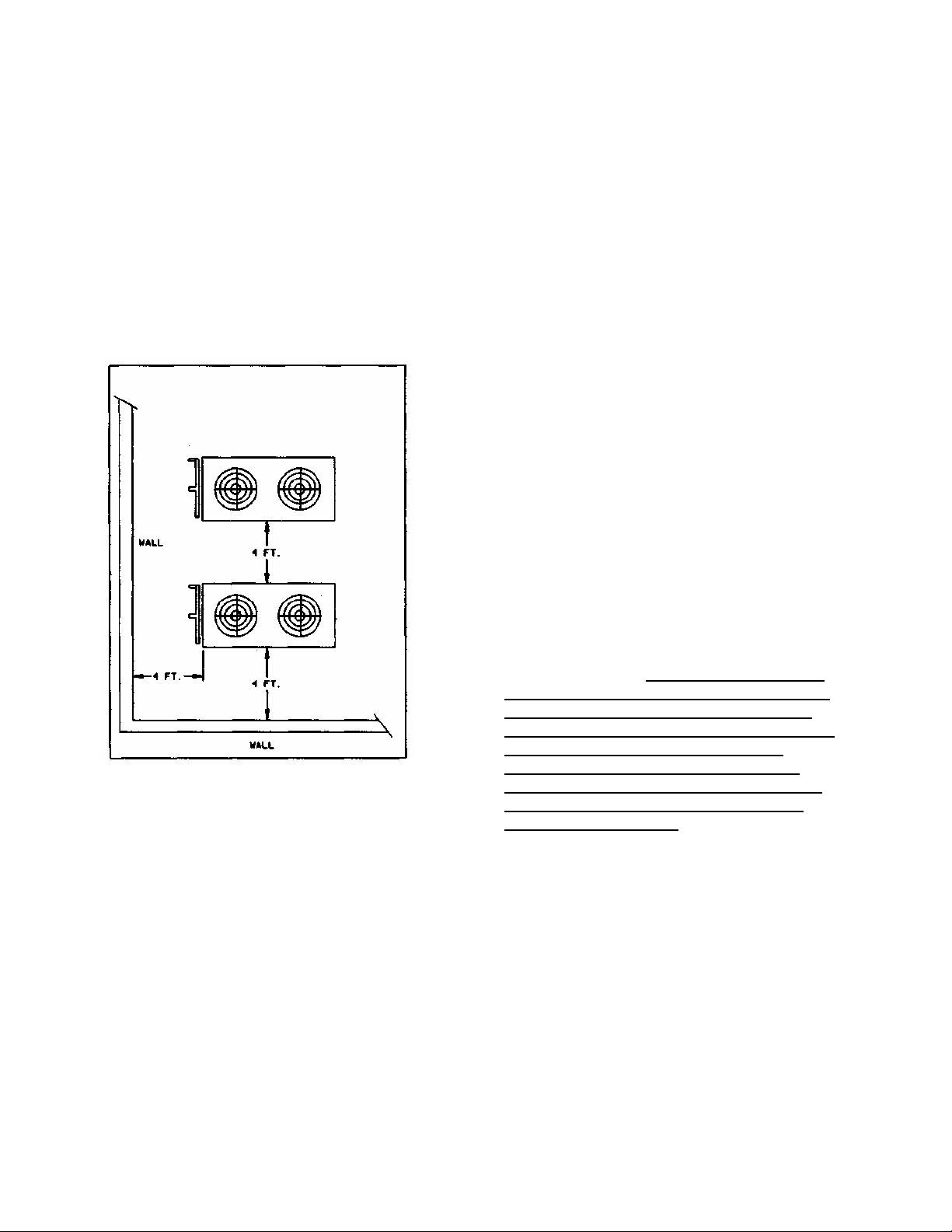

UNIT LOCATION

Do not locate any unit so as to be bordered by

tall obstructions on three or more sides. See

figure 2 for minimum clearance from

obstructions and between units. Short circuiting

of the air flow or the intake of warmer air from

another unit will seriously degrade the

performance of the air cooled condenser.

Noise consideration should also be considered

when locating an air cooled condenser.

Proximity to windows, walls, and surrounding

structures can cause objections by the

occupants. An acoustical expert should be

consulted when noise is of a particular

concern.

Structural supports and roof or platforms

should be sufficiently strong to support the

condensers operating weight. Consult with a

professional structural engineer to determine

safe platform loading.

• Refrigerant lines should be selected from

the tables on pages 25 and 26 of the

Russell Refrigeration Engineering Manua l.

Lines should never be selected on the

basis of the inlet and outlet fitting sizes on

the condenser.

If pull down loads, much greater than

design loads, are encountered, both

discharge and liquid lines should be sized

for the pull down BTUH load.

