Page 1

USER’S INFORMATION MANUAL

FOR COMMUNICATING MODULATING CONDENSING

GAS FURNACES

Recognize this symbol as an indication of Important Safety Information!

!

WARNING

!

IF THE INFORMATION IN THESE INSTRUCTIONS

IS NOT FOLLOWED EXACTLY, A FIRE OR EXPLOSION MAY RESULT, CAUSING PROPERTY DAMAGE, PERSONAL INJURY OR DEATH.

FOR YOUR SAFETY

!

— Do not store or use gasoline or other flammable

vapors and liquids, or other combustible materials

in the vicinity of this or any other appliance.

— WHAT TO DO IF YOU SMELL GAS

• Do not try to light any appliance.

• Do not touch any electrical switch; do not use

any phone in your building.

• Immediately call your gas supplier from a neighbor’s phone. Follow the gas supplier’s instructions.

• If you cannot reach your gas supplier, call the

fire department.

• Do not rely on smell alone to detect leaks. Due

to various factors, you may not be able to smell

fuel gases.

• U.L. recognized fuel gas and CO detectors are

recommended in all applications, and their

installation should be in accordance with the

manufacturer’s recommendations and/or local

laws, rules, regulations, or customs.

— Installation and service must be performed by

a qualified installer, service agency or the gas

supplier.

NOTE TO INSTALLER: REVIEW THIS

MANUAL WITH THE USER AND LEAVE

IT WITH THE EQUIPMENT.

DO NOT DESTROY. PLEASE READ

CAREFULLY AND KEEP IN A SAFE

PLACE FOR FUTURE REFERENCE.

WARNING

!

PROPOSITION 65: THIS PRODUCT CONTAINS

CHEMICALS KNOWN TO THE STATE OF CALIFORNIA TO CAUSE CANCER, BIRTH DEFECTS

OR OTHER REPRODUCTIVE HARM.

92-20802-98-00

Page 2

GENERAL INFORMATION

!

WARNING

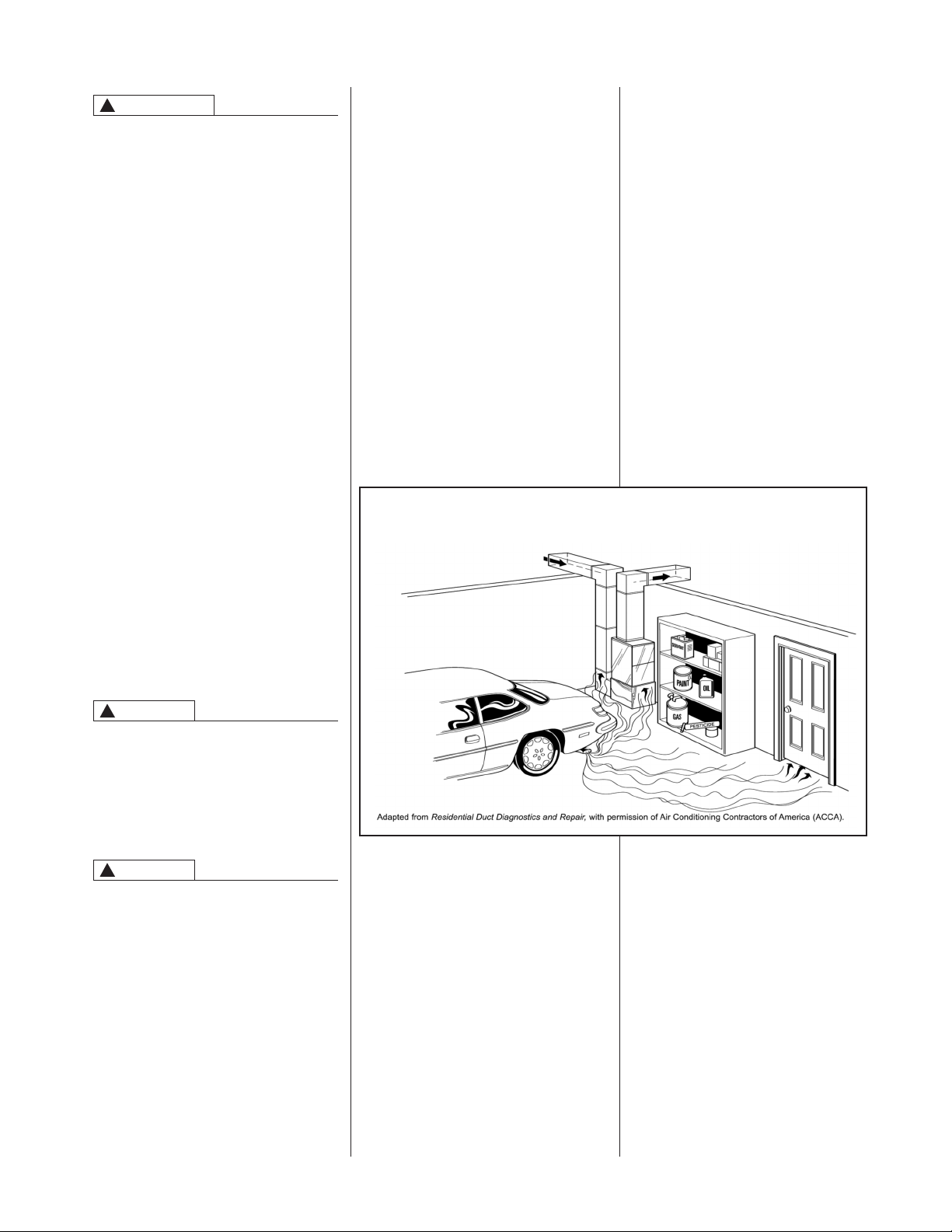

DUCT LEAKS CAN CREATE AN

UNBALANCED SYSTEM AND DRAW

POLLUTANTS SUCH AS DIRT, DUST,

FUMES AND ODORS INTO THE

HOME CAUSING PROPERTY DAMAGE. FUMES AND ODORS FROM

TOXIC, VOLATILE OR FLAMMABLE

CHEMICALS, AS WELL AS AUTOMOBILE EXHAUST AND CARBON

MONOXIDE (CO), CAN BE DRAWN

INTO THE LIVING SPACE THROUGH

LEAKING DUCTS AND UNBALANCED DUCT SYSTEMS CAUSING

PERSONAL INJURY OR DEATH (SEE

FIGURE 1).

