Rudd RPQL-018JEZ Installation Manual

FORM NO. P11-780 REV. 1

Supersedes Form No. P11-780

The Rheem Prestige Series™ RPQL- JEZ Heat Pump Outdoor

units can provide year-round heating and cooling comfort for residential, multi-family and light commercial applications. They are

designed to operate with Rheem indoor units with cooling and

heating capacities certified under the ARI Certification program.

The following additional features, plus its energy-saving characteristics, make the RPQL- JEZ Heat Pump outdoor unit an excellent

choice for new construction or upgrading your present system.

The Rheem Prestige Series™ RPQL- JEZ Heat Pumps are the

result of an ongoing development program for improved efficiencies. With SEER’s up to 15.5, these units continue a tradition of

high efficiency.

■

The Comfort Control System™ provides on-board diagnostics

and fault history for heat pumps with single-phase compressors

by detecting system and electrical problems without adding sensors. It can also communicate “fault codes” to enabled “L terminal”

thermostats. The integrated diagnostics with Active Protection

prevents compressor operation when potentially harmful conditions are detected.

■

7-Segment LED Display is exclusive only to Rheem products.

The information-display quickly and accurately shows technicians

the source of malfunctions.

■

Features a five-year conditional unit replacement warranty

when properly installed with a new Rheem Air Handler OR

Rheem Indoor Coil with a Rheem Gas Furnace.

■

Compressor sound blanket is standard to provide quiet operation.

■

Attractive, louvered wrap around jacket protects coil from weather

extremes and yard hazards. Top grille is steel reinforced for extra

strength. Cabinet is powder painted for all weather protection.

■

Four sided outdoor coil design allows compressor operation with

access panel removed.

■

Air is discharged upward away from bushes and shrubs. The discharge pattern of the top grille provides minimum air restriction,

resulting in quiet fan operation.

■

Combination Grille/Motor Mount secures the fan motor to the

underside of the discharge grille.

■

Removable top grille provides access to the outdoor fan motor

and outdoor coil.

■

Compressor compartment offers additional protection from the

elements and reduces operating noise.

■

Single speed, 8-pole fan motor is designed for quieter, energysaving operation.

■

Non-cycling reversing valve and demand defrost.

■

All models meet or exceed a 1000-hour salt spray test per ASTM

B117 Standard Practice for Operating Salt Spray Testing

Apparatus.

HEAT PUMPS

Equipped with

the Award Winning

Comfort Control System

™

• Increased Reliability

• On-Board Diagnostics

• Fault Recall

• Active Protection

™

RPQL- JEZ

15 SEER Models

Efficiencies up to 15.5 SEER/13 EER/10 HSPF

Nominal Sizes 1

1

/

2 to 5 Tons

[5.28 kW] to [17.6 kW]

Seven Models

Cooling Capacities

18,300 to 60,500 BTU/HR

[5.36 kW] to [17.73 kW]

HSPF up to 9.00

“Proper sizing and installation of equipment is critical to achieve optimal performance. Split system air conditioners and heat pumps must be matched with

appropriate coil components to meet ENERGY STAR criteria. Ask your Contractor for details or visit www.energystar.gov <http://www.energystar.gov/>.”

earth friendly refrigerant

2 Rheem Heating, Cooling and Water Heating

■

The Rheem exclusive 7-Segment LED Display easily shows system

operating status codes and diagnostic codes.

■

A Sealed Switch replaces the standard

contactor and features optical control

and latching mechanism. The sealed

switch prevents infiltration of insects and

dust. A minimal

switching arc, by the

optical control, offers

greater reliability. The latching mechanism consumes less power while reducing chatter.