Gas velocities provided by the fine size

selection tables are adequate for oil return

in either horizontal runs or vertical risers.

To ensure proper oil return follow these two

steps:

1. Pitch horizontal runs in the direction of flow

1/4 inch per foot.

2. Provide traps at the bottom of each riser

and every 15 feet up the riser. These traps

should be formed of short sweep street

ells.

FIGURE 2: MINI. CLEARANCES

PLAN VIEW

REFRIGERANT PIPING

All piping should be done in accord with The

Safety Code for Mechanical Refrigeration"'

(ANSI/ASHRAE15-1992) and The Code for

Pressure Piping" (ANSI B31.1) as well as all

applicable local and national codes.

Units are available in both single and double

width fan versions. The double width fan

models have two coils that may be used as

independent condensers, or may be field

coupled in parallel to perform as one

condenser. Factory fabricated manifold

saddles are available as an optional feature.

All refrigerant piping must be well supported so

that line vibration or expansion and contraction

forces are not imposed on the condenser

piping connections. All piping connected to

the condenser must be supported as close

to the condenser as possible, especially

whan the circuit is a single tube connection

leading out of the condenser core as

typically seen on multiple circuit units.

Never handle the condenser or use any of

the piping headers or connections as a

support or lifting point.

• A high pitched noise seeming to come from

the condenser or discharge line with

accompanying line vibration comes from

compressor pulsation. Install a discharge

line orifice (if available from the

compressor manufacturer) or a discharge

line muffler at the compressor.

• Reduced loads by capacity reduction may

require special piping arrangement not

covered by this document. For these

situations consult your engineer, or

ASHRAE Refrigeration Manual.

• Use double risers only where specifically

required by specifications.

• The use of an oil separator of adequate

size tends to minimize oil return problems

and compressor pulsation problems. When

oil separators are used with condensers, a

discharge line check valve at the oil

separator outlet must be employed.

Always make sure that the voltage applied

to the unit matches the voltage rating of the

unit as indicated on the unit's nameplate.

START-UP

Prior to start-up check the following items:

1. Check fans for freedom of movement.

• Install the refrigerant sight glass

immediately at the receiver outlet. If a sight

glass is required at the drier outlet, a

second sight glass should be used. If a

long liquid line run or substantial liquid line

rise is required, it may be advisable to

install a sight glass in the liquid line at the

expansion valve inlet. Only the sight glass

at the receiver outlet should be used to

determine if additional refrigerant must be

added.

• Where multiple condensers are required,

all condensers must be at the same level,

and piped in parallel. Branches must be the

same size and length.

REFRIGERANT CHARGE

• Charging of a system should be carried out

using visual reference to the refrigerant

sight glass. Charging should be stopped

when the sight glass becomes clear. Care

must be taken when charging a system

with a blended or near azeotropic

refrigerant. If you are unfamiliar with the

proper charging procedures, contact your

refrigerant supplier for assistance.

2. Check all fan blade set screws, motor

mounts, and mounting leg fasteners.

3. Check that the nameplate voltage matches

the power supply voltage.

4. Upon start-up check the rotation of all fans

to insure that air is being discharged up ou t

of the fan discharges. If discharge is wrong,

correct by reversing 2 of the motor leads in

the junction box.

MAINTENANCE

Maintenance of the air cooled condenser is

extremely important for extended life and peak

performance. The following is a recommended

maintenance schedule. Site conditions will

dictate the frequency of this maintenance plan.

The equipment warranty does not cover

corrosion, misuse, or misapplication of the

condenser.

1. Shut all power off to the air cooled

condenser and refrigeration system at the

closest disconnect switch and use a lock to

prevent others from turning power ba ck on

to the unit.

WIRING

• Single phase fan motors are used on

models VAC 5 thru 19, and are pre-wired

to provide the closest possible balance on

three phase networks. Motors are available

as, or can be re-wired for single phase

network in the field. Contact the factory for

instructions. All single phase motors are

inherently protected.

• Where three phase motors are used on the

larger model VAC and VEQ models, the

motors are inherently protected. All three

phase motors are dual voltage and can be

quickly converted in the field by

repositioning the voltage change device

(VCD) located inside the motor.

2. Remove fan guards.

3. Remove all targe debris (leaves, paper,

cardboard, plastic film, etc.) from the top

as well as beneath the unit. Keep the area

clean around the condenser by removing

loose debris around the air cooled

condenser.

4. Inspect the unit for damaged fins caused

by the debris. Comb out any bent fins with

a fin comb. Inspect the unit for signs of

corrosion. Note the area and amount of

corrosion in your maintenance reports.

5. Should the heat transfer surface require

cleaning use the following procedure. Use

a cleaning solution that is compatible with

the finned material and any protective

Loading...

Loading...