• IF AIR-MOVING EQUIPMENT OR

DUCTWORK IS LOCATED IN

GARAGES OR OFF-GARAGE

STORAGE AREAS - ALL JOINTS,

SEAMS, AND OPENINGS IN THE

EQUIPMENT AND DUCT MUST BE

SEALED TO LIMIT THE MIGRATION OF TOXIC FUMES AND

ODORS INCLUDING CARBON

MONOXIDE FROM MIGRATING

INTO THE LIVING SPACE.

• IF AIR-MOVING EQUIPMENT OR

DUCTWORK IS LOCATED IN

SPACES CONTAINING FUEL

BURNING APPLIANCES SUCH AS

WATER HEATERS OR BOILERS ALL JOINTS, SEAMS, AND OPENINGS IN THE EQUIPMENT AND

DUCT MUST ALSO BE SEALED TO

PREVENT DEPRESSURIZATION

OF THE SPACE AND POSSIBLE

MIGRATION OF COMBUSTION

BYPRODUCTS INCLUDING CARBON MONOXIDE INTO THE LIVING

SPACE.

!

NOTICE

IMPROPER INSTALLATION, OR

INSTALLATION NOT MADE IN

ACCORDANCE WITH THE CSA

INTERNATIONAL (CSA) CERTIFICATION OR THESE INSTRUCTIONS,

CAN RESULT IN UNSATISFACTORY

OPERATION AND/OR DANGEROUS

CONDI-TIONS AND ARE NOT COVERED BY THE UNIT WARRANTY.

!

NOTICE

IN COMPLIANCE WITH RECOGNIZED CODES, IT IS RECOMMENDED THAT AN AUXILIARY DRAIN PAN

BE INSTALLED UNDER ALL EVAPORATOR COILS OR UNITS CONTAINING EVAPORATOR COILS THAT

ARE LOCATED IN ANY AREA OF A

STRUCTURE WHERE DAMAGE TO

THE BUILDING OR BUILDING CONTENTS MAY OCCUR AS A RESULT

OF AN OVERFLOW OF THE COIL

DRAIN PAN OR A STOPPAGE IN

THE PRIMARY CONDENSATE DRAIN

PIPING. SEE ACCESSORIES SECTION OF THESE INSTRUCTIONS

FOR AUXILIARY HORIZONTAL

OVERFLOW PAN INFORMATION

(MODEL RXBM).

IMPORTANT INFORMATION

ABOUT EFFICIENCY AND

INDOOR AIR QUALITY

Central cooling and heating equipment

is only as efficient as the duct system

that carries the cooled or heated air. To

maintain efficiency, comfort and good

indoor air quality, it is important to have

the proper balance between the air

being supplied to each room and the air

returning to the cooling and heating

equipment.

Proper balance and sealing of the duct

system improves the efficiency of the

heating and air conditioning system and

improves the indoor air quality of the

home by reducing the amount of airborne pollutants that enter homes from

spaces where the ductwork and / or

equipment is located. The manufacturer

and the U.S. Environmental Protection

Agency’s Energy Star Program recommend that central duct systems be

checked by a qualified contractor for

proper balance and sealing.

FIGURE 1

MIGRATION OF DANGEROUS SUBSTANCES, FUMES, AND ODORS INTO LIVING SPACES

RECEIVING

Immediately upon receipt, all cartons

and contents should be inspected for

transit damage. Units with damaged cartons should be opened immediately. If

damage is found, it should be noted on

the delivery papers, and a damage claim

filed with the last carrier.

• After unit has been delivered to job

site, remove carton taking care not to

damage unit.

• Check the unit rating plate for unit

size, electric heat, coil, voltage,

phase, etc. to be sure equipment

matches what is required for the job

specification.

• Read the entire instructions before

starting the installation.

• Some building codes require extra

cabinet insulation and gasketing

when unit is installed in attic applications.

If installed in an unconditioned

•

pace, apply caulking around the

s

ower wires, control wires, refriger-

p

nt tubing and condensate line

a

here they enter the cabinet. Seal

w

he power wires on the inside where

t

hey exit conduit opening. Caulking

t

s required to prevent air leakage

i

nto and condensate from forming

i

nside the unit, control box, and on

i

lectrical controls.

e

• Install the unit in such a way as to

allow necessary access to the

coil/filter rack and blower/control

compartment.

• Install the unit in a level position to

ensure proper condensate drainage.

Make sure unit is level in both directions within 1/8”.

• Install the unit in accordance with

any local code which may apply and

the national codes. Latest editions

are available from: “National Fire

Protection Association, Inc.,

Batterymarch Park, Quincy, MA

02269.” These publications are:

• ANSI/NFPA No. 70-(Latest Edition)

National Electrical Code.

• NFPA90A Installation of Air

Conditioning and Ventilating

Systems.

• NFPA90B Installation of warm air

heating and air conditioning systems.

• The equipment has been evaluated

in accordance with the Code of

Federal Regulations, Chapter XX,

Part 3280.