■

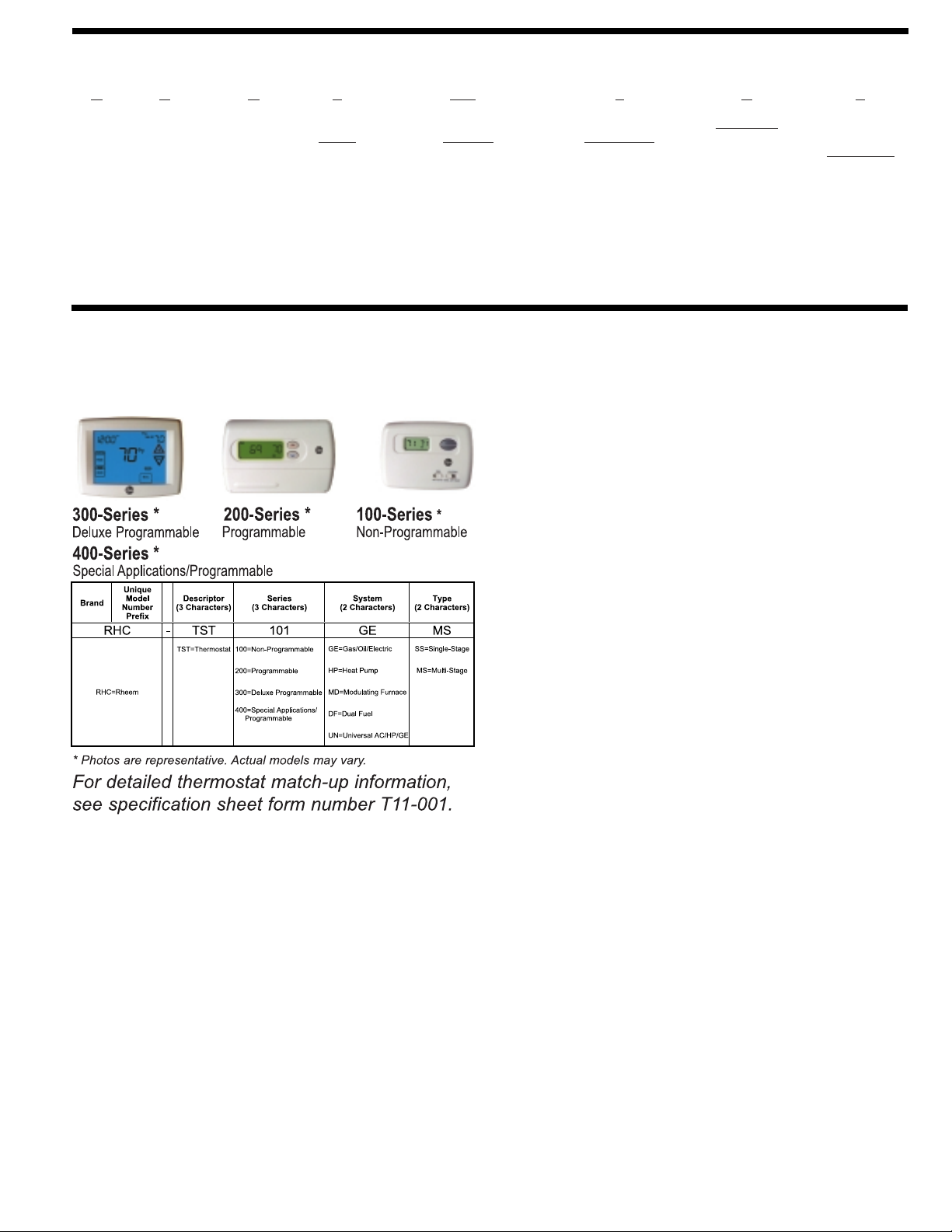

The Status Indication and System Diagnostics feature thermostat

communication capability, built-in diagnostics, high & low voltage

monitoring and high & low pressure switch monitoring. The thermo-

stat communication capability alerts the homeowner to any necessary

service requirements. Faster, more accurate

service is provided by the built-in diagnostics, by providing the HVAC professional

with dependable information. With the high

and low voltage monitoring feature, the control provides alerts for out-of-range conditions. In addition, high and low pressureswitch monitoring prevents the system from

operating outside of its normal parameters.

■

The fault recall feature will allow for the last six fault-codes to be

displayed, and will retain these codes even if power failure occurs.

■

Built-in short-cycle protection allows the compressor to restart easily without oil removal.

■

A 30-second minimum run-time for every compressor call enables

oil to return to the compressor.

■

Active Protection monitors the system to prevent nuisance lockouts

and prevents compressor operation

when potentially harmful conditions

are detected.

■

The compressor and fan are controlled

independently, which reduces the

starting load and light dimming.

■

A manual push-button is offered to

operate the compressor and fan for 5

seconds to allow for an operation

check.