2

Page 3

INTRODUCTION TO YOUR FURNACE

Thank you for the purchase of your new modulating gas furnace! This furnace is designed to be the ultimate in heating

comfort and is the only true modulating gas furnace available

on the market today.

The modulating gas furnace provides a superior level of

comfort due to the interaction of seven basic components:

Variable Output Thermostat - Whereas conventional ther-

•

mostats only send an On/Off signal to the furnace, the thermostat for the modulating furnace system is specially

designed to indicate the exact heating requirements of the

conditioned space. This is accomplished by a logic control

routine that accurately senses the space load, minimizes

recovery times, reduces temperature swings and optimizes

system efficiency and performance.

• Fully Communicatiing Thermostat Modulating Gas Valve -

The gas valve has the conventional redundant solenoid

valves for inherent safety, but also has a third operator for

capacity control. This operator is actually a servo valve

which varies the input rate of the furnace proportionally to

the signal from the controller. The modulating furnace can

operate anywhere from 40% to 100% of the nameplate input

of the furnace.

Furnace Controller - The furnace controller provides all of

•

the ignition and safety functions of the typical IFC as well as

nterpreting the signals from the thermostat. The furnace

i

controller will optimize furnace performance by monitoring all

thermostat and temperature inputs and insuring the stable

operation of the inducer, gas valve and indoor blower motor.

• ECM Variable Speed Blower - The airflow through the duct

ork is varied to meet the load demand. Airflow as low as

w

300 CFM is achieved by the response of a brushless permanent magnet variable speed blower motor.

• Two Speed Draft Inducer - To insure clean combustion

and peak efficiency, the induced draft motor speed is adjust-

d based on the gas valve setting to provide the proper

e

amount of combustion air to the burners.

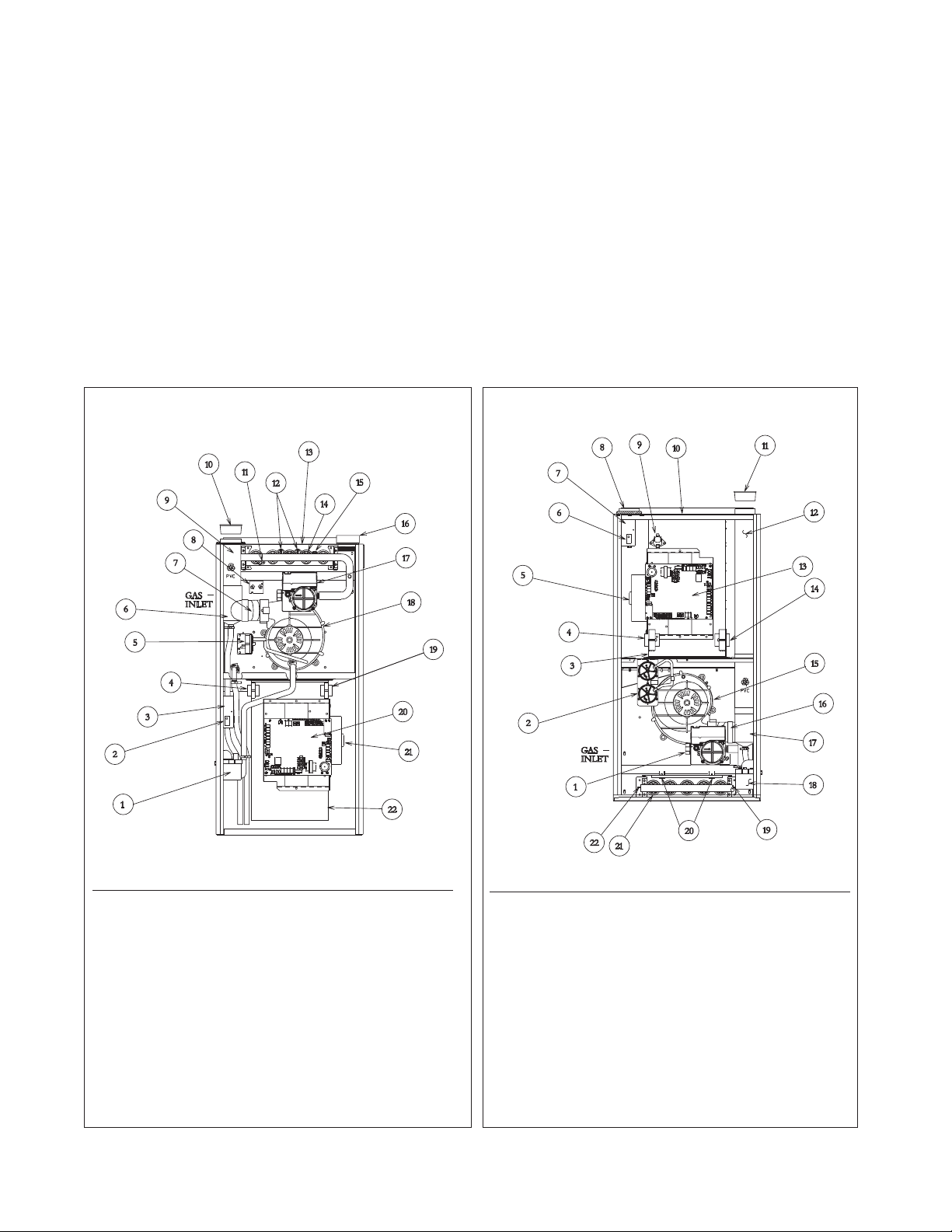

FIGURE 2

UPFLOW FURNACE

ITEM

NO. PART NAME

1 CONDENSATE TRAP

2 DOOR SWITCH

3 JUNCTION BOX

4 TRANSFORMER

5 PRESSURE SWITCH ASSEMBLY

6 EXHAUST TRANSITION

7 CONNECTOR

8 MAIN LIMIT

9 EXHAUST AIR PIPE

10 VENT CAP SHIPPING PLUG

11 FLAME SENSOR

12 OVERTEMPERATURE SWITCH

ST-A1123-01_01

ITEM

NO. PART NAME

13 TOP PLATE

14 BURNER

15 IGNITER

16 COMBUSTION AIR INLET

17 GAS VALVE

18 INDUCED DRAFT BLOWER

19 POWER FACTOR CHOKE

20 INTEGRATEDFURNACE CONTROL

21 BLOWER MOTOR

22 BLOWER HOUSING

FIGURE 3

DOWNFLOW FURNACE

ITEM

NO. PART NAME

1 GAS VALVE

2 PRESSURE SWITCH ASSEMBLY

3 BLOWER HOUSING

4 POWER FACTOR CHOKE

5 BLOWER MOTOR

6 DOOR SWITCH

7 JUNCTION BOX

8 COMBUSTION AIR INLET

9 HALC

10 TOP PLATE

11 VENT CAP SHIPPING PLUG

12 OUTLET AIR PIPE

ST-A1123-01_02

ITEM

NO. PART NAME

13 INTEGRATEDFURNACE CONTROL

14 TRANSFORMER

15 INDUCED DRAFT BLOWER

16 CONNECTOR

17 EXHAUST TRANSITION

18 CONDENSATE TRAP

19 IGNITER

20 OVERTEMPERATURE SWITCH

21 BURNER

22 FLAME SENSOR

3

Page 4

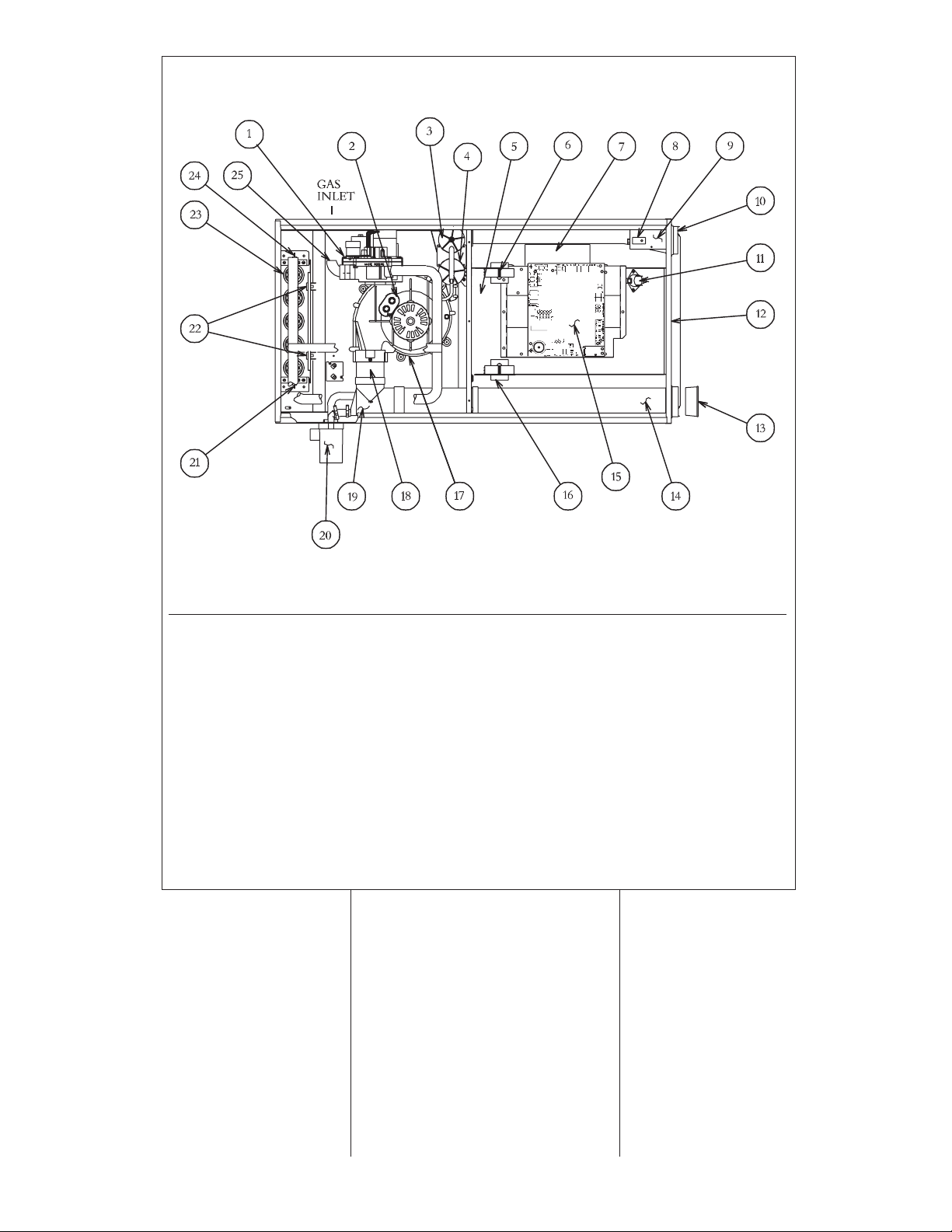

➤ FIGURE 3

ORIZONTAL FURNACE (-)GJD

H

ITEM

NO. PART NAME

1 GAS VALVE

2 CAPACITOR (FOR INDUCER)

3 LOW PRESSURE SWITCH

4 HIGH PRESSURE SWITCH

5 BLOWER HOUSING

6 POWER FACTOR CHOKE

7 BLOWER MOTOR

8 DOOR SWITCH

9 JUNCTION BOX

10 COMBUSTION AIR INLET

11 HALC

12 TOP PLATE

13 VENT CAP PLUG

ITEM

NO. PART NAME

14 OUTLET AIR PIPE

15 INTEGRATED FURNACE CONTROL

16 TRANSFORMER

17 INDUCED DRAFT BLOWER

18 CONNECTOR

19 EXHAUST TRANSITION

20 CONDENSATE TRAP

21 IGNITER

22 OVERTEMPERATURE SWITCH

23 BURNER

24 FLAME SENSOR

25 FACTORY-INSTALLED STREET ELBOW

ST-A107801.S01

4

Page 5

• Supply Air Sensors - This thermister assembly, is a field

installed air probe, communicate the furnace temperature

rise to the integrated furnace control. The integrated furnace

control uses this information to calculate field conditions during calibration to insure optimal efficiency and comfort during

normal operation.

his furnace has been designed to give you many years of

T

efficient, dependable home comfort. With regular maintenance, this furnace will operate superbly year after year.

INSTALLATION INFORMATION

Please take the time to fill out the information below and

read this manual to familiarize yourself with operation, maintenance schedule, and safety operation.

IMPORTANT: READ THESE INSTRUCTIONS THOR-

UGHLY BEFORE ATTEMPTING TO OPERATE THIS

O

FURNACE.

Date Installed

Dealer Name

Address

City

State Zip

Telephone No.

FURNACE

Model No.

Serial No.

SAFETY PRECAUTIONS

SIGNAL WORDS

There are some safety precautions

which must be understood and followed by all users of equipment such

as your furnace, where flames, gas,

electricity and rotating parts are present. To alert you to the above potential hazards, we use the signal words

“WARNING” and “CAUTION” throughout this manual and safety labels

attached to the furnace.

Read carefully and pay special attention to all warnings and cautions in this

manual. They are defined and

designed as follows to help you recognize and avoid the potential hazards of

operating this furnace:

WARNING

!

Indicates a potentially hazardous

situation which, if not avoided,