■

In order to save time and money,

replacement automotive fuses can be

utilized instead of replacing the entire control board.

STANDARD FEATURES

RPQL- JEZ Heat Pump Outdoor Units

1. Scroll compressor is hermetically sealed and incorporates internal

high temperature motor overload protection, and durable insulation

on the motor windings. It is externally mounted on rubber grommets

to reduce vibration and noise.

2. Enhanced Compressor Protection—Features an enhanced

defrost control, auto-reset high pressure control, and auto-reset

low pressure control to provide compressor protection under

abnormally high head pressure conditions (outdoor fan failure,

restriction, dirty coil, etc.) or abnormally low suction pressure conditions (restrictions, TEV failure, loss of charge, indoor blower failure,

etc.) while eliminating nuisance tripping sometimes experienced with

conventional control systems.

3. Compressors have an internal pressure relief assembly to protect

against excessive pressure differential.

4. All refrigerant connections are on the exterior of the unit, located

close to the ground for neat appearing installations.

5. Cabinet is constructed of powder painted galvanized steel. The full

wrap-around louvered grille protects the coil from damage.

6. Enhanced compressor sound blanket is standard.

7. Demand Defrost Control—Provides complete defrost when defrost

is required.

8. Non-Cycling Reversing Valve—Eliminates discharge noises on

each heating cycle.

9. Hot Gas Muffler—Reduces noise in heating cycle.

10. Bi-Directional Filter Drier—Standard on RPQL- JEZ models

(shipped – not installed).

11. Service valves are standard on all models.

12. Refrigerant Metering—TEV accurately meters refrigerant into

indoor and outdoor coils.

13. Copper tube—aluminum fin coils are used on all models.

14. The control box is located in the top corner of the cabinet providing

for easy access through a service panel.

15. Service valves are standard on all models.

16. Field connections for power and control wiring are kept separate.

17. Every unit is factory charged and run-tested.

18. Separate compressor compartment for easy service access.

19. Drawn, painted basepan for extra corrosion resistance and sound

reduction.

20. The RPQL- JEZ has a 10 year limited compressor warranty, plus a

5 year conditional unit replacement warranty. See General Terms of

Limited Warranty for more details.

21. Hard Start Kits—Standard on all JEZ models.

22. Control Box Cover.

FEATURES & BENEFITS OF THE COMFORT CONTROL SYSTEM

™

SCROLL® COMPRESSOR

The scroll compressor is the key to efficiency for this Rheem model. It’s

the latest in high-efficiency compressor technology. The advanced scroll

compressor offers low noise and vibration characteristics and features

tolerance to liquid refrigerant and system contamination. The scroll

compresor also has low start torque, eliminating start problems in the

field. And its unique design enables the RPQL- JEZ Heat Pump to

perform efficiently, quietly and dependably.

Rheem Heating, Cooling and Water Heating 3

Field Installed Accessories

■

Low Ambient Control—Allows low temperature operation in the cooling

cycle down to 0°F [-17.8°C] outdoor temperature. It is recommended that

this control be installed in units to be operated for cooling at outdoor

ambient temperatures under 70°F [21°C]. (Model No. RXAD-A08)