could result in property damage,

serious injury or death.

CAUTION

!

Indicates a potentially hazardous

situation which, if not avoided,

could result in property damage,

or minor or moderate injury.

AC SYSTEM

Model No.

Serial No.

INDOOR COIL

Model No.

Serial No.

POSSIBILITY OF FIRE OR

EXPLOSION

WARNING

!

THIS FURNACE OPERATES BY

BURNING GAS INSIDE YOUR

HOME. THIS CREATES THE POSSIBILITY OF FIRE OR AN EXPLOSION WHICH CAN RESULT IN

PROPERTY DAMAGE, PERSONAL

INJURY OR DEATH. YOU MUST

READ AND FOLLOW ALL OF

THESE SAFETY PRECAUTIONS

TO HELP ENSURE SAFE OPERATION OF YOUR FURNACE.

• Do not test for gas leaks with a match

or flame.

• Do not use this furnace with any other

gas than the one listed on the rating

plate.

• Follow the furnace lighting instructions carefully to be sure all gas

fumes are cleared before lighting the

furnace.

• Check carefully for gas before lighting

a furnace. Do not rely on smell alone

to detect gas. Use a UL recognized

fuel gas detector and a soap and

water solution on the pipes to check

for gas leaks.

• A damaged gas control knob can

cause gas to leak. Do not hit or damage the knob. Do not force the knob

with tools. Use only your hand to turn

it to “ON” or “OFF”. Call the a quali-

fied installer, service agency or the

gas supplier immediately if you have

problems turning the knob.

• Should overheating occur, or the gas

valve fail to shut off the gas supply,

turn off the manual gas valve to the

furnace before turning off the electrical supply.

• Soot buildup indicates a serious combustion problem that requires immediate correction. Turn the gas supply

“OFF” until the furnace is repaired.

Contact a qualified installer, service

agency or the gas supplier immediately to inspect the furnace.

• Do not place, store or use gasoline or

other flammable vapors and liquids

on, against, or around the furnace

jacket.

• Do not store combustible materials

near the furnace. The furnace must

have adequate clearances from all

combustible materials such as clothing, paper, cardboard, wood or cleaning materials to prevent them from

igniting.

• Keep any furnace installed in an attic

or other insulated space free and

clear of insulating material. Examine

the furnace area when installing the

furnace or adding insulation. Some

materials may be combustible.

• Any additions, changes or conversions required in order for the furnace

to satisfactorily meet the application

needs should be made by a qualified

installer, service agency or the gas

supplier, using factory specified or

5

Page 6

approved parts. Read your Warranty.

Contact the WARRANTOR for conversion information. This furnace was

equipped at the factory for use on

NATURAL GAS ONLY. Conversion

to LP GAS requires a special kit supplied by the WARRANTOR.

DANGER FROM

ASPHYXIATION

WARNING

!

THIS FURNACE OPERATES BY

BURNING GAS INSIDE YOUR

HOME. IMPROPER OR INCOMPLETE BURNING OF THIS GAS

CAN RESULT IN THE FORMATION

OF CARBON MONOXIDE. IF

INTRODUCED INTO THE LIVING

SPACE, THIS CAN CAUSE DIZZINESS, NAUSEA, OR DEATH BY

ASPHYXIATION. YOU MUST

READ AND OBSERVE THE SAFETY RULES BELOW TO PREVENT

OXYGEN DEPLETION OR

UNBURNED GAS OR COMBUSTION FROM ESCAPING INTO THE

LIVING SPACE OF YOUR RESIDENCE.

• Do not operate this furnace without

provisions for an adequate combustion air supply.

• Do not allow snow, ice, or any other

debris to accumulate in or around the

exhaust and intake terminations of

this furnace. These are extended

through the roof or horizontally

through the sidewall of the structure.

See Figures 5 & 6. Blockage of the

intake and exhaust can result in inadequate combustion air as well as

inadequate unit performance or nuisance tripping.

FIGURE 5

STANDARD VERTICAL

DIRECT VENTING

FIGURE 6

STANDARD HORIZONTAL

IRECT VENTING

D

• Prevent flue gases from escaping into

your residence. Deterioration of the

venting system, or soot build-up can

cause leaks into the system. Have a

qualified installer, service agency or the

gas supplier replace damaged parts or

repair obstructions in a deteriorated

vent system immediately.

• Do not use this furnace if any part has

been under water. A flood-damaged

furnace is extremely dangerous.

Attempts to use the furnace can result

in fire or explosion. A qualified service

agency should be contacted to inspect

the furnace and to replace all gas controls, control system parts, electrical

parts that have been wet or the furnace,

if deemed necessary.

• To prevent carbon monoxide poisoning,

all blower doors and compartment covers must be replaced after the furnace

is serviced. Do not operate the unit

without all panels and doors securely in

place.

SYSTEM OPERATION

INFORMATION

• Keep the air filters clean. Your heating

system will operate more efficiently and

provide better heating, more economically.

• Arrange your furniture and drapes so

that the supply air registers and return

air grilles are unobstructed.

• Close doors and windows. This will

reduce the heating load on your system.

• Avoid excessive use of exhaust fans.

• Do not permit the heat generated by

television, lamps, or radios to influence

the thermostat operation.

• If you desire to operate your system

with constant air circulation, consult

your thermostat manual or please ask

advice from a qualified installer, service

agency or the gas supplier.

IMPORTANT: FOR COMPLETE

OPERATION AND SET UP OF YOUR

THERMOSTAT REFER TO THE MANUAL INCLUDED IN THE LITERATURE

PACKET SHIPPED WITH THIS FUR-

I407

NACE.

I407

STARTING YOUR

FURNACE

LIGHTING INSTRUCTIONS

This appliance is equipped with a direct

spark ignition device. This device lights

the main burners each time the room

thermostat calls for heat. DO NOT try to

light the burner by hand. See lighting

instructions on the furnace.

1. Remove the burner access door.

2. Set the thermostat to the lowest setting.

. Turn the gas control knob counter-

3

lockwise to the “ON” position.

c

4. Replace the burner access door.

5. Turn on the electrical power.

6. Set the room thermostat to a point

above the room temperature to light

the main burners. After the burners are

lit, set the room thermostat to a desired

temperature.

WARNING

!

BE SURE THAT THE MANUAL GAS

CONTROL HAS BEEN IN THE “OFF”

POSITION FOR AT LEAST FIVE

MINUTES. DO NOT ATTEMPT TO

MANUALLY LIGHT THE MAIN

BURNERS. FAILURE TO FOLLOW

THIS WARNING CAN CAUSE A

FIRE OR AN EXPLOSION RESULTING IN PROPERTY DAMAGE, PERSONAL INJURY OR DEATH.

7. If the appliance will not operate, follow

the instructions “To Turn Off Gas To

The Appliance” and call your service

technician or gas supplier.

TO TURN OFF GAS TO THE

APPLIANCE

WARNING

!

SHOULD OVERHEATING OCCUR

OR THE GAS SUPPLY FAIL TO

SHUT OFF, SHUT OFF THE MANUAL GAS VALVE TO THE APPLIANCE BEFORE SHUTTING OFF

THE ELECTRICAL SUPPLY. FAILURE TO DO SO CAN CAUSE AN

EXPLOSION OR FIRE RESULTING

IN PROPERTY DAMAGE, PERSONAL INJURY OR DEATH.

IMPORTANT: SHUT OFF THE MANUAL

GAS VALVE LOCATED IN THE GAS

SUPPLY PIPING OUTSIDE THE FURNACE CASING.

1. Set the thermostat to the lowest setting.

2. Turn off all electric power to the appliance on which service is to be performed.

3. Remove the burner access door.

4. Turn the gas control knob to the “OFF”

position.

5. Replace the burner access door.

6

Page 7

SEQUENCE OF OPERATION

Startup For Systems Configured

With Communications

WARNING

!

INSTALLATION OF LINE VOLTAGE AND GAS MUST BE PERFORMED ACCORDING TO

INSTRUCTIONS WRITTEN IN

THIS MANUAL. FAILURE TO DO

SO COULD RESULT IN INJURY

OR DEATH.

When the furnace is configured for

communications, the components on

the network (i.e. furnace, thermostat

and condenser) must establish communications before engaging a heat (or

other) thermostat demand. The procedure for establishing communications

is automatic and is described below.

Once the communicating wiring is

properly installed and the furnace is

connected to line voltage, the system

can be turned on. The thermostat will

display the following text :

SEARCHING

is displayed several times for several

seconds. Next, the text

FURNACE FOUND

and

AIR CONDITIONER FOUND

or

HEAT PUMP FOUND

(depending on which is installed in the

system) will be displayed. The process

can take several minutes (up to a maximum of 30) to complete. If these messages are not displayed within 30 minutes after energizing the system, communications can not be established.

There are many reasons why communications may not be established –

including improper settings of the

“TERM” and “BIAS” switches (see

BIAS/ TERMINATION) and improper

wiring.