■

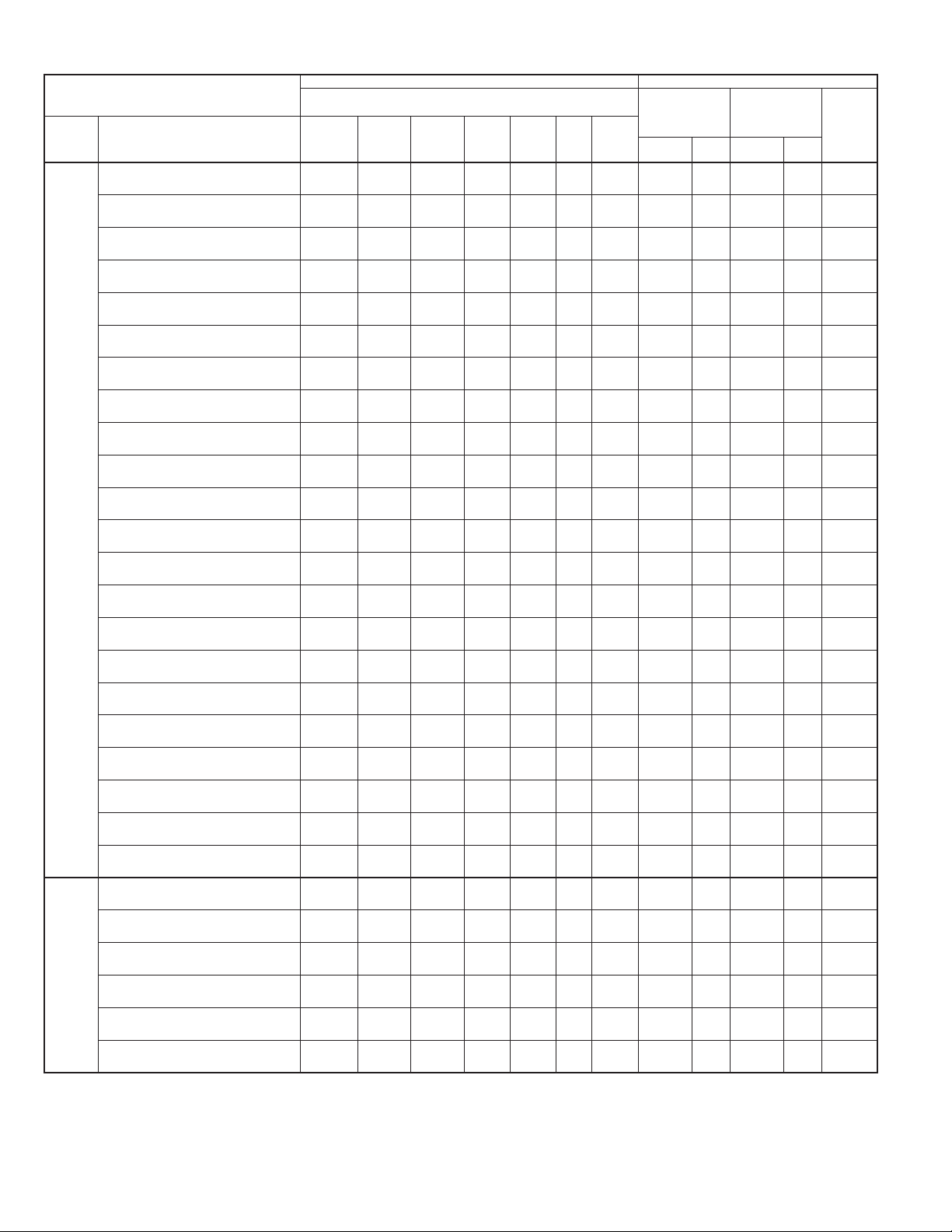

Thermostats

■

Compressor Crankcase Heater—Available through PROSTOCK®.

■

Thermostats and Subbases—Available through PROSTOCK®.

■

Blower Time Delay Control—RXMD-C04.

■

Fossil Fuel Kits—RXPF-01

RXPF-02

R P Q L — 018

COOLING

CAPACITY

018 = 18,000 BTU/HR [7.03 kW]

024 = 24,000 BTU/HR [7.03 kW]

030 = 30,000 BTU/HR [8.79 kW]

036 = 36,000 BTU/HR [10.55 kW]

042 = 42,000 BTU/HR [12.31 kW]

048 = 48,000 BTU/HR [14.07 kW]

060 = 60,000 BTU/HR [17.58 kW]

J E Z

RHEEM REMOTE

HEAT PUMP

Q = 15 SEER DESIGN

SERIES

L = R-410A

ELECTRICAL

DESIGNATION

J = 208/230V-1-60

VARIATIONS

E = EQUIPPED WITH

THE COMFORT

CONTROL SYSTEM

™

COOLING

CONNECTION

FITTING

Z = SWEAT

W/SCROLL

Model Number Identification

[ ] Designates Metric Conversions

Rheem Heat Pump System

More than a reverse cycle air conditioner, it’s a specially designed combination Winter/Summer comfort system using a single indoor coil

for heating and cooling.

For all season home comfort, performance and energy conservation, choose a Rheem RPQL- JEZ Heat Pump and a RHSL, RHLL, or

RHKL Series Air Handler.