The order in which these messages will

be displayed will depend on which

components are energized first. The

order listed here assumes that the furnace and condenser are energized at

the same time. If not, the order of display will be in the order that the components are turned on.

hen the system has found all neces-

W

ary components, the text area of the

s

ommunicating thermostat will go

c

lank. This is an indicator that the sys-

b

em is operating properly. Proceed by

t

ngaging a typical thermostat call to

e

etermine if operation is correct as

d

escribed in the section of this book

d

itled START UP PROCEDURES” to

t

est heating, cooling and fan operation

t

nd to make necessary adjustments.

a

Heating Cycle Initiation

The heating cycle is always initiated by a

24 volt signal on W of the thermostat.

When the controller senses a heat call or

with a communicating signal from a communicating thermostat, the following

sequence occurs:

• High and low pressure switches are

checked to insure contacts are open.

• Inducer is powered on high speed for a

thirty (30) second prepurge.

• Pressure switches are monitored as

the inducer creates the vacuum to

close the contacts.

• The gas valve servo or solenoid is

energized at 100%. (No flow yet.)

• The controller generates a spark

across the electrodes.

• The main solenoid on the gas valve is

energized, allowing gas to flow to the

burners.

• When flame is proven, the ignition control is de-energized - 8 second maximum trial time.

• The gas valve maintains 100% rate

through the warm-up period - 20 seconds.

Heating Cycle Response

The heating cycle is always initiated by a

24 volt signal on W1 or with a communicating signal from a communicating thermostat. When the controller senses a

heat call, the following sequence occurs:

MODULATING FUNCTION:

(“W” and “V” signal inputs, refer to dip

switch set SW2 on IFC)

fter the warm-up period, the furnace

A

ill respond to the thermostat demand

w

y adjusting the gas valve pressure and

b

lower speed anywhere between 40% to

b

00% heating capacity.

1

➤ TWO-STAGE FUNCTION:

(Two-stage function only applies when

both switches of SW2 are in the “ON”

position and a two-stage thermostat is

installed 24V.)

After the warm-up period, the furnace

will respond to the thermostat demand

by adjusting the gas valve pressure and

blower heating speeds to the “W” signal

values. “W” only = 40% gas valve pressure and blower heating speed. “W2” =

65% gas valve pressure and blower

heating speed for first five minutes and

100% thereafter. Also, if the call for heat

ends, the furnace terminates at the present rate.

➤ SINGLE-STAGE FUNCTION:

(“W” signal only)

After the warm-up period, the furnace

will respond to the thermostat demand

by altering the gas valve pressure and

blower speed as follows:

Phase 1: 0 to 5 minutes = 40% of furnace capacity (gas valve output and

blower speed)

Phase 2: 5 to 12 minutes = 65% of furnace capacity (gas valve output and

blower speed)

Phase 3: After 12 minutes = 100% of

furnace capacity (gas valve output and

blower speed)

NOTE: If the call for heat ends during

any phase, the furnace will terminate

immediately at the firing rate of that

phase.

Heating Cycle Termination

(“W” signal only, refer to dip switch set

SW2 on IFC)

When the heat call is removed, the heating cycle will end and the furnace will

shut down and return to the proper off

cycle operation.

MAINTENANCE

IMPORTANT: IT IS RECOMMENDED

THAT AN ANNUAL INSPECTION OF

YOUR FURNACE BE MADE BY A

QUALIFIED INSTALLER, SERVICE

AGENCY OR THE GAS SUPPLIER.

DURING THE ANNUAL INSPECTION,

IT IS RECOMMENDED THAT 120VAC

POWER BE TURNED OFF, THEN

BACK TO THE ON POSITION.

REAPPLYING120VAC INITIATES A

CALIBRATION CYCLE TO ENSURE

OPTIMUM SYSTEM OPERATION.

WARNING

!

THIS FURNACE CONTAINS MOVING/ROTATING COMPONENTS

AND USES HOUSEHOLD ELECTRICAL CURRENT. FOLLOW THE

SAFETY RULES BELOW TO

AVOID CUTS, BURNS OR ELECTRICAL SHOCK WHICH CAN

RESULT IN SEVERE PERSONAL

INJURY OR DEATH.

POSSIBILITY OF BURNS

OR ELECTRICAL INJURY

• Do not perform any service or maintenance on the furnace while it is operating. Read and follow the service

instructions provided with this furnace

before beginning any service or maintenance work.

• Do not open the blower compartment,

disassemble, or remove any components while the furnace is operating.

This may expose sharp edges or

points which could cause cuts, hot

surfaces which could cause burns,

and electrical circuits which could

cause shocks.

7

Page 8

• Instruct children on the safety hazards associated with furnaces. Keep

children away from the furnace at all

times.

CAUTION

!

DO NOT OPERATE YOUR SYSTEM FOR EXTENDED PERIODS

WITHOUT FILTERS. A PORTION

OF THE DUST ENTRAINED IN

THE AIR MAY TEMPORARILY

LODGE IN THE AIR DUCT RUNS

AT THE SUPPLY REGISTERS.

ANY RECIRCULATED DUST WILL

BE HEATED AND CHARRED BY

CONTACT WITH THE FURNACE

HEAT EXCHANGER. THIS

RESIDUE WILL SOIL CEILINGS,

WALLS, DRAPES, CARPETS AND

OTHER HOUSEHOLD ARTICLES.

FIGURE 7

UPFLOW SIDE FILTER LOCATION

FILTER MAINTENANCE

Have your qualified installer, service

agency or the gas supplier instruct you

on how to access your filters for regular

maintenance.

• Keep air filters clean at all times.

Vacuum dirt from filter, wash with

detergent and water, air dry thoroughly and reinstall.