To choose an Air Handler designed for use with the RPQL- JEZ Heat Pump, refer to the Performance Data Tables and/or the air handler

specification sheet.

4 Rheem Heating, Cooling and Water Heating

Performance Data ARI Standard Conditions—RPQL- JEZ

Note: Only these combinations of indoor/outdoor units are approved and any other combinations should not be used.

➀ Highest sales volume tested combination required by DOE test procedures. [ ] Designates Metric Conversions

ARI Cooling Performance ARI Heating Performance (70°F [21°C] Indoor)

95°F [35°C] DB Outdoor Air

Net

Sens.

BTU/H

[kW]

[4.2]

[4.1]

[4.1]

[4.1]

[4.1]

[4.2]

[4.1]

[4.2]

[4.1]

[4.1]

[4.1]

[4.1]

[4.1]

[4.1]

[4.2]

[4.1]

[4.2]

[4.1]

[4.1]

[4.1]

[4.2]

[4.0]

[5.3]

[5.1]

[5.2]

[5.3]

[5.3]

[5.3]

Net

Latent

BTU/H

[kW]

4,350

[1.3]

4,350

[1.3]

4,450

[1.3]

4,450

[1.3]

4,450

[1.3]

4,350

[1.3]

4,450

[1.3]

4,350

[1.3]

4,450

[1.3]

4,450

[1.3]

4,350

[1.3]

4,450

[1.3]

4,450

[1.3]

4,450

[1.3]

4,350

[1.3]

4,450

[1.3]

4,350

[1.3]

4,450

[1.3]

4,450

[1.3]

4,450

[1.3]

4,350

[1.3]

4,350

[1.3]

6,050

[1.8]

6,050

[1.8]

6,000

[1.8]

6,050

[1.8]

6,050

[1.8]

6,050

[1.8]

Snd.

SEER

Rate

EER

13.00 15.50 70

11.50 14.00 70

12.00 15.50 70

12.00 15.50 70

13.00 15.50 70

13.00 15.50 70

13.00 15.50 70

13.00 15.50 70

13.00 15.50 70

12.00 15.50 70

11.50 14.00 70

12.00 15.50 70

12.00 15.50 70

13.00 15.50 70

13.00 15.50 70

13.00 15.50 70

13.00 15.50 70

13.00 15.50 70

12.00 15.50 70

13.00 15.50 70

13.00 15.50 70

12.00 14.00 70

13.00 15.00 70

11.50 14.00 70

12.00 14.50 70

12.00 14.50 70

13.00

15.00 70

12.00 15.00 70

Indoor

CFM

dB

[L/s]

625

[295]

650

[307]

600

[283]

600

[283]

600

[283]

625

[295]

600

[283]

625

[295]

600

[283]

600

[283]

650

[307]

600

[283]

600

[283]

600

[283]

625

[295]

600

[283]

625

[295]

600

[283]

600

[283]

600

[283]

625

[295]

600

[283]

800

[378]

800

[378]

800

[378]

800

[378]

800

[378]

800

[378]

Outdoor Air

47°F [8.5°C] DB/

43°F [6°C] WB

DOE High Temp.

BTU/H

[kW]

17,200

[5.0]

17,800

[5.2]

17,200

[5.0]

17,200

[5.0]

17,200

[5.0]

17,200

[5.0]

17,200

[5.0]

17,200

[5.0]

17,200

[5.0]

17,300

[5.1]

17,800

[5.2]

17,200

[5.0]

17,200

[5.0]

17,200

[5.0]

17,200

[5.0]

17,200

[5.0]

17,200

[5.0]

17,200

[5.0]

17,300

[5.1]

17,200

[5.0]

17,200

[5.0]

17,600

[5.2]

23,000

[6.7]

23,600

[6.9]

23,200

[6.8]

23,200

[6.8]

23,000

[6.7]

23,000

[6.7]

COP

4.02

3.68

4.00

4.00

4.04

4.02

4.04

4.02

4.04

3.98

3.68

4.00

4.00

4.04

4.02

4.04

4.02

4.04

3.98

4.02

4.02

3.78

3.72

3.48

2.62

3.64

3.68

3.66

Outdoor Air

17°F [–8.5°C] DB/

15°F [–9.5°C] WB

DOE Low Temp.