• After filters are cleaned and returned

to the furnace, be sure doors are

properly reinstalled. If you are not

totally sure of this procedure, consult

qualified installer, service agency or

the gas supplier.

REMOVING FILTERS

FILTER IN BOTTOM OR SIDE

LOCATION

1. Remove the blower compartment

access door.

2. Disengage the filter retaining rod and

pull filter out.

. Clean filter and reinstall.

3

4. Replace the blower compartment

access door.

LUBRICATION

The blower motor and induced draft

motor are permanently lubricated by

the manufacturer and do not require

further attention.

IMPORTANT: DO NOT ATTEMPT TO

LUBRICATE THE BEARINGS ON THE

BLOWER MOTOR OR THE INDUCED

DRAFT BLOWER MOTOR. ADDITION

OF LUBRICANTS CAN REDUCE THE

MOTOR LIFE AND VOID THE WARRANTY.

The blower compartment and motor

should be inspected and cleaned periodically by your qualified installer, service agency or the gas supplier to prevent the possibility of overheating due

to an accumulation of dust and dirt on

the windings or on the motor exterior.

And, as suggested elsewhere in these

instructions, keep the air filters clean

because dirty filters can restrict airflow

and the motor depends on sufficient air

flowing across and through it to keep it

from overheating.

FIGURE 8

UPFLOW BOTTOM FILTER INSTALLATION

I332

COMBUSTION AIR AND

VENT SYSTEM

1. It is recommended that an annual

inspection of your furnace’s combustion air and vent system be done by

a qualified installer, service agency

or the gas supplier.

WARNING

!

IF DIRT, RUST, SOOT OR SCALE

ACCUMULATIONS ARE PRESENT,

DO NOT OPERATE THE FURNACE.

INSPECT THE HEAT EXCHANGER

FOR LEAKS. LEAKS CAN CAUSE

TOXIC FUMES TO ENTER THE

HOME AND CAUSE CARBON

MONOXIDE POISONING OR DEATH.

2. Turn OFF the electrical supply to the

furnace and remove the access

doors.

3. Inspect the gas burners for dirt, rust

or scale and clean as necessary.

4. Inspect the flue connection area and

vent pipe. Be sure that the vent connector is in place and slopes upward

and is physically sound, without

holes or excessive corrosion.

5. Be sure that the return air duct connections are physically sound, are

sealed to the furnace casing and terminate outside the space containing

the furnace.

ADS-5422-01

8

Page 9

WARNING

!

CHECK THE VENT PIPE SECTIONS

FOR DETERIORATION AND CHECK

JOINT FITTINGS FOR THEIR

INTEGRITY. IF IT HAS BECOME DISCONNECTED TOXIC FUMES CAN

ENTER THE HOME AND CAUSE

CARBON MONOXIDE POISONING

R DEATH. DO NOT OPERATE THIS

O

FURNACE. APPROPRIATE SERVICE

MUST BE APPLIED.

6. Be sure the physical support of the furnace is sound, without sags, cracks,

etc. around the base so as to provide a

seal between the support and the base.

7. Look for the obvious signs of deterioration of the furnace.

8. If the furnace is free of the above conditions, replace the access doors and

restore electrical power to the furnace.

9. Start the furnace and observe its operation. Watch the burner flames to see if

they are bright blue. If a suspected malfunction is observed, or the burner

flames are not bright blue, call for

appropriate service.

IGURE 9

F

DOWNFLOW FILTER INSTALLATION

AIRFLOW

CONDENSATE

This furnace is equipped with a pressure

switch which will shut off the main burners

if the condensate drain line becomes

blocked.

Be sure this condensate drain line does

not become blocked or plugged. Visual

inspection of the condensate flow can easily be made while the furnace is in operation. Use a flashlight to illuminate the discharge end placed in the sewer opening.

See Figures 11, 12 & 13.

Clean and flush the condensate tube to

make sure condensate flows freely while

the furnace is in operation.

IMPORTANT: IT IS RECOMMENDED

THAT AT THE BEGINNING OF THE

HEATING SEASON, THE CONDENSATE

TRAP BE INSPECTED BY A QUALIFIED

INSTALLER, SERVICE AGENCY OR THE

GAS SUPPLIER FOR DEBRIS OR

BLOCKAGE. A BLOCKED CONDENSATE

TRAP CAN CAUSE WATER TO BACK UP

INTO THE PRIMARY HEAT EXCHANGER

AND LEAD TO NUISANCE TRIPPING OF

THE OVER TEMPERATURE SWITCHES

OR PRESSURE SWITCHES.

IMPORTANT: IT IS RECOMMENDED

THAT AT THE BEGINNING OF THE

HEATING SEASON THE CONDENSATE

NEUTRALIZER, IF USED, BE REPLACED

BY A QUALIFIED INSTALLER, SERVICE

AGENCY OR THE GAS SUPPLIER.

FIGURE 10

HORIZONTAL -- FILTER INSTALLATION

((-)GJD MODELS)

A

IR

A

IR

FLOW

A087001.S01

F

L

O

W

MARKINGS

It is recommended that an annual inspection and cleaning of all furnace markings

be made to assure legibility. Attach a

replacement marking, which can be

obtained through the distributor, if any are

found to be illegible or missing.

A087101.S01

9

Page 10

IGURE 11

F

UPFLOW CONDENSATE DRAIN

EFER TO

R

NSTALLATION

I

ANUAL.

M

FIGURE 12

DOWNFLOW CONNECTION

112001.S01

A

REFER TO INSTALLATION

MANUAL

10

A112001.S01

Page 11

FIGURE 13

HORIZONTAL CONDENSATE DRAIN

11

Page 12

12

CM 0409

Loading...

Loading...