BTU/H

[kW]

10,400

[3.0]

10,900

[3.2]

10,400

[3.0]

10,400

[3.0]

10,400

[3.0]

10,400

[3.0]

10,400

[3.0]

10,400

[3.0]

10,400

[3.0]

10,500

[3.1]

10,900

[3.2]

10,400

[3.0]

10,400

[3.0]

10,400

[3.0]

10,400

[3.0]

10,400

[3.0]

10,400

[3.0]

10,400

[3.0]

10,500

[3.1]

10,400

[3.0]

10,400

[3.0]

10,800

[3.2]

13,900

[4.1]

14,500

[4.2]

14,100

[4.1]

14,000

[4.1]

13,900

[4.1]

14,000

[4.1]

DOE

Region

IV

HSPF

COP

2.60 9.50

2.38 9.50

2.56 9.50

2.56 9.50

2.58 9.50

2.58 9.50

2.58 9.50

2.58 9.50

2.58 9.50

2.56 9.50

2.38 8.50

2.56 9.50

2.56 9.50

2.58 9.50

2.58 9.50

2.58 9.50

2.58 9.50

2.58 9.50

2.56 9.50

2.58 9.50

2.58 9.50

2.44 9.00

2.44 9.00

2.30 8.50

2.40 8.50

2.40 8.50

2.42 9.00

2.42 9.00

Outdoor

Unit

RPQL-

Rev.

11/14/08

018JEZ

024JEZ

Model Numbers

Indoor

Coil and/or

Air Handler

RHLL-HM2417 (RCSL-H*2417A*) ➀

RCFL-H*2414A*

RCFL-H*2414A* (RGFD-06?MCK?)

RCFL-H*2414A* (RGFD-07?MCK?)

RCFL-H*2414A* (RGGD-06?MCK?)

RCFL-H*2414A* (RGGD-07?MCK?)

RCFL-H*2414A* (RGJD-06?MCK?)

RCFL-H*2414A* (RGJD-07?MCK?)

RCFL-H*2414A* (RGLR-07?AMK?)

RCFL-H*2414A* (RGPR-05?BMK?)

RCFL-H*2417A*

RCFL-H*2417A* (RGFD-06?MCK?)

RCFL-H*2417A* (RGFD-07?MCK?)

RCFL-H*2417A* (RGGD-06?MCK?)

RCFL-H*2417A* (RGGD-07?MCK?)

RCFL-H*2417A* (RGJD-06?MCK?)

RCFL-H*2417A* (RGJD-07?MCK?)

RCFL-H*2417A* (RGLR-07?AMK?)

RCFL-H*2417A* (RGPR-05?BMK?)

RCFL-H*2417A* (RGPR-07?AMK?)

RHKL-HM2417 (RCSL-H*2417A*)

RHSL-HM1817 (RCSL-H*2417A*)

RHLL-HM2417 (RCSL-H*2417A*) ➀

RCFL-H*2414A*

RCFL-H*2414A* (RGFD-06?MCK?)

RCFL-H*2414A* (RGFD-07?MCK?)

RCFL-H*2414A* (RGGD-06?MCK?)

RCFL-H*2414A* (RGGD-07?MCK?)

Total

Capacity

BTU/H

[kW]

18,700

[5.5]

18,300

[5.4]

18,400

[5.4]

18,400

[5.4]

18,400

[5.4]

18,700

[5.5]

18,400

[5.4]

18,700

[5.5]

18,500

[5.4]

18,400

[5.4]

18,300

[5.4]

18,400

[5.4]

18,400

[5.4]

18,500

[5.4]

18,700

[5.5]

18,500

[5.4]

18,700

[5.5]

18,500

[5.4]

18,400

[5.4]

18,500

[5.4]

18,700

[5.5]

18,100

[5.3]

24,000

[7.0]

23,600

[6.9]

23,800

[7.0]

24,000

[7.0]

24,000

[7.0]

24,000

[7.0]

80°F [26.5°C] DB/67°F [19.5°C] WB Indoor Air

14,350

13,950

13,950

13,950

13,950

14,350

13,950

14,350

14,050

13,950

13,950

13,950

13,950

14,050

14,350

14,050

14,350

14,050

13,950

14,050

14,350

13,750

17,950

17,550

17,800

17,950

17,950

17,950

Loading...

Loading...